Abstract

This chapter introduces our study on development of core–shell silica particles containing quantum dot (QD) for fluorescence imaging and medical diagnostics and is composed of six sections. The first section is Introduction. The second section describes development of methods for preparing colloid solutions of core–shell particles composed of core of nanoparticles and shell of silica. Two types of methods, both of which are sol-gel methods using raw chemicals such as sodium silicate solution and silicon alkoxide, were successfully performed for silica coating of the nanoparticles. For the method using the silicon alkoxide, an amine-free method, or a method without amine that is usually used as a catalyst for the sol-gel method, could be also developed. The third section describes fabrication of core–shell particles containing QD. QD/silica core–shell particles (QD/SiO2), multilayered core–shell particles composed of QD, silica (inner silica shell), gadolinium compounds (GdC) and silica (outer silica shell) (QD/SiO2/GdC/SiO2), and QD/SiO2 particles with immobilized Au nanoparticles (QD/SiO2/Au) were fabricated by using our amine-free method. The fourth section describes an effect of silica shell on photostability of QD. The silica shell was rigid enough to prevent O2 molecules from reaching surfaces of the QD, which maintained their photostability. In addition, the silica shell produced from silicon alkoxide stabilized their photo-property more effectively. The fifth section describes fluorescence imaging techniques using the core–shell particles containing QD. Various tissues in mouse could be imaged by detecting fluorescence emitted from the QD/SiO2 particle colloid solutions with an in vivo imaging system (IVIS). The QD/SiO2/GdC/SiO2 particle colloid solution simultaneously functioned as a fluorescent marker and high-contrast MRI agent. The colloid solution of QD/SiO2/Au particles functioned as a contrast agent for dual imaging processes based on fluorescence and X-ray absorption. The last section is on Conclusion.

Access provided by CONRICYT-eBooks. Download reference work entry PDF

Similar content being viewed by others

Introduction

Imaging processes are quite useful and are frequently used to make medical diagnoses. In particular, imaging processes that use X-ray (Kim et al. 2010; Kitajima et al. 2012; Melendez-Ramirez et al. 2012) and magnetic resonance (Secchi et al. 2011; Telgmann et al. 2013; Yu et al. 2013) are generally used to make medical diagnoses. The performance of these imaging processes can be improved using agents with imaging abilities that are called contrast agents. Various contrast agents are commercially available, and examples of typically used commercial contrast agents include solutions containing iodine compounds for X-ray imaging and Gd complexes for magnetic resonance imaging (MRI).

Iodine-related contrast agents are not dragged through fluids well because of their small size. Consequently, they are not able to stay in living bodies for long periods of time, which makes it difficult to take steady images. Adverse reactions against iodine can also occur (Zhao et al. 2011; Thomsen 2011). Gd complexes face the same challenges as iodine-related contrast agents, due to their short residence times in bodies and their toxicity (Gauden et al. 2010; Marshall and Kasap 2012). Developing contrast agent particles and increasing their apparent particle sizes are promising solutions to address such problems, as increases in projected areas would consequently increase their residence times.

Coating particles with inert shells is a method to control adverse reactions, as the particles cannot contact living tissue. Our research group recently investigated the development of methods to prepare colloidal solutions of core–shell particles with a core composed of necessary materials for X-ray or MRI imaging and a silica shell that is inert to living bodies and subsequently tested their imaging properties (Ayame et al. 2011; Morimoto et al. 2011; Kobayashi et al. 2007, 2012a, 2013a, b). These methods were based on the sol-gel reaction, i.e., hydrolysis and condensation of silicon alkoxide in the presence of particles such as nanoparticles containing iodine, where compound nanoparticles were prepared by mixing an aqueous AgClO4 solution with an aqueous KI solution (Ayame et al. 2011; Kobayashi et al. 2012a, 2013b), or nanoparticles containing Gd compounds (GdC) that were prepared using a homogeneous precipitation method (Morimoto et al. 2011; Kobayashi et al. 2007, 2013a). These particle colloid solutions revealed imaging abilities that were noteworthy.

Metallic Au nanoparticles can also be utilized for X-ray imaging (Menk et al. 2011; Peng et al. 2012; Wang et al. 2013). However, they are toxic (Lasagna-Reeves et al. 2010; Cui et al. 2012; Schulz et al. 2012), although their toxicity is not as serious as that of iodine-related and Gd-related contrast agents. Metallic Au nanoparticles face the same challenges as these contrast agents due to their short residence times. With these problems in mind, our research group developed silica-coating methods for metallic Au nanoparticles and methods to fabricate silica-coated Au nanoparticles (Au/SiO2) using the sol-gel process and investigated their X-ray imaging properties (Kobayashi et al. 2011, 2012b, 2013c, d, 2014, 2015a). Metallic Au nanoparticles have unique optical properties that can be measured by surface plasmon resonance (SPR), which is sensitive to factors such as nanoparticle shape, size, and surrounding dielectric constant (Liz-Marzán et al. 1996). This sensitivity is expected to be useful for evaluating the performance of silica-coated nanoparticles. Accordingly, this chapter focuses on metallic Au nanoparticles and introduces our studies on the process of silica coating of Au nanoparticles.

In addition to imaging processes that use X-ray and magnetic resonance, fluorescence imaging is also used to make medical diagnoses. To improve the quality of the fluorescence images, materials called fluorescent markers are used. Representative fluorescent markers include polystyrene microspheres that contain fluorescent organic dyes called fluorescent microspheres and luminescent II-VI semiconductor nanoparticles called quantum dots (QDs), both of which are commercially available. QD nanoparticles are suitable for use in fluorescence imaging because they are chemically stable, their fluorescence wavelengths can be easily modified by changing their size and their atomic composition, and they can be excited to a wide range of wavelengths. However, the Cd contained in the II-VI semiconductor is toxic to the human body. Silica coating of these nanoparticles is a useful way to decrease their toxicity. To address the challenges associated with these fluorescent microspheres, our research group extended our proposed silica-coating methods to the silica coating of QDs and the fabrication of silica-coated QD (QD/SiO2) (Kobayashi et al. 2010a, b, 2012c, 2013e, 2015b, c) and conducted studies on fluorescence imaging processes using these silica-coated particles (Kobayashi et al. 2012c, 2013e, 2015b, c). In this chapter, we focus on the silica-coated particles containing QDs, and we also introduce our recent studies.

The use of multiple imaging processes is an effective way to make precise medical diagnoses, as each imaging process has different limitations. Materials composed of components with different properties are able to serve multiple functions. For example, composite particles with magnetic and fluorescence properties have been of great interest for applications such as cell labeling (Vuu et al. 2005; Guo et al. 2005; Lin et al. 2006; Selvan et al. 2007), biosensing (Dubus et al. 2006), and use in diagnostic medical devices (Guo et al. 2006; Salgueiriño-Maceira and Correa-Duarte 2007). Additionally, particles containing QDs and Au and those containing QD and GdC are able to simultaneously act as fluorescent markers and X-ray contrast agents or as fluorescent markers and MRI contrast agents, respectively. In this chapter, we also introduce our recent studies on the development of composite particles containing QDs and other functional materials.

Silica Coating of Nanoparticles

Nanometer-sized colloidal particles are nanoparticles with special applications in science and technology because they exhibit unique optical and catalytic properties that set them apart from bulk materials (Brus 1986; Ekimov et al. 1993; Kimura 1989; Henglein 1989; Zhang et al. 2000; Pang et al. 2001; García-Santamaría et al. 2002). Properties of these nanoparticles can be preserved if suitable stabilization methods can be developed to address their general tendency to aggregate. Generally, the stabilization of colloids is performed using surface modification processes, either by enhancing double-layer interactions or by adsorbing macromolecules that form a physical barrier against other approaching particles (Chen et al. 2000). One method to obtain colloidal stabilization is the deposition of a homogeneous shell using an inorganic material, such as silica, to achieve core–shell geometry (Liz-Marzán et al. 1996; Ung et al. 1998; Marinakos et al. 1999; Hardikar and Matijević 2000; Hall et al. 2000; Mulvaney et al. 2000; Kobayashi et al. 2001; Cho et al. 2001; Tago et al. 2001; Wang et al. 2001). The role of the silica shell is twofold; it provides greatly enhanced colloidal stability in water, and the shell thickness can also be used to control the distance between the core particles within assemblies (Liz-Marzán et al. 1996; Ung et al. 1998; Marinakos et al. 1999; Hardikar and Matijević 2000; Hall et al. 2000; Mulvaney et al. 2000; Kobayashi et al. 2001; Cho et al. 2001; Tago et al. 2001; Wang et al. 2001). Based on these characteristics, extensive studies have been conducted on the silica coating of nanoparticles using liquid-phase procedures (Zhang et al. 2011; Rosenholm et al. 2011; Wu et al. 2011; Bahadur et al. 2011; Kunzmann et al. 2011; Mojić et al. 2012; Lee et al. 2012: Oh and Kim 2013; Kalantari et al. 2013; Vaz et al. 2014). In particular, much work on silica coating related to Au nanoparticles has been reported over the years (Jung et al. 2010; Liu et al. 2010; Schulzendorf et al. 2011; Torimoto et al. 2011; Wu et al. 2011; Huang et al. 2013; Li and Zhu 2013). There are two types of silica coating methods, both of which use raw chemicals such as sodium silicate solution and silicon alkoxide. This section introduces our studies on the silica coating of Au nanoparticles.

The Silica-Coating Process Using a Sodium Silicate Solution

Au nanoparticles can be coated with silica using a sodium silicate solution following a previously reported method (Kobayashi et al. 2001). This method includes two steps: (1) modification of the metal nanoparticle surface to make it vitreophilic using silane coupling agents such as silicon alkoxides with amino or thiol groups as surface primers and (2) slow silica deposition in water in a sodium silicate solution. A typical procedure is as follows: First, an Au nanoparticle colloid solution was prepared by heating an aqueous HAuCl4 solution in the presence of sodium citrate (Na-cit). A freshly prepared aqueous solution of 3-aminopropyl trimethoxysilane (APMS) was added to the Au nanoparticle colloid solution under vigorous magnetic stirring. The color of the mixture turned wine red within a few minutes, which indicated the production of Au nanoparticles (Hayat 1989). A sodium silicate solution with pH 10–11 (adjusted with a cation-exchange resin) was added to the mixture of the APMS and Au nanoparticle colloid solution, which resulted in a solution with pH of approximately 8.5. The resulting solution was then allowed to stand for 1 week to allow the active silica to polymerize onto the primed Au particle surface and form silica shells.

The Direct Silica-Coating Process Using Silicon Alkoxide

Various techniques using silicon alkoxide for the silica coating of Au nanoparticles have been proposed (Jung et al. 2010; Liu et al. 2010; Schulzendorf et al. 2011; Torimoto et al. 2011; Wu et al. 2011; Huang et al. 2013; Li and Zhu 2013). Previously proposed methods consist of three steps – the two steps performed in the method using sodium silicate, followed by the extensive growth of silica shells through a sol-gel reaction of silicon alkoxide in an ethanol/ammonia mixture (Liz-Marzán et al. 1996). These steps work well but require long reaction times to grow thick shells. Coupling agents can be used to activate metal particle surfaces for sodium silicate reactions. However, the coupling agents and sodium silicate can introduce impurities to the particles. Therefore, a simplified and more rapid method that does not place coupling agents between the metal core and the silica shell is desirable. Our research group previously proposed a method to directly coat citrate-stabilized gold nanoparticles with silica shells using a seeded polymerization technique based on the Stöber method (Mine et al. 2003).

The direct silica coating method does not require any coupling agents and is based on a method that our group used to prepare monodispersed silica particles (Nagao et al. 2000; Mine and Konno 2001). Au nanoparticles were prepared using a method similar to that described in the previous section. The sol-gel seeded growth process has been used by several groups to grow submicron- or even micron-sized silica particles (Bogush et al. 1988; Nagao et al. 2000; Mine and Konno 2001) and to introduce functionalities within colloid particles (Verhaegh and van Blaaderen 1994). However, these studies generated particles that had cores that were also made of silica, mostly eliminating particle aggregation. The addition of ammonia as a catalyst for tetraethyl orthosilicate (TEOS) hydrolysis leads to an increase in the ionic strength of the solution due to the dissociation of ammonia. Because an increase in ionic strength compresses the double layers on solid materials such as colloidal particles (Singh and Song 2007; Yilmaz et al. 2007; Li and Xu 2008), double-layer repulsion between nanoparticles is small at high ionic strengths. Thus, an increase in ionic strength promotes aggregation of Au nanoparticles. Consequently, it is likely that the addition of ammonia is critical to obtain an even silica coating. Two methods of coating were examined for Au nanoparticles. In method A, aqueous ammonia was added to the Au colloid solution under vigorous stirring prior to the addition of the ethanol/water mixture. Silica coating was initiated by adding an ethanol solution of TEOS to the Au colloid solution. In method B, ammonia was added to the Au colloid solution under vigorous stirring after the addition of the TEOS/ethanol/water mixture. Subsequently, silica coating was initiated by adding aqueous ammonia to the Au colloid solution.

Method A generated Au nanoparticles that were coated with silica shells. The silanol groups generated by TEOS hydrolysis may have reacted with citrate anion groups adsorbed on the Au nanoparticles. This likely led to the formation of a silica layer by reacting further with other silanol groups produced by TEOS hydrolysis. However, a number of particles contained multiple Au nanoparticle cores, which were not spherical. An increase in the ionic strength of the solution due to the addition of ammonia likely led the nanoparticles to coalescence before the silica-coating process. The shape of the Au nanoparticle agglomerates seemed to determine the final anisotropic shape of the composite particles. In contrast to method A, method B generated particles that were mostly spherical with a single Au core. In this case, TEOS molecules were likely to be bound loosely to the Au nanoparticle surface, which then hydrolyzed and led to preferential deposition on the Au surface to form a silica shell upon injection of ammonia. This likely inhibited the aggregation of the Au particles. Therefore, method B is more suitable for silica coating.

In addition to discussions on methods A and B, concentrations of chemicals such as catalyst, water, and TEOS were investigated to optimize reaction conditions for homogeneous silica coating. These concentrations are important factors that also govern the morphology of Au/SiO2 particles. Two series of experiments were performed, where the concentration of reactants (either water or ammonia) was changed one at a time. Nanoparticles were prepared at different H2O concentrations, but the most Au nanoparticles were successfully coated with silica shells at low H2O concentrations. At high H2O concentrations, many Au core-free silica particles of various sizes were observed in addition to Au/SiO2 particles, and their sizes decreased with water concentration. In the seeded growth technique using silicon alkoxide, particle size and distribution seemed to depend largely on the electrostatic repulsion between particles during growth. According to Bogush and Zukoski (1991), an increase in water concentration in TEOS/ammonia/water/ethanol solutions dissociates ammonium hydroxide and increases electric conductivity, which corresponds to ionic strength. Because an increase in ionic strength reduces electrostatic repulsion between particles and promotes the growth of silica shells, changes in ionic strength are likely not what causes the formation of core-free silica particles. Because the dielectric constant of the water/ethanol mixture increases with water concentration, silanol groups on the surface of silica particles probably ionize with increasing water concentration. This likely results in an increase in electrostatic repulsion between generated particles. Therefore, silica nuclei generated during the early stages of the sol-gel reaction probably grew as stable secondary silica particles, rather than growing on existing cores.

Preparation of particles using different ammonia concentrations revealed that the Au core-free silica particles formed at low ammonia concentrations. In contrast, the proportion of core-free silica particles formed at high ammonia concentrations was less than 30% of all the particles. In the case of silica particles generated with seeded growth using TEOS condensation (Nagao et al. 2000; Mine and Konno 2001), the generation of secondary nuclei is known to strongly depend on ionic strength. This is due to the relation between particle repulsive forces and the size of the double layers. Addition of ammonia increases the ionic strength of the solution and catalyzes the hydrolysis and condensation of alkoxysilanes (Mine and Konno 2001). Thus, the high ammonia concentration used in this work should have reduced the double-layer repulsion between particles. Consequently, the formation of secondary silica particles should have been greatly reduced. Further increases in ammonia concentration resulted in the production of particles with Au particle aggregates, which had the tendency to distort the shape of the Au/SiO2 particles. Increases in ammonia concentration also increased ionic strength and facilitated Au particle aggregation, such that the Au cores likely aggregated before being coated with silica.

Figure 1 shows transmission electron microscopy (TEM) images of Au/SiO2 particles formed using various TEOS concentrations with optimized H2O and ammonia concentrations. Silica particles with multiple cores were not found under any of the experimental conditions. However, some core-free silica particles were observed, and they increased in amount as TEOS concentrations decreased. This is probably related to a decrease in ionic strength of the solutions, as well as the resulting increase in electrostatic repulsion between the Au and silica nuclei. However, most Au cores were surrounded by silica shells. Their thickness varied from 29 to 88 nm with increasing initial TEOS concentrations, which demonstrates that the thickness of the shells can be controlled within a certain range.

TEM images of Au/SiO2 particles synthesized with method B at TEOS concentrations of (a) 0.0005, (b) 0.001, (c) 0.005, (d) 0.01, and (e) 0.02 M. Water and ammonia concentrations were 10.9 and 0.4 M, respectively. The mole ratio of HAuCl4:H2O:NH3 was 1: 2.51 × 105:9.23 × 103 (Originated from Journal of Colloid and Interface Science 264 (2003) 385–390)

Figure 2a shows the ultraviolet–visible (UV–vis) extinction spectra for colloid solutions of Au nanoparticles and Au/SiO2 particles with different silica shell thicknesses. SPR absorption bands redshifted from 520 to 530 nm when thin silica shells were deposited. As shown in Fig. 2b, the bands blueshifted back above shell thicknesses of approximately 40 nm. SPR absorption bands in the visible spectrum were very sensitive to both particle size and shape and to the properties of the surrounding medium (Liz-Marzán et al. 1996). Variations in such bands under different parameters have been extensively studied (Doremus 1964; Kreibig and Genzel 1985; Farbman et al. 1992; Underwood and Mulvaney 1994; Liz-Marzán et al. 1996; Kobayashi et al. 2001). In particular, the effects of various silica shell thicknesses and use of various solvents have been predicted by Mie theory (Liz-Marzán et al. 1996). According to the literature, redshifts and blueshifts result from local increases in refractive indices and light scattering from large silica shells, respectively. Assuming that nanometer-sized particles can be accurately treated as dipole oscillators, the extinction cross section (Qext) can be calculated from electrostatics as a sum of the absorption cross section (Qabs) and the scattering cross section (Qsca) as follows:

UV–vis extinction spectra of colloid solutions of silica shell-free Au particles (Au colloid) and Au/SiO2 particles with various shell thicknesses (Fig. 2a). Refer to Fig. 1 for symbols and TEOS concentrations. Figure 2b shows the SPR peak position and predictions by Mie theory (Originated from Journal of Colloid and Interface Science 264 (2003) 385–390)

where R, ε, and λ represent the coated particle radius, the dielectric function, and the wavelength, respectively. The subscript c refers to the core, s refers to the shell, m refers to the medium material, and g is the volume fraction of the shell layer. εc was calculated using the Drude expression. Each parameter was taken from previously reported studies (Underwood and Mulvaney 1994). The dotted line in the same inset shows the maximum position obtained from these calculations (data taken from Liz-Marzán et al. 1996) using Mie theory and demonstrates that the optical properties of the Au/SiO2 particles produced in this work accurately reflect the Mie theory. This indicates that the calculations support the successful silica coating that was demonstrated in TEM observations.

The Amine-Free Silica-Coating Process Using Silicon Alkoxide

Most methods that use silicon alkoxide for the silica coating of Au nanoparticles are based on the Stöber method and utilize amine catalysts. The removal of amines from Au/SiO2 particles is desirable because the amines are harmful to living bodies. However, it is difficult to remove them after the silica-coating process because the amines are distributed throughout the silica shell. Thus, methods to produce Au/SiO2 particles without the use of amines are necessary. To this end, we previously proposed a method to prepare Au/SiO2 particles using sodium hydroxide (NaOH) instead of amines (Kobayashi et al. 2012b). Although the Au nanoparticles were successfully coated with silica using this method, the morphology of the Au/SiO2 particles such as their shapes and shell thicknesses could not be precisely controlled. In a preliminary experiment, the addition of a silane coupling agent to the Au nanoparticles was shown to affect the shape of the silica-coated Au nanoparticles. This section describes studies on the development of an amine catalyst-free method to prepare silica-coated Au nanoparticles (Kobayashi et al. 2011).

An Au/SiO2 nanoparticle colloid solution was prepared in a manner similar to the direct silica-coating method that used ammonia as a catalyst. H2O and NaOH concentrations were optimized by taking into account interactions among the Au nanoparticles, between the Au nanoparticles and silica nuclei, and among the silica nuclei. With the optimized concentrations of H2O and NaOH, TEOS concentrations were altered to change the thickness of the silica shells. Figure 3 shows TEM images of Au/SiO2 particles prepared with various TEOS concentrations. Low NaOH concentrations were optimal at low TEOS concentrations. The low ionic strength of the solutions remained after TEOS hydrolysis, which regulated the aggregation of Au nanoparticles prior to the formation of silica shells. An increase in the TEOS concentration increased shell thicknesses from 6.0 to 61.0 nm. According to the UV–vis spectra, the SPR band at approximately 520 nm redshifted with respect to the uncoated Au nanoparticles, and the shell thicknesses increased to a range of 0–22.2 nm. Above 22.2 nm, the SPR bands tended to blueshift back and the particles had increased in shell thickness. This tendency was also observed for particles prepared using the direct silica-coating method (Mine et al. 2003). This work utilizes a similar mechanism that depends on local increases in refractive indices and light scattering from large silica shells. The results also indicate that Au nanoparticles could be silica coated, and the thickness of the silica shells could be altered using this method.

TEM images of Au/SiO2 particles prepared at TEOS concentrations of (a) 0.3 × 10−3, (b) 0.5 × 10−3, (c) 1.0 × 10−3, (d) 3.0 × 10−3, (e) 5.0 × 10−3, and (f) 10 × 10−3 M. The NaOH concentrations were 0.5 × 10−3 and 1.0 × 10−3 M in the silica coating at 0.3 × 10−3-1.0 × 10−3 and 3.0 × 10−3-10 × 10−3 M TEOS, respectively. All the Au, APMS, and H2O concentrations were 4.3 × 10−5, 20 × 10−6, and 10.7 M in a series of the experiments, respectively (Reprinted from the Journal of Colloid and Interface Science 358 (2011) 329–333)

Fabrication of Quantum Dots/Silica Core–Shell Particles and Related Core–Shell Particles

The proposed silica-coating method has been extended to the silica coating of QDs (Kobayashi et al. 2010a, b, 2012c, 2013e, 2015b). Moreover, immobilization of Au nanoparticles on the surface of the obtained QD/SiO2 particles has been performed to grant QD/SiO2 particles’ multi-imaging abilities (Kobayashi et al. 2016). For both the silica coating and immobilization of Au nanoparticles, factors that govern particle morphology likely include ionic strength of solutions, surface potentials, and affinities between silica nuclei and QDs and between Au nanoparticles and QD/SiO2 particles. Investigations on the effects of these factors are required to precisely fabricate target particles. In this section, we introduce our recent studies on the development of methods to fabricate particles containing QDs.

Single Quantum Dot/Silica Core–Shell Particles

Nano-sized semiconductor particles such as CdS, CdSe, CdTe, and QDs have attracted special interest for demonstrating unique fluorescence properties for their particle sizes and compositions. Several types of QDs are commercially available. For example, the Invitrogen Corp. sells QDs as Qdot®. Qdot® with catalog numbers Q21571MP and Q21371MP are CdSexTe1-x nanoparticles coated with ZnS and surfaces modified with amino groups and carboxyl groups, respectively. Properties of core–shell silica particles that contain a single QD nanoparticle (single QD/SiO2) depend on the nature of the QD. Weak interactions between the QD nanoparticles result in large distances between them, which make it possible to utilize the properties of single QD/SiO2 particles. A single QD can be successfully silica coated using the modified Stöber method (Kobayashi et al. 2010a, b). In this section, we introduce our work on QDs with surfaces modified with carboxyl groups (Kobayashi et al. 2010b). The colloid solution of these QDs has an absorption edge of approximately 330 nm, a main fluorescence peak of approximately 750 nm, and volume-average sizes of approximately 10–12 nm as shown in Fig. 4a. A water/ethanol solution and a TEOS/ethanol solution were added to a colloid solution of QDs. Then, the silica-coating process was initiated by rapidly injecting an aqueous NaOH solution into the QD/TEOS colloid solution. The silica-coating process was continued for 24 h at room temperature. Concentrations of H2O and NaOH were optimized in the same manner as those used to prepare Au/SiO2 particles.

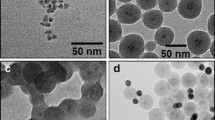

The results are summarized as follows: At low H2O concentrations, the QDs were not coated with silica, and the QDs aggregated because the low water concentration completely inhibited TEOS hydrolysis. An increase in H2O concentration resulted in the aggregation of silica-coated particles because the high water concentration increased the ionic strength of the solution, which promoted particle aggregation. At low NaOH concentrations, both QD/SiO2 and uncoated QDs were obtained, which were incorporated into the gel structure of silica. Low NaOH concentrations created a low ionic strength solution, which likely made the double-layer repulsion between the QDs and the silica nuclei low. Consequently, most silica nuclei were not deposited on the surface of the QDs but were consumed to form the silica gel. A further increase in NaOH concentration produced particles containing multiple QD cores. The excess NaOH increased the ionic strength of the solution, reducing the double-layer repulsion between particles. Due to a decrease in repulsion, the QD/SiO2 particles that were produced during early stages of the sol-gel reaction aggregated before the completion of the silica-coating process. Then, the aggregated particles were coated with silica, which resulted in the formation of larger particles containing multiple individual particles. With the optimized H2O and NaOH concentrations, TEOS concentrations were altered to change the thickness of the silica shells. Figure 5 shows TEM images of QD/SiO2 particles prepared using various TEOS concentrations. For all the TEOS concentrations examined, most of the particles consisted of quasi-perfect core–shells with one QD particle, and the size of the single QD/SiO2 particles increased from 20.1 to 38.1 nm in accordance with the increase in shell thickness resulting from increased TEOS concentrations. Thus, TEOS concentrations were found to affect the thickness of silica shells.

TEM micrographs of QD/SiO2 nanoparticles prepared at different TEOS concentrations of (a) 2.5 × 10−4, (b) 5 × 10−4, (c) 10 × 10−4, and (d) 50 × 10−4 M. All the water and NaOH concentrations were 5 M and 4 × 10−4 M in a series of the experiments, respectively (Reprinted from Journal of Sol-gel Science and Technology 55 (2010) 79–85)

According to electrophoretic light scattering (ELS) measurements, isoelectric points (IEP) of the QDs and single QD/SiO2 particles were approximately 3.5 and 2.4, respectively. The results indicated that the IEPs of the QDs shifted to lower pH upon being coated with silica. The IEP of single QD/SiO2 particles was in agreement with IEP values of 2.1–2.5, as observed in previous reports on silica particles prepared using the sol-gel process with TEOS (Wu et al. 2006; Song et al. 2008; Lee et al. 2008). These results strongly supported the TEM observations of quasi-perfect silica coating. The single QD/SiO2 colloid solution had an absorption edge of approximately 290 nm, and a main fluorescence peak was observed at approximately 745 nm. These wavelengths were approximately the same for the QDs, and there was no large difference in the intensity of fluorescence between the QD nanoparticles and the single QD/SiO2 particles. These results demonstrate that the fluorescence of QDs is not seriously affected by silica coating. There was no significant change to the fluorescence spectra several weeks after preparation, which indicates that the single QD/SiO2 particles were stable with respect to their fluorescence properties.

In medical applications, particles containing QD nanoparticles must flow without aggregating in blood vessels of the organism after injection because aggregation can slow or stop blood flow. To address this problem, silica coating has been extensively utilized, as silica-coated particles form stable colloids in various dispersions, much like silica particles. This provides steady particle flow in blood vessels. Particle size is an important factor that governs their colloidal stability because their surface energy, which determines colloidal dispersion and aggregation, depends on their curvature. Thus, studies on the effects of particle size on imaging are required to better understand the mechanism of imaging and for practical use of the particles. To this end, particles of different sizes were fabricated using different reaction conditions to investigate the effects of different particle sizes. The QD nanoparticles were silica coated via the sol-gel method using TEOS as described above (Kobayashi et al. 2010a, b). Two initial QD concentrations (high and low) were examined, and the particles produced using the high and low QD concentrations were labeled “S-QD/SiO2” and “L-QD/SiO2,” respectively. The QD/SiO2 colloid solution was concentrated by evaporating the solvent, centrifuging the sample, removing the supernatant, adding solvent, and redispersing the concentrated QD/SiO2 colloid solution. Figure 6b, c shows TEM micrographs of the QD/SiO2 nanoparticles. At a high QD concentration (S-QD/SiO2), most of the particles contained a single QD core. Decreasing the QD concentration increased the particle size and shell thickness of the QD/SiO2 particles. Because the TEOS concentration was greater than the QD concentration, the silica coating on each particle was thicker when made with a lower QD concentration than with a higher QD concentration. Consequently, the particle sizes and shell thicknesses increased.

The L-QD/SiO2 particles contained not only single QD core particles but also particles with multiple QD cores. These multiple cores appeared to be separate but near the center of the particles, which indicated that the QD nanoparticles grew small silica shells, aggregated, and then experienced further shell growth. The particles moved actively, exhibiting repeated microscopic flocculation and dispersion. Furthermore, it is noteworthy that an increase in the ionic strength of the solution was observed with the hydrolysis of TEOS. This increase was smaller in the case of low QD concentrations than high QD concentrations because the carboxyl groups on the surface of the QDs also contribute to increases in ionic strength. A large increase in ionic strength led to a reduction in the thickness of the double layer on solid materials, which consequently increased the collision frequency of particles and led to aggregation. In contrast, the low QD concentration solution created a small increase in ionic strength, which promoted the approach and flocculation of QD nanoparticles rather than the growth of QD nanoparticles upon aggregation. The shells most likely grew rapidly because of the presence of a large amount of TEOS relative to QDs. These flocculates experienced rapid shell growth and were coated with thicker silica shells. Consequently, QD/SiO2 particles containing multiple QD cores were produced under the L-QD/SiO2 preparation conditions.

Multiple Quantum Dot/Silica Core–Shell Particles

Single QD/silica core–shell particles (Kobayashi et al. 2010a, b, 2015b) have been shown to contain a single QD as a core. Therefore, fluorescence intensities of the individual particles are not expected to be high. To increase the fluorescence intensity of individual particles, the formation of particles composed of multiple QD nanoparticles as cores is promising and will be necessary as a future imaging technique. In this section, we introduce a method to produce silica particles that contain multiple QD nanoparticles (multiple QD/SiO2) (Kobayashi et al. 2016). The distance between QD nanoparticles can vary depending on the ionic strength of the solution, which is dictated by the concentrations of chemicals. An increase in ionic strength makes QD nanoparticles approach to other QD nanoparticles. If silica coating is performed using the previously described methods, the resulting silica-coated particles can contain multiple QD nanoparticles. Variations in the ionic strength of the solutions allow for the fabrication of multiple QD/silica core–shell particles. Based on these observations of ionic strength, the silica coating of QDs was performed at high concentrations using chemicals that created high ionic strength. The concentrations of TEOS and NaOH used were higher than those used in our method to generate silica particles with single QD cores (Kobayashi et al. 2010b). With the exception of TEOS and NaOH concentrations, the silica-coating process was conducted using the same procedure utilized to generate the single-core QDs. Figure 4b shows a TEM micrograph of multiple QD/SiO2 nanoparticles. Multiple QD particles were contained in the core of each silica particle. The high chemical concentrations provided high ionic strength for the solutions, which promoted aggregation of the QDs.

Then, the aggregates were coated with silica, or silica particles containing multiple QD nanoparticles were produced using the described methods. ELS measurements revealed that multiple QD/SiO2 particles had IEPs of approximately 2.1. Because the QD nanoparticles with carboxyl groups on their surface had an IEP of approximately 3.5 (Kobayashi et al. 2010b), this indicated that the IEP of the QDs shifted to a lower pH with the silica coating. The IEPs of multiple QD/SiO2 particles were in agreement with the IEP values of 2.1–2.5 that were observed for the silica particles prepared using the sol-gel method, which indicated that the QD nanoparticles were coated with silica shells. The TEM images support these observations and are shown in Fig. 4b. The fluorescence intensities of the colloid solutions of the particles composed of multiple QD nanoparticles, and single QDs were comparable at identical QD concentrations. Because the number of particles in a colloid solution for multiple QD nanoparticles should be smaller than that for single QDs at the same QD concentration, their comparable fluorescence intensities indicate that each particle of the multiple QD nanoparticles exhibited stronger fluorescence than the single QDs.

Multiple QD/SiO2 core–shell particles can also be fabricated using a sodium silicate solution (Zhou et al. 2005). First, an aqueous CdSO4 solution was mixed with sodium nitrilotriacetate (Na3NTA) to form a Cd-NTA complex. Then, an aqueous Na-cit solution was added to the solution of the Cd-NTA complex. Finally, a sodium selenosulfate (Na2SSeO3) aqueous solution that was prepared by stirring Se powder in a Na2SO3 aqueous solution at 70 °C for 24 h was added, and the mixture was then aged at room temperature for 5 days. During the aging process, CdSe QD is produced through the following process:

Aqueous solutions of 3-mercaptopropyltrimethoxysilane (MPS) and sodium silicate were added to the obtained CdSe QD nanoparticle colloid solution and then aged at room temperature for 5 days with vigorous magnetic stirring. This allowed silica to slowly polymerize onto the MPS-modified CdSe QD particle surface. Finally, the resulting dispersion was transferred into ethanol. This transfer made the excess silicate to precipitate out mainly onto existing cores, which led to an increase in the thickness of the silica shells. Figure 7 shows a TEM image of these CdSe QD/SiO2 particles. Plural CdSe QD nanoparticles were coated completely with a silica matrix.

It should be noted that no aggregation was observed for the silica-coated particles. It is unlikely for silica to deposit directly on the surface of the CdSe QD particles because of its low affinity. MPS is a bifunctional coupling agent that binds to surface Cd atoms through its mercapto groups. It has been successfully utilized to generate CdS QD/SiO2 particles (Correa-Duarte et al. 1998). The adhesion of the silicate moieties to the particle surface can only be made effective when a silane coupling agent is present in solution. The coupling agent acts as a surface primer and makes the colloid surface vitreophilic, which facilitates silicate deposition (Lifshitz et al. 1998). In the case of CdSe QDs, MPS was chosen because it contains a mercapto group. MPS was expected to directly bind to surface Cd2+ sites. Consequently, the silane groups were left pointing toward the solution phase, allowing the silicate ions to approach the particle surface through the silane groups. These silicate ions initiated the buildup of the silica shells, and the ethanol transfer process facilitated the growth of the silica shells. The observed silica-coated particles were coagulated, which indicated that they aggregated during the silica-coating process. Optimization of this procedure is required to perform silica coating, to control particle aggregation, and to produce uncoagulated silica-coated particles.

Multilayered Core–Shell Particles Composed of Quantum Dots, Gadolinium Compounds, and Silica

Materials composed of components with different properties should demonstrate multiple functions. Composite particles with fluorescent and magnetic properties have been of great interest for use in various applications as described earlier (Guo et al. 2005, 006; Vuu et al. 2005; Dubus et al. 2006; Lin et al. 2006; Salgueiriño-Maceira and Correa-Duarte 2007; Selvan et al. 2007). Following the characteristics of multi-functionalization of materials, particles containing QD and GdC can act as both fluorescent markers and MRI contrast agents. This section introduces studies on the development of a method to prepare multilayered core–shell particles composed of a core of QD, an inner silica shell, a middle GdC shell, and an outer silica shell. Because SiO2 particles are stable as colloids, core particles are expected to be stabilized by these colloids and the outer silica shell (Kobayashi et al. 2012c).

GdC can be produced through the reaction of a Gd salt and base. QD/SiO2 particles were coated with GdC using an acid/base reaction or a NaOH addition method in the presence of QD/SiO2 particles in a glass vessel with active stirring. The NaOH addition method is a process that precipitates soluble metal salts in alkaline solutions and is commonly used to make oxide-hydroxides. In the NaOH addition method, the GdC-coating process is performed in a water/ethanol solution. A mixture of a QD/SiO2 particle colloid solution and ethanol is added to water, followed by the successive addition of a Gd(NO3)3 aqueous solution and a NaOH aqueous solution. The reaction was carried out at room temperature for 24 h. No GdC-coated core–shell particles were produced. Instead, a gel network of GdC formed, and the network appeared to incorporate QD/SiO2 particles. There was a local increase in pH of the colloid solution upon addition of NaOH, which resulted in the generation of large amounts of GdC nuclei. The addition of NaOH increased the local ionic strength of the solution in the vicinity of the NaOH solution drops. Consequently, the aggregation of GdC nuclei and the successive formation of a gel network occurred simultaneously with the aggregation of the nuclei and the QD/SiO2 particles. During the formation of the gel network, the QD/SiO2 particles in the colloid solution were likely incorporated into the network.

Thermal decomposition of urea in an aqueous solution provides a slow and controlled supply of ammonia and carbon dioxide. The smooth pH increase resulting from the degradation of urea occurs in sync with the active release of OH− and CO32− ions, which usually leads to precipitation of hydrous metal oxide particles with controlled morphology. In contrast to the heterogeneous precipitation observed with the NaOH addition method, homogeneous precipitation results in the slow formation of precipitating agents in reaction mixtures that allows particles to ripen during precipitation and generate particles with better crystallinity, often with regular shapes and sizes. GdC should also be able to utilize the homogeneous precipitation method using a Gd salt and urea. This method was utilized to generate GdC coating. The GdC-coating process was performed in a water/ethanol solution containing Gd(NO3)3, urea, and a stabilizer in the presence of QD/SiO2 particles in a glass vessel under active stirring at 60 °C. The QD/SiO2 particles were coated with a GdC shell, although aggregation of the QD/SiO2/GdC particles was observed. Subsequently, the solution was heated to slowly decompose urea, and the pH of the solution increased gradually and homogeneously, which generated GdC nuclei. The slow decomposition of urea resulted in a slow increase in ionic strength of the solution. This controlled particle aggregation and the growth of GdC nuclei. Subsequently, the GdC nuclei were deposited on the surface of QD/SiO2 particles. This demonstrated that, relative to the NaOH addition method, the homogeneous precipitation method was a suitable method to introduce GdC coating onto QD/SiO2 particles.

The QD/SiO2/GdC particles were prepared using various stabilizers. In the cases of cetyltrimethylammonium bromide (CTAB) and sodium dodecyl sulfate (SDS), the QD/SiO2 particles were coated with a GdC shell but resulted in aggregation of the QD/SiO2/GdC particles, which also occurred in the absence of stabilizer. Because both CTAB and SDS are ionic surfactants, in addition these molecules have the potential to increase the ionic strength of solutions. Increases in ionic strength likely accelerated the aggregation of particles. The addition of polyvinylpyrrolidone (PVP) appeared to control aggregation and produced quasi-perfect multilayered QD/SiO2/GdC core–shell particles. Because PVP is a polymer dispersant, it probably did not have a significant effect on changing the ionic strength of solutions. Consequently, particle aggregation became unpronounced. Figure 8 shows TEM images of QD/SiO2/GdC particles prepared using the homogeneous precipitation method with various Gd(NO3)3 concentrations. At a low Gd(NO3)3 concentration, QD/SiO2 particles were coated with GdC but the resulting QD/SiO2/GdC particles were incorporated into the GdC gel network. An increase in the Gd(NO3)3 concentration generated quasi-perfect multilayered QD/SiO2/GdC particles but the resulting QD/SiO2/GdC particles appeared to aggregate. A further increase in Gd(NO3)3 concentration almost completely prevented particle aggregation, and the resulting QD/SiO2/GdC particles were highly dispersed. The particle colloid solutions were basic (i.e., pH > 7) for the examined Gd(NO3)3 concentrations, and this pH value decreased when the Gd(NO3)3 concentration was increased. Because the QD/SiO2/GdC particle surface was covered with GdC, properties of the QD/SiO2/GdC particle surfaces were expected to have similar characteristics to those of GdC particle surfaces. ζ-Potentials of GdC particles prepared with the homogeneous precipitation method increased with a decrease in pH. Accordingly, an increase in Gd(NO3)3 concentration could increase the ζ-potential of QD/SiO2/GdC particles. It is possible that the increased ζ-potential at high Gd(NO3)3 concentrations created a larger electric repulsion among the QD/SiO2/GdC particles than at low Gd(NO3)3 concentrations. Thus, highly dispersed QD/SiO2/GdC particles were generated at high Gd(NO3)3 concentrations.

TEM images of QD/SiO2/GdC nanoparticles prepared with homogeneous precipitation method at Gd(NO3)3 concentrations of (a) 3 × 10−5, (b) 3 × 10−4, and (c) 3 × 10−3 M. Initial concentrations of QD, urea, and PVP were 3.2 × 10−9 M, 0.5 M, and 1 g/L, respectively (Reprinted from Journal of Materials Science 47 (2012) 1852–1859)

Silica coating of the QD/SiO2/GdC particles was performed using the modified Stöber method with TEOS and NaOH in a water/ethanol solution at room temperature for 24 h. The QD/SiO2/GdC/SiO2 particles were washed by centrifugation, removal of the supernatant, addition of water, and sonication and by repeating this procedure three times. Figure 9 shows TEM images of QD/SiO2/GdC/SiO2 particles prepared with various TEOS concentrations. The QD/SiO2/GdC particles were coated with silica shells in all the TEOS concentrations examined. However, the QD/SiO2/GdC/SiO2 particles aggregated and connected with other QD/SiO2/GdC/SiO2 particles at low concentrations. Additionally, the resulting silica shells were so thin that the QD/SiO2/GdC/SiO2 particles were not colloidally stable. An increase in TEOS concentration increased the silica shell thickness, which controlled particle aggregation and produced quasi-perfect and highly dispersed QD/SiO2/GdC/SiO2 particles.

TEM images of QD/SiO2/GdC/SiO2 nanoparticles prepared at TEOS concentrations of (a) 5 × 10−4, (b) 1 × 10−3, and (c) 5 × 10−3 M. Initial concentrations of QD, Gd(NO3)3, urea, and PVP were 3.2 × 10−9 M, 3 × 10−3 M, 0.5 M, and 1 g/L, respectively (Reprinted from Journal of Materials Science 47 (2012) 1852–1859)

Quantum Dot/Silica Core–Shell Particles with Immobilized Au Nanoparticles

Materials with high X-ray absorption properties can be applied to X-ray imaging techniques. Iodinated contrast agents are usually used in imaging to obtain clear images. Typical X-ray contrast agents that are commercially available are iodine compounds that are homogeneously dissolved in solvents. However, iodine-based X-ray contrast agents are problematic because they can provoke adverse events such as allergic reactions (Zhao et al. 2011; Thomsen 2011) and cannot be administered to some patients. Consequently, Au has become a promising candidate for use in imaging because Au has high X-ray absorption and is less toxic than iodine compounds. Researchers have examined the use of Au nanoparticles as contrast agents to take nanometer images of tissues in living bodies (Menk et al. 2011; Peng et al. 2012; Wang et al. 2013). Taking advantage of the multi-functionalization of materials, particles containing QDs and Au can act as both fluorescent and X-ray contrast agents. This section introduces a proposed method to fabricate composite particles composed of QD/SiO2 core–shell particles and Au nanoparticles or QD/SiO2 core–shell particles with immobilized Au nanoparticles (QD/SiO2/Au). Immobilization facilitates the chemical interaction between metallic Au and amino groups.

A freshly prepared Na-cit aqueous solution was added to a HAuCl4 aqueous solution at a constant temperature of 80 °C under vigorous stirring, which produced a colloidal solution of Au nanoparticles. For efficient immobilization of Au nanoparticles on the QD/SiO2 particle surface, or the production of QD/SiO2/Au particles, amino groups were first introduced on the QD/SiO2 particle surface using (3-aminopropyl)triethoxysilane (APES) (QD/SiO2-NH2) because the alkoxide groups of the APES were expected to react with the OH groups on the silica surface of the QD/SiO2 particles. APES was added to the QD/SiO2 colloidal solution at room temperature. To immobilize the Au nanoparticles, ethanol, water, and the Au nanoparticle colloid solution were added in turn to the QD/SiO2-NH2 particle colloid solution at 35 °C, allowing the amino groups on the particle surface to coordinate with the surface of the Au nanoparticles.

The QD/SiO2-NH2 nanoparticles dispersed well in water and were colloidally stable, which indicated that the addition of APES had no serious effect on their colloidal stability in water. TEM observations (Fig. 10c) revealed that some particles appeared to form aggregates that were likely to precipitate. However, no precipitates were found in the particle colloid solution. These aggregates were thought to be produced during the preparation of TEM samples due to evaporation of solvent on the TEM grid. Similar to the QD/SiO2 nanoparticles, particles containing a few QD cores were observed. Their particle sizes were similar to those of the QD/SiO2 nanoparticles, which indicated that their core–shell structures were chemically stable even after the amination process. ELS measurements and TEM observations (Fig. 10b) indicated that the QD surfaces were covered with silica. The IEP shifted to 9.5 upon amination. Acid dissociation constants for amino groups in many types of amines, such as ammonia, alkylamine, and dialkylamine, range between 9 and 11, and the IEP of 9.5 was within the range. These results confirmed that the amino groups were successfully introduced onto the particle surfaces.

Figure 10d shows a TEM micrograph of the QD/SiO2/Au nanoparticles. All the Au nanoparticles were immobilized on the surface of particles, indicating that the Au nanoparticle immobilization was successful using the described method. Several Au nanoparticle-free particles were also observed, but the number ratio of Au nanoparticle/QD/SiO2-NH2 nanoparticles was less than 1/1. Further optimization of fabrication conditions such as concentrations of Au nanoparticles and QD/SiO2-NH2 nanoparticles in the final colloid solutions, reaction temperatures, and stirring rates is required to improve the efficiency of Au nanoparticle immobilization.

The Effect of Silica on the Photostability of Quantum Dots

One of the major difficulties in implementing the use of metal chalcogenide semiconductor nanoparticles in devices for practical applications is the prevention of light-induced surface reactions that can lead to the total oxidation of the nanoparticles. In the case of CdS nanoparticles, Henglein showed that CdS degraded under the influence of light in the presence of dissolved oxygen (Henglein 1982). Oxygen facilitates the oxidation of sulfide radicals that are generated through the formation of hole-anion pairs at particle surfaces through the following reaction:

where the subscript S indicates a surface atom. This process can be inhibited by preventing the CdS surface from contacting oxygen. The silica shells of particles should be useful in preventing this contact. Thus, silica shells may have an additional function as a physical barrier to prevent oxidation in addition to decreasing particle toxicity and increasing colloidal stability of particles. Prior to investigations on the fluorescence imaging properties of the nanoparticles, the effect of silica on the photostability of QDs was investigated. Two types of investigations were performed, including the effects of silica shells and a comparison between silica using sodium silicate solutions and silicon alkoxide.

Effect of Silica Shells

The QD/SiO2 used for this investigation was the same as in Fig. 7 (Zhou et al. 2005). UV–vis spectra revealed that extinction of the uncoated CdSe nanoparticle colloid solution decreased markedly with time, while that of the CdSe QD/SiO2 particle colloid solution remained constant. This indicated that the silica shell was rigid enough to prevent O2 from reaching the surfaces of the CdSe QDs. Figure 11 shows changes in photoluminescence (PL) intensity at different illumination times after exposure to an Ar laser (532 nm). The PL intensity of rhodamine 560 gradually decreased upon illumination, which reconfirmed instability of the organic dye. The PL intensity of the bare CdSe QDs increased rapidly in the initial stage of illumination. This seemed to result from photo annealing, which decreased the number of defect sites on the surface of the CdSe QDs. With a long duration of strong illumination, the PL intensity greatly decreased. This likely resulted from the CdSe QDs absorbing so many high-energy photons, which resulted in decomposition into elemental Cd and Se under the extreme conditions. Similar observations on CdS have been previously noted by Spanhel et al. (1987). In contrast, the PL intensity of CdSe QD/SiO2 remained mostly constant except for a slight increase during early stages of illumination. Here, the silica shell was likely rigid enough to confine the Cd and Se atoms within a fixed space and site, which maintained the structure of CdSe QDs.

Comparison of Silica Produced Using a Sodium Silicate Solution and Silicon Alkoxide

Silica can be fabricated from both silicon alkoxide and sodium silicate solutions. The two types of silica are compared in this section (Correa-Duarte et al. 2001). This investigation used CdS QD nanoparticles produced by mixing Cd(NO3)2 and Na2S aqueous solutions in the presence of Na-cit. Then, a freshly prepared aqueous solution of MPS and sodium silicate solution were added to the CdS QD particle colloid solution to form thin silica shells that colloidally stabilized the CdS QD particles. The pH of the resulting dispersion was adjusted to 8.5 and was allowed to stand for several days in a nitrogen atmosphere such that the silica could slowly polymerize onto the modified CdS QD particle surfaces. Two different methods were used to prepare silica gels loaded with nanoparticles. In method 1, the silica-coated CdS particle colloid solution was added to tetramethyl orthosilicate/methanol under vigorous magnetic stirring. Then, the final mixture was poured into a plastic cuvette, which was sealed with a rubber sheet to prevent evaporation. Formation of the silica gel was complete within hours. In method 2, a solution of sodium silicate was added to the CdS QD/SiO2 particle colloid solution with magnetic stirring. Once the addition of silicate was complete, the pH was adjusted to 7 with an aqueous HCl solution. The sample was then poured into a cuvette and quickly sealed with transparent plastic film. Formation of silica gel occurred over several hours.

In method 1, optical features of the silica such as color and luminescence were retained for weeks and even months. However, those produced using method 2 suffered from photodegradation in an unusual fashion. Although the entire sample was illuminated and the open end of the cuvette was sealed, the sample’s characteristic pale yellow color and its red luminescence gradually decreased from top to bottom in a time scale of weeks. These phenomena are closely related to the porosity of the silica. To characterize the porosity of the two samples, nitrogen sorption experiments were carried out to gain information on the pore size and specific surface areas of the silica. Surface area values were obtained from the isotherms via the Brunauer-Emmett-Teller expression, and average pore diameters were derived using the Barrett-Joyner-Halenda method and desorption branches of nitrogen sorption isotherms. The surface area obtained for method 1 was 674 m2/g, which was almost twice the value of 321 m2/g obtained for method 2. The calculated pore size for the silica generated using method 1 was 3.0 nm, which was significantly smaller than the 4.5 nm pore size that was calculated for method 2. This result indicated that the silica gel produced using sodium silicate had a much more open structure, such that the particle cores were more accessible to oxygen, which resulted in photodegradation. Accordingly, the silica gel produced from silicon alkoxide is expected to stabilize photo-properties of metal chalcogenide QDs.

Fluorescence Imaging

Quantum Dot/Silica Core–shell Particles

Fluorescence imaging of particles as small as molecules and nanometers in size will need to be developed to improve imaging abilities in the future. Our research group has developed a technique to measure fluorescence intensities of individual particles, using an instrument composed of an optical system equipped with a confocal microscope (Gonda et al. 2010; Hikage et al. 2010). The fluorescence intensity of each QD/SiO2 particle was measured using this system (Kobayashi et al. 2012c). The sample solution was pipetted onto a glass slide and covered with a glass cover slip. Particles were illuminated with a blue laser (488 nm), and the fluorescence images of the particles were obtained using an optical system consisting of an epi-fluorescent microscope with an oil immersion objective lens, a Nipkow disk-type confocal unit, and an electron multiplier type charge-coupled device camera. Figure 12a, b shows the fluorescence images of the QDs and QD/SiO2 particles, respectively. The fluorescence of the QDs contained in particles, confirmed as bright spots, was successfully detected using this setup.

An in vivo imaging system (IVIS) fluorimeter was also used for fluorescence imaging. The QD/silica particles used were fabricated following the method of producing multiple QD/SiO2 core–shell particles (Kobayashi et al. 2010b). The QD/SiO2 particles, to which poly(ethylene glycol) (PEG) was immobilized, were also used for IVIS imaging. The immune system recognizes hydrophobic materials as foreign, which limits blood circulation when such particles are used in vivo. PEGylation is a process where PEG is immobilized to a material; this process is often performed to make surfaces hydrophilic (Niidome et al. 2010; Basile et al. 2012; Yoshino et al. 2012; Ma et al. 2012; Otsuka et al. 2012; Lo et al. 2013). Our QD/SiO2 particles were also PEGylated. An aqueous solution of methoxy PEG silane (M-SLN-5000) was added to the QD/SiO2 particle colloid solution, where PEG groups were expected to be introduced to particle surface through a reaction between the silanol groups on surfaces of QD/SiO2 particles and the alkoxide groups of the M-SLN-5000. The QD/SiO2/PEG colloid solution was concentrated through the process of centrifugation, removal of supernatant, addition of solvent, and redispersion. Colloid solutions of QD particles, QD/SiO2 particles, and QD/SiO2/PEG particles successfully produced IVIS images. For all the colloid solutions, radiant efficiencies (RE) increased with an increase in QD concentration. The RE values tended to level off with an increase in QD concentration, which was probably due to concentration quenching. The RE values of the QD/SiO2 particle colloid solution were slightly larger than those of the QD particle colloid solution.

The QD nanoparticles are apt to aggregate due to nature of the nanoparticles. Such aggregation probably decreased the fluorescence intensity of the QD nanoparticles. In contrast, formation of a core–shell structure prevented the QD nanoparticles from aggregating because of the physical barrier created by the silica shell, which also helped retain their fluorescence intensity. Thus, it was noted that the silica coating had the ability to retain efficient fluorescence emissions of QDs. There was no large difference in RE values between the colloid solutions of QD/SiO2 particles and QD/SiO2/PEG particles. This indicated that PEGylation did not deteriorate fluorescence properties of the QDs. Figure 13a, c shows photographs and IVIS images of a mouse taken prior to and after injection of a QD/SiO2/PEG particle colloid solution. Fluorescence emissions increased with time after the injection. Figure 13d shows a photograph and an IVIS image of the mouse after injection and a subsequent laparotomy. Fluorescence emissions from the tissue were clearly observed, which indicated that the injected QD/SiO2/PEG particles were able to reach the tissues from the vein. Figure 14 shows IVIS images of various tissues taken prior to and after an injection. There were no large differences in fluorescence emissions between the kidney and heart prior to and after the injection. Emissions from the lung, liver, and spleen became strong after the injection. These results indicate that the QD/SiO2/PEG particles efficiently reached these tissues by flowing through the veins but were probably recognized as alien substances and contained within them, subsequently emitting strong fluorescence.

Photographs (A) and IVIS images (B) of mouse taken (a) prior to (b) at 5 min after and (c) at 1 h after injection of QD/SiO2/PEG particle colloid solution. The mouse (d) was the mouse (c), for which a laparotomy was performed (Reprinted from Journal of Sol-gel Science and Technology 66 (2013) 31–37)

IVIS images (B) of (a) heart, (b) lung, (c) liver, (d) spleen, and (e) kidney of mouse after injection of QD/SiO2/PEG particle colloid solution. These tissues were taken from the mouse (d) in Fig. 12. IVIS images (A) were taken as control (no injection) (Reprinted from Journal of Sol-gel Science and Technology 66 (2013) 31–37)

The effect of particle size on fluorescence imaging was also investigated (Kobayashi et al. 2015b). Figure 15 shows IVIS images for the QD, S-QD/SiO2, and L-QD/SiO2 colloid solutions. All the colloid solutions were successfully imaged, and based on fluorescence intensities or RE values, the images were improved in terms of visual clarity with increasing QD concentrations. For all the colloid solutions, the RE values increased linearly with increasing QD concentrations. Concentration quenching did not occur when we used the colloid solutions of interest. There was no significant difference in RE values of the colloid solutions. These results indicate that the silica-coating process and increased shell thickness did not degrade the QD fluorescence properties. Prior to the IVIS imaging of the mouse, the QD/SiO2 particle surfaces were PEGylated using M-SLN-5000. Figures 16 and 17 show the IVIS images for various mouse tissues extracted after particle injection followed by laparotomy. These tissues exhibited clear fluorescence for both QD/SiO2/PEG particle colloid solutions, which indicated that the injected particle colloid solutions reached the tissues from the vein. Figure 18 shows bar graphs summarizing Figs. 16 and 17. For comparison, the fluorescence emissions of various tissues prior to injection are shown in Fig. 18.

For the S-QD/SiO2/PEG particles, the emissions from the lung and liver were strong after the injection. Pulmonary embolism occurred due increased florescence in the lung. A large increase in RE in the liver indicated that the S-QD/SiO2/PEG particles efficiently reached these tissues via blood flow after passing through the lungs. In the liver region, we speculate that the particles were most likely recognized as foreign substances and trapped by the liver, which resulted in strong particle fluorescence emissions. The RE of the heart did not change significantly after the injection, which indicated that the colloid solution did not circulate through the body for a prolonged period. The RE values for the heart, lung, liver, and spleen for the L-QD/SiO2/PEG particles were approximately 4, 3, 94, and 8 times larger, respectively, than the corresponding RE values prior to the injection. The RE for the heart increased in contrast to the levels when the S-QD/SiO2/PEG particles were used, which implied the L-QD/SiO2/PEG particles circulated through the blood for a longer period of time than the S-QD/SiO2/PEG particles. The observed RE increases for the lung, the liver, and the spleen were smaller and larger, respectively, compared with the use of S-QD/SiO2/PEG particles. This indicated that the L-QD/SiO2/PEG particles passed through the lungs more efficiently and were more effectively trapped by the liver and spleen. Small particles tend to aggregate due to their large surface energy. The S-QD/SiO2/PEG particles aggregated and were trapped by the lungs, which caused pulmonary embolism. In contrast, the L-QD/SiO2/PEG particles did not aggregate significantly. This lack of aggregation allowed the particles to pass through the lungs and efficiently reach not only the liver but also the spleen, where they were trapped, and serves as another benefit in the form of smooth particle flow. This smooth flow promoted particle circulation in the blood vessels, which increased the RE for the heart. Thus, different radiant efficiencies were obtained for QD/SiO2/PEG particles of different sizes.

Multilayered Core–Shell Particles Composed of Quantum Dots, Gadolinium Compounds, and Silica

The fluorescence intensities of QD/SiO2/GdC and QD/SiO2/GdC/SiO2 particles were also measured using the optical system with a confocal microscope (Kobayashi et al. 2012c). The QD/SiO2/GdC and QD/SiO2/GdC/SiO2 particles used to fabricate the multilayered core–shell particles were the same as in Figs. 7c and 8a, respectively. Figure 11c, d shows fluorescence images of the QD/SiO2/GdC and QD/SiO2/GdC/SiO2 particles on glass plates. Bright spots were clearly detected, which derived from the fluorescence of the QDs contained in the particles. Fluorescence intensities were estimated from the brightness of fluorescence. As the number of layers increased, the fluorescence intensity of single particles tended to decrease. In particular, GdC coating decreased fluorescence intensities significantly. It was found that excitation and emission of QDs were prevented by optical absorption and scatter caused by the GdC layer, although silica layer did not affect the fluorescence intensity of QDs compared to the GdC layer. Our previous studies demonstrated that multilayered SiO2/GdC/SiO2 core–shell particles exhibited MRI abilities (Kobayashi et al. 2007). This implies that the multilayered core–shell particles obtained in this study will also function as an MRI contrast agent. This study indicated that the multilayered core–shell particles emitted strong fluorescence. In summary, the multilayered core–shell particles were harmless to living bodies and could simultaneously function as a fluorescent marker and high-contrast MRI agent.

Quantum Dots/Silica Core–Shell Particles Immobilizing Au Nanoparticles

IVIS imaging was performed using a QD/SiO2/Au particle colloid solution (Kobayashi et al. 2016), which was the same as observed in Fig. 9. Figure 19a shows an IVIS image of the QD/SiO2/Au particle colloid solution, which was successfully imaged. Its RE value was 2.23 × 107 (p/s/cm2/sr)/(μW/cm2). This value was converted into a value with respect to QD concentration to compare it with that of commercially available QDs. Because the colloid solution had a QD concentration of 8 × 10−7 M, the converted RE was 2.79 × 1013 (p/s/cm2/sr)/(μW/cm2)/M. According to our previous work (Kobayashi et al. 2013e), the RE of QD was 2.93 × 109 (p/s/cm2/sr)/(μW/cm2) at a QD concentration of 1 × 10−7 M, which corresponded to a converted RE value of 2.93 × 1016 (p/s/cm2/sr)/(μW/cm2)/M. This converted RE for the QD/SiO2/Au particle colloid solution was smaller than that of the commercial QD. The Au nanoparticle colloid solution absorbed visible light in a wide range around the wavelength of 521 nm. The fluorescence from the QD/SiO2/Au particles was probably diminished by this absorption, although the mechanism is still unclear. Although the converted RE for the QD/SiO2/Au particle colloid solution was small, the intensity of the RE was high enough to image a mouse, based on our previous experience with animal experiments. Figure 19b shows an IVIS image of a mouse after injection of the QD/SiO2/Au particle colloid solution. Fluorescence was clearly observed on the chest after injection into the chest wall, which indicated that fluorescence penetrated through the skin from inside the mouse. Its RE value was 3.30 × 107 (p/s/cm2/sr)/(μW/cm2). This value was approximately 1.5 times larger than the value of 2.23 × 107 (p/s/cm2/sr)/(μW/cm2) for the QD/SiO2/Au particle colloid solution, which indicated that the QD/SiO2/Au particle colloid solution could emit strong fluorescence even inside living bodies without quenching. The detection of large RE implied that the QD/SiO2/Au particles accumulated in the chest wall, although the reason behind the large RE is still unclear.

Figure 20b shows an X-ray image of the QD/SiO2/Au particle colloid solution. For comparison, an X-ray image of water is shown in Fig. 20a. The white contrast in the image of the QD/SiO2/Au particle colloid solution was lighter than that of water. The computed tomography (CT) value of the QD/SiO2/Au particle colloid solution was 1180 ± 314 Hounsfield units (HU) at a Au concentration of 5.4 × 10−2 M. This value was converted into a value with respect to the molar concentration of subject materials such as Au and I (i.e., converted CT value) to compare it with that of a commercial contrast agent. The converted CT value was estimated to be 2.19 × 104 HU/M with respect to the Au concentration. According to our previous work (Kobayashi et al. 2013d), the converted CT value with respect to the iodine concentration of Iopamiron 300 is 4.76 × 103 HU/M. The converted CT value of the QD/SiO2/Au particle colloid solution was larger than that of Iopamiron 300. Gold absorbs X-rays more than iodine on an atomic level because of its large atomic number, resulting in a larger converted CT value for the QD/SiO2/Au particle colloid solution. Thus, it was confirmed that the QD/SiO2/Au particle colloid solution had the ability to function as a highly sensitive X-ray contrast agent. Figure 20c shows an X-ray image of a mouse after it was injected with the QD/SiO2/Au particle colloid solution. The location of the particle colloid solution could be recognized clearly at the chest wall because of its light contrast. Its CT value was 1060 ± 374 HU, which was as high as the value obtained for the QD/SiO2/Au particle colloid solution (1180 ± 314 HU). Similar to the fluorescence images, the QD/SiO2/Au particle colloid solution could be clearly observed even inside live bodies without quenching.

CT images of (a) water, (b) the QD/SiO2/Au particle colloid solution, and (c) a mouse after the colloid solution was injected into its chest wall. The QD/SiO2/Au particle colloid solution was observed in the chest wall, as shown by the red circle (Reprinted from Applied Nanoscience 6 (2016) 301–307)

Another result worthy of noting is that when the mouse injected with the QD/SiO2/Au particle colloid solution was imaged simultaneously using IVIS and X-ray, the positioning of images by IVIS was identical to that of the X-ray images. This suggests that the colloid solution can function as a contrast agent for dual imaging processes.

Conclusion

This chapter introduced our recent studies on the development of methods to fabricate particles coated with silica shells using the sol-gel reaction, generate multilayered core–shell particles containing QDs and GdC, and immobilize Au nanoparticles on core–shell particles containing QDs. Successful silica coating of nanoparticles was confirmed by TEM observation and UV–vis spectroscopy of the Au/SiO2 core–shell particles. The silica-coating method was extended to fabricate QD/SiO2 core–shell particles. The QD/SiO2 core–shell particles were coated with GdC shells using a homogeneous precipitation method. The Au nanoparticles were immobilized on the surface of QD/SiO2 core–shell particles by modifying their surfaces with amino groups and then attaching the Au nanoparticles on the surface using amino groups. Fluorescence imaging processes using the particles containing the QDs were also introduced in this chapter. The particle colloid solution was applied to image mouse tissues using the IVIS technique. The multilayered core–shell particles composed of QD, GdC, and silica and the Au nanoparticle-immobilized QD/SiO2 core–shell particles are expected to have dual imaging functions and be able to function not only as a fluorescent marker but also as an MRI and X-ray contrast agent.

The studies described above indicate that the QD/SiO2 core–shell particles were able to be applied for use in various imaging techniques. Our previous studies have focused mainly on their imaging abilities. Further studies on subjects such as the toxicity of particle colloid solutions and precise mechanisms of surface coating and surface modification will be necessary for the practical implementation of such particles.

References

Ayame T, Kobayashi Y, Nakagawa T, Gonda K, Takeda M, Ohuchi N. Preparation of silica-coated AgI nanoparticles by an amine-free process and their X-ray imaging properties. J Ceram Soc Jpn. 2011;119:397–401.

Bahadur NM, Furusawa T, Sato M, Kurayama F, Siddiquey IA, Suzuki N. Fast and facile synthesis of silica coated silver nanoparticles by microwave irradiation. J Colloid Interface Sci. 2011;355:312–20.

Basile L, Passirani C, Huynh NT, Bejaud J, Benoit JP, Puglisi G, Pignatello R. Serum-stable, long-circulating paclitaxel-loaded colloidal carriers decorated with a new amphiphilic PEG derivative. Int J Pharm. 2012;426:231–8.

Bogush GH, Tracy MH, Zukoski CF. Preparation of monodisperse silica particles: control of size and mass fraction. J Non-Cryst Solids. 1988;104:95–106.

Bogush GH, Zukoski CF. Studies of the kinetics of the precipitation of uniform silica particles through the hydrolysis and condensation of silicon alkoxides. J Colloid Interface Sci. 1991;142:1–18.

Brus L. Electronic wave functions in semiconductor clusters: experiment and theory. J Phys Chem. 1986;90:2555–60.

Chen C, Takezako T, Yamamoto K, Serizawa T, Akashi M. Poly(N-vinylisobutyramide)-stabilized platinum nanoparticles: synthesis and temperature-responsive behavior in aqueous solution. Colloids Surf A. 2000;169:107–16.

Cho G, Fung BM, Glatzhofer DT, Lee J-S, Shul Y-G. Preparation and characterization of polypyrrole-coated nanosized novel ceramics. Langmuir. 2001;17:456–61.

Correa-Duarte MA, Giersig M, Liz-Marzán LM. Stabilization of CdS semiconductor nanoparticles against photodegradation by a silica coating procedure. Chem Phys Lett. 1998;286:497–501.

Correa-Duarte MA, Kobayashi Y, Caruso RA, Liz-Marzán LM. Photodegradation of SiO2-coated CdS nanoparticles within silica gels. J Nanosci Nanotechnol. 2001;1:95–9.

Cui W, Li J, Zhang Y, Rong H, Lu W, Jiang L. Effects of aggregation and the surface properties of gold nanoparticles on cytotoxicity and cell growth. Nanomed Nanotechnol Biol Med. 2012;8:46–53.

Doremus RH. Optical properties of small gold particles. J Chem Phys. 1964;40:2389–96.

Dubus S, Gravel JF, Drogoff BL, Nobert P, Veres T, Boudreau D. PCR-free DNA detection using a magnetic bead-supported polymeric transducer and microelectromagnetic traps. Anal Chem. 2006;78:4457–64.

Ekimov AI, Efros AL, Onushchenko AA. Quantum size effect in semiconductor microcrystals. Solid State Commun. 1993;88:947–50.

Farbman I, Lev O, Efrima S. Optical response of concentrated colloids of coinage metals in the near-ultraviolet, visible, and infrared regions. J Chem Phys. 1992;96:6477–85.

García-Santamaría F, Salgueiriño-Maceira V, López C, Liz-Marzán LM. Synthetic opals based on silica-coated gold nanoparticles. Langmuir. 2002;18:4519–22.

Gauden AJ, Phal PM, Drummond KJ. MRI safety; nephrogenic systemic fibrosis and other risks. J Clin Neurosci. 2010;17:1097–104.

Gonda K, Watanabe TM, Ohuchi N, Higuchi H. In vivo nano-imaging of membrane dynamics in metastatic tumor cells using quantum dots. J Biol Chem. 2010;285:2750–7.

Guo J, Yang W, Deng Y, Wang C, Fu S. Organic-dye-coupled magnetic nanoparticles encaged inside thermoresponsive PNIPAM microcapsules. Small. 2005;1:737–43.