Abstract

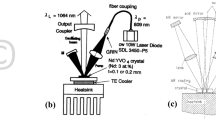

Solid-state lasers involving high-density active media are considered the most important types of lasers. The active medium of a solid-state laser consists of a transparent host material in which active species ions are introduced as an impurity. Desirable properties for such host materials include hardness, chemical inertness, absence of internal strain and refractive index variations, resistance to radiation-induced color centers, and ease of fabrication. Due to the relatively long upper-state lifetimes or broad-gain bandwidths of solid-state laser materials, the energy accumulated during a long optical pumping cycle can be released quickly in the form of a short, high peak-power pulse. Solid-state lasers are normally optically pumped by a flash lamp, an arc lamp or high-power laser diodes, providing enhanced brightness with improved beam quality, leading to output powers ranging from a few milliwatts to many kilowatts. However, the optical pump process in a solid-state laser material also results in the generation of deposited waste heat which causes thermo-optic distortion.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Acherjee B, Prakash S, Kuar AS, Mitra S (2014) Grey relational analysis based optimization of underwater Nd:YAG laser micro-channeling on PMMA. Proc Eng 97:1406–1415

Ahmed N, Darwish S, Alahmari AM, Shar MA (2016) Micro-channels by Nd:YAG laser beam machining: fabrication, microstructures, and micro-hardness profiles. Int J Adv Manuf Technol 85(9–12):1955–1968

Ascari A, Fortunato A, Guerrini G, Liverani E, Lutey A (2017) Long pulse laser micro welding of commercially pure titanium thin sheets. Proc Eng 184:274–283

Azhdast MH, Eichler HJ, Lang K-D, Glaw V (2016) Adhesion mechanism between laser sputtered Aluminum nano particles on Si-Wafer by Nd:YAG laser. In: Lasers and electro-optics (CLEO), 2016 Conference on. IEEE, pp 1–2

Azhdast MH, Kossatz M, Eichler HJ, Lang K-D, Glaw V (2017a) Comparison of nano particle implantation with picosecond lasers by concerning different wavelengths from Aluminum and Copper on Silicon wafer substrate. In: CLEO: applications and technology. Optical Society of America

Azhdast MH, Kossatz M, Eichler HJ, Lang K-D, Glaw V (2017b) Deposition of Al and Cu nanoparticles on silicon wafer using a picosecond Nd:YAG laser: an experiment-based parameter optimization guide. In: CLEO: QELS_Fundamental Science. Optical Society of America

Azhdast MH, Eichler HJ, Lang K-D, Glaw V (2018) Optimization parameters for laser-induced forward transfer of Al and Cu on Si-wafer substrate. In: The 6th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2018). Science and Technology Publications, pp 228–231

Chang YJ, Hsu JC, Ho CC, Luo YH, Kuoi CL (2016) Mask assisted laser percussion drilling. J Laser Micro/Nanoeng 54(5):056203

Chen M-F, Hsiao W-T, Wang M-C, Yang K-Y, Chen Y-F (2015) A theoretical analysis and experimental verification of a laser drilling process for a ceramic substrate. Int J Adv Manuf Technol 81(9–12):1723–1732

Das SR, Nian Q, Cargill AA, Hondred JA, Ding S, Saei M, Cheng GJ, Claussen JC (2016) 3D nanostructured inkjet printed graphene via UV-pulsed laser irradiation enables paper-based electronics and electrochemical devices. Nanoscale 8(35):15870–15879

Dong C, Gu Y, Zhong M, Lin L, Sezer K, Ma M, Liu W (2011) Fabrication of superhydrophobic Cu surfaces with tunable regular micro and random nano-scale structures by hybrid laser texture and chemical etching. J Mater Process Technol 211(7):1234–1240

Eisner K, Lang A, Schutte K, Bergmann HW (1996) Shock hardening as a novel technique for materials processing. In: Sayegh G, Osborne MR (eds) High-power lasers: applications and emerging applications. SPIE

Franco A, Romoli L, Musacchio A (2014) Modelling for predicting seam geometry in laser beam welding of stainless steel. Int J Therm Sci 79:194–205

García E, Viveros LDC, Vázquez E, Siller H, Rodríguez González CA (2018) Laser micro-spot welding of thin AISI 302 stainless steel sheets. In: Laser-based micro- and nanoprocessing XIII. International Society for Optics and Photonics, p 48

Harb CC, Ralph TC, Huntington EH, McClelland DE, Bachor HA (1997) Intensity-noise dependence of Nd:YAG lasers on their diode-laser pump source. J Opt Soc Am 14(11):2936–2945

Hongyu Z, Ming Z, Wang Y, Xiangchao Z, Yu Y, Wang R (2017) Laser percussion drilling of high temperature alloy and qualitative/quantitative characterization. J Laser Micro/Nanoeng 12(3):307–312

Huneus F, Lingel C, Zeller T, Heimes A, Tillkorn C, Janami K (2019) Compact line focus system for laser-based debonding of flexible electronic components. In: Klotzbach U, Kling R, Watanabe A (eds) Laser-based micro- and nanoprocessing XIII. SPIE

Irizalp SG, Saklakoglu N (2016) High strength and high ductility behavior of 6061-T6 alloy after laser shock processing. Opt Lasers Eng 77:183–190

Jiang X, Yu X, Deng X, Shao Y, Peng P (2019) Investigation on laser-induced shock pressure with condensed matter model and experimental verification. Exp Techniques 43:161–167

Jones JB, McNutt P, Tosi R, Perry C, Wimpenny DI (2012) Remanufacture of turbine blades by laser cladding, machining and in-process scanning in a single machine. Proceedings from the 23rd Annual International Solid Freeform Fabrication Symposium

Kang N, Verdy C, Coddet P, Xie Y, Yingqing F, Liao H, Coddet C (2017) Effects of laser remelting process on the microstructure, roughness and microhardness of in-situ cold sprayed hypoeutectic al-si coating. Surf Coat Technol 318:355–359

Khan M, Romoli L, Dini G, Fiaschi M (2011) A simplified energy-based model for laser welding of ferritic stainless steels in overlap configurations. CIRP Ann Manuf Technol 60(1):215–218

Kibria G, Doloi B, Bhattacharyya B (2016) Generation of defined micro-turning surface roughness on Al2O3 ceramic by pulsed Nd:YAG laser micro-turning process. Lasers Eng (Old City Publishing) 35

Kibria G, Lepcha LP, Shivakoti I, Doloi B, Bhattacharyya B (2018a) Pulsed Nd:YAG laser micro-turning of Alumina to study the effect of overlap factors on surface roughness performance. In: IOP conference series: materials science and engineering, vol 377. IOP Publishing, p 012185

Kibria G, Chatterjee S, Ishwer S, Doloi B, Bhattacharyya B (2018b) RSM based experimental investigation and analysis into laser surface texturing on titanium using pulsed Nd:YAG laser. In: IOP conference series: materials science and engineering, vol 377. IOP Publishing, p 012203

Kim JG, Chang WS, Yoon KK, Jeong S, Shin BS, Whang KH (2003) Microdrilling of PCB substrate using DPSS 3rd harmonic laser. In: Third International Symposium on Laser Precision Microfabrication, vol 4830. International Society for Optics and Photonics, pp 105–110

Liu B, Li B-Q, Li Z (2019) Selective laser remelting of an additive layer manufacturing process on AlSi10mg. Results Phys 12:982–988

Mai TA, Kling NU, Vágó N, Richerzhagen B, Stay K (2007a) Laser microjet® technology-fundamental study and highlights of it’s latest applications. Advanced Laser Applications Conference, Boston, MA.

Mai T, Richerzhagen B, Snowdon PC, Wood D, Maropoulos P (2007b) The laser microJet (LMJ): a multisolution technology for high quality micro-machining. In: Proceedings of SPIE – The International Society for Optical Engineering, vol 6459. International Society for Optics and Photonics

McCann R, Bagga K, Groarke R, Stalcup A, Vázquez M, Brabazon D (2016) Microchannel fabrication on cyclic olefin polymer substrates via 1064 nm Nd: YAG laser ablation. Appl Surf Sci 387:603–608

Nayak BK, Gupta MC (2010) Self-organized micro/nano structures in metal surfaces by ultrafast laser irradiation. Opt Lasers Eng 48(10):940–949

P’ng D, Molian P (2008) Q-switch Nd: YAG laser welding of AISI 304 stainless steel foils. Mater Sci Eng A 486(1–2):680–685

Perrottet D, Spiegel A, Amorosi S, Richerzhagen B (2005a) GaAs-wafer dicing using the water jet guided laser. CS Mantech 2005

Perrottet D, Spiegel A, Wagner F, Housh R, Richerzhagen B, Manley J (2005b) Particle-free semiconductor cutting using the water jet guided laser. In: Photon processing in microelectronics and photonics IV, vol 5713. International Society for Optics and Photonics, pp 240–247

Pritam A, Dash RR, Mallik RK, Parida AK (2018) Optimisation of hole characteristics in pulsed Nd:YAG laser micro-drilling of AISI 304 stainless steel by Taguchi method. In: IOP conference series: materials science and engineering, vol 377. IOP Publishing, p 012108

Rajab FH, Liauw CM, Benson PS, Li L, Whitehead KA (2017) Production of hybrid macro/micro/nano surface structures on Ti6Al4V surfaces by picosecond laser surface texturing and their antifouling characteristics. Colloids Surf B Biointerf 160:688–696

Ramakrishnan BP, Lei Q, Misra A, Mazumder J (2017) Effect of laser surface remelting on the microstructure and properties of al-al2cu-si ternary eutectic alloy. Scientif Rep 7(1)

Razi S, Madanipour K, Mollabashi M (2015a) Improving the hydrophilicity of metallic surfaces by nanosecond pulsed laser surface modification. J Laser Appl 27(4):042006

Razi S, Mollabashi M, Madanipour K (2015b) Laser processing of metallic biomaterials: an approach for surface patterning and wettability control. Eur Phys J Plus 130(12):247

Razi S, Madanipour K, Mollabashi M (2016) Laser surface texturing of 316L stainless steel in air and water: a method for increasing hydrophilicity via direct creation of microstructures. Opt Laser Technol 80:237–246

Ren XD, Huang JJ, Zhou WF, Xu SD, Liu FF (2015) Surface nano-crystallization of AZ91D magnesium alloy induced by laser shock processing. Mater Des 86:421–426

Rui Z, Tieli Z, Enbang L, Xin D, Zhiqiang C, Baigang Z, Wuqi W, Wang P, Jianquan Y (2005) 8.3 W diode-end-pumped continuous-wave Nd:YAG laser operating at 946-nm. Opt Exp 13(25):10116

Rui Z, Enbang L, Haifeng L, Wang P, Jianquan Y (2006) Contineouswave, 15.2W diode-end-pumped Nd:YAG laser operating at 946 nm. Opt Lett 31(12):1869–1871

Rung S (2013) Laserscribing of thin films using top-hat laser beam profiles. 8(3):309–314

Shanmugam NS, Buvanashekaran G, Sankaranarayanasamy K, Manonmani K (2009) Some studies on temperature profiles in AiSi 304 stainless steel sheet during laser beam welding using FE simulation. Int J Adv Manuf Technol 43(1–2):78–94

Shukla AK, Akash K, Palani IA, Manivannan A (2017) Laser assisted wet texturing of flexible polyethylene terephthalate substrate using Nd 3+: YAG laser for photovoltaics devices. Mater Sci Eng B 226:78–85

Sibailly O, Wagner F, Richerzhagen B (2004) Laser micromachining in microelectronic industry by water-jet-guided laser. In: Photon processing in microelectronics and photonics III, vol 5339. International Society for Optics and Photonics, pp 258–265

Singh SS, Baruah PK, Khare A, Joshi SN (2018) Effect of laser beam conditioning on fabrication of clean micro-channel on stainless steel 316L using second harmonic of Q-switched Nd:YAG laser. Opt Laser Technol 99:107–117

Sundar R, Ganesh P, Gupta RK, Ragvendra G, Pant BK, Kain V, Ranganathan K, Kaul R, Bindra KS (2019) Laser shock peening and its applications: a review. Lasers Manuf Mater Process 6(4):424–463

Tadamalle AP, Reddy YP, Ramjee E, Reddy V (2014) Evaluation of Nd: YAG laser welding efficiencies for 304L stainless steel. Proc Mater Sci 6:1731–1739

Tetsuya S, Higashihata M, Nakamura D, Asano T, Okada T (2013) Effect of laser annealing on optical properties of ion-implanted ZnO nanorods. J Laser Micro/Nanoeng 8(1):75–78

Tobias K, Stefan B, Stefan H (2013) Laser texturing of surfaces in thin-film silicon photovoltaics – a comparison of potential processes. Int J Adv Manuf Technol 8(3):222–229

Torims T (2013) The application of laser cladding to mechanical component repair, renovation and regeneration. In: DAAAM International Scientific Book 2013. DAAAM International, Vienna, pp 587–608

Trdan U, Hočevar M, Gregorčič P (2017) Transition from superhydrophilic to superhydrophobic state of laser textured stainless steel surface and its effect on corrosion resistance. Corros Sci 123:21–26

Tripathi K, Joshi B, Gyawali G, Amanov A, Lee SW (2016) A study on the effect of laser surface texturing on friction and wear behavior of graphite cast iron. J Tribol 138(1):011601

Velasquez T, Han P, Cao J, Ehmann KF (2013) Feasibility of laser surface texturing for friction reduction in surgical blades. In: ASME 2013 International Manufacturing Science and Engineering Conference collocated with the 41st North American Manufacturing Research Conference. American Society of Mechanical Engineers, p V001T01A009

Ventrella VA, Roberto Berretta J, De Rossi W (2010) Pulsed Nd:YAG laser seam welding of AiSi 316L stainless steel thin foils. J Mater Process Technol 210(14):1838–1843

Wagner F, Sibailly O, Vágó N, Romanowicz R, Richerzhagen B (2003) The laser microjet® technology–10 years of development. In: International Congress on Applications of Lasers & Electro-Optics, vol 2003. LIA, p M401

Wei K, Lv M, Zeng X, Xiao Z, Gao H, Liu M, Deng J (2019) Effect of laser remelting on deposition quality, residual stress, microstructure, and mechanical property of selective laser melting processed ti-5al-2.5sn alloy. Mater Character 150:67–77

Yu Y, Zhang M, Guan Y, Wu P, Chong X, Li Y, Tan Z (2019) The effects of laser remelting on the microstructure and performance of bainitic steel. Metals 9(8):912

Zhai P, Dong Z, Miao R, Deng X, Chen L (2015) Investigation on the laser-induced shock pressure with condensed matter model. Jpn J Appl Phys 11(1):41–45

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Section Editor information

Rights and permissions

Copyright information

© 2021 Springer Nature Switzerland AG

About this entry

Cite this entry

Deng, X., Hu, M. (2021). Optics and Apparatus for Solid State Laser Micro-processing. In: Sugioka, K. (eds) Handbook of Laser Micro- and Nano-Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-63647-0_5

Download citation

DOI: https://doi.org/10.1007/978-3-030-63647-0_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-63646-3

Online ISBN: 978-3-030-63647-0

eBook Packages: Physics and AstronomyReference Module Physical and Materials ScienceReference Module Chemistry, Materials and Physics