Abstract

Combined cooling, heating, and power (CCHP) is a well-known technology of sufficient utilization of low-grade thermal energy with the principle of thermal cascading. During the power production process, the waste heat can be made available for heating and/or cooling applications using thermally activated technologies, such as absorption chillers and adsorption chillers. It has the high primary energy efficiency, the environmental benefits and economic feasibility. In recent years, many CCHP systems have been applied successfully in industries such as cement factory, paper mill, and pharmaceutical factory; in various kinds of commercial buildings such as hotels, offices, and hospitals; and in small-scale buildings such as residential users. CCHP system is one of the distributed energy systems. A distributed energy system is a small- and medium-sized multifunction energy conversion system, which directly provides various forms of energy according to the needs of users. The CCHP system is not a simple superposition of several thermodynamic processes. Based on a certain principle or idea for the organic integration and integration of the integrated system, it is usually aimed at achieving different functional objectives and application conditions. On the basis of the integrated cascade utilization and other systems’ integration mechanism, the different processes of integration and the optimization of system integration selecting were selected, in order to realize different system functions. The researches in this field are very active in recent years. The concept, research status, hot spot of research and development trend of CCHP systems are introduced and analyzed in this chapter.

Access provided by CONRICYT-eBooks. Download reference work entry PDF

Similar content being viewed by others

Keywords

Background and Significance of Energy Conservation

Energy is not only an important material basis for the survival and development of humans, but also a powerful driving force to promote the development of national economy. At present, it has been the focus of attention in international political, economic, military, and diplomatic fields. Governments have to establish a reliable, safe, stable, and efficient energy supply security system as a national economic strategy for sustainable development.

Energy consumption has caused serious environmental pollution because of the increase in global average temperature. Specifically, the average temperature of the global surface has increased by 0.3–0.6 °C, and the sea level has risen by 10–25 cm in the past 100 years. As announced by the UNEP in 2007, global warming is an indisputable fact, which is mostly caused by human activities. If the emission reduction measures are still not taken, the average global temperature will rise by 0.2 °C in the next decade. Besides, the global average temperature will rise by 1–3.5 °C in 2100. These changes would endanger the survival and development of humanity.

Under the serious situation, energy-saving has aroused great attention from all over the world. Although new energy sources are being developed, vigorously saving conventional energy and continuously improving the efficiency of energy conversion and utilization have become urgent priorities.

Based on the situation of energy resources and technology development, the primary sources of energy will still be mostly fossil fuels in the twenty-first century, especially its first half. However, renewable energies (e.g., solar energy, wind energy, water energy, biomass energy, ocean energy, and geothermal energy) and nuclear energy are more and more important. The waste heat utilization system, the new technology of low temperature utilization, and the reasonable development of solar energy, wind energy, geothermal energy, as well as other renewable energy sources have caused great attention in the industries of refrigeration and air conditioning. So far, waste heat refrigeration technology has been mature. Lithium bromide absorption refrigeration technology has reached a considerable scale of development, and experienced practical application for many years. Ammonia water absorption refrigeration system has also been used in many countries. In the past 20 years, adsorption technology has been widely used for gas separation and purification. Due to the environmental friendliness of the adsorption system (It can use water, methanol, ammonia, and other media. Its ODP and GWP are 0), the developments of adsorption refrigeration and air conditioning equipment are great. Relevant researchers strengthened the study of more efficient adsorption refrigeration system in Japan, Europe, the United States, and China in the 1990s.

With the development of the society, the energy supply model of the whole world has been gradually developing from the first-generation energy system to the second-generation energy system. Different from the first-generation energy system, which has the characteristics of large-scale centralized power supply system, the second-generation energy system is better in terms of equipment miniaturization, miniaturization, the use of energy cascade and purification. This change reflects the important development direction of energy technologies in the future. CCHP (Combined Cooling, Heating, and Power) embodies the main features of the second-generation energy system. Therefore, CCHP has drawn wide attention from all over the world.

Concept of CCHP System

CCHP system is one of the distributed energy systems. A distributed energy system is a small- and medium-sized multifunction energy conversion system, which directly provides various forms of energy according to the needs of users. Different from the traditional centralized energy production and supply mode, which has large unit, large power plant, and large power grid, CCHP systems are distributed to the user side, in order to achieve higher energy utilization rate, lower energy costs, higher energy efficiency, better environmental performance, and other functional objectives. In fact, CCHP system is the main development direction and form of distributed energy resources.

The demands of users are briefly divided into power, cold, and heat in commercial, architecture, and small industries. The traditional independent system cannot fully meet the requirements of users. As a comprehensive distributed system based on energy cascade utilization, CCHP system is installed at the side of terminal user. Firstly, the engine is driven by primary energy to generate electricity. Then, waste heat is retrieved and utilized through the operation of various waste heat utilization equipment (absorption chiller, adsorption chiller, waste heat boiler, drying equipment, heat exchanger, etc.) to provide users with electricity, refrigeration, heating, hot water, and so on.

CCHP system has many remarkable advantages as follows:

Energy Saving and High Comprehensive Utilization Rate of Energy

Traditionally power is produced by burning fuel in the central power plant, and delivered to the user terminal through high and low voltage power networks. The average power generation efficiency of the traditional central power plant is 40%. Nevertheless, there is an energy loss of 7–8% in the process of transmission and distribution. Consequently, the total efficiency of the power plant and the power grid is only about 33%. At the same time, the cold and heat load demands have to be met individually. CCHP system is near the demand side, which can greatly reduce the transmission loss of power and can utilize waste heat to meet the needs for cold and heat. This part of energy is wasted in the traditional energy system. CCHP can not only improve the utilization ratio of low-grade heat energy, but also increase the heat load in summer and annual unit load rate, which would improve the efficiency of the unit. Finally, the comprehensive energy utilization rate of the system energy is improved, and the energy efficiency is increased from 40% to 70–90%.

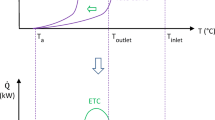

A simple comparison between the independent system and CCHP system is presented. The fuel heat of primary energy is used as the input value, and the obtained energy of the terminal buildings as the output value. Under the condition of the same output value, smaller input value represents higher comprehensive energy utilization rate. Fig. 1 shows this comparison.

When an electrical load of 58 kW, a cold load of 70 kW, and a heat load of 51 kW are provided to the user, the thermoelectric conversion efficiency of traditional independent energy system is only 33%. For boiler combustion heating, only 70% of the heat value is utilized due to the boiler efficiency and the heat loss of the pipeline. Refrigeration coefficient is 3.5 in the small air conditioning driven by electricity. Although the power efficiency of the CCHP system driven by a small prime mover is not high, its thermoelectric conversion efficiency can reach 27% and above, owing to the lower heat loss of transmission. According to the practical application situation, the waste heat recovery efficiency of generator unit is 53%. The COP of double-effect lithium bromide absorption chiller driven by waste heat can reach 1.15. The heat loss coefficient of heat exchanger and pipes is 10%. The power consumed by the pump and fan of the double-effect lithium bromide absorption chiller is 2.0 kW. On the basis of those energy transfer coefficients, the energy output is converted into primary energy demand. The input value of primary energy fuels in traditional independent energy system is 310 kW, while that of primary energy fuels in the CCHP system is 222 kW. The comprehensive energy saving rate can reach 28.4%.

Ability to Keep a Seasonal Balance of Energy Consumption

The refrigeration unit driven by waste heat is taken as refrigeration equipment by the CCHP system, such as absorption refrigeration unit and adsorption refrigeration unit. Compared with the compression refrigeration unit, the most outstanding advantage of absorption or adsorption refrigeration unit is power saving. For instance, the refrigeration capacity of 3500 kW absorption chiller can save about 890 kW of electricity. In consequence, a lithium bromide absorption chiller is equivalent to a small power station. Nonetheless, the needed investment in the power plant is very high. Equipment investment is 7000 RMB/kW, and an 890 kW power plant needs 6.23 million RMB. The construction period of the power plant is much longer than that of the refrigerator installation.

In summer, the problems such as the electricity shortage of air conditioning and the reduction of gas consumption are serious. The application of the CCHP system driven by gas can effectively alleviate the peak load, increase the demand for natural gas in summer, and thereby achieve the seasonal balance of energy consumption. In addition, natural gas is a kind of highly efficient energy. The comprehensive energy efficiency and economic benefits of the CCHP system driven by gas are highly remarkable.

Environmental Protection

The CCHP system has a great potential to reduce carbon emissions and air pollution. In September, 1997, five laboratories of U.S. Energy Department conducted a study called “US Carbide Reduction Program,” and detected a total of more than 200 techniques. The study found that the CCHP technology only takes up three of the detected techniques, namely advanced turbines, fuel cells, and integrated combined cycle. However, it can achieve nearly 10% of the expected reduction in carbide. Additionally, the new-generation turbines, fuel cells, and piston engines are smaller, more energy-efficient, and more flexible.

CCHP has a strong advantage, i.e., high energy saving, because of efficient energy cascade utilization. As the pollution of CCHP system is reduced, it is more environmentally friendly. Compared with the traditional energy system, the CCHP system can reduce pollutant emissions by 40%. If the CCHP system is driven by gas, its role in environmental protection is still great even in comparison with the large power generation boiler with a high combustion efficiency. SO2 pollution is approximately 0, and NOx pollution is reduced by 80%. The emission of CO2 is only 30–50% of the traditional energy system. In addition, the popularization and application of the CCHP system will reduce the total demand for fossil fuels (especially coal), which is beneficial to reducing the emission of CO2 and NOx indirectly.

From another perspective, the protection of the ozone layer is an urgent problem. Chlorine fluorine hydrocarbon refrigerant (CFC, HCFC) is widely adopted by refrigerating machine. It is a direct threat to the health of human beings due to the significant dissipation of its ozone layer. According to the amended proposals in the Montreal Protocol , CFC and transition material HCFC will be banned in the next period. The residual heat refrigeration technology used in the CCHP system is consistent with the general trend of the current energy development and environmental coordinated development. Absorption or adsorption refrigeration has neither CFC’s problem, nor greenhouse effect. Thus, it is a kind of environmentally friendly refrigeration.

Energy Security

Since the twentieth century, the popular view about the power industry is as follows: The larger the capacity of the generator unit is, the higher the efficiency is, and the lower the unit capacity investment and operating costs are. With the development of the energy industry, the development direction of the electric power industry is “large unit, large power plant and large power grids.” The increase in the number of large thermal power plant in the world threatens energy security. There is a hidden problem with the security, stability, and power supply quality of large-area interconnected power grid, which can lead to a large-area power outage.

As one of the distributed energy systems, the CCHP system is close to users or nearby power generation system, which is arranged by way of small scale, dispersion and directionality. The electricity and other forms of energy provided by the CCHP system preferentially meet the needs of local users. The CCHP system operates relatively independently. It can reduce the dependence on large power grid. Given this, the “big power grid,” which is much important for national economy and security but extremely fragile, is no longer isolated. It can be used as an important supplement to the centralized power generation and power grid, which greatly improves the reliability and security of the power system.

As a result, the reasonable combination of large power grid and distributed power supply is considered as an energy system with lower investment, lower energy consumption, and higher reliability. For this reason, it has become the development direction of the electric power industry in the twenty-first century. That is to say, the world power industry has already started to rely on the transitional “distributed” power system, which is widely combined by large power plants and small distributed power supply. The efficiency and quality of power supply as well as the problem of pollution can be greatly improved. Moreover, the CCHP technology has other advantages, such as the reasonable utilization of energy resources, excellent environmental performance, as well as the flexible distribution of cold and heat load. In a word, it is the main development direction of distributed power supply.

Development of CCHP System

In the early stage, the combined cooling heating and power system was developed on the basis of Combined Heat and Power (CHP) system. Actually, CHP system directly retrieves waste heat from the power cycle for heating to improve energy efficiency. At the beginning of the twentieth century, cogeneration had entered the stage of practical application. At that time, the main power means in the world was still coal-fired boiler steam turbine-driven power generation. As the thermal loads of the unit could contain each other, the unit load would be high whereas the heat load low, especially in summer. This would make it difficult to operate the unit and reduce its energy-saving economy.

The CCHP technology solved this problem, which combined the CHP with absorption or adsorption refrigeration technology. It enabled the thermal power plant to supply thermal energy and cold energy at the same time. In this case, the initial CCHP was based on the power plant. Since distributed energy system was proposed, the application field of the CCHP system has been greatly expanded. It can be widely used in the fields of power, cold, and heat demand, as well as industrial and civil applications, such as cement factory, paper mill, pharmaceutical factory, textile printing and dyeing factory, chemical smelting factory, commercial areas, residential areas, industrial parks, stadiums, hospitals, train station, airport, and ferry terminal.

Foreign Development Situation

The development of CCHP originated in foreign countries in 1970s. It first appeared in the United States. In 1938, the United States established the first CCHP system in a building in Tallahassee Du City. This system adopted six sets of absorption chiller, and the refrigerating capacity was 600 RT. However, the development of the CCHP in the United States actually began in 1978. The US Department of Energy began to promote the development of small cogeneration in 1978. The federal government specially formulated management policy utilities act (PUBPIA), and required utilities to purchase electricity from power suppliers independently, which greatly stimulated the development of cogeneration and renewable energy. During the period from 1980 to 1995, the capacity of the CCHP system installed by the United States increased from 45GW to 12GW, with an average increase of 2.2GW per year. With the US Department of Energy’s advocacy as well as the broad participation of natural gas, electricity, HVAC, other energy and manufacturing industries, the United States proposed the well-known “CCHP originality” and “CCHP 2020 program” in 1999. It publicized and promoted the distributed energy system technology as the “cross-century technology.” The plan intended to vigorously promote the distributed CCHP system within 20 years, which made the CCHP a model of primary energy use of commercial and office building. The integration of the energy system greatly promoted economic growth, improved the life quality of residents, and maximized the reduction of pollutant emissions. In addition, specific implementation plans for 2010 and 2020 were also proposed. According to the plans, the new commercial or office buildings in the United States would adopt the power supply mode of CCHP system in 2010. Five percent of the existing commercial office buildings would be turned into a distributed CCHP system for energy supply mode. By 2020, 50% of the new offices or commercial buildings would have adopted the power supply mode of CCHP system. That is to say, 15% of the functional systems of the existing commercial and office buildings would be turned into the CCHP system. At present, Building Cooling, Heating, and Power (BCHP) in the United States are developing rapidly. Besides, the distributed CCHP systems in schools, supermarkets, high-rise office buildings, and other large buildings are too numerous to enumerate. According to the estimates of the Distributed Power Coalition of America (DPCA), the US distributed power generation will increase the power generation capacity by 20%, to 35 GW from 2000 to 2020.

In Japan, great importance is attached to CCHP technology due to the lack of economic development and resources. The CHP system in Japan is the third largest public welfare system following gas and electric power supply systems. Early in end of the last century, the Japanese government vigorously encouraged the development of gas air-conditioning, which accounted for more than 85% of the central air-conditioning market. Air-conditioning units with more than 70% of large buildings used heat-driven absorption chiller, rather than electricity. These absorption refrigeration units and the CHP system formed the distributed CCHP system. The number of Japanese natural gas CCHP systems began to grow rapidly in 1989. By the end of March, 1997, the total number of natural gas cogeneration systems in Japan reached 820. The total installed power generation capacity was 1.42 million kW, including 3,00,000 kilowatts for 520 civilians, and 1.12 million kilowatts for 300 industries. There were more civil seats, while the industrial capacity was about four times as large as that of the civil aircraft. By 2004, the capacity of the distributed energy system in Japan, which could be represented by the distributed CCHP system, had achieved 7.78GW. It was expected to reach 10.02GW in 2010. The Japanese thermoelectric center did not include steam turbines and fuel cells. There were many successful engineering cases in Tokyo, Osaka, Sapporo, and other places. The size and influence of the CCHP projects in the Shinjuku district of Tokyo were relatively large. The project was officially launched in January, 1991. Its cooling capacity was 210,000 kW.

In Europe, the pressure on energy and environmental issues, the Kyoto Protocol in effect, as well as the development of CCHP technology has been paid more and more attention to with the advance of globalization. CCHP has developed more quickly, especially since the 1980s. In May, 1998, the first set of CCHP system Expo Village in Lisbon, Portugal, Europe, was put into operation, with a generating capacity of 5 MW, a cooling capacity of 60 MW, of heat supply capacity of 44 MW. It applied natural gas in gas turbine combustion power generation. Exhaust gas led the waste heat boiler to generate steam, which would be supplied to the urban heat pipe network and absorption refrigerating unit. In the past 20 years, the UK has installed more than 1000 distributed energy systems, covering places such as hotels, leisure centers, hospitals, university campuses, airports, public sector buildings, office buildings, and shopping malls. Among them, the CCHP system of Manchester Airport is more representative. Manchester Airport is one of the 20 largest airports in the world. The government decided to build a power supply system with a capacity of 6.4 MW for it in 1989, which supplied energy to the existing two terminals and the new terminal built in April, 1993. It is a system that operates in heating operation mode in winter and cooling operation mode in summer. The airport power is 7 MW. The total power of the new terminal is about 15–18 MW. The heat demand of the original two terminals in summer is 2 MW, and that in winter is 6 MW. Two reciprocating engines are utilized in the system. Heavy oil or natural gas is used as the fuel. The equipment also includes two sets of 5.9 MW waste heat boilers, which can supply hot water of 140°, and two sets of 4 MW dual fuel conventional boilers. The equipment will have at least a service life of 20 years. The contract amount of the whole project is 6.9 million pounds. The combined supply system generates about 72,000 MWh of power 1 year. The supply of heat needs the purchase of 178.5 TJ of natural gases. The annual gross output value of the system is approximately 1 million and 8,00,000 pounds. If people adopt the absorption refrigeration, they can save 50,000 pounds every year. After the implementation of the CCHP system, the system can reduce 50,000 t of CO2 emissions and1000 t of SO2 emissions per year. Both economic and environmental benefits are very significant. At the same time, other EU countries have also vigorously taken different measures, such as tax subsidies, to promote the implementation of cogeneration projects. For example, Italy has reduced 20–40% of fuel costs to encourage the building and application of CCHP system.

Development Situation in China

China established general policy of energy development in the early 1980s, namely the “energy development and conservation, the recent saving in priority.” On January 1, 1998, the energy conservation law of the People’s Republic of China was implemented. As pointed out in its Article 39, “the state encourages the development of the following general energy saving technologies: promotion of cogeneration, central heating, improving the efficiency of the thermal power unit, the development of energy cascade utilization technology, heat, electricity, cold and heat, electricity, gas triple for technology, improve the comprehensive utilization of heat energy.” The relevant government departments attached great importance to the development of combined heat and power. On August 22, 2000, the State Planning Commission, the State Economic and Trade Commission, the Ministry of construction, and the National Environmental Protection Bureau jointly issued the basis of the project (2000), i.e., the 1268 document, for the development and provisions of cogeneration. It clearly pointed out the aim to “encourage the use of clean energy, the development of heat, electricity, cold and heat, electricity, and gas production, in order to improve the comprehensive utilization of heat energy efficiency.” According to the 31st and 32nd clauses in the newly revised energy conservation law of People’s Republic of China, “the nation encourages industrial enterprises to adopt CHP technology, waste heat and pressure utilization technology, clean coal and advanced energy monitoring and control technology.” Besides, “power grid enterprises power shall according to the regulations of energy saving generation dispatching management, which was formulated by the relevant departments of the State Council, and people should arrange grid-connected operation of CHP, generator set using residual heat and pressure, generator sets that conformity with the comprehensive utilization of resources and power grids, which are clean, efficient and compliant.”

The CCHP system of Shanghai Pu Dong International Airport was projected in 1999. This project was formally put into use in 2000. The investment was about 36 million RMB. The airport energy supply mode adopted the principle of “high concentration and small dispersion.” That is to say, the CCHP unit could meet a large demand for cold, heat, and electricity load. For the places with a small load and relatively scattered position, the mode of independent energy supply was adopted. The first phase of the project required a total cooling capacity of 24,400 RT (85,800 kW) and heating capacity of 121 t/h (76,000 kW). This system consisted of a 4000 kW gas turbine generator, a 11 t/h boiler, four OM-type centrifugal water-cooled chillers with a refrigeration with a capacity of 4000 RT (14,080 kW), two YK-type centrifugal water-cooled chillers with a refrigeration capacity of 1200RT (4224 kW), four sets of steam double effect lithium bromide absorption chillers with a refrigeration capacity of 1500RT (5280 kW), three sets of 30 t/h and a 20 t/h gas/oil-fired steam boiler. They were mainly for the terminal, the office buildings of airport authorities, custom inspection building, catering and entertainment center, transportation, hotels, first-aid center, financial center as well as the supply of cold and heat load. The total area was about 590,000 m2, and the radius was 2.6 km. Based on the design calculation, the power load of the system was greater than 2500 kW. This could ensure that economy, electric power, steam cogeneration system, market power, fuel boiler, and steam generation price could be also consistent with the corresponding input. Shanghai Municipal Economic Commission formally approved the grid in March, 2001. As the air station and network began to lower electrical load, the capacity of the initial system was only about 2000 kW, and its economic performance was insufficient. In the end of June, 2002, the network load was again adjusted and transformed. In July, the Gas turbine could be operated at the rate of 70–80%, which would greatly improve the economy.

Taking the period between July and December in 2002, for example, the cost of natural gas was about 4,537,600 RMB for the cold heat and power cogeneration system. In order to obtain the same energy output, the traditional distribution system would need to cost 7,428,200 RMB. The difference between the two is 2,890,600 RMB. As can be seen, the economic benefit is remarkable.

Hot Spot of Research and Development Trend of CCHP System

The CCHP system is not a simple superposition of several thermodynamic processes. Based on a certain principle or idea for the organic integration and integration of the integrated system, it is usually aimed at achieving different functional objectives and application conditions. On the basis of the integrated cascade utilization and other systems’ integration mechanism, the different processes of integration and the optimization of system integration selecting were selected, in order to realize different system functions. Although the combined cooling and heating system has been applied to a certain degree at home and abroad, it is still in the development stage. A lot of studies have been carried out by scholars in various countries. The related research work is focused on the best internal structure of the system (e.g., unit type, unit capacity, and the combination optimization of various basic units), system energy control and operation management, system evaluation index and evaluation system, etc. At present, there are still many problems in the development of the cold heat and power cogeneration in China despite the impact of fuel price, initial investment, technical level, and other factors. Moreover, there are some limitations in the application field. Fortunately, this technology is still developing at a very fast speed under the guidance of relevant policies.

Hot Spots of Research

Best Internal Structure of the System

The application situation decides the component selection and combination mode of the cold heat and power cogeneration system. According to its function, the system can be divided into three subsystems, namely power system (power generation), heating system (heating, hot water, ventilation, etc.), and refrigeration system (refrigeration, desiccant, etc.). In each component of the system, the thermal unit and heat refrigeration equipment takes up the largest share of the initial investment system, as a main factor affecting the energy utilization efficiency of the system. Different thermodynamic prime mover determines the power generation efficiency, residual heat grade, and connection mode of the system, while the different waste heat refrigeration equipment determines the heat energy consumption and cooling output characteristics of the combined system. In the configuration of the CCHP system, the proper way to choose the appropriate thermal motive and waste heat thermoelectric refrigeration equipment according to the needs of users is not only a very important aspect for realizing the energy saving and economy of the system, but also one of the key factors that determine the success of the system. For the selection of thermal type, Wu et al. reviewed a large number of literatures about thermodynamic motive, and summarized the development trend, application scope, advantages and disadvantages of various thermal motive and technology. On the choice of equipment capacity, Cardona et al. proposed a method for determining the capacity of the thermodynamic prime mover in the combined system, which could determine its optimal capacity by the ratio of the prime mover’s capacity to the peak value of the user’s demand.

Refrigeration equipment mainly includes absorption refrigeration unit and adsorption chiller driven by waste heat. Both of their application scopes are more obvious. Due to their own capacity constraints (generally above 100 kW in the market), absorption refrigeration units generally apply to medium- and large-scale combined cooling heating and power system, and their heat source temperature is higher. Based on their characteristics, adsorption refrigeration units are suitable for small or micro cooling power system, which can drive the low-grade waste heat. For the capacity selection, Cardona et al. suggested that the optimal capacity of the refrigeration equipment driven by waste heat can be determined by the ratio of the capacity of the refrigeration equipment to the peak value of the user’s demand. Wang M.H. put forward the best cooling coefficient for the BCHP system equipment capacity choice, and pointed out that this method could improve the capacity of the refrigerating unit in the current system.

System Energy Control and Operation Management

As a kind of multipower system, the CCHP system’s energy control and operation management are very complicated. From the perspective of supply, the CCHP system is composed of different heat generation/conversion components. The heat provided by this system has great differences in quality and quantity. From the perspective of energy, users have different demands on all kinds of energy. For these reasons, most of the cases are in a state of change. This makes the energy management of the CCHP system have to take into account time and diversity. The research shows that the efficiency of each component and subsystem is reduced to different degrees when the CCHP system is operated under the condition of partial load, which will seriously affect the energy efficiency of the whole system. In comparison, the CCHP system can not only save energy, but also produce more energy even under poor operation conditions. Hence, it is essential to study its energy regulation and operation management characteristics, and achieve optimum system operation to improve the competitiveness of the CCHP system.

There are many researches on CCHP system energy management at home and abroad. Lee et al. put forward the concept of “energy flow” was put forward based on the optimal operation of the cold heat and power cogeneration system. Besides, they attributed the operation of optimization system to the optimization of “energy flow,” and used the fuzzy algorithm to determine the system’s energy operation management characteristics based on the CCHP system driven by gas turbine. Smith and others pointed out that the research would focus on variable load and the unsteady state characteristics of the system during the switching process in the future. Miguez set five kinds of operation mode for the annual working conditions of the joint supply system. Variable condition characteristics were changed by storage heat and power. They pointed out that factories could consider to get rid of the energy storage equipment and implement systematic process optimization or other methods, if they want to decrease system cost in the future. Colella put forward the method for constructing a thermal management subsystem to achieve the integrated management of heat energy of the combined system, according to the fuel cells of CCHP system. They optimized the different heat exchangers in the system, which made the heat utilization efficiency of the system reach the maximum. Furthermore, they pointed out that the combined independent system and the traditional system must solve some key system problems, including the insufficient ability to quickly adjust the electrical load and change the thermoelectric ratio, as well as the inadequate use of waste heat recovery capacity, etc. Benelmir et al. made thermal economics perspective analysis. They regarded the energy management of the combined system as a very complex concept related to the initial investment, the life cycle of the economy, and the price of energy.

In China, the optimal operation of the cold heat and power cogeneration system with energy storage device was studied. The related operation analysis software was compiled by Jiang et al. Zhang established a mathematical model of a CCHP system, which was based on gas turbine and absorption chiller. This model took the minimum operating cost as the optimization objective function, and obtained the optimal operation control strategy under different conditions. Liu gave constructive suggestions for the system energy management based on gas turbine and CBHB of waste heat boiler, taking into consideration not only the area of heat, heat transfer efficiency, and economy of the heat exchanger, but also the variable condition characteristics of the system. Zhang studied the 60 MW proton cogeneration system based on the thermal management exchange membrane fuel cell, and analyzed the system under the connected effects of fluid flow, temperature, system control strategy, and energy consumption. The optimal operation of the combined cooling and heating system in residential area was studied by Fang. On the basis of the simulation results of the steady-state gas turbine-combined cooling heating and power system, he established a system with total exergy efficiency and economic system as the objective functions as well as an optimization model of the compressor inlet air temperature, gas turbine, and steam load rate allocation for variable rate. According to finite time thermodynamics principle, Zhang derived the irreversible basic optimization relation of CCHP system when the effective energy output in the system was maximum, and determined the system optimization design parameters and the choice of the best working conditions. Jiang integrated the applications of engineering economics, system engineering, and optimization theory from the level of technical economy, applied the accounting model of the thermos economics theory of technology and economy. What is more, he optimized and analyzed the heat flux, effective energy flow, and cash flow of the system. Based on gas control heat pipe technology, Huangfu and Li put forward the concept of thermal management, constructed the experimental and engineering prototype, and applied it to the micro cooling system. Thermal manager plays the role of thermal management platform, and has the responsibility to realize the function of heat source temperature control and system thermal management, which has the advantages such as compact structure, flexible interface, simple control, and component integration.

System Evaluation Index and Evaluation System

In order to compare the advantages and disadvantages of different cooling heating and power systems, guide and optimize the design, as well as select and operate the system, specific evaluation indicators and a complete assessment system are needed. There is no perfect theory for the energy saving and economic evaluation of the combined system. Generally speaking, there are two energy analysis methods, namely the first law of thermodynamics and the second law of thermodynamics.

Havelsky put forward the primary energy consumption rate as the evaluation index of the energy efficiency of the system, i.e., the ratio of primary energy consumption to system output energy. Silveira et al. made an economic analysis of energy saving according to the combined independent system of molten carbonate fuel cell. The total energy efficiency and effective energy efficiency were taken as the evaluation indexes. Gorsek et al. analyzed the combined independent system based on steam turbine by referring to net present value, capital pay-off time, annual cost, and other evaluating indicators. Biezma et al. compared the economic evaluation indexes of 15 CCHP systems, and summed up the characteristics and application limitations of various evaluation methods.

Lv et al. revolved around energy utilization ratio and thermal economy, and commented the evaluation criterion of the combined cooling heating and power from different angles. They thought that the three standards on fuel consumption, exergonic efficiency, and economic exergonic efficiency would be more appropriate for synthetic evaluation. It can make a comprehensive evaluation, taking into account the aspects such as the payback period of investment, environmental protection, social benefit, and system reliability. With the coal consumption for power generation as evaluating indicator, Fu et al. analyzed the energy consumption of the whole CCHP system in terms of energy conversion and utilization. Additionally, they pointed out the unreasonable places of the engineering economic evaluation method of the current natural gas combined independent system, and proposed incremental evaluation method to evaluate the feasibility of the combined independent system. They also put forward the evaluating indicators, including incremental investment recovery period, annual operating cost reduction, equivalent thermal power plant power generation efficiency, and power generation cost, etc. Jia et al. pointed out the comprehensive evaluating indicators of CCHP system, such as primary energy consumption rate, the coal consumption for power generation, exergetic efficiency, fuel saving and equivalent thermodynamic coefficient, etc. The first three kinds of evaluating indicator were adopted, which can fully reflect the degree of energy utilization and the efficiency of the system energy conversion process. Huangfu et al. proposed a blend gray multiple-level association comprehensive evaluation method, which is a comprehensive evaluation method considered to have the ability to realize the scientific evaluation of the CCHP system. The method based on comprehensive employed analytic hierarchy process, fuzzy mathematics, and grey correlation theory; achieved the organic combination of the advantages of different methods; and improved the accuracy of optimization scheme. Feng compared several frequently used evaluation criteria. He thought that energy efficiency and economic exergetic efficiency were more suitable for the evaluation on the energy saving economic of the combined cooling heating and power system.

In accordance with the calculation of energy saving rate of the combined cooling heating and heating system in different modes of various gas turbines, absorption refrigerating machines, steam turbines and so on, Sun et al. analyzed the main factors affecting the energy saving of the combined supply system, and made the critical coal consumption to judge whether the CCHP system was energy saving. Deng et al. set up a thermal economic model involving the definition of fuel product, and quantified the relationship between the production of internal equipment and the production performance of the system under different conditions through exergy cost analysis, based on economic structure theory. They presented the miniature of the combined cooling heating and power system driven by gas engine. Through a comparative analysis of the performance evaluation indexes of cold heat and power cogeneration system, Xie et al. put forward the method considered to have characteristics such as high electric power efficiency, reasonability, feasibility, simpleness, and practicability, compared with primary energy utilization, exergetic efficiency and equivalent electric efficiency and so on. Fang et al. adopted thermal economics method to analyze the gas engine-driven heat pump’s CCHP system. They calculated and analyzed the subsystem’s exergy cost difference, exergy economic factor, and total system exergy economic coefficient under the influence of the factors such as different speeds, evaporating temperatures, condensing temperatures, and natural gas prices. They also pointed out the fact that this system needed improvement. He et al. put forward the evaluation criteria of energy cascade utilization based on the essential characteristics of the energy cascade utilization of CCHP system. They obtained the criterion by using the energy utilization ratio of power generation. Refrigeration and heat supplies were multiplied by different weight coefficients.

Development Trend

In recent years, the CCHP system has been gradually developing towards miniaturization, civil, integration, intelligence, and network. In the opinion of Kari and Arto, the combined power supply system with a rated generating power of less than 100 kW was a miniature combined cooling heating and power system, and that with a rated generating power of less than 200 kW was a small combined cooling heating and power system. As defined in Sullivan and Frost’s report Opportunities in European Micro Combined Heat and Power Markets, the miniature combined supply system is a combined power generation system with a rated generating power of less than 20 kW. The development trends of system miniaturization belong to the market demand and research needs of this technology at present.

Market Demands

The potential market for small and micro combined independent systems is very large, including 20 KW of cold and heat as well as 200 KW of commercial hot and cold power supply systems. Due to the relatively remote location and traffic inconvenience, power resources are very scarce, especially in some remote tourist areas, seaside villa, oil fields, and mountains. In order to solve the lack of electricity, heating, and air conditioning in these areas, we can adopt small or micro CCHP systems. Natural gas can provide energy, liquefied petroleum gas, and other gas fuels, as well as gasoline, diesel, and other liquid fuels to drive the system.

Research Needs

Conventional CCHP system has a big capacity, due to the high cost of the system and the large amount of energy consumption. It is very difficult to carry out the experimental research on energy matching and energy management in the conventional combined system. The small and micro combined supply system can provide a research platform for the CCHP system, which is convenient and economic for debugging. Especially, the conclusions drawn from the experimental study results can provide a foundation and reference for large capacity systems.

It Is Necessary to Provide an Effective Technical Approach for the Efficient and Rational Use of the High-Grade Energy of Natural Gas

With the development of its terminal product, the use of natural gas has become the current hot spot. Natural gas-driven small or micro CCHP has a great potential market, and a high comprehensive utilization efficiency of energy. It can relieve power tension, enrich natural gas terminal device, and promote environmental protection. In addition, its economic benefits and social benefits are significant. For example, the annual commercial housing area is more than 20 million m2 in Shanghai at present. The residential area accounts for 85%. If the annual increase of residential and commercial housing account for 2% and 15%, respectively, small or micro CCHP system should be adopted. Then, the annual increase in the use of the system area will reach 790,000 m2, so that it can reduce the power generation of the conventional coal-fired power plants. It is estimated that the emission of CO2 and NOx can reduce by 380,000 tons and 1280 t, respectively, each year. The research results of Peacock et al. show that micro combined supply system for the British families can reduce 9–16% of CO2 emission each year.

In recent years, more and more researches and applications of small or micro CCHP system have been carried out. Smith et al. established the domestic conceptual prototype of micro cogeneration system and heat pump combined operation with a rated power output of 1.5 kW. Besides, they proceeded to a thorough theoretical and experimental study to verify the efficiency and stability of the system. Míguez et al. studied the micro gas engine heat pump CCHP system based on an internal combustion engine, with a rated power generation of 3–4 kW. The system set up a variety of operation modes to meet the requirements of the whole year, and connected with the thermal storage equipment. The experimental prototype is shown in Fig. 2. Accadia et al. set up the micro combined heat and power system, for the families and small business purposes. The rated power generation was less than 15 W. Moreover, they deeply studied the selection of thermodynamic prime mover and the economy of the micro combined independent system. The experimental prototype is presented in Fig. 3. Colella and Gigliucci et al. separately studied the micro CCHP system based on fuel cell. They made an experimental prototype, with a rated power of 6 kW and 4 kW.

Malteser Hospital in Kamenz, Germany, set up a small cold cogeneration system based on adsorption refrigeration for the first time in Europe. The system stared to run in May, 2000. In the system, the regenerative apparatus collects waste heat from the fuel cell power and the heat of the solar energy, which would then go through the adsorption refrigerator for cooling. The refrigeration capacity of adsorption refrigeration equipment is 105 kW. Besides, a compression type refrigerating machine is installed in the system to adjust the cooling capacity.

Tokai Optical Co., Ltd. in Nagoya, Japan, introduced a small CCHP system based on adsorption refrigeration unit. The rated power of the diesel engine in the system is 185 kW. Engine waste heat is used for CCHP, which can be applied to the function of desiccant cooling and cooling. The system can reduce the energy consumption by 10% and decrease the emission of CO2 by 12%.

Wang’s research group established two micro CCHP experimental prototypes based on a gas engine and adsorption refrigeration unit with rated power generations of 12 kW and 16 kW, respectively, as shown in Figs. 4 and 5.

In summary, the development of CCHP system began during the energy crisis in the 1970s. It has drawn increasing attention due to its outstanding advantages, such as energy saving and environmental protection. Since the 1990s, it has experienced a great development. Besides, the researches in this field are very active in recent years. However, most of the researches are still in the investigation stage. The preliminary research is being carried out in depth. The results have laid a solid foundation for the subsequent researches.

References

Huang SY, Gao W (2013) Introduction to energy. Higher Education Press, Beijing (in Chinese)

Yan JJ, Huang JT, He MJ (2006) Combined cooling, heating and power technology. Chemical Industry Press, Beijing (in Chinese)

Wang RZ, Ding GL (2002) The latest refrigeration and air conditioning technology. Science Press, Beijing (in Chinese)

Dai YQ, Geng HB, Lu Z et al (1996) Lithium bromide absorption refrigeration technology and application. Mechanical Industry Press, Beijing (in Chinese)

Wang RZ, Wu JY, Dai YJ et al (2002) Adsorption refrigeration. Mechanical Industry Press, Beijing (in Chinese)

Chinese Academy of Sciences Sustainable Development Research Group (2003) China sustainable development report 2003. Science Press, Beijing (in Chinese)

Chinese Academy of Sciences (2003) High technology development report 2003. Science Press, Beijing (in Chinese)

Wei CB, Lu SX, Zhou ZY (2002) Practical refrigeration and air conditioning engineering handbook. Machinery Industry Press, Beijing (in Chinese)

Jin HG, Lin RM (2008) Comprehensive cascade utilization of energy and gas turbine total energy system. Science Press, Beijing (in Chinese)

Fu XZ, Xiao YM (2008) Building energy conservation principle and technology. Chongqing University Press, Chongqing (in Chinese)

Jiang ZM (2008) Reflections on energy issues in China. J Shanghai Jiaotong Univ 42(3): 345–359 (in Chinese)

Srivastava NC, Eames IW (1997) Review of developments in solid-vapour adsorption refrigeration and heat-pump systems. J Inst Energy 70(485):116–127

Meunier F (1998) Solid sorption heat powered cycles for cooling and heat pumping applications. Appl Therm Eng 18(9–10):715–729

Xu JZ (2002) The prospect of distributed power supply and combined cooling, heating and electricity. Energy Conserv Environ Prot 3:10–14. (in Chinese)

Wang RZ (2002) Some discussions on energy efficiency in building and hybrid energy systems. Acta Energiae Solaris Sinica 23(3):322–335. (in Chinese)

Maidment GG, Prosser G (2000) Use of CHP and absorption cooling in cold storage. Appl Therm Eng 20(12):1059–1073

Maidment GG, Zhao X, Riffat SB et al (1999) Application of combined heat-and-power and absorption cooling in a supermarket. Appl Energy 63(7):169–190

Zhu CZ (2000) Guilding principle for and enlightenment from coolant heat and power cogeneration in USA. Electr Power 9:91–95. (in Chinese)

Alexandria (2000) DOE advanced microturbine program update. Final ATS annual program review meeting. p 12

Jiang Y, Fu L (2001) New approach for Urban District heating with gas. Energy China 6:8–12. (in Chinese)

Kari A, Arto S (2004) Sustainable small-scale CHP technologies for buildings: the basis for multi-perspective decision-making. Renew Sust Energ Rev 8(5):401–431

Zhu CZ (2001) Combined heat and power, CCHP and small-sized CCHP. Energy Conserv Environ Prot 1:25–27. (in Chinese)

Smith MA, Few PC, Twidell JW (1995) Technical and operational performance of a small-scale combined heat-and-power (CHP) plant. Energy 20(12):1205–1214

Cai RX, Zhang N (2005) On distributed energy system. Sci Tech Rev 23(9):7–8. (in Chinese)

Xu JZ, Sui J, Jin HG (2004) State and trend of distributed energy systems. Sol Energy 14(4): 14–16. (in Chinese)

Wu CK, Xu JZ, Jin HZ (2000) The strategic development of energy science. World Sci Tech R D 22(4):1–6. (in Chinese)

Wang QY (2006) International comparison of China’s energy consumption per unit products and its implications. Int Pet Econ 2:24–30. (in Chinese)

Fan CY (1995) DHC system for the Shinjuku area in Tokyo. Heat Ventilat Air Cond 5:52–55. (in Chinese)

Qiang GF (1995) The present status and future prospects of over seas engineering projects for triple production and supply of thermal energy, electricity and refrigeration – the fourth in a series of technical reports on Cogeneation systems. J Eng Therm Energy Power 10(5):259–267. (in Chinese)

Li J, Gu C, Sun XT et al (2006) The conspectus of combined cooling heating and power and its development status. Sci Technol Econ Market 4:60–61. (in Chinese)

Li XR (1996) Application and benefit analysis of lithium bromide absorption refrigeration technology. Dist Heat 4:3–8. (in Chinese)

Li XR (1997) Centralized triple supply of development of domestic urban agglomeration. Dist Heat 6:19–21. (in Chinese)

Liu FQ, Zhang SF, Pan WG et al (2002) Off-design performance and thermodynamic analysis of a building cooling, heating and power generation system. Power Eng 22(5):2005–2010. (in Chinese)

Ling HX (2002) Application of natural gas cogeneration unit in Pudong International Airport. Urban Util 16(1):25–28. (in Chinese)

Liu CJ, Lu QJ, Li WY et al (2005) Application study on economic operation of district cooling system – summary of research on DHC economic operation in Pudong International Airport. Energ Technol 26(2):81–83. (in Chinese)

Lin ZH (2005) Combined cold heat and power system in energy Center of Shanghai Pudong International Airport. Shanghai Energy Conserv 6:158–164. (in Chinese)

Pan YH (2008) The implementation feasibility analysis of distributed energy supply in shanghai. Huadian Technol 30(9):77–79. (in Chinese)

The case study 93 of Energy – saving information dissemination center of National Development and Reform Commission (2007) Application of the system of combined cold heat and power in Beijing building of gas supply. Energy China 29(12):57–58. (in Chinese)

Wu DW, Wang RZ (2006) Combined cooling, heating and power: a review. Prog Energy Combust Sci 32(5–6):459–495

Cardona E, Piacentino A (2003) A methodology for sizing a trigeneration plant in mediterranean areas. Appl Therm Eng 23(13):1665–1680

Wang MH (2006) Optimal design combined of cold heat and power system in buildings by introducing the best cold turn coefficient. Energy Eng 5:61–65. (in Chinese)

Lee JB, Lyu SH, Kim JH (1994) A daily operation scheduling on cogeneration system with thermal storage tank. IEEE Trans 10:1295–1302

Smith MA, Few PC (2001) Domestic-scale combined heat and power system incorporating a heat pump: analysis of a prototype plant. Appl Energy 70(3):215–232

Smith MA, Few PC (2001) Second law analysis of an experimental domestic-scale cogeneration plant incorporating a heat pump. Appl Therm Eng 21(1):93–110

Smith MA, Few PC (2001) Modelling of a domestic-scale co-generation plant thermal capacitance considerations. Appl Energy 68(1):69–82

Miguez JL, Murillo S, Porteiro J et al (2004) Feasibility of a new domestic CHP trigeneration with heat pump: design and development. Appl Therm Eng 24(9):1409–1419

Porteiro J, Miguez JL, Murillo S et al (2004) Feasibility of a new domestic CHP trigeneration with heat pump: availability analysis. Appl Therm Eng 24(9):1421–1429

Colella WG (2003) Modeling results for the thermal management sub-system of a combined heat and power fuel cell system. J Power Sources 118(1–2):129–149

Benelmir R, Feidt M (1998) Energy cogeneration systems and energy management strategy. Energy Convers Manag 39(16–18):1791–1802

Liu FQ (2005) Thermo-economic optimization of heat recovery steam generators for BCHP systems. Gas Turbine Technol 18(2):52–56. (in Chinese)

Zhang YY (2006) Research on a simulated 60kW PEMFC cogeneration system for domestic application. J Zheijang Univ Sci A 7(3):450–457

Fang H (2006) Investigation into optimal operation of BCHP systems in the air-conditioning season. Gas Turbine Technol 19(1):43–49. (in Chinese)

Zhang XH (2005) The optimization performance of thermoelectric (cold) co-production system. J Eng Therm Energy Power 20(1):52–56. (in Chinese)

Jiang Y (2004) Thermal economic analysis of micro-gas turbine based CCHP system. J Univ Shanghai Sci Technol 26(5):485–489. (in Chinese)

Huangfu Y (2007) Study of integrated thermal management controller for internal combustion gas engine based micro-scale combined cooling, heating and power system application. A Dissertation for the Degree of Philosophy Doctor in Shanghai Jiao Tong University. (in Chinese)

Li S, Wu JY, Wang RZ et al (2007) Study of heat and mass transfer in integrated thermal management controller (ITMC) employed in waste heat recovery application. Energy Convers Manag 48(12):3074–3083

Fu L, Jiang Y (2003) Research on optimized operation of combined cooling, Heating and Power System-Case Analysis of Refrigeration. Proc Acad Conf Eng Mech Energy Util Chinese Soc Eng Thermophys 11:264–271. (in Chinese)

Fu L, Jiang Y (2003) Optimization research on the operation of combined cooling, heating and power system – model and algorithm. Proc Acad Conf Eng Mech Energy Util Chinese Soc Eng Thermophys 11:272–277. (in Chinese)

Zhang WK (2003) The BCHP cogeneration system’s configuration and its optimal application analysis. A Dissertation for the Degree of Master in Shanghai Jiao Tong University. (in Chinese)

Li S, Wu JY, Wang RZ (2008) Summary of research hotspots on the combined cooling, heating and power (CCHP) system. Refrig Air Cond 8(6):1–9. (in Chinese)

Silveira JL, Martins Leal E, Ragonha LF Jr (2001) Analysis of a molten carbonate fuel cell: cogeneration to produce electricity and cold water. Energy 26(10):891–904

Gorsek A, Glavic P (2003) Process integration of a steam turbine. Appl Therm Eng 23(10): 1227–1234

Biezma MV, San Cristobal JR (2006) Investment criteria for the selection of cogeneration plants – a state of the art review. Appl Therm Eng 26(5–6):583–588

Havelsky V (1999) Energetic efficiency of cogeneration systems for combined heat, cold and power production. Int J Refrig 22(6):479–485

Lv J, Wang ZZ (1998) A review of evaluation criteria for cold heat and power system. Energy Conserv 7:10–12. (in Chinese)

Fu L, Jiang Y (1999) Thermal economy performance of cold heat and power system based on coal consumption. J Eng Therm Energy Power 14(1):10–13. (in Chinese)

Fu L, Geng KC, Jiang Y et al (2006) Incremental evaluation method and economic analysis of thermoelectric (cold) co-production. Cogeneration Power Technol 2:5–8. (in Chinese)

Jia MS, Ling CM (2004) An analysis of several main evaluation models of combined cooling heating and power production. Refrig Air Cond 4(4):34–38. (in Chinese)

Huangfu Y, Wu JY, Wang RZ et al (2005) Study on comprehensive evaluation model for combined cooling heating and power system (CCHP). J Eng Thermophys 26(Sl):13–16. (in Chinese)

Feng ZB, Jin HJ (2005) Performance assessment of combined cooling, heating and power. J Eng Thermophys 26(5):725–728. (in Chinese)

Sun XT, Gu C, Rao ZF (2006) Thermal economy of gas cogeneration based on energy saving rate. Energy Conserv 9:27–29. (in Chinese)

Deng J, Wu JY, Wang RZ et al (2008) Performance evaluation of a micro-combined cooling heating and power system based on structural theory of thermal economy. J Eng Thermophys 29(5):731–736. (in Chinese)

Xie ZL, Sun ZG (2008) Studying of evaluation methods of combined cold heat and power system. Build Energy Environ 27(4):81–83. (in Chinese)

Feng Z, Yang Z, Chen YG (2009) Thermal economy analysis of cold heat and power system of heat pump in gas turbine. J Eng Therm Energy Power 24(5):597–603. (in Chinese)

He BB, Duan LQ, Yang YP (2009) Research on new evaluation criterion of CCHP system. J Eng Therm Energy Power 24(5):592–596. (in Chinese)

Frost & Sullivan (2006) Opportunities in European micro Combined Heat and Power (CHP) markets. Frost & Sullivan, New York

Accadia MD, Sasso M, Sibilio S et al (2003) Micro-combined heat and power in residential and light commercial applications. Appl Therm Eng 23(10):1247–1259

European Micro-CHP Markets, Draft report. May 2001

Peacock AD, Newborough M (2008) Effect of heat-saving measures on the CO2 savings attributable to micro-combined heat and power (μCHP) systems in UK dwellings. Energy 33(4):601–612

Míguez JL, Murillo S, Porteiro J et al (2004) Feasibility of a new domestic CHP trigeneration with heat pump: I. Design and development. Appl Therm Eng 24(10):1409–1419

Porteiro J, Míguez JL, Murillo S et al (2004) Feasibility of a new domestic CHP trigeneration with heat pump: II. Availability analysis. Appl Therm Eng 24(10):1421–1429

Colella WG (2003) Modelling results for the thermal management sub-system of a combined heat and power (CHP) fuel cell system (FCS). J Power Sources 118(1–2):129–149

Gigliucci G, Petruzzi L, Cerelli E et al (2004) Demonstration of a residential CHP system based on PEM fuel cells. J Power Sources 131(1–2):62–68

Wang RZ, Wang LW (2005) The green refrigeration technology driven by low-grade thermal energy-adsorption refrigeration. Chin Sci Bull 25(1):1–11. (in Chinese)

Hao XL, Zhang GQ (2005) Summarization on building combined cooling heating and power system. Gas Heat 25(5):67–73. (in Chinese)

Tang TB, Xia YF, Lu W et al (2003) Power failure of this year in USA and its inspiration to safe stable operation of power system in China. Electr Power Construct 24(11):2–4. (in Chinese)

Kong XQ (2005) Research of a micro CCHP system with gas engine and adsorption chiller. A Dissertation for the Degree of Philosophy Doctor in Shanghai Jiao Tong University. (in Chinese)

Kong XQ, Wang RZ, Huang XH (2002) Distributed energy resource (DER) systems: CCHP systems. China Construct Heat Refrig 5:5–7. (in Chinese)

Kong XQ, Li Y, Wang RZ (2006) Progress on the small-scale CCHP system with adsorption refrigeration. China Construct Heat Refrig 10:19–21. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Section Editor information

Rights and permissions

Copyright information

© 2018 Springer-Verlag GmbH Germany, part of Springer Nature

About this entry

Cite this entry

Li, Y., Kong, X. (2018). Introduction to CCHP Systems. In: Wang, R., Zhai, X. (eds) Handbook of Energy Systems in Green Buildings. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-49120-1_36

Download citation

DOI: https://doi.org/10.1007/978-3-662-49120-1_36

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-662-49119-5

Online ISBN: 978-3-662-49120-1

eBook Packages: EnergyReference Module Computer Science and Engineering