Abstract

Limestones have been widely used in the construction of archaeological and heritage structures in Jordan. These stone structures are facing degradation due to many deterioration factors. Exposure to atmospheric conditions results in deterioration in historic monuments. Limestone conservation identifies emerging issues and challenges that have to be investigated in detail. In this study, limestone deterioration and the development of its consolidation treatments by synthesizing nano-sized particles of calcium hydroxide that dispersed in an alcoholic medium were investigated through an examination of limestone from the archaeological site of Jerash and another fresh limestone sample. Many properties were observed before and after the treatment, to examine the performance of nano-lime as a consolidant. All of the tests were conducted in laboratory conditions. When most of the conservation interventions relied on using organic materials, which were later proven to be harmful to stone on long term, a pressing demand is calling on representing new smart materials by using nano-lime for limestone consolidation; due to their improved mechanical properties, their physicochemical compatibility as consolidant materials follow the principle of authenticity of historic monuments (Wharton 1995). Results have shown that the application of nano-lime prepared in propanol-1 significantly improved the mechanical properties of the treated limestone. Compressive strength increased about 48% for archaeological and 38% for fresh samples, while the drilling increased by 500% for fresh and 84% for archaeological limestones; it has no significant change on porosity, although water uptake value (w-value) decreased 20%.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

The history of humanity has been accompanied by the use of natural stones for buildings and monuments because of their availability, durability and aesthetic appearance (Siegesmund and Snethlage 2011). The situation was not different in Jordan, since natural stone is one of the most popular construction materials that have been used in since ancient times. It is used in building facades, concrete, foundations, floors and other architectural elements that form the building (Al-Share et al. 2012).

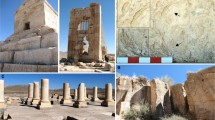

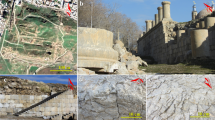

Samples for this study obtained from Jerash archaeological site (Gerasa) which is situated about 40 km north of Amman and about 30 km south of Irbid are shown in Fig. 1. Jerash (Gerasa) built to demonstrate luxury and power of the Roman empire as one of significant Decapolis cities, the city is well known historically and archaeologically for the presence of ancient Roman and Islamic settlements. Fresh limestone samples were obtained from the quarry. It is the conclusion of this paper/ that the quarryscapes of Gerasa (Jarash), Jordan. The quarry landscapes of Jarash offer an important opportunity to understand ancient Gerasa in its natural environment as well as its building materials. A number of quarry sites have been documented in the Jarash area as part of the quarryscapes project, including four major locations at Asfur, Al Shawahid, Wadi Suf, and Majar (Abu-Jaber et al. 2009). The quarries were used to extract building stone from the Upper Cretaceous Naur, Fuheis and Wadi As Sir Formations of the Ajloun Group.” Limestone is durable, but it deteriorates when subjected to the exterior, natural and weathering exposures such as wind, rain and thermal changes. The mechanism of deterioration is caused by mechanical, physical, chemical and biological factors. Physical degradation has occurred due to an action of water, temperature variations and abrasion; physicochemical mechanisms involve the recrystallization cycles of soluble salts without associated chemical change. Chemical reactions are caused by pollutants in the atmosphere by absorbing water from surroundings; it will be highly reactive when exposing to acids or harmful gases, so it will suffer from substantial deterioration (Johnson et al. 1996). Microbiological activity causes direct physical damage to the surface and promotes chemical attack via waste product (Amoroso and Fassina 1983). The results of those weathering phenomena are visually observed in historic buildings in different forms like flaking and scaling of the surface layers, cracks on the surface and in the stone, powdering, material loss in stone in various forms such as outbursts, granular and fragmental disintegration (Smith and Přikryl 2007). The interaction between stone materials and weathering factors controls the type and extent of stone damages. Also insufficient maintenance, improper restoration techniques or adaptive reuse of monuments have contributed to the stone damage.

During the last few decades, interdisciplinary researches and new technologies have been introduced in monuments conservation (Fitzner and Heinrichs 2001). Conservation aims to control the decay mechanisms, attempts to mitigate the degradation of archaeological stones and improves the performance of decayed stone through its physical, physico mechanical and chemical properties and lasting its survival without altering its visual and aesthetic characteristics. There is a growing awareness of the principle of minimum intervention of the need to limit the use of materials that might be harmful either to the stone or to the environment (Price and Doehne 2011). Consolidation as a part of conservation can refer to some superficial parts of a stone, like making the surface of the stone water-repellent, or as another option, it may concern its bulk. Bulk consolidation is a very complex operation; the penetration of the consolidating material is challenge binding it together and connecting it with the sound stone beneath, penetration of the consolidating material has been studied in many publications over the last 20 years. Of course, the treatment will need to be reasonably cheap, easy to apply and safe to handle (Price and Doehne 2011; Baglioni and Giorgi 2006).

Both organic and inorganic consolidants have been used for conservation treatments (Rodriguez-Navarro et al. 2013). Inorganic-based consolidants have the great advantage rather than organic and synthetic consolidants, are of good durability, and from a physicochemical point of view, are usually highly compatible with limestone structure. The most common inorganic consolidants are solutions of limewater or barium hydroxide in water (Giorgi et al. 2000).

In principle, calcium hydroxide Ca(OH)2 has been considered as the best compatible consolidant for carbonate-based stone like limestone because the maximum physicochemical compatibility can be achieved. When applying lime Ca(OH)2 as consolidant, it strengthens powdering and flaking layers. Due to carbonation, Ca(OH)2 turns into CaCO3, providing a crystalline network that is coherent with the carbonate substrate, which mechanically reinforces the degraded limestone surface. However, calcium hydroxide efficacy is quite limited mainly due to many reasons: poor solubility of calcium hydroxide in water (1.7 g/L at 20 °C) which has mitigated an extensive use of lime in limestone consolidation (Hansen et al. 2003). In order to overcome this issue, lime dispersion in water is being used, but lime dispersions in water are not stable as they have a very fast sedimentation rate, which leads to the formation of a white film on consolidated surfaces (Daniele and Taglieri 2011). And Limited penetration depth of lime Ca(OH)2 since its particle size is larger than most pores of limestone.

The nano-structures have opened new horizons for archaeological limestone consolidation, which represent a state of matter in between molecules and bulk structures, and are usually characterized by a large surface area that affects their physicochemical properties. Nano-structured materials (or simply nano-materials) have at least one dimension in the nanometre range, i.e. 10−9 m (Baglioni and Chelazzi 2013). Materials reduced to the nanoscale can suddenly show very different properties compared to what they exhibit on a macroscale: opaque substances become transparent (copper); stable materials turn combustible (aluminium); solids turn into liquids at room temperature (gold); insulators become conductors (silicon) (Kazemi et al. 2016). There is a significant impact on the reduction of cell size. As the size of the basic building blocks of a structure is reduced, the surface area per unit volume increases, as illustrated in Fig. 2. Scanning electron microscope (SEM) is a typical analytical device that allows us to visualize material morphology in the micro- to nanoscale (Doehne 2006).

The low solubility of calcium hydroxide in historic limewater was improved by using short-chain aliphatic alcohols such as ethanol, iso-propanol and n-propanol. Nano-lime consists of very small particles of calcium hydroxide suspended in alcohol; the average diameter is quoted as 150 nm with a range of 50–300 nm which is synthesized under specially controlled conditions. The smaller particle size of nano-lime has the advantages of achieving greater penetration into the pores, minimum alteration of the water kinetics and pore’s sizes. While the higher surface area/volume ratio allows greater reactivity (D’Armada and Hirst 2012). When a substrate is treated with nano-lime, calcium hydroxide is precipitated in the pores of calcareous materials as the alcohol evaporates. The overall carbonation process is represented by the following reaction:

As calcium hydroxide carbonates to calcium carbonate, it replaces lost binder or matrix in natural limestone, fixing fine cracks and deteriorated stone, and increasing strength and integrity. The hydroxide particles penetrate within the substrate pores and recreate a network of crystalline CaCO3 due to carbonation, bridging flaking parts. Therefore, the newly formed calcium carbonate is not merely a filler, but a true consolidant (Baglioni et al. 2014).

2 Experimental

For a better understanding of properties of the archaeological limestone from Jerash and a fresh limestone sample, the evaluation started with the determination of limestone properties related to consolidation such as tests defining the structure (e.g. porosity accessible to water (Nt), free porosity (N48) and capillary water uptake coefficient (w-value)) and mechanical strength (e.g. compressive strength, average drilling resistance and ultrasound). Consolidation means and methods were determined after reviewing the technical literature on nano-lime and other consolidants. The literature on the evaluation of nano-lime consolidants and RILEM guidelines tests defining the structure were reviewed to determine the shape and the size of limestone samples.

The application was conducted by immersing limestone samples into a nano-lime bath 10.5 g of nano-lime in 1.7 L of propanol-1. After immersion, the samples for 14 days in nano-lime solution were placed in the laboratory environment for 5 days for further carbonation process. The selected nano-lime consolidant used in this thesis was Ca(OH)2 synthesized in chemistry laboratory at Yarmouk University. The objective of laboratory-based evaluation and analysis was to determine the properties and performance of limestone and to assess to what extent the nano-lime consolidant improved the surface and internal cohesion without altering critical properties. Following guidelines of the RILEM test (Commission 25-PEM: protection et érosion des monuments: recommendations provisoires: tentative recommendations, 1980), the nano-lime consolidant was evaluated based on its compatibility with the archaeological limestone.

2.1 Preparing Stone Samples

The laboratory experiments were carried out on two carbonate stones that were collected from two different locations. Stone samples are very pure calcitic limestone formed almost of dolomite CaMg(CO3)2. They have quite different porosities (Fig. 3) with low mechanical characteristics, a high open porosity and large pore sizes. These stone characteristics seemed to be suitable for such a consolidation study focused on the stone strength enhancement.

X-ray powder diffraction (XRD) is a rapid analytical technique primarily used for phase identification of a crystalline material. The analysed material is finely ground and homogenized, and average bulk composition is determined. Random X-ray diffraction pattern was conducted by Shimadzu Lab X 6000 X-Ray diffractometer under the following operating system; CuKα radiation, 1.5418 Å in the labs of Faculty of Archaeology and Anthropology Department of Heritage conservation. Obtain grams (or more) of the material, as pure as possible. Grind the sample to a fine powder typically in a fluid to minimize inducing extra strain (surface energy) that can offset peak positions and to randomize orientation. Powderless than ~10 μm in size is preferred. Packing of fine powder into a sample holder then places it into a sample holder (Chipera and Bish 2002).

2.2 Synthesis of Ca(OH)2 Particles

-

a.

First Method—Alcoholic

As mentioned by (Ambrosi et al. 2001) in their article ‘Colloidal particles of Ca(OH)2: properties and applications to the restoration of frescoes’. Sodium hydroxide, NaOH, calcium chloride dihydrate, CaCl2â2H2O and propanol-1 (purity > 99.5%) were supplied by Merck, Darmstadt, Germany and were used without further purification.

NaOH solution (100 mL) (0.4M) and 100 mL of CaCl2 solution (0.2 M) were separately heated to the selected temperature in the range 60–90 °C. When the selected temperature was reached, the two solutions were rapidly mixed under stirring, keeping the temperature of the mixture constantly within ±1 °C.

The Ca(OH)2 suspension was allowed to gradually reach room temperature under a nitrogen atmosphere to avoid Ca(OH)2 carbonation. The supernatant solution was discarded, and the remaining suspension was washed three times with water to reduce NaCl concentration. Each time, the dilution ratio between the concentrated suspension and washing solution was about 1:10. The complete removal of NaCl from the suspension was controlled by AgNO3 tests.

-

b.

Second Method—Aqueous

Calcium chloride (CaCl2), sodium hydroxide (NaOH) and sodium bicarbonate (NaHCO3) supplied by Merck were used without further purification (Daniele et al. 2008). To obtain about 20 g of Ca(OH)2 nanoparticles, two different aqueous solutions of 900 ml, containing 0.3 mol/L of CaCl2 and 0.6 mol/L of NaOH, respectively, were prepared. The NaOH alkaline solution (used as precipitator) was added drop-wise into the CaCl2 solution (speed 4 mL/min, a temperature of 90 °C). After about 24 h, two distinct phases were observed: a limpid supernatant solution and a white precipitated phase. In order to remove the produced NaCl, several deionized water washings were performed to obtain aqueous nano-lime suspension (with concentration of 15 mg/mL).

3 Results and Discussion

3.1 X-Ray Diffraction (XRD)

The XRD identified calcite CaCO3 as major mineral and dolomite as traces for the archaeological limestone before and after treatment with nano-lime which are almost the same as shown in Fig. 4. This emphasizes the fact of compatibility of nano-lime as consolidant.

3.2 Morphological and Structural Analysis

Using tools that allow investigation at the nanoscale level was essential in this thesis, as nano-lime consolidant is composed of nanoscale particles. SEM micrographs, obtained on an alcoholic sample, are reported. Figure 5 shows a typical CA(OH)2 nanoparticles agglomerate, where the particles are crystalline and regularly shaped, range from 200 to 450 nm. Regarding particles crystallinity, these particles reveal typically crystalline features.

The following SEM images for aqueous method show how much agglomeration produced, this could be a huge obstacle for limestone consolidation; due to Limited penetration depth Fig. 6a, b.

4 Particle Size Distribution Data and Zeta Potential

The significance of zeta potential is that its value can be related to the short- and long-term stability of emulsions. Emulsions with high zeta potential (negative or positive) are electrically stabilized, while emulsions with low zeta potentials tend to coagulate, possibly leading to poor physical stability (Bhattacharjee 2016).

It has been shown that short-chain alcohols are highly effective in increasing the colloidal stability of Ca(OH)2 nanoparticles, which otherwise aggregate and settle rapidly when dispersed in water. Electrokinetic measurements show that Ca(OH)2 particles dispersed in water have a zeta potential of −34.1 mV Fig. 7, while in propanol-1, the zeta potential drops to −15.6 mV Fig. 8. The low dielectric constant of alcohol results in very small Debye lengths and reduced screening, if compared with water. This means that particles dispersed in propanol-1 will tend to aggregate due to attractive van der Waals forces. However, this is not what our experimental results show. Electrostatic interactions do not, thus, account for the increased kinetic stability of Ca(OH)2 dispersions in short-chain alcohols (Rodriguez-Navarro et al. 2013) (Figs. 9 and 10).

4.1 Results for Nt and N48

Nano-lime consolidation appears to have little to no impact on the pore structure of the limestone samples as shown in Fig. 11. The porosity value of the untreated and consolidated samples was almost identical, 2% change in total porosity. As shown in Fig. 8, which compares the volume of porosity accessible to water (Nt) for the two samples before and after consolidation. No obvious change in pore structure was observed from the test. This implied that the result was statistically not significant at 95% confidence level, and the change in the pore system was negligible.

For archaeological limestone samples, w-value is 9.6 kg/m2/√h before treatment and 7.72 kg/m2/√h after treatment Fig. 12. For fresh limestone samples, w-value is 2.45 kg/m2/√h before treatment and 1.77 kg/m2/√h after treatment Fig. 13. Experiments’ calculations reveal that nano-lime has more impact on fresh stone w-value with 27% reduction; for the archaeological samples, the reduction ratio is 19%.

Consolidant uptake value (c-value) for alcoholic nano-lime in archaeological sample = 5.14 kg/ m2/√h. c-value for alcoholic nano-lime in fresh sample = 1.1 kg/m2/√h. This is due to the presence of nanoparticles suspended in alcohol which causes the increase of the surface tension of alcohol. Consequently, the attraction force between the nano-lime solution and the surface of the pores will decrease and the c-value will also decrease.

4.2 Compressive Strength Results

Nano-lime consolidation resulted in the increased compressive strength of treated limestone samples. The average compressive strength of untreated and consolidated is provided in Table 1 that compares the mean value of the compressive strength for the untreated samples and consolidated samples. One application of nano-lime showed approximately 37% for fresh stone and 48% for the archaeological increase in compressive strength after a minimum of 14 days of curing of the nano-lime consolidant. This was conducted with a compressive strength machine (EleAutotest).

4.3 Average Drilling Resistance Results

For this experiment, using a Drilling Resistance Measurement System (DRMS), which measures the drilling resistance of stone materials and mortars, 5–7 readings were taken for five samples; the archaeological samples show a heterogeneous distribution of consolidant (Table 2).

4.4 Ultrasound Velocity Results

By using PUNDIT Ultrasonic Pulse Velocity (UPV) instruments, the average of ultrasound velocity increased for the archaeological samples 11% and for the fresh samples 4% (Table 3).

5 Conclusions

In this study, nano-dispersive calcium hydroxide solutions in propanol-1 alcohol with improved concentrations were successfully prepared. This thesis demonstrated that archaeological limestone can be strengthened by consolidation with propanol‐based nano-lime at low concentrations without displaying significant physicochemical changes. As given in Table 4, the results of all testing conducted in this thesis are summarized and provided with the statistical confirmation.

The results were obtained after 15 days of nano-lime application:

-

It is recommended to expand application time for better-improved properties.

-

The archaeological block was heterogeneous; few results were discarded.

-

The decision as to whether a nano-lime consolidant should be used on historic limestone is dependent on conditions and measurable property changes.

-

Environmental conditions will greatly affect the cure of nano-lime, and in situ testing must be performed to confirm laboratory test results.

-

The results of the investigations are used to suggest building conservation solutions for this particular site.

-

They also provide recommendations for future conservation options for archaeological limestone monuments and structure in Jordan.

5.1 Recommendations for Future Research

Like many other lime‐based building materials, the performance of the nano-lime consolidant is associated with the completion of the carbonation process, which may continue for many years. Therefore, to understand a long-term performance of nano-lime consolidant on limestone, further testing is required on the additional sample sets created for this research. This will allow performance evaluation of the nano-lime consolidant after longer curing (carbonation) period. The long-term durability of nano-lime has to be further studied by dilatation measurements and cyclic durability tests, along with micro-structural analyses similar to the ones performed in this study. Further research is needed for finding the appropriate application technique either in site or laboratory, like brushing, poultice or immersion. The role of the application technique is essential on the performance of consolidated limestone as this case.

References

Abu-Jaber, Nizar, al Saad, Ziad, & Smadi, Nihad. (2009). The quarryscapes of Gerasa (Jarash), Jordan. Geological Survey of Norway, Special Publication(12), 67–77.

Al-Share, Raed, Momani, Wasef, Obeidat, Asem, & Mansour, Nassar. (2012). Natural Stone in Jordan: Characteristics, Specifications and Importance in interior Architecture. American Journal of Scientific Research(82), 83–94.

Ambrosi, Moira, Dei, Luigi, Giorgi, Rodorico, Neto, Chiara, & Baglioni, Piero. (2001). Colloidal particles of Ca (OH) 2: properties and applications to restoration of frescoes. Langmuir, 17(14), 4251–4255.

Amoroso, Giovanni Giuseppe, & Fassina, Vasco. (1983). Stone decay and conservation: atmospheric pollution, cleaning, consolidation and protection: Elsevier Science Publishers.

Baglioni, Piero, & Chelazzi, David. (2013). Nanoscience for the Conservation of Works of Art: Royal Society of Chemistry.

Baglioni, Piero, Chelazzi, David, & Giorgi, Rodorico. (2014). Nanotechnologies in the conservation of cultural heritage: a compendium of materials and techniques: Springer.

Baglioni, Piero, & Giorgi, Rodorico. (2006). Soft and hard nanomaterials for restoration and conservation of cultural heritage. Soft Matter, 2(4), 293–303.

Bhattacharjee, Sourav. (2016). DLS and zeta potential–What they are and what they are not? Journal of Controlled Release, 235, 337–351.

Chipera, Steve J, & Bish, David L. (2002). FULLPAT: a full-pattern quantitative analysis program for X-ray powder diffraction using measured and calculated patterns. Journal of Applied Crystallography, 35(6), 744–749.

D’Armada, Paul, & Hirst, Elizabeth. (2012). Nano-lime for consolidation of plaster and stone. Journal of architectural conservation, 18(1), 63–80.

Daniele, V, & Taglieri, G. (2011). Ca(OH)2 nanoparticle characterization: microscopic investigation of their application on natural stones. WIT Transactions on Engineering Sciences, 72, 55–66.

Daniele, Valeria, Taglieri, Giuliana, & Quaresima, Raimondo. (2008). The nanolimes in Cultural Heritage conservation: Characterisation and analysis of the carbonatation process. Journal of cultural heritage, 9(3), 294–301.

Doehne, Eric. (2006). ESEM applications: From cultural heritage conservation to nano-behaviour. Microchimica Acta, 155(1–2), 45–50.

Fitzner, Bernd, & Heinrichs, Kurt. (2001). Damage diagnosis at stone monuments-weathering forms, damage categories and damage indices. ACTA-UNIVERSITATIS CAROLINAE GEOLOGICA(1), 12–13.

Giorgi, Rodorico, Dei, Luigi, & Baglioni, Piero. (2000). A new method for consolidating wall paintings based on dispersions of lime in alcohol. Studies in conservation, 45(3), 154–161.

Hansen, Eric, Doehne, Eric, Fidler, John, Larson, John, Martin, Bill, Matteini, Mauro,… de Tagle, Alberto. (2003). A review of selected inorganic consolidants and protective treatments for porous calcareous materials. Studies in Conservation, 48(sup1), 13–25.

Johnson, JB, Montgomery, Melanie, Thompson, GE, Wood, GC, Sage, PW, & Cooke, MJ. (1996). The influence of combustion-derived pollutants on limestone deterioration: 1. The dry deposition of pollutant gases. Corrosion science, 38(1), 105–131.

Kazemi, Elham, Ghamari, Mohammad Amin Khojasteh, & Neshanifam, Shokuh. (2016). The Application of Nanotechnology against Humidity in the Building Preservation of Tabriz Historical and Traditional City, Case Study: Blue Mosque, Tabriz.

Price, Clifford A, & Doehne, Eric. (2011). Stone conservation: an overview of current research: Getty Publications.

Rodriguez-Navarro, Carlos, Suzuki, Amelia, & Ruiz-Agudo, Encarnacion. (2013). Alcohol dispersions of calcium hydroxide nanoparticles for stone conservation. Langmuir, 29(36), 11457–11470.

Siegesmund, Siegfried, & Snethlage, Rolf. (2011). Stone in architecture. Springer, 4th ed. doi, 10(1007), 978–973.

Smith, BJ, & Přikryl, R. (2007). Diagnosing decay: the value of medical analogy in understanding the weathering of building stones. Geological Society, London, Special Publications, 271(1), 1–8.

Wharton, A. J. (1995). Refiguring the Post Classical City: Dura Europos, Jerash, Jerusalem and Ravenna (p. 71). Cambridge: Cambridge University Press.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Alomary, R., Al-Naddaf, M., Sekhaneh, W.A. (2019). Laboratory Evaluation of Nanoparticles for Consolidation of Limestone in Archaeological Site of Jerash. In: Hawkes, D., et al. Conservation of Architectural Heritage. Advances in Science, Technology & Innovation. Springer, Cham. https://doi.org/10.1007/978-3-030-10871-7_4

Download citation

DOI: https://doi.org/10.1007/978-3-030-10871-7_4

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-10870-0

Online ISBN: 978-3-030-10871-7

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)