Abstract

Photocatalysis speeds up the photoreaction in the presence of a catalyst. TiO2 has low toxicity, less resistance and less corrosion and has semiconductor properties. Its strong oxidative potential of the positive holes oxidizes water to create hydroxyl radicals. Moreover, TiO2 has been proven to be a tremendous photocatalyst compound by which many organic substrates have been shown to be oxidatively degraded under UV irradiation. In this research the photocatalytic effect of TiO2 on degradation of Brilliant Green (BG) was studied. In conjunction the effect of dopants such as Zn and Cu on photocatalysis of TiO2 were also studied. Structural and morphological properties of TiO2 were characterized by SEM and XRD. From this research the initial concentration of sample, pH of samples, chemical structure of dyes and catalyst loading were most valuable parameters for dye degradation. TiO2 showed excellent result on degradation of BG compared with doped TiO2. 99% degradation was obtained in presence of TiO2, followed by TiO2/Zn for 87% and TiO2/Cu for 46%. TiO2 doped with transition metals can increase or decrease photocatalytic degradation of dyes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Introduction

Environmental pollutant is the major cause for most of health illness. Water is the main source of contamination and pollution which effects health through biomagnification. Water gets polluted by harmful chemicals, dyes, oils etc. All the wastewater that contains harmful chemicals is drained into nearby water bodies. This causes water pollution and will lead to various health problems to flora and fauna. Among the pollutants of water, dyes play a major role. Most of the dyes released from the pharma and textile industries are mutagenic, toxic and teratogenic that can cause serious health hazards to humans and live stock [1]. Dyes released into environment can impart color to water and also decrease or stop capacity of water reoxygenation by blocking sunlight thereby increasing BOD value. Therefore these conditions can prevent or disturb the growth of aquatic plants and animals [2, 3]. The color removal from wastewater from industries is the main concern in green chemistry [4]. Removal of dyes from wastewater has become a tough issue due to their stable character under harsh condition and biodegradation resistance [5]. There have been reports on usage of natural materials like coconut husk, sunflower stalks, barley husk, lemon peels, rice husk to remove dyes [6]. Advanced oxidation process (AOP) of photocatalysis is really efficient in industrial effluent treatment process with more success rates. Many studies reported that TiO2 nanoparticles are an excellent photocatalysts for decolorization of dyes. TiO2 microparticles are less toxic, less resistance and less corrosive than other photocatalysts [7, 8]. TiO2 oxidation is also known as a type of “green” or environmental friendly method [9]. TiO2 nanoparticles are used extensively because of its intensity and very high refractive index. We used dopants such as Zn and Cu to observe the efficiency of TiO2 microparticles on dye degradation. Doping techniques are used to incorporate metal ions to enhance photocatalytic effects of TiO2 nanoparticles. Metal ions such as Cobalt, Iron, Nickel, Tungsten, Zinc can be incorporated during preparation [10, 11].

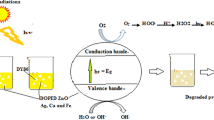

BG is also known as Ethanaminium,N-[4-[[4(diethylamino) phenyl] phenylmethylene] -2,5-cyclohexadien-1-yli-dene]-N-ethyl-,sulfate. The chemical formula is C27H34N204S and molecular weight is 482.64 g/mol.BG is chiefly used in modern textile industries. They are also used in staining and biological applications such as large intestine staining, skin staining, to color fibers, printed circuit boards, inks and also used in antiseptic preparation which is active against Gram-positive bacteria. BG will cause some degree of hypersensitivity reactions, carcinogenicity, microbial and fish toxicity [12]. TiO2 nanoparticles has been proven to be a tremendous photocatalyst by which many organic substrates have been shown to be oxidatively degraded and undergoes complete mineralization to give much safer byproduct Carbon dioxide (CO2) under UV exposure [13]. Typically TiO2 nanoparticles are used and studied in the treatment of water such as textile waste water, ground water etc [14]. Numerous studies have been conducted on performance of TiO2 nanoparticles, as they showed that relatively high surface area of catalyst per unit of reactor volume [15]. In aqueous environment, TiO2 generates hydroxyl radicals, which endorse the oxidation of organics under UV irradiation [16]. This has been successfully engaged in the mineralization of several hazardous chemicals such as dyes, phenols, haloaromatics, halogenated biphenyls and more. In this research for the first time TiO2 microparticles alone and TiO2 along with dopants such as Zn and Cu microparticles are used to check the photocatalytic activity for degradation of BG under UV radiation. This photocatalytic reaction takes place at room temperature and the intermediate products are less non-toxic because they are completely mineralized to CO2. Morphological and structural properties are evaluated using SEM and XRD respectively.

Materials and methods

Preparation of Titanium dioxide microparticles

15 ml of titanium isopropoxide was transferred into 250 ml beaker and added with 30 ml of distilled water (DW). The contents were stirred for 20 minutes till the contents were clear. 2.2 g of CTAB was transferred into a 100 ml clean beaker and 20 ml of DW was added to it and the contents were stirred for 5 minutes till the solution was clear. The dissolved CTAB was added to the beaker containing titanium isopropoxide. Then, required quantity of NH4OH was transferred dropwise by means of burette into the beaker containing titanium isopropoxide and CTAB. The contents were continuously stirred with the help of magnetic stirrer for 2 hours after addition of NH4OH. After 2 hours, the contents were filtered using Wattman filter paper and precipitate was washed with DW for 10 to 15 times. After sufficient washing, the precipitate was dried in hot air oven for 5 hours at 90°C. The dried powder was annealed at 400°C for 3 hours in a furnace.

Titanium dioxide doped with 1 wt.% Zn microparticles and 1 wt.% Cu microparticles

The preparation was similar to that of TiO2 except that 1wt. % Zn and 1wt. % Cu were dissolved in DW and added to the mixture before adding NH4OH.

Preparation of dye sample and photocatalyst loading

4 ppm of BG was prepared by using DW as solvent. Absorption maximum of BG was determined at 624 nm by using UV–vis double beam spectroscopy (JAS.CO, V-630 model and having power AC100V-240 V, 50/60 Hz, Class 1 protect and made in Japan). 3 aliquots of 4 ppm BG were taken in beakers and in each aliquot 100 mg, 200 mg and 300 mg of TiO2 nanoparticles were suspended (similar procedure for TiO2/Zn and TiO2/Cu nanoparticles). Each aliquot is then subjected to continuous stirring. The reaction is carried out in presence of UV light (30 W). A small portion of sample is withdrawn from each aliquot and centrifuged (Hettich Zentrifugen – EBA 20) at 4000 rpm for 30 minutes. The supernatant solution was used for measuring the absorbance. Absorbance of each sample is measured at a time interval of 5 min, 30 min, 60 min, 120 min and 180 min.

Results and discussion

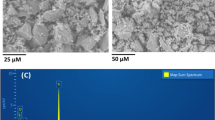

Characterization of TiO2, TiO2/Zn and TiO2/Cu microparticles by using SEM

Figure 1 shows surface morphology of microparticles with high-resolution images of the sample. These images gave irregular and angular shape with the grain size and diameter of about 20–50 μm. TiO2 doped with Cu gave more porous structure than TiO2 alone this may be attributed to prevention of TiO2 agglomeration. TiO2 doped with Zn is almost similar to the structure of pure TiO2.

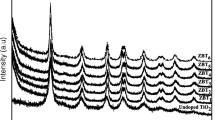

XRD

Figure 2 shows the XRD patterns of (a)TiO2, (b)TiO2/Zn and (c) TiO2/Cu annealed at 400°C for 3 hours. In Figure 2a,b and c XRD patterns exhibited strong diffraction peaks at 25.2°, 37.8°, 47.9°,54.0° and 62.6° confirming the anatase TiO2 All the peaks were similar with the standard spectrum. If there is increase in particle size then the peak intensity of diffraction pattern will increase proportionally. It can be seen that all samples have the anatase structure. Both Zn2+ and Cu2+ doping in the sol–gel method did not alter the crystal form of TiO2

The absorbance maximum of BG was determined using UV–vis double beam spectroscopy (JAS.CO V-630). The lambda max of a solution of concentration 4 ppm was found to be 624 nm Figure 3(a).

Photocatalysis of TiO2on Brilliant Green

1 g/L to 3 g/L of TiO2 microparticles were added to an aliquot of 4 ppm BG to determine TiO2 nanoparticles efficiency in decolorization. Catalyst loading of 2 g/L showed better degradation rate than 1 g/L and 3 g/L. About 87% degradation was obtained within 1 hour for all concentrations of catalyst. However, 99% degradation was obtained for catalyst loading of 2 g/L at 2 hours and 1 g/L and 3 g/L at 3 hours (Figure 4). Increase in the concentration of catalyst shows an increase in dye degradation for the first few minutes. This is due to the fact that number of dye molecules adsorbed and photon absorbed increases with increase in catalyst loading. The increase in degradation was probably due to an increase in availability of catalytic sites and adsorption sites.

Initially, the degradation of BG was fast, mostly between 30 min and 60 min. However, the increase of catalyst loading beyond the optimum may result in the agglomeration of catalyst particles, hence the part of the catalyst surface become unavailable for photon absorption and degradation rate decrease. Consequently, at certain minutes 3 g/L catalyst loading shows a slight decrease in further degradation. This may be due to the blockage of UV penetration in sample that lead to decrease in degradation rate. Optimum concentration is essential for efficient decolorization and degradation.

BG is a triphenylmethane dye which is having 3 phenyl rings. TiO2 showed excellent degradation of 99% of catalyst loading, whereas TiO2/Zn (Figure 5) showed degradation of 87% and TiO2/Cu (Figure 6) showed degradation of 46%. Almost 99% of dye decolorization and degradation occurred at 2nd hour in presence of 2 g/L of TiO2 (Figure 3). At 3rd hour 1 g/L and 3 g/L also showed 99% of BG degradation. Therefore, TiO2 is a good photocatalyst among other catalyst on BG degradation. This may be attributed to the nature of BG. The PH of 4 ppm solution of BG is 5.5 The pH can influence adsorption of dye molecule on the photocatalyst to stimulate photooxidation to take place [17]. Few studies stated that TiO2 particles tend to agglomerate and surface for dye adsorption and photon absorption will be reduced in acidic conditions. Whereas, some journal stated that hydroxyl radicals are easier to be generated by oxidizing, more hydroxide ions available and process is enhanced in alkaline medium [18]. So the effect of unmodified TiO2 on BG can be credited to weakly basic PH of BG.

Photocatalysis of TiO2/Zn on Brilliant Green

1 g/L to 3 g/L of TiO2/Zn microparticles were added to 4 ppm BG to determine TiO2/Zn microparticles efficiency in degradation. Catalyst loading of 3 g/L showed better degradation rate than 1 g/L and 2 g/L. In this case, higher the catalyst loading higher the degradation rate. At 3 hours, under UV irradiation sample degradation of 70%, 77% and 87% was observed for 1 to 3 g/L respectively. The effect of Zn as dopant decreased the effect of TiO2 by 13%. The retardation effect of Zn on photodecomposition rate may be attributed to suppression of hydroxyl radicals due to entrapment of conduction band electrons by the adsorbed metal ions.

The presence of metal ions such as Cu2+ and Zn2+, decreased the rate of BG degradation. TiO2 showed an excellent degradation of 99% on BG at 2 hours for a catalyst loading of 2 g/L. whereas, TiO2/Zn showed only 87% with 3 g/L of catalyst loading and TiO2/Cu showed only 46% with catalyst loading of 1 g/L.

Photocatalysis of TiO2/Cu on Brilliant Green

1 g to 3 g/L of TiO2/Cu nanoparticles are added to an aliquot of 4 ppm BG to determine TiO2/Cu nanoparticles efficiency in decolorization and degradation. Catalyst loading of 1 g/L showed better degradation rate than 2 g and 3 g/L. About 46%, 42% and 44% degradation are observed at 3 hours respectively under UV exposure (Figure 7). Dopants may not have the same effect on trapping electrons and/or holes on the surface or during interface charge transfer because of the different positions of the dopant in the host lattice. Consequently, the photocatalytic efficiency would be different for different types of dopants [19, 20].

Comparison between TiO2, TiO2/Zn and TiO2/Cu

TiO2 showed excellent result on degradation of BG compared with doped TiO2. 99% degradation was obtained in presence of TiO2, followed by TiO2/Zn for 87% and TiO2/Cu for 46%. TiO2 doped with transition metals can increase or decrease photocatalytic degradation of dyes. The percentage of dopant is necessary to be determined and the optimum % of dopant is between 0.06 and 1.0 for wastewater degradation [21]. In this study TiO2 was doped with 1 wt.% of Zn and Cu. The effect of Zn as dopant decreased the effect of TiO2 by 13%. The retardation effect of Zn on photodecomposition rate may be attributed to suppression of hydroxyl radicals due to entrapment of conduction band electrons by the adsorbed metal ions. The presence of metal ions such as Cu2+ and Zn2+, decreased the rate of BG degradation these results are in accordance with Chiang et al., [22]. Several reasons may be attributed for the effect of decreased activity in presence of dopant which includes nature of dye, pH, sample concentration, concentration of dopant etc.

Conclusion

In this research, a study has been carried out on photocatalytic activity of TiO2, TiO2/Zn and TiO2/Cu microparticles on BG their physical and chemical characterization was done by SEM and XRD. The obtained results comply with that of standard. Photocatalytic effect of unmodified and modified TiO2 nanoparticles were successfully studied in this work. Unmodified TiO2 is a good choice for cationic dye such as BG. The nature and structure of dyes were important parameter to choose a suitable photocatalyst. On other hand, catalyst loading should also be considered as a parameter. For different dyes different catalyst loading is needed. The degradation efficiency of unmodified TiO2 is 99% for BG at 2 g/L of catalyst loading during a period of 120 min under UV exposure.

References

Mekkawy HA, Ali MO, El-Zawahry AM: Toxic effect of synthetic and natural food dyes on renal and hepatic functions in rats. Toxicol Lett. 1998, 95: 155-

Song YL, Tai J, Bai B: TiO2-Assisted photodegradation of direct blue 78 in aqueous solution in sunlight. Water Air Soil Pollu. 2010, 213: 311-

Wang S: Oxidative degradation of dyes in water using Co2+/H2O2 and Co2+/peroxymonosulfate. Dyes Pigments. 2008, 76: 714-

Khehra MS, Saini HS, Sharma DK, Chadha BS, Chimni SS: Comparative studies on potential of consortium and constituent pure bacterial isolates to decolorize azo dyes. Water Res. 2005, 39: 5135-

Couto SR: Decolouration of industrial azo dyes by crude laccase from Trametes hirsute. J Hazard Mater. 2007, 148: 768-

Elizalde-Gonzailez MP, Pelaiez-Cid AA: Removal of textile dyes from aqueous solutions by adsorption on biodegradable wastes. Environ Technol. 2003, 24: 821-

Doll TE, Frimmel FH: Removal of selected persistent organic pollutants by heterogeneous photocatalysis in water. Catal Today. 2005, 101: 195-

Tsai WT, Lee MK, Su TY, Chang YM: Photodegradation of bisphenol- A in a batch TiO2 suspension reactor. J Hazard Mater. 2009, 168: 269-

Hoffmann MF, Martin ST, Choi W: Environmental application of semiconductor photocatalysis. J Chem Rev. 1995, 95: 69-

Tong T, Zhang J, Tian B, Chen F, He H: Preparation of Fe3+−doped TiO2 catalysts by controlled hydrolysis of titanium alkoxide and study on their photocatalytic activity for methyl orange degradation. J Hazard Mater. 2008, 155: 572-

The CM, Mohamed AR: Role of Titanium Dioxideand ion-doped Titanium dioxide on photocatalytic degradation of organic pollutants (phenolic compounds and dyes)-A Review. J Alloy Compd. 2011, 509: 1648-

Vachálková A, Novotný L, Blesová M: Polarographic reduction of some triphenylmethane dyes and their potential carcinogenic activity. Neoplasma. 1996, 43: 113-

Fox M, Dulay M: Heterogenous photocatalysis. Chem Re. 1993, 93: 341-357.

Sayılkan F, Asilt¨urk M, Tatar P, Kiraz N, Arpac E, Sayılkan H: Photo-catalytic performance of Sn-doped TiO2 nanostructured mono and double layer thin films for Malachite Green dye degradation under UV and vis- lights. J Hazard Mater. 2007, 144: 140-146.

Rahman MA, Muneer M: Photodegradation of norfloxacin in aqueous suspensions of titanium dioxide. J Environ Sci Health. 2005, 40: 247-

Gnaser H, Huber B, Ziegler C: Encycl. Nanosci. Nanotechnol. Edited by: Nalwa HS. 2004, Los Angeles: American Scientific Publishers, 505-535. Vol.6

Sohrabi MR, Ghavami M: Photocatalytic degradation of Direct Red 23 dye using UV/TiO2: Effect of operational parameters. J Hazard Mater. 2008, 153: 1235-

Concalves MST, Oliveira-Campos AMF, Pinto MMS, Plasencia PMS, Queiroz MJRP: Chemosphere. 1991, 39: 781-

Barakat MA, Schaeffer H, Hayes G, Ismat-Shah S: Photocatalytic … Metal ions in photocatalytic systems. Appl. Catal. B Environ. 2004, 57: 23-

Pouretedal H, Norozi A, Keshavarz MH, Semnani A: Nanoparticles of zinc sulfide doped with manganese, nickel and copper as nanophotocatalyst in the degradation of organic dyes. J Hazard Mater. 2009, 162: 674-

Akpan UG, Hameed BH: Parameters affecting the photocatalytic degradation of dyes using TiO2-based photocatalysts: a review. J Hazard Mater. 2009, 170: 520-

Chiang K, Amal R, Tran T: Photocatalytic degradation of cyanide using titanium dioxide modified with copper oxide. Adv Environ Res. 2002, 6: 471-

Acknowledgements

The authors are grateful to the management of the Masterskill university of health science, Malaysia for promoting research and providing financial support in carrying out this investigation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

In this research SM conducted experiments on photocatalytic degradation. RA who is corresponding author for this manuscript supervised, evaluated the progress of the study and prepared manuscript. RP designed experimental procedures and prepared the manuscript. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License ( https://creativecommons.org/licenses/by/2.0 ), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Munusamy, S., Aparna, R.s.l. & Prasad, R.g.s.v. Photocatalytic effect of TiO2and the effect of dopants on degradation of brilliant green. sustain chem process 1, 4 (2013). https://doi.org/10.1186/2043-7129-1-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2043-7129-1-4