Abstract

To manufacture ice cream and frozen dairy dessert of the highest quality, it is essential to have ingredients of excellent quality, a mix that is formulated and balanced to provide proper function of each component, and excellent processing, freezing, and hardening processes. However, the selection of high-quality ingredients is, without doubt, the most important factor in successful manufacture of frozen desserts. The clean, fresh, creamy flavor desired in ice cream can be achieved only by the use of ingredients that have been carefully produced and handled and are themselves of excellent flavor quality. Frozen desserts can be made with a wide variety of ingredients, which can be grouped by category (fat sources, milk solids-not-fat [MSNF] sources, water sources, sweeteners, stabilizers, and emulsifiers). The functions and limitations of the components of mixes were described in Chap. 2. This chapter will focus on the sources and selection of the mix ingredients to supply the major components.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

Introduction

To manufacture ice cream of the highest quality, it is essential to have ingredients of excellent quality, a mix that is formulated and balanced to provide proper function of each component, and excellent processing, freezing and hardening processes. However, the selection of high-quality ingredients is, without doubt, the most important factor in successful manufacture of frozen desserts. The clean, fresh, creamy flavor desired in ice cream can be achieved only by the use of ingredients that have been carefully produced and handled and are themselves of excellent flavor quality. Frozen desserts can be made with a wide variety of ingredients, which can be grouped by type as shown in Table 3.1. The functions and limitations of the components of mix were described in Chap. 2, Table 2.1. This chapter will focus on the sources and selection of the mix ingredients. The approximate composition and density of selected ingredients used in frozen dairy dessert mix are shown in Table 3.2. Regulations for permissible ingredients may differ by country, as discussed in Chap. 2. The contributions of all of these components to the structure and texture of ice cream are discussed in Chap. 11.

Composition of Milk

Because milk is the source of dairy ingredients in ice cream, it is important to understand its composition and properties. Readers are referred to Walstra et al. (2006) or Fox and McSweeney (2003, 2006, 2009) for further details of milk composition and properties. Milk is comprised of water, milk fat, and milk solids-not-fat (MSNF). The latter two components comprise the total milk solids. MSNF are the solids of skim milk and include lactose, proteins, minerals, water-soluble vitamins, and enzymes plus some minor constituents (Table 3.3). These solids are also referred to as skim milk solids or serum solids. Milk is produced in the mammary gland from constituents supplied via the blood. Some constituents filter or dialyze into the milk, but most are synthesized in the mammary tissues and are secreted by the gland. Milk is a structurally complex physiochemical system. Its components are dispersed in true solution (lactose, whey proteins, some minerals, and minor components), as colloids (casein and complexed minerals) and as an emulsion (milk fat).

Milk fat is suspended in milk as tiny globules that are held in an emulsified state. Charges on the globule membranes cause them to be repulsed from each other. They are lighter in weight than the serum (skim milk) that surrounds them so they rise slowly in milk to form a layer of concentrated fat called cream. Some cows produce proteins called agglutinins that are adsorbed on surfaces of the fat globules. Agglutinins cause fat globules to stick together, and this increases the rate of creaming (cream formation). Normal milk contains about 2.4 billion fat globules per mL, and the globules vary in size from 0.5 to 10 μm in diameter or larger, depending on the breed of cow and stage of lactation. The layer of phospholipid, proteins, and other molecules that surrounds fat globules protects the glycerides from being hydrolyzed (split apart with the addition of water) by natural or microbial lipases in the serum phase of the milk. Milk fat is comprised mainly of triglycerides, which are in turn comprised of three fatty acids and glycerol, C3H8O3, connected through ester linkages.

Milk fat contains about 250 different fatty acids with numbers of carbon atoms in them ranging from 4 to 24, but only 11 of these fatty acids are present at 1% or greater. About one-third of these fatty acids contain one or more double bonds between carbons in the carbon chain. These are called unsaturated fatty acids, and they have lower melting points than do fatty acids of the same carbon chain length that are fully saturated with hydrogens. Milk fat is unique in its content of fatty acids that have short chains of carbon atoms. These fatty acids are butyric (C4), caproic (C6), and caprylic (C8). By combining long-chain saturated fatty acids with short-chain and unsaturated fatty acids in the triglycerides, the mammary tissues of the cow produce milk fat that is melted at body temperature (37°C) but is a semisolid at room temperature (as in butter at 22°C). At freezing/whipping temperatures after aging, 4°C, about two-thirds of the fat will be solid (the other third still liquid), and this plays an extremely important role in fat structuring (discussed in Chap. 11). Blends of nondairy fats, discussed below, often mimic this “two-thirds solid at 4°C” rule of thumb.

Substances associated with milk fat besides the triglycerides include the phospholipids, lecithin, cephalin, and sphingomyelin; the sterols, cholesterol, and ergosterol; the carotenoids, carotene, and xanthophyll; and the vitamins, A, D, E, and K. Lecithin is formed by replacing one fatty acid of a triglyceride with phosphoric acid and choline, the latter being a nitrogenous base that is a part of the B vitamin complex. Milk contains about 0.075% lecithin and cephalin, and milk fat contains about 0.6% lecithin. Cholesterol is the principle sterol in milk, comprising about 0.015%, and 75–85% of it is associated with the lipid fraction. Ergosterol is the precursor of vitamin D, and carotene is the precursor of vitamin A. Beta-carotene imparts the yellow color to milk fat.

The proteins of milk are subdivided into caseins and whey proteins. Caseins comprise 75–80% of the total protein of milk and occur only in milk. The major casein proteins are αs1-, αs2-, β-, and κ-casein. They occur together as colloidal micelles in milk and can be removed by ultracentrifugation. Casein micelles can be observed by electron microscopy as porous spheres. Their diameters range from 50 to 500 nm. Micellar casein carries large amounts of calcium and phosphate principally, but also other minerals including magnesium and citrate. It is precipitable with proteolytic enzymes (e.g., chymosin or rennin), alcohols that dehydrate the micelles, salts that combine with it, and acids that neutralize its charge at approximately pH 4.6. Casein micelles are otherwise very stable, especially to heat. Whey proteins are comprised of α-lactalbumin, β-lactoglobulin, serum albumin, immune globulins, and some minor proteins. Whey proteins are not precipitated with acid at pH 4.6 nor by chymosin, but they begin to be precipitated by heat at about 77°C (170 °F). Whey proteins contain no phosphate whereas some fractions contain sulfur.

Lactose or milk sugar is dissolved in milk and as such is responsible for the major part of the reduction in freezing point of milk below that of water. Lactose, which is found only in milk, is a disaccharide made up of glucose and galactose. It is only about 1/5 to 1/6 as sweet as sucrose. This carbohydrate is fermentable by many lactic acid-producing bacteria that are commonly added to fermented products. The lactose content of milk normally ranges from 4.8 to 5.1%. It is a reducing sugar that is optically active, having a specific rotation of 52.5°. In solution, lactose exists in two forms with the β-form comprising about 60% and the remainder in the α-form, depending on the temperature. Crystalline lactose exists in three forms, α-lactose hydrate, C12H22O11 · H2O; α-lactose anhydride, C12H22O11; and β-lactose anhydride, C12H22O11. The crystals of lactose occur in many forms and are of high importance to ice cream manufacturers because of the possibility of their formation in the frozen product giving it a “sandy” texture (see further details below).

The nonvolatile salts of milk are the minerals that are found in the ash that remains after heating milk at a high temperature in a muffle furnace to completely oxidize the organic constituents. The mineral content of milk ranges from 0.65 to 0.75%, while the average content of minerals in the salt form is 0.9% (Table 3.3). These mineral salts, in the forms of citrates, phosphates, or oxides, affect the functional and nutritional properties of milk. Calcium and phosphorus are the most important minerals of milk both nutritionally and functionally. Calcium and phosphate are both carried within the casein micelle and play important roles in micelle stability. Milk contains many trace elements, and their concentrations are dependent on the type and composition of rations fed to cows.

Numerous other inorganic and organic substances occur in milk, some of which produce effects far out of proportion to their concentrations. These minor constituents include gases, enzymes, nonprotein nitrogenous substances, flavorful substances, non-lactose carbohydrates, vitamins, and pigments. The gases, carbon dioxide, nitrogen, and oxygen, are dissolved in milk in the approximate volume percentages of 4.5%, 1.3%, and 0.5%, respectively. The gas content decreases on heating milk or exposing it to vacuum.

The enzymes of milk may be produced in the mammary gland during the secretory process or by bacteria growing in the milk. The enzymes that occur naturally in milk include acid and alkaline phosphatases, lipase, esterases A, B, and C, xanthine oxidase, protease, amylase, catalase, and carbonic anhydrase. Enzymes, being proteins, may be inactivated by heat, and they tend to be most active at the body temperature of the cow.

Of the 19 vitamins normally present in fresh raw milk, vitamins A, B12, riboflavin, thiamin, and niacin are present in significant concentrations. Riboflavin is responsible for the green color of whey.

The nonprotein nitrogenous substances of milk include ammonia, urea, creatine, and free amino acids. The flavorful substances, other than the main constituents, include carbonyl compounds, lactones, and methyl sulfides.

Fat Ingredients

The fat component of frozen dairy dessert mixes increases the richness of flavor (especially milk fat), is a good carrier and synergist for added flavor compounds, produces a characteristic smooth texture by lubricating the palate, helps to give body, and aids in producing desirable melting properties. The fat in a mix also aids in lubricating the freezer barrel while the ice cream is being frozen. Limitations on excessive use of fat in a mix include cost, a hindered whipping ability, decreased consumption due to excessive richness, and high caloric value. During freezing of ice cream, the fat emulsion that exists in the mix will partially coalesce (destabilize) as a result of emulsifier action, air incorporation, ice crystallization, and high shear forces of the dasher and scraper blades in the dynamic freezer barrel. This partial coalescence is necessary to set up the structure and texture in ice cream, which is similar to the structure in whipped cream. Structural formation is discussed in detail in Chap. 11.

Milk Fat

Milk fat contributes significantly to the rich, full, and creamy flavor and to the smooth texture of ice cream. Part of the flavor contribution comes from the short-chain, volatile fatty acids that are part of the triglycerides of milk fat, particularly butyric acid. (When cleaved from the triglyceride, however, butyric acid contributes to the flavor defect of rancidity; see Chaps. 5 and 14 for further details.) The best source of milk fat for ice cream mix is fresh cream from fresh milk. If the quality is good, free from rancidity and lipid oxidation, cream provides the best flavor of all the milk fat-based ingredients. It is liquid, which facilitates ease of handling. However, it is also likely the most expensive of the various fat sources. Cream, like milk, supports the growth of bacteria well, so it should be stored at 4°C (39 °F) or less. The titratable acidity of cream containing 40% fat should not exceed 0.10%. In traditional and premium formulations, cream is often combined with concentrated or dried milk (whole or nonfat), the major source of concentrated MSNF, and with milk (whole or nonfat), which provides the water to balance the mix. The disadvantage to the use of cream is that, because of its perishability, a constant supply is necessary. Some ice cream manufacturers separate their own cream from milk while others purchase the cream from other dairies. Sweet cream may be relatively expensive and difficult to obtain in good quality at certain seasons and in some markets. These factors often make it necessary for manufacturers to consider other sources of milk fat.

Frozen cream is sometimes stored during the months of surplus and low price. Only the best fresh cream should be stored frozen. It should be pasteurized at 75°C for 15 min to minimize development of off flavors. Milk and cream should be protected from contact with copper or iron. These metals dissolve in milk and cream catalyzing oxidation that imparts oxidized (cardboard-like and metallic) flavor during storage of frozen cream. This is the reason why dairy equipment is constructed of stainless steel, plastic, rubber, or glass. Frozen cream should be stored at −25°C for not more than 6 months. Although storing cream frozen may be economical, flavor is never quite as good as when the cream was fresh. Rancid, fishy, oily, and tallowy flavors are likely to result from oxidation of frozen cream. However, legal regulations may prohibit addition of antioxidants to cream. Added sugar (10%) helps frozen cream retain freshness and to melt faster with limited separation of fat, since the sugar dissolves in the aqueous phase and lowers its freezing point, hence creating an unfrozen solution that surrounds and protects the fat globules. However, the added sugar represents additional volume that must be stored in the frozen state. A good rule of thumb in making mixes is to use a maximum of 60% frozen cream with 40% fresh sweet cream.

Cream that has been separated twice (so-called “plastic” cream, due to its rheological properties) can be a source of concentrated fat for frozen desserts. It contains about 80% milk fat and has a consistency similar to that of butter. It is prepared by separating and then reseparating cream of 30–40% fat through a special separator. Although plastic cream is stored and handled the same as butter, it has the advantage over butter of essentially retaining the fat-in-serum emulsion of cream. Because some of the emulsion may be broken during separation and cooling of the product in a swept-surface heat exchanger, it is necessary to ensure complete homogenization and emulsification of mixes made with plastic cream, as with mixes made with butter, butter oil, or frozen cream.

Unsalted butter (sweet butter) of good quality can be an important source of milk fat for frozen desserts. It may be comparatively less expensive than cream, can be transported at low cost, can be stored at 4°C (39 °F) or lower, preferably freezer temperatures, for several weeks to months with little loss in quality, and is nearly always available. Salted butter would produce undesirable salty flavors in the mix and affect the freezing point, increasing the unfrozen water content, but the use of unsalted butter means that the preservative properties of the salt are not present, so storage temperatures must be sufficiently low for adequate preservation and shelf life. The off flavors common to defective butter (whey, storage, oxidized/metallic, old cream, or rancid) will impart very undesirable flavors to ice cream. The use of butter in ice cream mixes often results in undesirable freezing properties, if it has not been properly homogenized and emulsified. This is because both composition and physical structure of butter differ from those of cream. Churning of cream into butter releases much of the natural emulsifiers, components of the milk fat globule membrane, from the ruptured fat globules into the buttermilk. Furthermore, the emulsion is broken and inverted during churning, and it must be restored to a fat-in-serum form in the ice cream mix. This can be done by proper re-emulsification, that is, sufficient homogenization and protein and emulsifier content for fat globule membrane formation. Another major disadvantage of butter is the difficulty with handling a solid and blending it into the mix. It often requires more physical handling than would a liquid source such as cream. It also must be melted and dispersed into the liquid mix during preparation, and this can be difficult. Therefore, the use of butter is mostly limited to batch pasteurization operations. If it is pre-blended for HTST systems, it must be first melted and then dispersed hot into the milk. This causes a loss of regeneration capacity in the pasteurizer (see Chap. 5).

Anhydrous milk fat (butter oil) can be a source of milk fat for ice cream mix manufacture. It is especially desirable for reconstituted products manufactured in countries where there is no domestic supply of dairy ingredients. Anhydrous milk fat stores better than butter without as much concern for oxidation, due to the fact that it has virtually no moisture in it. This fact also makes it more economical to transport. For mix manufacture, it is handled in much the same way as butter.

Milk fat–sugar blends are made by mixing butter or anhydrous milk fat with sucrose alone or with a blend of sucrose and MSNF. The product is a physical blend only as the sugar does not dissolve into the fat. Upon reconstitution of the blend in water with heating, the sucrose will readily dissolve into the water phase. Therefore, these blends are handled in much the same way as butter during mix making. The advantages of using such blends reside in the convenience during storage and mix handling for some processors depending on plant configuration. These blends can also be transported across some international borders as a nondairy blend, since the majority component is sugar, and this often reduces tarification. Microbial growth is inhibited by the low water activity of milk fat–sugar blends; therefore, they keep well at −18°C for up to 1 year.

Milk fat can be fractionated into a hard fraction (high-temperature melting fraction, enriched in saturated triglycerides) and a soft fraction (low-melting temperature fraction, enriched in unsaturated triglycerides) by using a thermal crystallization process, and this is done industrially in Europe to produce fractions that are either liquid or solid at 20°C (sometimes referred to as olein or stearin, respectively). Whereas the hard fraction is a value-added product with enhanced functionality for the baking industry, the soft fraction can be utilized by the ice cream industry to advantage. It is enriched in C18:1, C18:2, and C18:3 fatty acids, thereby reducing the saturated fat content, which may be of interest for perceived nutritional benefit. This product is more prone to oxidation than either milk fat or the hard fraction, so has to be of high quality for ice cream application. As long as the usage level does not exceed approximately half of the milk fat content in the mix, there should be sufficient solid fat at freezer temperature to obtain adequate fat structuring properties in the ice cream, and this can be controlled by modifying the emulsifier level as needed (Abd El-Rahman et al. 1997). Modifications to the diet of the cow can also modify fatty acid profiles, causing enrichment in unsaturated fatty acids. Gonzalez et al. (2003) showed successful incorporation into ice cream of high-oleic and high-linoleic fractions of milk fat, with incorporation limits also dictated by oxidation potential and the necessity of sufficient solid fat for adequate levels of fat structuring. Bazmi et al. (2007) observed that milk fat which had been enriched in its soft fraction (olein) showed a higher ability for aeration with a more uniform air bubble size distribution and bubbles coated with a thicker layer of fat droplets for enhanced stability. They concluded that enrichment of milk fat with its soft fraction would enhance foaming properties and foam stability in ice cream.

Nondairy Fats

Fats and oils from plant (vegetable) sources are used extensively as fat sources in ice cream in the United Kingdom, parts of Europe, Asia and Latin America, and to an increasing extent in North America, as discussed in Chap. 2 (legal nomenclature of these products varies by country, as also discussed in Chap. 2). They are generally much less expensive than milk fat. Five factors of great interest in selection of fat source are the rate at which the fat crystallizes (which determines, in part, the aging time); the crystal structure of the fat; the temperature-dependent melting profile of the fat, especially at refrigerator and freezer temperatures (both factors determine how well the fat aggregates on freezing); the content of high-melting triglycerides, which can produce a waxy, greasy mouthfeel; and the flavor and purity of the oil. High molecular weight triglycerides are generally flavorless themselves, but often carry other flavor components. Likewise, they can play a role in the release of flavoring agents during consumption. For example, Hyvonen et al. (2003) reported a slightly faster flavor release from ice cream with vegetable fat compared with dairy fat.

For optimal partial coalescence during freezing, it is important that the fat droplet contain an intermediate ratio of liquid:solid fat at the time of freezing. If too much oil is present during dynamic freezing, it spreads at the air surface, leading to collapse of the air bubbles and undesirable texture. It is difficult to quantify this ratio as it is dependent on a number of compositional and manufacturing factors; however, one-third to two-thirds crystalline fat at 4–5°C is a good working rule (see discussion of fat partial coalescence in Chap. 11 for further details). The polymorphic form of the fat may also affect the distortion of the fat globule caused by crystallization, which can have a large impact on the rate of partial coalescence of the fat during freezing. Thus, information about solid fat content alone is insufficient to predict the capacity of the fat to form appropriate structures within the ice cream.

Crystallization of fats occurs in three steps: subcooling of the oil (below the equilibrium crystallization temperature) to induce nucleation, heterogeneous or homogeneous nucleation (or both), and crystal propagation. In bulk fat, nucleation is predominantly heterogeneous, with crystals themselves acting as nucleating agents for further crystallization, and subcooling is usually minimal. However, in an emulsion, each droplet must crystallize independently of the next. For heterogeneous nucleation to predominate, there must be a nucleating agent available in every droplet, which is often not the case. Thus in emulsions, homogeneous nucleation and extensive subcooling are expected.

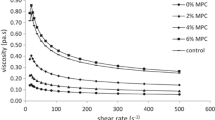

The melting profiles for a range of bulk fats that are used in ice cream formulations are illustrated in Fig. 3.1. Emulsified fats may show considerably higher liquid oil contents, depending on the holding time after cooling and on the crystallization kinetics. Milk fat contains about 30% liquid oil at the temperature of whipping/freezing in the scraped-surface freezer (the temperature at which fat structuring occurs); however palm kernel oil (PKO) and coconut oil will be much harder whereas palm oil will be somewhat softer and the other various sources of vegetable oils (corn, sunflower, safflower, canola, peanut, etc.) will remain uncrystallized. The type of crystallization within a fat can also be quite complex. PKO, for example, which is comprised mostly of saturated fats, shows only one broad melting range. These triglycerides form mostly compatible mixed crystals. Likewise coconut oil is comprised largely of medium chain triglycerides that produce a very solid and very stable fat. Choo et al. (2010) reported that virgin coconut oil could be used in ice cream formulations but that it lowered the melting resistance of the ice cream compared to milk fat, due to its high solid fat content at the whipping/freezing (fat structuring) temperature. Palm oil, on the other hand, shows two melting temperature ranges, the higher melting temperature range related to trisaturated triglycerides and the lower melting range related to mixed saturated and unsaturated triglycerides, which are not compatible in mixed crystals. Two distinct populations of crystals can give rise to differing properties of the fats.

Blends of oils often used in ice cream manufacture are selected to take into account such physical characteristics as flavor, solid fat content and fat crystallization characteristics, availability, stability during storage, and cost. Hydrogenation was used extensively in the past to achieve the appropriate melting characteristics, but recent concerns about elevated levels of trans unsaturated fatty acids in hydrogenated fats have resulted in a move back toward more natural, unhydrogenated fats and appropriate blending to achieve desired functional properties. Thermal crystallization can be used to fractionate palm oil (or any fat or oil with a wide temperature range of melting) into palm stearin (hard fraction) and palm olein (soft fraction). Also new to the fats and oils markets are several cultivars (e.g., sunflower) that have been produced with enriched monounsaturated oil content and reduced polyunsaturated fat content, for greater stability against oxidation and enhanced shelf life. For ice cream use, PKO and coconut oil are often blended with an unsaturated oil to reduce the solid fat content, whereas palm oil may have sufficient liquid fat content.

Im et al. (1994) determined that the content of unsaturated fatty acids in frozen desserts could be increased considerably with minimal risk of oxidation of the stored ice cream. They found no effects on the sensory quality or functional properties when they used a mixture of canola oil and soybean oil with milk fat in making a frozen dessert containing 10% fat. The mixture of 7.8 parts milk fat:3 parts canola oil:1.2 parts soybean oil provided a ratio of 3:2:1 of saturated to monounsaturated to polyunsaturated fatty acids. Frozen dessert with the fatty acids in a ratio of 1:1:1 of saturated to monounsaturated to polyunsaturated was more prone to oxidation. Persson (2009) also reported on the development of a nutritionally optimized fat blend for ice cream manufacture with enhanced unsaturated fat content but good fat structuring properties due to the crystallization properties of the fats utilized in the blend.

Sung and Goff (2010) focused on the development of a structural fat network in ice cream as influenced by the solid:liquid fat ratio at the time of freezing/whipping. The solid fat content was varied with blends of a hard fraction of PKO and high-oleic sunflower oil (HOSO) ranging from 40 to 100% PKO. It was found that blends comprising 60–80% solid fat produced the highest rates of fat destabilization that could be described as partial coalescence (as opposed to coalescence), lowest rates of meltdown, and smallest air bubble sizes. Lower levels of solid fat produced fat destabilization that was better characterized as coalescence, leading to loss of structural integrity, whereas higher levels of solid fat led to lower levels of fat network formation and thus also to reduced structural integrity. Mendez-Velasco and Goff (2011, 2012) showed that higher levels of unsaturated oils can be incorporated into fat blends for ice cream by using either unsaturated emulsifiers to enhance fat structuring with minimal amounts of solid fat or by homogenizing liquid oil droplets separately from solid fat droplets and by maintaining the liquid oil in a more stable emulsified state (higher levels of adsorbed protein) to allow the solid fat droplets to participate more completely in fat structuring. The contribution of solid fats and liquid oils to ice cream structure is discussed further in Chap. 11.

Fat Replacers

The development of high-quality, lower fat alternatives to traditional ice cream products has been an area of active interest and work for many years, due to consumer interest in low-fat products and nutritional recommendations to lower fat intakes. As a result, a large amount of product development time has been used in searching for a combination of ingredients that will replace the textural and flavor characteristics of fat in ice cream (Ohmes et al. 1998; Aime et al. 2001). These often involve the use of fat replacers. High-quality frozen desserts containing 5–6% fat can be produced without fat replacers, but mixes containing less than 4% fat usually require additional ingredients specifically chosen for their fat-replacing properties. Fat replacers can be carbohydrate, protein, or lipid based. Their main requirement is to provide fewer calories to the product than do traditional fat sources, either through reduction of required weight in the mix or through caloric reductions per unit weight of ingredient. Ice cream products are very complex systems, both in structure and flavor, and fat contributes greatly to both. In creating products that are meant to deliver to the consumer the same attributes as ice cream but with less fat or calories, it is imperative that the structural contribution of fat be considered to the same extent as is flavor. The goal is to deliver high-quality products and develop lasting market share for these products. A great deal of technical literature exists on the various properties of the fat replacement ingredients being marketed by a number of commercial firms. Readers are referred to Wylie-Rosett (2002), Jonnalagadda and Jones (2005), and Ognean et al. (2006) for further details on the composition, properties, efficacy, and safety of fat replacers/substitutes.

Several terms have been used to describe the extent and efficacy of fat replacement. “Fat replacer” is the generic term used to encompass all the related terms. The term “extender” is used to define partial removal of fat from a particular food and substitution with a replacement ingredient. “Substitutes” or “analogs” have the characteristics of fats but contain fewer calories or no calories. “Mimetics” replace part of the fat of a product; they imitate a particular function(s) but not all functions of fat in a food.

The fat-based replacers currently available are monoglycerides, structured lipids, and sugar-fatty acid polyesters. Protein-based fat replacers contain microparticulated protein particles or modified whey protein concentrates (WPCs) that simulate colloidal fat. There is a wide range of carbohydrate-based fat replacers including those derived from modified starches or maltodextrins of various sources, microcrystalline cellulose (MCC), methyl cellulose, hydroxypropyl methyl cellulose, polydextrose, pectin, inulin, and various other dietary fibers. Each of these will be described briefly below.

Emulsifiers are commonly used in ice cream to promote fat destabilization. They can also be used to advantage in low-fat products primarily because they promote the finer distribution of air bubbles and ice crystals enhancing smoothness. In aqueous solutions, they also can form micelles and crystallize into unique structures that have colloidal properties. Recommended concentrations of mono- and diglyceride with 60% alpha mono content are 0.5% in a 3% fat low-fat frozen dessert and 0.6% in a 0% fat mix (Barford 2001).

Structured lipids refer to combined short- and long-chain fatty acid triacylglycerols combined to provide unique fat-like properties with only half the calories (∼5 kcal/g). One product on the market, known generically as salatrim from “short and long acyl triglyceride molecules,” combines acetate, propionate, and butyrate short-chain fatty acids with long-chain stearate. It has been suggested for use in low-fat frozen desserts.

Carbohydrate fatty acid polyesters are synthetic products that have fat-like properties but are nondigestible and pass through the body unaltered. Olestra, a sucrose-based fatty acid polyester with 8–10 fatty acids esterified to sucrose hydroxyl groups, is one such product that has received considerable attention. It has also been suggested for use in low-fat frozen desserts, although due to concerns about the effect of olestra on absorption of other nutrients and its effect on stool, its use has also raised some concerns (Wylie-Rosett 2002). Currently there is little or no use of olestra in frozen dessert products.

Protein-based fat replacers are typically derived from WPC. These proteins are usually processed by thermally aggregating under shear to produce minute particles (0.5–2-um diameter) that can promote a creamy textural sensation. This process is called microparticulation. Size of the particulates is an important determinant of mouthfeel. The particles, being hydrophobic on their surfaces due to their content of nonpolar amino acids, resist interactions with each other. They can be spray dried and reconstituted without affecting particle integrity. They hold water and disperse well in aqueous systems. Simplesse is one such commercially available microparticulated whey protein. The application of simplesse into frozen dessert products has recently been studied by Aykan et al. (2008). They showed an improvement in texture from the use of Simplesse in light and low-fat formulations, although it also led to higher mix viscosity. Other modified WPCs have also been developed (e.g., DairyLo) to provide fat replacement properties.

Maltodextrins have been widely used as bulking agents in reduced-fat ice creams. These products are starch hydrolysates (see “Corn Sweeteners” in the next section) with DE <20, but those with fat-replacing properties are typically DE <10. As our understanding of starch digestibility has improved, the development of digestion-resistant starches has also provided new opportunities for fat replacement and caloric reduction. Maltodextrins have lost the starch granular structure and are completely soluble, but they can form thermoreversible gels or macromolecular networks that give rise to their fat mimetic properties. Hence, they can impart a creamy mouthfeel to low-fat frozen desserts with some success.

MCC is comprised of cross-linked, microscopic, insoluble aggregates of aligned cellulose polymers. MCC is usually combined with carboxymethyl cellulose (CMC) to make a colloidal blend (e.g., Avicel). It is primarily used to provide a colloidal particle to low-fat products to improve their creamy mouthfeel perception. Colloidal MCC requires high shear and homogenization for proper dispersion and functionality. It can be used advantageously in low-fat mixes at a rate of 0.2–0.8%.

Methylcellulose and hydroxypropyl methylcellulose are surface-active polymers that form films in solution then gel upon heating, which gives rise to lubricating properties and creaminess in the mouth simulating mouth coating by fat. These molecules have both polar and nonpolar substituents that permit them to reduce interfacial tension between films that are formed between water and fats. Hydroxypropyl methylcellulose has been suggested for use in low-fat frozen desserts. Typical use levels are 0.2–0.8%.

Polydextrose (e.g., Litesse) is a randomly bonded melt condensation polymer of dextrose and lesser amounts of sorbitol and citric acid. It resists breakdown by the enzymes of the human digestive tract so that it yields just 1 kcal/g. The small degree of digestion that produces this caloric output resides in the bacteria of the intestines. The primary function of polydextrose is as a bulking agent. It replaces the bulk of sugar when sugar is replaced by a high-potency sweetener. Polydextrose itself is not sweet, but it has some fat-sparing properties when used in frozen desserts. Solutions of polydextrose have higher viscosities than sucrose or sorbitol at equivalent concentrations. This higher viscosity contributes to desirable mouthfeel. At equivalent solids substitution levels, polydextrose combined 60:40 with sorbitol provides the same freezing point depression as does sucrose.

There have also been several recent developments in the use of other dietary fibers in fat-reduced frozen dessert products. Once such example is the current interest in oat fiber ingredients (e.g., Oatrim, enriched in beta-glucan), for use in low-fat frozen desserts, due also in part to their perceived benefits to health as a dietary fiber. Another dietary fiber of recent interest is inulin, a fructose oligosaccharide of DP 4–20. It has recently been studied in frozen dessert applications by Akalm et al. (2008) and by Aykan et al. (2008), both showing an improvement in sensory qualities although higher mix viscosities. Pectin-based fat replacers are also available. They are comprised of either high methoxyl or low methoxyl pectins, which are well known for their water binding and gelling properties. When processed under high shear, particles are formed that help to create fat mimetic properties.

Other gums and cellulosic substances can mimic some of the functions of fat. They contribute to viscosity, to foam stability, and to control of ice crystal growth. Some blends of gums interact synergistically to form microscopic spherical particles that mimic the rheology and mouthfeel characteristics of emulsified fat. These blends may contain guar, locust bean, and xanthan gums; carrageenan; sodium CMC; and MCC.

Schmidt et al. (1993) studied the rheological, freezing, and melting properties of ice milks manufactured with protein-based or maltodextrin-based fat alternatives. They concluded that the protein-based alternatives produced products more similar to ice cream than did the carbohydrate-based products. This was due in part to the functional contributions of proteins, especially in the area of emulsification and air incorporation, and also to the colloidal nature of the microparticulated proteins. The same was concluded by Liou and Grün (2007).

No fat replacer is satisfactory for all applications. Used in combinations, they can compensate for the loss of several functions of fat. Chief among their deficiencies are lack of creaminess, milk fat flavor, and ability to carry fat-soluble flavors (Hyvonen et al. 2003; Frost et al. 2005; Liou and Grün 2007). It has proven much easier to develop high-quality “light,” reduced-fat products with good consumer acceptability compared to low-fat or nonfat products, which require use of some combination of the fat replacers discussed above.

Milk Solids-Not-Fat/Protein Ingredients

MSNF contributes significantly to the flavor and texture of ice cream. If cream is used as the fat source in ice cream or if milk or skim milk is used as the principal water sources (discussed below), then these ingredients supply some MSNF to the mix, but it is insufficient to deliver the functionality required from the proteins and to develop enough total food solids. Therefore, all ice cream formulations must include a unique source of MSNF, usually either concentrated or dried milk sources, to reach sufficient levels in the mix. MSNF have an indirect effect on flavor. The proteins help give body and a smooth texture to the ice cream, through emulsification of the fat, foam formation and stability of the air bubbles, and viscosity enhancement in the unfrozen phase. Protein content is usually 3–4% in the mix (from a conventional 9–12% MSNF source at 36% protein), although the minimum quantity depends in part of the ratio of casein proteins:whey proteins. Since the processing steps occur sequentially, it may be difficult to deliver optimal protein functionality, for example, a protein present for its good foaming properties may adsorb onto fat interfaces before the foaming step, making it unavailable for foam stability. The optimal protein blend for ice cream, however, has to find the right combination to deliver the best functionality at the least cost.

Lactose adds total solids to the formulation, adds to the sweetness produced largely by the added sugars, and contributes also to the freezing point depression of the other sugars. Lactose can be problematic, however, both due to the number of consumers who are lactose malabsorbers (lactose intolerance, see Chap. 15) and also its low solubility and tendency to crystallize, creating the defect of sandiness (see Chap. 12). For these reasons, excessive lactose concentrations should be avoided. Lactose content is usually less than 6–7% in the mix, although the limit before sandiness is a problem that depends considerably on the stabilizer that has been used.

The mineral salts from MSNF sources carry a slightly salty flavor that rounds out the finished flavor of ice cream. They also contribute to freezing point depression (see Chap. 6), which needs to be carefully considered when using whey ingredients that are high in mineral salt content.

Concentrated Milks

Plain concentrated (condensed, evaporated) skim milk has been the traditional source of MSNF for mixes, used more frequently than any other source of concentrated milk products due to several advantages it can bring to mix quality and manufacturing convenience. It contains 25–35% MSNF and is prepared by evaporating water from skim milk using vacuum and heat. Modern evaporators with high vacuum and multiple effects do not expose the milk to high temperature during processing, so they produce excellent flavor. The liquid nature of the product helps manufacturers with mix ingredient handling. Concentrated milks are normally pasteurized but not sterilized, so the product is perishable and must be refrigerated. A regular supply of fresh product is necessary, since the shelf life is limited.

Sweetened condensed milk is sometimes used as a source of concentrated MSNF. It has a unique, slightly caramelized flavor that can be used to distinguish the flavor of a particular mix. The added sugar (40–44%) improves the keeping quality over that of plain concentrated products, because sugar raises the osmotic pressure and lowers the water activity (a w). Sweetened condensed milk is highly viscous; hence it is not so easily handled as is plain concentrated milk. A common defect in this milk is the formation of large lactose crystals. As the product is made, minute crystals of lactose are induced in it by seeding the concentrate with lactose powder while cooling. If these crystals grow excessively large, the texture will be sandy.

Superheating concentrated milk to a high temperature increases the viscosity at ordinary temperatures. The use of superheated condensed milks in ice cream increases firmness and resistance to melting of the ice cream, especially in formulations where no stabilizers or emulsifiers are used, but also increases cooked flavor. Because superheated concentrated products cost more than plain concentrated products and carry a higher risk of being defective, they are mostly used when manufacturers wish to omit stabilizers. Another method of achieving the same result is to pasteurize the mix for an extended time.

The titratable acidity test can be applied to concentrated milk products. When the products are diluted to the same MSNF concentration as skim milk, the acidity should be approximately the same as fresh skim milk, about 0.15%.

Dried Skim and Whole Milk

Skim milk power (nonfat dry milk) is an excellent traditional source of MSNF when concentrated milks are unavailable, expensive, or inconvenient. It should be purchased in only such quantities as will be used in several weeks and, preferably, should be kept in cold storage. Otherwise, staleness is likely to develop. Low, medium, or high heat powders can be used successfully in ice creams. The denaturation of whey proteins caused by high preheating temperatures tends to produce desirable body and texture characteristics in ice cream, especially when time and/or temperature of mix pasteurization is/are not held above the regulatory minimums. However, the lower the preheating treatment, the better the “fresh” flavor that should be expected. The storability, availability, and low moisture content of skim milk powder are important advantages, but being hygroscopic and prone to oxidize, it must be protected well from moisture, heat, and oxygen during storage. It is also available in the instantized form, which aids in solubility in situations when blending is difficult, such as in small operations. However regular spray-dried skim milk powder is used almost exclusively in frozen dessert mixes due to its lower cost. High-quality skim milk powder is bland, slightly cooked and mildly sweet in flavor, lightly cream colored, free of caking, easily soluble, and hydrates well to its pre-dried structure.

Although significant advances have been made in the technology of production, packaging, and storage of dry whole milk, it is used infrequently in frozen desserts. The major reason is the high risk that whole milk powders will become oxidized and contribute a stale flavor.

Whey Products

Dry whey solids are used widely in frozen desserts, because they are relatively inexpensive sources of milk solids. Federal standards in the US permit substitution of up to 25% of the MSNF as whey solids. In Canada and the EU, there is no legal restriction. Whey contains water, lactose, whey proteins, and a small amount of fat but very little casein. While skim milk powder contains 54.5% lactose and 36% protein, whey powder contains 72–73% lactose and only about 10–12% protein. Thus, it can aggravate some of the problems associated with high lactose, viz., lowered freezing point and potential for sandiness. The only advantage of whey powder is its low cost.

However, an increasing number of whey products are available that have high protein and reduced lactose contents. Most are processed by membrane technology. There has been a great deal of attention to the use of these whey products in ice cream. While the lactose is the problematic component of whey, the whey protein provides very good functional properties. Thus, many of these products can provide much higher quality than can traditional whey ingredients. The level of lactose in whey can be reduced by enzymatic hydrolysis to glucose and galactose; however, the freezing point depression effect of the higher monosaccharide content can cause problems. Ash content in whey can be reduced by demineralization. WPCs with similar protein and lactose contents to skim milk solids can be produced by ultrafiltration (Fig. 3.2). This process utilizes a membrane that allows only low molecular weight components to pass through it, so when whey is ultrafiltered, the retentate becomes enriched in protein as permeate (the solution of water, lactose, and minerals) is continually removed. Protein content can vary from low values of 20–25% to 75% or more, depending on the amount of permeate removed.

Whey protein functionality differs from that of micellar casein, due to the very different structures involved. Sourdet et al. (2002, 2003) studied the effects of varying whey protein to casein ratios in ice cream formulations and heat treatments on structure and stability in ice cream. They showed that enhanced whey protein ratios, to an optimum, could improve ice cream characteristics, but heat treatment played an important role in whey protein functionality. Whey proteins can be modified to improve functionality for ice cream mix through either high-pressure processing (Lim et al. 2008a, b; Huppertz et al. 2011) or through heat aggregation (Relkin et al. 2006). Whey protein isolates (WPI) from ion exchange processing, which contain no lactose, are also available for blending with other ingredients to provide the MSNF content desired for ice cream formulations when no lactose is desired. WPI has been shown to increase mix viscosity and increase ice cream hardness and melting resistance (Akalm et al. 2008).

Milk Powder Blends

It has become common practice to utilize milk protein-based powder blends in ice cream formulations as a replacement source for some of the traditional sources of MSNF. These are proprietary blends of WPCs, milk protein concentrates (MPCs) or skim milk powder, caseinates, and whey powders formulated with less protein than skim milk powder, and thus less cost. The ratio of casein proteins:whey proteins is also decreased relative to the traditional sources of MSNF. They are available from a number of milk ingredient suppliers. However, they must be blended with an appropriate balance of whey proteins and caseins to fulfill the functional roles of proteins in ice cream. Often, the protein has been modified physically, chemically, or enzymatically to improve its functionality. Caution must be exercised in excessive use of these powders, as they do contain higher amounts of lactose than skim milk powder and protein may be limiting in some applications. Experimentation with individual mix formulations is thus required.

Other Milk Solids-Not-Fat Ingredients

Special commercial milk protein products are often used as constituents of ice cream mix. These products include sodium caseinate, MPCs and other delactosed milk products, modified MSNF, certain mineral salts, and combinations of some of these products with whey products. The products function to improve whippability, resistance to heat shock, and body and texture.

It is possible to produce concentrated protein products from the casein portion of milk proteins, the most common for use as a food ingredient being sodium caseinate. A small percentage of sodium caseinate in ice cream (0.5–1%) may be useful in contributing to functional properties, particularly aeration and emulsification. However, the functionality of sodium caseinate is different than that of micellar casein, the form in which it is found in milk ingredients. Thus, its functional properties need to be considered when proposing its use. It can contribute positively to aeration. It thus serves as an aid to whipping and tends to improve texture. It also provides very good emulsification of the fat, but may lead to an emulsion that is too stable to undergo the required degree of partial coalescence. This can be offset by using emulsifiers to replace caseinate at the fat–serum interface, although caseinate is more difficult to displace than micellar casein. It is most desirable to have the caseinate in the serum phase rather than at this interface. The risk of introducing a stale flavor via sodium caseinate can be significant.

The main purposes of using low lactose products in ice cream are to reduce the risk that sandiness will develop during storage of the product and to provide alternative products to consumers who are lactose malabsorbers. Additionally, because lactose, being dissolved, lowers the freezing point of the mix, removal of a portion of it permits drawing of ice cream from the freezer at a higher temperature than if all of the lactose is left in the product. The use of low lactose milk solids may increase apparent mix acidity, because the increased protein concentration increases the concentration of buffering substances in the product. However, increasing the protein concentration of a mix can improve texture and resistance to heat shock.

Low lactose milk solids are derived from skim milk that has been ultrafiltered (UF) or diafiltered. For example, concentrating skim milk by UF to one-half its initial volume reduces the total lactose by one-half while concentrating the proteins to double their initial concentration (Fig. 3.1). If the retentate from the process (permeate is the water and dissolved materials that pass through the ultrafiltration membrane) is brought back to volume with water, and the process of filtration under pressure is repeated to reduce the volume to one-half the initial volume (referred to as diafiltration), only one-fourth of the initial lactose will remain in the retentate. Use of such MPCs in place of traditional sources of MSNF has resulted in smoother texture, higher freezing point, and harder body of ice cream (Alvarez et al. 2005). Higher protein in frozen desserts made with retentate increases the amount of water of hydration and thus can reduce the amount of stabilizer needed. By adding an alternative carbohydrate, such as dextrose, to the mix, the freezing point can be lowered and the body softened (Geilman and Schmidt 1992). Patel et al. (2006) increased protein content in ice cream mix by 30%, 60%, or 90% using MPC or WPC and showed that increased protein content led to smaller ice crystal size and firmer texture. Use of UF retentate and, particularly, diafiltered retentate to replace MSNF, and especially to replace whey solids, in frozen desserts greatly increases the amount of the dessert that can be eaten without the chance of discomfort by lactose malabsorbers.

Nondairy Protein Ingredients

There are a number of nondairy frozen desserts in the market, based on soy ingredients, nut ingredients, and other combinations. These are discussed in more detail in Chap. 15. Nondairy proteins have also been added to dairy mixes, where allowed depending on the legal jurisdiction (e.g., such is not permitted in the United States or Canada). Pereira et al. (2011) showed that up to 20% of milk protein could be substituted for soy protein in ice cream formulations. The soy-supplemented formulations exhibited good physical properties. Beyond 20% substitution, however, flavor problems developed.

Sources of Water

Potable Water

All mixes require a source of water to standardize the content of fat and MSNF. Good quality mixes can be prepared from the fat and MSNF sources described above and water. However it may also be common practice to use fluid milk as the main source of water. If water is used, it must be high quality and potable, free of contamination. Water varies in pH, alkalinity, and hardness, but unless any of these parameters are extreme, water does not need to be chemically treated (e.g., softened or mineral-adjusted) before use. When water is used to balance the mix, a larger portion of dry or concentrated skim milk is used to supply MSNF compared to milk.

Milk, Skim Milk, and Buttermilk

Fresh milk or skim milk can be used in the mix to provide the source of water necessary for balancing the formulation whenever available at reasonable prices, as it is also usually an economical and high-quality source of MSNF. Fat present in whole milk must be accounted for when determining the required amount of the concentrated fat source. Fresh whole or skim milk must have a low titratable acidity, a low bacteria count, and a clean flavor. It should be noted, though, that the contribution of MSNF from milk and cream (if used as the fat source) is insufficient to reach the level of MSNF required in most ice cream formulations, thus requiring the use of a concentrated source of MSNF, as discussed above.

Sweet cream buttermilk is obtained by churning cream that has not developed detectable acidity, that is, cream that is of a quality suitable for use in any retail product. Sweet cream buttermilk can also be used as a source of water and MSNF in the mix and has beneficial effects on the whippability of mixes and contributes richness of flavor. Buttermilk is especially desirable in ice cream made without added emulsifiers, low in fat content, or with any form of de-emulsified milk fat (e.g., butter), because it may be enriched in milk fat globule membrane material that is segregated from butter during the churning process. Concentrated or dry buttermilk may also be available, to be used as a concentrated source of MSNF. Buttermilk or concentrated buttermilk should be treated as any other fresh pasteurized milk product. Dry buttermilk can be kept for several weeks to a few months depending on storage conditions (store in a dry cool place), type of package (protect from air and moisture), moisture content, and the initial quality. Because dry buttermilk normally contains a higher fat content than dry skim milk (churning is less efficient at fat removal than centrifugal separation), it may be prone to oxidation during prolonged storage, especially at elevated temperatures. The significant fat content of the buttermilk needs to be considered in calculating fat content within the mix.

Sweeteners

Many kinds of nutritive sweeteners are used in ice cream (Tables 3.1, 3.2, and 3.4). They include cane and beet sugars, many types of corn sweeteners, maple sugar, honey, invert sugar, fructose, molasses, malt syrup, brown sugar, and lactose. The traditional and still the most common choice of sweetener system in mixes is a combination of sucrose (10–12%) and corn sweeteners derived from hydrolysis of corn starch (corn syrup solids, CSS, usually 3–5%). The main function of sweeteners is to increase the acceptance of the product by making it sweet and by enhancing the pleasing creamy flavor and the delicate fruit flavors. Lack of sweetness produces a flat taste; too much tends to overshadow desirable flavors. The desired sweetness of ice cream is that approximately equivalent to 13–16% sucrose in a 36–38% total solids mix. Sweetness depends on the concentration of sweetener in the water of the mix; thus, decreasing the water of the mix is equivalent to increasing the sweetness. Sweeteners, being dissolved, lower the freezing point of the mix, and this leads to an increased rate of melting. High levels can also reduce whippability, especially important for batch freezer operation. The major considerations in blending sweeteners are relative sweetness, contribution to total solids, and freezing point depression of the mix.

Sucrose: Crystalline and Liquid

Sucrose, commonly known as granulated or table sugar, is made from sugar cane or sugar beets. Being crystalline, it is approximately 99.9% solids (i.e., carries very little water or other impurities) and has a density of 1.588 g/mL. It is highly soluble so is available also as a syrup containing approximately 67% solids. Sucrose remains soluble in ice cream to very low temperatures (∼ -20°C, depending on the formulation). To freeze-concentrate sucrose to >65% saturation requires ∼90% of the water in a normal formulation to be frozen and the kinetics of crystallization at such low temperature and high viscosity are formidably slow. Hence it generally remains supersaturated at <-20°C. In very rare instances, sucrose has crystallized from ice cream at these low temperatures, although the factors contributing to this are unknown. Sucrose concentrations in mix formulations are limited by high levels of sweetness. Sucrose depresses the freezing point; each 1% increase in sucrose in an ice cream mix lowers the freezing point about 0.1°C (0.2 °F) (see Calculations in Chap. 6). Sucrose may be used as the sole sweetener in ice cream with excellent results, especially in high solids (e.g., premium or superpremium) formulations where the additional body from CSS is not wanted. However, use of sucrose as the sole sweetener in ices or sherbets may result in formation of crystals on the surfaces. This defect in ices and sherbets can be avoided by using one part of dextrose to 3.5 parts of sucrose.

Syrups or liquid sweeteners provide the convenience of handling in large systems, since the metering of them can be controlled with computers and in-line metering devices. The total solids content of sucrose syrups can be measured with hydrometry or refractometry and reported as °Brix, a scale which is calibrated by density of % sucrose solutions (Table 3.4). Another scale used with hydrometers is °Baumé, which is calibrated against density of % salt solutions, although this is presently in far less use than °Brix. The Baumé and Brix scales can be related for sucrose syrups as shown in Table 3.5.

Corn Sweeteners

It has been common practice in the industry for many years to substitute sweeteners derived from corn starch or other starch sources such as potato, tapioca, rice, oat, or wheat for a portion or all of the sucrose. A typical conventional sweetener blend for an ice cream mix usually includes 10–12% sucrose and 3–5% CSS (corn starch hydrolysate syrup, commonly referred to as “glucose solids,” but not to be confused with glucose, the monosaccharide). The use of CSS in ice cream is generally perceived to provide enhanced smoothness by contributing to a firmer and more chewy texture, to provide better meltdown characteristics, to bring out and accentuate fruit flavors, to reduce heat shock potential, which improves the shelf life of the finished product, and to provide an economical source of solids.

Starch is a high molecular weight polymer of the monosaccharide glucose (also known commonly as dextrose) and is comprised of two fractions, amylose, a linear fraction, and amylopectin, a branched fraction (waxy starch). During the hydrolysis process, amylose and amylopectin are continually and systematically cleaved at the 1,4 glucosidic linkages by enzymes (randomly by α-amylase to reduce total molecular weight, and sequentially by either glucoamylase to produce dextrose or β-amylase to produce maltose) resulting in controllable mixtures of medium (oligosaccharides) and low (dextrose, maltose, maltotriose) molecular weight units (Fig. 3.3). Each bond hydrolyzed produces a free aldehyde group that has the same reducing ability as does dextrose. This makes it possible to monitor the process of hydrolysis, the extent of which is termed the dextrose equivalent or DE.

Maltodextrins are only slightly hydrolyzed; consequently they range in DE from 4 to 20 and are only slightly sweet. Maltodextrin can be used in the production of low-fat frozen desserts where it is desirable to find ingredients that contribute greatly to body in low solids formulations. There are several maltodextrin ingredients available that are specifically designed for low-fat systems. The medium molecular weight saccharides (dextrins) are effective stabilizers and slow the formation of large ice crystals, thus improving heat-shock resistance. They also improve cohesive and adhesive textural properties, resulting in positive contributions to the body and meltdown of ice cream. The smaller molecular weight sugars provide smoothness, sweetness, and flavor enhancement. Dextrose, being a monosaccharide, causes greater freezing point depression than sucrose, maltose, or lactose. With the appropriate use of enzyme technology, corn syrup manufacturers have the ability to control the ratios of high to low molecular weight components, and the ratios of maltose, the disaccharide, to dextrose, the monosaccharide. High maltose syrups reduce the effect of dextrose on freezing point.

Starch hydrolysate products having 20 to about 70% of the glucosidic linkages broken are known as corn syrups. They are classified based on degree of conversion as low conversion, 28–38 DE; regular conversion, 39–48 DE; intermediate conversion, 49–58 DE; and high conversion, 59–68 DE. The ratio of higher to lower molecular weight fractions can be estimated from the dextrose equivalent (DE) of the syrup. Figure 3.3 shows that as the DE increases, the sweetness increases but the freezing point decreases, and the contribution to viscosity and chewiness in the mouth decreases. Thus, optimization of DE and concentration of corn sweeteners are required for the most beneficial effects. These sweeteners are available in liquid (∼80% solids) or dried form. Densities of liquid products based on composition are shown in Table 3.6. Dry products are also available that have been agglomerated to produce powders with high wettability and little dust. Ice cream manufacturers usually use liquid or dry corn syrup products with a 28–42 DE.

With further enzyme processing (using glucose isomerase), dextrose can be converted to fructose (Fig. 3.3), as in the production of high fructose corn sweeteners (HFCS). The resultant syrups are much sweeter than sucrose, although they have more monosaccharides and thus contribute more to freezing point depression than does sucrose. The most commonly used type is HFCS 42. It contains 42% fructose, 52% dextrose, and 6% higher saccharides. HFCS 90 is a super sweet mixture of 90% fructose, 7% dextrose, and 3% higher saccharides. Compared with sucrose, high fructose corn syrups (42, 55 and 90%) are from 1.8 to 1.9 times as sweet and lower the freezing point nearly twice as much (Table 3.4). Another product of the corn syrup industry is high maltose syrup. Whereas high fructose syrup is high in monosaccharide composition, high maltose syrup would be high in disaccharide composition, which would have been closer to the same impact on freezing point depression as sucrose, compared to fructose. Satisfactory use of HFCS requires optimization of the concentrations of all sweeteners, to achieve the right balance of sweetness, freezing point depression, and total solids. Blends of high fructose syrup (mostly for sweetness), high maltose syrup (to balance the freezing point depression), and low-DE syrup (to enhance mix viscosity and ice cream body) can be utilized to provide appropriate sweetness, freezing point depression, and total solids, in the absence of sucrose (Goff et al. 1990a, b).

Pure crystalline glucose (dextrose) and fructose are also available from the corn sweetener industry. These are both monosaccharides and thus should not be used alone. They can be used in combination with other sweeteners to achieve the desired freezing point depression and ice cream firmness. Dextrose is a white granular material that contains approximately 99.8% sugar solids. Because it is only about 80% as sweet as sucrose, 1.25 parts of dextrose are required to replace 1 part of sucrose. Dextrose lowers the freezing point nearly twice as much as does sucrose on a weight for weight basis, because it has about one-half the molecular weight of sucrose.

Maple and Brown Sugars

Maple sugar and brown sugar contain characteristic flavoring components that limit their use in ice cream. For example, only 6% of maple sugar in the mix will produce a distinct maple flavor. An additional impediment to their use is their comparative high cost.

Both maple and brown sugar are very high in sucrose. Maple sugar contains about 86% sucrose, 10% moisture, and 4% invert sugar, whereas maple syrup contains about 52% sucrose, 45% moisture, and 3% invert sugar.

Honey

Honey is comprised of about 74.5% invert sugar, 17.5% moisture, 2% sucrose, 2% dextrin, and 4% miscellaneous matter. It is used in ice cream principally to provide honey flavor in a honey–vanilla ice cream. The milder flavored and lighter colored honeys are generally preferred. Sweet clover or alfalfa honeys are most commonly used. Usually both the desired sweetness and honey flavor will be provided by a combination of 9% honey and 8% sucrose. If more honey is used, freezing and hardening difficulties may be experienced. There is also the possibility of using honey in combination with low- or medium-DE CSS, because they do not depress the freezing point as much as do other sweeteners. A combination of 12% honey and 8% low-DE CSS would allow the use of a greater percentage of honey without freezing difficulties. Honey flavor may blend poorly with other flavors, aside from honey–vanilla, so the addition of other flavors to honey-flavored ice cream is seldom advisable.

Sugar Alcohols

The group of mono- and disaccharide sugar alcohols, the polyols, includes sorbitol, mannitol, xylitol, erythritol, lactitol, maltitol, isomalt, and some related hydrogenated starch hydrolysates. They are extensively described in Wilson (2007) and Nabors (2001). Their main use in frozen dairy desserts is in low-sugar or sugar-free formulations. Generally, they contribute to a much lower glycemic index than conventional sweeteners so they are very beneficial in the diets of insulin-dependent diabetics (Whelan et al. 2008). Since the numbers of people with diabetes is increasing at an alarming rate, the interest in formulations containing the sugar alcohols is also increasing for both consumers and manufacturers (see Chap. 15 for a discussion of formulations). They are often combined with the intense sweeteners to arrive at satisfactory combinations, for example, maltitol and sucralose to match both the freezing curve and sweetness of sucrose-containing formulations. They also function as bodying/bulking agents, sweeteners, and crystallization inhibitors. These substances vary in their relative sweetness, freezing point depression, solubility, heat of solution (cooling effect), stability, laxation potential, caloric content, and cost. Although polyols are considered fully caloric in Canada (4 kcal/g), the European Union recognizes a caloric value of 2.4 kcal/g as an acceptable average for all polyols for labeling purposes. In the United States, self-determination of the caloric content is permitted, and some of the acknowledged values from the FDA are 2.6 kcal/g for sorbitol, 1.6 kcal/g for mannitol, 2.4 kcal/g for xylitol, 2.1 kcal/g for maltitol, 2 kcal/g for lactitol, and 2 kcal/g for isomalt.

Sorbitol and mannitol are monosaccharide alcohols found naturally in fruit juices of apples, pears, cherries, and plums. Mannitol is the major constituent of manna, an exudate of the ash tree, or as a component of mushrooms and marine algae. Sorbitol and mannitol can also be produced by hydrogenation of glucose and fructose, respectively. Both weigh the same, but sorbitol is 0.6× as sweet while mannitol is 0.5× as sweet as sucrose. Sorbitol is hygroscopic while mannitol is not. They both provide a cooling effect in the mouth due to their negative heat of solution. As monosaccharides, they have twice the freezing point depression effect as sucrose on a per weight basis. Both are generally recognized as safe (GRAS) in the USA and are approved for use in Canada, the EU, and many other countries. The laxation thresholds, in g/day, are considered to be 50 for sorbitol and 20 for mannitol.

During digestion, small amounts of sorbitol and mannitol are slowly absorbed through the wall of the small intestine and metabolized by the liver. However, most of the utilization occurs in the colon where the polyols are converted to volatile fatty acids by bacteria. Because they enter the glycogenolytic pathways without dependence on insulin, polyols do not cause appreciable increases in blood glucose levels when eaten.

Xylitol is a five-carbon polyol with similar sweetness as sucrose. It is the sweetest of the polyols and has the most cooling effect. As a lower molecular weight sweetener than the monosaccharides, it could not be used in ice cream at a one-to-one replacement for sucrose due to its freezing point depression effect.

Maltitol differs from sorbitol and mannitol in its physical properties because it is hydrogenated maltose, a disaccharide. It provides similar freezing point depression and sweetness as sucrose and does not provide the cooling effect of sorbitol and mannitol. Its laxation threshold is set at 100 g/day before a warning label must be used. It is widely approved for food use in many countries. Because it mimics the properties of sucrose well, it is probably the most extensively used of the polyols for ice cream manufacture.

Lactitol is the product of hydrogenation of lactose, thus also a disaccharide polyol. It has similar freezing point characteristics to sucrose, but it has only 0.3–0.4× the sweetness of sucrose. Its use is permitted in most countries.

Isomalt forms when sucrose is enzymatically rearranged to isomaltulose and the latter is hydrogenated. Sorbitol and mannitol are equimolar building blocks of isomalt. It is approximately one-half as sweet as sucrose and is non-cariogenic but tends to crystallize because of low solubility in water (25% at 20°C compared to 67% for sucrose).

Combinations of the sugar alcohols, starch hydrolysates, and oligosaccharides have been studied for their contributions to mix rheology, ice cream thermal characteristics and physical properties, and sensory quality (Soukoulis et al. 2010). The thermal melting profile of the mix, ice cream hardness, and meltdown rate (structural collapse) were all affected by variations in the sugar alcohols, as expected, but these physical properties were found to correlate well with sensory properties, suggesting the importance of these variables in product development of novel sweetener-modified formulations. Whelan et al. (2008) likewise reported that once freezing profiles of sugar alcohol-containing products were matched to controls, all other variables were also found to match well. Sweetness of such formulations can be modified by the high-potency sweeteners (described next) with no further effect on physical properties.

Nonnutritive Sweeteners

Many high-potency sweeteners are either commercially available or are in various stages of testing and regulatory approval. With increasing levels of diabetes in the USA and globally, consumer interest in no sugar added or sugar-free formulations is rising, hence so too is the use of these sweeteners not only in caloric management but also in diabetes management (Gougeon et al. 2004). They are used successfully in some products, soft drinks for example, where sweetness is desired but total solids and other physical characteristics of sucrose, for example, freezing point depression, are not important. In ice cream and related products, however, total solids and freezing point depression are very important to consider when replacing sugar for caloric reduction or blood glucose control. It is perhaps easy to find a high-potency sweetener to replace the sweetness of sucrose and CSS, but what is then used to produce freezing point depression and to build total solids without contributing to blood glucose or caloric intake? Polydextrose is one such low-calorie bulking agent that can be used at a significant concentration without greatly affecting viscosity, but it contributes little to freezing point depression. Another factor to consider in looking at sugar replacement for caloric reduction is that the sugars contribute only a small fraction of the calories in frozen desserts compared to the contribution of fat. Therefore, fat replacement should be targeted first and sugar replacement only if further reductions are required. The more common high-potency sweeteners are described below, but these limitations to their use should be recognized. Intense, nonnutritive sweeteners are extensively described in Wilson (2007), Gougeon (2004), and Nabors (2001). Some of them are in fact digested and thus caloric, but they are often considered nonnutritive due to the very low concentrations required in foods to provide adequate sweetness.

The use of these sweeteners in diabetes management is receiving ever-increasing attention. Current evidence confirms that low-calorie sweeteners do not stimulate appetite or affect mechanisms that regulate hunger and satiety. Intakes of up to the acceptable daily intake value for each of aspartame, sucralose, saccharine, and cyclamate do not affect glycemic control or blood lipids in persons with diabetes (Gougeon 2004).

Saccharin, discovered in 1879 at Johns Hopkins University, is an organic compound that produces no glycemic response. It is approximately 300–500 times as sweet as sucrose but produces a slight aftertaste on its own. It can withstand long periods of storage as well as heat. It has been thoroughly studied throughout its history and, despite earlier concerns about its safety, has been declared safe by numerous scientific bodies. It is widely permitted in more than 100 countries including the USA, but its use in manufactured products, including ice cream, may be restricted.

Aspartame (common trade name NutraSweet) was discovered in 1965 by a chemist who was attempting to develop an antiulcer medicine. It is the methyl ester of two amino acids, l-aspartic acid (aspartate) and l-phenylalanine, both of which occur naturally in foods. Furthermore, it is digested in the same manner as other amino acids. However, it contributes few calories to a serving of ice cream because of the low concentration of it needed to sweeten as compared with sucrose (∼200 times as sweet as sucrose). The taste of aspartame is quite similar to that of sucrose. It shows sweetness synergy with several other sweeteners, for example, saccharin and acesulfame K, and enhances some flavors. At high temperature in dry environments, aspartame undergoes hydrolysis and loss of sweetness, but this is not an issue in the normal pasteurization of ice cream mixes. More than 100 scientific studies were conducted to support the food additive petition made to the US Food and Drug Administration, making it one of the most thoroughly studied food additives in history. Its safety continues to be critically and comprehensively monitored and thus far confirmed. Persons with the rare hereditary disease phenylketonuria (PKU) must control their intake of phenylalanine from all sources, including aspartame. These persons, about 1 in 15,000, are diagnosed at birth by a blood test performed on all newborn. Because aspartame use in foods may introduce a new source of phenylalanine in the diet, products containing this sweetener must carry a warning statement on the label. Aspartame has been declared safe by numerous scientific bodies, the Joint FAO/WHO Expert Committee on Food Additives of Codex Alimentarius and the regulatory agencies of more than 100 countries around the world, including the USA and the EU.