Abstract

The artificial production, in laboratories, of organs and biological structures, by adequately placing and combining ex vivo cells, synthetically produced tissue patches, and supporting biomaterials, is no more a matter of science fiction but a present relevant research challenge already providing promising results, included under an innovative area called “biofabrication.”

If organs could be artificially produced, patients would benefit from more rapid surgical interventions; compatibility would be highly promoted, as they would be produced ex vivo from the own patient’s cells; and aspects such as organ piracy would be limited (nowadays around 10 % of organs used for transplantation worldwide comes from illegal activities).

The socio-economical impact of synthetic organ production is comparable to that of the whole pharmaceutical industry, what explains the interest it has arisen in the last decade, with several new companies aiming at improving state-of-the-art tissue engineering procedures for starting 3D tissue construction.

In addition, novel scientific journals are being devoted to these advances, and it is just a matter of time that related concepts and techniques are included in the syllabuses of teaching programs at universities, what would be very positive for the evolution of this area.

This chapter provides a brief introduction to this field of research, discussing most relevant advances on materials science, design tools, and manufacturing technologies that are working for making biofabrication a viable alternative to conventional therapeutic procedures. Main present difficulties and research challenges are also discussed.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

14.1 Introduction: The Manufacture of Biological Systems

We have seen that in the context of medical device development and the biomedical industry, one of the major areas of application for these rapid prototyping technologies is tissue engineering. Since the 1980s, outstanding researchers like Eugene Bell and Robert S. Langer, both professors at the MIT, began looking at how to produce scaffolds with materials and geometries that were suitable for cell culture and tissue growth and could be used in surgical operations (Langer and Vacanti 1993).

The gradual progress in the field of biodegradable polymers together with the advances in more flexible rapid manufacturing technologies means that at present, complex geometry scaffolds can be obtained to which living cells with growth factors adhere and multiply until they cover the scaffold. Having reached this stage, the set (scaffold + coating) is implanted into the damaged parts of the body. After being implanted, the cells adapt to their environment and reproduce the functions of the surrounding tissue, while the scaffold is gradually reabsorbed (Hollister 2005; Gómez Ribelles et al. 2010). All this has led to changes in the approach to solving many surgical problems.

It is hoped to continue work on this progress with a view to obtaining three-dimensional biological structures that will 1 day lead to the additive fabrication of human organs. The firm EnviosionTec GmbH has already developed the Bioplotter® (see Sect. 14.5) with which small three-dimensional structures are being obtained by the “layer-by-layer” deposit of cells together with biocompatible material, and the initial use of the concept of a “bioprinter” looks promising.

A larger number of printing technologies based on appropriately modified conventional RP technologies are being sought, which are progressively leading to more affordable machines (DigiLab Inc., Sect. 14.5).

This progress may open up new horizons to the treatment of many diseases by combining synthetic and biological materials to produce veins, capillaries, arteries, bones, and soft organs, or at least part of them. By using machines with several heads that can deposit different materials, biological tissue could be directly obtained with synthetic implants pre-integrated into them. This would endow the newly generated tissue with mechanical consistency.

However, there is still a long way to go, not only regarding the precision of these “bioprinters” and the biological and biomedical materials they are capable of depositing but also regarding the manufacture of structures larger than 1cm3. It would appear that the development of a capillary network to provide the newly generated three-dimensional cell structures with nutrients is currently one of the major limitations (Mironov et al. 2009; Bartolo and Bidanda 2008, 2009).

There is also an important need for further progress in the design field, so as to obtain more adequate biomimetic CAD files, for subsequent manufacture of biostructures. Relevant progresses in the field of high-precision medical imaging, together with software for handling such medical images as design inputs, are proving to be very relevant.

Organizing specific work sessions to facilitate information exchange among researchers is a particularly useful idea, usually within a framework of bioengineering congresses, where rapid prototyping applications in the medical sector, especially those oriented to biofabrication, can be discussed, and people can join forces to go forward together.

Worth mentioning are the “World Bioprinting Congresses,” the “International Workshop on Bioprinting and Biopatterning,” and the “International Conferences on Biomedical Electronics and Devices” – Biodevices 2008, 2009, 2010, 2011, and 2012. Relevant journals in the field include “Bioinspiration and Biomimetics” and “Biofabrication.”

This chapter provides a brief introduction to these topics, after discussing main applications of biofabrication for the biomedical field in next section.

14.2 Overview of Applications for the Biomedical Sector

The final objective of research in the biofabrication area is the artificial production of organs and biological structures in laboratories, by adequately placing and combining ex vivo cells, synthetically produced tissue patches, and supporting biomaterials. If organs could be artificially produced, patients would benefit from more rapid surgical interventions; compatibility would be highly promoted, as they would be produced ex vivo from the own patient’s cells; and aspects such as organ piracy would be limited. The applications in medicine, if this final objective is achieved, are endless; however, partial results, in the way to final achievement, are already providing interesting applications briefly discussed here.

Advances in the field of biofabrication are actually improving tasks and procedures linked to tissue engineering, as novel machines allow for the combined manufacture of biosubstrates with incorporated living cells and nutrients, hence enhancing cell growth and tissue formation for transplantation (Jakab et al. 2010).

Some biodevices for surgical interventions, such as sutures, are being seeded with cells (normally hMSCs) with the help of 3D printers designed ad hoc, thus accelerating tissue repair and recovery from surgical procedures (Kanani 2012).

New materials and biomaterials are continuously being discovered, in the search for more adequate substrates and supports for cell growth, and special attention is being paid to unconventional biomaterials as candidates for tissue engineering, as well as for other fields of technology, such as secretions from animals and plants (spider silk, plant resins) (Lenaghan et al. 2011).

In addition, progresses on imaging technologies, aimed initially at improving diagnosis, if adequately combined with design and modeling tools, are also being of help for promoting biomimetic designs but also for replicating the structures of novel bio- and meta-materials and in silico assessing their behavior, as detailed in next section.

14.3 Advances and Challenges Linked to Biomaterials

Materials science has devoted great efforts in the last decades of twentieth century to the development (mainly synthesis/extraction and processing) of new materials and material families (such as polymers, polymer-matrix composites, metallic foams, superalloys), and main advances during the first decade of the twenty-first century focus also on that direction (artificial muscles, biopolymers, materials from natural origin). These advances have completely changed the engineering world and reshaped the whole product development process, with outstanding impact in several fields including automotion, aeronautics, architecture, design, electronics, information and communication technologies, energy, and biosciences.

Parallel advances in design and simulation tools are providing very adequate resources for modeling such novel and often complex materials, whose behavior is in many cases not yet fully characterized or understood. Therefore, besides the continued search for new materials capable of producing biocompatible devices, additional challenges linked to characterization and precise simulation are also needed for promoting the global biodevice development process.

Some relevant characterization tools (both oriented to biomaterials and to more specific biodevices) are covered in Chap. 15 and are normally oriented to an assessment of overall long-term mechanical performance and stability. More linked to modeling tasks are advances in medical imaging technologies, especially micro-CT, whose current precision, reaching around 25–50 μm, is high enough for the detailed reconstruction of most corporal structures (Shi et al. 2008; Guo et al. 2010).

Figure 14.1 includes some application examples of the use of micro-CT technology to the 3D reconstruction of complex materials (and biomaterials) for subsequent modeling and simulation linked to studies in the field of materials science. Once reconstructed, they can also be used, thanks to Boolean operations (see Sects. 7.2 and 7.3), for designing the inner structure of several biomimetic biodevices and prostheses. The linkage between medical imaging, CAD programs, and FEM-based simulation modules can be a great help for assessing the adequate performance of a biomimetic structure, once adapted to the geometry of novel prostheses and biodevices, before the investing in the manufacture of prototypes for preproduction validation trials.

Examples from the SkyScan micro-CT series. (a) SkyScan 1172 high-resolution micro-CT scanner. (b) Glass fibers of composite material. (c) Hollow walls of Ni foam, rendering of internal micro-architecture for subsequent CAD modeling. (d) Application to the reconstruction of wood. Applications linked to the reconstruction of biomaterials for further use in biomimetic designs and materials science (Images courtesy of SkyScan company [www.skyscan.be])

The examples provided in Fig. 14.1, courtesy of SkyScan company, show reconstructions of the glass fibers of a composite material, of a nickel foam, and of a porous wood. Similar results can be obtained from micro-CT of polymers, ceramics, biopolymers, and other biomaterials such as bone, as well as biostructures, which can help to design biomimetic scaffolds for tissue engineering.

14.4 Advances and Challenges Linked to Biodesign Tools

Advances for promoting biofabrication approaches are not only linked to finding more adequate materials and processing technologies compatible with cell deposition but also to additionally exploring design processes capable of providing alternative approaches or complementary solutions, to those based on medical imaging-based reconstructions.

The term “biomimesis” (from Greek “bios” (life) and “mimesis” (imitation)) is linked to the study of nature’s models, principles, designs, and processes to imitate them or find new inspiration for solving human problems (Benyus 2002). Main applications of biomimesis are aimed at finding new ways of producing food or energy, novel methods of manufacture, innovative therapeutic solutions, and overall management of mankind and its relations. In this handbook (mainly in Chaps. 5, 6, 10, 11, 12, and 14), we have focused on summarizing and providing methods for designing special biodevices, with features trying to imitate those from human organs, tissues, and structures, for enhancing final performance.

In this section we reintroduce two important possibilities for promoting the development of biomimetic devices, one based on multi-scale mathematical modeling of biostructures and the other based on medical imaging-based reconstructions, for additionally highlighting the possibility of combining or alternating such methods.

Chapter 6 already introduced the possibility of using fractal models for the design of biodevices with controlled surface properties or geometries imitating those from the body. Here we provide an additional example of the use of such models, more linked to biomimetics and to the modeling of (bio)materials, than to the design of a final biodevice. We have focused on imitating the lotus flower leaves, whose microstructure is famous for providing self-cleaning properties (Barthlott and Neinhuis 1997).

In the mathematical model included below, final multi-scale surface z(x,y) can be considered as the sum of two different surfaces (z m (x, y) and z n (x, y)), each providing a relevant component at a different scale level. In our case, the microscopic bump−like behavior of the lotus flower leaves can be approximated by using a regular surface defined by z m (x, y), for obtaining 10 μm size details. For introducing an additional level of precision (irregularities in the range of hundreds of nanometers), z n (x, y) proves to give positive results if based on fractal models. The following equations give the height “z” of the surface, when assessing the function over a grid of points given by their (x, y) coordinates.

The model uses several random functions (A k , B k , C k ) and several control constants (λ, α, k), and an initial height function “z 0 ” can also be introduced. According to the model, fractal dimension “D” of the generated surface can be obtained from the expression “D = 3−α,” for having an indication on how completely the fractal appears to fill space. Related Matlab program can be found in the annexes of the handbook. Figure 14.2 shows the result of the biomimetic design:

Example of multi-level biomimetic CAD design based on the lotus flower leaves’ surface for producing special contact phenomena (Adapted from A. Díaz Lantada et al. Biodevices 2012)

Further incorporation of different scale terms can lead to more precise control of final geometry or for imitating other biological structures, as shown in Fig. 14.3, which includes some additional micrometric bumps.

Biomimetic multi-scale design based on combining conventional and fractal geometries, according to proposals from Chap. 6

Final prostheses, designed on the basis of such fractal models, for controlling roughness, skewness, and surface/volume ratio, aiming at improving biocompatibility and long-term stability, are also possible. Figure 14.4 shows a fractal cylinder, which could be adapted to designing the tubular parts of knee or hip prostheses, among other biodevices. They can also be manufactured following additive and subtractive procedures (Díaz Lantada et al. 2012; De la Guerra Ochoa et al. 2012).

Figure 14.5 shows the alternative approach, based on digitalization, instead of on analytical modeling. It provides, courtesy of SkyScan company, examples of high-resolution reconstructions of biological structures, such as the capillaries of a mouse lung, the whole reconstruction of a mouse knee, or the inner micro-architecture of a frog femur. The process can also be used for corporal structures, although it requires larger appliances.

Examples from the SkyScan micro-CT series. (a) SkyScan 1,176 high-performance in vivo micro-CT scanner. (b) Mouse lung sample. (c) Application to the reconstruction of a mouse knee (in vivo scanning). (d) Frog femur, rendering of internal micro-architecture (CTan and CTvol programs). Applications linked to the reconstruction of corporal structures for subsequent personalized design of implantable medical devices (Images courtesy of SkyScan company [www.skyscan.be])

It is necessary to note that, thanks to advances in the linkage between medical imaging technologies and CAD-CAE-CAM resource, once more versatile and effective 3D bioprinters are developed (capable of manufacturing whole implantable organs), the reconstructions will probably be carried out on the basis of original information taken from the patient’s body, similar to those shown below, so as to provide personalized solutions.

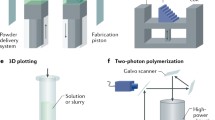

14.5 Advances and Challenges Linked to Biomanufacturing Technologies

Conventional desktop printers deposit microbubbles of ink, with remarkable precision, for writing documents, and state-of-the-art very simple 3D printers (see information provided by the wiki of the “RepRap” project) are also capable of extruding fused polymers, gels, and even molten chocolate, for obtaining three-dimensional prototypes with complex geometries in different materials.

Therefore, the technology for depositing cells, coming within a liquid or gel-like matrix, and further constructing sheets and three-dimensional tissues, already exists. A simple combination of already available resources and additional research, focused on supporting such cell growth, through an adequate vascularization and nutrient supply, is making biofabrication a reality.

Relevant recent results have already been obtained by using alternative methods, such as laser printing of cells into 3D scaffolds, which uses the propulsive force from laser-induced shock wave to propel cells gently into a substrate (Ovsianikov et al. 2010) or layer-by-layer extrusion of gelatin/alginate with seeded stem cells, for bioprinting small 3D biostructures (Norotte et al. 2009; Li et al. 2009; Marga et al. 2012). The use of concurrent additive manufacture of scaffolding structures based on biodegradable thermoplastics and cells suspended in gels (different extruders would print different materials, as support, and provide also cells and nutrients) has also been proposed (Melchels et al. 2012).

In fact some commercially available resources already exist, which are already providing excellent support to research tasks linked to further advances in these directions, as detailed further on.

In Europe, EnvisionTec GmbH provides its “3D-Bioplotter™” (already in its fourth generation) (see Fig. 14.6) which also includes some examples of attainable devices, including a scaffold for tissue engineering, a bioplotted biomimetic jaw, and bioplotted biomimetic nose.

(a) Envisiontec 3D-BioplotterTM fourth generation machine. (b) Vertical cut trough a bioplotted scaffold (conventional woodpile structure). (c) Bioplotted jaw. (d) Bioplotted nose (Images courtesy of envision TEC GmbH [www.envisiontec.de])

The “3D-Bioplotter™” stands out for its versatility, as it can build parts by combining up to five materials with automated tool change, for its fast plotting speed, while maintaining appropriate accuracy, and for the possibility of printing up to five types of cells per object.

Actually the “3D-Bioplotter™” has the capacity of fabricating scaffolds using the widest range of materials of any singular rapid prototyping machine, from soft hydrogels and biomaterials (agar, alginate, fibrin, chitosan, collagen, gelatin), over polymer melts (PLLA, PCL, PLGA), up to hard ceramics (hydroxyapatite, tricalcium phosphate) and metals (titanium), although these last harder materials require a sintering post-process.

In the United States, Digilab Inc. offers its “Cell Jet Cell Printer,” which stands out for its special focus on gentle cell deposition and for handling and delivering cell suspensions. Some tailoring to final application is also affordable. The current and potential uses of the cell printer include, but are not limited to:

-

Delivering cell suspensions into micro-fluidic chips/high-throughput cell-based assay platforms

-

Dispensing cell suspensions in customized patterns to form microarrays on standard or custom microscope slides (or other substances), most commonly for developing/performing cell-based assays

-

Delivering cell suspensions (in cell culture media or hydrogels) at defined locations in 2 and 3 dimensions onto preformed scaffolds (such as biological sutures/tissue construct scaffold), in order to populate the scaffold

-

Dispensing cell suspensions in custom patterns on a surface, for migrational studies or to study interaction of cells among each other or with growth factors

-

Delivering cell suspensions to micro-wells in a various diagnostic/research devices made of silicon, PDMS, or other substances, where manual delivery of sample is difficult, time consuming, or simply impossible

-

Dispensing other reagents or growth factors or biologically relevant substances in a suspension, in addition to cells, to targeted locations/patterns in a similar manner

-

De novo biofabrication of relatively simple tissue constructs

Next, Figs. 14.7 and 14.8 include some results from the highly interesting Ph.D thesis from Christian Kanani, focused on improving the processes of seeding cells onto biological scaffolds (Kanani 2012).

Upper image: Prototype of the Digilab’s “Cell Jet Cell Printer”. Lower image: Representative image of a 96-well plate seeded with hMSCs using the cell printer. Cytoplasms of live cells show a bright green calcein signal. Nuclei of dead cells show a red ethidium homodimer-1 signal. All nuclei show a blue Hoechst 33,342 signal (Images courtesy of Digilab Inc. taken from C. Kanani Thesis. [www.digilabglobal.com and www.digilabglobal.com/celljet])

Upper image: Cell printer’s tip positioned over the thread bundle (biological suture made of fibrin) ready to begin dispensing hMSC suspension. Lower image: Image of a thread bundle after seeding hMSC suspension with help of the cell printer. Green = phalloidin (F-actin filaments of cytoplasm of seeded hMSCs). Red = ethidium homodimer-1 (Images courtesy of Digilab Inc. taken from C. Kanani thesis. [www.digilabglobal.com and www.digilabglobal.com/celljet])

Figure 14.7 shows a prototype of the Digilab’s “Cell Jet Cell Printer,” with different reservoirs for dispensing cells and the dispensing tip on action. Two or four dispensing tips can be also used. Lower images shows an image of a 96-well plate seeded with hMSCs using the cell printer. Cytoplasms of live cells show a bright green calcein signal and nuclei of dead cells show a red ethidium homodimer-1 signal. All nuclei show a blue Hoechst 33,342 signal, so the Digilab is perfectly useful for cell seeding upon different types of scaffolds and structures.

Figure 14.8 shows a more demanding task, linked to seeding a surgical suture with hMSCs for promoting final biocompatibility and helping faster tissue repair and recovery from surgery. Upper image shows the cell printer’s suspending tip positioned over the thread bundle (biological suture made of fibrin) ready to begin dispensing hMSC suspension. Lower image shows a thread bundle after seeding hMSC suspension with help of the cell printer. Green = phalloidin (F-actin filaments of cytoplasm of seeded hMSCs). Red = ethidium homodimer-1.

Such ex vivo trial helps to validate the approach, and similar procedures can become generally used for promoting the efficiency of surgical interventions, once these cell printers are more widely available.

Researchers wishing to obtain additional information on related advances may wish to visit Digilab’s website (www.digilabglobal.com) and have a more detailed look at the conference papers and publications linked to the use of the “Cell Jet Cell Printer” and related “synQUAD Technology” (capable of dispensing drop by drop down to 20 nL and up to several microliters of fluids).

Main challenges of bioplotters and cell printers are still linked to constructing more complex and bigger tissue constructs mimicking the complex structures of complete organs (Melchels et al. 2012). Combined advances in medical imaging, design technologies, and materials science will surely find solutions to such challenges, as the “hardware” (automated biomanufacturing machines) for biofabrication is already working properly and providing effective solutions, as Figs. 14.6, 14.7, and 14.8 have shown.

14.6 Main Conclusions and Future Research

The artificial production, in laboratories, of organs and biological structures, by adequately placing and combining ex vivo cells, synthetically produced tissue patches, and supporting biomaterials, is no more a matter of science fiction but a present relevant research challenge already providing promising results, included under an innovative area called “biofabrication.”

If organs could be artificially produced, patients would benefit from more rapid surgical interventions; compatibility would be highly promoted, as they would be produced ex vivo from the own patient’s cells; and aspects such as organ piracy would be limited. The actual socio-economical impact of synthetic organ production is even comparable to that of the whole pharmaceutical industry, what clearly explains the interest it has arisen in the last decade, with several new companies aiming at improving state-of-the-art tissue engineering procedures for starting 3D tissue construction.

This chapter has aimed to provide a brief introduction to this field of research, discussing some relevant advances on materials science, design tools (either based on analytical modeling or on digital reconstruction), and manufacturing technologies that are currently working for making biofabrication a viable alternative to conventional therapeutic procedures.

Even though main challenges of bioplotters and cell printers are still linked to constructing more complex and bigger tissue constructs, mimicking the complex structures of complete organs, combined advances in medical imaging, design technologies, and materials science are already providing interesting solutions, and the “biomanufacturing machines” are already commercial and effective. Final whole organ printing is just a matter of time.

The promotion of collaboration between researchers may prove essential for reaching final objectives of biofabrication in perhaps a couple of decades, for instance, following the example of the “RepRap” project collaborative wiki, which is encouraging many researchers to introduce additive manufacture as an additional support for their research. These kinds of “do-it-yourself” rapid prototyping machines can also be adapted to 3D printing of biomaterials and cells, as an easy and affordable way of obtaining resources for conceptual validations linked to tissue engineering and biofabrication.

References

Barthlott, W., Neinhuis, C.: Purity of the sacred lotus, or escape from contamination in biological surfaces. Planta 202, 1–8 (1997)

Bartolo, P.J.S., Almeida, H., Laoui, T.: Rapid prototyping and manufacturing for tissue engineering scaffolds. Tissue Eng. 36(1), 1–9 (2009)

Bartolo, P.J.S., Bidanda, B.: Biomaterials and Prototyping Applications in Medicine. Springer, New York (2008)

Benyus, J.M.: Biomimicry: Innovation Inspired by Nature. Harper Collins, New York (2002)

Díaz Lantada, A., Lafont Morgado, P., Echávarri Otero, J., Chacón Tanarro, E., De la Guerra Ochoa, E., Munoz-Guijosa, J.M., Muñoz Sanz, J.L.: Biomimetic computer-aided design and manufacturing of complex biological surfaces. In: Biodevices 2012 – International Conference on Biomedical Electronics and Devices. IEEE-EMBS, Vilamoura (2012)

De la Guerra Ochoa, E., Del Sordo Carrancio, D., Echávarri Otero, J., Chacón Tanarro, E., Díaz Lantada, A., Lafont Morgado, P.: The influence of textured surfaces on the lubrication of artificial joint prostheses. In: Biodevices 2012 – International Conference on Biomedical Electronics and Devices. IEEE-EMBS, Vilamoura (2012)

Gómez Ribelles, J.L., Monleón Pradas, M., García Gómez, R., Forriol, F., Sancho-Tello, M., Carda, C.: The role of three-dimensional scaffolds in the regeneration of joint cartilage. In: Biodevices 2010 – International Conference on Biomedical Electronics and Devices: Special Session on Rapid Prototyping for Improving the Development of Biodevices. IEEE Engineering in Medicine and Biology Society, Valencia (2010), 20–23 Jan 2010

Guo, X., Liu, X., Zhang, B., Hu, G., Bai, J., et al.: A combined fluorescence and microcomputer tomography system for small animal testing. IEEE Trans. Biomed. Eng. 58, 2876–2883 (2010)

Hollister, S.J.: Porous scaffold design for tissue engineering. Nat. Mater. 4, 518–524 (2005)

Jakab, K., Norotte, C., Marga, F., Murphy, K., Vunjak-Novakovic, G., Forgacs, G., et al.: Tissue engineering by self-assembly and bio-printing of living cells. Biofabrication 2, 022001 (2010)

Kanani, C.: Cell printing: a novel method to seed cells onto biological scaffolds. Ph.D. thesis, Worcester Polytechnic Institute (2012)

Langer, R.S., Vacanti, J.P.: Tissue engineering. Science 260, 920–926 (1993)

Lenaghan, S.C., Serpersu, K., Xia, L., He, W., Zhang, M., et al.: A naturally occurring nanomaterial from the Sundew (Drosera) for tissue engineering. Bioinspir. Biomim. 6, 0460009 (2011)

Li, S.J., Xiong, Z., Wang, X.H., Yan, Y.N., Liu, X.H., Zhang, R.J., et al.: Direct fabrication of a hybrid cell/hydrogel construct by a double-nozzle assembling technology. J. Bioact. Biocompatible Pol. 24, 249–265 (2009)

Marga, F., Jakab, F., Khatiwala, C., Shepherd, B., Dorfman, S., Hubbard, B., Colbert, S., Gabor, F., et al.: Toward engineering functional organ modules by additive manufacturing. Biofabrication 4, 022001 (2012)

Melchels, F.P.W., Domingos, M.A.N., Klein, T.J., Malda, J., Bartolo, P.J., Hutmacher, D.W.: Additive manufacturing of tissues and organs. Prog. Polym. Sci. (2012). doi:10.1016/j.progpolymsci.2011.11.007

Mironov, V., Trusk, T., Kasyanov, V., Little, S., Swaja, R., Markwald, R., et al.: Biofabrication: a 21st century manufacturing paradigm. Biofabrication 1(2), 022001 (2009)

Norotte, C., Marga, F.S., Niklason, L.E., Forgacs, G., et al.: Scaffold free vascular tissue engineering using bioprinting. Biomaterials 30, 5910–5917 (2009)

Ovsianikov, A., Gruene, M., Pflaum, M., Koch, L., Maiorana, F., Wilhelmi, M., Haverich, A., Chichkov, B., et al.: Laser printing of cells into 3D scaffolds. Biofabrication 2, 014104 (2010)

Shi, H., Farag, A.A., Fahmi, R., Chen, D.: Validation of finite element models of liver tissue using micro-CT. IEEE Trans. Biomed. Eng. 55, 978–985 (2008)

Some Interesting Related Websites

http://reprap.org/wiki/RepRap. Accessed Mar 2013

http://www.digilabglobal.com. Accessed Mar 2013

http://www.digilabglobal.com/celljet. Accessed Mar 2013

http://www.envisiontec.de. Accessed Mar 2013

http://www.fractal-bio.com. Accessed Mar 2013

http://www.skyscan.be. Accessed Mar 2013

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer Science+Business Media, LLC

About this chapter

Cite this chapter

Lantada, A.D. (2013). Biofabrication: Main Advances and Challenges. In: Lantada, A. (eds) Handbook on Advanced Design and Manufacturing Technologies for Biomedical Devices. Springer, Boston, MA. https://doi.org/10.1007/978-1-4614-6789-2_14

Download citation

DOI: https://doi.org/10.1007/978-1-4614-6789-2_14

Published:

Publisher Name: Springer, Boston, MA

Print ISBN: 978-1-4614-6788-5

Online ISBN: 978-1-4614-6789-2

eBook Packages: EngineeringEngineering (R0)