Abstract

The production of secondary materials from waste materials requires, in most cases, significantly lower energy amounts than the primary material production of raw materials. Along with lower energy demand, the greenhouse gas emissions produced are also lower. The duty of a modern waste management system should therefore be to collect and sort the waste materials in a way that the highest amounts of single material fractions with the highest qualities can be generated. In this contribution, the greenhouse gas balances of the theoretical treatment of the household waste, if collected as mixed waste in sanitary landfills, in waste incineration plants, or in mechanical-biological treatment plants, are compared to the existing separate waste collection and treatment in Germany in 2014. The results show that the treatment of the mixed collected household waste in sanitary landfills would lead to a significant release of greenhouse gases. The treatment in MBTs with the recovery of valuables and the further disposal of the biologically stabilized fraction on landfills, as well as the treatment of the high calorific fraction (also called refuse derived fuel – RDF) in RDF plants, coal-fired power plants, or cement kilns, would lead to small amounts of avoided greenhouse gas emissions. The thermal treatment in waste incineration plants would lead to moderate amounts of avoided greenhouse gases. Only with the actually practiced separate collection and treatment of household waste were significant amounts of greenhouse gas emissions avoided. In total, this is approximately 5.5 million tons of carbon dioxide equivalents for approximately 45.5 million tons of separate collected and treated household waste in Germany in 2014.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- Greenhouse gas accounting

- Greenhouse gas mitigation

- Household waste

- Material recycling

- Separate collection

1 Cumulative Energy Demand and Global Warming Potential

The production of materials for the final manufacturing of goods needs energy, and this energy is usually connected to the release of greenhouse gas (GHG) emissions. The more extensive the treatment processes are, the more energy is used, and the higher the global warming potential (GWP) of a material is.

1.1 Cumulative Energy Demand and Global Warming Potential of Primary Material Production

Primary materials like metals are usually produced from ores and are processed in several treatment steps. Different kinds of plastics are usually produced from crude oil, paper from wood, and glass from different raw materials. Along the process chain of the materials, energy is used for the excavation of raw materials, their transport, their processing, and their final production. Figure 1 shows the cumulative energy demand (CED) [4] and the respective global warming potential (GWP) of the primary production of different materials.

The production chain of aluminum (the excavation of bauxite, the crushing and grinding of the bauxite, the production of aluminum oxide from the intermediate hydroxide, and the final production of aluminum by melt flow electrolysis) is very energy intensive, especially in units of primary energy because of the electricity consumption for the reduction of the oxide [5]. For the production of one ton of aluminum, almost 176 MJ of energy are used. This high energy consumption leads to a release of high amounts of greenhouse gas emissions of almost 17 tons of CO2 equivalents per ton (Mg CO2,eq/Mg) of aluminum [1]. CED and the corresponding GWPs for other industrial metals, such as copper and especially for steel, are lower because for the chemical reduction, no electricity is used. Copper has a CED of approx. 70 MJ, and the production of one ton has a GWP of approx. 6 Mg of CO2,eq. The reducing agent, at least for sulfidic ores, is sulfur. For steel (reduction of iron ore is performed with coke), these numbers are with approx. 23 MJ/Mg and less than 2 Mg CO2,eq/Mg of steel even lower. The CED of most bulk plastics is in the range of copper, around 70 MJ/ton. But the GWP of the plastics production is in the range of steel between approx. 1 and 3 Mg of CO2,eq/Mg [6]. Paper and especially glass have a low CED of approx. 41 and approx. 17 MJ/Mg, respectively. The GWP of their production with approx. 1 Mg of CO2,eq/Mg is also comparatively low [2].

1.2 Global Warming Potential of Primary and Secondary Material Production and Greenhouse Gas Emissions Avoided by Material Recycling

The recovery and the recycling of waste materials and the production of secondary materials have a much lower CED than primary material production. Usually, the waste materials just have to be sorted, cleaned from other fractions, and finally treated (e.g., melted for metals, glass, and most plastics). This leads to a much lower GWP for the secondary material production. A comparison of the GWP between the primary and secondary material production is illustrated in Fig. 2.

The savings of greenhouse gas emissions by secondary material production are particularly high for metals. The production of secondary aluminum (1.7 Mg of CO2,eq/Mg) releases just 10% of the GHG emissions versus the primary production (16.9 Mg of CO2,eq/Mg). Accordingly, 95% of greenhouse gas emissions can be avoided. For steel and copper, the reduction potential is approx. 35%, for most plastics around 50%, and for paper and glass at least 20%. Figure 3 shows the amount of GHG emissions that can be avoided by the production of secondary materials.

Especially the production of secondary aluminum, with approx. 15 Mg of CO2,eq/Mg and copper with approx. 4 Mg of CO2,eq/Mg, has very high GHG reduction potential. But also the production of steel and plastics has reduction potential of approx. 1 Mg of CO2,eq/Mg for secondary material.

Based on these numbers, it should be the duty of waste management to collect and sort the waste materials to generate the highest amounts of single material fractions with the highest qualities.

2 Greenhouse Gas Accounting

The accounting of GHGs is always based on many pieces of data and several assumptions. GHG accounting in the waste management sector in particular, with its different treatment and processing options, is not trivial. On the one hand, the treatment of the waste generates GHG emissions in the consumption (electrical power and heat) of the treatment plants, as well as from different degradation and oxidation processes. On the other hand, the production of power and heat and the recovery of secondary materials from waste treatment processes avoid GHG emissions.

The amount of released and avoided GHG emissions heavily depends on:

-

Treated waste type

-

Composition of waste type

-

Amount of renewable (biogenic) and nonrenewable (fossil) carbon

-

Energy consumption/efficiency of the treatment facilities

-

Substitution scenarios (e.g., energy mix that is used)

-

Substitution factors for the recovery of secondary materials

-

Accounting of only climate-relevant or also climate-neutral emissions

-

Accounting of only CO2 or also CH4 and N2O

The following calculations are based on German conditions (waste composition, energy mix, efficiency of German waste treatment plants, …) with the accounting of only climate-relevant GHG emissions and of CO2, CH4, and N2O. Climate-relevant emissions are those emissions that lead to an increase of GHG emissions in the atmosphere. All CH4 and N2O emissions belong to these emissions, as well as all emissions that are generated by the thermal oxidation of fossil-fixed carbon, like in plastics. All CO2 emissions that are released by biological degradation processes or thermal oxidation of carbon fixed in organic matter (plastics excluded) are by definition climate neutral.

3 Treatment of Mixed Municipal Solid Waste

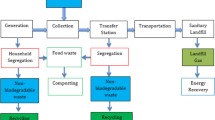

Household waste can be either collected as mixed waste and treated/disposed of in landfills, waste incineration plants, or sorting plants like mechanical (biological) treatment plants or separately collected and treated. Figure 4 compares the mixed and source-separated waste collection and waste treatment regarding the effort in collecting and separating the waste, as well of the amounts and qualities of recovered secondary materials and residues.

The collection of source-separated household waste involves a higher effort regarding collection (more bins, more and different collection vehicles, more collection logistics), but because of the higher homogeneity of the collected waste, it requires a lower effort in post-sorting the different waste types. Finally, higher amounts of materials in higher qualities can be separated, and lower amounts of residues have to be disposed of.

The waste collection occupies a large part of the cost of waste management but has a negligible effect on the greenhouse gas emissions released compared to the treatment/disposal of the waste. Thorneloe calculated that the United States released GHG emissions of 0.5 and 1 million Mg of CO2 equivalents for the collection and transportation of 116 million tons of municipal solid waste (MSW) in 1974 and 197 million tons of MSW in 1997 [7]. That makes approx. 50 kg of CO2,eq/Mg MSW. The amount of transported waste for the collection of mixed or source-separated waste remains the same, though more and maybe smaller vehicles have to be used for the transport of source-segregated wastes.

A rough calculation shown in Table 1 shows that the GHG emissions that have to be accounted for the production of the trucks are very small, and with the release of GHG emissions of approx. 30 kg of CO2,eq/Mg MSW for the transportation, a suitable result of approx. 33 kg of CO2,eq/Mg of collected MSW can be assumed.

3.1 Landfill

If German MSW would be collected as mixed waste and disposed of on sanitary landfills, most of the biodegradable material would be degraded under anaerobic conditions, and the carbon would be transferred to CO2 and CH4. The carbon fixed in biogenic material and not degraded by microorganisms is stored (carbon sequestration) in the landfill. It is assumed that 70% of the carbon in biogenic materials is degraded and 30% is sequestrated in the landfill. Further parameters used for the calculation are:

-

Organic carbon in the wet MSW: 142 kg/Mg wet waste (ww)

-

Methane correction factor (MCF): 0.95

-

Fraction of methane by volume (F): 0.55

-

Methane recovery rate (R): 0.6

-

Oxidation factor (OX): 0.1

-

Electrical net efficiency power unit: 35%

-

Thermal net efficiency power unit: 10

-

Methane slip power unit in vol.% CH4: 0.5%

Figure 5 shows the release of more than 500 kg of CO2 equivalents per ton of landfilled mixed MSW in the form of methane. In the generation of electricity, fossil fuels out of the electricity mix of Germany would be substituted, and 120 kg of CO2,eq/Mg MSW would be avoided. Together with 12 kg of CO2,eq/Mg MSW for the delivery of district heat and 156 kg of CO2,eq/Mg MSW for sequestrated carbon, total GHG net emissions of 239 of CO2,eq/Mg MSW are calculated.

It should be pointed out that the disposal on an open dump would generate net GHG emissions of 1,153 kg of CO2,eq/Mg MSW.

3.2 Mechanical-Biological Treatment

The aim of the mechanical-biological waste treatment (MBT) is to recover some valuable materials and to split the rest into a high caloric and a low calorific fraction. The low calorific fraction is further biologically stabilized and finally landfilled, and the high calorific fraction (also called refuse-derived fuel – RDF) thermally utilized in RDF plants, coal-fired power plants, or cement kilns.

In modern MBT plants, approx. 80% of the ferrous and approx. 50% of the nonferrous metals can be recovered. Beside metals, sometimes valuable plastics like PET or glass are also recovered. If the low calorific material is anaerobically treated, some biogas can be produced and thermally used. In German MBTs, 59% of the input can be recovered as RDF, 13% is finally landfilled, and 2.4% is recovered as other recyclables (plastics, glass, wood, biowaste) and 2.3% as metals. One percent of the material can be converted to biogas. Thirteen percent is converted into CO2 and H2O during the aerobic treatment of the low calorific fraction, and the final seven percent is further treated in other treatment plants [8]. Based on the data from Ketelsen and Kanning [8], 55% of the RDF produced is finally treated in RDF-fired power plants with net efficiencies of 18.5% electrical power and 20.5% thermal [9], 17% in waste incineration plants with net efficiencies of 11.8% electrical and 31% thermal [10], 10% in coal-fired power plants with net efficiencies of 36.3% electrical and 1.6% thermal [11], and 12% in cement kilns where the fuel mix of the cement kilns [12] is substituted.

Figure 6 shows the release of some minor amounts of GHG emissions from MBT plants, some higher amounts from the degradation of the stabilized low calorific fraction on the landfill, and the highest amount from the incineration of the produced RDF. In total, 434 kg of CO2,eq/Mg-treated MSW would be released. Through the production of biogas and the generation of energy in the MBTs, and from the generation of energy out of the landfill gas, some minor amounts of GHG emissions would be avoided. The highest amount of more than 400 kg of CO2,eq/Mg MSW would be avoided by the generation of electricity and heat out of the high calorific fraction and the substitution of regular fuels in cement kilns.

In total a reduction of GHG, net emissions of 0.015 kg of CO2,eq/Mg wet MSW would be the result.

3.3 Waste Incineration

The primary target of waste incineration is the safe and environmentally sound disposal of waste. The second target is the recovery of energy. The incineration of the waste and the oxidation of the fossil-fixed carbon, e.g., in plastics into CO2, lead to a release of climate-relevant GHG emissions. On the other hand, the generation and delivery of energy in the form of electricity and heat avoids greenhouse gas emissions. Also, the recovery of some metals from the incinerator bottom ash avoids GHGs. The energy efficiency of German waste incineration plants in 2014 was on average approx. 12% electrical for the delivery of electric power and approx. 31% for thermal energy (district heat and steam) [10]. On a European level, the values are similar. In a weighted average, the electrical efficiency is 14.9%, and the efficiency for thermal energy is 34.6% [13]. Figure 7 shows the GHG balance if the mixed, collected MSW would be treated in waste incineration plants.

The emission of CO2 in the incineration would lead to 324 kg of CO2,eq/Mg wet MSW, and the generation of nitrous oxides is negligible. From the generation and delivery of electricity and heat together, 337 kg of CO2,eq/Mg wet MSW would be avoided. Additionally, approx. 30 kg of CO2,eq/Mg wet MSW would be avoided through the recovery of metals from the incinerator bottom ash. Because of the relatively low average energy efficiencies of the German waste incineration plants and the therefore relatively small amount of avoided GHG emissions, in total, only a small amount of 39 kg of CO2,eq/Mg wet MSW would be avoided from the treatment of the mixed collected MSW in waste incineration plants. Waste incineration plants with exclusive heat production achieve efficiencies of 77.2% [13], resulting in a much higher amount of avoided GHG emissions of 112 kg of CO2,eq/Mg wet MSW.

3.4 Comparison of Mixed Municipal Solid Waste Treatment Options

The three technological solutions for treating mixed municipal solid waste perform differently in terms of released greenhouse gases and also in the recovery of secondary materials and energy to avoid greenhouse gases. Figure 8 shows these differences calculated in advance in an overview.

In 2014, approx. 45.5 million Mg of mixed household municipal solid wastes were collected in Germany [14]. If this material would be disposed of on sanitary landfills, almost 11 million Mg of CO2 equivalents would have been released. The material treated in MBT with the recovery of some valuables, the splitting of the rest into a high caloric and a low calorific fraction where the low calorific fraction would be further biologically stabilized and finally landfilled and the high calorific fraction (RDF) would be further thermally utilized, would avoid, in total, approx. 0.7 million Mg of CO2 equivalents. The material thermally treated in waste incineration plants would avoid approx. 1.8 million Mg of CO2 equivalents in total. This comparison already shows that the pretreatment of mixed MSW, either mechanically-biologically and/or thermally, leads to a significant reduction in greenhouse gas emissions from the waste management sector.

With these two more advanced technologies, the energy content of the waste is used to produce electricity and heat and/or substitute regular fuels, but only metals are recovered as secondary resources. As already described in Fig. 3, other materials also, like different plastics, paper, or glass, have high GHG-reduction/substitution potential. But only with the separate collection of these materials can secondary resources be recovered in high amounts and high qualities to further improve the GHG balance of the waste management sector in Germany.

4 Treatment of Source-Separated Waste Fraction

Source-separated waste is more homogeneous and thereby easier and more efficient to treat. The amount of recovered recyclables/materials and their quality is usually higher than for mixed MSW.

4.1 Limits of Source Separation

Different types of waste can be separately collected directly at households, at container locations, or at recycling centers. For various reasons, people are not always able to sort their waste into the correct waste bin, and often people are too lazy to sort, and valuables end up in the mixed residual waste bin. As a result, false materials can be found in the bins of the different separate collected waste types, which makes proper recycling difficult and lowers the recycling rates. Also, a high amount of waste is still disposed of in the mixed residual waste bin. Figure 9 shows the distribution of the 45.6 million Mg of household waste in Germany in 2014 in the different separately collected waste types.

Still, more than 30% of the household waste in Germany is collected as mixed residual waste. In the following chapters, the amount of materials that are wrongly disposed of in their respective bins is also described.

4.2 Glass

In Germany in 2014, 2.445 million Mg of glass was collected separately [14]. Almost 100% of this collected glass was mechanically treated to remove false fractions of ceramics, paper and aluminum, as well as tinplate caps. Approx. 10% of the collected glass was false fractions that were removed [15], and approx. 2.2 million Mg were recycled. With the substitution factor of glass with 0.45 Mg of CO2,eq/Mg recycled glass, approx. 1 million Mg of CO2 equivalents were avoided. In addition, approx. 3,100 Mg of aluminum and 8,200 Mg of tinplate were recovered [15]. With recycling losses of approx. 60% for aluminum and approx. 10% for tinplate, finally, approx. 1,200 Mg of aluminum and 7,400 Mg of tinplate were recycled. With the substitution factors of aluminum with 15.18 and for tinplate with 1.19 Mg of CO2,eq/Mg additionally, approx. 28,000 Mg of CO2 equivalents were avoided.

In total, more than 1 million Mg of CO2 equivalents were avoided in Germany in 2014 through the separate collection and treatment of glass and its impurities.

4.3 Paper

Almost 8 million Mg of waste paper was separately collected in 2014 [14]. Almost 100% was post-sorted in waste paper sorting plants, and only a small amount was thermally treated and composted. Approx. 23% was removed as rejects [15], and approx. 6.1 million Mg were recycled. With the substitution factor of 0.27 Mg of CO2,eq/Mg for paper, around 1.65 million Mg of CO2 equivalents were avoided. The recovered rejects are usually thermally treated, often in in-house thermal treatment plants. Information about the composition of the rejects (containing plastics, cellulose fibers, …) and the recovered amount of energies are not available. Thus, it was assumed that the same amount of CO2 equivalents was avoided through energy production, as it was released by the generation of GHGs through the combustion of the plastics it contained. In addition, a relatively small amount of 66,000 Mg was thermally treated [14]. We assume the treatment in RDF-fired power plants that leads to the avoidance of approx. 45,000 Mg of CO2 equivalents. Finally, approx. 30,000 Mg of waste paper was composted. We assume that the compost can be used as fertilizer with a substitution factor of 0.01 Mg of CO2,eq/Mg [16], leading to an avoidance of just 300 Mg of CO2 equivalents.

In total, almost 1.7 million Mg of CO2 equivalents were avoided in 2014 in Germany through the separate collection and treatment of paper.

4.4 Light Packaging Waste

5.7 million Mg of light packaging material was separately collected in Germany in 2014. Almost 0.2 million Mg were directly treated in waste incineration plants, and about 0.8 million Mg were directly thermally treated, primarily in RDF-fired plants [14]. It is assumed that for the treatment of light packaging material for both together, in incineration plants and RDF-fired plants, the amount of released and avoided GHG emissions is balanced. A detailed calculation is impossible because neither the exact composition of the treated material is known nor the amount of electricity and heat that was produced from this material.

The major part of approx. 4.7 million Mg of the collected light packaging material was mechanically treated to recover materials for recycling. In these material recovery facilities (MRF), approx. 1.3 million Mg were recovered as false fractions and treated in waste incineration plants. Again, because of no information about the composition of this material, the GHG balance of this treatment is assumed to be balanced. Table 2 shows the final treated amounts of valuable materials in the form of plastics, tinplate, aluminum, and composites and how much was finally recovered for thermal treatment and material recycling.

As shown in Table 2, because of process losses, only 78% of the plastics, 84% of the tinplate, 35% of the aluminum, and 75% of the composites could be transferred into secondary materials [15]. As a result, approx. 1.6 million Mg/a of the recovered materials were finally thermally treated, and approx. 1.4 million Mg of secondary materials were produced.

The amount of secondary materials produced multiplied with the respective GHG substitution factors in Fig. 3, leading to avoided GHG emissions of approx. 1.66 million Mg of CO2 equivalents (for composites, the substitution factor for paper of 0.27 Mg of CO2,eq/Mg was used – these recovered composites consist primarily of paper – and an average factor for plastics of 0.91 Mg of CO2,eq/Mg). The thermal treatment of plastics and composites in RDF-fired plants is calculated to a GHG balance of approx. 0.4 million Mg of released CO2 equivalents for plastics and of approx. 0.1 million Mg of avoided CO2 equivalents for composites.

In total, the separate collection and treatment of packaging materials avoided approx. 1.4 million Mg of CO2 equivalents in 2014.

4.5 Biowaste

Biowaste includes separately collected biowaste and biodegradable garden and park waste totaling 9.9 million Mg in 2014 [14]. Only small amounts of approx. 0.3 million Mg were thermally treated. We assume the treatment takes place in specific biomass power plants with a calculated GHG substitution factor of 0.309 Mg of CO2,eq/Mg. The thermal treatment leads to avoided GHG emissions of approx. 90,000 Mg of CO2 equivalents.

Approx. 25% (approx. 2.5 million Mg) of the biologically treated biowaste is processed anaerobically in digestion plants and approx. 75% (approx. 7.4 million Mg) decomposed in composting plants. Depending on the quality of the treatment of biowaste in the composting and digestion plants, and depending on the substitution scenario for the produced compost and/or digestate, different GHG emission and substitution factors can be found in the literature. For the German case numbers, around 0.08 Mg of CO2,eq/Mg of biowaste for digestion and around 0.01 Mg of CO2,eq/Mg for composting is listed in the literature [17, 18]. With these substitution factors avoided, GHG emissions of approx. 0.2 million Mg of CO2 equivalents can be calculated for the digestion and approx. 75,000 Mg of CO2 equivalents for the composing.

In total, the separate collection of biowaste (including garden and park waste) avoided approx. 0.36 million Mg of CO2 equivalents in 2014.

4.6 Bulky Waste

Almost 2.5 million Mg of bulky waste were separately collected in 2014 in Germany. Approx. 0.3 million Mg were directly incinerated in waste incineration plants [14]. With a calculated GHG substitution factor of 0.18 Mg of CO2,eq/Mg, approx. 56,000 Mg of GHG emissions were avoided. Approx. 0.8 million Mg were thermally treated. We assume the thermal treatment took place in specific biomass power plants or in RDF-fired plants with a calculated GHG substitution factor of 0.586 Mg of CO2,eq/Mg. This leads to an avoidance of GHG emissions of approx. 0.5 million Mg of CO2 equivalents. The rest of the bulky waste, approx. 1.4 million Mg, respectively, was material recycled. A high percentage of the bulky waste consisted of wood. The material recycling of wood is, from the global warming potential point of view, not useful, because only small amounts of GHG emissions are released during deforestation and in the sawmill. Only a negligible 0.004 Mg of CO2,eq/Mg were avoided [19]. Some metals were recovered from the recycled bulky waste material, but no exact data is available, so no GHG balance could be calculated.

In total, the separate collection and treatment of bulky waste avoided approx. 0.53 million Mg of CO2 equivalents.

4.7 Residual Waste

The separate waste types not collected in household waste are disposed of as mixed residual waste. In Germany in 2014, a total of approx. 14.2 million Mg were collected. Approx. 11.9 million Mg were directly incinerated in waste incineration plants, and approx. 2.3 million Mg were treated in MBTs [14]. With the calculated substitution factors of 0.039 Mg of CO2,eq/Mg mixed residual waste in waste incineration plants and 0.015 Mg of CO2,eq/Mg for the MBT path (see also Fig. 8), the waste incineration avoided approx. 0.46 million Mg of CO2 equivalents and the MBT path of approx. 0.04 million Mg.

In total, the treatment of the mixed residual waste avoided approx. 0.5 million Mg of CO2 equivalents in 2014.

4.8 WEEE and Other Separately Collected Waste Fractions

In Germany, in addition, almost 0.6 million Mg of waste electric and electronical equipment (WEEE) and almost 2.3 million Mg of other waste fractions like composites, metals, and textiles were separately collected. No reliable data about recovered secondary materials and or GHG substitution factors for the treatment processes are available in the literature. Therefore, in this article, no further calculations were made. But the high content of valuable materials and the high GHG substitution potential of provided secondary materials already expect large quantities of avoided GHGs.

4.9 Comparison of Separately Collected Waste Amounts and Their Potential to Reduce Greenhouse Gases

As described in the previous chapters, the amounts of separately collected wastes do not correspond to the amounts of avoided GHG emissions. Figure 10 shows the comparison between the amounts of separately collected waste types and their corresponding amount of avoided GHG emissions in Germany for 2014.

The comparison shows that the separate collection of glass had the best performance in terms of reduction of GHGs. With 5% of the collected waste amount, approx. 18% of the avoided GHG emissions were realized (substitution factor: 0.414 Mg of CO2,eq/Mg). With 13% of the separately collected waste amount, the treatment of packaging waste achieved 25% of the overall avoided GHG emissions (substitution factor: 0.245 Mg of CO2,eq/Mg). The separate collection of paper and bulky waste reaches equal efficiencies with substitution factors around 0.215 Mg of CO2,eq/Mg. The treatment of the mixed residual waste with a share of 31% of all collected waste avoided 9% of the overall emissions avoided (substitution factor: 0.035 Mg of CO2,eq/Mg), and the biowaste/degradable garden and park waste (23% of the amount and only 7% of the avoided GHG emissions and a substitution factor of only 0.036 Mg of CO2,eq/Mg) delivered the worst results.

Finally, it can be stated that the treatment of all separately collected wastes results in a negative GHG balance, or in the avoidance of GHG emissions. The energy and/or the secondary materials that were recovered in each case avoided more GHGs as released by the treatment processes.

5 Comparison of the Different Waste Treatment Options

Household waste can be collected as mixed waste in one bin, and environmentally sound waste disposed of in sanitary landfills, thermally treated in waste incineration plants, or mechanically and biologically/physically treated in mechanical-biological/physical treatment plants (see Sect. 3). As an alternative, different waste types can be separately collected and treated to recover more secondary materials and to thermally treat the material which is not possible to recycle. Figure 11 shows, as a result, the comparison of the GHG balances of these four basic options for the treatment of German household waste in 2014.

The comparison shows that the separate collection of different waste types and their individual treatment in Germany performs, with a GHG substitution factor of in average 0.129 Mg of CO2,eq/Mg, better than all three other options of mixed waste collection and treatment. In total, approx. 5.5 million Mg of CO2 equivalents were avoided by the separate waste collection and treatment in Germany in 2014.

6 Summary and Conclusions

With the actual German conditions, the treatment of separately collected household waste performs better than the treatment options of mixed household waste. Only small amounts of valuables (generally metals) are recovered if mixed waste is treated in MBTs or waste incineration plants. The recovery of energy is more in focus, but at the moment, the efficiency of energy recovery in Germany for waste incineration plants, and also for RDF plants, is for both relatively low. With higher efficiencies, especially with a higher recovery rate of heat in the form of delivered steam and/or district heat, the thermal treatment options (waste incineration and MBT with thermal utilization of the produced RDF) can reach the amount of avoided GHG emissions of the separate waste collection and treatment.

Also, for the separately collected waste fractions, there is potential for improving the treatment to recover more materials and energy, e.g., only 25% of the separately collected packaging waste is finally transferred to secondary materials; approx. 75% is finally incinerated/thermally treated.

The production of compost from the separately collected biowaste and biodegradable garden and park waste avoids only very small amounts of GHG emissions. In terms of reducing GHGs, the incineration of this material would be much more efficient. Here, the discussion of climate protection versus resource efficiency starts. In terms of the recovery of nutrients like phosphorus to conserve resources, biological treatment and compost production are very useful.

It is also important to mention that the GHG balance is only one aspect of a decision-making process. For environmental protection, aspects like ozone depletion or acidification also have to be taken into account (LCA). And finally, economic factors/drivers often influence the decision of a collection and treatment system.

From the authors’ point of view, the separate collection of different waste types is part of a modern waste management system, and only with source separation or very efficient (and expensive) material recovery facilities can secondary materials be recovered in high qualities to save natural resources and avoid high amounts of GHG emissions.

Finally, it should be noted that China, with more than 1 billion Mg/a of household waste, has a huge potential for the recovery of secondary materials and a high potential to avoid GHGs.

References

Globales Emissions-Modell Integrierter Systeme (2017) GEMIS version 4.95

Gromke U, Detzel A (2006) Ökologischer vergleich von büropapieren in anhängigkeit vom faserstoff. In: Auftrag der initiative pro recyclingpapier. Institut für Energie- und Umweltforschung Heidelberg GmbH, Heidelberg

Patel M (1999) KEA für produkte der organischen chemie – erarbeitung von basisdaten zum energieaufwand und der umweltbelastung von energieintensiven produkten und dienstleistungen für öko-bilanen und öko-audits. Fraunhofer-Institut für Systemtechnik und Innovationsforschung (FhG-ISI), Karlsruhe

Verein Deutscher Ingenieure (2012) VDI 4600, Cumulative energy demand (KEA) – terms, definitions, methods of calculations. Beuth Verlag, Berlin

Simon FG, Holm O (2016) Exergetic Considerations on the recovery of metals from waste. Int J Energy 19(3):352–363

Fritsche UR, Hochfeld C, Jenseit W, Rausch L, Lützkendorf T, Eiermann O, Kohler N, Ziesing HJ, Patel M (1999) KEA: mehr als seine zahl – basisdaten und methoden zum kumulierten energieaufwand (KEA): im Auftrag des umweltbundesamtes

Thorneloe SA, Weitz A, Nishtala SR, Yarkoshy S, Zannes M (2002) The impact of municipal solid waste management on greenhouse gas emissions in the United States: technical paper. J Air Waste Manage Assoc 52:1000–1011. ISSN: 1047-3289

Ketelsen K, Kanning K (2006) ASA-strategie 2030 - ressourcen- und klimaschutz durch eine stoffspezifische abfallbehandlung - herausforderungen, chancen, perspektiven. Im Auftrag der ASA e.V. – Arbeitsgemeinschaft Stoffspezifische Abfallbehandlung, Hannover

Hoffmann G, Wünsch C, Schnapke A, Schingnitz D, Baumann J, Brunn L, Günther M, Wagner J, Bilitewski B (2011) Nutzung der potenziale des biogenen anteils im abfall zur energieerzeugung. Im Auftrag des umweltbundesamtes, Dessau-Roßlau. ISSN: 1862-4804

Interessengemeinschaft der thermischen abfallbehandlungsanlagen in Deutschland e.V.: ITAD Jahresbericht 2013

Fehrenbach H, Giegrich J, Schmidt R (2007) Ökobilanz thermischer entsorgungssysteme für brennbare Abfälle in Nordrhein-Westfalen. Im Auftrag des ministeriums für umwelt und naturschutz, landwirtschaft und verbraucherschutz des landes Nordrhein-Westfalen, Düsseldorf

Verein Deutscher Zementwerke e.V. (2015) Environmental data of the German cement industry, Düsseldorf

Reimann DO (2012) Results of specific data for energy, R1 plant efficiency factor and net calorific value (NCV) of 314 European WtE plants. CEWEP, Energy Report, III (status 2007–2010)

Statistisches Bundesamt: Umwelt – Abfallbilanz (Abfallaufkommen/verbleib, abfallkennzahlen, abfallaufkommen nach wirtschaftszweigen) 2014 (2016) Statistisches Bundesamt, Wiesbaden

Schüler K (2016) Aufkommen und verwertung von verpackungsabfällen un Deutschland im Jahr 2014, Iim Auftrag des Umweltbundesamtes, Dessau-Rosslau. ISSN: 1862-4804

Springer C (2010) Vom substitutionspotential und der energiebilanz des komposts zum entwurf eines effizienzpasses für biologische Abfallbehandlungsanlagen, Disserstation, Bauhaus-Universität Weimar

Kehrens B (2012) Klima-contra ressourcenschutz, in Humuswirtschaft & Kompost aktuell, Ausgabe 3

Voigt R, Knappe F, Lazar S, Höke S (2012) Optimierung der verwertung organischer abfälle, im auftrag des umweltbundesamtes, Dessau-Rosslau. ISSN: 1862-4804

Dehoust G, Schüler D, Voigt R, Gierich J (2010) Klimaschutzpotenziale der abfallwirtschaft – am beispiel von siedlungsabfällen und Altholz. Im Auftrag des Umweltbundesamtes und des Bundesverbandes der Deutschen entsorgungswirtschaft e.V., Dessau-Rosslau. ISSN: 1862-4804

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this chapter

Cite this chapter

Wünsch, C., Simon, FG. (2017). The Reduction of Greenhouse Gas Emissions Through the Source-Separated Collection of Household Waste in Germany. In: Maletz, R., Dornack, C., Ziyang, L. (eds) Source Separation and Recycling. The Handbook of Environmental Chemistry, vol 63. Springer, Cham. https://doi.org/10.1007/698_2017_35

Download citation

DOI: https://doi.org/10.1007/698_2017_35

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-69071-1

Online ISBN: 978-3-319-69072-8

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)