Abstract

In this paper, we propose mathematical model and a computational algorithm for simulation of thermoporoelastic medium with damage. The model considers a two-phase medium consisting of a porous skeleton and a mobile fluid. The medium state is described by the system of mass, momentum and energy conservation laws. To take into account the energy consumption for material damage, the additional term in energy conservation law is introduced. Constitutive relation are obtained by using the Coleman-Noll procedure, which ensures the fulfillment of the thermodynamic consistency principle. Damage of the medium is modeled within the framework of the continuum damage theory. The computational algorithm in fully three-dimensional formulation is based on the finite element method. Mesh is built using tetrahedral Taylor-Hood elements. We present some verification tests and the results of the synthetic test calculation demonstrating effects arising from thermal formation treatment.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Thermoporoelasticity

- Continuum damage mechanics

- Thermodynamic consistency principle

- Finite element method

1 Introduction

Nowadays, one of the most recent problems in oil engineering is estimation of efficiency of various enhanced oil recovery (EOR) techniques. With regard to hard-to-recover oil formations, one of the most advanced enhanced oil recovery method is thermal treatment, which consist in supplying heat to the reservoir by heat-transfer fluid injection or by conductive heat exchange.

Simulation of the reservoir processes induced by these EOR techniques can only be performed using coupled approaches which account for multiphysics nature of the reservoir processes,—including but not limited to fluid flow with temperature depended properties, chemical reactions, geomechanical processes. In addition, under the high pressures and temperatures in the reservoir it can be observed significant deformations affecting the structure of the pore space, which leads to the formation of microcracks and reservoir damage. These processes have a significant impact on the rock’s elastic properties and flow in the reservoir.

Currently, one of the most common approaches, implemented in various commercial software accurately resolve different temperature dependent flow effects, is the so-called “compositional” modeling. These models are widely used in applied simulation but they do not account for deformation and damage. Consideration of geomechanical effects, if happen, usually is based on simplified “split” models which are not themodynamically consistent [1, 2]. In turn, thermodynamically based models for coupled flow, geomechanics and damage are exists but rarely used in industrial strength settings [3].

The present paper proposes mathematical model for description of the thermoporoelastic medium taking into account damage processes. The model is thermodynamically consistent, i.e. it satisfies second law of thermodynamics. Also, in the work we presented computational algorithm based on the finite element method.

2 Mathematical Model

2.1 Conservation Laws

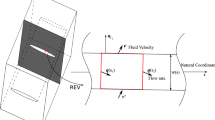

Consider the elementary volume \(\varOmega \) which contains two continuums—skeleton and fluid. At the time moment \(t = t_0\) the positions of the material volumes of the skeleton \(\varOmega _s(t_0)\) and fluid \(\varOmega _f (t_0)\) are the same, and the phase velocities are \({\varvec{v}}_s\) and \({\varvec{v}}_f\) respectively. Let us write the basic conservation laws for both continuums at the time moment \(t = t_0\).

The fluid mass conservation law has the form:

where \(\rho _f\) is true fluid density, i.e. fluid mass related to the volume occupied by it, \({\varvec{w}}\)—flux vector equaled to \({\varvec{w}}= m_f/\rho _f \left( {\varvec{v}}_f - {\varvec{v}}_s \right) \).

Let \({\varvec{f}}\) be external force, \({\varvec{b}}_{\alpha }^{\text {int}}\)—interaction forces density of phase \(\alpha \) (\(\alpha =s\) for skeleton, \(\alpha =f\) for fluid) with other phases, \( {\varvec{\sigma }} _{\alpha }\)—partial stress tensor. In this case, the momentum conservation law has the form of [4]:

Denote total stress tensor by \( {\varvec{\sigma }} = {\varvec{\sigma }} _f + {\varvec{\sigma }} _s\). Then, given that \( {\varvec{b}}_f^{\text {int}} + {\varvec{b}}_s^{\text {int}} = 0\), after summing up the Eq. (2) for skeleton and fluid we get:

Consider a thermoporoelastic medium in which, as a result of deformations, can occur a fractured zone—diffuse damage, which is the micro-fracture zones formation in the solid phase. It is significant that the characteristic dimension of the cracks is substantially smaller than the dimension of the medium representative volume. For this reason, the damage is described by a quantity defined in space (having a scalar form in the simplest case).

In accordance with the classical concepts of the crack propagation mechanics, it is necessary to supply a certain amount of energy to form a unit surface area of a crack. For this reason, it is natural to introduce into consideration the part of the total energy of the system associated with the damage of the medium. Then for domain volume \(\varOmega (t) = \varOmega _s(t) = \varOmega _f(t)\) the equation describing the energy conservation law and taking into account the damage of the material has the form of:

with

Here K—kinetic energy of the system, U—internal energy, P—external forces power, Q—heat flux, \(\varPi \)—energy consumption for material damage per unit of time, \(e_{\alpha }\) – phase specific internal phase energy, \({\varvec{q}}\)—heat flux density vector, \( {\varvec{Y}} \)—energy dissipation rate associated with material damage, \( {\varvec{D}} \)—damage variable tensor.

Passing from the skeleton partial stress tensor to the total stress tensor, we get the following expression:

2.2 Derivation of Constitutive Relations

We write the second law of thermodynamics without external sources in the form:

where \(S = m_s s_s + m_f s_f\) is total entropy,

Define the Helmholtz free energy for the phase \(\alpha \) as \(\psi _{\alpha } = e_{\alpha } - Ts_{\alpha }\). Then, applying the laws of momentum and energy conservation, entropy inequality can be represented as the sum of skeleton \(\delta _s\), fluid \(\delta _f\) and thermal dissipation \(\delta _t\):

where

Suppose that the stress tensor of a fluid is spherical, fluid flow follows the Darcy’s law, and the heat flux is determined from the Fourier law. In this case, it can be shown that \(\delta _f+\delta _t \geqslant 0\). Then, according to the Coleman-Noll procedure [6], to satisfy the entropy inequality (8) it is enough that:

In accordance with the principle of equipresence, we obtain an expression for skeleton dissipation:

where \( {\varvec{\varepsilon }} \)—infinitesimal strain tensor, \( {\varvec{\varepsilon }} = (\nabla \otimes {\varvec{\xi }} + (\nabla \otimes {\varvec{\xi }} )^2) / 2\), \( {\varvec{\xi }} \)—displacement vector.

We introduce the Gibbs energy \(g_s\) such that \(m_s g_s= m_s \psi _s - p m_f / \rho _f\). Then:

The implementation of the thermodynamic consistency principle requires the validity of entropy inequality (6) for any history of states, as well as the independence of the constitutive relations from the choice of reference configuration. For this it is suffices to fulfill the inequality (13), setting:

which provides \(\delta _s = 0\).

In this case, after linearization the constitutive relations for the skeleton and fluid are of the form:

where \( {\varvec{\gamma }}, {\varvec{\omega }}, {\varvec{\theta }}, {\varvec{\eta }}\)—tensors of damage coefficients, also the following notations are used \(\varDelta f = f - f^0\) for all f:

Here M, N are Biot modulus, \(K_f\) stands for fluid bulk modulus, \(\alpha _{f,\varphi }\) temperature expansion coefficients.

To proceed further we introduce the following assumptions: the influence of inertial forces is negligible; the skeleton velocity is negligible compared to fluid velocity; the kinetic energy of the fluid is neglected in comparison with the value of the internal energy; the influence of external forces is neglected; damage variable is a scalar function of the strain tensor and affects only the elastic coefficients tensor by the formula \(C(D)=C(1-D)\).

With regard to these assumptions, the system of Eqs. (1), (3), (5), (15), has the form:

To close this system of equations, the constitutive relations (15) and damage propagation law [7] are used:

where \(\tilde{\varepsilon }\) is given by:

with \(\varepsilon _i\) being principal strains.

The system (16) is solved by the finite element method. Implicit scheme was used for temporal discretization of the system. To solve the non-linear system arose at each time step, the Newton method was utilized. To increase the stability of solution, the mass matrices were lumped [8].

Space discretization of the Eq. (16) was performed on tetrahedral mesh with quadratic basis functions for displacements and linear for pressure and temperature (Taylor-Hood elements [9]). A feature of this type of finite elements is the satisfaction of the so-called \(\inf \)-\(\sup \) conditions (Ladyzhenskaya–Babuska–Brezzi condition). The fulfillment of these conditions provides stability of the solution for the poroelasticity problem. The numerical integration was performed using second-order Gauss quadrature formulas.

3 Numerical Results

3.1 Mandel’s Problem

Mandel [10] presented an analytical solution for the three-dimensional consolidation of poroelastic material in which there is a non-monotonic pore pressure evolution (Mandel-Cryer effect). In the original formulation, a sample of poroelastic material with a length of 2a and a height of 2b saturated with fluid is considered. The sample is fixed between two rigid impermeable plates, and a distributed load with a force of 2F is applied to the upper face.

In this test, the linear dimensions of the sample were \(1 \times 1 \times 1\) m. The vertical stress applied on the top face is 1 kPa. The initial pressure and displacements are vanishing. The pore pressure distribution along the x axis and displacement projections along the x and z axes were calculated. The obtained values were compared with a known analytical solution. The results are presented in Figs. 1 and 2.

3.2 One-Dimensional Non-isothermal Expansion

The problem of one-dimensional sample thermal deformation is considered. Sample dimensions are \(a \times a \times h\). The base of the sample is fixed on the surface, the lateral borders allow only vertical displacement, the upper boundary is free. It is assumed that the sample is thermally isolated and has a temperature \(T_0\) at the initial time. The upper boundary has a constant temperature equal to \(T_0 + \theta _0\).

The problem has an analytical solution obtained using the Laplace transform [11]. Testing was performed for various time points from 10 to 200 h. The results are presented in Fig. 3.

3.3 Damage Evolution Near Injection Well

Simulation the damage evolution in a small region near the well at the initial times was carried out on a model of size \( 1 \times 1 \times 1\) m. The initial reservoir pressure was assumed to be 200 bar, the initial temperature \(100^\circ \)C, and the initial stress in the reservoir in the x and y directions was 300 and 330 bar respectively. In the corner point of the domain, there is an injection well with a cylindrical shape with a radius of 0.1 m, operating with a constant injection rate of 0.5 m\(^3\)/day.

To simulate the damage evolution, the following parameters were used: \(D_{\text {lim}}\) \(D_{\text {off}}\) assumed to be equal 1, \(\varepsilon _c \) and \(\varepsilon _{\text {off}}\) are equal to 0.0002 and 0.015 respectively. Other model parameters are listed in the Table 1. Dynamic parameters distribution for the moments of 2 h, 1 and 10 days after the start of the well are presented in the Fig. 4.

4 Conlusion

We presented a thermodynamically consistent mathematical model and a computational algorithm for calculating damage in a thermoporoplastic medium. The damage of the medium is modeled within the framework of the continuum damage theory. The model takes into account the effects of skeleton deformation, fluid flow, and non-isothermal effects. The system of equations consists of the basic conservation laws (mass, momentum, energy) and the kinetic equation for the damage variable. For the closure of a system of equations, the constitutive relations obtained by Coleman-Noll procedure are used.

This paper also presents a numerical algorithm based on the finite element method in a fully three-dimensional formulation. The validity of the algorithm is confirmed in a number of test examples. Also an example of synthetic model test is presented for estimating the propagation of damage near injection well, which inject fluid at high temperature. According to the calculations in the near-wellbore zone, a significant damage of the rock is observed.

References

Murakami, S., Ohno, N.: A continuum theory of creep and creep damage. In: Ponter, A.R.S., Hayhurst, D.R. (eds.) Creep in Structures, pp. 422–444. Springer, Heidelberg (1981). https://doi.org/10.1007/978-3-642-81598-0_28

Lemaitre, J. (ed.): Handbook of Materials Behavior Models, Three-Volume Set: Nonlinear Models and Properties. Elsevier, Amsterdam (2001). https://doi.org/10.1007/978-3-7091-2806-0

Kondaurov, V.I., Fortov, V.E.: Osnovy Termomekhaniki Kondensirovannoi Sredy (Fundamentals of the Thermomechanics of a Condensed Medium). Izd. MFTI, Moscow (2002). [In Russian]

Kondaurov, V.I.: Mechanics and termodynamics of saturated porous medium. M.: MFTI (2007). [In Russian]

Bazarov, I.P., Gevorkyan, E.V., Nikolaev, P.N.: Nonequilibrium Thermodynamics and Physical Kinetics. Izd. Mosk. Univ, Moscow (1989). [In Russian]

Coleman, B.D., Noll, W.: The thermodynamics of elastic materials with heat conduction and viscosity. Arch. Ration. Mech. Anal. 13(1), 167–178 (1963). https://doi.org/10.1007/978-3-642-65817-4_9

Pogacnik, J., OSullivan, M., OSullivan, J.: A Damage Mechanics Approach to Modeling Permeability Enhancement in Thermo-Hydro-Mechanical Simulations. In: Proceedings, pp. 24-26 (2014)

Neuman, S.P.: Saturated-unsaturated seepage by finite elements. In J. HYDRAUL. DIV., PROC., ASCE (1973)

Taylor, C., Hood, P.: A numerical solution of the Navier-Stokes equations using the finite element technique. Comput. Fluids 1(1), 73–100 (1973). https://doi.org/10.1016/0045-7930(73)90027-3

Mandel, J.: Consolidation des sols (tude mathmatique). Geotechnique 3(7), 287–299 (1953)

Carter, J.P., Booker, J.R.: Finite element analysis of coupled thermoelasticity. Comput. Struct. 31(1), 73–80 (1989). https://doi.org/10.1016/0045-7949(89)90169-7

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this paper

Cite this paper

Meretin, A., Savenkov, E.B. (2019). Simulation of Coupled Flow and Damage in Porous Medium. In: Karev, V., Klimov, D., Pokazeev, K. (eds) Physical and Mathematical Modeling of Earth and Environment Processes (2018). Springer Proceedings in Earth and Environmental Sciences. Springer, Cham. https://doi.org/10.1007/978-3-030-11533-3_14

Download citation

DOI: https://doi.org/10.1007/978-3-030-11533-3_14

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-11532-6

Online ISBN: 978-3-030-11533-3

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)