Abstract

Here, we describe detection of single nucleotide polymorphism (SNP) in genomic DNA samples using a NanoBioArray (NBA) chip. Fast DNA hybridization is achieved in the chip when target DNAs are introduced to the surface-arrayed probes using centrifugal force. Gold nanoparticles (AuNPs) are used to assist SNP detection at room temperature. The parallel setting of sample introduction in the spiral channels of the NBA chip enables multiple analyses on many samples, resulting in a technique appropriate for high-throughput SNP detection. The experimental procedure, including chip fabrication, probe array printing, DNA amplification, hybridization, signal detection, and data analysis, is described in detail.

Access provided by CONRICYT – Journals CONACYT. Download protocol PDF

Similar content being viewed by others

Key words

- NanoBioArray (NBA )

- DNA microarray

- Microfluidics

- PDMS chip

- Gold nanoparticles

- Single nucleotide polymorphism (SNP )

1 Introduction

Variations in single nucleotide polymorphism (SNP ) in the KRAS gene are important cancer biomarkers, and detection of these SNP variations is crucial for selection of the appropriate type of therapy for patients [1]. Currently, various methods are used for SNP detection and they can be categorized in three major groups based on DNA sequencing, real-time PCR and DNA hybridization [2]. Hybridization -based techniques, such as the DNA microarray, are simple and have the high sample-throughput potential. However, these techniques rely on diffusion-based mass transport to deliver target strands to the probe sites, and therefore a long hybridization time is required [3]. To address the issue, Wang et al. developed a microfluidic method which used the centrifugal force in a CD-like chip to induce a liquid flow to facilitate the mass transport and delivery of the target strands [4, 5]. In this method, the chip is made by sealing two PDMS slabs consisting of channels consecutively to the circular glass chip. First, the PDMS slab consisting of radial channels is sealed with the glass chip to create an array of radially patterned probe lines (Fig. 1). Second, after removing the first slab, the second PDMS slab consisting of spiral channels is sealed with the same glass chip, and the target strands are introduced through the channels (Fig. 2). DNA hybridization between the targets and the probes occurs at the intersections of spiral channels with the radial probe lines. Using this microfluidic method, multiple fungal pathogenic samples, of up to 100, were analyzed simultaneously [4]. Although this method is proved to be fast and efficient, SNP detection entails high-temperature hybridization which complicates the experimental procedure. To avoid the use of high temperature, SNP detection of target oligonucleotide and PCR products is conducted at room temperature using gold nanoparticles (AuNPs) [6–8]. In this AuNP method, the target strands are loaded on the surfaces of AuNPs prior to introduction to the channels of the NBA chip. Involvement of the target bases in binding with the surfaces of AuNPs changes the mechanism of DNA hybridization [9], which favors the target binding to the perfectly matched (PM) probe, but not the mismatched (MM) probe, and enables the SNP detection without the use of high temperature.

Schematic diagram of probe array printing along radial channels in the CD-NBA chip (reproduced from ref. [4] with permission from Elsevier)

Schematic diagram of DNA hybridization in the spiral channels in the CD-NBA chip (reproduced from ref. [4] with permission from Elsevier)

Herein, we report the detailed experimental procedure of SNP discrimination at room temperature in the CD-like NBA chip. In this method, the DNA probes are introduced into the radial channels of the chip for probe printing. Then, the genomic DNAs are amplified using PCR , and purified. The DNAs are loaded on the surfaces of AuNPs, and introduced into the spiral channels of the chip for hybridization.

2 Materials

Prepare all aqueous solutions using ultrapure deionized (DI) water (resistance of 18 MΩ/cm at 25 °C).

2.1 PDMS Chip Fabrication

-

1.

Negative photoresist SU-8 50 and its developer (MicroChem Corp, Newton, MA, USA).

-

2.

Circular silicon wafers of 4-in. diameter (Cemat Silicon SA, Warszawa, Poland).

-

3.

SYLGARD 184 silicon elastomer kit (Dow Corning Corp., Midland, MI, USA).

-

4.

Pyrex crystallizing dish (500 mL).

-

5.

Piranha solution: 70 % of sulfuric acid (98 %) and 30 % of hydrogen peroxide (30 %).

-

6.

Photomask: design the channel pattern using a CAD software (Visual Basic or L-Edit) and print the photomask at high-resolution (>3000 dpi).

-

7.

NOX solution: Dilute concentrated Liqui-Nox (Alconox, White Plains, NY, USA) in 10 volumes of DI water.

-

8.

Silicone sealant 732 (Dow Corning Corp., Midland, MI, USA).

-

9.

Dimethyldichlorosilane solution (repel silane), 2 % in octamethylcyclotetrasiloxane.

-

10.

Spin-coater WS-400 (Laurell Technologies Corp., North Wales, PA, USA).

-

11.

Near UV exposure system (Bachur & Associates, San Jose, CA, USA).

2.2 Surface Aldehyde Functionalization

-

1.

Circular glass chips of 4-in. diameter (Precision Glass & Optics, Santa Ana, CA, USA).

-

2.

Sparkleen detergent: Dissolve 10 % of Sparkleen powder in DI water in a wash bottle.

-

3.

APTES solution: Prepare 2 % v/v of 3-aminopropyltriethoxysilane (APTES) in anhydrous ethanol.

-

4.

PBS buffer 20×: Dissolve 60.00 g NaCl, 2.00 g KCl, 14.4 g Na2HPO4 and 2.4 g KH2PO4 in 500 mL of DI water and keep the solution at room temperature.

-

5.

Glutaraldehyde solution: Mix 20 mL glutaraldehyde (25 %), 5 mL PBS 20×, and 75 mL of DI water (see Note 1 ).

2.3 Probe Array Printing

-

1.

Probe stock solution: Prepare 500 μM DNA probes in DI water. See Table 1 for probe sequences.

Table 1 The sequences of probe and primer oligonucleotides -

2.

Immobilization buffer: Prepare 0.15 M of sodium bicarbonate and 1.5 M of NaCl in DI water.

-

3.

Probe solutions: Mix 2 μL of probe stock solution in 38 μL of immobilization buffer.

-

4.

Reduction solution: Add 50 mg sodium borohydride, 0.75 mL PBS 20×, 0.1 mL Triton X 100 (10 %), 5 mL ethanol 95 % in a Falcon tube and dilute the mix with DI water to 20 mL.

-

5.

Blocking solution: Dissolve 20 mg of bovine serum albumin in 20 mL DI water.

-

6.

In-house built rotating platform.

2.4 Polymerase Chain Reaction

-

1.

KRAS genomic DNA samples (Horizon Discovery Ltd., Cambridge, UK).

-

2.

DNA amplification kit (Life Technologies, Burlington, ON, Canada): 10× amplification buffer, dNTP solution, MgCl2, and Taq DNA polymerase.

-

3.

Forward primer: Prepare 5 μM solution in DI water (see Table 1).

-

4.

Reverse primer: Prepare 5 μM solution in DI water (see Table 1).

-

5.

DNA amplification mixture: Mix 10 μL of 10× amplification buffer, 10 μL of dNTP solution, 10 μL of forward primer, 6 μL reverse primer, 5 μL MgCl2, 0.5 μL Taq DNA polymerase, 5 μL DNA template, and 53.5 μL DI water in a 0.6-mL Eppendorf tube.

-

6.

Thermocycler (Perkin Elmer, Waltham, MA, USA).

-

7.

QIAquick nucleotide removal kit: spin columns, buffer PNI, buffer PE, buffer EB, and collection tubes.

-

8.

Tabletop microcentrifuge.

2.5 DNA Hybridization

-

1.

5-nm gold nanoparticle (AuNP) solution (Sigma Life Sciences, Oakville, ON, Canada).

-

2.

Saline sodium citrate (SSC) 10×: Dissolve 44.3 g sodium citrate and 87.6 g of NaCl in 1000 mL of DI water and adjust the pH to 7 using 0.1 M HCl.

-

3.

Sodium dodecyl sulfate (SDS) 1.5 %: Add 150 mg of SDS solid to 15 mL DI water.

-

4.

Target solutions: Mix 4 μL of purified PCR products, 3.5 μL of AuNP solution, and 6.5 μL of DI water in a microcentrifuge tube. Place the tube in a water bath on a hot plate at 95 °C for 5 min. Cool down the solution by placing it in an ice bath for 5 min. Centrifuge the tube. Add 2 μL of SSC 10× and 4 μL of SDS 1.5 % and mix.

-

5.

SA-Cy5 solution (50 μg/mL): Mix 5 μL of streptavidin-Cy5 stock solution (1 mg/L) with 10 μL of Tween 20 (1.5 %) and 85 μL of DI water.

2.6 Fluorescence Detection and Data Analysis

-

1.

Confocal laser fluorescent scanner (Typhoon 9410, GE Healthcare).

-

2.

IMAGEQUANT 5.2 software.

3 Methods

3.1 Polydimethylsiloxane (PDMS) Chip Fabrication

-

1.

Place the silicon wafer inside a Pyrex dish and add 100 mL of piranha solution to the dish in the fume hood (see Note 2 ). Place the dish on a hot plate and incubate the solution for 15 min. at 80 °C. Swirl the dish once every minute.

-

2.

Remove the wafer and rinse it with water, ethanol (95 %) and water. Dry the wafer by nitrogen gas.

-

3.

Spin coating: Adjust the center of the silicon wafer on the stage of the spin coater and pour ~3 mL of SU-8 at the center of the wafer. Spin the wafer at a rate of 500 rpm for 5 s, and then of 3000 rpm for 30 s to create a SU-8 layer of 35 μm thick on the wafer.

-

4.

Soft bake: bake the wafer at 65 °C for 5 min. to remove the SU-8 solvent.

-

5.

Create the channel pattern on the coated wafer by covering it with the photomask and expose the uncovered SU-8 to UV radiation (270 mW/cm2) for 5 s initiate polymer cross-linking.

-

6.

Hard bake: Bake the wafer at 95 °C for 3 min. to complete the polymer cross-linking of the exposed SU-8.

-

7.

Pattern development: Add 20 mL of SU-8 developer solution to the wafer in a Pyrex dish to dissolve the unexposed SU-8. Shake the solution for 10 min. at room temperature. The channel pattern should now show up on the wafer. Thereafter, dry the wafer by nitrogen gas (see Note 3 ). This is the master mold to be used later for PDMS casting.

-

8.

Create a circular border on the wafer around the patterned region with silicone sealant 732 and leave the silicone to cure for 1 day at room temperature.

-

9.

Prepare 10:1 mixture of PDMS elastomer base to curing agent, and leave the mixture at −20 °C for 1 h in order to remove the air bubbles introduced during mixing.

-

10.

Treat the surface of master mold with the repel silane solution (a release agent) and leave the solution for 5–10 min to dry.

-

11.

PDMS casting: pour the PDMS elastomer mixture on the master mold until a layer with 2 mm thickness is attained. Leave the elastomer to cure and harden at room temperature for 1 day.

-

12.

Cut the edges of the PDMS slab using a blade and then gently demold and release the slab from the master mold surface.

-

13.

Create the chip reservoirs using a sharpened hole punch (gauge 18 or 1.5-mm diameter). Insert the punch from the channel side of the chip. After punching all reservoirs, wash the chip with NOX solution and dry it by nitrogen gas.

3.2 Surface Aldehyde Functionalization

-

1.

Wash the glass chip with Sparkleen solution and rinse it with water.

-

2.

In the fume hood, place the chip inside a Pyrex dish and add 100 mL of piranha solution (see Note 2 ). Place the dish on a hot plate and heat the chip in the solution at 80 °C for 15 min. Swirl the dish once every minute.

-

3.

Remove the chip and rinse it with water, ethanol (95 %) and water. Dry the chip by nitrogen gas (see Note 3 ).

-

4.

In the fume hood, place the chip inside a Pyrex dish and add 100 mL of APTES solution. Purge the solution with nitrogen gas. Seal the dish with Parafilm and incubate at room temperature for 20 min. Swirl the dish once every minute.

-

5.

Remove the chip from the Pyrex dish. Rinse the chip with 95 % ethanol (see Note 4 ). Dry the chip by nitrogen gas and incubate it in the oven for 1 h at 120 °C (see Note 5 ).

-

6.

Place the glass chip in the Pyrex dish. Add 100 mL of glutaraldehyde solution. Put a lid on the dish and place it in the fridge for 1 h.

-

7.

Remove the chip from the fridge, wash it with DI water, and dry with nitrogen gas.

3.3 Probe Array Printing

-

1.

Seal the PDMS slab with radial channels on the aldehyde-functionalized glass chip.

-

2.

Add 0.5 μL of probe solution to the inlet reservoirs and the CD-NBA chip and place the chip on the rotating platform. Fill the radial channels by spinning the platform at 400 rpm for 3 min, incubate the solutions inside the channels for 20 min. at room temperature, and then drive the solutions out by spinning the chip at 1800 rpm for 1 min.

-

3.

Peel off the PDMS slab, wash the chip with DI water, and dry it by nitrogen gas.

-

4.

Put the chip in a Pyrex dish. Add the reduction solution and incubate it at room temperature for 20 min. Swirl the dish once every minute. Remove the chip and wash it with DI water.

-

5.

Add the blocking solution to the chip in a Pyrex dish and incubate it at room temperature for 15 min. Swirl the dish once every minute. Remove the chip, wash it with DI water, and dry it with nitrogen gas.

3.4 DNA Amplification and Purification

-

1.

Prepare the DNA amplification mixture in an Eppendorf tube as given in Subheading 2.4, item 5. Add 50 μL of mineral oil to the top of the mixture and place the tube in the thermocycler.

-

2.

Thermocycling protocol: initiate denaturation at 95 °C for 3 min, execute 30 cycles of denaturation (95 °C) 40 s, annealing (55 °C) for 30 s, and extension (72 °C) for 60 s, and complete the reaction at 72 °C (final extension) for 10 min.

-

3.

Remove the tube from the thermocycler. Add 10 volumes of Buffer PNI to one volume of the PCR product solution and mix.

-

4.

Put a QIAquick column in a tube. Add the PCR product solution to the column and flow the solution through by centrifuging the tube at 6000 rpm (3600 rcf) for 1 min.

-

5.

Discard the flow-through and place the column back into the same tube. Add 750 μL of diluted Buffer PE (mix 6 mL Buffer PE with 24 mL anhydrous ethanol) to the column. Centrifuge the tube at 6000 rpm for 1 min.

-

6.

Discard the flow-through and place the column back in the same tube. Centrifuge the tube at 13,000 rpm (17,900 rcf) for an additional 1 min (see Note 6 ). Place the QIAquick column in a clean 1.5 mL microcentrifuge tube. Add 40 μL of DI Water to the center of the QIAquick membrane, let the column stand for 1 min, and centrifuge the column for 1 min at 13,000 rpm (see Note 7 ).

3.5 DNA Hybridization

-

1.

Seal the PDMS slab with spiral channels against the glass chip printed with radially patterned probe lines.

-

2.

Add 1 μL of target solutions to the inlet reservoirs of the spiral channels and place the chip on the rotating platform. Spin the chip at 700 rpm for 10 min.

-

3.

Add 0.5 μL of SA-Cy5 solution to the inlet reservoirs of the spiral channels and place the chip on the rotating platform. Spin the chip at 1500 rpm for 3 min.

-

4.

Peel off the PDMS slab, wash the glass chip with DI water, and dry it with nitrogen gas.

3.6 Fluorescence Detection and Data Analysis

-

1.

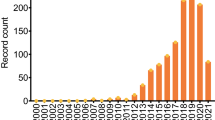

Put the glass chip on the Typhoon scanner. Adjust the excitation and emission wavelengths at 633 and 670 nm, respectively. Scan the chip at a resolution of 10 μm (Fig. 3).

Fig. 3 DNA hybridization between PCR products amplified from four different KRAS samples. Original scanned image showing (a) 24 spiral × 4 radial channels of CD-NBA chip, (b) the inset inside the blue box and (c) the resulted histogram. DNA hybridization occurred between PCR products amplified from four different KRAS samples and the oligonucleotide probes immobilized on the surface of CD-NBA chip. One of the four samples was wild-type (W′) and the other three carried the mutations of G12A (A′), G12D (D′), and G12V (V′) at the KRAS gene codon 12

-

2.

Analyze the scanned image using IMAGEQUANT software. In order to obtain the signal intensity of the spots: draw a line across multiple spots, go to analysis window, and choose “create graph.” The signal intensity of each spot is represented by a peak. Take the intensity of the baseline beside each peak as the background. The corrected signal intensity of each spot is the height of the corresponding peak minus the background.

4 Notes

-

1.

Glutaraldehyde is toxic and strongly irritant and it should be handled with care inside the fume hood. Glutaraldehyde degrades at room temperature and it should be stored at 4 °C.

-

2.

Piranha solution is a hazardous and corrosive solution. Handle it with extreme caution. Use personal protective equipment such as full face shield and heavy-duty gloves. Always add hydrogen peroxide to the acid, not vice versa, and add the liquid very slowly.

-

3.

Occasionally, some SU-8 residues remain, and they appear like dusts on the master mold surface. These residues can be removed by purging the surface with nitrogen gas, rinsing the wafer with NOX solution or performing the SU-8 development step for a second time.

-

4.

Carefully inspect the chip for any dirt or stain on its surface. Repeat the wash and dry step until the surface is clean.

-

5.

APTES-functionalized glass slides should not be in contact with water until after the 1-h incubation at 120 °C. Use dry glassware in the APTES-functionalization step and the subsequent incubation step.

-

6.

Residual ethanol from the Buffer PE will not be completely removed unless the flow-through is discarded before this additional centrifugation.

-

7.

Elution efficiency of the purified PCR product is dependent on pH. The maximum elution efficiency is achieved between pH 7.0 and 8.5.

References

Parsons BL, Myers MB (2013) Personalized cancer treatment and the myth of KRAS wild-type colon tumors. Discov Med 15:259–267

Domagała P, Hybiak J, Sulżyc-Bielicka V, Cybulski C, Ryś J, Domagała W (2012) KRAS mutation testing in colorectal cancer as an example of the pathologist’s role in personalized targeted therapy: a practical approach. Pol J Pathol 3:145–164

Sedighi A, Li PC (2014) Challenges and future trends in DNA microarray analysis. Compr Anal Chem 63:25–46

Wang L, Li PC (2010) Optimization of a microfluidic microarray device for the fast discrimination of fungal pathogenic DNA. Anal Biochem 400:282–288

Wang L, Li PC, Yu H-Z, Parameswaran AM (2008) Fungal pathogenic nucleic acid detection achieved with a microfluidic microarray device. Anal Chim Acta 610:97–104

Wang L, Li PC (2010) Gold nanoparticle-assisted single base-pair mismatch discrimination on a microfluidic microarray device. Biomicrofluidics 4:032209

Sedighi A, Li PC (2014) Kras gene codon 12 mutation detection enabled by gold nanoparticles conducted in a nanobioarray chip. Anal Biochem 448:58–64

Sedighi A, Li PC (2013) Gold nanoparticle assists SNP detection at room temperature in the nanoBioArray chip. Int J Mat Sci Eng 1(1):45–49

Sedighi A, Li PC, Pekcevik IC, Gates BD (2014) A proposed mechanism of the influence of gold nanoparticles on DNA hybridization. ACS Nano 8(7):6765–6777

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer Science+Business Media New York

About this protocol

Cite this protocol

Sedighi, A., Li, P.C.H. (2016). High-Throughput DNA Array for SNP Detection of KRAS Gene Using a Centrifugal Microfluidic Device. In: Li, P., Sedighi, A., Wang, L. (eds) Microarray Technology. Methods in Molecular Biology, vol 1368. Humana Press, New York, NY. https://doi.org/10.1007/978-1-4939-3136-1_10

Download citation

DOI: https://doi.org/10.1007/978-1-4939-3136-1_10

Publisher Name: Humana Press, New York, NY

Print ISBN: 978-1-4939-3135-4

Online ISBN: 978-1-4939-3136-1

eBook Packages: Springer Protocols