Abstract

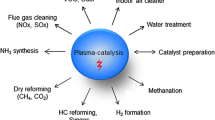

Plasma catalysis has been demonstrated as a promising alternative to thermal catalysis for environmental clean-up and the synthesis of platform chemicals and fuels from different feedstocks at low temperatures. There have been considerable and increasing research activities in this emerging and interdisciplinary field in recent years. However, plasma catalysis, particularly using a single-stage configuration, is a very complex process involving both gas-phase reactions driven by the plasma and plasma-assisted surface reactions. A number of challenges need to be addressed to achieve significant advancement in this field and the full potential of this emerging technology.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Plasma catalysis has been demonstrated as a promising alternative to thermal catalysis for environmental clean-up and the synthesis of platform chemicals and fuels from different feedstocks at low temperatures. There have been considerable and increasing research activities in this emerging and interdisciplinary field in recent years. However, plasma catalysis, particularly using a single-stage configuration, is a very complex process involving both gas-phase reactions driven by the plasma and plasma-assisted surface reactions. A number of challenges need to be addressed to achieve significant advancement in this field and the full potential of this emerging technology.

11.1 Scientific and Engineering Challenges

11.1.1 Experimental Challenges

In general terms, most of our existing information about plasma catalysis has come from experiments performed under a variety of conditions in which the products were measured in the output gas stream and the catalyst might be characterized before and after processing. Such gas-phase analyses are restricted to stable species (which might include some by-products and very long-lived intermediates such as ozone) but contain no information about short-lived intermediates. In addition, there is always a possible complication that reactions unconnected with the studied plasma catalysis process might occur after processing either in the tubing or the collection vessel but before sampling. Similarly, analysis of the surface of the catalyst after the experiment will only yield information about the strongly bound or long-lived products or intermediates and may become contaminated post experiment but before analysis.

The need is to be able to routinely measure not just the final products but also the intermediates, i.e. we need in situ measurements to extend our ex situ ones giving us information that can aid the formation and validation of accurate reaction mechanisms. These measurements will be performed both in the gas-phase and on the catalyst surface. They can be of time-averaged concentrations for these species, but even more valuable would be to be able to measure their time evolution and know how they vary in different parts of the reactor. Also we would like to identify the species in the boundary layer just above the surface as well as what is absorbed onto the surface. Knowing the variation in concentration of all the species in the gas-phase on moving away from the surface and also in the direction of the gas flow will yield valuable information, i.e. we need to obtain 2- or 3-D maps of the gas-phase species in the reactor. As an example of what can be achieved, the reader could refer to the 2-D imaging of OH and toluene in an atmospheric gliding arc study of the destruction of toluene in air using a planar laser beam and detected the spatially resolved laser-induced fluorescence [1]. There is no catalyst in that experiment, but one can easily imagine the extension to plasma catalysis. An alternative is to use some of the variety of laser absorption or fluorescence techniques where the laser beam can be moved in the reactor relative to the catalyst surface. Teramoto et al. [2] give an example of measuring OH radical profiles in humid air plasma as a function of distance from an electrode. Temporal information can also be obtained using a pulsed plasma system and undertaking the detection after the pulse with a variable delay. This can be applied to absorption and fluorescence systems using pulsed lasers to give information about ground-state species and also for excited species using time resolved UV/visible or infrared emission.

Analysis of species on the catalyst surface can be achieved in situ and in real time using some infrared techniques such as diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS), attenuated total reflection (ATR) and absorption [3,4,5]. These techniques have a sensitivity for species located on and a short distance into the catalyst surface (of the order of microns). These techniques have all been used in a plasma environment, and the DRIFTS and absorption measurement have already been applied successfully to plasma–catalytic systems. They are capable of time-resolved measurement with a resolution of about 1 s and have been combined with parallel gas-phase measurements [3].

11.1.2 Theoretical Calculations and Modeling Challenges

Theoretical and computational methods currently play an important role in the understanding and development of plasma catalysis, and their role will continue to increase. At various levels, they can provide an understanding based on an assumed model, which is inevitably approximate to some extent but can be used to replicate and extend the results of experiments and to provide information to inform the design of new experiments and processes. The experimental information obtained from in situ measurements on the gaseous and surface species can be used in conjunction with quantum mechanical calculations of the reaction pathways in terms of their energetics and configurations coupled with modeling and simulations of the dynamics on such reaction pathways to gain an understanding of the reaction dynamics in these plasma catalytis systems. The calculations can make predictions about the nature of intermediates, the time profiles of the evolution and decay of the different species that can be compared with experiments, thereby validating the assumptions made. Inevitably, the calculations may be of reduced dimensionality for computational convenience, and we can expect to see that restriction disappearing as computational power and the associated software develop [6,7,8,9,10]. Considerable progress is being made at the moment in the use of modeling to explain and evaluate the electrical effects of discharges with packing [11,12,13] including the effect of different gas mixtures [12]. These calculations are forerunners of models for the effect of packing in plasma catalysis. Models are being developed for different plasma types such as dielectric bed discharges, gliding arc and microwave systems [14,15,16] that are stepping stones towards the incorporation of a catalyst.

Hensen et al. have developed a microkinetic methodology for describing the mechanism of catalytic reactions that makes use of density functional theory (DFT) quantum calculations of the surface reaction potential energies for the intermediates and calculates the kinetics without any assumptions of the critical reaction pathway incorporating the dynamic changes of the surface during the reaction. This has been applied to the Fischer–Tropsch process [17, 18]. For the purposes of describing a plasma–catalytic process, it would be necessary to incorporate in a dynamic manner the effect of the plasma on the binding of species to the surface and on the nature of the transition state. Kim et al. [19] have presented a kinetic method to elucidate the key steps involved in the plasma–catalytic processing of the dry reforming of methane with CO2 by using experimental results at a range of temperatures as input. They can separate the gas-phase reactions taking place from those on the Ni surface. In contrast to thermal catalysis for this reaction that shows Arrhenius behavior, the plasma catalytic systems exhibit a non-Arrhenius temperature dependence. A value for the energy barrier for plasma catalysis obtained from the relationship between rate constant and input power is 20 kJ/mol to be compared with the activation energy for thermal catalysis of 70 kJ/mol. They attribute the reduction to an energetically favorable interaction between plasma-generated vibrationally excited CH4 and the Ni sites on the catalyst.

11.1.3 Engineering Challenges

Compared with the developments and progress that are being made by experiment and theory, there is comparatively little progress being made with scaling up plasma catalytis systems to the industrial scale. Many experiments are now focusing on the energy efficiency of the processing and attempting to benchmark results with competing techniques. These benchmark parameters are important in allowing different plasma catalysis experiments to be compared among themselves in terms of the effectiveness of different plasma types, different catalysts and other system variables and as the means of comparing plasma catalysis with other competing technologies. An excellent example of this approach can be found in the recent work of Snoeckx and Bogaerts for the conversion of CO2 [20].

When considering possible scale-up and industrial applications of plasma catalysis, a whole life cost analysis must be performed to determine if the process will be economically competitive [21]. Unless a process can be developed which has 100% selectivity for the desired product, there can be additional costs associated with separating a range of products such as the use of pressure swing adsorption or membranes that require additional capital and energy input. A promising recent development has been the hybridization of a dielectric barrier discharge (DBD) reactor with a solid oxide electrolyser cell (SOEC) for the conversion of CO2 into CO and O2 where the SOEC removes oxygen from the reactor as it is formed, preventing the back reaction of CO and O2 to reform CO2 allowing complete conversion of the CO2 [22].

Many of the catalysts that are being used in the present experiments involve expensive and scarce metals, and effort must be applied to using catalysts that are inexpensive. It is also necessary to evaluate the long-term performance of the catalyst in a plasma environment to demonstrate that it is at least as good as in the thermal experiment. Interestingly, most of the catalysts used in plasma catalysis are identical to the ones used in the analogous thermal experiment. We need to break free of this mind-set and use the accumulated knowledge of our studies to identify the specific characteristics of a successful catalyst in plasma catalysis and go for the goal of designing catalysts specifically for use in a plasma catalysis system. This way we might achieve better conversions, selectivities and higher energy efficiencies.

11.2 The Future

Despite at least 25 years of worldwide research into plasma catalysis, the vast majority of experiments are of the laboratory scale and are probing the mechanism of plasma catalysis. Considerable progress is being made in gaining an understanding of the intricacies of the mechanism of plasma catalysis, and this is significantly assisted by the theoretical and computational studies. There has been an evolution of emphasis from exhaust gas remediation and NOx removal, through volatile organic compounds (VOCs) destruction to the current focus on energy-related topics such as methane reforming for syngas and hydrogen production, oxidative conversion of methane, gas-to-liquid conversion of hydrocarbons and reutilization of carbon dioxide and its implications for energy storage. It is vital for the research to remain relevant as it gives it impact and helps to secure funding. However, there will come a time when all this promise must be realized and blue skies research must be scaled up, be commercialized and enter the hard commercial world. When will plasma catalysis make this next step? It has to be before goodwill towards continued funding goes cold. The question to reflect upon is what we now need to do that we have not yet done to make this step. We need to identify and exploit the unique features of plasma catalysis processing (e.g. simplified construction, portability, rapid response, low-temperature operation, etc.). Consideration must be given to application into niche areas of low throughput versus competition with existing high-volume processes. Much to consider over the next 25 years!

References

Gao, J., Zhu, J., Ehn, A., Aldén, M., & Li, Z. (2017). In-situ non-intrusive diagnostics of toluene removal by a gliding arc discharge using planar laser-induced fluorescence. Plasma Chemistry and Plasma Processing, 37, 433–450.

Teramoto, Y., Kim, H. H., Ogata, A., & Negishi, N. (2014). Measurement of OH (X2Σ) in immediate vicinity of dielectric surface under pulsed dielectric barrier discharge at atmospheric pressure using two geometries of laser-induced fluorescence. Journal of Applied Physics, 115, 133302.

Jia, Z., Wang, X., Thevenet, F., & Rousseau, A. (2017). Dynamic probing of plasma-catalytic surface processes: Oxidation of toluene on CeO2. Plasma Processes and Polymers, 14, 1600114.

Klages, C.-P., Hinze, A., & Khosravi, Z. (2013). Nitrogen plasma modification and chemical derivatization of polyethylene surfaces - an in situ study using FTIR-ATR spectroscopy. Plasma Processes and Polymers, 10, 948–958.

Stere, C. E., Anderson, J. A., Chansai, S., Delgado, J. J., Goguet, A., Graham, W. G., Hardacre C., Taylor S. F. R., Tu, X., Wang, Z., & Yang, H. (2017). Non-thermal plasma activation of gold-based catalysts for low-temperature water-gas shift catalysis. Angewandte Chemie, International Edition, 56, 5579–5583.

Neyts, E. C., & Bogaerts, A. (2014). Understanding plasma catalysis through modelling and simulation-a review. Journal of Physics D: Applied Physics, 47, 224010.

Somers, W., Bogaerts, A., Van Duin, A. C. T., Huygh, S., Bal, K. M., & Neyts, E. C. (2013). Temperature influence on the reactivity of plasma species on a nickel catalyst surface: An atomic scale study. Catalysis Today, 211, 131–136.

Tennyson, J., Rahimi, S., Hill, C., Tse, L., Vibhakar, A., & Akello-Egwel, D. (2017). QDB: A new database of plasma chemistries and reactions. Plasma Sources Science & Technology, 26, 055014.

Bogaerts, A., De Bie, C., Eckert, M., Georgieva, V., Martens, T., Neyts, E., & Tinck, S. (2010). Modeling of the plasma chemistry and plasma-surface interactions in reactive plasmas. Pure and Applied Chemistry, 82, 1283–1299.

Aerts, R., Tu, X., Van Gaens, W., Whitehead, J. C., & Bogaerts, A. (2013). Gas purification by nonthermal plasma: A case study of ethylene. Environmental Science & Technology, 47, 6478–6485.

Koen Van, L., & Annemie, B. (2016). Fluid modelling of a packed bed dielectric barrier discharge plasma reactor. Plasma Sources Science and Technology, 25, 015002.

Zhang, Y., Wang, H. Y., Jiang, W., & Bogaerts, A. (2015). Two-dimensional particle-in cell/Monte Carlo simulations of a packed-bed dielectric barrier discharge in air at atmospheric pressure. New Journal of Physics, 17, 12.

Van Laer, K., & Bogaerts, A. (2015). Improving the conversion and energy efficiency of carbon dioxide splitting in a zirconia-packed dielectric barrier discharge reactor. Energy Technology, 3, 1038–1044.

De Bie, C., Martens, T., van Dijk, J., Paulussen, S., Verheyde, B., Corthals, S., & Bogaerts, A. (2011). Dielectric barrier discharges used for the conversion of greenhouse gases: modeling the plasma chemistry by fluid simulations. Plasma Sources Science and Technology, 20, 024008.

Heijkers, S., Snoeckx, R., Kozák, T., Silva, T., Godfroid, T., Britun, N., Snyders, R., & Bogaerts, A. (2015). CO2 conversion in a microwave plasma reactor in the presence of N2: Elucidating the role of vibrational levels. Journal of Physical Chemistry C, 119, 12815–12828.

Cleiren, E., Heijkers, S., Ramakers, M., & Bogaerts, A. (2017). Dry reforming of methane in a gliding arc plasmatron: towards a better understanding of the plasma chemistry. ChemSusChem, 10, 4025-4036.

van Santen, R. A., Markvoort, A. J., Filot, I. A. W., Ghouri, M. M., & Hensen, E. J. M (2013). Mechanism and microkinetics of the Fischer-Tropsch reaction. Physical Chemistry Chemical Physics, 15, 17038–17063.

Filot, I. A. W., van Santen, R. A., & Hensen, E. J. M. (2014). The optimally performing Fischer-Tropsch catalyst. Angewandte Chemie-International Edition, 53, 12746–12750.

Kim, J., Go, D. B., & Hicks, J. C. (2017). Synergistic effects of plasma-catalyst interactions for CH4 activation. Physical Chemistry Chemical Physics, 19, 13010–13021.

Snoeckx, R., & Bogaerts, A. (2017). Plasma technology - a novel solution for CO2 conversion? Chemical Society Reviews, 46, 5805-5863.

Hessel, V., Cravotto, G., Fitzpatrick, P., Patil, B. S., Lang, J., & Bonrath, W. (2013). Industrial applications of plasma, microwave and ultrasound techniques: Nitrogen-fixation and hydrogenation reactions. Chemical Engineering and Processing, 71, 19–30.

Mori, S., Matsuura, N., Tun, L. L., & Suzuki, M. (2016). Direct synthesis of carbon nanotubes from only CO2 by a hybrid reactor of dielectric barrier discharge and solid oxide electrolyser cell. Plasma Chemistry and Plasma Processing, 36, 231–239.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Whitehead, J.C. (2019). Plasma Catalysis: Challenges and Future Perspectives. In: Tu, X., Whitehead, J., Nozaki, T. (eds) Plasma Catalysis. Springer Series on Atomic, Optical, and Plasma Physics, vol 106. Springer, Cham. https://doi.org/10.1007/978-3-030-05189-1_11

Download citation

DOI: https://doi.org/10.1007/978-3-030-05189-1_11

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-05188-4

Online ISBN: 978-3-030-05189-1

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)