Abstract

Synthetic chemistry has played a significant role in the development of natural products chemistry, and the histories of the two fields are inextricably intertwined. Biology, isolation, structure elucidation, and synthesis are central to marine natural products chemistry and many advancements in the past 40 years have come in response to the challenges presented by compounds from the oceans. In this chapter we present an overview of marine natural products synthesis through a looking glass that focuses on some selected total syntheses from the past 40 odd years. In this light we can only provide a snapshot of where the field currently stands and the road that has led here. The vectors that define the size of the field and the constraints of this forum unfortunately do not cross, and as such it is not possible to be comprehensive. We direct the reader to recent reviews that cover the field in greater detail.

Access provided by Autonomous University of Puebla. Download reference work entry PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Some Beginnings: Cypridina hilgendorfii Luciferin and Tetrodotoxin

Synthetic chemistry has played a significant role in the development of natural products chemistry, and the histories of the two fields are inextricably intertwined [1]. Biology, isolation, structure elucidation, and synthesis are central to marine natural products chemistry, and many advancements in the past 40 years have come in response to the challenges presented by compounds from the oceans. This chapter presents an overview of marine natural products synthesis through a looking glass that focuses on some selected total syntheses from the past 40 odd years. In this light we can only provide a snapshot of where the field currently stands and the road that has led here. The vectors that define the size of the field and the constraints of this forum unfortunately do not cross, and as such it is not possible to be comprehensive. We direct the reader to recent reviews that cover the field in greater detail [2].

The papers that founded the science of marine natural products chemistry are difficult to identify, although there is little doubt that contemporaneous efforts by scientists in the United States and Japan in the period of 1955–1965 were responsible for the birth of the field. Notable research in this light includes early work by Paul Scheuer at the University of Hawaii into the causative agent of ciguatera poisoning [3], which later led to the structure of palytoxin [4], and by Yoshimasa Hirata at Nagoya University into the structure of the luciferin from the sea firefly Cypridina hilgendorfii (now Vargula hilgendorfii). It is instructive to consider some of the early work from Nagoya as it provides an illustration of the challenges in structure elucidation at the time and historical significance of total synthesis in structure confirmation.

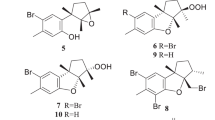

Heroic efforts to secure crystalline luciferin from Cypridina hilgendorfii by Osamu Shinomura (Nobel Laureate in 2008 for the discovery of green fluorescent protein) (see Chap. 24) in the laboratory of Yoshimasa Hirata in the period of 1955–1960 produced material [5] that ultimately culminated in a structure proposal that was published in 1966 as part of a series of three papers [6]. The structure elucidation, which was predicated on careful degradative studies and comparisons to known compounds, suggested luciferin to be 7 (Scheme 11.1). Oxidation would lead to oxyluciferin, 8, which was known to be degraded to etioluciferin and α-keto-β-methylglutaric acid by acid hydrolysis. In an accompanying paper, Yoshito Kishi confirmed the structure by total synthesis (Scheme 11.2) and ushered in the beginnings of an important role for synthesis in marine natural products chemistry: structure confirmation when limited amounts of natural material were available [6, 7].

The structure of tetrodotoxin was arrived at almost simultaneously by three groups – Hirata-Goto, Tsuda, and Woodward – and involved an extensive process of degradation and painstaking spectroscopic analysis [8, 9]. The absolute stereochemistry was secured in 1972 by X-ray analysis, and was followed only 2 years later by Kishi’s remarkable total synthesis. The Kishi synthesis commenced with oxime-substituted p-benzoquinone 9, which could be subjected to a sequence of SnCl4-catalyzed Diels–Alder reaction with butadiene and Beckmann rearrangement to give 11. Selective reduction of the C5 ketone with sodium borohydride and epoxidation of the di-substituted olefin led to tricycle 12. A sequence of 15 steps transformed enone 12 into tetraacetate 13. Baeyer–Villiger oxidation broke open the decalin ring system and formed bridged tricycle 14. A series of modifications installed the remaining oxidation functionalities to give diol 15. Diol cleavage with periodic acid followed by treatment with base closed the final two rings to give tetrodotoxin, 16.

Almost 30 years after Kishi’s synthesis of racemic tetrodotoxin [10], the first asymmetric syntheses of this molecule were reported by the groups of Isobe [11] and Du Bois [12]. The intervening three decades had provided a wealth of new methods that could be brought to bear on the synthesis problems posed by tetrodotoxin and both syntheses leveraged these advances. However, in a similar vein to the Kishi work, strategic aspects of the two syntheses were also focused on the functionalization of the cyclohexane core of the molecule.

Key steps for the functionalization of the cyclohexane core of tetrodotoxin from Isobe’s synthesis are shown in Scheme 11.3a. Silyl enol ether 17 (derived from 2-acetoxy-tri-O-acetyl-d-glucal in 23 steps) was subjected to an intramolecular aldol reaction mediated by TBAF, and subsequent elimination with trichloroacetylchloride-pyridine provided enone 18 in >70% yield. Further manipulations advanced 18 to 19, and upon treatment with potassium tert-butoxide in THF, the primary carbamate underwent heteroconjugate addition to produce oxazolidinone 20 in 90% yield. The final key functionalization of the cyclohexane was achieved by an interesting intramolecular O-alkylation of enolate 22 by the epoxide to give 23. With 23 in hand, the first asymmetric synthesis of tetrodotoxin (16) was completed by a 15-step sequence consisting of largely straightforward transformations.

(a) Key cyclohexane functionalization reactions from Isobe’s synthesis of (-)-tetrodotoxin. Reagents and conditions: (1) TBAF, THF-H2O then Cl3CCOCl, DMAP, pyridine, >70%; (2) t-BuOK, THF, 90%; (3) DBU, o-dichlorobenzene, 130°C, >68%. (b) Du Bois’s synthesis of (-)-tetrodotoxin. Reagents and conditions: (1) (a) 1.5 mol% Rh2(HNCOCPh3)4, CCl4, (b) NH3·BH3, CH2Cl2-MeOH, 75% (two steps); (2) 10 mol% Rh2(HNCOCF3)4, PhI(OAc)2, MgO, PhH, 65°C, 77%

In a distinctly different approach, Du Bois and Hinman relied on their newly developed CH bond insertion reaction methodology [13] as the cornerstone of their efforts to functionalize the central cyclohexane ring (Scheme 11.3b). Treatment of diazoketone 24 (available in nine steps from d-isoascorbic acid) with 1.5 mol% Rh2(HNCOCPh3)4 in CCl4 results in a CH insertion reaction to give a cyclohexanone that is subsequently reduced with NH3·BH3 to give alcohol 25 in 75% yield over the two steps. Advancement of 25 to carbamate 26 was achieved by a 14-step sequence, and set the stage for the second CH bond insertion. Subjecting this carbamate to conditions related to earlier methods developed in the Du Bois laboratories resulted in CH bond insertion of the carbamate to form oxazolidinone 27 in 77% yield. Given the structural complexity of the substrate, the yield for this reaction is truly remarkable, and nicely underscores the utility of this reaction in a target-oriented setting. A sequence of seven steps led to tetrodotoxin (16).

The challenges to synthesis presented by tetrodotoxin’s structure were met by employing distinctly different strategies over the course of three decades. The Kishi synthesis employed a classic Diels–Alder reaction with substrate-based stereocontrol for reactions that further functionalized the core of the molecule. Isobe’s synthesis relied on an intramolecular aldol reaction and conjugate addition to form two key bonds on a highly functionalized intermediate and the Du Bois synthesis showcases strategic avenues opened by advances in CH insertion reactions on highly functionalized compounds (Fig. 11.1).

2 The Continuing Role of Synthesis in Structure Elucidation, Confirmation, and Correction: Palmerolide A, Diazonamide A, Azaspiracid-1, and Palau’amine

The rise of modern spectroscopic methods such as NMR that began in the 1960s resulted in significant numbers of new structures being determined each year, and with increasing ease. Indeed, a survey of the structures recorded in MarinLit by the decade of their initial description shows that the 1960s produced 12 structures; the 1970s, 310 structures; the 1980s, 873; the 1990s, 1,459; and the period 2000–2009 produced 4,781 new structures [14]. In this section we consider a number of contemporary examples where synthesis has played roles in structure elucidation, structure confirmation, or structure corrections. Synthesis remains particularly important in the context of questions of stereochemistry, especially when the amounts of material isolated are small enough to permit connectivity to be established.

2.1 Palmerolide A

Palmerolide A (28) is a complex 20-membered macrolide isolated from an Antarctic tunicate Synoicum adareanum [15]. The original structure was described in 2006, and underpinned by the reported potent and selective cytotoxicity toward melanoma cells (UACC-62 LC50 = 18 nM), there was an immediate flurry of activity that resulted in the first total syntheses by the De Brabander [16] and Nicolaou [17] groups (Scheme 11.4). These two total syntheses are instructive because they illustrate (1) the balance of new methods and well-used reactions in the context of a complex macrolide synthesis, (2) the speed with which contemporary total synthesis can provide structural information, and (3) the application of retrosynthetic analysis in the context of macrolide synthesis.

A key step in the De Brabander synthesis was a Suzuki cross coupling of vinyl iodide 31 with pinacolboronate 30, which proceeded smoothly in the presence of Pd(PPh3)4 with Tl2CO3 as base to yield 35 (79%) (Scheme 11.5). Acylation of the alcohol with 29 using Yamaguchi conditions (69%), followed by removal of the TES ethers with PPTS in MeOH, led to 36 in 95% yield. The key Horner–Wadsworth–Emmons macrocyclization was achieved by a two-step protocol consisting of selective primary alcohol oxidation with PhI(OAc)2/TEMPO to yield the aldehyde, and subsequent treatment with K2CO3 and 18-crown-6 in toluene at room temperature to provide 37 in 70% yield over these two steps. Enone 37 was then converted to acyl azide 38 in five steps (92%). Upon heating under reflux in benzene, Curtius rearrangement occurred to give an intermediate isocyanate that was intercepted with 2-methyl-1-propenylmagnesium bromide at –78°C to install the N-acyl enamine and give 39 in 76% yield over these two steps. Removal of the TMS ether with HF•pyr buffered with pyridine (95%) and introduction of the carbamate with Cl3CC(O)NCO gave 40 (95%) and all that was required at this juncture to complete the synthesis was removal of the TBS and TIPS ethers. This was achieved with TBAF in THF at 0°C to give palmerolide A (28) in 41% yield.

De Brabander’s synthesis of palmerolide A. Reagents and conditions: (1) cat. Pd(PPh3)4, Tl2CO3, THF, H2O, rt, 79%; (2) 29, 2,4,6-trichlorobenzoyl chloride, Et3N, DMAP, PhMe, rt, 69%; (3) PPTS, MeOH, 0°C, 95%; (4) (a) PhI(OAc)2, TEMPO, CH2Cl2 H2O, room temp; (b) K2CO3, 18-C-6, PhMe, 60°C, 70% (two steps); (5) PhH, reflux then 2-methyl-1-propenylmagnesium bromide, −78°C, 76% (two steps); (6) HF·pyr, pyr, THF, rt, 95%; (7) Cl3CC(O)NCO, CH2Cl2, 0°C, Al2O3, room temp, 95%; (8) TBAF, THF, 0°C, 41%

Unfortunately, the spectroscopic data for synthetic palmerolide A (28) was not consistent with that reported for the natural product, and after careful analysis of both the stereochemical assignments for the synthetic material and the natural product, De Brabander and coworkers concluded that the C19 and C20 stereochemistry was likely enantiomeric to that originally proposed by Baker. Synthesis of the proposed structure was achieved from ent-31 (Scheme 11.6), and this provided material 41 that was identical to palmerolide A with the exception of the sign of optical rotation. As such the structure of palmerolide A was reassigned by synthesis to be the enantiomer of 41. Contemporaneous with the work, the Baker group also published a reassignment based on degradative studies [18].

The Nicolaou synthesis of the originally proposed structure for palmerolide A involved Stille cross-coupling of 33 and 34 to produce 42 in 67% yield. Acylation with the mixed anhydride derived from 42 under Yamaguchi conditions followed by a four-step sequence gave the ring-closing metathesis precursor 43 [19], which was then treated with 20 mol% of the second generation Grubbs catalyst, and smooth cyclization at room temperature occurred to give 44 in 76% yield. The synthesis was completed by Pd-catalyzed amidation [20] of the vinyl iodide 44 with 45 to yield 28. As was the case in the De Brabander studies, Nicolaou and co-workers concluded that the correct structure was 41, and a synthesis of this compound was also completed by the same strategy as delineated in Scheme 11.7. The Nicolaou group has continued to study palmerolide A’s chemistry and biology, and palmerolide A also continues to stimulate substantial synthesis activity from other groups [21].

Nicolaou’s synthesis of the originally proposed structure for palmerolide A. Reagents and conditions: (1) 25 mol% Pd(dba)2 Ph3As, LiCl, NMP, 23°C, 67%; (2) 20 mol% Grubbs II cat., CH2Cl2, 23°C, 76%; (3) 45, CuI, Cs2CO3, N,N’-dimethylethylenediamine, DMF, 23°C, 44% based on 36% recovered starting material

2.2 Diazonamide A

The intricate architecture of diazonamide A 46, isolated from Diazona angulata, was first described by Lindquist, Fenical, and Clardy in 1991 (Fig. 11.2) [22]. The initial structure was secured by X-ray crystallography of the related diazonamide B, and synthesis efforts, driven in part by interest in the impressive anti-mitotic activity, quickly followed [23].

A landmark paper by the Harran group disclosed the synthesis of diazonamide A in 2001 [24]. The synthesis, shown in Scheme 11.8, involved an initial macrocyclization of iodide 47 by Heck reaction to produce 48. Protection of the phenol and stoichiometric dihydroxylation using 49 gave diol 50, which underwent pinacol rearrangement upon exposure to p-TsOH to produce aldehyde 51 as a single diastereomer. A 12-step sequence led to 52, and the second macrocycle was formed by a photochemical Witkop reaction to yield 53 as a single atropisomer. Chlorination of the indole and the proximal oxazole produced 54, and a further four steps led to diazonamide A (46). At this juncture it became immediately apparent that the synthesized structure was not the same as natural diazonamide A, especially by comparison of 1H NMR data. On the basis of synthetic work and reinterpretation of the X-ray crystallographic data, Harran proposed that the structure of diazonamide A be revised to 55.

Harran’s synthesis of the original structure proposed for diazonamide A. Reagents and conditions: (1) Pd2(dba)3 (3 mol%), 2-(di-tert-butylphosphanyl)biphenyl (6 mol%), Ag3PO4, THF, 75°C, 82%; (2) t-BuOK, THF, 2-bromoethyltriflate, (3) 49, toluene, −78°C to −25°C, 68% (two steps); (4) TsOH, toluene, 95°C, >54%; (5) hν (300 nm), 0.005 M, LiOAc, epichlorohydrin, CH3CN–H2O, 32–40%; (6) NCS, THF, 32°C, 60%

The newly revised structure of diazonamide A, 55, was ratified by total synthesis in the Nicolaou laboratories only 1 year later (Scheme 11.9) [25]. The synthesis commenced with a Friedel–Crafts alkylation of Cbz-tyrosine methyl ester with 56 to give 57 (after reintroduction of the Boc carbamate). A nine-step sequence led to macrocycle 58, which was then exposed to Gabriel–Robinson cyclodehydration conditions and radical cyclization to give macrocycle 59. Installation of the chlorines followed by selective BOC deprotection and DIBAL-H- initiated ring closure led to intermediate 60. Hydrogenolysis of the Cbz- protecting group and installation of the peptide side chain completed the synthesis of diazonamide A, 55.

Nicolaou’s synthesis of diazonamide A. Reagents and conditions: (1) CbzTyrOMe, p-TsOH, 1,2-DCE; (2) (Boc)2O, aqueous NaHCO3/dioxane, 21% (two steps); (3) POCl3, pyridine; (4) hν, epichlorohydrin, LiOAc, MeCN/H2O, 16% (two steps); (5) NCS, CCl4/THF; (6) TFA; (7) DIBAL-H, THF, 29% (three steps); (8) H2, Pd(OH)2/C; EtOH, (9) EDC, HOBt, NaHCO3, DMF, 82% (two steps)

With the structure of diazonamide A secured by the combined efforts of Harran in pursuit of the originally proposed connectivity and Nicolaou in providing the confirmation of structure by synthesis, more recent efforts have focused on diazonamide as a vehicle for methods development and investigations of the underlying biology. Four further total, or formal, syntheses, have been completed. Key elements of the Harran total synthesis of diazonamide A are shown in Scheme 11.10 [26]. Oxidative cyclization produced 62 in a very direct fashion from compound 61, which was transformed, via a seven-step sequence, to macrocycle 63. The second macrocycle was then formed via Witkop reaction to give bis-macrocycle 64 which was then taken on to diazonamide A via a seven-step sequence. MacMillan completed a total synthesis of diazonamide A in 2011 via use of an organocatalytic conjugate addition of thioester 65 with catalyst 66 to give enal 67 [27]. Enal 67 was then taken through a four-step sequence to give macrocycle 68, which underwent a Kelly-type intramolecular Suzuki coupling to give bis-macrocycle 69. The total synthesis was then completed via addition of the chlorine residues and deprotection to afford diazonamide A.

Both Sammakia and Magnus have completed formal total syntheses that employ interesting and elegant approaches to the C10 quaternary center (Scheme 11.11) [28]. In the case of the Sammakia synthesis, an intramolecular nucleophilic aromatic substitution reaction was used to form the quaternary center at the same time as closing one of the macrocycles (70 → 71). In light of strategic considerations that balance the importance of formation of the macrocycles against the challenges inherent in the diastereoselective formation of the C10 center, this is the most direct solution to date. The Magnus synthesis was highlighted by the rearrangement of 72–73, a process that is formally a Friedel–Crafts reaction.

2.3 Azaspiracid-1

A more complex example of the role of total synthesis in structure correction comes from Nicolaou’s synthesis of azaspiracid-1, a complex alkaloidal polyether first described in 1998 by Takeshi Yasumoto and coworkers [29]. In 2003, Nicolaou and co-workers established by total synthesis [30, 31] that the initially proposed structure for azaspiracid-1 was incorrect (74, Scheme 11.12). Subsequent degradative studies and synthesis were required to revise the structure of azaspiracid-1 [32]. In work described in 2003, upon realizing that there were structural questions remaining to be resolved, the first path was to degrade natural azaspiracid-1 to smaller fragments and then locate the positions of error by synthesis. This approach was also expected to allow the determination of the relative stereochemistry between the ABCDE and FGHI domains. To this end, an authentic sample of azaspiracid was reacted with TMSCHN2 and the methyl ester obtained was treated with NaIO4, which resulted in cleavage of the C20–C21 bond. This provided lactone 75 and aldehyde 76, which were subjected to short sequences of common transformations to yield alcohol 77 (the stereochemistry shown for this compound corresponds to that originally proposed).

Chemical degradation and derivatization of azaspiracid-1 (originally proposed structure) to C1–C20 alcohol 77 and C21–C40 lactone 75. Reagents and conditions: (1) TMSCHN2, MeOH, 25°C; (2) NaIO4, MeOH/H2O (4:1), 25°C, ∼100% over two steps; (3) NaBH4, MeOH, 25°C, ∼90%; (4) 78, 90 mol% [Pd2dba3], LiCl, AsPh3, DIPEA, syringe pump addition of stannane; (5) HF·pyr, THF-pyr; (6) NIS, NaHCO3, THF, 38% (three steps); (7) TBAF, THF, 88%

Synthetic materials for comparison with structures 76 → 77 were prepared by coupling of 78 and 79 by a Pd(0)-mediated Stille coupling to give dihydropyran 80. Removal of the TES ether with HF·pyridine, followed by treatment with N-iodosuccinimide to induce iodoetherification, produced iodoether 81 in 38% yield (for the three steps). Two further steps gave 82 and comparison of the spectral data for this compound with compound 75 showed them to be the same. This established that the structure of the compound obtained by degradation is in fact diastereomeric in terms of the stereochemistry around the E ring to that which was originally proposed. A synthesis of the compound in which the FGHI rings were enantiomeric was also completed by this route, but it did not match the data for 83. These, and related, synthetic studies established the absolute stereochemistry for this domain. The availability of synthetic materials also allowed questions regarding the connectivity and stereochemistry of the ABCD ring-containing domain to be answered. Desilylation of previously synthesized compound 83 to give 84 allowed for a comparison with degradation product 77. The spectroscopic data for these two samples differed substantially, particularly in the A ring. Progress towards a corrected structure was assisted by comparison of NMR data with a related compound, lissoketal (85) [33]. Based on this comparison, a new structure for 77 in which the A-ring double bond has been relocated was proposed; however, final resolution of the problem did not come until the synthesis of several closely related structures had been completed. Based on this work, the stereochemistry and connectivity shown in compound 86 was secured as being correct.

Armed with the information gleaned from these studies, and the earlier synthesis, plans could be laid to complete a total synthesis of the revised structure 87, by employing the key couplings shown in Fig. 11.3.

Key steps of the synthesis are shown in Scheme 11.13. Malic acid–derived tetrahydrofuran 88 was treated with TMSOTf in CH2Cl2 at low temperature to induce the desired deprotection–spirocyclization sequence to give 89 in 89% yield as a single stereoisomer. A sequence of six steps led to allylic carbonate 90, and deoxygenation of this compound to give 91 was achieved by employing a modification of an earlier- described Pd-catalyzed method [34] which produced the desired compound in 82% yield (with 7:1 selectivity for the Δ7,8 olefin). After advancement to pentafluorophenyl ester 92, introduction of the C21–C27 domain involved acylation of the dithiane anion derived from 93 to give 94 in 50% yield. Six further steps provided compound 95 which served as the key precursor to the A → E domain for the final steps of the synthesis. The crucial coupling of the ABCD and FHI subunits occurred by Pd-mediated Stille-type reaction between allylic acetate 95 and dihydropyranyl stannane 96 to give 97 in 55% yield. Removal of the C34 TES ether (TBAF, 80%) and iodoetherification with N-iodosuccinimide produced 98 in an impressive 62% yield given the complexity of the substrate. The synthesis was then completed by a short sequence of six steps that consisted of redox chemistry and protecting group manipulations. Material obtained by this route matched all characterization data for the natural product.

2.4 Palau’amine

The complex hexacyclic architecture of palau’amine (99) has long stood as one of the major challenges of organic synthesis [35]. In 2007, the geometry of the azabicyclo [3.3.0] octane core was determined to be trans 100, rather than the proposed cis [36]. Using this information, Baran and coworkers were able to successfully complete a total synthesis of palau’amine [37]. The synthetic strategy was based on the premise that a “macro palau’amine” could be generated from 101 and an irreversible transannular cyclization would yield the desired target (Scheme 11.14). To prepare 101, Baran converted the cyclopentane core 102 (available in 19 steps) to the hemiaminal 103 in 64% yield, using a selective silver(II)-oxidation protocol. Conversion to the 2-aminoimidazole was achieved by reaction of 103 with cyanamide, and this compound was brominated (Br2, TFA, TFAA) to afford the bromide 104 in 35% yield for the two steps. After initial efforts to introduce an intact pyrrole failed, the key pyrrole 101 was prepared in 44% yield by reacting bromide 104 with amino ester 105 (AcOH, THF), then heating in TFA. Reduction of the azide groups was achieved by reaction with hydrogen gas and palladium acetate, and this was then followed by reaction with EDC to form the macrocycle. Without isolating the material, TFA was added and the solution heated at 70°C to trigger the critical transannular cyclization and generate palau’amine 100 in 17% yield (from 101).

A comprehensive coverage of other examples of the role of synthesis in structure reassignment is not possible here, but some further examples are highlighted in Fig. 11.4. The reader is directed to an excellent review by Snyder and Nicolaou that covers in detail this topic [38].

3 In Pursuit of Nature’s Perfection: Biosynthetic Principles and the Synthesis of Hemibrevetoxin B, Methyl Sarcophytoate, Longithorone, and 11,11′-Dideoxyverticillin

3.1 Hemibrevetoxin B

Much has been made of the proposed biosynthesis of the ladder polyether class via cascade epoxide cyclizations (for a review that also details the alternative Townsend oxidative cyclization process see: [39]), as exemplified for brevetoxin B (113) below in Scheme 11.15. Early work in the field of polyethers took guidance from these ideas, and Nicolaou provided a solution to the problem of the preference for so-called 5-exo vs. 6-endo cyclization manifolds for the cyclization of hydroxy epoxides by incorporation of a proximal alkene (Scheme 11.16a, 114 → 115) [40]. This approach has seen broad application, however more recent results from Jamison have demonstrated the possibility for direct cyclization of hydroxy-poly epoxides 121 and 122 to tris-pyran 123 and tetra-pyran 124 (Scheme 11.16b). These reactions are uniquely possible in H2O as solvent [41].

Nakanishi–Nicolaou hypothesis [110]

Holton’s synthesis of hemibrevetoxin B125 [42] is based partly on these principles and is shown in Scheme 11.17 [43]. The first key union of subunits involved a Negishi coupling between organozinc 126 (Scheme 11.17, prepared from the corresponding iodide, which was in turn prepared from benzyl β-d-arabinopyranoside in 12 steps) and iodide 127 (prepared from tri-O-acetyl-d-glucal via a 13-step sequence), which provided 128 in 75% yield. Lactone hydrolysis with lithium hydroxide, followed by iodolactonization with N-iodosuccinimide, produced iodolactone 130(75%). A sequence of six steps converted 129 to epoxide 130, which upon treatment with N-(phenylseleno)phthalimide underwent cyclization to give polycycle 131 as a single diastereoisomer in 83% yield. This sequence presumably is initiated by electrophilic selenation of the double bond, subsequent epoxonium ion formation, and termination by trapping by the free alcohol. Routine manipulations converted 131 to 132 via a sequence of four steps, and set the stage for formation of the oxepane ring by ring-closing metathesis (Scheme 11.17). Upon exposure of 132 to Grubbs’ second-generation catalyst, in benzene at reflux, ring-closure to yield 133 occurred in 85% yield. A sequence of 11 steps was used to convert 133 to hemibrevetoxin B, 125.

Cascade epoxide cyclization–based biosynthesis of polyethers such as hemibrevetoxin B. Reagents and conditions: (1) 3 mol% PdCl2(dppf), THF, rt, 76%; (2) (a) LiOH, THF–H2O, 0°C; (b) NIS, 2,6-lutidine, –10°C, 75%; (3) N-(phenylseleno)phthalimide, (CF3)2CHOH, 0°C, 83%; (4) 10 mol% Grubbs II catalyst, PhH, 80°C, 85%; (5) (a) NaIO4, Et2O/tBuOH/H2O; (b) (EtO)2P(O)CH2C(O)N(Me)OMe, NaH, THF; (c) H2, 20% Pd(OH)2/C, EtOAc; (d) TMSCl, Et3N, CH2Cl2; (e) DIBAL-H, THF, −78°C, 79% (five steps)

3.2 Methyl Sarcophytoate and Longithorone A

Diels–Alder reactions have repeatedly proven their worth in the area of complex molecule synthesis, and in the cases of some natural products, the application of the Diels–Alder reaction after consideration of potential biosynthetic pathways can lead to the rapid assembly of molecules. Two recent examples are considered here. The synthesis of biscembranoid methyl sarcophytoate (135), which was developed by Nakata and coworkers [44], employs a Diels–Alder reaction between methyl sarcoate and another complex cembrane as the key step (Scheme 11.18). When 136 was heated with 137 in PhMe at 100°C for 1.5 days, the desired adduct 138 was obtained in 22% yield. Removal of the acetonide by treatment with aqueous AcOH completed the synthesis (50% for the final step). Notwithstanding the exact sequencing to reactions (and the use of protecting groups in the case of the laboratory synthesis), it seems likely that this process mimics the likely biogenesis.

The key elements of the Schmidt hypothesis for the biosynthesis of the longithorones were borne out in Shair’s total synthesis of longithorone A (139) [45]. The synthesis highlights the strategic power of “biomimetic” Diels–Alder reactions and the utility of enyne metathesis reactions for the assembly of complex dienes. The key steps of the synthesis are shown in Scheme 11.19.

Shair’s total synthesis of (-)-longithorone A. Reagents and conditions: (1) (a) 30–50 mol% Grubbs I, ethylene, 45°C, >20:1 atropisomer ratio; (b) TBAF, THF, 0°C, 31% (two steps); (2) (a) NaCNBH3, TFA, CH2Cl2, 69% (b) TBSOTf, iPr2NEt, 0°C, 75%; (3) 0.5 eq Grubbs I, ethylene, 31%; (4) (a) TFA, Et3SiH, CH2Cl2, (b) PPTS, EtOH 45°C, 46% (two steps), (c) Dess-Martin periodinane, CH2Cl2, 99%; (5) Me2AlCl, CH2Cl2, –20°C, 70%; (6) (a) TBAF, THF, 0°C, (b) PhI(O), MeCN-H2O, 0°C → 25°C, 90% (two steps)

Enyne 140 underwent enyne metathesis followed by TBS deprotection to give cyclophane 141 with excellent selectivity for the desired atropisomer. Deoxygenation and protection led to diene 142. Alkyne 143 was treated with Grubbs’ catalyst to give diene 144. Ionic hydrogenation, followed by deprotection and oxidation, afforded aldehyde 145. An intermolecular Diels–Alder reaction between diene 142 and enal 145 gave cyclohexene 146. Deprotection followed by transannular Diels–Alder cycloaddition completed Shair’s total synthesis of (-)-longithorone A, 139.

3.3 (+)-11,11′-Dideoxyverticillin A

The dimeric epidithiodiketopiperazine alkaloids, as represented by (+)-11,11′-dideoxyverticillin A (147), are challenging synthetic targets that can be unraveled quickly by consideration of biosynthetic principles. Such an analysis led Movassaghi to a synthesis plan that was based on exploiting the dimerization of radicals 148 (Schemes 11.20) [46].

The dimerization precursor 149 was readily prepared in 58% yield by first reacting diketopiperazine 150 with bromine (MeCN, 0°C), then methylation with methyl iodide and potassium carbonate (Scheme 11.21). Reductive dimerization of 149 with tris(triphenylphosphine)cobalt (I) chloride in acetone gave the dimer 151 in 46% yield. After much experimentation, it was determined that the desired tetraol 152 could be prepared by oxidation with 4.8 equivalents of bis(pyridine)silver(I) permanganate in dichloromethane. This provided the tetraol 152 as a single diastereomer in an impressive 63% yield. However, it was found that 152 was highly acid and base sensitive, and while it could be transformed into the target molecule, it was a low-yielding process. It was discovered that these difficulties could be overcome by conversion to the diol 153. This was prepared in 55% yield by selective protection using t-butyldimethylsilyl chloride and 5 mol% of Fu’s PPY catalyst [47]. Reaction with potassium trithiocarbonate and trifluoroacetic acid, followed by addition of ethanolamine gave a tetrathiol 154, which could be readily converted to the target molecule by reaction with potassium triiodide. This impressive sequence proceeded in 35% overall yield. Clearly, the success of this strategy suggests that the proposed biosynthetic sequence is plausible.

Movassaghi’s synthesis of (+)-11,11′-dideoxyverticillin. Reagents and conditions:(1) Br2, MeCN, 0°C, 76%; (2) MeI, K2CO3, acetone, rt, 77%; (3) CoCl(PPh3)3, acetone, rt, 46%; (4) Py2AgMnO4, CH2Cl2, rt, 63%; (5) TBSCl, 5 mol% PPY, NEt3, DMF, rt, 55%; (6) 5% Na(Hg), NaH2PO4, MeOH, rt, 87%; (7) K2CS3, TFA, CH2Cl2, rt, 56%; (8) HOCH2CH2NH2, acetone, rt, then KI3, pyridine, CH2Cl2, rt, 62%

4 New Reactions and New Strategies: Azaspiracid-1, Amphidinolide A1, Bryostatin 16, Ningalin B, and Cyanthiwigins U and F

4.1 Azaspiracid-1

Complex natural products such as the azaspiracids have also served as excellent vehicles for the development and application of new synthetic methods. Subsequent to the Nicolaou synthesis, Evans reported a total synthesis of (+)-azaspiracid-1 (155 the enantiomer of the natural product) [48]. An overview of the synthesis plan is shown in Scheme 11.22, and ultimately the key building blocks can be traced to compounds 158, 159, and 160. This plan called for the preparation of these compounds by Sn(II)- and Cu(II)-catalyzed asymmetric reactions that are part of a suite of powerful methods developed in the Evans group in the period 1990–2010, and azaspiracid-1 was expected to provide a worthy testing ground for the utility of these reactions in complex molecule synthesis.

Access to the ketone 161 was achieved in 13 linear steps, starting with an asymmetric Mukaiyama aldol reaction of (silyloxy)furan 162 with N-phenyl glyoxamide (163), in the presence of 10 mol% of chiral Sn2+ complex 164 (Scheme 11.23). This reaction afforded the lactone 165 in 67% yield and >99% ee after recrystallization, and was followed by reduction of the double bond using Crabtree’s catalyst [49] to give 166. Transformation of this material to the required aldehyde 161 was achieved in a further 12 steps. Ketone 167 and aldehyde 168 could be accessed from the same intermediate, chiral tetrahydropyran 165. The initial step of the sequence used to prepare 170 was the hetero Diels–Alder cycloaddition between 171 and 172 in the presence of Cu2+ complex 173 to give 174 in 84% yield and with excellent control of enantio- and diastereoselectivity. Simple reduction over Pd/C with H2 gave 170, and access to the E-ring fragment 167 from 170 was achieved by firstly forming the lactol thioether 175, then epimerization of the ester substituent with potassium t-butoxide. This epimerization provides a tetrahydropyran with all four substituents equatorial. Reduction of the ester group with DIBAL-H afforded the aldehyde 168. To access the third fragment required for the synthesis of EFGHI sulfone, the chiral tetrahydropyran 170 was transformed to the tosylate 169 via a four-step sequence as detailed in Scheme 11.26. The tosylate was then converted to the desired HI-ring fragment 167 by Wacker oxidation and azide displacement.

Evans’ synthesis of key building blocks for azaspiracid-1. Reagents and conditions: (1) 10 mol% 164, CH2Cl2, –78°C, 67% after recrystallization (>95% ee); (2) H2,2 mol% [(cod)Ir(PCy3)(py)]PF6, CH2Cl2, 98%; (3) 2 mol% 173, 3 Å MS, Et2O, –40°C, 84%; (4) H2, Pd/C, EtOAc, 95% of 170; (5) PhSH, BF3.OEt2, CH2Cl2, –20°C, 83%; (6) t-BuOK, THF, –50°C, 88% (d.r. 96:4); (7) DIBAL-H, toluene, –94°C → –78°C, 93%; (8) Et3SiH, BF3•OEt2, CH2Cl2, 0°C, 91%; (9) LiAlH4, Et2O, 0°C, 91%; (10) I2, PPh3, imid., CH3CN/benzene, rt → 60°C, 94%; (11) t-BuLi, THF, –78°C, then TsCl, –78°C → 0°C, 95%; (12) O2, PdCl2, CuCl, H2O, DMF, 89%; (13) NaN3, DMSO, 50°C, 98%

With access to all the required fragments, attention was focused on fragment assembly by a series of aldol couplings (Scheme 11.24). First, ketone 167 and aldehyde 161 were coupled together using a chelate-controlled Mukaiyama aldol addition of enolsilane 176 with the aldehyde 161 in the presence of freshly prepared MgBr2.OEt2 to give the desired compound 177 as a single diastereomer in 93% yield. The second aldol coupling employed a boron-mediated aldol reaction between 172 and aldehyde 168 to give aldol adduct 178 as an inconsequential 60:40 mixture of diastereomers. Removal of the TBS ethers by aqueous HF in acetonitrile also resulted in cyclization to afford the FG bicyclic ketal as mixture of diastereomers. This mixture was oxidized with Dess–Martin periodinane to afford ketone 179. At this juncture removal of the PMB ether with DDQ and reduction of the azide led to formation of the HI spiroaminal system 180 in 77% yield for the two steps. This ketone 180 was transformed to the desired EFGHI sulfone 181 and was methylenated using Tebbe’s reagent in the presence of pyridine. Oxidation of the sulfide was carried out in the presence of pyridine to ensure that the sulfur group was not lost. With the assembly of the EFGHI sulfone 181, the synthesis of azaspiracid-1 was almost complete. Coupling of the two major fragments was achieved by deprotonation of the sulfone 181 with n-BuLi, then addition of the aldehyde 182. Quenching at –78°C with pH5 buffer afforded a near 1:1 mixture of lactol diastereomers, 183 and 184, in 50% overall yield. Fortunately, the diastereomers are separable by chromatography and the undesired alcohol 183 could be transformed to the desired material 184 by oxidation under Swern conditions and diastereoselective reduction. Removal of the silyl protecting groups and a two-step oxidation of the C1 terminus provided (+)-azaspiracid-1 (155). The convergent approach allows the synthesis to proceed in just 26 linear steps, providing a nice example of complex molecule synthesis underpinned by powerful new asymmetric methods for the preparation of building blocks.

Evans’ synthesis of the EFGHI sulfone fragment of (+)-azaspiracid-1 and completion of the synthesis. Reagents and conditions: (1) LiHMDS, TMSCl, Et3N, THF, –78°C, 89%; (2) MgBr2 OEt2, CH2Cl2, 0°C, 93%; (3) Cy2BCl, iPr2NEt, CH2Cl2, –78°C, then 168, –78°C → 0°C; (4) HF, H2O, CH3CN, 0°C, 92% (two steps); (5) Dess-Martin periodinane, pyr., CH2Cl2, 85%; (6) DDQ, pH 7 buffer, CH2Cl2, 0°C; (7) H2, Pd/C, THF, 77% (two steps); (8) 181, n-BuLi, –78°C, then 182, NaOAc/AcOH buffer, –78°C → rt, 27% of 183 and 23% of 184; (9) (COCl)2, DMSO, Et3N, CH2Cl2, –78°C → –20°C, 60%; (10) LiBH4, CH2Cl2, –40°C, 56%

4.2 Amphidinolide A1

The amphidinolides have proven themselves a fertile environment for the development of new methods and strategies and, at the same time, have provided many instances of where synthesis has been able to assist in the structure assignment. This has always been a challenging task for this class in large part due to the minute amounts of material that are often initially isolated. The story of (+)-amphidinolide A1 [50] is noteworthy in this context as an example of the value of synthesis to the structure elucidation of complex marine natural products (Scheme 11.25). Kobayashi’s initially proposed structure 185 was synthesized in 2002 in independent efforts by the groups of Trost [51], Pattenden [52], and Maleczka [53]. None of these efforts however produced material that matched the reported data which suggested that there were questions regarding the stereochemistry of the molecule remaining to be answered. This puzzle was solved in 2004 by Trost and Harrington when they described the structure elucidation of (+)-amphidinolide A1 (186) by a combination of total synthesis and NMR analysis [54] (Scheme 11.25).

The synthesis highlights Trost’s new methodology for the construction of 1,4-dienes by the Ru-catalyzed coupling of alkenes and alkynes (Scheme 11.25) [55].The first subunit coupling was achieved by reaction of 188 with 189 in the presence of Cp*Ru(MeCN)3PF6 as catalyst was employed. This catalyst provided the branched product 190 in 23% yield (39% yield based on recovered starting material). A straightforward sequence of three steps provided acid 191 which was coupled to the potentially sensitive epoxy alcohol 192 under Kita’s conditions [56] to give ester 193 in 51% yield. After removal of the triethylsilyl ethers with TBAF–AcOH, [Cp*Ru(MeCN)3]PF6-catalyzed macrocyclization of 194 provided amphidinolide A1, 186. Although the yield may seem modest (33% or 38% based on recovered starting material), this is an impressive example of the remarkable selectivity of the Ru-catalyzed alkene–alkyne addition. The spectral data for synthetic material matched very well to the natural product with only two protons deviating from that reported by greater than 0.01 ppm (the two deviations were by 0.03 ppm and by 0.02 ppm), the 13C NMR spectrum deviated by 0.1 ppm or less in CDCl3, J values in three solvents were also in agreement, and the optical rotation was also consistent with reported data (synthetic [α]] 24D +56° (c 0.05, CHCl3) cf. reported [α]] 24D +46° (c 1.0, CHCl3)). Even with these excellent comparisons, in the absence of authentic material for comparison, Trost and Harrington conclude their paper with guarded comments:

In conclusion, we have employed a combination of synthesis and NMR spectroscopy as tools to determine the correct structure of amphidinolide A1. Although the lack of a sample of the natural product prevents a definitive comparison, the excellent correlation [of our synthetic compound] strongly suggests it is (+)-amphidinolide A1.

4.3 Bryostatin 16

The bryostatin family of macrolides have attracted significant attention over the years since the initial description of bryostatin 1 by Pettit and Clardy [57]. Synthetic highlights include five total syntheses [58], the development of a detailed pharmacophore model [59], and the preparation of much simplified functional analogs [60]. Here we highlight the total synthesis of bryostatin 16 (195) by Trost and Dong [39], which employs a number of new(er) transition metal–catalyzed reactions and underscores the value of new reactions in the arena of target synthesis: the longest linear sequence is only 26 steps. As detailed in Scheme 11.26, it was envisaged that the macrocycle could be formed from 196 using a palladium-catalyzed alkyne–alkyne coupling, followed by a metal-catalyzed 6-endo-dig cyclization. The key substrate 196 would be assembled from the fragments 197, 198, and 199.

A chemoselective ruthenium-catalyzed tandem alkene-alkyne coupling/Michael addition (13 mol% CpRu(MeCN)3PF6, DCM) was used to form the cis-tetrahydropyran 200 in 34% yield (80% based on recovered starting material) (Scheme 11.27). Although modest in its conversion, the strategic power of this reaction for subunit assembly is impressive. The macrocycle 202 was generated in 56% yield by reaction of 201 with 12 mol% of palladium acetate and 15 mol% tris(2,6-dimethoxyphenyl)phosphine in PhMe at room temperature. It was found that the reaction had to be run at low concentration (0.002 M) and that the choice of solvent and the ligand/palladium ratio were critical to the success of the reaction. Treatment of the resulting alcohol 202 with a cationic gold catalyst (Au(PPh3)SbF6, NaHCO3) initiated a 6-endo-dig cyclization and afforded the desired ring system in 73% yield. After pivalation of the secondary alcohol to give macrocycle 203, efforts focused on the global deprotection to afford bryostatin 16. After some experimentation, it was found that treatment of 203 with five equivalents of tetrabutylammonium fluoride gave bryostatin 16, 195, in 52% yield.

4.4 Ningalin D

Complex alkaloids such as ningalin D (204) present substantial challenges for synthesis, and although cross-coupling chemistry is a dominant strategy for polyaromatic compounds, Boger has showcased the utility of alternative methods to produce an essentially ideal synthesis. In this case he completed a nine-step synthesis of ningalin D (204), which proceeds in 19% overall yield [61] (Scheme 11.28). The tetrasubstituted pyrrole 205 was rapidly assembled by firstly utilizing an inverse electron demand heterocyclic azadiene Diels–Alder reaction between symmetrical alkyne 206 and readily available tetrazine 207 to give symmetrical 1,2-diazine 208 in 87% yield. Reaction with 30 equivalents of zinc in trifluoroacetic acid at room temperature leads to cleavage of the diazine ring, followed by in situ cyclization to generate the pyrrole 205 in 64% yield. After alkylation of 205, the aryl C and D rings were formed by double Dieckmann condensation by reaction with NaH in DMF at room temperature. The resulting diphenol 209 was triflated, and the F and G aryl rings were attached via a double Suzuki coupling with boronic acid 210. Efforts to convert 211 into ningalin D were hampered by the steric congestion of the esters. However, hydrolysis of 211 with anhydrous hydroxide, followed by a modified Curtius rearrangement, afforded permethylated ningalin D 212 in a remarkable 70% yield. Clearly, the expected diamine was oxidized in situ and the resulting imines were hydrolyzed upon workup to generate the desired biphenylene quinone methide system. The ten methyl ethers were removed by reaction of 212 with 15 equivalents of BBr3 to provide ningalin D, 204, in 96% yield.

The Boger synthesis of ningalin B, 204. Reagents and conditions: (1) toluene, 110°C, 87%; (2) Zn, TFA, rt, 64%; (3) 3,4-dimethoxyphenyl ethyl iodide, CsCO3, DMF, 60°C, 92%; (4) NaH, DMF, 25°C, 81%; (5) Tf2O, pyridine-CH2Cl2, 0°C → 5°C, 92%; (6) (PPh3)4Pd, LiCl, 1 M aq. K2CO3-DME, 80°C, 88%; (7) t-BuOK, H2O, DMSO, 80°C, 84%; (8) DPPA, iPr2NEt, CH2Cl2, 25°C; then H2O, THF, air, reflux, 70%; (9) BBr3, CH2Cl2, –78°C → rt, 96%

4.5 Cyanthiwigins U and F

The cyanthiwigin family of diterpenoids have stimulated the development of new methods and strategies (for a review see, [62]). For example, the Phillips–Pfeiffer synthesis of cyanthiwigin U (213) employed an efficient tandem metathesis reaction to convert bridged bicycle 214 into fused tricycle 215 in >43% yield (Scheme 11.29) [63]. Reduction of the more electrophilic carbonyl group with LAH gave 216, and addition of isopropyllithium to the other carbonyl group gave bis-allylic alcohol 217. Pyridinium chlorochromate oxidation resulted in formation of the cycloheptenone and, at the same time, gave Dauben oxidative transpostition of the cyclopentenol to provide 218. Simple addition of methyllithium completed the synthesis.

In a similar vein, Stoltz and Enquist completed a total synthesis of cyanthiwigin F (219) that was underpinned by reaction development (Scheme 11.30) [64]. Earlier studies into the asymmetric Tsuji decarboxylative allylation reaction [65] had provided a method for the conversion of 220 into 221 by treatment with catalytic Pd(0) in the presence of phosphino-oxazoline 222. Subsequent enol-triflation and cross-coupling with the organozinc derived from iodide 223 gave 224 and set the stage for a ring-closing metathesis with Grubbs–Hoveyda catalyst (second generation) and simultaneous cross metathesis of the other olefin with vinylboronate 225. An oxidative workup gave aldehyde 226 in 51% yield. Radical cyclization proceeded smoothly to produce tricyclic compound 227, which could be advanced to cyanthiwigin F (219) by conversion of the cyclopentanone ring to the enol triflate and cross coupling with i-propylmagnesium chloride.

Stoltz’s total synthesis of cyanthiwigin F. Reagents and conditions: (1) 222, Pd(dmdba)2, Et2O,78%; (2) (a) KHMDS, PhN(Tf)2, THF; (b) 223, Zn, TMSCl, 1,2-dibromoethane, THF; Pd(PPh3)4, 57% (two steps); (3) Grubbs-Hoveyda II, 225, PhH; NaBO3, THF/H2O 51%; (4) t-BuSH, AIBN, PhH, 57%; (5) (a) KHMDS, PhN(Tf)2, THF; (b) i-PrMgCl, CuCN, THF, Pd(dppf)Cl2, 38% (two steps)

5 At the Edges of the Known Universe of Molecular Complexity

The marine environment produces some remarkably complex structures, and these compounds have in turn stimulated tremendous efforts in total synthesis. In this section we briefly highlight the synthesis of ladder polyethers, but in advance of doing so we present four molecules that represent substantial complexity in Fig. 11.5. All of these molecules are accessible by synthesis: ciguatoxin CTX3C (227) was made by Hirama and Inoue in 2001 [66]; palytoxin (228) by Kishi and Suh in 1994 [67]; norhalichondrin B (229) by Kishi (1992) [68] and Phillips (2009) [69]; and phorboxazole A (230) by Forsyth (1999) [70], Smith (2001) [71], Williams (2003) [72], Pattenden (2003) [73], and White (2006) [74].

The Nicolaou group was one of the first to engage in synthetic studies directed toward the ladder polyethers, and among the many total syntheses from the group in this area there has been a significant amount of reaction discovery and development, which we briefly highlight here (Scheme 11.31). For example, the formation of cyclic ethers by thiohemiacetal formation (231 → 233) and reductive removal of the sulfur to give structures of type 234 has seen widespread use by many groups. An especially creative solution to the formation of bis-oxepane rings is the reductive cyclization of dithionolactones (235 → 236) and their subsequent conversion to 238 by desulfurization and hydrogenation [75].

Early technologies from Nicolaou for complex ladder polyether synthesis. (a) Reductive etherifications, and (b) formation of bis-oxepanes by reductive coupling of dithionolactones. Reagents and conditions: (1) AgNO3, NCS, SiO2, 2,6-lutidine, CH3CN, 3 Å MS, 92%; (2) Ph3SnH, AIBN, PhCH3, 110°C, 95%; (3) sodium naphthalenide, THF, –78°C; MeI, 80%; (4) nBu3SnH, AIBN, PhCH3, heat, 99%; (5) H2, Pd(OH)2, EtOAc, 70%

Elements of the methods described above were employed in Nicolaou’s first total synthesis of brevetoxin B (113), the closing steps of which are shown in Scheme 11.32 [76]. Subunit coupling by Wittig reaction between phosphonium salt 239 and aldehyde 240 gave 241 after removal of the TMS ether. Reductive etherification by the two-step approach outlined above gave 242 in an impressive 85% yield, and the synthesis was completed in five further steps.

More recently, Sasaki and coworkers have completed a synthesis [77] of gymnocin A (243), a polyether toxin from the red tide dinoflagellate Karenia mikimotoi [78]. The total synthesis employed some daring applications of their earlier-developed method for polyether synthesis based on a β-alkyl Suzuki–Miyaura coupling followed by hydroboration and reductive etherification as the key strategy for subunit couplings. The key steps involved in the assembly of the complete A → N ring system are summarized in Scheme 11.33. Hydroboration of complex enol ether 244 with 9-BBN to give borane 245 is followed by cross-coupling with nonacyclic enol triflate 246 in the presence of Pd(PPh3)4 to give 247. Given the very high complexity of the substrates, the yield for this reaction is a remarkable 81%, and should serve to underscore the power of contemporary cross-coupling reactions in complex settings. Conversion of 247 to the precursor for acetal formation was achieved by a four-step sequence: (a) hydroboration-oxidation, (b) protection as the triethylsilyl ether, (c) removal of the p-methoxybenzyl ether, and (d) oxidation to produce ketone 248 (56% overall yield for four steps). Treatment of 249 with ethanethiol in the presence of Zn(OTf)2 provided the desired thioacetal 250 in 40% yield along with 38% of thioacetal 251 in which one of the tert-butyldimethylsilyl ethers had been removed. This compound was readily resilylated to produce 250. Reductive desulfurization under radical conditions with AIBN and triphenylstannane converted the thioacetal into the desired ether 252 in an impressive 98% yield. Compound 252, which contains the complete A → N ring system, was converted to gymnocin A, 243, by an eight-step sequence.

Closing steps of Sasaki’s total synthesis of gymnocin A. Reagents and conditions: (1) 9-BBN, THF, rt; (2) 245+ 246, 3 M Cs2CO3, Pd(PPh3)4, DMF, rt, 81%; (3) BH3·SMe2, THF, 0°C → rt then NaOH, H2O2, 75%; (4) (a) TESOTf, 2,6-lutidine, CH2Cl2, rt, (b) DDQ, CH2Cl2, pH 7 phosphate buffer, 0°C, 79% (two steps); (5) TPAP, NMO, 4 Å MS, CH2Cl2, rt, 95%; (6) (a) LiHMDS, TMSCl, Et3N, THF, –78°C, (b) OsO4, NMO, THF–H2O, rt, (c) TIPSOTf, 2,6-lutidine, CH2Cl2, rt, 85% (three steps); (7) EtSH, Zn(OTf)2, MeNO2, 0°C → rt, 40% 252, 38% 251; (8) TBSOTf, 2,6-lutidine, CH2Cl2, rt, 71%; (9) Ph3SnH, AIBN, PhMe, 110°C, 98%

6 Gram-Scale Synthesis: Moving Toward Realistic Supply of Compounds for Preclinical Evaluation

One of the major challenges of marine natural products is the limited supplies available from the natural source, which often stymies further investigation into the biological properties. Many marine natural products cannot be evaluated as clinical agents due to these limited supplies, and the development of a practical synthetic route is absolutely critical to the further development of such compounds.

One of the best examples of the value of total synthesis in providing realistic supplies of a natural product is discodermolide, 253, which is a biologically active polyketide isolated in just 0.002 wt.% from the marine sponge Discodermia dissoluta [79]. The potent biological activity, coupled with the scarce supply from its natural source, has triggered intense activity in the total synthesis community [80]. Schreiber’s group reported the first total synthesis, which confirmed the relative stereochemistry and established the absolute configuration [81]. As summarized in Fig. 11.6, his retrosynthetic analysis gave three key fragments, 254, 255, and 256, with a Nozaki–Kishi coupling and an enolate alkylation being the critical bond-forming steps.

Since this work, a further 11 total syntheses have been reported from the academic groups of Smith [82], Paterson [83], Myles [84], Marshall [85], Panek [86], and Ardisson [87]. Of these syntheses, the groups of Smith and Paterson having refined their initial efforts and have reported fourth and third generation syntheses, respectively. As illustrated in Scheme 11.34, Smith’s group utilized a Wittig reaction (C8–C9) and a Negishi cross-coupling (C14–C15) to assemble his key fragments, which allowed the generation of discodermolide in 9% overall yield and 17 steps for the longest linear sequence. While Paterson’s initial syntheses had used boron aldol couplings, the difficulties of scale-up led his group to develop a third-generation synthesis where a Still–Gennari olefination was utilized. This resulted in an improved overall yield of 11.1%.

The advances made by these academic syntheses, in particular the efforts by the groups of Smith and Paterson, led Novartis to proceed with a total synthesis that could be carried out on an industrial scale so that over 60 g of discodermolide could be prepared [88]. This synthesis can be viewed as a hybrid of Smith and Paterson’s routes, using the Paterson β-aldol disconnection at C6–C7 and the Smith–Marshall cross-coupling at C14–C15 as the key assembly steps. The three key fragments (257, 258, 259) are generated from the common precursor, 260, originally reported by Smith. The synthesis proceeded in 25 steps (longest linear sequence) and 1.1% overall yield (Scheme 11.35). The common precursor 260 was prepared in three steps from the readily available aldehyde 261 and propionimide 262 and allowed the generation of 29 kg of material. As summarized in Scheme 11.35, 263 can be transformed into each of the key fragments (257, 258, 259), using routes related to Smith’s syntheses. While Smith had used a Negishi cross-coupling to generate 264 from iodides 258 and 259, the Novartis group chose to use a Suzuki cross-coupling, as originally reported by Marshall. Thus, iodide 259 was converted to the borane and coupled with iodide 258 using Pd(dppf)2Cl2 as the catalyst. This key reaction proceeded in 73% yield on kilogram scale. To complete the synthesis, the Novartis group decided to utilize the endgame developed by Paterson. Accordingly, 264 was transformed into enal 265 in a nine-step sequence, with only two chromatographic separations required. After extensive experimentation, a reagent-controlled boron aldol coupling of aldehyde 265 and ketone 257, using (+)-Ipc2BCl, gave 67 g of the aldol product 266 (50–55% yield). An Evans-Saksena reduction (Me4NBH(OAc)3, 73% yield) generated the C5-stereocenter stereoselectively and treatment with 3 N HCl was used to achieve global deprotection and lactonization and afforded discodermolide (253). This remarkable synthesis allowed the generation of 64 g of discodermolide, which allowed Novartis to initiate clinical trials. Unfortunately, toxicity issues have meant that these trials were discontinued [89].

Other complex marine natural products where “gram-scale” synthesis has provided materials for further evaluation include spongistatin (267) [90–96], kapakahines(268),(269)[97, 98],and iejimalide B (270) [99] (Fig. 11.7).

7 Supply by Synthesis: The Arrival of Halaven® and Yondelis® in the Clinic

In 2007, trabectedin (or ET-743, 271), under the brand name Yondelis®, was approved in the European Union for the treatment of soft tissue sarcoma, becoming the first marine natural product to be used in the treatment of cancer. It was originally isolated from the colonial ascidian Ecteinascidia turbinata and biological investigations revealed that it was a potent anti-cancer agent [100]. While aquaculture was initially used by PharmaMar to generate quantities of the compound for pre-clinical evaluation, the low yield, just 1 g being obtained from 1 t of ascidian, meant that this strategy would not be viable economically [101]. Thus, it was realized that an efficient, practical synthesis was the only realistic way that trabectedin could be supplied to the clinic.

The first total synthesis was developed by Corey and coworkers in 1996 and involved generation of the ten-membered lactone 272 via the trapping of a quinone methide intermediate as a key step (Scheme 11.36) [102]. Overall, the synthesis proceeded in 36 steps with a yield of 0.72%. Further work by Corey’s group led to an enhancement in the overall yield (2.04%) but no reduction in the step count [103].

The synthesis provided an avenue for the generation of more material, but it was recognized by PharmaMar that the scale-up of this synthesis would be difficult. Using the key design principles of the Corey synthesis, they developed an efficient semi-synthesis from cyanosafracin B (277), which is readily available from fermentation from the bacteria Pseudomonas fluorescens [104]. As illustrated in Scheme 11.37, they were able to transform cyanosafracin B (277) into the alcohol 279 in 12 steps and 6% overall yield. Alcohol 279 can then be transformed into the quinone methide precursor 280 in three steps, using the protocols developed by Corey. The end game of the semi-synthesis was based on Corey’s work, with some key changes in the protecting groups used and the ordering of the steps. Conversion to ten-membered lactone 282 was achieved in 58% yield, using the one-pot protocol developed by Corey. In contrast to Corey, the MOM and Troc protecting groups were removed first. The required α-keto lactone was generated in 57% yield using Corey’s transamination protocol (4-methylpyridinium-4-carboxaldehyde iodide, DBU, (CO2H)2). To complete the synthesis, the final tetrahydroisoquinoline system was introduced using a diastereoselective Pictet–Spengler condensation with 5-(2-aminoethyl)-2-methoxyphenol (283) in the presence of silica gel in 90% yield, and then, the nitrile group was substituted using silver nitrate in acetonitrile and water to afford trabectedin (271) in 90% yield. Overall, the semisynthesis requires 21 steps and proceeds in 0.96% overall yield. More importantly, it can be carried out on an industrial scale and is being used to provide the clinical supply of Yondelis®.

The PharmaMar semi-synthesis of trabectedin (Yondelis®). Reagents and conditions: (1) (a) TrocCl, pyridine, CH2Cl2; (b) MOMBr, i-Pr2NEt, DMAP, CH3CN; (c) Zn, aq AcOH; (d) NaNO2, AcOH, THF, H2O, 36% (four steps); (2) (a) 281, EDC.HCl, DMAP, CH2Cl2; (b) Bu3SnH, (PPh3)2PdCl2, AcOH, CH2Cl2; (c) (PhSeO)2O, CH2Cl2; 78% (three steps); (3) DMSO, Tf2O, CH2Cl2; i-Pr2NEt; t-BuOH; (Me2N)2 C = N-t-Bu; Ac2O, 58%; (4) (a) TMSCl, NaI, CH2Cl2, CH3CN; (b) Zn, aq AcOH; (c) [N-methylpyridinium-4-carboxaldehyde]I, DBU, (CO2H)2; (d) 283, silica gel, EtOH; (e) AgNO3, CH3CN, H2O, 36% (five steps)

Other groups have been active in the area, with the groups of Fukuyama [105] and Zhu [106] each reporting total syntheses. Danishefsky [107] and Williams [108] have also reported formal syntheses, intersecting with key intermediates in the Fukuyama synthesis.

In 1992, samples of synthetic halichondrin B (284) and several intermediates were provided by the Kishi group to the Eisai Research Institute (Andover, MA) with a goal of evaluating in vitro and in vivo activity. In a significant discovery, the C1–C38 diol 285 was found to have a substantial fraction of the activity observed for the parent halichondrin B (Scheme 11.38) [109]. Evolution of this compounds ultimately produced E7389, eribulin mesylate (286), which was approved as a treatment for refractory breast cancer in November 2010 by the United States FDA.

The Eisai synthesis of eribulin mesylate (286) employs much of the technology laid down in Kishi’s studies on norhalichondrin B and halichondrin B (for a review see [110]). We pick up the synthesis here at the point of subunit couplings: Nozaki–Hiyama–Kishi coupling of aldehyde 287 with vinyl iodide 288 and subsequent base-induced cyclization provided a 3:1 mixture of C27 diastereomers favoring the desired product (Scheme 11.39). The PMB ether was then removed to yield 289, at which point the diastereomers were separable. Alcohol 289 was converted to sulfone 290 in four steps. Deprotonation of 290 with n-BuLi, followed by addition to aldehyde 291 and oxidation gave 292. Removal of the sulfone group with samarium (II) iodide, Nozaki–Hiyama–Kishi macrocyclization, and allylic alcohol oxidation gave enone 293. Exposure of 293 to TBAF buffered with imidazole hydrochloride, followed by PPTS in CH2Cl2, installed the polycyclic ketal domain, and the product 294 could be converted to eribulin mesylate by selective mesylation of the terminal alcohol and then aminolysis with NH3 in EtOH. While current demand for clinical supply of Halaven is unknown, it is clear that Eisai’s route has the capacity to provide multi-hundred-gram batches of API. Subsequent to regulatory approval by the FDA, Halaven has been approved for use in Singapore, Japan, and the European Union.

The Eisai synthesis of eribulin mesylate (Halaven®). Reagents and conditions: (1) 0.5% NiCl2/CrCl2, 4:1 THF-DMF; (2) KHMDS, THF; (3) DDQ, CH2Cl2, aqueous buffer, 44% (three steps); (4) n-BuLi, then 291; (5) Dess-Martin periodinane, 82% (two steps); (6) SmI2, THF-MeOH; (7) 1% NiCl2/CrCl2, 4:1 THF-DMF; (8) Dess-Martin periodinane, 60% (three steps); (9) TBAF, imidazole.HCl; (10) PPTS, CH2Cl2, 90% (two steps); (11) MsCl, collidine, 90%; (12) EtOH saturated with NH3, MsOH (five equiv), 93%

8 Conclusions and Future Perspectives

In this chapter, we have provided an overview of marine natural products synthesis that highlights some of the long-held rationales for the endeavor as well as the interplay between methods and strategy development in the context of challenging structures. These agendas will remain central to the science of synthesis, but the development of “gram-scale” syntheses and the arrival of Yondelis® and Halaven® in the clinic have ushered in an era in which synthesis may well be able to provide material that can address problems in human health.

9 Study Questions

-

1.

In Scheme 11.2, Kishi uses a series of stereoselective processes to prepare tetrodotoxin. Provide a stereochemical rationalization of the following reactions: (a) The conversion of 9 to 10 and (b) The conversion of 11 to 12.

-

2.

The Witkop reaction has been used by researchers to prepare the macrocycle of the diazonamide structure. Provide a mechanism for this reaction.

-

3.

In Baran’s synthesis of palau’amine, he generates the pyrrole 101 by reaction of bromide 104 and amino ester 105. Provide a mechanism for this transformation.

-

4.

Phillips’ synthesis of cyanthiwigin U involves the conversion of bicylic compound 214 to tricyclic compound 215. Provide a mechanism.

-

5.

Provide a mechanism for the intramolecular enyne metathesis that converts 140 to 141 in Shair’s synthesis of longithorone A.

-

6.

Evans uses a chelate-controlled Mukiyama aldol reaction to generate 177. Provide a stereochemical rationale for the formation of 177 as a single diastereomer.

-

7.

Boger’s synthesis of ningalin D generates a tetra-substituted pyrrole 208 in two steps, from 206 to 207. Provide a mechanistic rationale for each synthetic step.

References

(a) Corey EJ, X-M Cheng (1995) The logic of chemical synthesis. Wiley-Interscience, New York; (b) Nicolaou KC, Sorensen EJ (1996) Classics in total synthesis: targets, strategies, methods. Wiley-VCH, Weinheim; (c) Nicolaou KC, Snyder SA (2003) Classics in total synthesis II: more targets, strategies, methods. Wiley-VCH, Weinheim; (d) Nicolaou KC, Chen JS (2011) Classics in total synthesis III: further targets, strategies, methods. Wiley-VCH, Weinheim

(a) Morris JC, Nicholas GM, Phillips AJ (2007) Marine natural products: synthetic aspects. Nat Prod Rep 24:87–108; (b) Morris JC, Phillips AJ (2008) Marine natural products: synthetic aspects. Nat Prod Rep 25:95–117; (c) Morris JC, Phillips AJ (2009) Marine natural products: synthetic aspects. Nat Prod Rep 26:245–265; (d) Morris JC, Phillips AJ (2010) Marine natural products: synthetic aspects. Nat Prod Rep 27:1186–1203; (e) Morris JC, Phillips AJ (2011) Marine natural products: synthetic aspects. Nat Prod Rep 28:269–289; (f) Nicholas GM, Phillips AJ (2006) Marine natural products: synthetic aspects. Nat Prod Rep 23:79–99

Scheuer PJ (1994) Tetrahedron perspective number 2: ciguatera and its off-shoots – chance encounters en route to a molecular structures. Tetrahedron 50:3–18

Moore RE, Scheuer PJ (1971) Palytoxin: a new marine toxin from a coelenterate. Science 172:495–498

Shimomura O, Goto T, Hirata Y (1957) Crystalline Cypridina luciferin. Bull Chem Soc Jpn 30:929–933

(a) Kishi Y, Goto T, Hirata Y, Shimomura O, Johnson FH (1966) Cypridina bioluminescence I: structure of Cypridina luciferin. Tetrahedron Lett 3427–3436; (b) Kishi Y, Goto T, Eguchi S, Hirata Y, Watanabe E, Aoyama T (1966) Cypridina bioluminescence II structural studies of Cypridina luciferin by means of a high resolution mass spectrometer and an amino acid analyzer. Tetrahedron Lett 7:3437–3444; (c) Kishi Y, Goto T, Inoue S, Sugiura S, Kishimoto H (1966) Cypridina bioluminescence III total synthesis of Cypridina luciferin. Tetrahedron Lett 7:3445–3450

White EH, Karpetsky TP (1971) Unambiguous synthesis of Cypridina etioluciferamine. Application of titanium tetrachloride to the synthesis of pyrazine N-oxides. J Am Chem Soc 93:2333–2335

(a) Goto T, Kishi Y, Takahashi S, Hirata Y (1965) Tetrodotoxin. Tetrahedron 21:2059–2088; (b) Tsuda K, Ikuma S, Kawamura M, Tachikawa R, Sakai K, Tamura C (1964) Tetrodotoxin. VII. On the structures of tetrodotoxin and its derivatives. Chem Pharm Bull 12:1357–1374; (c) Woodward RB (1964) The structure of tetrodotoxin. Pure Appl Chem 9:49–74

American Chemical Society (1964) Tetrodotoxin has hemilactal structure: Japanese and U.S. scientists find independently that the potent neurotoxin in pufferfish is identical to tarichatoxin. Chem Eng News 42(23):42–43

Kishi Y, Fukuyama T, Aratani M, Nakatsubo F, Goto T, Inoue S, Tanino H, Sugiura S, Kakoi H (1972) Synthetic studies on tetodotoxin and related compounds. IV. Stereospecific total synthesis of DL-tetrodotoxin. J Am Chem Soc 94:9219–9221

Ohyabu N, Nishikawa T, Isobe M (2003) First asymmetric total synthesis of tetrodotoxin. J Am Chem Soc 125:8798–8805

Hinman A, Du Bois J (2003) A stereoselective synthesis of (–)–tetrodotoxin. J Am Chem Soc 125:11510–11511

Espino CG, Du Bois JJ (2001) A Rh-catalyzed C-H insertion reaction for the oxidative conversion of carbamates to oxazolidinones. Angew Chem Int Ed 40:598–600

(a) MarinLit database, Department of Chemistry, University of Canterbury, Christchurch, New Zealand. http://www.chem.canterbury.ac.nz/marinlit/marinlit.shtml. (b) Blunt JW, Personal communication

Diyabalange T, Amsler CD, McClintock JB, Baker BJ (2006) Palmerolide A, a cytotoxic macrolide from the antarctic tunicate Synoicum adareanum. J Am Chem Soc 128:5630–5631

Jiang X, Liu B, Lebreton S, De Brabander JK (2007) Total synthesis and structure revision of the marine metabolite palmerolide A. J Am Chem Soc 129:6386–6387

Nicolaou KC, Guduru R, Sun Y-P, Banerji B, Chen DY-K (2007) Total synthesis of the originally proposed and revised structures of palmerolide A. Angew Chem Int Ed 46:5896–5900

Lebar M, Baker BJ (2007) On the stereochemistry of palmerolide A. Tetrahedron Lett 48:8009–8010

Nicolaou KC, Bulger PG, Sarlah D (2005) Metathesis reactions in total synthesis. Angew Chem Int Ed 44:3281–3284

Shen R, Porco JA Jr (2000) Synthesis of enamides related to the salicylate antitumor macrolides using copper-mediated vinylic substitution. Org Lett 2:1333–1336

(a) Chandrasexhar S, Vijeender K, Chandrsekhar G, Reddy CC (2007) Towards the synthesis of palmerolide A: asymmetric synthesis of C1–C14 fragment. Tetrahedron: Asymm 18:2473–2478; (b) Penner M, Rauniyar V, Kaspar LT, Hall DG (2009) Catalytic asymmetric synthesis of palmerolide a via organoboron methodology. J Am Chem Soc 131:14216–14217; (c) Cantagrel G, Meker C, Cossy J (2007) Synthetic studies towards the marine natural product palmerolide A: synthesis of the C3-C15 and C16-C23 fragments. Synlett 19:2983–2986

Lindquist N, Fenical W, Van Duyne GD, Clardy J (1991) Isolation and structure determination of diazonamides A and B, unusual cytotoxin metabolites from the marine ascidian Diazona chinesis. J Am Chem Soc 113:2303–2304

Lachia M, Moody C (2008) The synthetic challenge of diazonamide A, a macrocyclic indole bis-oxazole marine natural product. Nat Prod Rep 25:227–253

(a) Li J, Jeong S, Esser L, Harran PG (2001) Total synthesis of nominal diazonamides – part 1: convergent preparation of the structure proposed for (-)-diazonamide A. Angew Chem Int Ed 40:4765–4769; (b) Li J, Burgett AWG, Esser L, Amezcua C, Harran PG (2001) Total synthesis of nominal diazonamides – part 2: on the true structure and original of natural isolates. Angew Chem Int Ed 40:4770–4773

Nicolaou KC, Bella M, Chen DY-K, Huang X, Ling T, Snyder SA (2002) Total synthesis of diazonamide A. Angew Chem Int Ed 41:3495–3499

Burgett AWG, Li Q, Wei Q, Harran PG (2003) A concise and flexible total synthesis of (-)-diazonamide A. Angew Chem Int Ed 42:4961–4966

Knowles RR, Carpenter J, Blakey SB, Kayano A, Mangion IK, Sinz CJ, MacMillan DWC (2011) Total synthesis of diazonamide A. Chem Sci 2:308–311

(a) Mai CM, Sammons MF, Sammakia T (2010) A concise formal synthesis of diazonamide a by the stereoselective construction of the C10 quaternary center. Angew Chem Int Ed 49:2397–2400; (b) Cheung CM, Goldberg FW, Magnus P, Russell CJ, Turnbull R, Lynch V (2007) An expediant formal total synthesis of (-)-diazonamide A via a powerful, stereoselective O-Aryl to C-Aryl migration to form the C10 quaternary center. J Am Chem Soc 129:12320–12327

Satake M, Ofuji K, Naoki H, James KJ, Furey A, McMahon T, Silke J, Yasumoto T (1998) Azaspiracid, a new marine toxin having unique spiro ring assemblies, isolated from Irish mussels, Mytilus edulis. J Am Chem Soc 120:9967–9968

Nicolaou KC, Li Y, Uesaka N, Koftis TV, Vyskocil S, Ling T, Govindasamy M, Qian W, Bernal F, Chen DYK (2003) Total synthesis of the proposed azaspiracid-1 structure, part 1: construction of the enantiomerically pure C1-C20, C21-C27 and C28-C40 fragments. Angew Chem Int Ed 42:3643–3648

Nicolaou KC, Chen DYK, Li Y, Qian W, Ling T, Vyskocil S, Koftis TV, Govindasamy M, Uesaka N (2003) Total synthesis of the proposed azaspiracid-1 structure, part 2: coupling of the C1-C20, C21-C27 and C28-C40 fragments and completion of the synthesis. Angew Chem Int Ed 42:3649–3653

(a) Nicolaou KC, Vyskocil S, Koftis TV, Yamada YMA, Ling T, Chen DYK, Tang W, Petrovic G, Frederick MO, Li Y, Satake M (2004) Structural revision and total synthesis of azaspiracid-1, part 1: intelligence gathering and tentative proposal. Angew Chem Int Ed 43:4312–4318; (b) Nicolaou KC, Koftis TV, Vyskocil S, Petrovic G, Ling T, Yamada YMA, Tang W, Frederick MO (2004) Structural revision and total synthesis of azaspiracid-1, part 2: definition of the ABCD domain and total synthesis. Angew Chem Int Ed 43:4318–4324

Hopmann C, Faulkner DJ (1997) Lissoketal, a spiroketal from the Palauan ascidian Lissoclinum voeltzkowi. Tetrahedron Lett 38:169–170

Nakamura H, Ono M, Shida Y, Akita H (2002) New total syntheses of (+)-macrosphelides C, F and G. Tetrahedron: Asymm 13:705–713

Kinnel RB, Henning PG, Scheuer PJ (1993) Palau’amine: a cytotoxin and immunosuppressive hexacyclic bisguanidine antibiotic from the sponge Stylotella agminata. J Am Chem Soc 115:3376–3377

(a) Kobayashi H, Kitamura K, Nagai K, Nakao Y, Fusetani N, van Soest RWM, Matsunaga S (2007) Carteramine A, an inhibitor of neutrophil chemotaxis, from the marine sponge Stylissa carteri. Tetrahedron Lett 48:2127–2129; (b) Buchanan MS, Carroll AR, Addepalli R, Avery VM, Hooper JNA, Quinn RJ (2007) Natural products, stylissadines A and B, specific antagonists of the P2X7 receptor, an important inflammatory target. J Org Chem 72:2309–2317; (c) Grube A, Köck M (2007) Structural assignment of tetrbromostyloguanidine: does the relative configuration of the Palau-amines need revision? Angew Chem Int Ed 46:2320–2324

Seiple IB, Su S, Young IS, Lewis CA, Yamagachi J, Baran PS (2009) Total synthesis of palau-amine. Angew Chem Int Ed 122:1113–1116

Nicolaou KC, Snyder SA (2005) Chasing molecules that were never there: misassigned natural products and the role of chemical synthesis in modern structure elucidation. Angew Chem Int Ed 44:1012–1044

Koert U (1995) Oxidative polycyclization versus the “polyepoxide cascade”: new pathways in polyether (bio)synthesis? Angew Chem Int Ed Engl 34:298–300

Nicolaou KC, Duggan ME, Hwang C-K, Somers PK (1985) Activation of 6-endo over 5-exo epoxide openings. Ring-selective formation of tetrahydropyran systems and stereocontrolled synthesis of the ABC ring framework of brevetoxin B. J Chem Soc Chem Commun 1359–1362

Vilotijevic I, Jamison TF (2007) Epoxide-opening cascades promoted by water. Science 317:1189–1192

Prasad AVK, Shimizu Y (1989) The structure of hemibrevetoxin-B: a new type of toxin in the Gulf of Mexico red tide organism. J Am Chem Soc 111:6476–6477

Zakarian A, Batch A, Holton RA (2003) A convergent total synthesis of hemibrevetoxin B. J Am Chem Soc 125:7822–7824

Ichige T, Okano Y, Kanoh N, Nakata M (2007) Total synthesis of methyl sarcophytoate. J Am Chem Soc 129:9862–9863

(a) Layton ME, Morales CA, Shair, MD (2001) Biomimetic Synthesis of (-)-longithorone. J Am Chem Soc 124:773–775; (b) Morales CA, Layton ME, Shair MD (2004) Synthesis of (-)-longithorone A: using organic synthesis to probe a proposed biosynthesis. Proc Natl Assoc Soc 101:12036–12041

Kim J, Ashenhurst J, Movassaghi M (2009) Total synthesis of (+)-11,11’-dideoxyverticillin A. Science 324:238–241

Hodous B, Fu GC (2002) Enantioselective synthesis of quaternary stereocenters via intermolecular C acylation of silyl ketene acetals: dual activation of the electrophile and the nucleophile. J Am Chem Soc 125:4050–4051

(a) Evans DA, Kværnø L, Mulder JA, Raymer B, Dunn TB, Beauchemin A, Olhava EJ, Juhl M, Kagechika K (2007) Total synthesis of (+)-azaspiracid-1. Part 1: synthesis of the fully elaborated ABCD aldehyde. Angew Chem Int Ed 46:4693–4697; (b) Evans DA, Dunn TB, Kværnø L, Beauchemin A, Raymer B, Olhava EJ, Mulder JA, Juhl M, Kagechika K, Favor DA (2007) Total synthesis of (+)-azazpiracid-1. Part 2: synthesis of the EFGHI sulfone and the completion of the synthesis. Angew Chem Int Ed Engl 46:4698–4703

Crabtree RH, Davis MW (1986) Directing effects in homogeneous hydrogenation with [Ir(cod)(PCy3)(py)]PF6. J Org Chem 51:2655–2661

(a) Kobayashi J, Ishibashi M, Nakamura H, Ohizumi Y, Yamasu T, Sasaki T, Hirata Y (1986) Amphidinolide A, a novel antineoplastic macrolide from the marine dinoflagellate amphidinium sp. Tetrahedron Lett 27:5755–5758; (b) Kobayashi J, Ishibashi M, Hirota H (1991) 1 H- and 13 C-nmr Spectral investigation on amphidinolide, an antileukemic marine macrolide. J Nat Prod 54:1435–1439

Trost BM, Chisholm JD, Wrobleski ST, Jung M (2002) Ruthenium-catalyzed alkene-alkyne coupling: synthesis of the proposed structure of amphidinolide A. J Am Chem Soc 124:12420–12421

Lam HW, Pattenden G (2002) Total synthesis of the presumed amphidinolide. Angew Chem Int Ed 41:508–511

Maleczka RE Jr, Terrell LR, Geng F, Ward JS III (2002) Total synthesis of proposed amphidinolide A via a highly selective ring-closing metathesis. Org Lett 4:2841–2844

Trost BM, Harrington PE (2004) Structure elucidation of (+)-amphidinolide A by total synthesis anf NMR chemical shift analysis. J Am Chem Soc 126:5028–5029

(a) Trost BM, Indolese A (1993) Ruthenium-catalyzed addition of alkenes to acetylenes. J Am Chem Soc 115:4361–4362; (b) Trost BM, Indolese AF, Mueller TJJ, Treptow B (1995) A Ru catalyzed addition of alkenes to alkynes. J Am Chem Soc 117:615–623; (c) Trost BM, Toste FD (1999) A new Ru catalyst for alkene-alkyne coupling. Tetrahedron Lett 40:7739–7743; (d) Trost BM, Toste FD (2000) Ruthenium-catalyzed cycloisomerizations of 1,6- and 1,7-enynes. J Am Chem Soc 122:714–715; (e) Schnaderbeck M (1998) The Ruthenium Catalyzed Alder-Ene Reaction. Ph.D. Thesis, Stanford University, 1998; (f) Sundermann MI (2000) The Ruthenium Catalyzed Alder-Ene Reaction: Macrocyclization and Studies of Alternate Catalysts. PhD thesis, Stanford University, 2000

Kita Y, Maeda Y, Omori K, Okuno T, Tamura Y (1993) A novel efficient synthesis of 1-ethoxyvinyl esters and their use in acylation of amines and alcoholsL synthesis of water-soluble oxaunomycin derivatives. Synlett 4:273–275