Abstract

The constitutive models of rock are essentially the general depictions of the mechanical responses of rock mass under complex geological environments. Statistical distribution-based constitutive models are of great efficacy in reflecting the rock failure process and the stress–strain relation from the perspective of damage, while most of which were achieved by adopting Drucker–Prager criterion or Mohr–Coulomb criterion to characterize microelement failure. In this study, underpinned by Hoek–Brown strength criterion and damage theory, a new statistical damage constitutive model, which is simple in terms of model expression and capable of reflecting the strain softening characteristics of rock in post-peak stage, was established. First, the rock in the failure process was divided into infinite microelements including elastic part satisfying Hooke’s law and damaged part retaining residual strength. Based on strain equivalence hypothesis, the relation between rock microelement strength and damage variable was derived. By assuming the statistical law of microelement strength obeying Weibull distribution and the microelement failure conforming to Hoek–Brown criterion, the new statistical damage constitutive model based on Hoek–Brown criterion was, therefore, gained. The mathematical expressions of the corresponding model parameters were subsequently deduced in accordance with the geometric characteristics of the deviatoric stress–strain curve. Last, the existing conventional triaxial compression test data of representative rock samples under different confining stresses were employed to compare with the theoretical curves by proposed model, the consistency between which was quantified by utilizing the correlation factor evaluation method. The result indicated that the proposed model could well describe the entire stress–strain relationship of rock failure process and manifest the characteristics of rock residual strength. It is of great significance to the researches on rock damage and softening issues and rock reinforcement treatments.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The heterogeneity of rock mass makes it quite a complex system, and the mechanical behavior and deformation mechanism of rock or rock mass is one of the most concerning problems in the geotechnical field [1]. Since the concept of rock entire stress–strain curve was proposed [2], scholars and experts at home and abroad began to study rock constitutive models other than the classical elastoplastic model [3]. Whereafter, those popular rock constitutive models, such as Drucker–Prager criterion [4], Mohr–Coulomb criterion [5], Hoek–Brown criterion [6] and so on, were rapidly developed in scientific researches and engineering applications.

Rock is a kind of brittle material with original damage and defects. Numerous researches have shown that rock failure showed progressive characteristics [7,8,9]. The strength of rock gradually decays to residual strength with the continuous development of deformation when the external load exceeds its compressive strength, causing strain softening performances. From the microscopic perspective, the macroscopic nonlinear mechanical behavior of rock can be regarded as the superposition effect of inhomogeneous microscopic damage, while such inhomogeneity can be described by certain probability distributions. In this case, the concept of rock statistical damage constitutive was put forward by combining continuous damage theory and statistical strength theory on the basis of effective stress concept and strain equivalence hypothesis [10]. Therefore, the establishment of rock constitutive models based on the random distribution of internal defects in rock has become an effective approach to studying the rock stress–strain relationships and reproducing the entire process of rock deformation and failure, which has attracted the worldwide research attentions.

On the basis of strain strength theory, Tang [11] took the axial strain as the statistical distribution variable and conducted a damage study on the rock failure process. Chen [12] established a damage constitutive model effectively reflecting the residual strength in the post-peak stage of rock failure. Liu et al. [13] proposed a damage model in the form of logistic equation to simulate the stress–strain relation of rocks based on the uniaxial compression tests of three types of rock. Cao et al. [14,15,16,17] proposed the concept of rock microelement strength and the corresponding measuring method, which can reasonably embody the influence of complex stress state, providing a new research approach for the establishment of the statistical damage evolution equation of rocks. According to the current published literatures, the adopted failure criterion types describing the rock microelements strength are mostly the maximum tensile strain criterion [13], Mohr–Coulomb criterion [18], or Drucker–Prager criterion [19] due to their simple expressions. However, Shi et al. [20] stated that the axial strain cannot accurately represent the rock microelement strength, causing certain application limitations to the strain-based damage constitutive models. Besides, assuming the microelement failure conforms to Drucker–Prager criterion lacks rationality since the results by Drucker–Prager criterion is conservative [21]. While Mohr–Coulomb criterion fails to describe the rock strength in low-stress or tensile-stress zone. In addition, its linear relation expression does not agree well with the parabolic shape of the rock failure envelope [22].

To avoid the deficiencies caused by above rock failure criteria and manifest the mechanical performances and the deformation characteristics of rock materials as accurately as possible, this study investigated the combination of Hoek–Brown criterion and damage statistical distribution theory to predict the entire stress–strain curve in conventional triaxial test. It was assumed that the strength characteristics of rock microelements follows the statistical law of Weibull distribution, and the Hoek–Brown criterion was considered as the statistical distribution variable of these microelements. Then, based on the effective stress principle, the statistical constitutive model of rock damage under the confining stress was derived by strict mathematical deduction, which was subsequently verified by comparing with the triaxial test data of representative rock materials.

2 A brief review to Hoek–Brown criterion

In 1980, Hoek and Brown established the Hoek–Brown criterion by means of statistical analyses of hundreds of rock triaxial test data and numerous rock mass field test results and combining theoretical research and practical test results of rock properties [6, 23], which considers the low-stress and tensile-stress areas as well as the influence of the confining pressure on rock strength, and well embodies the nonlinear behavior of rock failure. Since then, this criterion has become the most widely used and influential criterion in the field of rock mechanics [24, 25]. The Hoek–Brown criterion can be expressed as:

where σ1 and σ3 are the maximum and minimum principal stresses, respectively, (MPa), σci is the unconfined compressive strength (MPa), and mi is a material constant that reflect the hardness of intact rocks. According to Hoek and Brown [22], σci is the dominant parameter that sets the scale of the rock mass failure curve on the σ1 versus σ3 plot. Using the experience of engineering geologists from laboratories and engineering field as a guide, Hoek et al. [26] presented a relatively comprehensive and detailed method for determining the specific value of mi, which covers the texture and mineral composition of various rock materials.

Subsequently, Hoek [27] improved the original Hoek–Brown criterion so that it can be applied to different rocks and rock masses, and proposed the generalized Hoek–Brown rock mass criterion, which can be defined as:

where mb, s, and a are empirical parameters that reflect rock mass characteristics; Among them, mb and a are related to rock mass classification, whereas s represents the fragmentation degree of rock mass. The value of s ranges within 0.0 ~ 1.0, wherein s = 1.0 signifies intact rock mass.

To quantify these empirical parameters, Hoek [28] introduced the disturbance parameter D to take the blast effects and stress release into consideration and proposed a new method for determining the values of mb, s, and a based on the geological strength index (GSI), a system of rock mass characterization that was developed to link the failure criterion of rock mass to engineering geology observations from the views of the structure and the surface quality in the field, as presented by the following equations.

where GSI ranges from approximately 10 (for extremely fractured rock mass) to 100 (for intact rock mass); D is dependent on engineering experience, and D = 1 for completely disturbed rock mass while D = 0 for undisturbed rock mass. Obviously, mb and s are closely associated with GSI and D, while a is merely dependent on GSI.

The generalized Hoek–Brown rock mass strength criterion defined s and a on the basis of the original criterion so that they can be applied to low-quality rock masses (fractured rock mass), especially under the condition of low confining stress. As a result, it has gained wide acceptance as a tool for estimating the strength characteristics of fractured rock mass, which was adopted by the rock mechanics community because of the lack of suitable alternatives. While, in general, it has been found to provide satisfactory estimates, there are several questions on the limits of its applicability. Except for the service limit of GSI system, the Hoek–Brown criterion is only applicable for confining stresses within the range defined by σ3 = 0 and the transition from shear to ductile failure [29], at which point σ1 = 4.0σ3 [30] or σ1 = 3.4σ3 [31]. Besides, it is inapplicable when massive rock is in a state of relatively high confinement [32], or in massive to moderately jointed hard rock having high values of GSI [33].

3 Establishment of the statistical damage constitutive model

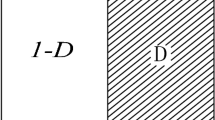

As previously implied, the randomly distributed micro defects in rocks are the main factors that cause rock damage and nonlinear mechanical behavior in the triaxial compression process (Fig. 1) [34]. For simplifications, the anisotropic rock material was regarded as an isotropic material, and its damages were considered as isotropic damages [34, 35]. According to Lemaitre strain equivalence theory and the concept of effective stress [36], the relationship between the nominal maximum principal stress σ1 and the effective maximum principal stress σ1* of isotropic damage can be expressed as:

From Eq. 6, it can be inferred that σ1 = 0 when Drock = 1. This result indicates that the rock fails to bear loads in completely damaged state. However, laboratory tests demonstrated that rock materials at the post-peak stage of the stress–strain curve usually have reserved certain bearing capacity (residual stress σr) due to the influence of friction and confining pressure, which is an important finding in the stability assessment of rock engineering. On this basis, the nominal maximum principal stress σ1 can be divided into two parts: the effective maximum principal stress σ1* provided by undamaged rock component and residual stress σr provided by damaged rock component [37]. Equation 6 should be modified into:

Because of the particularity of triaxial test equipment, the direct measuring result of laboratory triaxial compression test is generally deviatoric stress–strain curve [38]. In this case, the deviatoric stress–strain curve was chosen as the research object to avoid unnecessary errors. Therefore, Eq. (7) can be rewritten as:

Drock is the ratio of damaged microelements (Ndam) to the total number of microelements (Ntol) (Eq. 9).

To establish the model, a series of assumptions of the rock microelements must be made clearly in advance for better understanding:

(1) The rock material is homogenous, continuous and brittle [39].

(2) The undamaged microelements conform to the linear elastic constitutive law before the failure.

The rock material is divided into infinite microelements, and the microdefects can be regarded as the damaged microelements, in which case the compaction stage will not be taken into account and the undamaged microelements show linear elastic properties directly at the initiation of loading. In accordance with Hooke’s law, Eq. 10 can be obtained:

where E is the elastic modulus of the rock material and ε1* is the effective strain of the elastic part of the rock material.

(3) The failure of undamaged microelement is instantaneous, and the yield satisfies the Hoek–Brown criterion (Eq. 1).

(4) The statistical law of the microelements strength is assumed to follow the Weibull distribution [40] (Eq. 11).

The failure of rock materials is probabilistic due to the random distribution and growth of various scale defects, and the number of damaged microelements can be quantified by the statistical damage mechanics theory [41]. In the researches on the damage and fracture of rock and concrete, literature [42] shows that Weibull distribution, underpinned by statistical theory of brittle failure, is applicable to the fracture process of materials. Besides, through comparing the damage constitutive models of different distributions, Li et al. [43] have pointed out that Weibull distribution-based statistical constitutive model was the most suitable one to reflect the stress–strain relation for brittle rocks. By the same method, Chen et al. [44] also believed that using Weibull distribution to describe the microelement strength was more reasonable. Thus, Drock can be expressed as Eq. 12 by substituting Eq. 9 to Eq. 11.

where β and γ are both the Weibull distribution parameters.

The coordination relationship between the damage of the rock microelement and the deformation of the undamaged part indicates that the effective strain equals to the axial strain (\(\varepsilon_{{1}}^{*} { = }\varepsilon_{{1}}\)). Since rock damage mainly occurs in the axial direction with few lateral damages, it can be considered that \(\sigma_{2}^{*} = \sigma_{2}\) and \(\sigma_{3}^{*} = \sigma_{3}\). By combining with Eqs. 10 and 12, Eq. 8 can be rewritten as:

The Hoek–Brown criterion can be expressed in the form of the effective stress invariant [45].

where I1* is the first invariant of the effective stress (\(I_{1}^{*} = \sigma_{1}^{*} + \sigma_{2}^{*} + \sigma_{3}^{*}\)), J2* is the second invariant of the effective stress deviation (\(J_{2}^{*} = \frac{{\left[ {\left( {\sigma_{1}^{*} - \sigma_{2}^{*} } \right)^{2} + \left( {\sigma_{2}^{*} - \sigma_{3}^{*} } \right)^{2} + \left( {\sigma_{3}^{*} - \sigma_{1} } \right)^{2} } \right]}}{6}\)), and θσ is the Lode angle. In conventional triaxial compression tests, \(\sigma_{2}^{*} = \sigma_{3}^{*}\) and θσ = 30°. Consequently, fHB(σ*) can be calculated as:

For the conventional triaxial test for intact rocks, Eq. 1 can be rewritten as:

Let y = (σ1−σ3)2 and x = σ3, and the specific values of σci and mi can be fitted using the least squares method.

The geometric conditions of the rock deviatoric stress–strain curve indicate that the derivative of the curve at the peak is zero. By calculating the derivative of Eq. 13, inputting the peak coordinate, and setting the derivative equal to zero, the following relationship can be obtained:

By substituting Eq. 17 into Eq. 13, β and γ can be determined:

At the same time, it should be emphasized that the established model also has its limitations. The most obvious one is the application limitation of Hoek–Brown criterion which was previously mentioned. Second, a series of assumptions and simplifications were made during the model establishment, thus it can only be applied when rock materials satisfy those. Finally, according to the mathematical expression of the model, it is closely related to the elasticity modulus E and residual strength σr of rock materials. As a result, to obtain an expectant result, it is suggested to be utilized to describe the test data which have obvious linear stage and residual stage.

4 Verification

The triaxial test results presented in existing literatures were used to validate the rationality of the statistical damage constitutive model based on Hoek–Brown criterion. Considering the nonlinearity of stress–strain curves, the image observation method should not be used as the only criterion to evaluate the matching effect between the predicted values and test values, which is subjective. Therefore, the correlation factor δ was introduced [46].

where σ(i) and σi are the respective maximum principal stresses of the predicted and observed samples and n is the number of the samples included in the evaluation. Evaluation criteria were established on the basis of the different values of δ to evaluate the matching effect (Table 1).

(1) Triaxial test results of sandstone presented in literature [47]

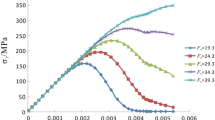

The deviatoric stress–strain curves of sandstone are plotted in Fig. 2. The Hoek–Brown parameters σci (57.59 MPa) and mi (9.94) were obtained by fitting the test values of σ1–σ3 and σ3 in accordance with Eq. 16 (Fig. 3), and the specific values of β and γ were then calculated. Table 2 lists the relevant equation parameters for different values of σ3 (0, 5, 10, 15, 25, and 35 MPa). The predicted deviatoric stress–strain curve under the specific confining pressure can be obtained through the previously enumerated steps. Figure 4 illustrates the comparison of the predicted curves and test results. The predicted curves conform well with the test results in Fig. 4, and the values of δ in Table 3 indicate that the two have a relatively good agreement. However, the agreement is relatively weaker when σ3 = 0 MPa, in which case the test result has a distinct compaction stage. This finding suggests that the damage constitutive equation can accurately simulate the entire deviatoric stress–strain response during the failure process of sandstone in the triaxial test to some extent.

(2) Triaxial test results of sandstone presented in literature [48]

Similarly, the deviatoric stress–strain curves of sandstone (Fig. 5) were selected to demonstrate the validity of the proposed model. The necessary parameters were substituted to Eqs. 13, 15, 16, 18, and 19 to obtain the predicted curves, and the evaluation results calculated using Eq. 18 are summarized in Table 4. Figure 5 and Table 4 imply the good agreement between the test results and the predicted curves, thereby confirming the rationality and feasibility of the proposed model. However, only the test data under three confining pressures were included in this analysis, which may make it relatively inaccurate in determining the specific values of mi and σci, and ultimately, causing worse evaluations of the correlation between the test results and predicted curves by the value of δ.

(3) Triaxial test results of rock-like materials presented in literature [49]

To verify the applicability of the proposed model to other kinds of rock materials, part of triaxial test results of cemented sand under different confining stresses (σ3 = 0.2, 0.3, and 0.4 MPa) were also employed to analyze and compare with theoretical curves. The execution steps were similar to that of sandstone. The comparison and evaluation results are presented in Fig. 6 and Table 5. Figure 6 indicates that the predicted curves coincide well with the test results. The value of δ is approximately 0.85–0.9 (Table 5) corresponding to the evaluation standard of qualified correlation and nice correlation and, therefore, confirms the rationality and applicability of the proposed model. The relatively small value of δ can be ascribed to the obvious nonlinear deformation in the initial compaction stage, which causes the predicted curve to locate above the test results. Equation 20 indicates that the calculated value of δ will be small because the value of xi is smaller than that of x(i).

5 Conclusion

(1) Given that the existing statistical damage constitutive models rarely consider the Hoek–Brown criterion, the present study assumed that the statistical law of rock microelement strength follows Weibull distribution and rock microelement yields obeying Hoek–Brown criterion to establish a new statistical damage constitutive model which considers the rock softening and reflects the entire stress–strain relationship, and is simple in terms of expression.

(2) The conventional triaxial test results of representative rock materials were compared with the theoretical curves obtained using the proposed model. In addition, the correlation factor evaluation method was utilized to evaluate the consistency. The results revealed that the new model can effectively reproduce the deviatoric stress–strain response during the failure process of tested rocks.

(3) Hoek–Brown criterion not only applies to intact rocks, but also can describe the strength characteristics of rock mass relatively accurately. Therefore, the model in this paper may be further applied to the stress–strain relation of rock mass, which reflects a wide applicability.

Data availability

Some or all data, models, or code that support the findings of this study are available from the corresponding author upon reasonable request.

References

Zhao YL, Zhang CS, Wang YX, Lin H. Shear-related roughness classification and strength model of natural rock joint based on fuzzy comprehensive evaluation. Int J Rock Mech Mining Sci. 2021;137:17. https://doi.org/10.1016/j.ijrmms.2020.104550.

Cook N. The failure of rock. Int J Rock Mech Mining Sci Geomech Abstracts. 1965;2:389–403.

Wang SS, Xu WY. A coupled elastoplastic anisotropic damage model for rock materials. Int J Damage Mech. 2020;29:1222–45. https://doi.org/10.1177/1056789520904093.

Shao S, Shao SJ, Wang Q. Strength criteria based on shear failure planes and test verification on loess. Geotech Test J. 2019;42:347–64.

Geng HS, Xu HF, Gao L, Chen L, Wang B, Zhao X. Elastic modulus and strength of rock-like material with locked-In stress. Math Probl Eng. 2018;2018:1–17.

Hoek E, Brown ET. Empirical strength criterion for rock masses. J Geotech Eng Div. 1980;106:1013–35.

Feng WL, Qiao CS, Niu SJ, Yang Z, Wang T. An improved nonlinear damage model of rocks considering initial damage and damage evolution. Int J Damage Mech. 2020;29:1117–37. https://doi.org/10.1177/1056789520909531.

Chen Y, Lin H, Ding X, Xie S. Scale effect of shear mechanical properties of non-penetrating horizontal rock-like joints. Environ Earth Sci. 2021;80:192. https://doi.org/10.1007/s12665-021-09485-x.

Lin H, Zhang X, Wang YX, Yong R, Fan X, Du SG, et al. Improved nonlinear Nishihara shear creep model with variable parameters for rock-like materials. Adv Civil Eng. 2020;2020:7302141. https://doi.org/10.1155/2020/7302141.

Krajcinovic D, Silva MAG. Statistical aspects of the continuous damage theory. Int J Solids Struct. 1982;18:551–62.

Tang CA. Catastrophe in rock unstable failure. Beijing: Beijing: China Coal Industry Publishing House; 1993.

Chen K. Constitutive model of rock triaxial damage based on the rock strength statistics. Int J Damage Mech. 2020;29:1487–511. https://doi.org/10.1177/1056789520923720.

Liu DQ, He MC, Cai M. A damage model for modeling the complete stress-strain relations of brittle rocks under uniaxial compression. Int J Damage Mech. 2018;27:1000–19. https://doi.org/10.1177/1056789517720804.

Cao W, Fang Z, Tang X. A study of statistical constitutive model for soft and damage rock. Chin J Rock Mechan Eng. 1998;17:628–33.

Cao WG, Zhao MH, Liu CX. Study on the model and its modifying method for rock softening and damage based on Weibull random distribution. Chin J Rock Mechan Eng. 2004;23:3226–31.

Cao WG, Zhang S. Study on the statistical analysis of rock damage based on Mohr-Coulomb criterion. J Hunan University. 2005;32:43–7.

Cao WG, Zhao MH, Liu CX. Study on rectified method of Mohr-Coulomb strength criterion for rock. Chin J Rock Mechan Eng. 2005;24:2403–8.

Lin H, Lei D, Yong R, Jiang C, Du S. Analytical and numerical analysis for frost heaving stress distribution within rock joints under freezing and thawing cycles. Environ Earth Sci. 2020;79:305. https://doi.org/10.1007/s12665-020-09051-x.

Zhang HM, Yuan C, Yang GS, Wu LY, Hossein M. A novel constitutive modelling approach measured under simulated freeze–thaw cycles for the rock failure. Eng Comp. 2019;35:1–14.

Shi C, Jiang XX, Zhu ZD, Hao ZQ. Study of rock damage constitutive model and discussion of its parameters based on Hoek-Brown criterion. Chin J Rock Mechan Eng. 2011;30:2647–52.

Cao RL, He SH, Wei J, Wang F. Study of modified statistical damage softening constitutive model for rock considering residual strength. Rock Soil Mech. 2013;34:1652–67.

Hoek E, Brown ET. The HoekeBrown failure criterion and GSI-2018 edition. J Rock Mech Geotech Eng. 2019;11:445–63.

Hoek E, Brown ET. Underground excavations in rocks. London: Institution of Mining and Metallurgy; 1980.

Shen J, Shu Z, Cai M, Du S. A shear strength model for anisotropic blocky rock masses with persistent joints. Int J Rock Mech Mining Sci. 2020;134:104430. https://doi.org/10.1016/j.ijrmms.2020.104430.

Shen JY, Jimenez R. Predicting the shear strength parameters of sandstone using genetic programming. Bull Eng Geology Environ. 2018;77:1647–62. https://doi.org/10.1007/s10064-017-1023-6.

Hoek E, Brown ET. Practical estimates of rock mass strength. Int J Rock Mech Mining Sci. 1997;34:1165–86.

Hoek E. Strength of rock and rock masses. ISRM News J. 1994;2:4–16.

Hoek E. Hoek-Brown failure criterion-2002 edition. In Proceedings of the fifth North American rock mechanics symposium. 2002; 1:18–22

Deng C, Hu H, Zhang T, Chen J. Rock slope stability analysis and charts based on hybrid online sequential extreme learning machine model. Earth Sci Inf. 2020;13:729–46.

Schwartz AE. Failure of rock in the triaxial shear test. Rolla, USA: US Symposium on Rock Mechanics; 1964. p. 109–51.

Mogi K. Pressure dependence of rock strength and transition from brittle fracture to ductile flow. Bulletin Earthquake Research Institute; 1966. p. 215–32.

Kaiser PK, Kim B, Bewick RP, Valley B. Rock mass strength at depth and implications for pillar design. In: Van Sint Jan M, Y P, editors. Deep mining 2010, Proceedings of the fifth international seminar on deep and high stress mining. Santiago, Chile: Australian Centre for Geomechanics; 2010. p. 463–76.

Bewick RP, Kaiser PK, Amannc F. Strength of massive to moderately jointed hard rock masses. J Rock Mech Geotech Eng. 2019;11:126–39.

Zhang X, Lin H, Wang YX, Yong R, Zhao YL, Du SG. Damage evolution characteristics of saw-tooth joint under shear creep condition. Int J Damage Mech. 2021;30:453–80. https://doi.org/10.1177/1056789520974420.

Zhang X, Lin H, Wang Y, Zhao Y. Creep damage model of rock mass under multi-level creep load based on spatio-temporal evolution of deformation modulus. Arch Civil Mech Eng. 2021;21:71. https://doi.org/10.1007/s43452-021-00224-4.

Desai GFS. Constitutive model with strain softening. Int J Solids Struct. 1987;23:733–50.

Zhang HM, Meng XZ, Yang GS. A study on mechanical properties and damage model of rock subjected to freeze-thaw cycles and confining pressure. Cold Regions Sci Technol. 2020;174:14. https://doi.org/10.1016/j.coldregions.2020.103056.

Zhang M, Wang F, Yang Q. Statistical damage constitutive model for rocks based on triaxial compression tests. Chin J Geotech Eng. 2013;35:1965–71.

Xie S, Lin H, Wang Y, Cao R, Yong R, Du S, et al. Nonlinear shear constitutive model for peak shear-type joints based on improved Harris damage function. Arch Civil Mech Eng. 2020;20:95. https://doi.org/10.1007/s43452-020-00097-z.

Lyu Q, Tan JQ, Dick JM, Liu Q, Gamage RP, Li L, et al. Stress-Strain Modeling and Brittleness Variations of Low-Clay Shales with CO2/CO2-Water Imbibition. Rock Mech Rock Eng. 2018;52:2039–52.

Gao F, Xie HP, Zhao P. Fractal properties of Weibull modulus and strenth of the rock. Chin Sci Bull. 1993;38:1427–30.

Xu SL, Zhao GF. A study on probability model of fracture toughness of concrete. Chin Civil Eng J. 1988;21:10–23.

Li YW, Jia D, Rui ZH, Peng JY, Fu CK, Zhang J. Evaluation method of rock brittleness based on statistical constitutive relations for rock damage. J Petrol Sci Eng. 2017;153:123–32.

Chen S, Qiao C, Ye Q, Khan MU. Comparative study on three-dimensional statistical damage constitutive modified model of rock based on power function and Weibull distribution. Environ Earth Sci. 2018;77:108–16.

Zheng YR. Principle of geotechnical plastic mechanics: generalized plastic mechanics. Beijing: China Building Industry Press; 2002.

Chou YL, Huang SY, Sun LY, Wang IJ, Yue GD, Cao W, et al. Mechanical model of chlorine salinized soil-steel block interface based on freezing and thawing. Rock Soil Mech. 2019;40:41–52.

Wang JB, Song ZP, Zhao BY, Liu XR, Liu J, Lai JX. A study on the mechanical behavior and statistical damage constitutive model of sandstone. Arab J Sci Eng. 2018;43:5179–92. https://doi.org/10.1007/s13369-017-3016-y.

Yang SQ, Jiang YZ. Triaxial mechanical creep behavior of sandstone. Mining Sci Technol (China). 2010;20:339–49.

Tan C, Yuan MD, Shi YS, Zhou BS, Li H. Statistical damage constitutive model for cemented sand considering the residual strength and initial compaction phase. Adv Civil Eng. 2018;2018:1410893.

Acknowledgements

This paper gets its funding from project (51774322) supported by National Natural Science Foundation of China; Project (2018JJ2500) supported by Hunan Provincial Natural Science Foundation of China. The authors wish to acknowledge these supports. The anonymous reviewer are gratefully acknowledged for his valuable comments on the manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, Y., Lin, H., Wang, Y. et al. Statistical damage constitutive model based on the Hoek–Brown criterion. Archiv.Civ.Mech.Eng 21, 117 (2021). https://doi.org/10.1007/s43452-021-00270-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-021-00270-y