Abstract

Sesame is a widely cultivated oilseed and both its cake and oil present high nutritional quality and economic value. The importance of this seed has grown as new research is made. Initial research has been performed in the application of pulsed electric fields (PEF) and high voltage electrical discharge (HVED) technologies on sesame cake and sesame seeds. Some of the currently published results are presented in this chapter. HVED technology is based on the phenomenon of electrical breakdown in water, which induces physical and chemical processes. Both pulsed electric fields and high voltage electrical discharges efficiently damaged sesame seed cells; this damage increased with the applied energy input. The permeabilization caused in the seeds by the electrical treatments significantly raised the oil yield when compared to untreated seeds. However, a significant amount of oil was lost in water during the electrical treatment step. The results also demonstrated that extraction assisted by PEF or HVED could be effective techniques to increase yield of polyphenol, lignan, and protein extraction from sesame cake and improve kinetics of diffusion. These technologies can potentially reduce the use of ethanol as a solvent for phenolic compounds extraction and the need of higher temperatures to improve diffusion.

Access provided by CONRICYT-eBooks. Download reference work entry PDF

Similar content being viewed by others

Keywords

Introduction

Sesame crops present great economic potential, mainly due to do their high oil content. The importance of this seed has grown as new research is made. In addition to being rich in oil, sesame has high protein content and is rich in fibers, vitamins, and antioxidants. The main sesame antioxidants are lignans and lignan glucosides; these compounds are present in both sesame oil and sesame cake. Sesame processing, as well as processing of other oilseeds, involves pressing for oil extraction, which produces a seed cake. This cake, therefore, can be considered a by-product. Sesame cake is conventionally used for cattle feed; however, proteins and phenolic compounds can be successfully extracted from this product.

By-products from food processing are promising sources of bioactive compounds of great interest. For this reason, in the last decade, research involving these residues has increased markedly. Among the strategies for valorization of by-products are the extraction and purification of bioactive compounds and proteins, which is an area of interest for both industry and research.

Conventional methods of compounds recovery from vegetable matrixes often involve mechanical disintegration and/or pressing with following extraction using strong organic solvents. The efficiency of these methods depends on the degree of cell membrane permeabilization. Recently, several techniques have been studied with the goal of reducing time, costs, energy consumption, and solvent use. Among them are ultrasounds and microwave-assisted extraction, high pressure, pulsed electric fields (PEF), and, more recently, high voltage electrical discharges (HVED). Pressing and solvent extraction are the most common processes used for oil recovery from seeds. When solvents are used, they provide higher oil yields; however, the oil obtained is of lower quality. To improve pressing efficiency, thermal, mechanical, chemical, and enzymatic pretreatments can be performed. Besides these pretreatments, the application of PEF and HVED emerges as possibilities to provide a gentle, low-temperature, and highly effective process to pretreat the seeds. In both contexts aforementioned, PEF and HVED are associated to their effect on the cell wall and/or on the cell membrane. These structural changes have the potential to increase mass transfer during extraction or pressing.

Sesame

Sesame (Sesamum indicum L.) is an oilseed belonging to the Pedaliaceae family. Sesame seeds are flat and have reduced size and color varying from white to black; they are widely cultivated mainly due to their high oil content, varying between 46% and 56% (Namiki 1995). Sesame oil is rich in unsaturated fatty acids such as oleic and linoleic acid and has several secondary constituents of great importance in their chemical properties such as sesamol, sesamin, and sesamolin. These compounds have antioxidant properties that avoid oxidation and provide good chemical stability to the sesame oil when compared to other vegetable oils. Oil production is the main reason for cultivation of sesame (Namiki 1995). Figure 1 presents the unit operations (dashed line boxes) and products generally involved in sesame processing.

As can be observed in Fig. 1, sesame cake is an oil industry by-product . In several sesame seed-producing countries, this product is used only as animal feed or even discarded. However, studies reveal that sesame cake is rich in antioxidants, suggesting that it could have different applications in the food industry (Reshma et al. 2010; Mohdaly et al. 2011). Antioxidants obtained from sesame by-products can be used in food, to increase their stability, through the prevention of lipid oxidation, and for direct human and animal consumption to protect biomolecules and structures (as membranes and ribosomes) from oxidative damage (Mohdaly et al. 2011).

Composition, Cultivation, and Economical Aspects

Sesame seed composition, according to the Nutrient Database for Standard Reference (USDA), is water (4.7%), protein (17.7%), total fat (49.7%), carbohydrate (23.5%), total fiber (11.8%), and sugar (0.3%). Studies show that the fat content can vary between 45% and 50% and that proteins can represent up to 20% of the seed weight (Reshma et al. 2010). According to Ramachandran et al. (2007), sesame cake has protein, fiber, ashes, and water content around 35%, 7.6%, 12%, and 17%, respectively. Protein contents in sesame cake, however, can be higher, up to 60%.

Sesame is originally from Africa, being most wild species of the Sesamum genus still found in this continent; on the other hand, in Asia are found most of the cultivated species. Sesame cultivation adapts to semiarid conditions in different parts of the world, being an important option for income source in semiarid regions. World production of these seeds in 2014 was of 5.469 million tons, with a cultivated area of 6.709 million ha. The main producing regions are Asia and Africa which are responsible for 42% and 55% of the world production, respectively. Among the Asian countries, the main producers are China, India, and Myanmar (FAO 2014). Sesame cake productions is estimated to be very high, considering that 70% of the seed crops are destined to oil production (Namiki 1995).

Oil

Oil and fats are esters of fatty acids and glycerol. Most of the time, they occur in the form of triglycerides, in which three fatty acids are attached to the glycerol. Fatty acids contain the carboxyl group (COOH) and an aliphatic carbon chain of variable length. With few exceptions, fatty acids are linear, range in size from 4 to 24 carbons, and contain an even number of carbons. The chains can be saturated (having no double bonds), monounsaturated (one double bond), or polyunsaturated (two or more double bonds).

Sesamum indicum L. seed oil is of unsaturated type and contains mainly the fatty acids oleic C18:1(38.84%) and linoleic C18:2 (46.26%) (Nzikou et al. 2009). The oil can be classified in the oleic-linoleic acid group. Oleic acid is a monounsaturated fatty acid member of the subgroup called long chain fatty acids (LCFA) (from 14 to 18 carbon atoms). Oleic acid is by far the most widely distributed and abundant fatty acid in nature (few fats known to contain less than 10%) where it is mainly found as glycerol ester. Linoleic acid is a polyunsaturated fatty acid (PUFA) with two cis double bounds also member of the subgroup called long chain fatty acids (LCFA), from 14 to 18 carbon atoms. Linoleic acid is one of the most important polyunsaturated fatty acids in human food because of its prevention of distinct heart vascular diseases (Boelhouwer 1983). High unsaponifiable matters content (1.76%) guarantees the use of the oils in cosmetics industry.

Proteins

Vegetal proteins are of great importance in human nutrition, and there is a constant search for new sources of these proteins to be used directly in the diet, as an ingredient, or in diet supplementation. Therefore, the development of a sesame protein isolate can provide the food industry a new option.

The defatted sesame flour, which concentrates the protein, has around 50% protein. Sesame amino acid profile shows that this seed is low in lysine and threonine and rich in methionine and cysteine. The last two are frequently considered limiting amino acids in vegetables. Moreover, different from other oilseeds, sesame is also rich in tryptophan. Considering this profile, it is possible to assume that sesame proteins can be used in combination with other vegetable proteins. Moreover, sesame amino acids complement the amino acids in soy proteins, which could be of great interest (Hwang 2005; Ramachandran et al. 2007).

Proteins from sesame can be obtained through the direct use of sesame cake or flour (after oil extraction – see Fig. 1), or they can be extracted to obtain protein concentrates and isolates with higher purity. Analysis performed in these concentrates shows that their functional proprieties are similar to soy protein (Kanu et al. 2007).

Phenolic Compounds and Antioxidant Activity

Sesame is rich in antioxidants including phenolic compounds and tocopherols. The phenolics of interest in sesame are physiologically active lignans and their glucosides . The main lignans present in these seeds are sesamin and sesamolin; however, sesame also contains trans-caffeic, trans-p-coumaric, and trans-ferulic acid as well as traces of p-hydroxybenzoic acid (Shahidi and Naczk 2004).

Lignans from sesame have been studied for many years; however, more recently, lignan glucosides were found in sesame, mainly in sesame-defatted cake, since these are hydrophilic antioxidants. Among sesame lignan glucosides, the most important are sesaminol, pinoresinol, and sesamolinol, where sesaminol and triglucoside are present in the highest amounts (Moazzami et al. 2006). Due to the presence of these glucosides, sesame by-products, such as shells and cakes and flours, were used (Suja et al. 2004; Sarkis et al. 2015b).

Studies involving sesamin, sesamolin, and sesamol have showed positive effects of these substances on hypertension and hypercholesterolemia reduction, as well as their neuroprotective effects (Chen et al. 2005), among others. Moreover, recent research has been developed on the health effect of sesaminol triglucoside (Liao et al. 2010). It is important to point out that protein and polyphenol bioavailability is related to the way these compounds interact. Polyphenols can interact irreversibly with proteins and digestive enzymes, hindering their absorption (Brunet et al. 2002).

Pulsed Electric Fields and High Voltage Electrical Discharges for Oil Extraction from Sesame Seed

Usual Oil Extraction Processes: Pressing and Solvent Extraction

Oil extracted from seeds can be used for cooking or as salad oil; as an ingredient in paint, cosmetics, and soap; and even as fuel.

Historically, a simple, hand-operated cylinder pump was used to press flat plates or hollow cages attached to the hydraulic ram against a fixed-position ram. It allowed considerably high pressure to be exerted and involves the use of hydraulically operated rams. This type of press developed into a motorized hydraulic pump system that pressed the seed bag and then released a press cake. The next improvement in extracting oil was the screw press or expeller. Screw presses use an electric motor to rotate a heavy iron shaft, which has flights, or worms built into it to push the seeds through a narrow opening. The pressure of forcing the seed mass through this slot releases part of the oil, which comes out through tiny slits in a metal barrel fitted around the rotating shaft (Chapuis et al. 2014). Expellers have a continuous flow of seed through the machine in contrast to the hydraulic system described above, which uses small, individual packages or batches of seed. To release as much oil as possible, the seeds must be dried to rather low moisture content and exposure to high temperature causes darkening of the oil. It also causes some scorching or overheating of the meal. The meal contains protein which, if undamaged, may be used for either human food, sesame flour, for example, or animal feed such as sesame meal. Because most press or expeller processes overheat the meal and leave too much of the high-value oil in the seedcakes, methods of extracting the oil with solvents were developed.

Seeds with low oil content are processed by solvent methods alone. In other cases, presses are used first to extract part of the oil and then solvents (hexane) extract the oil that remains in the seeds. Because of their efficiency, processes employing solvents to extract vegetable oils in large quantities are in wide use, and solvent extraction equipment is readily available commercially. Solvent extraction of vegetable oils, which recovers more oil than earlier methods and leaves more usable meal, begins to be economically attractive in different scenarios: where large quantities of seed can be processed (at least 200 tons per day for continuous-feed processes); where storage, transportation, power, water, and solvent supply are adequate; and where occupational safety and training standards can be enforced. There are solvent extraction plants with capacities of up to 4,000 tons per day.

When solvents are used, they provide higher oil yields; however, the oil obtained using this methodology is of lower quality. For this reason, pressing is most commonly used for oils with high nutritional values as sesame (Willems et al. 2008) .

Intensification of the Oil Extraction

Plants Oil Recovery with Pulsed Electric Fields and High Voltage Electrical Discharges

To improve pressing efficiency, thermal, mechanical, chemical, and enzymatic pretreatments can be performed. In this way, the press can be feed with raw or treated seeds (Savoire et al. 2013). These pretreatments need to be chosen carefully since they can affect the oxidative stability of the oils and of the lignans in the product (Hwang 2005). Besides these pretreatments, the application of pulsed electric fields (PEF) and high voltage electrical discharges (HVED) emerges as possibilities to provide a gentle, low-temperature, and highly effective process to pretreat the seeds.

The application of high-intensity electric fields could be used for the recovery of plant oils. For example, PEF has been evaluated as a pretreatment for oil extraction from maize (Guderjan et al. 2005). Maize germ oil contains high amount of unsaturated fatty acids and of vitamin E, thus owing nutritional benefits. Additionally, it is stable in oxygen and, at low temperatures, has a neutral taste and color stability. These are the reasons why it is mainly used as salad oil, in margarines, and as frying oil in the industry (Orthoefer and Sinram 1987). It occurs as a by-product of the wet-milling process in the starch industry. The main purposes of this steeping process are to soften the kernel for separation of the different components, to inhibit microorganisms, and to produce white starch. The wet-milling process is divided in the main parts: soaking in steepwater, supplemented with sulfur and lactic acid at the pH of 3.8 at 50 °C for 48 h, coarse grinding, germ separation, washing, drying, and finally oil extraction. For an application of PEF, such pretreated germs are not eligible because of their loss of germination capacity during the steeping process and furthermore due to the drying at high temperatures of 80–120 °C after harvesting. It is thus necessary to previously soak the germs in water for a subsequent effective PEF treatment of maize. The moisture content when the germs were pulsed was of approximately 60%. This modified process scheme for the production of maize germ oil increased amounts of phytosterols (up to 32.4%) and allowed obtaining higher oil yield (up to 88.4%) as compared to the classical extraction scheme. By using hull fractions during the extraction additionally to a mild application of PEF (0.6 kV/cm) on maize germs, the yield of phytosterols increased by 32.4%.

Sesame Oil Extraction with Pulsed Electric Fields and High Voltage Electrical Discharges

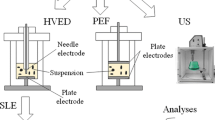

The application of PEF and HVED has also been performed on sesame seeds for oil extraction intensification (Sarkis et al. 2015b). The industrial sesame oil production is based on seed drying, cleaning (to remove stone, dust, etc.), and then pressing by using an expeller. This process is repeated to extract maximum oil. Oil is then filtered on filter press and packed. As it is the case for maize processing, it is necessary to soak the sesame seeds for a subsequent effective electrical pretreatment. A new extraction scheme was thus proposed (Sarkis et al. 2015b) (Fig. 2). For the comparison, different treatments were applied in the seeds before pressing: untreated sesame (without immersion and drying) (U); immersion in water followed by drying (ID); immersion in water, drying, and grinding (IDG); and immersion, PEF, or HVED treatment (40–240 kJ/kg) and subsequent drying. The immersion allowed to increase the seed moisture content from 3.6 ± 0.5% to 39.05 ± 0.05%. Drying was performed after the treatments (seed moisture content reached a value between 5% and 8%) for the subsequent pressing step (1 h–100 bars).

Schematic diagram of the seed processing steps for (a) electrically treated seeds and (b) ID (immersed and dried) and IDG (immersed, dried, and grinded) samples (With permission from Sarkis et al. (2015b))

When comparing the oil yield obtained after all treatments (Fig. 3), without considering what was the oil lost in water (during the electrical treatment step), grinding was the best treatment followed by PEF and HVED treatments. These electrical treatments, however, yielded better results than the sample when only immersed and dried, showing a significant effect of the pulses and discharges in the cell membrane and/or wall. The HVED treatment at 160 kJ/kg provides the same oil yield as the ID sample, and if 240 kJ/kg are applied, the yield is equivalent to what is obtained for the U sample.

Oil yield for all treatments performed: not considering the oil lost in water (a) and considering the oil lost in water (b). For each treatment, values not sharing a common superscript letter differ significantly at p < 0.05. “a” represents the higher oil yield and “f” the lowest (With permission from Sarkis et al. (2015b))

PEF treatment increased the oil yield by 4.9%, and HVED, if accounted oil losses in water, resulted in the extraction of 22.4% more oil when samples are compared to control. The grinded sample presented higher oil yield than PEF and lower than HVED.

However, a significant amount of oil was lost in water during the electrical treatment step. When calculating the oil yield by taking into account the amount of oil lost in water, HVED at energy input levels between 160 and 240 kJ/kg were the best pretreatments, significantly better than grinding, which was the second best treatment. Furthermore, all HVED treatment presented superior oil yields than PEF-treated seeds. It is important to point out that immersing and drying the sample caused some damage to the seeds that significantly increased the oil extraction. The best HVED treatment can be performed at 160 kJ/kg which was able to extract 89.1% of the total oil. This represents an increase of 22.4% and 6.6% when compared to the ID and the IDG samples, respectively. For PEF, the best treatment energy was 40 kJ/kg. In this case the oil yield was 71.6%, and this value is 4.9% higher than the yield obtained for the ID seeds and 10.9% smaller compared to the yield observed for grinded seed. When considering the oil quality, the lignan profile of the sesame oil obtained from all analyzed treatments showed the presence of sesamin and sesamolin and demonstrated that the electrical treatment did not alter this profile.

The PEF effect on the seeds was significant, resulting on better oil yields than that achieved with the immersed and dried seeds. This effect may result from the electropermeabilization suffered by the seeds during this pretreatment. PEF acts on the cell membrane by forming pores, but does not change the product structure (Vorobiev and Lebovka 2008). On the other hand, the application of electrical discharges results on the fragmentation of the particles, which significantly increased the oil extraction. As pointed out by Boussetta and Vorobiev (2014), the fragmentation of the seeds during the application of discharges is caused by the propagation of shock waves and explosion of the main cavitation bubble, which generates several small cavitation bubbles. These phenomena damage the seeds and increases permeabilization in cell walls as well as membranes. This occurs only during HVED and not with PEF treatment a consequence of the arc formed during discharges. The higher extraction efficiency of HVED can be linked to the fragmentation due to the arc formation (Boussetta and Vorobiev 2014). It is significant to mention that, even though PEF provided lower oil yields, there are advantages to the application of this technology. Since PEF preserves the product structure, there is no oil loss in the water, and, as it has been showed in literature (Boussetta et al. 2012), PEF could facilitate subsequent separation steps between the solids and the treatment water.

Regarding the HVED technology, two important concerns can be raised: the formation of an oil/water emulsion during the HVED treatments and the need of additional procedures during the extraction (soaking and drying) which could increase costs. Previous studies were performed using membranes for oil recovery and show that the process is feasible (Li et al. 2009). Furthermore, we believe that new setups could be develop to diminish the use of water during the electrical treatments and reduce the formation of an emulsion. Concerning the additional steps during extraction, the soaking and drying procedures should be further evaluated and optimized. The study on sesame seed oil extraction is still in its initial steps and concerns only bench-scale experiments so far.

Pulsed Electric Fields and High Voltage Electrical Discharges Effects for Phenolics Extraction from Sesame Cake

Sesame cake has been discovered to be rich in lignan glucosides , which are hydrophilic antioxidants and, thus, are not extracted with the oil. Other important aspect of this cake is the high protein content of important nutritional value. Both proteins and phenolic compounds can be extracted and purified, for the obtaining of new ingredients. This section covers the current data on extraction of proteins and phenolics from sesame seed cake.

Conventional extraction of compounds, such as proteins and polyphenols, generally involves mechanical disintegration of vegetable matrixes, high temperatures, and/or the use of strong organic solvents. In recent times, several alternative techniques have been studied with the goal of reducing cost, energy consumption, and extraction time. Among them are pulsed electric fields (PEF) and high voltage electrical discharges (HVED). Only a small number of works have been performed using the aforementioned technologies and oilseeds. Research involving polyphenol and proteins extraction has been performed recently for sesame seed cake by Sarkis et al. (2015a). The study analyzed the effects of different parameters (solvent type and concentration and temperature) in order to enhance extraction of polyphenols, lignans, and proteins from sesame cake through the application of PEF and HVED with different energy inputs.

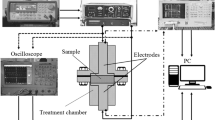

The energy inputs evaluation was performed using a pulsed high voltage power supply (Tomsk Polytechnic University, Tomsk, Russia). Each pulse or discharge performed by the equipment provides 40 kV, considering the electrode gap; for PEF application, the electric field was 13.3 kV/cm. Pulse or discharge duration was 10 μs and frequency was 0.5 Hz (2 s between pulses or discharges). Energy inputs vary from 0 to 291 kJ/kg (treatment times from 1 to 7 ms), and the treatment efficiency was evaluated trough the permeabilization index (ZC) and the polyphenol and protein concentration. Results are presented in Fig. 4.

Energy input versus (a) electrical permeabilization index (ZC), (b) total polyphenols in the extracts, and (c) protein concentration in the extract for PEF (13 kV/cm) and HVED (40 kV) (With permission from Sarkis et al. (2015a))

Experiments showed cell permeabilization increased with energy input for both treatments, PEF and HVED. The maximum cell damage for PEF was of 67%, obtained after 125 kJ/kg, and for HVED this damage was of 90%, reached after 83 kJ/kg. Results show that both treatments affected sesame cake; after treatment most of the cell membranes were permeabilized. Figure 4b, c shows the variation of polyphenols and protein extracted during treatments and for the control sample (proteins are not shown for control as they were below the concentration limit). Results showed an important correlation between extraction yield and permeabilization index ; this was observed only in this work for sesame, but it has been previously demonstrated for flaxseed cake (Boussetta et al. 2013b).

Figure 4 shows that whatever the case HVED resulted in higher cell permeabilization, this can be explained due to the different phenomena involved in each methodology. The arc which is formed inside the treatment chamber with HVED increases significantly the extraction yield (Boussetta et al. 2013a). Furthermore, when discharges are applied, the cake is grinded as a consequence since it produces shock waves that cause a highly turbulent mixing environment, improving extraction (Boussetta and Vorobiev 2014).

The work of Sarkis et al. (2015a) also evaluated diffusion after PEF and HVED pretreatments using 83 kJ/kg. Diffusion of total phenolics and lignans where evaluated in water/ethanol systems with varying ethanol concentration from 0% to 50% ethanol. Both, phenolics and lignans, were released from the solid to the solvent more significantly in the first 20 min. After this initial period, the diffusion of the solutes from the cake increased slowly. When compared to a control sample, without pretreatment, PEF- and HVED-treated samples presented phenolic concentration 2.6 and 3.2 times higher than control after 10 min, respectively. When ethanol was used, the extraction efficiency was very similar for both electrical pretreatments. Although when water was used as a solvent, HVED extracted more phenolics in the first 20 min of diffusion. An evident effect of the use of discharge in the extraction of solutes in water was also observed by El-Belghiti et al. (2005) and Grémy-Gros et al. (2008).

Experiments performed with sesame cake lignans (Sarkis et al. 2015a) using PEF and HVED showed similar results. Analyses were performed using high-performance liquid chromatography (HPLC) (Rangkadilok et al. 2010). Both treatments increased the extraction of lignans and the effect of HVED was more pronounced. Also, for the pretreated samples, concentration reached the maximum at a time of approximately 20 min, which was not observed for control. After 10 min in a 30% ethanol solution, the total amount extracted of the main lignan was 3.2 and 2.6-folds higher for HVED- and PEF-treated samples, respectively, when compared to the untreated sample. As HVED treatments can produce active species, it is important to be concerned about the quality of the extracts obtained. When sesame cake lignans were evaluated using HPLC, the main lignan peak for the HVED-treated sample had a different retention time when compared to the other samples (control and PEF). This difference could be related to the reaction between the lignans in the extracts and some of the active species generated in secondary reactions of the discharges, such as hydroxyl radicals, atomic oxygen, and ozone (Locke et al. 2005). However, when the ultraviolet (UV) spectrum was evaluated, both peaks presented the same maximum absorption bands, 237 and 291 nm, which indicates that they are both lignan glucosides (Sarkis et al. 2015a).

Diffusion of proteins and polyphenols in different temperatures (20–60°) suggests that, if electrical treatments are applied to sesame seed cake, it is possible to reduce the diffusion temperature. This observation of a “cold” extraction was expected, since previous studies from literature found the same effect (Loginova et al. 2011).

Conclusions

Both pulsed electric fields and high voltage electrical discharges efficiently damaged sesame seed cells. This damage increased with the applied energy input. The permeabilization caused in the seeds by the electrical treatments significantly raised the oil yield when compared to the untreated seeds. The increases in oil expression reduced the amount of cake produced, but still it is important to point out that the obtained cake was rich in proteins and polyphenols. Extraction assisted by PEF or HVED is an effective technique to increase yields of polyphenol, lignan, and protein recovery from sesame cake and improve kinetics of diffusion. PEF or HVED technologies can reduce the use of ethanol as a solvent for phenolics extraction and the need of heat to improve diffusion. Both technologies can be thus efficient alternatives to be used as pretreatments prior to oil extraction from sesame seed and for sesame cake valorization.

References

Boelhouwer C (1983) Trends in chemistry and technology of lipids. J Am Oil Chem Soc 60:457–462

Boussetta N, Vorobiev E (2014) Extraction of valuable biocompounds assisted by high voltage electrical discharges: a review 17(3):197–203

Boussetta N, Grimi N, Lebovka NI, Vorobiev E (2012) “Cold” electroporation in potato tissue induced by pulsed electric field 115(2):232–236

Boussetta N, Lesaint O, Vorobiev E (2013a) A study of mechanisms involved during the extraction of polyphenols from grape seeds by pulsed electrical discharges. Innov Food Sci Emerg Technol 19:124–132

Boussetta N, Turk M, De Taeye C et al (2013b) Effect of high voltage electrical discharges, heating and ethanol concentration on the extraction of total polyphenols and lignans from flaxseed cake. Ind Crops Prod 49:690–696. doi:10.1016/j.indcrop.2013.06.004

Brunet MJ, Bladé C, Salvadó MJ, Arola L (2002) Human Apo A-I and rat transferrin are the principal plasma proteins that bind wine catechins. J Agric Food Chem 50:2708–2712. doi:10.1021/jf011257z

Chapuis A, Blin J, Carré P, Lecomte D (2014) Separation efficiency and energy consumption of oil expression using a screw-press: the case of Jatropha curcas L. seeds. Ind Crops Prod 52:752–761

Chen PR, Chien KL, Su TC et al (2005) Dietary sesame reduces serum cholesterol and enhances antioxidant capacity in hypercholesterolemia. Nutr Res 25:559–567

El-Belghiti K, Rabhi Z, Vorobiev E (2005) Effect of centrifugal force on the aqueous extraction of solute from sugar beet tissue pretreated by a pulsed electric field. J Food Process Eng 28:346–358. doi:10.1111/j.1745-4530.2005.00413.x

FAO (2014) FAOSTAT. In: FAOSTAT. http://faostat3.fao.org/

Grémy-Gros C, Lanoisellé J-L, Vorobiev E (2008) Application of high-voltage electrical discharges for the aqueous extraction from oilseeds and other plants. In: Vorobiev E, Lebovka N (eds) Eletrotechnologies for extraction from food plants and biomaterials. p 286

Guderjan M, Töpfl S, Angersbach A, Knorr D (2005) Impact of pulsed electric field treatment on the recovery and quality of plant oils. J Food Eng 67:281–287

Hwang LS (2005) Sesame oil. In: Shahidi F (ed) Bailey’s industrial oil and fat products, 6th edn. Wiley, Hoboken, pp 537–576

Kanu PJ, Kerui Z, Haifeng Q, Kanu JB (2007) Sesame Protein 11: Functional properties of sesame (Sesamum indicum L.) Protein isolate as influenced by pH, temperature, time and ratio of flour to water during its production. Asian J Biochem 2:289–301

Li L, Ding L, Tu Z et al (2009) Recovery of linseed oil dispersed within an oil-in-water emulsion using hydrophilic membrane by rotating disk filtration system. J Memb Sci 342:70–79. doi:10.1016/j.memsci.2009.06.023

Liao CD, Hung WL, Lu WC et al (2010) Differential tissue distribution of sesaminol triglucoside and its metabolites in rats fed with lignan glycosides from sesame meal with or without nano/submicrosizing. J Agric Food Chem 58:563–569. doi:10.1021/jf9028046

Locke BR, Sato M, Sunka P et al (2005) Electrohydraulic discharge and nonthermal plasma for water treatment. Ind Eng Chem Res 45:882–905

Loginova KV, Vorobiev E, Bals O, Lebovka NI (2011) Pilot study of countercurrent cold and mild heat extraction of sugar from sugar beets, assisted by pulsed electric fields. J Food Eng 102:340–347

Moazzami AA, Andersson RE, Kamal-Eldin A (2006) HPLC analysis of sesaminol glucosides in sesame seeds. J Agric Food Chem 54:633–638

Mohdaly AAA, Smetanska I, Ramadan MF et al (2011) Antioxidant potential of sesame (Sesamum indicum) cake extract in stabilization of sunflower and soybean oils. Ind Crops Prod 34:952–959

Namiki M (1995) The chemistry and physiological functions of sesame. Food Rev Int 11:281–329. doi:10.1080/87559129509541043

Nzikou JM, Matos L, Bouanga-Kalou G et al (2009) Chemical composition on the seeds and oil of sesame (Sesamum indicum L.) grown in Congo-Brazzaville. Adv J Food Sci Technol 1:6–11

Orthoefer FT, Sinram RD (1987) Corn oil: composition, processing and utilization. In: Watson SA, Ramstad PE (eds) Corn-chemistry and technology. American Association of Cereal Chemistry, St. Paul, p 892

Ramachandran S, Singh SK, Larroche C et al (2007) Oil cakes and their biotechnological applications – a review. Bioresour Technol 98:2000–2009

Rangkadilok N, Pholphana N, Mahidol C et al (2010) Variation of sesamin, sesamolin and tocopherols in sesame (Sesamum indicum L.) seeds and oil products in Thailand. Food Chem 122:724–730

Reshma MV, Balachandran C, Arumughan C et al (2010) Extraction, separation and characterisation of sesame oil lignan for nutraceutical applications. Food Chem 120:1041–1046

Sarkis JR, Boussetta N, Blouet C et al (2015a) Effect of pulsed electric fields and high voltage electrical discharges on polyphenol and protein extraction from sesame cake. Innov Food Sci Emerg Technol 29:170–177. doi:10.1016/j.ifset.2015.02.011

Sarkis JR, Boussetta N, Tessaro IC et al (2015b) Application of pulsed electric fields and high voltage electrical discharges for oil extraction from sesame seeds. J Food Eng 153:20–27. doi:10.1016/j.jfoodeng.2014.12.003

Savoire R, Lanoiselle JL, Vorobiev E (2013) Mechanical continuous oil expression from oilseeds: a review. Food Bioprocess Technol 6:1–16

Shahidi F, Naczk M (2004) Phenolics in food and nutraceuticals. CRC Press, Boca Raton

Suja KP, Abraham JT, Thamizh SN et al (2004) Antioxidant efficacy of sesame cake extract in vegetable oil protection. Food Chem 84:393–400

Vorobiev E, Lebovka N (2008) Pulsed electric fields induced effects in plant tissues: fundamental aspects and perspectives of applications. In: Vorobiev E, Lebovka N (eds) Electrotechnologies for extraction from food plants and biomaterials. Springer, New York, pp 39–81

Willems P, Kuipers NJM, Haan AB De (2008) Hydraulic pressing of oilseeds: experimental determination and modeling of yield and pressing rates. J Food Eng 1:8–16

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this entry

Cite this entry

Sarkis, J.R., Boussetta, N., Vorobiev, E. (2017). Application of Pulsed Electric Energies for Oil and Polyphenol Extraction from Sesame Cake and Sesame Seeds. In: Miklavčič, D. (eds) Handbook of Electroporation. Springer, Cham. https://doi.org/10.1007/978-3-319-32886-7_119

Download citation

DOI: https://doi.org/10.1007/978-3-319-32886-7_119

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-32885-0

Online ISBN: 978-3-319-32886-7

eBook Packages: EngineeringReference Module Computer Science and Engineering