Abstract

We review the NH3–SCR catalytic chemistry, focusing specifically on the steps involving NO2. For this purpose we use results from the mechanistic investigation of several SCR catalysts performed in our labs during the last decade, and complement them with other data from the literature. According to the resulting picture, the reactivity of NO/NO2 + NH3 over Fe- and Cu-promoted zeolites at low temperatures is consistent with previous mechanistic proposals for the Fast SCR chemistry over vanadium-based catalysts as well as over BaNa-Y zeolites. In such a general chemistry, the following roles are attributed to the three main SCR reactants: (1) NO2 forms surface nitrates and nitrites via a disproportionation route; (2) NO reduces the nitrates to nitrites; (3) NH3 decomposes/reduces the nitrites to N2. The related individual reaction steps have been identified by transient reaction analysis and confirmed by in situ FT-IR techniques. Formation of unselective reaction products (NH4NO3, N2O) is also explained by the nitrates reactivity. From a kinetic point of view, Step 2 is the most critical one at low temperature, being blocked by NH3 below 140–160 °C. A red-ox interpretation of Step 2 is also discussed, wherein the very high Fast SCR reaction rates are attributed by the extreme activity of the nitrates in catalyst reoxidation. Altogether, the proposed mechanistic picture is able to explain the observed stoichiometry, selectivity, and kinetics of the NO/NO2 + NH3 reacting system over both V-based and metal-promoted zeolites catalysts.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

As discussed in other chapters of this book, ammonia SCR was first introduced over three decades ago to control NOx emissions from power stations and other stationary sources. It is nowadays an extensively investigated and very well-known process, being still the best available commercial DeNOx technology for efficiency, selectivity, and economics.

It relies primarily on the so-called Standard SCR reaction, wherein NH3 reduces NO in the presence of oxygen to harmless N2 and H2O. Classical catalysts are ternary mixed oxide systems based on V2O5–WO3/TiO2, and the operating temperature window is rather narrow, namely 300–400 °C.

At the beginning of the new century, the automotive industry started to develop NH3—or urea SCR systems to reduce NOx contained in the exhaust gases of internal combustion engines operated with excess air, such as, for example, Diesel engines. To transfer the SCR technology from stationary sources to vehicles, however, the OEMs had to face a number of engineering challenges. Many such challenges have to do with the more complex chemistry resulting from the presence of NO2 in the SCR reacting system in addition to NO. In most EGA configurations, in fact the exhaust gases from the engine, containing mostly NO, are passed over an oxidation catalyst (DOC) before reaching the SCR converter downstream. Over the DOC, HCs and CO are completely oxidized, and NO is partially oxidized to NO2. But NO2 originates additional reactions over the SCR catalyst, including the very important Fast SCR reaction, which boosts the DeNOx activity at low temperature, especially over V-based and Fe-zeolite catalysts.

Indeed, at the start of the mobile SCR applications the catalytic mechanism and the kinetics of the full NO–NO2–NH3 reacting system were still largely debated, preventing an effective quantitative description. The aim of this contribution is to review the catalytic chemistry associated with the urea SCR technology, focusing specifically on the steps involving NO2: for this purpose we will use data and results from the investigation of several SCR catalysts performed in our labs during the last decade.

In the following we will address first the adsorption—desorption of NOx on SCR catalysts to show that not only the storage of ammonia, as universally recognized, but also the storage of nitrates on the catalyst surface may be quite relevant to the dynamic behavior of SCR systems. We will then proceed to prove that such surface nitrates are not just spectators, but actually play a crucial role in the SCR catalytic chemistry. This will set the stage for demonstrating the individual mechanistic steps associated with the important Fast SCR reaction, using transient reaction analysis. The mechanisms of ammonium nitrate formation and of the NO2–SCR reaction will be also discussed. Potential implications of the resulting overall mechanistic picture will be illustrated in the last section of the chapter: here, we will introduce the Enhanced SCR reaction, wherein nitrates, rather than being formed and converted as intermediates, are intentionally cofed (in the form of an aqueous solution of ammonium nitrate) along with NO and NH3 to the SCR catalyst in order to boost the low-temperature DeNOx activity to the same levels of the Fast SCR reaction, without the need of including NO2 in the NOx feed mixture.

2 Experimental

Catalytic activity data herein reported were collected over state-of-the-art commercial vanadium-based, Fe- and Cu-promoted zeolite SCR catalysts. The original monolith samples were crushed to powder, sieved, and loaded in a quartz microflow reactor (60–80 mg) consisting of a quartz tube (6 mm i.d.) placed in an electric oven. This experimental setup affords isothermal operation of fast transients in a chemical regime, free of any diffusional intrusions. He as carrier gas enables evaluation of N-balances.

The reactor outlet was directly connected to a quadrupole mass spectrometer (Balzers QMS 200) and to a UV-analyzer (ABB LIMAS 11HW) in parallel. NH3, NO, NO2, N2O, O2, and He were dosed from bottled calibrated gas mixtures by mass flow controllers, while water vapor was added by means of a saturator. The catalyst temperature was measured by a K-type thermocouple directly immersed in the catalytic bed.

The catalysts were typically conditioned in a T-ramp at 5 °C/min up to 600 °C in 8 % O2 v/v, and 8 % H2O v/v followed by hold at 600 °C for 5 h. Kinetic runs included transient and steady-state isothermal experiments in the 150–550 °C temperature range. Typical feed concentrations of NOx and NH3 ranged between 0 and 1,000 ppm, always in the presence of O2 (8 % v/v), H2O (8 % v/v) unless otherwise specified, with balance He. A detailed description of the experimental equipment and procedures can be found elsewhere [1–3].

3 Surface Storage of NOx

3.1 NO2 Adsorption/Desorption

It has been well known for many years that NH3 gets strongly adsorbed onto the acidic SCR catalysts and reacts with NOx from the adsorbed state. Indeed, the dynamic behavior of SCR converters is largely dominated by the balance between the rates of NH3 adsorption, desorption, and surface reaction [4] with NOx. On the other hand, NO is known to adsorb in negligible amounts onto SCR catalysts; however, this is not the case for NO2. Figure 9.1 compares NO2 concentration step feed experiments over a Cu- and a Fe-zeolite SCR catalyst. It is clearly apparent that NO2 is stored in significant amounts onto both catalysts until saturation: at the same time, NO evolution is observed.

Temporal evolution of NO2, NO outlet concentrations and of NO/∆NO2 during NO2 step feed experiments over commercial Cu- and Fe-zeolite catalysts. T = 50 °C. Feed composition: NO2 = 1000 ppm, H2O = 1 % v/v, O2 = 0 % v/v. Adapted from [8]

Several literature reports confirm, in fact, that zeolite catalysts are able to adsorb NO2 in the form of nitrates. NO2 chemisorption can be described by the following two-step mechanism, schematically representing disproportionation and heterolytic chemisorption of NO2 to form surface nitrites and nitrates, step (9.1), followed by NO2 oxidizing the nitrites to nitrates, step (9.2):

The combination of (9.1) and (9.2) results in the following global stoichiometry,

where one mole of gaseous NO is produced for every three moles of adsorbed NO2. Figure 9.1 confirms that such a proportion was approximately respected in our experiments: e.g., a NO/ΔNO2 ratio of about 0.35 was indeed observed over the Cu- and the Fe-zeolite systems, in agreement with (9.3).

The nitrates storage capacity of the two zeolite systems at 50 °C was determined from Fig. 9.1 taking into account the stoichiometry of reaction (9.3), resulting in about 0.87 and 0.50 mmol/gactive phase for the Cu- and the Fe-zeolite, respectively. Expectedly, the storage capacity was found to decrease with increasing adsorption temperature.

In a first attempt to confirm the presence of nitrates onto the catalyst surface, and in order to study their thermal stability, TPD runs were performed after saturation of the catalyst samples with NO2. During the temperature ramps evolution of NO2, NO and oxygen were indeed recorded, in line with what was already observed over other zeolite systems [5, 6] and over V2O5–WO3/TiO2 catalysts [7].

Figure 9.2 compares the NO2 traces from TPD runs after NO2 adsorption at 50 °C over the Fe- and the Cu-zeolite catalysts. In addition to the low-T peak associated with physisorbed species, an important NO2 peak from nitrates decomposition was observed above 200 °C over both systems: it appears however that nitrates formed by NO2 disproportionation were more stable on the Cu catalyst. This aspect is possibly correlated with the different activity performances exhibited by the two catalysts in the Fast SCR and in the NO2–SCR reactions [8, 9].

NO2 concentration profiles during TPD (T = 50–550 °C at 20 K/min, GHSV = 193,000 Ncc/h/gap (Fe), 266,000 Ncc/h/gap (Cu)) after NO2 adsorption (Feed: 1,000 ppm NO2, T = 50 °C, 3 % H2O, 0 % O2, balance He). Adapted from [9]

3.2 FTIR in Situ Study of NO2 Adsorption

FT-IR in situ transient reaction analysis was also applied to investigate in more depth NO2 storage on a commercial Fe–ZSM–5 (Zeolyst) sample [10]. The FT-IR data were collected in the transmission mode in a flow cell adapted to ensure full mixing and a fast response to isothermal concentration step changes of the feed concentration. The study clearly identified the formation of various ferric nitrates as the prevailing and stable terminal products of NO2 storage on Fe–ZSM–5. Other detected surface intermediates included nitrosonium ions (\( {\text{NO}}^{+}\)) in cationic position, likely exchanging the proton of the Si–OH–Al bridge in the zeolites, originated by disproportionation/heterolytic chemisorption of NO2 [6], and Fe(II) NO nitrosyls from NO adsorption onto reduced Fe sites. The formation of nitrite (NO2 −) intermediates was not detected, which is explained by their high reactivity and/or by the superposition of their IR features on the reflexes of the zeolites: their participation in the surface chemistry is however quite likely, in view of the detection of NO+ adspecies, which share the same N oxidation state (+3) and are closely related to the nitrites by equilibria such as NO+ + O2− ← → NO −2 . Such conclusions are well in line with several recent publications from the IR spectroscopy literature addressing the adsorption of NO2 on metal-exchanged zeolites [11–13].

3.3 Effect of the Catalyst Redox State on NO2 Adsorption

The effect of the catalyst red-ox state on the adsorption of NO2 on Fe- and Cu-promoted zeolite SCR catalysts has been found to be also quite significant [14]. In this study, the catalysts were either preoxidized or prereduced prior to NO2 adsorption by exposing them to O2 or to NH3, respectively, at high temperature. For both catalytic systems, results from the analysis of the gas phase during NO2 step feed changes in the absence of gaseous water emphasize an important role of the catalyst red-ox state in the dynamics of NO2 adsorption: the molar ratio of released NO to converted NO2 was close to 1/3 in the case of oxidized catalysts, in line with the two-steps mechanism leading to the formation of surface nitrates, reactions (9.1)–(9.3), but was significantly greater when the catalyst was prereduced. This is shown for example for the Fe-zeolite in Fig. 9.3a, b. The extra NO evolution is explained considering that, before being stored in the form of nitrates, NO2 effectively oxidizes the reduced catalyst, while being reduced to NO.

NO2 adsorption and TPD over Fe-zeolite. Adsorption phase: T = 200 °C, Q = 71 cm3/min (STP), NO2 = 1,000 ppm, O2 = 2 % v/v (only for green lines), carrier gas = He; TPD: T-ramp = 20 °C/min, Q = 71 cm3/min (STP), He flow. a NO/(NO in2 –NO out2 ) as a function of time during the first 500 s of NO2 feed. b NO concentration as a function of time during the first 500 s of NO2 feed. c NO2 concentration as a function of time during the first 500 s of NO2 feed. d NOx concentration as a function of catalysts temperature during TPD phase. Black lines = prereduced sample. Red lines = preoxidized sample. Green lines = preoxidized sample in the presence of oxygen during adsorption phase. Adapted from [14]

It was also found that the initial catalyst red-ox state influences the amount of nitrates adsorbed on the catalyst surface, the prereduced sample exhibiting a greater storage capacity (see Fig. 9.3c, d). In line with the literature reports [13], the greater amount of stored nitrates observed on the prereduced samples of both catalysts can be justified invoking the redispersion of Fe and Cu ions during the reduction phase, which thus provides additional sites for nitrates storage.

Another interesting finding from this study was that, in the case of the Fe-zeolite, the NO2 adsorption/desorption dynamics over the preoxidized catalyst were essentially unaffected by the presence of gaseous oxygen (see Fig. 9.3a–d).

A different situation was noted in the case of the Cu-zeolite catalyst, for which a significant effect of the oxygen on the NO2 adsorption dynamics was apparent. Indeed, when oxygen was present in the feed stream together with NO2, a lower amount of NO was produced upon NO2 step feed with respect to what observed over both the preoxidized and the prereduced samples, with NO/ΔNO2 ratio of about 0.35–0.38 in line with those expected from an oxidized catalyst. Accordingly, we can speculate that the preoxidizing procedure was not completely effective over the tested Cu-zeolite sample. Indeed the catalyst, prior to NO2 adsorption, was flushed with helium at 200 °C. We can thus assume that, in the case of the tested Cu-zeolite a partial reduction of the catalytic surface occurred at 200 °C during the catalyst exposure to an inert atmosphere [15]. This was not observed in the case of the Fe-zeolite, which suggests a greater reducibility of the Cu catalyst.

Thus, it seems now well established that the presence of NO2 in the NH3–SCR reacting system involves the formation of nitrates adspecies in significant amounts over both Fe- and Cu-promoted zeolites catalysts. The similarity with the chemistry of NOx storage onto Pt–Ba/Al2O3 Lean NOx Traps (LNT) has been noted in this respect [16]. At this point, the question is whether such species are just spectators or rather participate actively in the NH3–SCR mechanism. We address this important issue in the next paragraph.

4 The Role of Surface Nitrates in the Fast SCR Mechanism

4.1 NH3 + NOx Temperature Programmed Reaction (TPR) Runs

Information concerning the involvement of surface nitrates in the NO/NO2–NH3 SCR reactivity is provided by Fig. 9.4, wherein we compare the T-dependences of NO conversion over a Fe-zeolite catalyst measured during four different NO + NH3 Temperature Programmed Reaction (TPR) experiments with equal space velocities and heating rates (20 K/min), but with different feed gas compositions [1].

Temperature programmed reaction experiments over Fe- ZSM-5. Wcat = 0.080 mg, Flow rate = 72 cm3/min (STP). Curve A (Slow SCR): Feed = 1 % H2O, 0 % O2, NH3 = 1,000 ppm, NO = 1,000 ppm + He. Curve B (Standard SCR): Feed = 1 % H2O, 2 % O2, NH3 = 1,000 ppm, NO = 1,000 ppm + He. Curve C (Fast SCR): Feed = 1 % H2O, 0 % O2, NH3 = 1,000 ppm, NO = 500 ppm, NO2 = 500 ppm + He. Curve D: Feed = 1 % H2O, 0 % O2, NH3 = 1,000 ppm, NO = 1,000 ppm + He over catalyst pretreated with NO2 (1,000 ppm) + H2O (1 %) at 60 °C. Adapted from [1]

In the experiment associated with curve A the feed included NO + NH3 (1,000 ppm each) + H2O (1 % v/v), but no oxygen: the observed temporal evolution of the outlet concentrations, indicating the onset of a DeNOx activity only above 300 °C, was found expectedly in agreement with the so-called “Slow” SCR reaction, i.e., the poorly active DeNOx reaction between NO and NH3 which proceeds in the absence of oxygen,

When the same Temperature Programmed Reaction (TPR) experiment was replicated with 2 % O2 v/v in the feed (curve B), a greater DeNOx activity was observed as a result of the occurrence of the Standard SCR reaction (9.5) instead of the slower reaction (9.4).

Curve C shows the even much higher DeNOx activity resulting from running the same T-ramp with a feed containing 1,000 ppm of NH3 and 500 ppm each of NO and NO2: curve C is of course representative of the NO (and NOx) conversion in the Fast SCR reaction (9.6):

Whose rate is known to largely exceed the rate of Standard SCR (9.5) at low temperatures.

During the fourth and final Temperature Programmed Surface Reaction (TPSR) experiment, associated with curve D, a feed containing NO + NH3 (1,000 ppm each) + H2O (1 % v/v), but no oxygen and no NO2, was passed over a catalyst sample preexposed to 1,000 ppm of NO2 + 1 % H2O at 60 °C. Figure 9.4 shows that during the initial part of this T-ramp, up to about 200 °C, the evolution of the NO conversion matched closely that observed in the case of the Fast SCR TPR run, curve C. In the following part of the experiment the NO conversion dropped sharply close to zero, before eventually approaching the behavior observed for the Slow SCR reaction, i.e., curve A.

A plausible rationalization of the similarity between the initial parts of curves C (Fast SCR) and D (NO + NH3 over catalyst pretreated with NO2) in Fig. 9.4 is that in both cases NO and ammonia in the feed were reacting with surface nitrates, either directly and simultaneously formed via NO2 disproportionation (curve C), or previously formed and stored on the catalyst during its pretreatment with NO2 (curve D). It is worth emphasizing that in this experiment the DeNOx activity in the presence of surface nitrates (but in the absence of gaseous NO2) was found virtually identical to that associated with the Fast SCR reaction in the low temperature region up to about 200 °C. This is quite consistent with other transient experiments showing that both over Fe-zeolite [1] and over V2O5/WO3/TiO2 [17] the rate of reduction of ammonium nitrate at the catalyst surface by NO at low temperature (around 170 °C) was essentially identical to that of the Fast SCR reaction.

The drop of NO conversion exhibited by curve D at T > 200 °C in Fig. 9.4 is explained by depletion of surface nitrates; in fact, in another similar experiment (not reported), wherein the catalyst had been pretreated with NO2 at 150 °C rather than at 60 °C, an earlier drop in the NO conversion was observed due to the reduced amount of nitrates stored at the higher temperature. Eventually, the match between curves D and A at T > 300 °C confirms the absence of any residual oxidizing agent (but NO) in the final part of the T-ramp experiment over the NO2 pretreated sample.

Similar TPR experiments performed over a Cu-zeolite catalyst provided similar results.

4.2 Role of Nitrates in the NO/NO2–NH3 SCR Mechanism

The TPR data in Fig. 9.4 clearly prove that the DeNOx activity grows with increasing oxidizing potential of the SCR reaction environment. Essentially, they provide a ranking of the oxidizers involved in the NH3–SCR reactions, with NO being a poorer oxidizer than O2, which is in turn a much less powerful oxidizer than NO2/nitrates. This is in line with a red-ox interpretation of the NH3–SCR chemistry wherein catalyst reoxidation is the slow, rate controlling step of the red-ox cycle at low temperature [7, 18]. In addition, the comparative analysis of curves C and D in Fig. 9.4 further demonstrates that the oxidizing power of NO2 is actually not different from that of surface nitrates. While this result does not rule out a direct participation of NO2 in the SCR chemistry, it suggests however that surface nitrates, rather than gaseous NO2, may be responsible for the rapid catalyst reoxidation in the case of the Fast SCR reaction over Fe-zeolites, as proposed in the past for V-based catalysts [7].

So far we have proven that not only nitrates are stored onto Fe- (and Cu-) zeolite catalysts in the presence of NO2, but also that they do participate effectively in the NH3–SCR catalytic chemistry, being indeed responsible for the very high DeNOx activity associated with the Fast SCR reaction. In the next paragraph we make use of transient reaction analysis to elucidate in more detail the reactivity of surface nitrates with NO and NH3, i.e., the SCR reactants: in so doing, we will also explore the individual steps of the Fast SCR mechanism.

5 Mechanistic Studies by Transient Response Methods

We summarize in this Section a kinetic investigation of the NO2–related SCR reactions performed by running transient response experiments over a Cu-zeolite catalyst [2]. Its goal was to challenge our mechanistic understanding of the SCR catalytic chemistry on a quantitative basis, describing the kinetics of the important NO/NO2–NH3 SCR reactions by a set of pseudoelementary steps, rather than adopting empirical global rate equations. The transient kinetic runs consisted of isothermal concentration step changes, temperature programmed desorption (TPD), and temperature programmed surface reaction (TPSR) experiments. All the runs were performed in the absence of oxygen in order to prevent any contributions from the Standard SCR and NH3 oxidation reactions, since the study was intentionally focused on the mechanistic role of NO2. On the opposite, water was always included in the feed stream, in line with real engine exhausts composition. The experimental results were used to estimate intrinsic rate parameters of all the reaction steps in a detailed kinetic mechanism [2]. For the purpose of the present contribution, however, we will discuss the mechanistic information only on a qualitative basis.

5.1 Reactivity of Surface Nitrates with NO and with NH3

Assuming that nitrates have been formed by NO2 interaction with the catalyst, as shown in the previous paragraph, we proceed here to examine their reactivity with ether one of the other two Fast SCR reactants, namely NO and NH3.

The reactivity of surface nitrates with NO is demonstrated by a transient experiment where we first adsorbed NO2 (1,000 ppm, concentration step change, in a stream of water (3 % v/v) and Helium) on the Cu-zeolite at 200 °C, then we added 1,000 ppm of NO to the water/Helium feed stream, and eventually performed a T-ramp where the catalyst temperature was linearly increased from 200 to 550 °C at 20 °C/min.

The results of the full experiment are displayed in Fig. 9.5. In the first stage, saturation of the catalyst by NO2 is apparent, with the associated NO evolution indicating formation of surface nitrates according to (9.1)–(9.3).

NO TPSR with preadsorbed nitrates. Nitrates adsorption phase (not shown)—T = 200 °C, Feed: NO2 = 0−1,000 ppm, H2O = 3 % v/v, O2 = 0 %. NO TPSR—Feed: NO = 0−1,000 ppm, H2O = 3 % v/v, O2 = 0 %. Isothermal phase temperature = 200 °C, T-ramp = 20 °C/min. Adapted from [2]

Upon NO feed an immediate evolution of NO2 was detected, then the latter species rapidly dropped to zero while NO approached its feed value. A similar behavior had been observed also over V-based [19] and Fe-zeolite SCR catalysts [20]. In analogy, also over the herein tested Cu-zeolite the formation of NO2 was likely associated with the prompt reduction of nitrates to nitrites by NO and the subsequent reaction of nitrites and nitrates to give NO2, according to the reverse of reactions (9.2) and (9.1), respectively. During the subsequent T-ramp (TPSR phase), only a limited additional oxidation of NO with corresponding production of NO2 was detected, again likely related to the reduction of adsorbed nitrates. The presence of residual surface nitrates during the TPSR phase was also confirmed by additional dedicated TPSR runs with NH3, not reported for brevity, which showed some N2 evolution. An analogous test was also performed at 50 °C (not shown), which confirmed the same qualitative behavior, thus emphasizing the reducibility of surface nitrates by NO at temperatures as low as 50 °C, as also observed over Fe-zeolites [1].

Figure 9.6 shows that, on the contrary, when the same TPSR experiment was replicated with a step feed of NH3 instead of NO, no reaction was detected: ammonia is thus unable to reduce the surface nitrates at 200 °C (as well as at lower temperatures, results not shown), which is apparently paradoxical, since NH3 is in principle a much better reducing agent than NO. Indeed, subsequent T-ramp experiments evidenced the reduction of surface nitrates by NH3, but only starting from T > 220 °C [21].

NH3 TPSR with preadsorbed nitrates. Nitrates adsorption phase—T = 200 °C, Feed: NO2 = 0−1,000 ppm, H2O = 3 % v/v, O2 = 0 %. NH3 TPSR—Feed: NH3 = 0−1,000 ppm, H2O = 3 % v/v, O2 = 0 %. Isothermal phase temperature = 200 °C. Adapted from [2]

Thus, a preliminary conclusion here is that surface nitrates formed via NO2 disproportionation, though thermally stable, are readily reduced at very low temperature by NO, if available, forming NO2, while their direct reduction by NH3 proceeds only at higher temperatures.

Next, we discuss how such a reduction step contributes to the overall SCR pathways leading from NOx + NH3 to N2.

5.2 The Role of Nitrites

Mechanistic studies over Fe-zeolite catalysts [1, 20, 21] suggest that at temperatures as low as 150–200 °C and in the presence of NH3, the nitrites intermediate (NO2 −) produced by NO2 disproportionation, reaction (9.1), preferentially reacts with ammonia, if present, forming unstable ammonium nitrite which readily decomposes to N2 and H2O according to (9.7) [22, 23]:

Decreasing the catalyst temperature results instead in favoring the oxidation of nitrites by NO2, i.e., reaction (9.2), with consequent NO formation and corresponding decrease of the N2 evolution. The same qualitative trend was observed over a Cu-zeolite system, as shown by a set of dedicated experimental runs discussed in the following. The tests consisted first in the isothermal adsorption of NH3, obtained feeding 1,000 ppm of NH3 (concentration step change), 3 % v/v H2O, and balance He at a constant temperature (200 °C). Then, after removing NH3 from the feed and flushing the catalyst with H2O and Helium, still at the same temperature, the catalyst was exposed to a 1,000 ppm NO2 step feed. Finally the temperature was linearly increased at a constant rate of 20 °C/min up to 550 °C in order to clean the catalyst surface. The same test was repeated decreasing the temperature of the isothermal phase to 150 °C and to 120 °C. Figure 9.7 compares the results collected during the NO2 feed transient at 200 °C (Fig. 9.7a) and 120 °C (Fig. 9.7b).

Reactivity of NO2 with preadsorbed NH3. NH3 adsorption phase (not shown)—Feed: NH3 = 0−1,000 ppm, H2O = 3 % v/v, O2 = 0 %. NO2 feed phase—Feed: NO2 = 0−1,000 ppm, H2O = 3 % v/v, O2 = 0 %. a T = 200 °C. b T = 120 °C. Adapted from [2]

In both tests, the NO2 outlet trace exhibited first a dead time, then it slowly grew and eventually approached the feed concentration level. Also, immediate evolution of N2 and NO was recorded at both temperatures upon NO2 feed, then the signals of the same species slowly decreased with time, eventually approaching zero. Figures 9.7a, b clearly point out however that the increase of catalyst temperature from 120 to 200 °C over the Cu-zeolite resulted in an incremented NO formation and a corresponding decreased N2 evolution: a higher temperature thus favors the reduction of nitrites by ammonia, reaction (9.7), against the oxidation of nitrites to nitrates, reaction (9.2), in line with what reported for Fe-zeolites.

These data thus prove that the reactivity of surface nitrites with ammonia. Reaction (9.7) provides the crucial (but facile) selective pathway to dinitrogen in the NO/NO2–NH3 SCR catalytic chemistry.

5.3 Overall Mechanistic Scheme

Based on the data presented and discussed so far, the reactivity of NO/NO2 + NH3 over Fe- and Cu-promoted zeolites at low temperatures appears consistent with what previously reported over vanadium-based catalysts [7, 17, 19, 24] as well as with the mechanistic proposals for the Fast SCR chemistry over BaNa-Y [22, 23].

In such a chemistry, the reactivity demonstrated in the previous paragraphs attributes the following roles to the three main SCR reactants: (1) NO2 forms surface nitrates and nitrites via a disproportionation route; (2) NO reduces the nitrates to nitrites; (3) NH3 decomposes/reduces the nitrites to N2. The related basic reaction steps, originally identified by transient reaction analysis and recently confirmed also by in situ FT-IR [10] over Fe–ZSM–5, are summarized in Table 9.1.

This chemistry explains the optimal 1:1 molar ratio of NO and NO2 in the Fast SCR reaction. It also explains the full range of selectivities observed upon varying the NO2/NOx feed ratio [25–28]. In the presence of NO2 excess (NO2/NOx > ½), in fact, incomplete reduction of nitrates by NO, the critical step R7 in Table 9.1, is responsible for the undesired formation of NH4NO3 at very low temperatures (step R6 in Table 9.1), and of N2O at intermediate temperatures (step R8 in Table 9.1).

5.4 Ammonia Blocking of Nitrates Reduction

We have shown in Sect. 9.5.2 that the reduction of surface nitrates by NO, the key step in the Fast SCR mechanism over Me-exchanged zeolites and V-based catalysts, is active already at 50 °C. A dedicated study over an Fe-BEA catalyst [20] pointed out, however, that in the presence of ammonia the reaction between NO and nitrates is stopped and proceeds only on raising the temperature up to 140–160 °C, which thus represents an intrinsic lower bound to the Fast SCR activity. Similar results were reported for a BaNa-Y zeolite [5].

The NH3 blocking effect is possibly associated with a strong interaction between ammonia and nitrate species when both are present on the catalyst surface. More specifically, at low temperature NH3 could react with nitrates to form ammonium nitrate precursors (or strongly interacting ammonia-nitrate adspecies), e.g.,

thus blocking the critical reactivity of nitrates with NO. Only upon increasing the temperature or reducing the NH3 concentration, nitrates are released due to dissociation of the ammonia-nitrate complex, as the (9.8) equilibrium is shifted to the left [5, 20].

Notably, the inhibiting effect of NH3 on the Fast SCR activity at low temperature is not due to the ammonia competitive chemisorption on the catalytic sites, but occurs because ammonia captures a key intermediate in an unreactive form. In this respect, one way to partially prevent this undesired effect is to modify the equilibrium of ammonium nitrate dissociation, e.g., by increasing the temperature or by decreasing the gas-phase ammonia concentration. Since the blocking effect is related to the acid properties of the formed nitrates, another possibility to moderate its negative impact on the Fast SCR reactivity at low T would be to modify the catalyst acid/base properties in order to favor the interaction of ammonia with the catalyst sites rather than with the nitrates [5].

5.5 Considerations on the Red-ox Nature of the NH3–SCR Mechanisms

It is worth noticing that the steps discussed above for the Fast SCR chemistry, reaction (9.6) does not involve changes in the formal oxidation state of the catalytic sites. In fact, formation of nitrates and nitrites occurs via disproportionation of NO2 (steps R1 + R2 in Table 9.1), reduction of nitrates to nitrites is compensated by the simultaneous oxidation of NO to NO2 (step R3), and decomposition of nitrites to N2 by NH3 (step R5) is also red-ox neutral. Accordingly, we can expect that in the presence of NO2, a strong oxidizer, the SCR catalyst sites remain at their highest oxidations states. This is a substantial difference from the case of the Standard SCR reaction (9.5), wherein reduction of NO by NH3 to N2 does involve catalyst reduction, and therefore closure of the catalytic cycle requires catalyst reoxidation by O2 (likely a rate limiting step at low temperature). Recent published work based on in situ FTIR studies over Fe–ZSM–5 [10] and on X-Ray Absorption Spectroscopy investigations of Cu-CHA [29] confirms that only fully oxidized metal sites (Fe(III) and Cu(II), respectively) are present at the catalyst surface under Fast SCR conditions, so with NO2, whereas a mixed situation, including both oxidized and reduced sites, prevails under Standard SCR conditions, i.e., in the absence of NO2.

It is worth emphasizing, however, that these results do not rule out a Mars-Van Krevelen mechanism for the Fast SCR chemistry, as they simply show that the balance between oxidized and reduced catalytic sites is shifted toward the former ones in the presence of NO2. Indeed, it has been shown that over a V-based catalyst the global reaction (9.6), and specifically its key step R7 in Table 9.1, is actually associated with a red-ox cycle involving the very effective reoxidation of reduced sites by surface nitrates [7]. In fact, step R7 did not proceed over a V-free WO3/TiO2 sample, due to the lack of the red-ox catalytic sites associated with the V component [7]. In the framework of a general red-ox interpretation of the SCR mechanisms, this explains the higher rate of the Fast SCR reaction as compared to the Standard SCR chemistry, wherein the less active gaseous oxygen is responsible for the slower, rate limiting catalyst reoxidation step [30]. Notably, the result of the NO/NO2–NH3 transient experiments in the previous Sections, where O2 was not included in the feed mixture, point out that gaseous oxygen is not needed for NOx conversion, being replaced by nitrates as the oxidizing species in the red-ox cycle.

Thus, not only nitrates adspecies, formed upon inclusion of NO2 in the SCR reacting system, participate in the NO/NO2–NH3 catalytic chemistry: their role as strong oxidizers is indeed critical for the very important Fast SCR activity.

5.6 Higher Temperatures: The NO2–SCR Reaction

Contrary to NO (Fig. 9.5), ammonia was unable to reduce directly nitrates up to 200 °C over V-based and metal-promoted zeolites catalysts (Fig. 9.6): but what happens at higher temperatures?

Figure 9.8 shows a transient experiment over Cu-zeolite in which the catalyst was first saturated with nitrates, feeding NO2 at 50 °C. Then the NO2 feed was shut off, the ammonia feed was started, and the temperature was linearly increased up to 550 °C. Clearly, ammonia did not react with surface nitrates at low temperature, but starting from about 230 °C ammonia consumption was observed, with formation of nitrogen mainly (the minor formation of N2O is discussed in the next paragraph). This reaction stopped when all the surface nitrates were depleted. So ammonia is able to reduce nitrates as well, but only at higher temperature if compared to NO.

NH3 TPSR with preadsorbed nitrates over Cu-zeolite. Nitrates adsorption phase—T = 50 °C, Feed: NO2 = 0−1,000 ppm, H2O = 3 % v/v, O2 = 0 %, balance He. NH3 TPSR—Feed: NH3 = 0−1,000 ppm, H2O = 3 % v/v, O2 = 0 %, balance He. Isothermal phase temperature = 50 °C, T-ramp = 20 °C/min. [2]

The run in Fig. 9.8, showing the reactivity of nitrates with ammonia, has been compared with a Temperature Programmed Reaction run over the same catalyst, where the feed included gaseous ammonia and NO2, and during which we also observed consumption of ammonia, and production of N2 and of N2O. Most interestingly, the N2 temporal evolution observed in this case matched closely the one in Fig. 9.8. This strongly suggests that the reactivity of surface nitrates with ammonia is the same as that of NO2 with ammonia, that is, the NO2 SCR reaction:

whose mechanism is therefore likely associated with the direct oxidation of ammonia by surface nitrates. Again, similar data and conclusions apply also to other SCR catalysts [2, 21].

5.7 Selectivity Issues: The Formation of NH4NO3, N2O

The reactivity of nitrates has to do not only with the selective (to N2) and desired Fast and NO2 SCR reactions, but also with the unselective reactions responsible for the formation of undesired by-products.

At low temperatures, below 200 °C, ammonia is not able to reduce nitrates, but it can however react with them to form ammonium nitrate [18, 24],

In our early study over a V-based catalyst [24], reaction (9.10) was identified by the stoichiometry of NO2 + NH3 conversion, and of N2 formation. Ammonium nitrate, formed and deposited onto the catalyst, could not of course be directly detected, but its formation was confirmed both by the lack in the N-balance, by dedicated IR analyses performed on the catalyst downloaded from the reactor after the experiment, and by subsequent TPD runs which showed formation of N2O (see Fig. 9.9), in line with the well-known thermal decomposition of ammonium nitrate,

TPD of preadsorbed NH4NO3 over WO3/TiO2. Carrier gas = He. T-ramp = 20 °C/min. Reprinted from [7]

Again, similar findings apply also to the new generation of metal-promoted zeolites [1, 2].

Hence, in the presence of NO2 not only the activity of SCR catalysts, but also their selectivity appears to be governed by the reactivity of nitrates. When NO is available in addition to NH3, and the temperature exceeds a threshold related to the dissociation of ammonium nitrate, the desired reduction of the surface nitrates by NO can proceed effectively, resulting in the most efficient selective DeNOx pathway, i.e., the Fast SCR reaction. On the other hand, if an excess of NO2 prevails in comparison to NO, the unselective pathways (9.10) and (9.11) will prevail at lower and higher temperatures, respectively.

6 Feeding Nitrates: The Enhanced SCR Reaction

6.1 The Boosting Action of Ammonium Nitrate

The role of nitrates as key intermediates in the Fast SCR mechanism has been fully confirmed in recent years by the discovery of the so-called “Enhanced SCR” reaction [3, 31],

Reaction (9.12) involves the selective catalytic reduction of NO by its reaction with ammonia and with nitrate species, supplied, e.g., in the form of aqueous solution of ammonium nitrate sprayed into the gaseous feed stream to the SCR catalyst. Reaction (9.12) results in very high DeNOx efficiencies at low temperatures, similar to those of Fast SCR, even though no NO2 is fed to the SCR catalyst. Accordingly, it can in principle replace reaction (9.6) in boosting the DeNOx activity without, however, any need of preoxidizing NO to NO2 upstream of the SCR converter.

The enhancement of the SCR activity is best illustrated by Fig. 9.10, which shows the temporal evolution of the NO, NH3 and NO2 outlet concentrations during a transient run at 205 °C over an Fe–ZSM–5 washcoated monolith catalyst. Initially, only equimolar amounts of NH3 and NO (1,000 ppm each) were fed to the catalyst in a nitrogen stream, with negligible conversion. At t = 1450 s, O2 (2 % v/v) was added to the reactor feed, resulting in the onset of only a limited conversion of NO and NH3 (about 15 %) associated with the Standard SCR reaction (9.5). At t = 2800 s, a pump started to inject an aqueous solution of ammonium nitrate in the test reactor feed stream, resulting in feed concentrations of 340 ppm NH4NO3 and 1 % H2O v/v. As a consequence, the outlet NO and NH3 concentrations dropped rapidly, eventually approaching after a few oscillations the conversion (68 %) predicted by reaction (9.12) in case of complete depletion of the limiting reactant NH4NO3. NO2 evolution was negligible (<10 ppm) during the whole transient.

Transient experiment over the Fe-ZSM-5 catalyst at T = 205 °C, GHSV = 33,000 h−1. Temporal evolution of NO, NH3, and NO2 outlet concentrations upon addition of a 2 vol % O2 to 1,000 ppm NO, 1,000 ppm NH3 in N2 (at t = 1450 s); b 340 ppm NH4NO3 + 1 vol % H2O to 1,000 ppm NO, 1,000 ppm NH3, 2 % O2 in N2 (at t = 2800 s). Adapted from [31]

It is clearly apparent from Fig. 9.10 that addition of ammonium nitrate to NO–NH3–O2 dramatically increased the low temperature NO reduction activity over Fe–ZSM–5. Furthermore, the added NH4NO3 itself was totally and selectively converted according to reaction (9.12). The substantial enhancement of the NOx removal efficiency due to NH4NO3 addition as compared to the Standard SCR was confirmed also at higher temperatures, though it progressively decreased with growing temperature.

The “Enhanced SCR” chemistry was further examined in a similar transient experiment at 205 °C (GHSV = 36,000 h−1), wherein the Fe–ZSM–5 catalyst was first exposed to a feed containing 500 ppm NO, 750 ppm NH3, 0 % O2 in N2, to which an aqueous solution of nitric acid, corresponding to feeding 250 ppm HNO3 and 1 % H2O, was added in a second stage. In this case a steady-state conversion of both NO and NH3 close to 90 % was observed, consistent with the stoichiometry of

which is of course equivalent to reaction (9.12) upon considering dissociation of NH4NO3 into ammonia and nitric acid. Thus, the observed activity enhancement is likely due to the participation of nitrate species in the reaction. The result of this particular experiment points out as well that oxygen is unnecessary for NO conversion, again in agreement with (9.12) or (9.13).

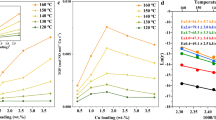

Figure 9.11 compares steady-state NOx and ammonia conversions in Standard (feed: 1,000 ppm NO, 1,000 ppm NH3, 2 % O2, 1 % H2O in N2) and Fast SCR (feed: 500 ppm NO, 500 ppm NO2, 1,000 ppm NH3, 2 % O2, 1 % H2O in N2) runs over the Fe-zeolite catalyst with those measured when feeding 1,000 ppm NO, 1,000 ppm NH3, 2 % O2 in N2 along with 340 ppm of NH4NO3 + 1 % H2O.

Effect of the addition of 340 ppm of NH4NO3 to the feed stream on the steady-state NOx and ammonia conversions over the Fe-ZSM-5 catalyst as a function of temperature temperature in comparison to Standard and Fast SCR. GHSV = 33,000 h-1. Feed = 1,000 ppm NO, 1,000 ppm NH3, 1 % H2O, 2 % O2 in N2. Standard SCR runs: NO2/NOx = 0; Fast SCR runs: NO2/NOx = 1/2. Adapted from [3]

When only NO and ammonia were fed to the system with oxygen and water, the activity was poor, conversion being still far from complete even at 350 °C. The outlet concentration levels of NO and ammonia were in line with the occurrence of the Standard SCR reaction (9.1); however, at temperatures above 300 °C a growing negative deviation from the expected 1/1 NO/NH3 molar consumption ratio was observed, possibly related to the onset of the ammonia oxidation, which is known to proceed on Fe-zeolites in this temperature range [1, 20, 21, 27]. When an equimolar mixture of NO and NO2 (500 ppm each) was fed to the Fe-zeolite catalyst along with ammonia, though, 100 % conversions were observed already at 200 °C, in line with the strong sensitivity of Fe-zeolite catalysts to the NO2 feed content and with the corresponding high activity of the Fast SCR reaction (9.6) [1, 27, 32, 33].

In the case of the runs with NH4NO3 feed, the steady-state NO and ammonia conversions were as high as 68 % (i.e., limited by the feed concentration of ammonium nitrate) already at 200 °C, and they remained more or less stable up to 250 °C, when they began to grow slowly with temperature. The outlet concentrations measured in the range 200–250 °C are consistent with the stoichiometry of reaction (9.12): actually they correspond to the stoichiometric limit imposed by the feed concentration of ammonium nitrate and further originate from the poor activity of the Standard SCR reaction over this catalytic system.

At temperatures in excess of 250 °C the situation was modified: both the NO and the ammonia conversion increased, eventually approaching 100 % at the highest temperatures. Notably, NO2 was not detected in significant amounts at any investigated temperature.

The incremented activity is due to the increasing contributions of the Standard SCR reaction and of the ammonia oxidation with growing temperature. At these temperatures also the “NO2–SCR” reaction should be taken into account,

whose mechanism is likely associated with the oxidation of ammonia by surface nitrates [21], as discussed in Sect. 9.5.6 above: ammonia oxidation, either by oxygen or by nitrates, is responsible eventually for the reduced NOx/NH3 conversion ratio.

Thus, Figs. 9.10 and 9.11 confirm that over Fe–ZSM–5 addition of ammonium nitrate to the feed stream resulted in promoting the DeNOx activity with respect to the Standard SCR reaction. Due to the substoichiometric feed contents of NH4NO3 in these runs, the NOx conversion of the Fast SCR reaction was not reached. N2O formation was found to be very limited, and comparable to what observed under Fast SCR conditions. Similar results were obtained in the case of V2O5–WO3/TiO2 SCR catalysts [3].

In a subsequent study, the effects of different operating variables, namely space velocity (between 18 and 75 kh−1), temperature (between 180 and 250 °C), and ammonium nitrate feed content (between 20 and 100 % of the stoichiometric feed concentration), were systematically investigated over a commercial V-based Haldor Topsøe catalyst in order to identify the best process conditions [34]. Data from this study confirmed the occurrence of the very active Enhanced SCR reaction over the V-based catalyst, and pointed out that the added NH4NO3 itself was totally and selectively converted. As shown for example in Fig. 9.12, the addition of AN to the feed stream at 200 °C leads to a significant increase in the NOx conversion compared to the Standard SCR reaction at all the investigated space velocities. The upper Fast SCR bound was approached, but the substoichiometric AN feed contents (100 and 200 ppm) limited the NO conversions associated with the E-SCR reaction. Notably, the NOx conversions were identical within experimental error when feeding either ammonium nitrate (AN) or NO2 in the same proportions (i.e., same AN to NO or NO2 to NOx feed ratio).

NOx steady-state conversions versus GHSV over V2O5–WO3/TiO2 in NO–NH3–O2 runs (Standard SCR), NO/NO2–NH3–O2 runs (Fast SCR) and NO–NH3–O2–AN or NO–NH3–O2–NO2 runs with different AN/NO or NO2/NOx feed contents (1/5, 2/5) at 200 °C. Feed: 500 ppm NOx, 100–200 ppm AN, 500 ppm NH3, 10 % O2, 10 % H2O + N2. Reprinted from [34]

Experiments were also performed feeding the stoichiometric amount of ammonium nitrate (250 ppm). In these cases, however, the measured NOx conversions did not reach those of Fast SCR: this was ascribed to an incomplete conversion of the stoichiometric AN feed content due to competition with the Standard SCR activity, causing buildup of AN on the catalyst and thus inhibiting the DeNOx activity. N2O formation was found negligible at all the reaction conditions which granted a complete conversion of the AN injected in the feed stream.

In terms of DeNOx efficiency, the best result of this study was collected at 180 °C with a space velocity of 18 kh−1: at these conditions the NOx conversion increased from 40 % in the absence of AN feed up to 86–93 % with the feed containing 200 or 250 ppm of AN. Furthermore, on decreasing the NH3/NO feed ratio from 1 down to 0.85, the ammonia slip was reduced below 10 ppm while maintaining the NOx conversion at its stoichiometric limit.

6.2 Analysis of the Enhanced SCR Chemistry

It is worth noticing that both the Fast SCR and the Enhanced SCR chemistries can be formally represented according to a simple sequential scheme, that we originally proposed for the Fast SCR mechanism only. We showed by transient kinetic experiments [17] that at temperatures as low as 150–170 °C the Fast SCR reaction proceeds via a two-step sequence in which ammonium nitrate is first formed from NO2 and NH3, reaction (9.14), and then reacts with NO, reaction (9.15):

The sum of (9.14) and (9.15) yields in fact the Fast SCR, reaction (9.6), wherein NO2 is a reactant and NH4NO3 acts as an intermediate. The same sequence, however, also describes the Enhanced SCR chemistry, wherein however NH4NO3 is now a reactant and NO2 becomes an intermediate: the stoichiometry of reaction (9.12) is obtained in this case adding (9.15), multiplied by two, to (9.11).

Clearly, the analogy between the Fast SCR and the Enhanced SCR chemistries has deeper roots than just a combination of stoichiometries. It actually originates from the key mechanistic role played by nitrates adspecies in both reactions. Such nitrates are either formed via NO2 dimerization, disproportionation, and heterolytic chemisorption in the Fast SCR chemistry (see Sect. 9.5.3 and Table 9.1), or are formed directly by nitric acid adsorption when feeding aqueous solutions of NH4NO3 or nitric acid in the case of Enhanced SCR. It is well known that ammonium nitrate participates in the dissociation equilibrium (9.16) with nitric acid and ammonia,

Once formed, the nitrates adspecies can then participate in the same catalytic steps involved in the Fast SCR mechanism, namely their rate controlling reduction by NO to nitrites, followed by the rapid reaction of nitrites with NH3 to give dinitrogen, along the same pathways already outlined in Sect. 9.5.3 above [3]. This is in fact consistent with the observation that feeding nitrate species in aqueous solution rather than gaseous NO2 results in a DeNOx activity similar to that of the Fast SCR reaction. In both cases the strong promotion of NOx reduction at low temperature results from the extreme oxidizing properties of the nitrates, which can speed up the rate limiting step of catalyst reoxidation in the SCR red-ox cycle [4, 7, 35, 36].

From a conceptual standpoint, injecting nitrates in order to reduce NOx may seem quite paradoxical. Nevertheless, data prove that this is indeed effective for promoting the DeNOx activity at low temperature.

7 Summary and Conclusions

Our understanding of the NH3–SCR catalytic chemistry in the presence of NO2 has greatly improved in the last few years. The key has been the identification of the crucial role of surface nitrates, which do not act as terminal reaction products, as originally suspected, but are directly responsible for the very high Fast SCR activity. It is also found that the reactivity of nitrates is quite general, being similar over the classical ternary V–W–Ti SCR catalysts as well as over the new generation of Fe- and Cu-promoted zeolite catalysts. These results open the way to chemically consistent, accurate, reliable, and comprehensive simulation models of SCR-based EGA systems, as required by the automotive industry in order to fulfil the upcoming emissions regulations.

References

Grossale A., Nova I., Tronconi E., Chatterjee, D., Weibel, M., J.Catal. (2008) 256:312–322

Colombo M, Nova, I, Tronconi E., Catalysis Today (2012) 197: 243– 255.

Forzatti, P, Nova, I, Tronconi, E, Ind. Eng. Chem. Res. ( 2010) 49: 0386–10391

Nova, I, Beretta, A, Groppi, G, Lietti, L, Tronconi, E, Forzatti P,“Monolithic catalysts for NOx removal from stationary sources”, in “Structured catalysts and reactors”, 2nd Edition, Edt.s A. Cybulski and J.A. Moulijn, Taylor and Francis 2006, p. 171–214

Savara, A, Danon, A, Sachtler, WMH, Weitz, E. Physical Chemistry Chemical Physics (2009) 11:1180–1188.

Yeom,Y, Li, M, Savara, A, Sachtler, WMH, Weitz, E., Catalysis Today (2008) 136: 55–63.

Tronconi E, Nova I, Ciardelli C, Chatterjee D, Weibel M., Journal of Catalysis (2007) 245(1):1–10

Colombo, M, Nova I, Tronconi E, Applied Catalysis B: Environmental (2012) 111– 112:433–444

Grossale, A Nova I, Tronconi E, Chatterjee, D, Weibel, M, Topics in Catalysis, (2009) 52:1837–1841

Ruggeri, MP, Grossale, A, Nova I, Tronconi E, Jirglova, H, Sobalik, Z, Catalysis Today (2012) 184: 107–114

Rivallan, M, Ricchiardi, G, Bordiga, S, Zecchina A, J. Catal (2009) 264: 104

Iwasaki, M, Shinjoh, H, J. Catal, (2010) 273: 29

Ahrens, M, Marie, O, Bazin, P, Daturi, M, J. Catal (2010) 271: 1

Colombo, M, Nova I, Tronconi E, Applied Catalysis B: Environmental, (2012) 111–112: 434–444

Szanyii, J, Kwak, JH, Zhu, H, Peden, CHF, Physical Chemistry Chemical Physics (2013) 15: 2368–2380

Forzatti, P, Lietti, L, Nova I, Tronconi E, Catalysis Today (2010) 151: 202–211.

Ciardelli C, Nova I, Tronconi E, Chatterjee D, Bandl-Konrad B, Chemical Communications (2004) 23:2718–271.

Koebel, M, Madia, G, Raimondi, F, Wokaun, A, J. Catal. (2002) 209 159

Nova I, Ciardelli C, Tronconi E, Chatterjee D, Bandl-Konrad B, Catalysis Today (2006) 114(1):3–12

Grossale A., Nova I., Tronconi E., Journal of Catalysis, (2009) 265: 141–147.

A. Grossale, I. Nova, E. Tronconi, Catalysis Letters, 130 (2009) 525–531.

Chen, HY, Sun, Q, Wen, B, Yeom, YH, Weitz, E, Sachtler, WMH, Catalysis Today, (2004) 96 1–10.

Li, M, Yeom, YH, Weitz, E, Sachtler, WMH, Journal of Catalysis, 235 (2005) 201–208.

Ciardelli C, Nova I, Tronconi E, Bandl-Konrad B, Chatterjee D, Weibel M, Krutzsch B, Applied Catalysis B: Environmental (2007) 70(1–4):80–90

Kröcher, O, Devadas, M, Elsener, M, Wokaun, A, Söger, N, Pfeifer, M, Demel, Y, Mussmann, L, App. Catal. B: Environ. (2006) 66: 208

Devadas, M, Kröcher, O, Elsener, M, Wokaun, A, Mitrikas, G, Söger, N, Pfeifer, M, Demel, Y, Mussmann, L, Catal. Today (2007) 119: 137

Grossale A., Nova I., Tronconi E., Catal. Today, (2008) 136:18.

Colombo M, Nova I, Tronconi E Catal Today (2010) 151 (3–4):223–230

McEwen, JS, Anggara, T, Schneider, WF, Kispersky, VF, Miller, JT, Delgass, WT, Ribeiro, FH, Catalysis Today (2012) 184: 129–144.

Hoj, M, Beier, MJ, Grunwaldt, JD, Dahl, S, Applied Catalysis B: Environmental (2009) 93:166–176

Forzatti P, Nova I., Tronconi E., Angewandte Chemie International Edition, (2009) 48(44):8366–8368

Brandenberger, S.; Kroecher, O.; Tissler, A.; Althoff, R. The State of the Art in Selective Catalytic Reduction of NOx by Ammonia Using Metal-Exchanged Zeolite Catalysts. Catal. ReV.: Sci. Eng. 2008, 50 (4), 492–531.

Sjovall, H.; Blint, R. J.; Gopinath, A.; Olsson, L. A Kinetic Model for the Selective Catalytic Reduction of NOx with NH3 over an Fe-zeolite Catalyst. Ind. Eng. Chem. Res. 2010, 49 (1), 39–52

Forzatti P, Nova I., Tronconi E., Kustov, A, Thøgersen, JR, Catalysis Today (2012) 184: 153–159

Busca G, Lietti L, Ramis G, Berti F, Appl. Catal. B: Environmental (1998) 18:1.

Nova I, Ciardelli C, Tronconi E, Chatterjee D, Weibel M, AIChE Journal (2009) 55(6) 1514–1529

Acknowledgments

The financial support of Daimler AG (Germany) to our investigation of NH3–SCR during many years is gratefully acknowledged. The authors are indebted to Dr. Bernd Krutzsch, Dr. Michel Weibel, and Dr. Volker Schmeisser (Daimler) for many useful suggestions and discussions.

The work on the Enhanced SCR concept has been financially supported by Haldor Topsoe A/S (DK) and more recently by the European Integrated Project “CO2 Reduction for long distance transport” (CORE), EU Grant Agreement no. 284909.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer Science+Business Media New York

About this chapter

Cite this chapter

Tronconi, E., Nova, I. (2014). The Role of NO2 in the NH3–SCR Catalytic Chemistry. In: Nova, I., Tronconi, E. (eds) Urea-SCR Technology for deNOx After Treatment of Diesel Exhausts. Fundamental and Applied Catalysis. Springer, New York, NY. https://doi.org/10.1007/978-1-4899-8071-7_9

Download citation

DOI: https://doi.org/10.1007/978-1-4899-8071-7_9

Published:

Publisher Name: Springer, New York, NY

Print ISBN: 978-1-4899-8070-0

Online ISBN: 978-1-4899-8071-7

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)