Abstract

As in many countries, policy makers in China see the production of biofuel as an important strategy for energy independence and sustainable development. As a promising feedstock of second generation biodiesel,Jatropha curcasL. (JCL) is being massively planted on marginal land in China because the Chinese policy framework has provided a good opportunity for the promotion of JCL biodiesel and China has favorable conditions for JCL cultivation and relatively mature processing technology. However, despite its potential contribution to energy production and greenhouse gas emission reduction, the production of JCL biodiesel is facing many challenges, which are to be dealt with before JCL biodiesel is produced on a massive scale. It is suggested that more efforts be laid in designing policy package for JCL biodiesel production, especially incentive policies for producers, and making institutional arrangement for sustainable production and management.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

Introduction

Along with the rapid economic growth, China’s consumption of energy is continuously increasing. Since 1998, the consumption of energy in China has been increasing at a rate of 5%, which is three times higher than the world average. China is now the second largest importer of oil in the world. In 2005, China imported 168 million tons of crude oil, which accounts for 42.9% of the total amount of domestic consumption. As projected, China will reach the peak of energy consumption, that is, 4.18 billion tons of standard coal equivalents, in 2020 (EPASEA-NIC2008). To meet its demand for energy, China highly depends on importing energy. According to the International Energy Agency, China’s import of petroleum will account for about 77% of its total demand by 2020, and 84% by 2030 (IEA2005). Thus, it is a hard task to meet the demand for diesel in China in the long term (Li2001). In the next two decades, China will face a severe energy supply challenge.

Given abundant coal reserves compared to the insufficient supply of oil and gas, China has mainly relied on coal for its energy in the past decades. China’s energy structure is dominated by coal, which accounted for 68.8% of the total energy consumption in 2006 (EPASEA-NIC2008). Along with the consumption of fossil energy, air pollution and the emission ofcarbon dioxide(CO2) have also attracted the concerns of Chinese government and academia. As pollution from the burning of coal becomes more and more, it is an urgent task to search for environment-friendly alternatives to fossil fuel. Moreover, along with the worldwide concerns on global warming, China is facing international pressures for the reduction of greenhouse gas (GHG) emission. The emission of CO2equivalent is projected to be 5.2 billion tons and 5.6 tons in 2015 and 2020, respectively (EPASEA-NIC2008).

The increases in crude oil prices and the concern for environmental protection gave an impetus to the search of renewable alternative sources of oil (Shay1993; Runge and Senauer2007; Hazell and Pachauri2006). Among the renewable energy to be developed, liquid biofuels, including bioethanol and biodiesel, is a priority for development because it can be used in existing engines. Moreover, the production and use of biofuel has the potential of reducing dependence on petroleum, improving environmental quality, lowering the emission of greenhouse gas (GHG), promoting rural development, and providing farmers job opportunities (Krawczyk1996; FAO2008; Wiesenthal et al.2009). As in many other countries, the production of biofuel in China is seen as an alternative to reduce the pressure induced by the increasing oil scarcity and to achieve sustainable development.

In 2005, China became the world’s third largest biofuel producer with an output of one million tons, behind Brazil and the US (USDA2006). In 2006, the National Development and Reform Commission (NDRC) of China set the threshold of 15% biofuel as the target to be meet by the fuel transportation system by 2020 (USDA2006). The State Forest Administration (SFA) of China set the target of 13 million hectares to be planted with oilseed species suitable for biodiesel production by 2010. The expectation of the Ministry of Science and Technology (MOST) is to reach the production of 1.5-2 million tons of biodiesel by 2010 and 12 million tons by 2020 (GTZ 2006).

The production of first generation biofuels whose feedstock is agricultural crops will have a negative effect on food security if produced in large quantities (Runge and Senauer2007; Huang et al.2009). In2007, food prices on the international market increased by 15.6% and those in China by 10.8% on a year to year basis (NBSC2008). Using woody plants produced from non-agricultural land as feedstock to produce second generation biofuel will not affect food security and can be more conducive to respect the environment than first generation biofuels. That is, sustainable biofuel production will be better achieved with a shift from the production of first generation biofuel to that of second generation biofuel including lignocellulosic ethanol from biomass crops and biodiesel from oilseed tree species (FAO2008; Flavin2008). The rise in food prices has thus triggered the production priority from first generation to second generation biofuel.

While the second generation bioethanol is facing a technological challenge, second generation biodiesel is attracting more and more attention throughout the world due to its technological easiness of production. Second generation biodiesel is a promising fuel, but its production is challenged by high cost and limited availability of oil resources. The availability and sustainability of sufficient supplies of less expensive feedstock will be a crucial determinant in delivering a competitive biodiesel to commercial fueling stations. One way of reducing biodiesel production costs is to use less expensive fatty acid containing feedstocks, such as inedible oils, animal fats, waste food oil and byproducts of vegetable oil refining (Veljkovic et al.2006). Fortunately, biodiesel can be produced from inedible vegetable oils, mostly from seed-bearing trees and shrubs. There are 151 families, 697 genera and 1,554 species of oilseed plants of which 30 species have the potential of becoming feedstock for biodiesel production. However, only a few of these species can be cultivated as biodiesel feedstock plantations on waste land. So far, the Ministry of Science and Technology of China is targeting at producing biodiesel fromJ. curcas(JCL),Pistacia chinensisBunge, Xanthoceras sorbifoliaBunge, andCornus wilsonianaWangerin.

JCL receives the largest attention because it does not compete with food uses, it has excellent oil characteristics and it is distributed all over tropical and subtropical climates across the developing world (Heller1996; Openshaw2000). In China, the diesel oil consumption was 67.15 million tons in 2000, 85.3 million tons in 2005 and will be 133 million tons in 2015 (Li2001). Thus, JCL biodiesel has a large market potential.

Since China has the largest population in the world and the lowest farmlandper capita(less than 0.1 hectare), it is thus impossible to use farmland to produce biofuel on a large scale (Wang et al. 2005). However, China has a lot of mountains and marginal lands which are suitable for the plantation of arborous and shrub oilseed plants. The cultivation of these plants can not only provide raw material for the biofuel industry, but also promote the restructuring of rural industry and increase farmers’ income. Moreover, the cultivation of these plants on marginal or waste land in a sustainable way can also contribute to ecological rehabilitation. Being such an oilseed, JCL is considered as a priority feedstock species in China, as in many other countries.

Biofuel Policies in China

The development of renewable energy has become an important component of China’s energy development and sustainable development strategies. The Chinese government has adopted many policies and measures to develop renewable energy and address the issue of climate change. The promotion of biofuel was listed in the “National plan for scientific and technological industrialization programs” in May 2003. Accordingly, the Ministry of Science and Technology launched the “10th 5-year plan for biofuel technology development” in 2004. The agricultural and forest biomass program, supported by a national special fund, was started in 2005. According to its “Middle and Long Term Development Plan of Renewable Energy,” China set an ambitious target of an annual production of 10 million tons of biofuel by 2020 (NDRC2008). The “law for renewable energy” was also approved in 2005 and came into force starting from January 1, 2006. In 2007, the first national standard for biodiesel was designed and put into practice. In China’s “11th five-year plan framework for national economic and social development”, it was highlighted that more efforts should be invested in the development of renewable energy, especially by improving the production capacity of power stations running on biomass, bioethanol and biodiesel. These policies and measures laid a solid foundation for biodiesel as a substitute to fossil diesel to enter fuel market and provided a legal basis for providing subsidized loan and tax discount to companies involved in biodiesel production.

In 2007, concerns over food security led China’s central government to control the use of grain-based feedstock for biofuel production and to reorient the country’s bioenergy plans toward perennial crops to be grown on marginal land. That is, neither biofuel should be derived from feedstock competing with crops from foodlands nor should they compete with human and livestock access to food. In addition, biofuels should not be harmful to the environment (MOA2007). China has the largest human population, accounting for 22% of the world population, but it has only 120 million hectares farmland, i.e., 7% of the total world area available for farming. Thus, the limited farmland will be used to grow food crops so as to feed the large population. The expansion of grain-derived biofuel is prohibited in order to alleviate the pressure on food security, while non-crop feedstock is encouraged, including sweet sorghum, cassava, sweet potato and other non-grain crops. As a non-grain crop, JCL has emerged as a high potential biodiesel feedstock because of its adaptability to diverse growing conditions. Provincial governments in Southwest China have drafted plans to increase the area of JCL planting by over one million hectares in the next decade (Weyerhaeuser et al.2007).

To promote the development of low-carbon economy is another justification for the production of biofuel. Chinese government has announced many related policies since 2006, including the “National Assessment Report on Climate Change”, “China’s National Climate Change Program”, “Decision on the strengthening of energy saving work”, and “The comprehensive work plan for energy saving and emission reduction”. All of these policies have laid out a development plan for the energy system, and will contribute a lot to the control and mitigation of GHG emissions in China. In particular, in November 2009, Chinese government announced its target of reducing the emission of CO2by 40–45% per unit of GDP in 2020 over the level of 2005. To meet this target, biofuel, especially second generation biofuel, is considered as an important alternative for fossil fuel (Wang et al.2010; Liu et al.2010).

To encourage the development of biofuels industry, a set of incentive policies was implemented in 2007; they include (i) mandatory mixing of 10% bioethanol in gasoline in nine provinces to secure the biofuel market; (ii) waiving the 5% consumption tax on bioethanol and refunding the 17% value added tax; and (iii) direct subsidies to biofuel plants of about $ 200 per ton (Qiu et al.2008). These policies resulted in a rapid increase in the output of biofuel in China. In 2007, China is among the largest bioethanol producers in the world with an output of 1.3 million tons of bioethanol.

Subsidies to biofuel feedstock producers are indispensable to promote the integration of non-grain biofuel in the present Chinese energy market. In 2007, the Ministry of Finance of China released a policy to encourage the use of non-food feedstock to produce biofuels by providing subsidies and other forms of financial support to people involved in the production of biofuels (China Daily2007). Specifically, farmers involved in feedstock production for biofuel manufacture started to receive a subsidy of 3,000 yuan (1 yuan = $ 0.16; April 2012) for each hectare of forest and 2,700 yuan for each hectare of non-grain agricultural crops. As far as JCL plantation is concerned, the producers are to be subsidized by a rate of 3,000 yuan for each hectare of JCL plantation.

JCL and Its Development in China

JCL in China

JCL is a small tree or shrub belonging to the family of Euphorbiacae. JCL has great potential for the production of biodiesel due to its adaptability to the environment, especially to drought, but also to soil of poor quality. JCL was introduced into China 300 years ago; its growth in the wild is found in the tropical or subtropical area, such as the dry and hot valleys of Guangdong, Guangxi, Hainan, Fujian and Taiwan, especially Yunnan, Guizhou and Sichuan (Wu and Zong2007). In Yunnan Province, JCL can typically grow at an altitudinal range of 600–1,400 m above sea level (Zeng2006). In Yunnan Province, JCL mainly grows between 600 and 1,400 m and can survive in plains, hills and valley slopes between 700 and 1,600 m (Yuan et al.2007). In Guizhou Province, JCL is mainly distributed in the southern and southwest parts, mainly in dry and hot valleys in the basins of Nanpan River, Beipan River and Hongshui River at an altitude range of 275–800 m (Chen et al.2006). In Sichuan Province, JCL is mainly distributed in the dry-hot valleys below 1,600 m (Xu et al.2008).

According to preliminary statistics, the natural growth of JCL in Yunnan, Guizhou, and Sichuan provinces is about 33,000 hectares (Wu and Zong2007). Over the past several years, the area of JCL plantation has been gradually increased as more effort has been made in the development of biodiesel. It is reported that the area of JCL plantation was 680,000 hectares in Yunnan, more than 17,300 hectares in Sichuan in 2007, and 15,300 hectares in Guangxi by the end of July 2008. Despite its strong ecological adaptation, existing JCLs are mainly distributed on the sides of villages and homestead, banks of ditches and channels, alluvion of rivers, valleys and the lower end of slopes. For example, the distribution of existing JCL resources in Yunnan Province is shown in Table6.1.

Before cultivation for biodiesel production, JCL has been used (i) for fencing or hedging along rivers and road sides and its seed oil was mainly used to produce lubricant and lacquer (Zheng et al.2008); (ii) as raw material for green manure in Nanpan River, Beipan River of Guizhou and Panzhihua of Sichuan; (iii) for soap fabrication in Qiaojia County of Yunnan Province; and (iv) recently to prevent soil erosion in Binchuan County of Yunnan Province and Panzhihua, in Liangshan prefectures of Sichuan Province (Xiang et al.2008).

Yield of JCL seeds varies greatly with eco-climatic conditions. In their literature survey of JCL seed yields in India, Mali, Nicaragua, Paraguay, Thailand and Cape Verde, Achten et al. (2008) showed that the annual yield of JCL seeds was 0.3–5 tons per hectare with a few reports of 6.7 tons per hectare in India and 8 tons per hectare in Mali. At a conference on the production of biodiesel from JCL held in Wageningen in the Netherlands in March 2007, participating experts agreed that a yield of 4–5 tons per hectare is feasible. However, the upper limit of seed yield (5 tons per hectare) has never been confirmed by JCL growers. As soon as the first year of plantation, JCL can bear fruit in small quantities and the fruit yield can reach 4–5 kg per tree 4 or 5 years later if the plantation is well-managed. However, if trees are planted on barren hills and fed by rain, the yield per tree is not expected to overcome 1–1.25 kg (Kumar et al.2003).

In China, He at al. (2007) found that the seed yield is between 300 and 600 fruits per tree with an average of 200 fruits per tree and a maximum of 1,500 fruits per tree according to a survey of 10 JCL plots in Honghe Prefecture of Yunnan whose trees were between 5 and 20 years old (Table6.2). Because there are usually three seeds in each fruit and the weight of a single seed is 0.5–0.75 g (Zheng et al.2008), the seed yield is 0.54–1.08 kg per tree with an upper limit of 2.70 kg per tree. In Guizhou province, Chen et al. (2006) found that seed yield of JCL was between 2 and 4 kg per tree older than 5 years. After studying the population of JCL in Sichuan, Xu et al. (2008) found that the seed yield of JCL in the wild was 750–2,250 kg ha−1. In summary, the seed yield of JCL is 0.6–4.5 tons per hectare at the present levels of technology and management in China.

In each fruit, there are usually three seeds and occasionally, only two seeds. The weight of the seeds is about 55–65% of that of the fruit (Table6.2). The JCL seeds are black and toxic. The dry JCL fruit is mainly composed of water (4.4–4.7%), protein (17.8–28.9%), fat (52.9–57.4%), and cellulose (3.7–4.3%) (Chen et al.2006).

The characteristics of JCL seeds from different regions of Yunnan are shown in Table6.3. According to the nine samples taken from different parts of Yunnan, the weight per 100 seeds is about 48.2–72.3 g, of which the kernel accounts for more than 60%. The oil rate ranges from 32.2 to 40.2% of seeds and 50.0–61.3% of kernels. These oil yields were obtained using the mechanical extraction method, which is widely used in Yunnan. However, larger oil rate can be obtained from seeds by chemical extraction.

Development of JCL Biodiesel in China

China started the research and development of JCL biodiesel two decades ago. During the period of 1986–1990, the project of “Demonstration project on the development and application of wild plant oil as alternative fuel” was initiated in Sichuan province. This research was conducted in locations where JCL is found in the wild and considered factors such as cultivation technique, extraction of JCL oil and biodiesel fabrication. Since then, further researches have been done on the distribution, growth, seed yield, oil characteristics, provenance test, and techniques for JCL plantation in the three southwest provinces. In particular, some elite JCL varieties screened according to their sites of origin, adaptability, seed quality and seed oil content were used to establish mother plantations. Among the most important projects that were implemented later on, one can note “the study and applied techniques of oilseed plants” by the Chinese Academy of Science and “the joint project of poverty alleviation through the development of green energy in minority ethnic areas” by the Chinese government and the UNDP. These investigations boosted knowledge accumulation on production techniques, germplasm collection, physiological analysis, biochemical characterizations and genetic diversity in JCL.

The establishment of JCL plantation on a massive scale started mainly in southwest China, including Yunnan, Sichuan and Guizhou provinces. Mountains are the major terrain in these provinces, especially in Yunnan where 94% of the land area is upland or mountains. The government’s strategy for JCL plantation has focused on barren lands, which is a specific term used in Chinese agriculture and forest management, referring to lands that are not being used for obvious productive purposes, including some lands that are in fact used for grazing livestock. The provinces just quoted have large portion of land that can be used for JCL plantation, since much of the upland or mountains are barren land. The barren land is mainly owned by the government or village collectivities enjoying the right to use the land contracted to individual households. Therefore, a significant portion of the land area planned for JCL plantation is likely to be collectively owned, but under contract of individual households.

In 2006, the Ministry of Finance, the National Development and Reform Commission, the Ministry of Agriculture, the State Taxation Administration and the State Forestry Administration jointly enacted the “Statute on supporting financial as well as tax policies for the development of bioenergy and biochemical engineering”. Since then, the three provinces have made plans for the establishment of 1.667 million hectares of JCL plantations on waste or marginal lands within 10–15 years, including 0.667 million hectares in Yunnan, 0.6 million hectares in Sichuan, and 0.4 million hectares in Guizhou. According to the State Forestry Administration, the total areas of JCL plantation in the three provinces was 0.15 million hectares, which accounts for more than 95% of China’s total JCL plantations by the end of 2008. During the same year, the national development and reform committee of China approved the participation of some small and giant companies, such as Sino-Pec and Petro China to pilot projects for the production of JCL biodiesel.

The Production Process of JCL Biodiesel

The JCL biodiesel production chain can be divided into four stages: (i) production of JCL seeds through cultivation; (ii) extraction and processing of JCL oil; (iii) distribution and retailing of final products; and (iv) consumption of JCL biodiesel. Here we defineJCL biodieseleither as the refined JCL oil or the JCL methyl esters (JME), both blended with fossil diesel. Of course, in the case of JCL oil considered as an end product, no conversion or transesterification reaction is required.

The Production of JCL Seeds

Despite many literatures on the establishment and management of JCL plantations, the basic process of JCL seed production can be summarized as shown in Fig.6.1.

JCL trees can be propagated by seedling, cutting and micro-propagation. Since the survival rate of cutting plantation is low and the cost of micro-propagation is much higher than that of seedling or cutting, JCL plantation is mainly established with seedlings.

Land preparation mainly comprises of terracing, digging holes (40 × 40 × 40 cm), applying green manures and soil erosion control. However, not all sites need every of the activities depending on their conditions. Irrigation is mainly applied in the first year after plantation is established. In the dry season, the plantation will be watered twice a week. Also, for some areas with a level of annual rainfall larger than 2,500 mm, irrigation is not necessary.

The physico-chemical conditions of the JCL plantation are commonly corrected with chemical fertilizers, green manures and JCL seed cakes. In the course of site preparation, green manure is put into the holes. Chemical fertilizers are applied after seedlings are transplanted for the first 3 years. Each 3 years, about 100 g of urea and 250 g of NPK are applied to each tree in the first part of the year, followed by top dressing with 100 g of urea for each tree. From the fourth year to the 30th year of plantation, JCL seed cake and green manure are used instead of chemical fertilizers. According to Openshaw (2000), one kg of seed cake is equivalent to 0.15 kg of NPK fertilizer (N:P:K = 4:2:1).

To control weeds and fungi, the application of herbicides and fungicides is necessary. The main herbicide used is glyphosate; it is applied using simple sprayer. In dry season, the control of weeds by manual cutting is also applied. JCL is a disease-tolerant plant and can be used to produce insecticides. The damage from pest attack is not significant in China. However, carbendazim should be applied to control diseases caused by fungi.

Extraction and Conversion of JCL Oil

Under this industrial activity, the JCL oil is extracted and converted into biodiesel. The JCL oil is mainly extracted using two methods: chemical method using solvent extraction with n-hexane and the mechanical method using an engine driven-expeller. Because of its simple technology, the latter is widely used (Fig.6.2). The oil is then converted into biodiesel through transesterification by methyl esterification.

The ripe fruits are plucked from JCL trees, sun dried and then de-husked. To prepare seeds for mechanical extraction, they should be heated at sun for several hours or roasted for 10 min so as to reduce the oil viscosity. If chemical extraction is chosen, the shelling of seeds can increase the yield of oil.

The characteristics of JCL oil are shown in Table6.4. JCL oil is not suitable for direct use in engines because of its viscosity. The high viscosity of JCL oil may result in incomplete fuel combustion, formation of carbon deposits in engines and reduction of engine life span. Significant reduction in viscosity can be achieved by dilution of vegetable oil with diesel in varying proportions (Pramanik2003). Among blends, the blends containing up to 30% (v/v) JCL oil have viscosity values close to that of fossil diesel and up to 50% diesel can be substituted by JCL oil without any major operational difficulties of compression ignition (CI) engine. Forson et al. (2004) showed that the 97.4% diesel/2.6% JCL fuel blend produced the maximum values of brake power and brake-thermal efficiency as well as the minimum values of specific fuel consumption and, thus, JCL can be used as an ignition-accelerator additive for diesel fuel.

Many scholars have analyzed emissions by mixtures of JCL biodiesel and diesel. As compared with fossil diesel, the combustion of B10, a blend of 10% of JCL biodiesel and 90% of diesel, reduces the emissions ofnitrogen oxide(NOx),hydrocarbon(HC),carbon monoxide(CO) andparticulate matter(PM) by 5.3%, 9.1%, 15.9%, and 8.9%, respectively, but the deposited carbon is slightly higher (Hu et al.2010). These results are consistent with those of Prasad et al. (2000) concerning the emission of NOx, but are in contradiction with those of Kumar et al. (2003) regarding the emission of CO. The emission ofaldehydes,sulphur dioxide(SO2) and CO2by fossil diesel has also been reported to decrease upon increasing contribution of JCL biodiesel to blends (Lou et al.2010).

Although significant reduction in viscosity can be achieved by dilution of JCL oil with diesel in varying proportions, the oil quality will be improved and there will be less long-term problems if JCL oil is converted into biodiesel. The process of oil conversion into biodiesel is as shown in Fig.6.3.

JCL biodiesel satisfies the international standards of diesel fuel for CI engines (Table6.5). Compared to diesel, JME have higher cetane number and flash point, a similar calorific value and lower sulfur content. Therefore, JCL biodiesel has an overall performance close to that of diesel and thus can be used as a substitute for diesel (Chen et al.2006).

Environmental and Economic Performances of JCL Biodiesel

Only the mechanical method has been investigated here because it is far more widely used than the chemical method. Since JCL oil can be used in engines after it is blended with fossil diesel or converted into JME through transesterification reaction, JCL biodiesel can be JME or a mixture of JCL oil and diesel. Here we analyze the environmental, economic and energy (3E) performance of JCL seed oil while that of JME is available in Wang et al. (2011). As mentioned earlier, the lifecycle of JCL biodiesel consists of four stages: JCL cultivation, oil extraction and refining, biodiesel production, and use in engines.

The analysis includes the assessments of 3E performance associated with direct inputs and construction of facilities, such as manufacturing machines, housing, etc. as well as with manual labor, such as planting, pruning, fruit collection and drying, weeding, etc. The calculations are based on one hectare of JCL plantation for 30 years.

Indices used to assess the 3E performance are financial net present value (NPV), CO2equivalent balance (CEB) and net energy ratio (NER). The NPV is the difference between the present value of the flow of revenues and the present value of the flow of costs. The CEB is the difference between the total sequestrated CO2, reduced CO2emissions and total emitted CO2equivalent. The NER is the ratio of total energy outputs to the total energy inputs.

The allocation of costs to co-products is based on their monetary values on the market. The credits for allocating environmental and energy burdens are based on displacement effects. Although parts of the JCL tree can be exploited for a number of uses, such as medicines, insecticides, fuel, fertilizer, etc., this study considered seed cake as a fertilizer and the parts involved in fuel stock as substitutes to coal.

Carbon Balance at Production Level

When JCL oil is directly blended with fossil diesel, its lifecycle carbon balance is shown in Table6.6. It shows that the production and use of JCL oil has a positive carbon balance (Wang and Lu 2011). The effect of carbon emission reduction by the diesel substitution with JCL oil tends to become more consistent when seed yield is increased. The major contributors to carbon balance are JCL biomass stock and JCL oil. The combustion of fruit husks can also reduce carbon emission when they are used to replace coal as a fuel.

The major GHG emissions come from the application of fertilizers together with the transportation of seeds and fertilizers. The JCL plantation will be fertilized with chemical fertilizers, green manure and JCL seed cakes. In the course of site preparation, green manure is put into the holes. Chemical fertilizers are applied after seedlings are transplanted throughout the first three years. In each of the three years, about 100 g of urea and 250 g of NPK will be applied to each tree in the first part of the year, followed by top dressing with 100 g of urea for each tree. From the fourth year to thirtieth year of plantation, JCL seed cake and green manure will be used instead of chemical fertilizers. According to Openshaw (2000), one kg of seed cake is equivalent to 0.15 kg of NPK fertilizer (N:P:K = 4:2:1). Although much direct energy is used in the oil extraction stage, the GHG emission associated to this processing step is relatively small.

Economic Performance of JLC Oil Production

The Cost of Seed Production

The production of JCL seeds starts from seedling cultivation to seeds delivered to oil extraction plants, involving activities including transplanting, site preparation, tending, seed collection, etc. To estimate the revenue of seeds, we used the present price of JCL seed that is 2 yuan/kg.

Taking a seed yield of 1,485 kg/ha (around 500 pieces of fruits per tree) as an example, the total cost at the seed production stage is 73,609 yuan/ha and its components are as shown in Table6.7. Obviously, the main costs are associated with fruit drying and husk removal, fruit collection, fertilization, fungicide treatments and weeding.

The seed yield of JCL varies with the local conditions. The FNPV of seed production (FNPVs) and the breakeven price of seeds would be different as seed yield changes. Assuming that the JCL tree has an annual yield of 100, 300, 500, 700, 900, 1,100, 1,300 or 1,500 fruits per tree, which are corresponding to an annual seed yield of 297, 891, 1485, 2,079, 2,673, 3,267, 3,861 or 4,455 kg/ha, respectively, the relationship between the FNPVsand yield is as shown in Fig.6.4. It reveals that the FNPVstends to increase as the seed yield is increased. When the price of seeds is 2 yuan/kg, the FNPVswill be positive only if the seed yield is higher than 3 tons/ha. Obviously, the yield of seeds is one of the important determinants of the financial feasibility of biodiesel production.

Cost of Mechanical Extraction of JCL Oil

When a mechanical extraction method is used, the stage of oil extraction starts from the heating of seeds to the refined JCL oil. When the yield of seeds is 1,485 kg/ha, the total cost of the processing of JCL seeds is 2,321.91 yuan/ton and its components are shown in Table6.8. It shows that the major cost is from seed purchase (seed price is 2 yuan/kg), which accounts for 86.13% of the total cost while the sum of all other costs accounts for about 14.87% only.

As shown in Table6.3, the crude oil content ranges from 32.2% to 40.2% in seeds when oil is extracted using an engine driven-expeller. According to researchers’ recent survey at an oil extraction plant of Er-Kang Science and Technology Co. Ltd. in Yunnan province, the yield of refined oil is a little lower at ∼30.4%. Based on the specific gravity of JCL oil and total costs (Table6.8), the cost of producing 1 liter JCL oil is calculated to be 6.99 yuan/liter when the seed price is 2 yuan/kg.

Financial Analysis of JCL Oil Final Product

When both the stages of seed production and oil extraction are considered together or produced by a single producer and JCL oil is used as an end-product, the financial feasibility associated with different seed yields is shown in Table6.9. Since most oil plants are not far away from refueling station and the shared transportation cost for each unit of JCL oil is negligible, the cost associated with oil distribution is neglected.

Table6.9shows that the major cost is incurred at the seed production stage and the financial net present value tends to decrease as the seed yield increases. The reason is that the cost increases with the JCL oil production when the cost is higher than the revenue of producing an extra unit of oil. In short, the more JCL oil is produced, the more the producer will lose. As expected, both the total cost and revenue increase with seed yield. However, the breakeven price of JCL oil decreases as the seed yield of JCL plantation increases. Moreover, when seed yield increases, the percentage of the costs associated with seed production tends to decrease even if the total cost increases.

Subsidies Required for JCL Oil Production

Subsidies are required for both JCL seed producer and oil processors if a given level of biodiesel production is targeted. At the stage of seed production, subsidies can be provided on the basis of seed weight or the area of JCL plantation. Assuming that both the seed producers and processors will receive a margin of 10%, the two kinds of subsidy rates are shown in Table6.10. It shows that subsidies are required if the seed yield is lower than 3 tons/ha and the amount to be paid tends to decrease as the seed yield increases. Obviously, the current rate of subsidy, 3,000 yuan/ha of biofuel feedstock is sufficient to stimulate the production of JCL seeds by companies at a wide range of geo-climatic conditions.

At the stage of oil extraction, subsidies can be provided based on the volume of JCL oil. As previously calculated, the break-even prices of oil extracted with mechanical methods is 6.99 yuan/l, respectively. Based on the present local price of diesel, 5.89 yuan/l, the subsidy is found to be 1.88 yuan/l, when a margin of 10% is assumed. Obviously, the increase of diesel price might provide incentive for investors to produce JCL oil. For better environment and energy security, it is desirable for government to provide producers subsidy as long as there is an economic justification.

When the whole production chain is considered, subsidy is required even if the seed yield is as high as 3.86 tons per ha. A single producer who produces both JCL seeds and oil will lose even if it receives subsidy for seed production. That is, subsidy is also required for oil extraction and refining. However, there is no specific incentive policy for oil extraction and refining in China yet, which is probably the reason why the JCL biodiesel industry grows only very slowly and few JCL oil processing plants are established.

Energy Efficiency of Production and Use of JCL Oil

According to the average calorific values and specific gravities of diesel and JCL oil, it was calculated that 1 liter of diesel has a calorific value equivalent to 0.994 liters of JCL oil. Thus, we consider in the following that, in terms of energy content, 1 liter of JCL oil is equivalent to 1 liter of diesel. The energy efficiency is an important indicator to evaluate the eco-performance of a renewable energy resource. It was assessed with the following indicators:

where EE1is the ratio of theheat value(HV) of biodiesel per unit to the energy used to produce that unit of biodiesel; HVbiodieselis the heat value of biodiesel; HVenergy-inputis the heat value of the energy necessary to produce one unit of biodiesel; EE2is the ratio of the heat value of biodiesel and co-products and that of the input energy; EE3is the ratio of the heat value of biodiesel and that of direct energy inputs.

The major energy use for the production of JCL biodiesel is from the application of herbicides, insecticides, chemical fertilizers as well as the extraction and refining of oil, which are common for the end products of Jatropha oil and JME.

The energy attributed to chemicals is mainly an indirect energy input, i.e., the energy inputs for the production of these chemicals. For example, the energy used for the production of glyphosate and carbendazim are 454 MJ/kg and 397 MJ/kg (Tzilivakis et al.2005), respectively. Because of a low level of mechanization, the energy inputs in JCL management is 2.28 MJ/h (Kallivroussis 2002); it is mainly due to fruit collection and drying, husk removal, planting and tending. The direct energy input is mainly used in the extraction and refining of JCL oil, as well as for the transportation of seeds, fertilizers and end products. When JME is the end product, additional energy inputs are required for the oil transesterification.

The energy consumption for buildings (office and workshops) as well as the machineries for oil extraction and further processing was estimated according to the energy coefficients in Yáñez Angarita et al. (2009). The energy content of the produced biodiesel was estimated according to the thermal performance and emission of JCL oil given in Agarwal and Agarwal (2007). Limited by data, the energy consumption of machinery is only composed of the portions in the production of cast steel, structural steel and stainless steel used in the machinery sets while those in the processes of fabrication were not included.

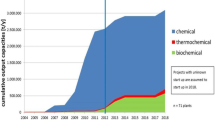

When refined JCL oil was the end product, its energy inputs were counted starting from its processing site to its distribution site. For example, when the seed yield is 1,485 kg/hm2and oil is extracted with a mechanical method, the composition of energy input is shown in Fig.6.5. The major energy input is for oil extraction and refining, fungicide or pesticide application and fertilization. The energy output includes the chemical energy in the JCL oil, which is 37.83 ∼ 39.20 MJ/l (Augustus 2002; Sahoo 2009; Baitiang et al. 2008) and the biomass energy in twigs, woods and leaves.

The energy efficiencies for different levels of seed yield are shown in Table6.11. The results show that both E2and E3are greater than one, which means that JCL is energy-efficient for these parameters, but E1depends on seed yield and the method used for oil extraction. When mechanical extraction method is applied, E1will only be greater than one when the seed yield is greater than 1,200 kg/ha. Because of higher energy consumption for chemical extraction, the energy efficiency will not be greater than one even if the level of seed yield is as high as 3,861 kg/ha (data not shown).

Therefore, since E2is greater than one for all levels of seed yields, it is concluded that the production and use of JCL oil will be energy-efficient if all energy outputs including twigs, woods and leaves are fully used. If only the direct energy input is considered the energy efficiency is higher, as shown by EE3.

The production of either JCL oil or JME is not financially sustainable as it can be concluded from the comparison of JME lifecycle and 3E performances (Wang et al.2011). Transesterification reaction incurs additional costs. However, as a co-product of JME, glycerin shares 8.1% of the total costs. As a result, the FNPV of JME is only slightly higher than that of JCL oil. Similarly to the case where JCL oil is used as an end product, the lifecycle carbon balance of JME is also positive. Intuitively, more GHG will be emitted for the production of JME because more inputs are needed. However, as a coproduct of JME, glycerol adds a credit to the lifecycle carbon balance of JME, and consequently the lifecycle carbon balance of JME is higher than that of JCL oil. For both Jatropha oil and JME, the E1, E2 and E3 are greater than one. However, because an additional process of transesterificaiton reaction is required, the energy efficiency of JME is slightly lower than that of JCL oil.

Challenges and Suggestions

The promotion of JCL biodiesel is directly driven by the scarcity of oil and by the social pressure for the reduction of GHG emission. The development of rural areas and the rehabilitation of degraded ecological system are other indirect drivers. The Chinese policy framework has provided a good opportunity for the production of JCL biodiesel. However, despite this opportunity, the production of JCL biodiesel is still facing many challenges, which are to be dealt with before JCL biodiesel is produced on a massive scale.

Challenges

Biodiesel is theoretically an environment-friendly alternative to fossil fuel and has huge potential to mitigate the future energy needs of the country and to impart economic prosperity in the poor and backward areas of the country. However, the production of biodiesel is still an emerging industry. The commercialization of JCL biodiesel in China is fairly recent since commercial seedling production began in 2005. Although China has set an ambitious target at establishing biodiesel bases and achieving energy independence, there is still lack of sufficient scientific and technological information for the production of JCL biodiesel. For example, what is the optimal combination of inputs so as to minimize the production cost and how can the JCL seed yield be improved? Although the research on JCL cultivation in China can date back to 1970s with much effort carried out with germplasm development and tissue culture, little attention has been given to the technology for the industrial production of its biodiesel, especially concerning the valorization of its by-products. Before rapidly scaling up JCL plantation acreage, more scientific and technological studies are required so as to avoid unnecessary costs and to lay a foundation for the growth of biodiesel industry responding to society needs.

The ecological impacts of the production system of JCL biodiesel also deserve concern. Being an exotic species in most growing areas, the impact on biodiversity due to a change of land use towards JCL large scale cultivation is expected to be negative. Impact on biodiversity will be especially negative if natural systems, such as forests, are to be cleared. Heavy machinery and high fertilizer application are also the drivers towards a negative impact. However, JCL can generate environmental benefits too. Besides its potential contribution to the reduction of GHG emission, JCL plantations may generate economic value by facilitating the ecological restoration of barren lands. Although no literature on the impacts of a change in land use due to JCL plantation is available so far, JCL is strongly believed to be able to control and prevent soil erosion and it has ever been practically used for erosion control in southwest China. Because the production of JCL biodiesel is at present not financially sustainable, the study of ecological impacts as an economic input associated with biodiesel production can also provide more information on the economic justification of JCL. To design polices effective for the promotion of JCL biodiesel requires information from both systematic and site-specific studies.

In China, the development of biodiesel industry is still in its infancy. While much effort has been taken towards the establishment of JCL plantations, the mechanism for its industrialization only received very few concerns. There is a lack of institutional management to coordinate seed producers, oil processors, oil distributors, and supporting agencies. For example, farmers are only involved in providing labors and renting land to companies involved in seed production and are not voluntary for JCL planting and exploration because the production of JCL seeds is not cost effective. Companies are motivated to establish JCL plantation because of government’s subsidies. While subsidies are provided in terms of area of JCL plantation rather than seed yield, the incentive function of subsidy cannot be guaranteed and the distribution of subsidy among producers should be clarified according to the differences of production stages. Moreover, there is also a lack of national recommendations for standards of biodiesel quality.

The basic structure of many current institutions reflects views of land, natural resources and people, which are fundamentally different from those proposed under ecosystem management with its themes of holism, dynamism, complexity and uncertainty (Kessler1994). The difference is partly a result of the complexity of the subject. It is also because we have failed to recognize the linkages between the ways people relate to nature and the character of our institutions. The biodiesel production system is a social ecological system with human production activities interacting with the ecosystem, but the exact requirements for institutional change are unclear. In order to manage the social-ecological system of JCL biodiesel in a sustainable way, a better understanding of the relationships between institutions and the production system is required.

The biggest challenge for the industrialization of JCL biodiesel is the lack of sufficient land for JCL plantation so as to meet the policy target for biodiesel production. For example, the consumption of diesel in Yunnan province was 5.56 million tons in 2010. Assuming the constant diesel consumption in future, about 0.83 million tons of biodiesel is required in order to meet the B15 target. However, the land areas suitable for JCL plantation is estimated to be 0.675 million hectares (Liu et al.2010). According to the current yield of JCL seeds, the maximum annual output of biodiesel would be 0.62 million tons if all suitable lands are used. Obviously, the potential biodiesel production will not allow the meeting of the policy target. Moreover, as compared to other provinces in China, Yunnan has the largest land areas suitable for JCL plantation and its consumption of diesel is relatively small. That is, the potential of B15 in other provinces is lower than that in Yunnan province. Therefore, the promotion of biodiesel alone cannot achieve the policy target and other alternatives should also be developed.

Governments across the world have approved legislative instruments to foster the biofuel industry according to one or several different targets, such as oil dependency reduction (e.g., EU, USA, China), setting up domestic market (e.g., Brazil), reducing carbon emission (e.g., EU, USA) or/and contributing to rural development (e.g., China, India). External incentives are applied to achieve the biofuel targets set by national administrations. Biofuels are being developed in a very complex, dynamic and diverse context. In assessing performance of biofuel policies, there is a need for sustainable development framework using criteria based on the potential social, economic and environmental impacts (Amiguna et al.2011). However, many policies are being recommended and developed by focusing on a single or a few specified targets while the sustainability of the production system is not well addressed. For example, there is no incentive policy for oil extraction and refining yet. Moreover, biofuel policies have distributional implications for consumers and producers, farm and nonfarm sectors, global trade in food and biofuels, and the price of land and other scarce resources (Khanna et al.2010). As a type of biofuel, JCL biodiesel is facing the same policy problems in its development course.

Suggestion

To invest in JCL biodiesel requires an economic justification in a framework of social benefit cost analysis. As the biodiesel production is not financially sustainable yet, synergic services other than biodiesel production should be investigated for JLC with the purpose to increase its attractiveness. Such synergic services are related to the concept ofnatural capital, which consists of both non-renewable resources (e.g., minerals and soil reserves) and renewable resources (e.g., plants, animals and water). The natural capital supports the production of goods and services on which society depends (Chapin et al.2009). Natural capital and its derived goods and services are the preconditions or the basis for the economic development. Actually, it is impossible for humans to create human-made capital without the support from natural capital (Daly1990). The sustainable production of biodiesel can thus be considered as an investment in natural capital. Gains in natural capital can be made when biofuel development is integrated with ecological restoration because the costs for ecological restoration can be reduced and the ecological service increased. Ecological restoration using JCL can lead to an increase in natural capital in terms of soil improvements and water conservation; biodiesel-driven restoration of degraded ecosystems can also increase terrestrial carbon sequestration (Zhuang et al.2010).

The environmental and energy lifecycle performance of JCL biodiesel can be improved by (i) increasing the oil extraction efficiency; (ii) selective breeding for high yielding varieties concerning seed quantity and weight as well as oil quality and quantity; (iii) creating specific machinery for de-husking and fruit collection in order to reduce the cost of seed production; (iv) value addition from co-products of biodiesel production. For example, the leaves can be used to feed silkworm, the pruned twigs can be used as a source of medicinal compounds and the raw material for pesticide production; (v) optimization of ecosystem management and green manure that would reduce the energy consumption associated to pesticides, herbicides, fertilizers, oil extraction and refining; (vi) by applying low energy input herbicides, such as atrazine and cyanazine or by manual weeding and by using fruit husks as an alternative to coal (Wang et al.2011).

Social parameters of JCL biodiesel development including the psychological factors (cognitive and cultural) that shape farmer’s values and beliefs must be integrated to policy strategy (English2008), since the understanding of biodiesel economics is important, but not sufficient. Integrated package of policy measures also needs to enforce and implement the concepts of sustainable development and natural capital. According to such recommendations, a set of sustainability index and indicators should be designed to guide policy makers and production managers. From the mix of policy tools available to support the promotion of the JCL biodiesel industry, it is necessary to identify the most effective and sustainable ones. Alternatively, new tools should be created if those currently available are insufficient.

Before agreements on institutional arrangement for JCL biodiesel production can be set, additional institutional analyses of JCL production system are needed concerning (i) the extent to which existing laws, policies, and regulations may constrain or promote the development and implementation of JCL production policies, programs, and practices; (ii) the design of institutional mechanisms for a national approach of the economical-ecological management of biodiesel production; (iii) the adoption of an economical-ecological management approach as a management philosophy eventually requiring internal organizational changes and new arrangements among resource management agencies; and (iv) the development of methodological approaches for the investigation of institutional questions concerning the objective related to the sustainable management of JCL biodiesel production. The answer to these institutional questions will play an important role in achieving the sustainable production of JCL biodiesel. For example, an institutional decision supporting the integration of JCL biodiesel production with the domestic and/or international carbon market may provide producers with extra revenue from selling carbon credits.

References

Achten WMJ, Verchot L, Franken YJ, Mathijs E, Singh VP, Aerts R et al (2008) Jatropha bio-diesel production and use. Biomass Bioenergy 32:1063–1084

Agarwal D, Agarwal AK (2007) Performance and emissions characteristics of JCL oil (preheated and blends) in a direct injection compression ignition engine. Appl Therm Eng 27:2314–2323

Amiguna B, Musangob JK, Stafford W (2011) Biofuels and sustainability in Africa. Renew Sustain Energy Rev 15:1360–1372

Anon (2007) Biofuel makers to get subsidy. China Daily 27 (No. 8620).

Augustus GDPS, Jayabalan M, Seiler GJ (2002) Evaluation and bioinduction of energy components ofJatropha curcas. Biomass Bioenergy 23:161–164

Baitiang T, Suwannakit K, Duangmukpanao T, Sukjamsri C, Topaiboul S, Chollacoop N et al (2008) Effects of biodiesel and JCL oil on performance, black smoke and durability of single-cylinder diesel engine. J Met Mat Miner 18(2):181–185

Chapin FS, Kofinas IIIGP, Folke C (2009) Principles of ecosystem stewardship: resilience-based natural resource management in a changing world. Springer, NY

Chen B, Deng B, Yu J, Huang H (2006) The survey study ofJatropha curcasL. in Guizhou Province. For By-prod Spec China 6:55–57

Daly H (1990) Toward some operational principles of sustainable development. Ecol Econ 2:1–6

IEA (International Energy Agency) (2005) World energy outlook 2005. Paris, International Energy Agency

English M (2008) Socioeconomic considerations with biofuels production. The proceedings of China–US workshop on bioenergy consequences for global environmental change. Beijing, China pp 42–44

FAO (2008) Bioenergy, food security and sustainability towards an international framework. HLC/08/INF/3. Rome

Flavin C (2008) Time to move to a second generation of biofuels. Worldwatch Institute, Washington, DC

Forson FK, Oduro EK, Hammond-Donkoh E (2004) Performance ofJatropha curcasL. oil blends in a diesel engine. Renew Energy 29(7):1135–1145

GTZ (German Technical Cooperation). 2006. Liquid Bio-fuel for Transportation: Chinese Potential and Implications for Sustainable Agriculture and Energy in the 21st Century. Beijing: GTZ

Hazell P, Pachauri RK (2006) Bioenergy and agriculture: promises and challenges. International Food Policy Research Institute 2020, Washington, DC. Focus 14

He L, Lang N, Ma H, Zheng K, Peng M (2007) Analysis on chemical components in Seeds ofJatropha curcasfrom Honghe prefecture. J West China For Sci 36(4):69–74

Heller J (1996) Physic Nut.Jatropha curcasL. Promoting the conservation and use of underutilized and neglected crops. Institute of Plant Genetics and Crop Plant Research/International Plant Genetic Resources Institute, Gatersleben/Rome

Hu Z, Tan P, Lou D (2010) Experimental research of diesel taxis fueled by jatropha biodiesel blends. J Tongji Univ (Nat Sci) 38(6):898–902

Huang J, Qiu H, Michiel K, Erika M, van Veen W (2009) Impacts of bioethanol development on China’s regional agricultural development. China Econ Quar 8(2):727–742

Jin X, Wang H, Liu J (2009) Financial analysis. Press of Renmin University of China, Beijing

Kallivroussis L, Natsis A, Papadakis G (2002) The energy balance of sunflower production for biodiesel in Greece. Biosyst Eng 81(3):347–354

Kessler WB (1994) Significant barriers to further progress of ecosystem management. Paper presented at the institutional problem analysis workshop, Stevenson, 20–22 Oct 1994. On file at the Water Resources Research Center, University of Arizona, Tucson

Khanna M, Scheffran J, Zilberman D (2010) Handbook of bioenergy economics and policy. Natural Resource Management and Policy 33, Springer, Washington. p 439

Krawczyk T (1996) Biodiesel—Alternative fuel makes inroads but hurdles remain. Inform 7:801–829

Kumar MS, Ramesh A, Nagalingam B (2003) An experimental comparison of methods to use methanol and JCL oil in a compression ignition engine. Biomass Bioenergy 25:309–318

Liu, Y. Lu, H. Liang, B.; and Chen, P(2007) Pre-esterification ofJatropha curcasL. seed oil for biodiesel production. China oils and fats. 32 (7):43–46

Li Z (2001) Analysis of the demand and supply diesel in Chinese market. Intl Petroleum Econ 9(4):5–6

Liu W, Lu D, Zhang L, Wang L, Zhao J, Li S et al (2010) The framework and science basis for China’s low-carbon economic development. Shangwu Press, Beijing

Lou D, Shi J, Hu Z, Li B (2010) Research on unregulated emissions in diesel engine fueled with biodiesel fromJatropha curcasoil. Chinese Intern Combust Engine Eng 31(5):69–73

Luo F, Guo J, Wang Z, Liang Y (2011) Injection and performance of diesel engine fueled withJatropha curcasoil. J Jiangsu Univ (Natural Science edition) 32:287–291

MOA (Ministry of Agriculture) (2007) Development planning of China’s bioenergy industry (2007–2016), China’s Ministry of Agriculture Beijing, China

NBSC (National Bureau of Statistics of China) (2008) China statistical yearbook. China Statistical, Beijing

NDRC (2008) Annual compilation of costs and benefits of China’s agricultural production. China Statistical, Beijing

Openshaw K (2000) A review ofJatropha curcas: an oil plant of unfulfilled promise. Biomass Bioenergy 19:1–15

EPASEA-NIC (Environmental Planning Academy of State Environmental Administration and National Information Center) (2008) Analyzing and predicting China’s environmental economic status and trends in 2008–2020. China Environmental Science, Beijing

Pramanik K (2003) Properties and use ofJatropha curcasoil and diesel fuel blends in compression ignition engine. Renew Energy 28:239–248

Prasad CMV, Krishna MVSM, Reddy CP, Mohan KR (2000) Performance evaluation of non-edible vegetable oils as substitute fuels in low heat rejection diesel engines. Proceedings of the Institution of Mechanical Engineers Part D. J Automobile Eng 214:181–187

Qiu H, Huang J, Keyzer M, Van Veen W (2008) Policy options for China’s bio-ethanol development and the implications for its agricultural economy. China World Econ 16:112–124

Runge, C., and B. Senauer (2007). How Biofuels Could Starve the Poor. Foreign Affairs.http://www.foreignaffairs.com/articles/62609/c-ford-runge-and-benjamin-senauer/how-biofuelscould-starve-the-poor; 2007 [15.06.09]

Sahoo PK, Das LM (2009) Process optimization for biodiesel production from Jatropha, Karanja and Polanga oils. Fuel 88:1588–1594

Shay EG (1993) Diesel fuel from vegetable oils: status and opportunities. Biomass Bioenergy 4:227–242

She Z, Liu D, Tan P (2005) Methylation ofJatropha curcasL. seed oil. China Oils Fats 30(9):34–36

Tzilivakis J, Warner DJ, May M, Lewis KA, Jaggard K (2005) An assessment of the energy inputs and greenhouse gas emissions in sugar beet production in the UK. Agric Syst 85:101–119

USDA (United States Department of Agriculture) (2006) Bio-fuels: an alternative future for agriculture. GAIN report number: CH6049

Veljkovic VB, Lakicevic SH, Stamenkovic OS, Todorovic ZB, Lazic KL (2006) Biodiesel production from tobacco (Nicotiana tabacum L.) seed oil with a high content of free fatty acids. Fuel 85:2671–2675

Wang T (2005) A survey of the woody plant resources for biomass fuel in China. Sci Technol Rev 5:12–14

Wang Y, Liu Y, Li X, Hu F, Cai C, Yang D et al (2010) China sustainable development strategy report 2010: green development and innovation. Science, Beijing

Wang Z, Calderon M, Ying L (2011) Lifecycle assessment of the economic, environmental and energy performance ofJatropha curcasL. biodiesel in China. Biomass Bioenergy 35:2893–2902

Wang Z, Lu Y. (2011) Lifecyle environmental, economic and energy performance of the seed oil ofJatropha curcasL. as biodiesel. Res Environ Yangtze Basin 20(1):61–67

Weyerhaeuser H, Tennigkeit T, Su Y, Kahrl F (2007) Biofuels in China: an analysis of the opportunities and challenges ofJatropha curcasin Southwest China. ICRAF Working Paper Number 53. Available fromhttps://jatropha.uni-hohenheim.de/fileadmin/einrichtungen/jatropha/Biofuels_in_China-An_Analysis_of_the_Opportunities_and_Challenges_of_Jatropha_curcas_in_Southwest.pdf

Wiesenthal T, Leduc G, Christidis P, Schade B, Pelkmans L, Govaerts L et al (2009) Biofuel support policies in Europe: lessons learnt for the long way ahead. Renew Sustain Energy Rev 13(4):789–800

Wu Z, Zong W (2007) Prospect for producing bioenergy fromJatropha curcasL. Sci News 14:15

Xiang Z, Luo Q, Hu M, Xiang Y (2008) The geographical provenances and distribution ofJatropha curcasL. in China. China For Sci Technol 22(6):13–19

Xu J, Fei S, He Y, Cai X, Chen X, Lei C (2008) The quantitative characteristics and regeneration ofJatropha curcaspopulations in Sichuan Province. J Sichuan For Sci Technol 29(1):1–6

Yáñez AEE, Lora EES, da Costa RE, Torres EA (2009) The energy balance in the palm oil-derived methyl ester (PME) life cycle for the cases in Brazil and Colombia. Renew Energy 34(21):2905–2913

Yuan L, Zhao Q, Kang P, Yang L, Zhao J, Gou P et al (2007) Investigation of geographical distribution and evaluation ofJatropha curcasin Yunnan province. Southwest China J Agric Sci 20(6):1283–1286

Zeng J (2006) A energy plant with a promising potential for development—JCL. Yunnan For 27(2):21

Zhang W, Song H, Wei X, Liu Z (2001) The adaptability ofJatropha curcasin Yuanmo County. Agric Technol 21(1):22–25

Zheng K, Lang N, Zhang R, Peng M, Guo W (2008) The distribution and growth status ofJatropha curcasL. in Honghe. J For Sci Western China 36:101–104

Zhuang J, Gentry RW, Yu GR, Sayler GS, Bickham JW (2010) Bioenergy sustainability in China: potential and Impacts. Environ Manage 46:525–530

Acknowledgement

This research report is based on investigations funded by the National Natural Science Foundation of China (71063024) and the Economy and Environment Program for Southeast Asia (EEPSEA, No. 003591-180).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2012 Springer Science+Business Media New York

About this chapter

Cite this chapter

Wang, Z. (2012). Producing Jatropha Biodiesel in China: Policies, Performance and Challenges. In: Carels, N., Sujatha, M., Bahadur, B. (eds) Jatropha, Challenges for a New Energy Crop. Springer, New York, NY. https://doi.org/10.1007/978-1-4614-4806-8_6

Download citation

DOI: https://doi.org/10.1007/978-1-4614-4806-8_6

Published:

Publisher Name: Springer, New York, NY

Print ISBN: 978-1-4614-4805-1

Online ISBN: 978-1-4614-4806-8

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)