Abstract

This article briefly reviews research developments on “green polymer chemistry” and focuses on the studies recently performed by our group and related work by some other groups. The green character of polymer synthesis has been viewed from the standpoint of starting materials, polymerization catalyst, reaction solvent, and polymer recycling. Starting materials employ biobased renewable resources such as lactic acid (LA), itaconic anhydride (IAn), succinic anhydride, 1,4-butane diol, etc. Green catalysts include enzymes like lipase and protease. Green solvents are water, supercritical carbon dioxide, and ionic liquids; in particular, water is often used for emulsion systems. From LA and IAn, methacyloyl-polymerizable macromonomers were derived and their copolymerization with a (meth)acryroyl monomer in miniemulsion produced a graft copolymer having LA graft chains. The copolymers are classed as bioplastics from their biomass content (≥25 wt%) and are applicable for coatings. LA chain-containing comb polymers and a star-type polymer were prepared, the latter being currently employed as a coating material. The mechanism of catalysis of the enzymes in the oligomerization of LA alkyl esters was examined to reveal direct evidence that a deacylation step determines the enantioselection. Lipase catalysis was utilized for a polymer recycling system

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

In the last two decades, problems associated with stocks of fossil resources and the methods of energy generation have become extremely important concerns worldwide. These problems are related to the diminishing of resources such as oil, coal, and gas as well as the risks involved in generating atomic energy. The problems are also discussed from the environmental viewpoint, particularly regarding climate change and the need to decrease the amount of carbon dioxide emissions. In the chemistry field, the concept of “green chemistry” was first reported in 1998 [1, 2] and refers to environmentally benign chemistry and chemical technology for a sustainable society. In a similar meaning to green chemistry, “sustainable chemistry” or “green sustainable chemistry” is sometimes used (http://www.gscn.net). Concurrently, the concept of “carbon neutral” was proposed [3], which stresses the importance of employing biobased, renewable starting materials for the synthesis of industrial products to mitigate the carbon dioxide emissions. It is highly required, therefore, that polymeric materials are produced from biomass resources using benign production processes [1, 2, 4], and biobased chemical production from sugar has currently started at the industrial scale [5]. After the proposal of the green chemistry concept, the concept was extended to the field of polymer chemistry as “green polymer chemistry” in 1999, and in fact we have been conducting research based on this concept [6–23].

The concept of green chemistry involves twelve philosophical principles [1]. Among them, the use of renewable resources as starting substrates (starting materials) and green processes (synthetic reactions) are the most important issues for production of a variety of materials. The starting materials recommended are (1) renewable biobased materials, (2) nontoxic, and (3) environmentally benign. Green synthetic reactions involve (4) efficient catalytic reactions (not a molar reaction), (5) selective reactions to minimize side-products, (6) reactions under mild conditions at a lower temperature to save energy, and (7) reactions in a green solvent like water. From this viewpoint, we have recently conducted green polymer chemistry, e.g., synthesis of polyester-containing polymers by using biobased renewable starting materials and employing nontoxic, environmentally benign lipase enzyme as green catalyst. It should be mentioned that very recently “green polymer chemistry” has become a well-known keyword [20, 24, 25]. In view of the character of this special volume, the present review focuses mainly on our recent results together with the developments of related studies.

2 Green Starting Materials: Biobased Renewable Resources for Polymer Production

There are twelve important platform chemicals listed that are derived from biomass [26]. They include succinic acid, itaconic acid, and glycerol. Some other important biobased renewable chemicals such as lactic acid and 1,4-butanediol are produced via fermentation and/or chemo-enzymatic processes from various biomass sources like corn, sugarcane, wheat, etc. These platform chemicals have been used as starting materials for the production of polymers.

2.1 Lactic Acid-Derived Graft Copolymers Using the Macromonomer Method

Aliphatic polyesters like poly(ε-caprolactone), poly(butylene succinate), and poly(hydroxyalkanoate)s are widely used. An aromatic polyester of poly(ethylene terephthalate) is much more utilized practically. Poly(lactic acid) (PLA) is an aliphatic polyester and has recently attracted major attention. So far, PLA has been a leading polymer produced from biobased resources. High molecular weight PLA is already produced in various ways and used as a green plastic for electronic products, automobile parts, and in biomedical applications [27–40].

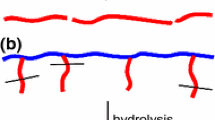

PLA has a drawback in its properties, however, which is due to breaking of the PLA chain through ester bond hydrolysis. Until now, various efforts have been made to decrease the bond breaking damage but so far it has been very difficult to suppress the hydrolysis completely. A possible solution to mitigate the damage is not to use PLA as a main chain, but to employ PLA as side chains. Figure 1 illustrates the concept [41].

The macromonomer technique is a practical and convenient method for preparing graft copolymers. So far, PLA has been prepared mainly via two ways: ring-opening polymerization (ROP) of lactide (a six-membered cyclic dimer of lactic acid) and direct polycondensation of lactic acid [29, 30]. Thus, we prepared graft copolymers having PLA side chains using the macromonomer technique via ROP. PLA macromonomers (MMm) having a methacryloyl polymerizable group with different PLA chain lengths (average length m = 4, 6, 8, 12, 18, and 30) were prepared via ROP of l-lactide using hydroxyethyl methacrylate (HEMA) initiator catalyzed by Sn(Oct)2, as given in reaction (1) in Scheme 1 [41, 42]. It is to be noted that the glass transition temperature (T g) and melting temperature (T m) values of MMm were as follows: m = 4 (−27°C), 6 (−17°C), 8 (−12°C), 12 (−8°C, 58°C), 18 (30°C, 105°C), and 30 (38°C, 151°C), i.e., when the LA chain length became longer, both values increased to close to those of PLA, ~60°C and ~170°C, respectively.

Radical copolymerization of MMm with a vinyl monomer was examined in an organic solvent or in a miniemulsion. MMm with m value lower than 12 was investigated for a miniemulsion system (see Sect. 2.5). Here, we give the results of solution copolymerization of MMm (having m values of 6, 12, 18, and 30) with n-butyl methacrylate (BMA) and methyl methacrylate (MMA). Various graft copolymers [PB(M)MA-g-PLAm] (reaction 2, Scheme 1) were obtained and their properties are given in Table 1 [41]. The copolymerization produced the copolymers in good to high isolated yields (≥54%), having molecular weight (M n) between 2.25 × 104 and 6.95 × 104. The copolymer composition was close to the feed monomer ratio, which means that the monomer reactivity ratio of BMA or MMA and MMm was also close, suggesting the formation of a random copolymer structure. In the copolymerization of BMA and MM6, both monomers showed the same copolymerizability, whereas in the case of BMA and MM30, the latter exhibited slightly less copolymerizability. The biomass content of the copolymers was in the range 34–71 wt%. According to the definition of the Japan BioPlastics Association proposed in 2006, “biomass plastic” denotes a plastic containing a biomass content higher than 25 wt%. In this regard, all the graft copolymers can be classed as biomass plastics.

The T g values of the graft copolymers are also given in Table 1. All the copolymers are amorphous without showing a melting point and are soluble materials. Transparent films were obtained; however, the films were very brittle so the pencil hardness of the copolymer samples was measured. In the four polymer samples having PBMA chains, the higher the T g value, the greater the hardness. The reason may be mainly due to the higher T g value with longer PLA chains. A higher T g value with PMMA chains reflects the higher T g value of PMMA (105°C), which is a relatively hard material. These graft copolymers will find useful applications as biomass plastics.

2.2 Graft Copolymers Based on Itaconic Anhydride and Lactic Acid

Itaconic anhydride (IAn) and lactic acid (LA) were employed as renewable starting materials. PLA-graft copolymers were synthesized via two approaches (as shown in Scheme 2) [43]. First, the macromonomer approach utilized IAn for Sn-catalyzed synthesis of PLA-containing macromonomers (IAn-PLA Macro). The macromonomer was radically copolymerized with BMA, n-butyl acrylate (BA), MMA, and ethyl methacrylate (EMA) to efficiently give graft copolymers [PLA-Graft copolymer (I)] with M n up to 1.61 × 105 and a biomass content higher than 34 wt%. Second, the copolymer approach employed first IAn as comonomer for radical copolymerization with BMA, giving rise to IAn-BMA copolymer with M n higher than 5.76 × 104. Then, Sn-catalyzed grafting of PLA onto the IAn moiety of the copolymer produced PLA-Graft copolymer (II) with M n higher than 5.88 × 104 and a biomass content ≥29 wt%.

By using these two approaches employing IAn as a starting reactive material, PLA-graft copolymers were obtained as biomass plastics. The properties of PLA-Graft copolymers (I) were also examined, which revealed possible applications for coatings and plastics. Furthermore, the IAn-containing graft copolymers are a convenient starting biomass polymer, having a reactive IAn moiety in the main chain for further grafting or various functional group-introducing reactions.

2.2.1 Macromonomer Approach

IAn was employed for the first time to prepare an IAn-PLA macromonomer by utilizing the reactive nature of IAn with ring-opening. The macromonomer (IAn-PLA Macro) was prepared via a one-pot two-stage method [reactions (1) and (2) in Scheme 2]. IAn is an unsymmetrical anhydride, and the structure of IAn-PLA Macro given in reaction (2) was the major product, at around 90%. By varying the feed ratio of BuOH and l-lactide, it was possible to tune m values (m = 5, 6 and 12). The reaction yields were almost quantitative and the functionality of IAn-PLA Macro was realized at ~100% in all cases.

Radical copolymerization of IAn-PLA Macro with a vinyl monomer yielded PLA-Graft copolymer (I) according to reaction (3) in Scheme 2. Copolymerization using BMA as comonomer by AIBN initiator gave PLA-Graft copolymer (I) in high yields in bulk or in toluene, with M n, up to 1.1 × 105. In 1,4-dioxane, lower copolymer yields with lower molecular weight were obtained. Both IAn-PLA Macro and BMA are of methacryloyl-type structure; the former showed a little less radical copolymerization reactivity toward BMA. The biomass content of PLA-Graft copolymers was in the range of 34–70 wt%, indicating the biomass plastic nature of the graft copolymers.

Likewise, radical copolymerization of IAn-PLA Macro (I) with other three vinyl monomers (BA, MMA, and EMA) produced PLA-Graft copolymers (I) as shown in reaction (3) of Scheme 2. All these product copolymers are biomass plastics (biomass content 46–75 wt%).

Regarding the graft copolymer properties, a PLA-Graft copolymer (I) sample (Macro, m = 6.0) derived from BA typically gave a transparent film by casting from a chloroform solution. The sample had a molar ratio Macro:BA = 1.0:2.4, was of high molecular weight (M n = 161,000), had a T g value of 11.2°, and a high biomass content of 59 wt%. It showed a very good elastic property, as shown by the following data: Young's modulus, 316 kgf/cm2; tensile strength, 33.7 kgf/cm2; and elongation at break, 496.1%. These results suggest that the copolymers can be applied for coatings, soft films, etc. [41, 42].

On the other hand, using BMA as comonomer the PLA-Graft copolymer (I) (Macro, m = 6.0) having M n = 37,600 with biomass content of 53 wt% showed a T g value of 27.0°C. The copolymer composition was in a molar ratio Macro:BMA = 1.0:2.9. The copolymer sample was very hard and very brittle, as shown by elongation at break of 101.3%. It is understandable from the monomer structure that both the Macro and BMA have an α,α-disubstituted structure of CH2=CRR′ and, moreover, that the Macro contains a bulky PLA group of R=CH2C(=O)PLA. Thus, the resulting copolymer should have a main chain with condensed packing, resulting in non-flexible polymeric materials. Therefore, the copolymers from BMA may find applications in hard plastic materials requiring a tough nature, which can probably be accomplished via further crosslinking reactions. Graft copolymers (I) and (II) possess a –CO2H group in the main chain and, hence, they are derivative polymers of methacrylic acid. Their applications are also conceivable in this direction.

2.2.2 Copolymer Approach

The other way to produce PLA-graft copolymers is shown as reactions (4) and (5) in Scheme 2 [43]. First, IAn-BMA copolymer was prepared via radical copolymerization of IAn and BMA. IAn-BMA copolymers were obtained in good yields, with M n reaching 1.1 × 105. The next step was grafting the PLA chain onto IAn-BMA copolymer by Sn-catalyzed reaction of PLA to afford PLA-Graft copolymer (II) according to reaction (5) in Scheme 2. In one case, the value of M n = 5.76 × 104 for IAn-BMA copolymer was increased slightly to 5.88 × 104 after the grafting. The grafting reaction is a polymer–polymer reaction, which is generally harder than a polymer–monomer reaction and it is not easy to achieve a high conversion. Therefore, some portions of the anhydride group of the main chain remained unreacted. In this respect, the macromolecular approach seems more effective.

2.3 Comb Polymers via Macromonomer

Comb polymers are those having a graft chain at every repeating unit. Such copolymers can be derived by homopolymerization of a macromonomer (Scheme 3) [41]. Some results of the radical homopolymerization of MMm are given in Table 2 [41]. Normally, the radical polymerization of macromonomers needs a large amount of initiator and, hence, AIBN was employed at 10 mol%. But, regardless of the amount (1 or 5 mol%), polymer yield was relatively high and M n was between 2.19 × 104 and 9.00 × 104 (M w was between 2.67 × 104 and 11.0 × 104), showing a high molecular weight of the product comb polymers.

The biomass content was of course equal to that of the macromonomers MMm. Thus, various comb polymers having high biomass content up to 94 wt% were obtained. To our knowledge, this is the first instance of preparation of comb polymers having PLA as the pendant chain with high biomass content.

These comb polymers are white powders and are soluble materials. They possess T g values such that when the side chains of PLA became longer, the T g value became higher. These values reflect well the nature of the PLA chains, as observed with MMm monomers. They formed transparent films via the casting method. Their pencil hardness values (Table 2) were in a narrow range (2B–HB) with a monotonous change along the PLA chain length. For longer side-chain PLA length and, hence, higher T g, the comb polymer was a little harder. These comb polymers may be applied as soft materials.

2.4 Star-Shaped Lactic Acid Oligomers for Coating Applications

Multifunctional star-shaped oligo(lactic acid)s (oligoLAs) with reactive double bonds were synthesized from the oligoLA polyols. They have application as biobased curable coatings. The outline of the synthesis procedures is shown in Scheme 4, using pentaerythritol as an example of a polyol [44, 45].

The molecular weight M n of the star-shaped oligoLA polyol (l + m + n + o = 14) obtained by gel permeation chromatography (GPC) was 1,400 with M w/M n = 1.4. The polyol was shown to be amorphous by differential scanning calorimetry (DSC) and had about 88% biomass content. The polyol was applied as a test coating on the grip part of the Toyota personal mobility vehicle “i-REAL”; the coating was prepared via two-component thermal curing with mixing the polyol and a polyisocyanate hardener (Fig. 2) [44]. The biomass content of the cured coatings was 40 wt%.

Coatings on the grip part of TOYOTA personal mobility unit “i-REAL”. Reproduced from [44] with permission of the publisher

The product, a star-shaped oligoLA modified with a methacryloyl group (S-OLAM1) according to reaction (2) in Scheme 4, was of M n = 2,600 and M w/M n = 1.3, with an average of 4.6 methacryloyl groups per molecule and a biomass content of 41 wt% (63 wt% when succinic anhydride was counted as biomass). Instead of pentaerythritol, dipentaerythritol also gave another S-OLAM (S-OLAM2). These S-OLAMs were applied as UV-curable coatings. An example formulation was a mixture of S-OLAM2 (70 wt%), urethane hexaacrylate (30 wt%), and a photo-initiator (5 wt%). The film coating was prepared by air-spraying on polycarbonate and then irradiating using a mercury lamp to form the cured film, whose thickness was 15 μm. Performance data of the UV-cured coating film indicated good initial adhesion, humidity resistance, alkaline resistance, and abrasion resistance. The pencil hardness of the cured film was F, and the biomass content of the film was 29 wt% (44 wt% when succinic anhydride taken into account), showing that the film could be classed as a biomass plastic [44, 45].

2.5 Miniemulsion System

From the environmental viewpoint, the solvent used for coating or film-forming materials is important. The macromonomer technique was therefore applied to form a miniemulsion system of PLA-graft copolymers, as a typical example of the use of water as a green solvent. Four MMm macromonomers (m = 4, 6, 8, and 12; Scheme 1) were prepared and used as comonomer. In the copolymerization, BMA or BA was employed as the vinyl monomer (reaction 2, Scheme 1) [41]. Sodium dodecyl sulfate (SDS) and sodium dioctyl sulfosuccinate (PEREX), both anionic, were found to be appropriate surfactants. To form a stable emulsion system, ultrasound sonication was applied to the mixture of comonomers and surfactant in water before the copolymerization. Then, radical copolymerization was carried out (Table 3) [41, 42]. Relevant to the use of water as reaction solvent, Sect. 4 describes the use of green solvents in enzyme-catalyzed polymerizations.

With 1.0 or 3.0 wt% of the surfactant, all copolymerizations employing MM4, MM6, or MM8 as comonomer afforded a stable miniemulsion system before and after the reaction. However, the copolymerization system of MM12 gave a miniemulsion before the reaction, whereas after the reaction a small portion (3.9 wt%) of polymer aggregates formed and a stable miniemulsion system was not obtained. Thus, an average chain length longer than 12 was not appropriate for the copolymer emulsification, probably due to the hydrophobic nature of longer PLA chains or SDS not being an effective surfactant, even at 3.0 wt%.

It is to be noted that before and after the reaction, the particle size of the BA/MM6 system (113 and 99 nm, respectively) was much smaller than that of MBA/MM6 system (220 and 333 nm, respectively), both with PEREX 1.0 wt%. BA lacks methyl group and hence is able to form compact particles. The molecular weight of the copolymers was very high, with M n values ranging from 4.95 × 104 to 1.64 × 105 (M w values were from 1.01 × 105 to 1.98 × 105).

T g values of three graft copolymers (PBMA-g-PLAm with SDS 3.0 wt%) are 35°C for m = 4, 37°C for m = 6, and 40°C for m = 8. The T g value of PBMA is 20°C and, hence, these T g values were much enhanced by the graft chain; for longer graft chains, T g gradually increased. Physical properties are given in Table 3 for three graft copolymer samples of PBMA-g-PLAm (SDS 3.0 wt%, PLA component 34 wt%). The physical strength is higher with the longer graft chain (m = 8) than with the shorter graft chain (m = 4), whereas the elongation property is higher with the shorter chain than with the longer chain. That is, when the total amount of the PLA component is equal, the longer graft chains (yet with a smaller number of chains) govern the bulk nature of the copolymer rather than the shorter graft chains (even though there is a larger number of chains). This is a good example to demonstrate the property relationship between the graft chain length and the number of graft chains. All of graft copolymers are very elastic, soft materials as can be seen from the elongation data (Table 3) [41, 42].

3 Green Catalysts: Enzyme-Catalyzed Synthesis and Degradation of Polyesters

Enzymes are natural catalysts obtained from living systems. Generally, enzymatic reactions have the following characteristics: (1) high catalytic activity; (2) reaction under mild conditions with respect to temperature, pressure, solvent, pH of medium, etc., bringing about energetic efficiency; and (3) high reaction selectivity of regio-, enantio-, chemo-, and stereoregulation, giving rise to perfectly structure-controlled products. If these in vivo characteristics could be realized for in vitro enzymatic polymer synthesis (“enzymatic polymerization”) [13, 20], we may expect the following advantages: (1) perfect control of polymer structures; (2) creation of polymers with a new structure; (3) a clean, selective process without formation of by-products; (4) a low loading process with energy savings; and (5) biodegradable properties of the product polymers in many cases. These are indicative of the “green” nature of enzymatic catalysis for developing new polymeric materials. In fact, many of these expectations have been realized [13, 14, 16–23]. Enzymatic polymerization has been reviewed recently in a special volume [46].

Lipase (triacylglycerol acylhydrolase, EC 3.1.1.3) is an enzyme that catalyzes the hydrolysis of a fatty acid glycerol ester in vivo by bond cleavage; however, it was disclosed that lipase catalyzes a polymerization reaction to give polyesters in vitro with bond forming when the lipase catalyst and substrate monomer are appropriately combined for the reaction. This view seems logical because in vivo enzymatic reactions are virtually reversible. Lipase catalyzes hydrolysis of the ester bond through l-enantioselective cleavage. To conduct green polymer chemistry, we employed lipase as catalyst for synthesis of polymers and oligomers.

3.1 Lipase-Catalyzed Synthesis of Reactive Polyesters

Ring-opening polymerization (ROP) of cyclic esters (lactones) by lipase catalysis to produce polyesters was discovered in 1993 by our group [47, 48] and another [49]. The general method is given in Scheme 5 [19, 20].

Very recently, the ROP was extended to itaconic anhydride (IAn) as a new monomer for lipase-catalyzed ring-opening addition condensation polymerization (ROACP) involving dehydration to produce reactive polyesters [50]. Previously, ROACP reaction of another carboxylic acid anhydride such as succinic anhydride (SAn) or glutaric anhydride (GAn) and a diol using lipase as catalyst was reported to give polyesters in good yields under mild reaction conditions [51]. Attempts to obtain reactive polyesters using a similar reaction (ROACP of IAn and a diol) did not give the expected polyester. However, ROACP reaction of three components (IAn plus SAn or GAn plus a diol) at 25°C in toluene produced reactive polyesters in good to high yields (Scheme 6) [50]. As diols, 1,4-butane, 1,6-hexane, 1,8-octane, and 1,10-decane diols were used. From the SAn reactions, polyesters with M n values of 650–3,510, and with 1.3–2.6 IAn units per molecule, were obtained. From the GAn reactions, these values were 560–3,690 and 1.2–3.1, respectively. Crosslinking of product polyester indicated a reactive nature, giving a crosslinked hard solid polyester. These polyesters derived from renewable starting materials involve possible applications as macromonomer, telechelics, or crosslinking reagent and the vinylidene group(s) can be used for further modification reactions.

Model reactions using IAn and n-octyl alcohol gave useful information on the regioselectivity and substrate selectivity. The regioselectivity at IAn was about the same (~50%) for both α- and β-positions of IAn by lipase catalysis, whereas it was about 90% for β-selectivity with Sn(II) catalyst and without catalyst [43]. The selectivity of lipase catalyst is thought to explain the reactive polyester formation under mild reaction conditions [50].

An interesting ROP of a new cyclic monomer of an O-carboxylic anhydride derived from lactic acid with lipase catalysis is to be noted. The polymerization proceeded within a few hours at 80°C with liberation of carbon dioxide and gave PLA in high yields and high M n of up to 38,400, with low polydispersity M w/M n < 1.4 [52].

3.2 Enzyme-Catalyzed Oligomerization of Alkyl Lactates: Enantioselection Mechanism

New oligomerization reactions of alkyl lactates have been developed recently using enzymatic catalysis, where lipase [53] and protease [54] were employed as enzyme catalysts.

3.2.1 Lipase Catalysis

A recent paper reported that lipase-catalyzed ROP of lactide occurred with enantioselection of d-lactide [55]. Here, a new lipase-catalyzed enantioselective oligomerization of an alkyl lactate (RLa) is described (Scheme 7) [53]; Novozym 435-catalyzed polycondensation of alkyl d-lactates at 50°C gave oligo(d-lactic acid)s (oligoDLAs) at up to 82% yields with n = 2–7. Primary alkyl lactates of Et-, Pr-, and Bu-, showed a higher reactivity than longer alkyl lactates like Pe-, Hx-, Hp-, and Oc-. A secondary alkyl lactate of BuDLa showed a decreased reactivity. l-Lactates did not show any reactivity, i.e., enantioselection for D-isomers is very strict.

Michaelis–Menten equation (1) and, for simplicity, a pseudo-first order rate Eq. (2) were applied for the reaction analysis:

where E, S, and P denote enzyme, substrate, and product, respectively. Plots of the integrated form of equation (2) gave k values of 3.7 × 104 s−1 for MeDLa; 4.4 × 104 s−1 EtDLa; 3.7 × 104 s−1 PrDLa; and 3.4 × 104 s−1 BuDLa.

In order to elucidate the inhibition function of EtLLa toward the oligomerization of EtDLa, EtLLa was added to the EtDLa reaction. The reaction rate, namely the EtDLa consumption rate (ν 0 mol L−1 s−1), was evaluated and the values plotted according to Lineweaver–Burk plots. The plots demonstrated that inhibition of the oligomerization of EtDLa by EtLLa is of a “competitive” nature. From the plots, the Michaelis constant K m = 2.35 mol L−1 and the maximum rate V max = 1.48 × 10−3 mol L−1 s−1 were obtained.

Hydrolysis of BuDLa and BuLLa was conducted in THF at 50°C (Scheme 8) [53]. In contrast to the oligomerization, Novozym 435 catalysis induced the hydrolysis of both BuDLa and BuLLa substrates, although BuDLa was consumed faster than BuLLa. Without the enzyme, no hydrolysis reaction took place under similar reaction conditions. The approximate values were k = 2.1 × 104 L mol−1 s−1 for BuDLa and k = 0.92 × 104 L mol−1 s−1 for BuLLa; the d-isomer was hydrolyzed about 2.3 times faster than the l-isomer.

These findings led to elucidation of the mechanistic aspects of lipase (Novozym 435) catalysis: enantioselection is operated by the deacylation step as shown in Fig. 3 [53], where only dimer formation is shown for simplicity. It is well accepted that at first the monomer (substrate) is activated by enzyme with formation of an (R)-acyl–enzyme intermediate (enzyme-activated monomer, EM) [“acylation of lipase;” step (a) in Fig. 3]. Onto the activated carbonyl carbon of EM, the OH group of the d-lactate nucleophilically attacks to form an ester bond, liberating lipase enzyme and giving rise to d,d-dimer [ “deacylation of lipase;” step (b) in Fig. 3]. If, in place of the d-lactate monomer, the OH group of the d,d-dimer attacks EM, a d,d,d-trimer will be formed, and the repetition of this type of reaction results in the formation of higher d-oligomers. Since the l-lactate was not consumed, the reaction of EM with the OH group of l-lactate does not occur and the reaction shown in step (c) does not take place. On the other hand, hydrolysis of d-lactate also needs activation to form EM. Then, EM reacts with water to give d-lactic acid, as shown in step (d).

Lipase-catalyzed reaction pathways of d-lactates (a) and l-lactates (b): acyl–enzyme intermediate formation steps a and e, subsequent dimer formation steps b, c, f, and g, and hydrolysis steps d and h. ○ denotes that the step takes place, whereas × denotes that the step does not take place. In steps b, c, d, f, g, and h, the lipase leaving group is omitted

Concerning the reactions of l-lactate monomers, alkyl l-lactates were not consumed at all in the oligomerization. In the hydrolysis, alkyl l-lactates were hydrolyzed to give l-lactic acid [step (h) in Fig. 3]. This is a clear indication that step (e) actually took place to produce (S)-acyl–enzyme intermediate EM. However, neither the OH group of d-lactate nor the OH group of l-lactate was allowed to attack EM to give l,d-dimer via step (f) or l,l-dimer via step (g).

Although hydrolysis steps (d) and (h) in Fig. 3 (both deacylations) are not selective due to no chirality in the water molecule, esterification steps (b), (c), (f), and (g) (all deacylations) are enantioselective. The above results demonstrate that “the enantioselection is governed by the deacylation step”. Of the four steps, only step (b) was allowed to give d,d-dimer. The EM formation, via steps (a) and (e), was possible, however, from all alkyl (primary and secondary) d- and l-lactate monomers.

Figure 4 gives a generalized reaction mechanism of lipase (Novozym 435)-catalyzed oligomerization of alkyl lactates (RLa)s [53]. The acylation of RLa takes place regardless of whether it is the d- or l-isomer, as observed by their hydrolysis catalyzed by Novozym 435. In the oligomerization, however, the reaction of (R)-acyl–enzyme intermediate (EM) is only possible with the OH group of d-lactate or d-oligoLAs and not with that of l-lactate or l-oligoLAs. The (S)-acyl–enzyme intermediate, on the other hand, does not react with the OH group of d- and l-lactates or of d- and l-oligoLAs. Therefore, the deacylation step governs the enantioselection of the oligomerization.

The d-selective reaction of alkyl lactates by lipase catalysis has been applied for the optical resolution of d,l-isomers [56]. Typically, a mixture containing 90.4% BuLLa and 9.6% BuDLa was incubated with an immobilized lipase for 72 h, during which time d-selective oligomerization of BuDLa occurred. After distillation of the reaction mixture, the purity of BuLLa was increased to 98.6%, indicating that lipase catalysis provides a good enantiopurification method.

3.2.2 Protease Catalysis

In nature, proteases are known to hydrolyze proteins to give l-amino acid residues [57]. Proteases were therefore employed as a new catalyst and expected to cause l-enantioselective oligomerization of alkyl d- and l-lactates (RDLa and RLLa), in contrast to the lipase (Novozym 435)-catalyzed perfect d-enantioselective reaction of Scheme 7. The four proteases examined preferentially gave oligo(l-lactic acid)s (oligoLLAs; dimer ~ pentamer), with moderate to high yields. The enantioselection was l-/d-selective (56/28 to 25/4 in conversion % ratio), showing an opposite direction in enantioselection to that of the lipase [54].

Hydrolysis reaction of ethyl d- and l-lactates (EtLa)s catalyzed by protease were studied; EtLLa was consumed a little faster than EtDLa. The mechanism of the protease-catalyzed oligomerization was similar to that of lipase (as seen in Figs. 3 and 4), but in an l-selective manner; the enantioselection is governed by the deacylation step.

The opposite enantioselection of enzymatic catalysis by protease and lipase has been discussed in the case of PLA depolymerizing hydrolysis [58]. These two classes of enzymes are both serine hydrolases, possessing a catalytic triad of serine, histidine, and aspartic acid; the catalytic active site of the two classes, however, are topological mirror images [59–61]. This difference in the catalytic sites was considered responsible for the opposite selection, where protease was PLLA-preferential and was PDLA-specific [53, 54, 58]. The results of enantioselective oligomerization of alkyl lactates catalyzed by protease and lipase, therefore, may be similarly understood. The enantioselection of Novozym 435 was perfect, and lipases of other origin were not so strong. Proteases were less selective. This selectivity difference is probably because in living systems the substrate of lipase is an ester having an ester linkage like that of RLa, whereas the substrate of protease is a protein having an amide linkage.

3.3 Lipase-Catalyzed Degradation and Polymerization of Polyesters: New Method of Polymer Recycling

Using the characteristics of lipase catalysis, a new method of polymer chemical recycling was proposed [8]. The polyester samples used were poly(ε-caprolactone) (PCL), poly(12-docecanolide) (PDDL), and poly(1,4-butane adipate) (PBA). First, lipase CA-catalyzed degradation of PCL with molecular weight 6.0 × 104 at 60°C was performed in toluene. After 24 h, PCL almost disappeared via hydrolysis to give oligoCL with molecular weight of less than 500. A small amount of water in the reaction mixture is probably involved in the hydrolysis. The solvent was then removed under reduced pressure to give a waxy oligomer mixture containing lipase CA. The mixture was then kept at 60°C for 8 h, yielding a polymer with molecular weight 8 × 103.

The cycle of degradation–polymerization could be performed repeatedly and controlled by the presence or absence of the solvent, using the same catalyst in one pot. This method provided a concept for an environmentally benign process of polymer recycling, giving an example of green polymer chemistry. The concept is shown in Fig. 5 [8].

Similarly, chemical recycling of PCL was studied via two routes: the enzymatic conversion of PCL into CL oligomers, and the selective ring-closing depolymerization of PCL into di-CL [62]. Di-CL was readily polymerized by lipase CA catalyst to produce PCL. PBA is a biodegradable synthetic plastic obtained from 1,4-butane diol and adipic acid. PBA with M w of 2.2 × 104 was degraded into BA oligomers with M w of 600 by lipase CA catalyst. This cyclic BA was repolymerized into PBA having M w of 5.2 × 104, an even higher molecular weight than before [63]. PLA could be chemically recycled by lipase via repolymerizable cyclic oligomers having a low molecular weight of a few hundred. PLLA with M w 1.2 × 105 was transformed into cyclic oligomers by lipase CA catalyst at 100°C [64]. This principle was extended to the continuous degradation system using an immobilized lipase-packed column [65]. A similar recycling system was achieved by lipase catalysis for polyurethanes, poly(ester-urethane)s, and poly(carbonate-urethane)s [66]. Again, the principle of the above recycling systems is that ROP of lactones by lipase catalysis is reversible between polymers and oligomers and can be controlled by changing the reaction conditions.

The effects of the number of molecular branches and the stereochemistry of the PLAs on enzymatic degradation and alkaline hydrolysis have been reported [67]. PLA-containing polymers were prepared by using lipase-catalyzed ROP of lactide (l-lactide, d-lactide, and d,l-lactide). An increased number of PLA branches enhanced the enzymatic degradability and alkaline hydrolyzability when samples of similar M n were used. The proteinase-catalyzed hydrolysis was preferential for PDLPLA branches; however, alkaline hydrolysis did not show the stereochemical preference.

4 Green Solvents: Water, Supercritical Carbon Dioxide, and Ionic Liquids

In the context of green chemistry, water, supercritical carbon dioxide, and ionic liquids are regarded as typical examples of green solvents. The importance of reaction solvent was described in Sect. 2.5 for radical polymerization, so both enzyme-catalyzed polymerization and degradation have been performed using these solvents.

4.1 Ring-Opening Polymerization in Water and in Miniemulsion

ROP of lactones to various polyesters has been widely studied [19, 68]. Lipase-catalyzed ROP is normally carried out in bulk or in an organic solvent like toluene, 1,4-dioxane, or dibutyl ether [17, 19, 20].

Water was used as solvent for the first time in the lipase-catalyzed ROP of five lactone monomers, ε-CL, OL, UDL, DDL, and PDL (Scheme 5) [69, 70]. Macrolides of UDL, DDL, and PDL are less reactive than lactones of smaller ring size due to lower ring strain when using a usual chemical catalyst [71]. However, they showed higher reactivity in enzyme catalysis and were polymerized by lipase in water to produce the corresponding polyesters; typically, UDL gave polyUDL with M n 1,300 (M w/M n = 2.1) in 79% yields at 60°C for 72 h. DDL is hardly soluble in water; however, addition of the lipase gave a white emulsion-like solution, which allowed the ROP. In contrast, a mixture of the lipase and ε-CL or OL did not form an emulsion-like solution, and thus failed to induce the ROP. Therefore, it seems that the enzyme protein behaved like a surfactant [69–71].

A second example of the use of water as medium is the lipase-catalyzed ROP of a lactone in miniemulsions [72]. Typically, a mixture of PDL monomer, water, nonionic surfactant having a PEG chain of molecular weight 2,000, and hexadecane was vigorously stirred for 1 h at 45°C to give a miniemulsion system. To the mixture, a suspension of lipase PS in surfactant solution was added, and the resulting miniemulsion consisting of PDL nanodroplets was subjected to ROP with stirring at 45 or 60°C for up to 24 h to reach a full conversion of PDL. PolyPDL nanoparticles were obtained, which is considered to be a direct synthesis of biodegradable polymer nanoparticles (size < 100 nm). PolyPDL showed a bimodal molecular weight distribution; the majority was of high molecular weight (>2.0 × 105). It was possible to introduce a reactive group in the presence of an unsaturated alcohol or acid such as linoleic acid in the reaction system via esterification reactions.

4.2 Lipase-Catalyzed Polyester Synthesis and Degradation in Other Green Solvents

Supercritical carbon dioxide (scCO2) was employed for the first time to prepare polyesters via ROP of lactones. Lipase-catalyzed ROP of ε-CL proceeded to give a polymer (PCL) with molecular weight higher than 104. Copolymerization of ε-CL with DDL afforded a random copolyester. The enzymatic polycondensation between divinyl adipate and 1,4-butane diol also took place to produce the corresponding polyester [73]. Later, a similar study on ROP of ε-CL in scCO2 followed [74].

Hydrolytic degradation of PCL by lipase CA catalyst was studied in scCO2 [75]. The addition of acetone (5 vol%) accelerated the degradation of high molecular weight PCL to produce smaller molecular weight (<500) linear and cyclic oligomers, which could be repolymerized by the same catalyst. It is useful that scCO2 is easy to remove after the reaction to recover the catalyst, and the reaction can be recycled.

Ionic liquids are often used as reaction solvent for the synthesis and modification of polymers due to their green character [76]. The first paper on ionic liquids as solvent for enzymatic polymerization appeared in 2002. Lipase-catalyzed ROP of ε-CL and the polycondensation between diethyl adipate or sebacate and 1,4-butane diol were achieved in an ionic liquid such as 1-butyl-3-methyl-imidazolium salts ([bmim][PF6]). The ROP gave rise to PCL with M n of 4,200 (M w/M n = 2.7) in 97% yields at 60°C after 7 days [77]. Lipase CA-catalyzed ROP of ε-CL in three ionic liquids, [bmim][BF4], [bmim][PF6], and [bmim][(CF3SO2)2N], at 60°C for 24 h produced PCL with a higher M n of 7,000–9,500 (M w/M n ~ 2.4) in good yields. In the polycondensation of the above combinations, M n was up to 5,400 [78]. Since ionic liquids have high boiling points, with tunable nature for hydrophobicity and solubility, the polymerization of polar monomers (which are less soluble in an organic solvent) is suggested as an appropriate way.

A more recent paper reported that by using four kinds of ionic liquid, the ROP of lactide by lipase CA catalyst at room temperature for 24 h produced PLA having molecular weight values reaching 55,000 in 35% yields [79].

5 Conclusions

For conducting “green polymer chemistry”, the following aspects are stressed and it is very important that attention is paid to them. Typically, (1) starting materials are biobased renewable resources to mitigate use of fossil-based law materials; (2) synthesis or modification reactions are catalytic, not molar reactions; (3) catalysts are nontoxic and re-usable; (4) reaction solvents are environmentally benign to decrease use of organic solvents; and (5) product polymer structures are subjected to material recycling. The present article is concerned mainly with our recent research results performed in this direction. In particular, results employing lactic acid and itaconic anhydride suggest future materials, as shown in Sect. 2. Also, the characteristics of enzyme catalysis shown in Sect. 3 are to be noted.

It is important to keep paying attention to climate change and global warming, consumption of natural resources, and the method of energy generation and consumption; all of these issues are directly connected with the future environment. As polymer scientists, we are very much required to conduct green polymer chemistry to preserve the environment as well as we can.

References

Anastas PT, Warner JC (1998) Green chemistry: theory and practice. Oxford University Press, Oxford

Vorvath IT, Anastas PT (2007) Innovations and green chemistry. Chem Rev 107:2169–2173

Narayan R (2006) Biobased and biodegradable polymer materials: rationale, drivers, and technology exemplars. In: Khemani KC, Scholz C (eds) Degradable polymers and materials. ACS Symposium Series vol 939. Chap 18, pp 282–306. American Chemical Society, Washington, D.C.

Coates GW, Hillmyer MA (2009) A virtual issue of macromolecules: polymers from renewable resources. Macromolecules 42:7987–7989

Bomgardner MM (2012) A summer of start-ups for biobased chemicals. Chem Eng News 90(38):10–15

Kobayashi S (1999) Enzymatic polymerization – polymer synthesis catalyzed by a natural macromolecule. High Polym Jpn 48:124–127

Kobayashi S (1999) Enzymatic polymerization: a new method of polymer synthesis. J Polym Sci A Polym Chem 37:3041–3056

Kobayashi S, Uyama H, Takamoto T (2000) Lipase-catalyzed degradation of polyesters in organic solvents. A new methodology of polymer recycling using enzyme as catalyst. Biomacromolecules 1:3–5

Sakamoto J, Sugiyama J, Kimura S, Imai T, Itoh T, Watanabe T, Kobayashi S (2000) Artificial chitin spherulites composed of single crystalline ribbons of α-chitin via enzymatic polymerization. Mcromolecules 33:4155–4160

Ikeda R, Tanaka H, Uyama H, Kobayashi S (2000) A new crosslinkable polyphenol from renewable resource. Macromol Rapid Commun 21:496–499

Higashimura H, Fujisawa K, Moro-oka Y, Namekawa S, Kubota M, Shiga A, Uyama H, Kobayashi S (2000) New crystalline polymers: poly(2,5-dialkyl-1,4-phenylene oxide)s. Macromol Rapid Commun 21:1121–1124

Ikeda R, Tanaka H, Oyabu H, Uyama H, Kobayashi S (2001) Preparation of artificial urushi via an environmentally benign process. Bull Chem Soc Jpn 74:1067–1073

Kobayashi S, Uyama H, Kimura S (2001) Enzymatic polymerization. Chem Rev 101:3793–3818

Kobayashi S, Uyama H, Ohmae M (2001) Enzymatic polymerization for precision polymer synthesis. Bull Chem Soc Jpn 74:613–635

Uyama H, Kuwabara M, Tsujimoto T, Nakano M, Usuki A, Kobayashi S (2003) Green nanocomposite from renewable resources: plant oil–clay hybrid materials. Chem Mater 15:2492–2494

Kobayashi S, Uyama H (2003) Enzymatic polymerization. In: Kroschwitz JI (ed) Encyclopedia of polymer science and technology, 3rd edn. Wiley, New York, pp 328–364

Kobayashi S, Ritter H, Kaplan D (eds) (2006) Enzyme-catalyzed synthesis of polymers. Adv Polym Sci 194

Kobayashi S, Ohmae M (2007) Polymer synthesis and modification by enzymatic catalysis. In: Matyjaszewski K, Gnanou Y, Leibler L (eds) Macromolecular engineering: precise synthesis, materials properties, applications, vol 10, Wiley-VCH, Weinheim., pp 400–477

Kobayashi S (2009) Recent developments in lipase-catalyzed synthesis of polyesters. Macromol Rapid Commun 30:237–266

Kobayashi S, Makino A (2009) Enzymatic polymer synthesis: an opportunity for green polymer chemistry. Chem Rev 109:5288–5353

Kobayashi S (2010) Lipase-catalyzed polyester synthesis − a green polymer chemistry. Proc Jpn Acad Ser B 86:338–365

Kobayashi S (2011) Green polymer synthesis using enzyme catalysts. In: Misono M, Murahashi S (eds) Green chemistry – chemistry for sustainable society. Kodansha Scientific, Tokyo, pp 192–203

Kobayashi S (2012) Enzymatic polymerization. In: Matyjaszewski K, Moeller M (eds) Polymer science: a comprehensive reference, vol 5. Elsevier, Amsterdam, pp 217-237

Puskas JE, Sen MY, Seo KS (2009) Green polymer chemistry using nature’s catalyst, enzyme. J Polym Sci A Polym Chem 47:2959–2976

Cheng HN, Gross RA (eds) (2010) Green polymer chemistry: biocatalysis and biomaterials. ACS Symposium Series, vol 1043. American Chemical Society, Washington, D.C.

Werpy T, Petersen G (2004) Top value added chemicals from biomass. The National Renewable Energy Laboratory and DOE National Laboratory, Oak Ridge

Tsuji H, Ikada Y (2000) Properties and morphology of poly(L-lactide) 4. Effects of structural parameters on long-term hydrolysis of poly(L-lactide) in phosphate-buffered solution. Polym Deg Stab 67:179–189

Moon SI, Lee CW, Miyamoto M, Kimura Y (2000) Melt polycondensation of L-lactic acid with Sn(II) catalysts activated by various proton acids: a direct manufacturing route to high molecular weight poly(L-lactic acid). J Polym Sci A Polym Chem 38:1673–1679

Moon S-I, Lee CW, Taniguchi I, Miyamoto M, Kimura Y (2001) Melt/solid polycondensation of L-lactic acid: an alternative route to poly(L-lactic acid) with high molecular weight. Polymer 42:5059–5062

Dechy-Cabaret O, Martin-Vaca B, Bourissou D (2004) Controlled ring-opening polymerization of lactide and glycolide. Chem Rev 104:6147–6176

Gupta B, Revagade N, Hilborn J (2007) Poly(lactic acid) fiber: an overview. Prog Polym Sci 32:455–482

Fukushima K, Chang YH, Kimura Y (2007) Enhanced stereocomplex formation of poly(L-lactic acid) and poly(D-lactic acid) in the presence of stereoblock poly(L-lactic acid). Macromol Biosci 7:829–835

Jiang X, Smith MR III, Baker GL (2008) Water-soluble thermoresponsive polylactides. Macromolecules 41:318–324

Chuma A, Hom HW, Swope WC, Pratt RC, Zhang L, Lohmeijer BG, Wade CG, Waymouth RM, Hedrick JL, Rice JE (2008) The reaction mechanism for the organocatalytic ring-opening polymerization of L-lactide using a guanidine-based catalyst: hydrogen-bonded or covalently bonded? J Am Chem Soc 130:6749–6759

Jing F, Hillmyer MA (2008) A bifunctional monomer derived from lactide for toughening polylactide. J Am Chem Soc 130:13826–13827

Pitet LM, Amendt MA, Hillmyer MA (2010) Nanoporous linear polyethylene from a block polymer precursor. J Am Chem Soc 132:8230–8231

Nishida H, Andou Y, Watanabe K, Arazoe Y, Ide S, Shirai Y (2011) Poly(tetramethyl glycolide) from renewable carbon, a racemization-free and controlled depolymerizable polyester. Macromolecules 44:12–13

Inkinen S, Hakkarainen M, Albertsson A-C, Södergård A (2011) From lactic acid to poly(lactic acid) (PLA): characterization and analysis of PLA and its precursor. Biomacromolecules 12:523–532

Stoclet G, Seguela R, Lefebvre JM, Li S, Vert M (2011) Thermal and strain-induced chain ordering in lactic acid stereocopolymers: influence on the composition in stereomers. Macromolecules 44:4961–4969

Shin EJ, Jones AE, Waymouth RM (2012) Stereocomplexation in cyclic and linear polylactide blends. Macromolecules 45:595–598

Ishimoto K, Arimoto M, Okuda T, Yamaguchi S, Aso Y, Ohara H, Kobayashi S, Ishii M, Morita K, Yamashita H, Yabuuchi N (2012) Biobased polymers: synthesis of graft copolymers and comb polymers using lactic acid macromonomer and properties of the product polymers. Biomacromolecules 13:3757–3768

Ishimoto K, Arimoto M, Ohara H, Kobayashi S, Ishii M, Morita K, Yamashita H, Yabuuchi N (2009) Biobased polymer system: miniemulsion of poly(alkyl methacrylate-graft-lactic acid)s. Biomacromolecules 10:2719–2723

Okuda T, Ishimoto K, Ohara H, Kobayashi S (2012) Renewable biobased polymeric materials: facile synthesis of itaconic anhydride-based copolymers with poly(L-lactic acid) grafts. Macromolecules 45:4166–4174

Morita K, Yamashita H, Yabuuchi N, Hayata Y, Ishii M, Ishimoto K, Ohara H, Kobayashi S (2011) Application of star-shaped poly(lactic acid)s to two component and UV-curable coatings. J Network Polym Jpn 32:192–196

Morita K, Yamashita H, Yabuuchi N, Hayata Y, Ishii M, Ishimoto K, Ohara H, Kobayashi S (2011) Synthesis of star-shaped oligomeric lactic acids with reactive double bonds and their application to UV curable coatings. In: Proceedings of RadTech Asia 2011. RadTech Japan, Tokyo, pp 126–129

Palmans ARA, Heise A (eds) (2011) Enzymatic polymerisation. Adv Polym Sci 237

Uyama H, Kobayashi S (1993) Enzymatic ring-opening polymerization of lactones catalyzed by lipase. Chem Lett 1149–1150

Uyama H, Takeya K, Kobayashi S (1993) Synthesis of polyesters by enzymatic ring-opening copolymerization using lipase catalyst. Proc Jpn Acad B 69:203–207

Knani D, Gutman AL, Kohn DH (1993) Enzymatic polyesterification in organic media – enzyme-catalyzed synthesis of linear polyesters. 1. Condensation polymerization of linear hydroxyesters. 2. Ring-opening polymerization of ε-caprolactone. J Polym Sci A Polym Chem 31:1221–1232

Yamaguchi S, Tanha M, Hult A, Okuda T, Ohara H, Kobayashi S (2013) Green polymer chemistry: lipase-catalyzed synthesis of bio-based reactive polyesters employing itaconic anhydride as renewable monomer. Polym J doi:10.1038/pj.2013.62

Kobayashi S, Uyama H (1993) Enzymatic polymerization of cyclic acid anhydrides and glycols by a lipase catalyst. Macromol Chem Rapid Commun 14:841–844

Bonduelle C, Martin-Vaca B, Bourissou D (2009) Lipase-catalyzed ring-opening polymerization of the O-carboxylic anhydride derived from lactic acid. Biomacromolecules 10:3069–3073

Ohara H, Onogi A, Yamamoto M, Kobayashi S (2010) Lipase-catalyzed oligomerization and hydrolysis of alkyl lactates: direct evidence in the catalysis mechanism that enantioselection is governed by a deacylation step. Biomacromolecules 11:2008–2015

Ohara H, Nishioka E, Yamaguchi S, Kawai F, Kobayashi S (2011) Protease-catalyzed oligomerization and hydrolysis of alkyl lactates involving L-enantioselective deacylation step. Biomacromolecules 12:3833–3837

Hans M, Keul H, Moeller M (2009) Ring-opening polymerization of DD-lactide catalyzed by Novozyme 435. Macromol Biosci 9:239–247

Ohara H, Yamamoto M, Onogi A, Hirao K, Kobayashi S (2011) Optical resolution of n-butyl D- and L-lactates using immobilized lipase catalyst. J Biosci Bioeng 111:19–21

Hedstrom L (2002) Serine protease mechanism and specificity. Chem Rev 102:4501–4524

Kawai F, Nakadai K, Nishioka E, Nakajima H, Ohara H, Masaki K, Iefuji H (2011) Different enantioselectivity of two types of poly(lactic acid) depolymerases toward poly(L-lactic acid) and poly(D-lactic acid). Polym Deg Stab 96:1342–1348

Wilmouth RC, Clifton IJ, Robinson CV, Roach PL, Alpin RT, Westwood NJ, Hajdu J, Schofield CJ (1997) Structure of a specific acyl-enzyme complex formed between β-casomorphin-7 and porcine pancreatic elastase. Nat Struc Biol 4:456–462

Ollis DL, Cheah E, Cygler M, Dijkstra B, Frolow F, Franken SM, Harel M, Remington SJ, Silman I, Schrag J, Sussman JL, Vershueren KHG, Goldman A (1992) The α/β hydrolase fold. Protein Eng 5:197–211

Borén L, Martín-Matute B, Xu Y, Córdova A, Bäeckvall J-E (2006) (S)-selective kinetic resolution and chemoenzymatic dynamic resolution of secondary alcohols. Chem Eur J 12:225–232

Ebata H, Toshima K, Matsumura S (2000) Lipase-catalyzed transformation of poly(ε-caprolactone) into cyclic dicaprolactone. Biomacromolecules 1:511–551

Okajima S, Kondo R, Toshima K, Matsumura S (2003) Lipase-catalyzed transformation of poly(butylene adipate) and poly(butylene succinate) into polymerizable cyclic oligomers. Biomacromolecules 4:1514–1519

Takahashi Y, Okajima S, Toshima K, Matsumura S (2004) Lipase-catalyzed transformation of poly(lactic acid) into cyclic oligomers. Macromol Biosci 4:346–353

Osanai Y, Toshima K, Matsumura S (2003) Enzymatic degradation of poly(R, S-3-hydroxybutanonoate) to cyclic oligomers under continuous flow. Green Chem 5:567–570

Matsumura S (2007) Enzymatic synthesis of polyesters via ring-opening polymerization. Adv Polym Sci 194:95–132

Numata K, Srivastava RK, Finne-Wistrand A, Albertsson A-C, Doi Y, Abe H (2007) Branched poly(lactide) synthesized by enzymatic polymerization: effect of molecular branches and stereochemistry on enzymatic degradation and alkaline hydrolysis. Biomacromolecules 8:3115–3125

Lecomte P, Jerome C (2012) Recent developments in ring-opening polymerization of lactones. Adv Polym Sci 245:173–218

Namekawa S, Uyama H, Kobayashi S (1998) Lipase-catalyzed ring-opening polymerization of lactones in water. Polym J 30:269–271

Kobayashi S, Uyama H, Namekawa S (1998) In vitro biosynthesis of polyesters with isolated enzymes in aqueous systems and organic solvents. Polym Deg Stab 59:195–201

Uyama H, Takeya K, Kobayashi S (1995) Enzymatic ring-opening polymerization of lactones to polyesters by lipase catalyst: unusually high reactivity of macrolides. Bull Chem Soc Jpn 68:56–61

Taden A, Antonietti M, Landfester K (2003) Enzymatic polymerization toward biodegradable polyester nanoparticles. Macromol Rapid Commun 24:512–516

Takamoto T, Uyama H, Kobayashi S (2001) Lipase-catalyzed synthesis of aliphatic polyesters in supercritical carbon dioxide. e-Polymers 4:1–6

Loeker FC, Duxbury CJ, Kumar R, Gao W, Gross RA, Howdle SM (2004) Enzyme-catalyzed ring-opening polymerization of ε-caprolactone in supercritical carbon dioxide. Macromolecules 37:2450–2453

Takamoto T, Uyama H, Kobayashi S (2001) Lipase-catalyzed degradation of polyester in supercritical carbon dioxide. Macromol Biosci 1:215–218

Kubisa P (2005) Ionic liquids in the synthesis and modification of polymers. J Polym Sci A Polym Chem 43:4675–4683

Uyama H, Takamoto T, Kobayashi S (2002) Enzymatic synthesis of polyesters in ionic liquids. Polym J 34:94–96

Marcilla R, de Jeus M, Mecerreyes D, Duxbury CJ, Koning CE, Heise A (2006) Enzymatic polyester synthesis in ionic liquids. Eur Polym J 42:1215–1221

Yoshizawa-Fujita M, Saito C, Takeoka Y, Rikukawa M (2008) Lipase-catalyzed polymerization of L-lactide in ionic liquids. Polym Adv Technol 19:1396–1400

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Kobayashi, S. (2013). Green Polymer Chemistry: Recent Developments. In: Percec, V. (eds) Hierarchical Macromolecular Structures: 60 Years after the Staudinger Nobel Prize II. Advances in Polymer Science, vol 262. Springer, Cham. https://doi.org/10.1007/12_2013_236

Download citation

DOI: https://doi.org/10.1007/12_2013_236

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-03718-9

Online ISBN: 978-3-319-03719-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)