Abstract

Background

Spinosad is a macrolide insecticide with the tetracyclic lactone backbone to which forosamine and tri-o-methylrhamnose are attached. Both the sugar moieties are essential for its insecticidal activity. In biosynthesis of spinosad, the amino group of forosamine is dimethylated by SpnS and then transferred onto the lactone backbone by SpnP. Because the spinosad native producer is difficult to genetically manipulate, we previously changed promoters, ribosome binding sites and start codons of 23 spinosad biosynthetic genes to construct an artificial gene cluster which resulted in a 328-fold yield improvement in the heterologous host Streptomyces albus J1074 compared with the native gene cluster. However, in fermentation of J1074 with the artificial gene cluster, the N-monodesmethyl spinosad with lower insecticidal activity was always produced with the same titer as spinosad.

Results

By tuning expression of SpnS with an inducible promotor, we found that the undesired less active byproduct N-monodesmethyl spinosad was produced when SpnS was expressed at low level. Although N-monodesmethyl spinosad can be almost fully eliminated with high SpnS expression level, the titer of desired product spinosad was only increased by less than 38%. When the forosaminyl transferase SpnP was further overexpressed together with SpnS, the titer of spinosad was improved by 5.3 folds and the content of N-desmethyl derivatives was decreased by ~ 90%.

Conclusion

N-monodesmethyl spinosad was produced due to unbalanced expression of spnS and upstream biosynthetic genes in the refactored artificial gene cluster. The accumulated N-desmethyl forosamine was transferred onto the lactone backbone by SpnP. This study suggested that balanced expression of biosynthetic genes should be considered in the refactoring strategy to avoid accumulation of undesired intermediates or analogues which may affect optimal production of desired compounds.

Similar content being viewed by others

Background

Spinosad, the mixture of spinosyns A and D, is a fermentation derived insecticide with high activity against a variety of chewing insect pests and exceptional safety profiles [1, 2]. During spinosad biosynthesis, a linear polyketide chain is made first by polyketide synthases SpnA-E [3], and then the tetracyclic aglycone is formed by cross-bridging enzymes SpnF, J, L, M [4]. Rhamnose is biosynthesized from glucose-1-phosphate by Gtt, Gdh, Epi, and Kre proteins, added to the aglycone by the transferase SpnG [5] and then o-methylated by SpnH, I, K [6] to form the pseudoaglycone. Forosamine biosynthesis shares the common first two steps with rhamnose [7] producing TDP-4-keto-6-deoxy-d-glucose which is further converted into TDP-d-forosamine by SpnO, N, Q, R, and S. N-methylation of the forosamine catalyzed by SpnS occurs in a stepwise manner and the monomethylated product (N-monodesmethyl forosamine) can be released from the active site of SpnS [8]. Forosamine is transferred onto the pseudoaglycone by SpnP [9] to finally form spinosad. SpnP can also transfer N-monodesmethyl and N,N-didesmethyl forosamines to the pseudoaglycone to produce N-monodesmethyl and N,N-didesmethyl spinosad [8] (Fig. 1). The insecticidal activities of N-monodesmethyl and N,N-didesmethyl spinosad are both lower than spinosad. The LC50 of spinosyn A to Heliothis virescens larvae are 0.3 mg L− 1, while the LC50 of N-monodesmethyl spinosyn A (spinosyn B) and N,N-didesmethyl spinosyn A (spinosyn C) are 0.4 mg L− 1 and 0.8 mg L− 1 respectively [10]. The LC50 of N-monodesmethyl spinosyn D to Heliothis virescens larvae is seven times higher than that of spinosyn D (5.6 vs. 0.8 mg L− 1) [10]. Therefore, N-desmethyl spinosad is undesired byproduct in the fermentation.

Because the spinosad native producer Saccharopolyspora spinosa is difficult to genetically manipulate, its gene cluster has been cloned and expressed in heterologous hosts such as S. erythraea [11], S. coelicolor [12], and S. albus [13, 14]. Previously, we constructed an artificial gene cluster in which the 23 spinosad biosynthetic genes were grouped into 7 operons under control of Streptomyces constitutive strong promoters [14]. When the artificial gene cluster was expressed in S. albus J1074, the yield of spinosad was improved 328 folds compared with the native gene cluster. Besides spinosad, the less active byproduct N-monodesmethyl spinosad was also detected at the same titer as spinosad in the fermentation broth of S. albus J1074 containing the artificial gene cluster.

Tuning expression of biosynthetic genes is an important way to reduce undesired compound production or enhance desired compound production. For example, in erythromycin A fermentation, erythromycins B and C are recognized as undesired byproducts because they are much less active and cause greater side effects [15]. Chen et al. nearly completely eliminated erythromycins B and C and improved the titer of erythromycin A by 25% by tuning expression of two tailoring enzymes, the P450 hydroxylase EryK and S-adenosylmethionine-dependent O-methyltransferase EryG [16]. In this study, we revealed that N-desmethyl spinosad was produced due to unbalanced expression of the forosamine methyltransferase gene spnS and upstream biosynthetic genes which caused accumulation of N-desmethyl forosamine. By tuning expression of spnS, we reduced the content of undesired less active byproduct N-desmethyl spinosad by more than 90% in the fermentation broth of S. albus J1074. Furthermore, the yield of desired product spinosad was increased by 5.3 folds to 5.8 mg L− 1 through overexpressing spnS together with the forosamyltransferase gene spnP.

Results and discussion

Expression of the forosamine methyltransferase gene spnS affected production of spinosad and its N-desmethyl derivatives

Previously, we constructed an artificial gene cluster for efficient heterologous spinosad production in S. albus J1074 [14]. The artificial gene cluster consisted of all 23 spinosad biosynthetic genes grouped into 7 operons under control of strong constitutive promoters. In the fermentation broth of S. albus J1074 harboring the 7-operon artificial gene cluster (7op), besides the desired product spinosad, the less active analogue N-monodesmethyl spinosad was also detected (Fig. 2). The titer of N-monodesmethyl spinosyn A (spinosyn B) is the same as that of spinosyn A. In the forosamine biosynthesis, dimethylation of its amino group by SpnS occurs in a stepwise manner. The intermediates N,N-didesmethyl forosamine and N-monodesmethyl forosamine can also be transferred onto the macrolide backbone by SpnP. We speculated that the N-monodesmethyl spinosad was produced due to accumulation of N-monodesmethyl forosamine caused by insufficient expression of SpnS.

The spinosad 7-operon artificial gene cluster and its products. A Organization of the 7-operon artificial gene cluster. B HPLC-MS analysis (Base Peak Chromatogram) of spinosyns A and B produced in S. albus J1074 containing the 7-operon artificial gene cluster. C The MS2 fragmentation patterns of spinosyn A (top) and spinosyn B (down) produced in S. albus J1074. The fragment ion at m/z 142.1 and 128.1 are the characteristic forosamine and N-monodesmethyl forosamine fragments respectively. 189.1 is the characteristic trimethylrhamnose fragments [17]

To determine the effects of spnS expression level on biosynthesis of spinosad and its N-desmethyl derivatives, we inserted the cumate-inducible cymR-P21-cmt expression system [18] upstream of the spnS gene in the artificial gene cluster by recombineering to generate the cum-spnS recombinant gene cluster (Fig. 3A). Recombineering is a DNA engineering technique which uses homologous recombination mediated by phage proteins in E. coli [19]. In the cymR-P21-cmt expression system, the CmyR repressor binding on the cmt operator placed downstream of the P21 promoter will block transcription of downstream genes. The inducer cumate added in the medium can bind CmyR and restore the transcription.

Effects of the spnS expression level on biosynthesis of spinosad and its N-desmethyl derivatives. A Schematic representation of the cymR-P21-cmt-spnS expression system. B Titers of spinosyns A, B and C under different concentration of cumate added in the fermentation medium. Each fermentation was done in triplicate (n = 3). Error bars represent standard deviation. Differences were analyzed by one-way ANOVA and P < 0.05 was considered statistically significant. ***P < 0.001, **P < 0.01, *P < 0.05

During fermentation of S. albus J1074 containing the cum-spnS gene cluster, when no cumate inducer was added into the medium, spinosyn A, N-monodesmethyl spinosyn A (spinosyn B), and N,N-didesmethyl spinosyn A (spinosyn C) were all produced. The titer of spinosyn B is higher than that of spinosyn A which is higher than that of spinosyn C (Fig. 3B and Additional file 1: Fig. S1). Because the cymR-P21-cmt promoter is not completely tight [20], low level leaky expression of SpnS caused production of N-monodesmethyl forosamine and N,N-didesmethyl forosamine which were both transferred onto the macrolide backbone by SpnP. As the cumate concentration in the fermentation broth increased, titers of spinosyns B and C decreased. When more than 20 µM of cumate was added into the fermentation medium, production of spinosyn C cannot be detected and production of spinosyn B decreased by more than 87% compared with the production without cumate addition. The lowest spinosyn B production, decreased by 98%, was obtained when 50 µM of cumate was added (Fig. 3B and Additional file 1: Fig. S1 and Table S1).

As the production of spinosyns B and C decreased, the production of spinosyn A increased when less than 20 µM of cumate was added. However, when more cumate was added, the yield of spinosyn A did not increase further as the production of spinosyns B and C decreased.

Constitutive overexpression of spnS reduced production of N-desmethyl spinosyn A derivatives and improved spinosyn A production

In the cumate-inducible cymR-P21-cmt expression system, production of spinosyn A and its N-desmethyl derivatives was depended on the spnS expression level. We then replace the inducible cymR-P21-cmt expression system upstream of spnS with the strong constitutive kasOp* promoter [21] to generate the kas-spnS recombinant gene cluster (Fig. 4A). When the kas-spnS gene cluster was introduced into S. albus J1074, production of spinosyn A and its desmethyl derivatives are similar with the inducible cymR-P21-cmt expression system at high cumate concentration. Production of spinosyn C cannot be detected and production of spinosyn B decreased by 86% compared with the production from the original 7op gene cluster. The spinosyn A production from the kas-spnS gene cluster increased only 38% compared with the original 7op gene cluster (Fig. 4B).

Effects of constitutive spnS overexpression on productions of spinosyns A and B. A Schematic representation of the kasOp*-spnS expression system. B Titers of spinosyns A and B from different gene clusters. Each fermentation was done in triplicate (n = 3). Error bars represent standard deviation. Differences were analyzed by one-way ANOVA and P < 0.05 was considered statistically significant. ***P < 0.001, **P < 0.01, *P < 0.05

Constitutive overexpression of the forosamyltransferase gene spnP together with spnS further improved spinosyn A production

Above results suggested that although the amino group of forosamine was almost fully methylated in the spnS overexpression strain, a large quantity of fully methylated forosamine was not used for the biosynthesis of spinosad. We speculated that expression of the forosamyltransferase SpnP was not sufficient for fully transfer of forosamine to the spinosad pseudoaglycone. Two strong constitutive promoters (kasOp*, SA15p [22]) were inserted upstream of spnP in the kas-spnS gene cluster to generate recombinant gene clusters kas-spnP-kas-spnS and SA15-spnP-kas-spnS (Fig. 5A).

When the kas-spnP-kas-spnS and SA15-spnP-kas-spnS gene clusters were introduced into S. albus J1074 respectively, production of spinosyn C (N,N-didesmethyl spinosyn A) was not detected and production of spinosyn B (N-monodesmethyl spinosyn A) was low and similar with that in the kas-spnS strain (Fig. 5B). The titers of spinosyn A in the kas-spnP-kas-spnS and SA15-spnP-kas-spnS strains were 4.4 and 3.1 times higher than that in the kas-spnS strain, respectively. Finally, the spinosad (spinosyns A and D) production in S. albus J1074 was increased to 5.8 ± 0.4 mg L− 1 when both spnS and spnP were overexpressed under control of the kasOp* promoter (Fig. 5 C). This suggested that enhanced expression of SpnP significantly promoted transfer of forosamine to the pseudoaglycone and make the spinosad biosynthesis much more efficient.

Effects of both spnS and spnP overexpression on spinosyn A and its N-desmethyl derivatives. A Schematic representation of the kas-spnP-kas-spnS and SA15-spnP-kas-spnS expression system. B Yield of spinosyn B from different gene clusters. C Yield of spinosad (spinosyns A and D) from different gene clusters. Each fermentation was done in triplicate (n = 3). Error bars represent standard deviation. Differences were analyzed by one-way ANOVA and P < 0.05 was considered statistically significant. ***P < 0.001, **P < 0.01, *P < 0.05

Conclusion

A polyketide assembly line often produces multiple structurally related compounds, such as avermectins [23], erythromycins [15] and spinosyns [2]. Biosynthesis of less active components will compete substrates and energy with the most active components, therefore, eliminating the production of byproducts is important for enhancing the titer of the desired compounds. In this study, we improved spinosad production by tuning expressions of the forosamine methyltransferase and the forosaminyl transferase to reduce undesired less active N-desmethyl byproducts in the heterologous host S. albus J1074. On the other hand, fine tuning expression of tailoring enzymes can channel the biosynthesis to specific analogues such as them with different methylation status which is helpful for diversification of structures.

Gene cluster reconstruction has been widely employed in optimizing production of natural products [24,25,26]. The less active N-desmethyl spinosad byproduct was accumulated due to unbalanced expression of the forosamine methyltransferase gene and upstream biosynthetic genes when we refactored the spinosad gene cluster. Therefore, balanced expression of biosynthetic genes should be considered in the reconstruction strategy to avoid accumulation of undesired intermediates or analogues.

Methods

Bacteria strains, and culture conditions

Bacteria strains and plasmids used in this study were listed in Additional file 1: Table S2. Escherichia coli strains were grown at 37 °C in Luria-Bertani (LB) medium. Streptomyces albus J1074 were cultured at 30 °C on mannitol soya flour agar plates for spore preparation and conjugation. Concentrations of antibiotics used in this study were: chloramphenicol, 15 µg mL− 1; kanamycin, 15 µg mL− 1; ampicillin, 100 µg mL− 1; apramycin, 20 µg mL− 1 spectinomycin,60 µg mL− 1 for Escherichia coli and 50 µg mL− 1 of apramycin ;100 µg mL− 1 of trimethoprim lactate salt for Streptomyces.

DNA manipulation

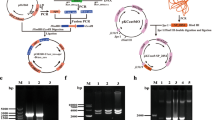

The cmyR-ampR-P21-cmt cassette was synthesized on the pUC57 vector by GENEWIZ (Suzhou, China). The cmyR-ampR-P21-cmt cassette flanked with homology arms was amplified by PCR using cum-1 and cum-2 (Additional file 1: Table S3). Then the cmyR-ampR-P21-cmt cassette was inserted upstream of the spnS gene on pBAC-spnNEW [14] by recombineering [19]. Correct pBAC-spnNEW-cum-spnS recombinants were identified by the ApaLI restriction analysis (Additional file 1: Fig. S2).

The ampicillin resistance gene (ampR), the kasOp* promoter and homology arms were fused with overlap extension PCR using amp-1 & 2 and kas-1 & 2 respectively (Table S3). Then the ampR-kasOp* cassette was inserted upstream of the spnS gene on pBAC-spnNEW [14] by recombineering [19]. Correct pBAC-spnNEW-kas-spnS recombinants were identified by the XhoI restriction analysis (Additional file 1: Fig. S2).

The spect-ccdB cassette fanked with two PacI restriction sites and homology arms was amplified with PCR using spect-1 and spect-2 (Additional file 1: Table S3) and the pR6K-spect-ccdB plasmid as the template. The hygromycin resistance gene on pBAC-spnNEW-kas-spnS was replaced with the spect-ccdB cassette using recombineering in E. coli GBred-gyrA462. Correct pBAC-spnNEW-kas-spnS-spect-ccdB recombinants were identified by the MscI restriction analysis (Additional file 1: Fig. S2).

The spnP gene, the kasOp* promoter or the SA15p promoter and homology arms were fused with overlap extension PCR using spnP-1& 2, kas-1 & 3 and SA15-1 & 2 respectively (Additional file 1: Table S3). Then the kasOp*/SA15p-spnP PCR product and PacI digested pBACspn-kas-spnS-spect-ccdB were recombined using linear-linear homologous recombination [27]. Correct pBAC-spnNEW-kas-spnS-kasOp*/SA15p-spnP were identified by the BamHI restriction analysis (Additional file 1: Fig. S2).

Above constructed spinosad expression vectors were transformed into S. albus J1074 by conjugation [28] for fermentation and high performance liquid chromatography–mass spectrometry analysis.

Fermentation and high performance liquid chromatography–mass spectrometry analysis of spinosad from engineered Streptomyces strains

Streptomyces strains were inoculated into 50 mL tryptic soy broth in 250-mL flasks as the seed culture and incubated at 30 °C with 220 rpm shaking for 3–4 days. 600 µL (1:50 dilution) seed culture was transferred into 30 mL fermentation broth (4% W/V glucose, 1% W/V glycerol, 3% W/V soluble starch, 1.5% W/V soytone, 1% W/V beef extract, W/V 0.65% peptone, 0.05% W/V yeast extract, 0.1% W/V MgSO4, 0.2% W/V NaCl, 0.24% W/V CaCO3) in 250 mL flasks, and incubated at 30 °C with 220 rpm shaking for 10 days. The 5mL fermentation cultures extracted with 3 × acetonitrile vortexed for 20 min, incubated for 30 min at room temperature. Then, the extract was evaporated and redissolved in 1 mL methanol. 10 µL extract was used for HPLC-MS analysis as described previously [14]. To quantify the amount of spinosad produced in S. albus J1074, standard spinosad was purchased from Sigma-Aldrich (cat. no. 33,706).

Availability of data and materials

All data for this study are included in this published article and its additional file.

References

Mertz FP, Yao RC. Saccharopolyspora spinosa sp. nov. isolated from soil collected in a sugar mill rum still. Int J Syst Evol Microbiol. 1990;40(1):34–9.

Huang KX, Xia L, Zhang Y, Ding X, Zahn JA. Recent advances in the biochemistry of spinosyns. Appl Microbiol Biotechnol. 2009;82(1):13–23.

Waldron C, Matsushima P, Rosteck PR Jr, Broughton MC, Turner J, Madduri K, et al. Cloning and analysis of the spinosad biosynthetic gene cluster of Saccharopolyspora spinosa. Chem Biol. 2001;8(5):487–99.

Kim HJ, Ruszczycky MW, Choi SH, Liu YN, Liu HW. Enzyme-catalysed [4 + 2] cycloaddition is a key step in the biosynthesis of spinosyn A. Nature. 2011;473(7345):109–12.

Isiorho EA, Liu HW, Keatinge-Clay AT. Structural studies of the spinosyn rhamnosyltransferase, SpnG. Biochemistry. 2012;51(6):1213–22.

Kim HJ, White-Phillip JA, Ogasawara Y, Shin N, Isiorho EA, Liu HW. Biosynthesis of spinosyn in Saccharopolyspora spinosa: synthesis of permethylated rhamnose and characterization of the functions of SpnH, SpnI, and SpnK. J Am Chem Soc. 2010;132(9):2901–3.

Madduri K, Waldron C, Merlo DJ. Rhamnose biosynthesis pathway supplies precursors for primary and secondary metabolism in Saccharopolyspora spinosa. J Bacteriol. 2001;183(19):5632–8.

Hong L, Zhao Z, Melancon CE 3rd, Zhang H, Liu HW. In vitro characterization of the enzymes involved in TDP-D-forosamine biosynthesis in the spinosyn pathway of Saccharopolyspora spinosa. J Am Chem Soc. 2008;130(14):4954–67.

Isiorho EA, Jeon BS, Kim NH, Liu HW, Keatinge-Clay AT. Structural studies of the spinosyn forosaminyltransferase, SpnP. Biochemistry. 2014;53(26):4292–301.

Sparks TC, Crouse GD, Durst G. Natural products as insecticides: the biology, biochemistry and quantitative structure-activity relationships of spinosyns and spinosoids. Pest Manag Sci. 2001;57(10):896–905.

Huang J, Yu Z, Li MH, Wang JD, Bai H, Zhou J, et al. High level of spinosad production in the heterologous host Saccharopolyspora erythraea. Appl Environ Microbiol. 2016;82(18):5603–11.

Li H, Pan Y, Liu G. Multiplying the heterologous production of spinosad through tandem amplification of its biosynthetic gene cluster in Streptomyces coelicolor. Microb Biotechnol. 2022;15(5):1550–60.

Tan GY, Deng K, Liu X, Tao H, Chang Y, Chen J, et al. Heterologous biosynthesis of spinosad: an omics-guided large polyketide synthase gene cluster reconstitution in Streptomyces. ACS Synth Biol. 2017;6(6):995–1005.

Song C, Luan J, Cui Q, Duan Q, Li Z, Gao Y, et al. Enhanced heterologous spinosad production from a 79-kb synthetic multi-operon assembly. ACS Synth Biol. 2019;8(1):137–47.

Staunton J, Weissman KJ. Polyketide biosynthesis: a millennium review. Nat Prod Rep. 2001;18(4):380–416.

Chen Y, Deng W, Wu J, Qian J, Chu J, Zhuang Y, et al. Genetic modulation of the overexpression of tailoring genes eryK and eryG leading to the improvement of erythromycin A purity and production in Saccharopolyspora erythraea fermentation. Appl Environ Microbiol. 2008;74(6):1820–8.

Lewer P, Hahn DR, Karr LL, Duebelbeis DO, Gilbert JR, Crouse GD, et al. Discovery of the butenyl-spinosyn insecticides: novel macrolides from the new bacterial strain Saccharopolyspora pogona. Bioorg Med Chem. 2009;17(12):4185–96.

Horbal L, Fedorenko V, Luzhetskyy A. Novel and tightly regulated resorcinol and cumate-inducible expression systems for Streptomyces and other actinobacteria. Appl Microbiol Biotechnol. 2014;98(20):8641–55.

Wang H, Li Z, Jia R, Hou Y, Yin J, Bian X, et al. RecET direct cloning and redab recombineering of biosynthetic gene clusters, large operons or single genes for heterologous expression. Nat Protoc. 2016;11(7):1175–90.

Horbal L, Luzhetskyy A. Dual control system - A novel scaffolding architecture of an inducible regulatory device for the precise regulation of gene expression. Metab Eng. 2016;37:11–23.

Wang W, Li X, Wang J, Xiang S, Feng X, Yang K. An engineered strong promoter for streptomycetes. Appl Environ Microbiol. 2013;79(14):4484–92.

Luo Y, Zhang L, Barton KW, Zhao H. Systematic identification of a panel of strong constitutive promoters from Streptomyces albus. ACS Synth Biol. 2015;4(9):1001–10.

Ikeda H, Omura S. Avermectin biosynthesis. Chem Rev. 1997;97(7):2591–610.

Shao Z, Rao G, Li C, Abil Z, Luo Y, Zhao H. Refactoring the silent spectinabilin gene cluster using a plug-and-play scaffold. ACS Synth Biol. 2013;2(11):662–9.

D’Agostino PM, Gulder TAM. Direct pathway cloning combined with sequence- and ligation-independent cloning for fast biosynthetic gene cluster refactoring and heterologous expression. ACS Synth Biol. 2018;7(7):1702–8.

Greunke C, Duell ER, D’Agostino PM, Glockle A, Lamm K, Gulder TAM. Direct pathway cloning (DiPaC) to unlock natural product biosynthetic potential. Metab Eng. 2018;47:334–45.

Fu J, Bian X, Hu S, Wang H, Huang F, Seibert PM, et al. Full-length RecE enhances linear-linear homologous recombination and facilitates direct cloning for bioprospecting. Nat Biotechnol. 2012;30(5):440–6.

Kieser T, Bibb MJ, Buttner MJ, Chater KF, Hopwood DA. Practical Streptomyces Genetics. Norwich, UK: John Innes Foundation; 2000.

Acknowledgements

The authors thank Jingyao Qu, Jing Zhu and Zhifeng Li from State Key Laboratory of Microbial Technology of Shandong University for help and guidance in LC-MS.

Funding

This work was supported by the National Key Research & Development Program of China 2018YFA0900400 & 2021YFC2101000, National Natural Science Foundation of China 32122049, the 111 Project B16030, the Fund for Distinguished Young Scholars of SDU, and the Taishan Scholar Program of Shandong Province tsqn201812008.

Author information

Authors and Affiliations

Contributions

HW, JF and YZ designed the experiments. XL, RG and JL conducted the experiments. HW and XL wrote the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

I hereby give the Journal of Microbial Cell Factories the right and permission to publish this article.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1: Figure S1.

SHPLC-MS Analysis (Base Peak Chromatogram) of Streptomyces albus J1074 with pBAC-spnNEW-cum-spnS under different cumate concentrations. Figure S2. Restriction analysis of recombinant BACs in this work. Table S1. Production of spinosyns A, B and C in Streptomyces albus J1074 with pBAC-spnNEW-cum-spnS under different cumate concentrations; Table S2. Strains and plasmids used in this work. Table S3. Primers used in this work.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Li, X., Guo, R., Luan, J. et al. Improving spinosad production by tuning expressions of the forosamine methyltransferase and the forosaminyl transferase to reduce undesired less active byproducts in the heterologous host Streptomyces albus J1074. Microb Cell Fact 22, 15 (2023). https://doi.org/10.1186/s12934-023-02023-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s12934-023-02023-3