Abstract

Xanthan is one of the most important biopolymers characterised by a high commercial value. Since the availability of essential nutrients influences its biosynthesis, the aim of this study was the optimisation of carbon, organic and inorganic nitrogen content in glycerol-based medium employing response surface methodology. The cultivation of strain Xanthomonas campestris ATCC 13951 was carried out under appropriate conditions on media with glycerol, peptone and ammonium-nitrate formulated according to Box-Behnken design (33), while the desirability function approach was used for determination of optimal nutrient levels. The final model predicts that the maximal amount of xanthan (12.95 g/L) is produced when the initial contents of glycerol, peptone and ammonium-nitrate in the medium are 32.96 g/L, 0.55 g/L and 0.73 g/L, respectively. To minimize the residual nutrient content and therefore the costs of effluent processing, additional optimisation was performed. In order to validate the optimisation model developed and examine the bioprocess success with crude glycerol as the sole carbon source, additional experiments were performed. The results represent reliable information for further investigations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Microbial polysaccharides, an important class of polymeric and renewable materials, are characterised by an unique combination of functional and physical–chemical properties, as well as rheological and film-forming behaviour, which makes them suitable for a wide range of commercial applications (Alves et al. 2010; Freitas et al. 2009). Industrial-scale production has been developed for only several biopolymers due to high manufacturing costs that are mainly related to the price of the carbon sources used for cultivation media preparation (Alves et al. 2011; Freitas et al. 2011; Giavasis et al. 2013; Sutherland 2001).

Xanthan or xanthan gum is one of the most important microbial polysaccharides biosynthesised by Xanthomonas campestris and by other Xanthomonas species (Palaniraj and Jayaraman 2011). Pseudoplastic behaviour and stability over a wide range of temperature and pH make this biopolymer suitable for application in different fields of food and non-food industries (Becker et al. 1998). Xanthan production involves two steps, first bacterium cultivation on medium which enhances biomass growth, and second stimulation xanthan biosynthesis by using an appropriate medium (Carignatto et al. 2011). Industrial production is usually carried out on medium which meets the needs of both stages of bacterium growth and biopolymer synthesis (Rosalam and England, 2006). For xanthan biosynthesis, the macroelements carbon and nitrogen, and microelements such as potassium, iron and calcium are essential medium ingredients (García-Ochoa et al. 2000). The commercial medium contains glucose or sucrose as carbon source, which plays a crucial role from the economic viewpoint of the bioprocess, considering the market price of these sugars (Li et al. 2016).

The total cost of industrial production can be reduced by optimising the composition of the medium based on alternative substrates that are less expensive than those mentioned above. Among them, glycerol is recognised as one of the most promising (Brandão et al. 2013; Freitas et al. 2011). During the last decade, biodiesel production has been continuously growing as a response to rapid fossil fuels depletion and their impact on global warming and pollution. It is an environmentally attractive alternative to fossil fuels, but on the other hand the economic viability of its production is concerning. The quantity of crude glycerol generated as the main by-product of the biodiesel industry is significant, about 10–20% of the total volume of biodiesel produced (Fan et al. 2010; Quispe et al. 2013). Besides the possibility to use glycerol in different industries, such as pharmaceutical, cosmetic and food, there is still the need to develop new applications (Tan et al. 2013). Investigating possible valorisation routes and fulfilling the potential to convert glycerol into high value products represents a challenge for many research groups. Currently, there is a focus on the possibility to utilise glycerol for cultivation media preparation as a carbon source. It could significantly decrease production costs of many bioprocesses and make them more economically effective (Fan et al. 2010; Freitas et al. 2010; Hejna et al. 2016; Moita et al. 2014; Thapa et al. 2013; Yazdani et al. 2007).

One of the biggest issues related to application of crude glycerol in biotechnology is its complex composition. Due to the presence of different impurities (methanol, ethanol, inorganic salts, metals, long chain fatty acids and soaps), the metabolic activity of applied producing strain can be inhibited, resulting in reduced biomass growth and therefore bioconversion of glycerol into desired products (Konstantinović et al. 2016). In general, the effect of impurities on bioprocess success depends on the origin of the crude glycerol and its concentration in the cultivation medium (Hejna et al. 2016). Possible solutions to overcome these problems are the use of microorganisms that are tolerant to the impurities in crude glycerol (Konstantinović et al. 2016), the application of appropriate treatments (Pan et al. 2019) and the implementation of fed-batch cultivation systems in which crude glycerol is added gradually (Samul et al. 2014). However, all of these activities can decrease the economic potential of processes that utilise crude glycerol as the raw material (Rahim et al. 2019).

Response surface methodology (RSM) is one of the most frequently used optimization methods in chemical and biochemical engineering (Assis et al. 2014; Ayyalusamy and Mishra 2018; Bajić et al. 2017; Grahovac et al. 2014; Rončević et al. 2019a). This efficient approach has been widely applied in various studies because the process of interest can be defined and explained by adequate mathematical equations. By analysing the individual influences and interactions of the parameters on the selected responses, RSM offers a great amount of necessary information about the system that can be used for its improvement (Bas and Boyaci 2007). This methodology is used in combination with statistical experimental design and the concept of a desirability function. Statistically designed experiments are very effective because they give more information about process performance with much less effort compared to the classical one-variable at-a-time approach (Ibrahim and Elkhidir 2011). Hence, the selection of an appropriate experimental plan is a key step in RSM application. The most preferred design for creating experiments is the Box-Behnken design (BBD) that is a class of rotatable or nearly rotatable second-order designs based on three-level incomplete factorial designs. It is more efficient than others (for example Central Composite Design) when examining the influence of three factors on selected responses. Another advantage of the BBD is that it does not contain combinations for which all factors are simultaneously at their highest or lowest levels. So these designs are useful in avoiding experiments performed under extreme conditions, for which unsatisfactory results might occur (Ferreira et al. 2007).

The aim of this study was the application of response surface methodology for optimisation of a glycerol-based medium for xanthan production by Xanthomonas campestris ATCC 13951. Mathematical relationships were defined to describe the carbon, organic and inorganic nitrogen content on the quantity and quality of the desired product, as well as the remaining nutrients content. Further, the models developed were used to find the optimal cultivation medium composition.

Materials and methods

Producing microorganism

The reference strain Xanthomonas campestris ATCC 13951 was used in these experiments as producing microorganism. The culture was stored at 4 °C on yeast maltose agar slant (YMA®, HiMedia, India) and subcultured at monthly intervals.

Cultivation media

The commercial medium (YMB®, HiMedia, India) was used for inoculum preparation, while xanthan production was performed on semi-synthetic glycerol-based media formulated by an applied experimental plan. The contents of commercial glycerol (15.0–45.0 g/L), peptone (0.0–1.2 g/L) as organic and ammonium-nitrate (0.0–1.2 g/L) as inorganic nitrogen sources were varied. All cultivation media were enriched with MgSO4 × 7H2O (0.5 g/L) and K2HPO4 (3 g/L) before pH value correction to 7.0 and sterilisation by autoclaving at 121 °C and 2.1 bar for 20 min.

Crude glycerol used in the validation experiments was obtained from a domestic biodiesel factory (Belgrade, Serbia) that uses waste oil as raw material for biodiesel production. Declared characteristics of the crude glycerol are: glycerol content 60.88% (w/w), moisture content 4.84% (w/w), methanol content 0.45% (w/w), organic matter content 95.12% (w/w), density 1.12 g/cm3 and kinematic viscosity 74.97 mm2/s.

Xanthan production

The xanthan production was carried out simultaneously in 300 mL Erlenmeyer flasks with a flask volume to medium volume ratio of 3:1. Inoculation was performed by adding 10% (v/v) of inoculum prepared in aerobic conditions at 26 °C and 150 rpm (laboratory shaker KS 4000i control, Ika® Werke, Germany) for 36 h. The biosynthesis was carried out in batch mode under aerobic conditions at 30 °C and 150 rpm for 168 h.

Xanthan recovery

The separation of bacterial cells from the cultivation broth was carried out by centrifugation at 10,000 rpm for 30 min (Hettich Rotina 380 R, Germany). Recovery of xanthan from the cell-free supernatant was achieved by the addition of precipitation agent, 96% (v/v) ethanol, in the presence of KCl as the electrolyte, using a modified method established by Flahive III et al. (1994). Supernatant was cooled to the temperature of 15 °C and ethanol was gradually added at constant stirring until the alcohol content in the mixture was 60% (v/v). After addition of half of the necessary ethanol amount, a saturated solution of KCl was poured into the supernatant until it reached 1% (v/v) of the content. When the precipitation procedure was completed, the mixture was kept on 4 °C for 24 h and then centrifuged (4000 rpm, 15 min). The precipitate was dried to a constant mass at 60 °C and the obtained data used to calculate the xanthan concentration. Dried precipitate represents raw xanthan with a moisture content of 10.88% and ash content of 19.72%, determined by standard drying methods (Helrich 1990).

Analytical methods

The samples of cell-free supernatants, obtained as previously described, were used to determine the residual contents of the nutrients. The preparation of samples for determination of nitrogen content included dilution prior to centrifugation.

Glycerol content was determined by high performance liquid chromatography (HPLC). The samples were filtered through a 0.45 μm nylon membrane (Agilent Technologies Inc, Germany) and then analysed. The HPLC instrument (Thermo Scientific Dionex UltiMate 3000 series) was equipped with a HPG-3200SD/RS pump, WPS-3000(T)SL autosampler (10 μL injection loop), Zorbax NH2 column (250 mm × 4.6 mm, 5 μm) and RefractoMax520 detector. 70% (v/v) acetonitrile was used as eluent with a flow rate of 1 mL/min and elution time of 20 min at a column temperature of 30 °C. The content of total nitrogen was determined using the Kjeldahl method (Helrich 1990).

The average molecular weight of produced xanthan was estimated based on the intrinsic viscosity of its 0.5% (w/v) solution in 0.1 M sodium-chloride using the method proposed by Milas et al. (1985).

Modelling and optimisation

The Box-Behnken design (33) (Ferreira et al. 2007) was used in this research to examine the influence of glycerol, organic and inorganic nitrogen content on xanthan production. The factor variables and their values were glycerol (X1: 15.0–45.0 g/L); peptone (X2: 0.0–1.2 g/L) and ammonium-nitrate (X3: 0.0–1.2 g/L) content. For the description of the responses (Y1: xanthan concentration (g/L), Y2: xanthan molecular weight (g/moL), Y3: residual glycerol content (g/L) and Y4: residual nitrogen content (g/L), experimental data were fitted to a second-degree polynomial model:

where b0 represents the intercept, bi respresents the linear, bii the quadratic and bij the interaction effect of the factors.

Statistical analyses of the experimental data, definition of mathematical models and generation of response surface plots were performed using Statistica software v13.2 (Dell Inc., USA). The data were statistically processed by the analysis of variance at the significance level of α = 0.05. The adequacy of the models was evaluated by the coefficient of determination (R2) and p value of the model. Defined mathematical equations and method of desirability function were applied for the determination of optimal values of the examined factors, which was done with the software package Design-Expert 8.1. (Stat-Ease, Inc., USA).

Results and discussion

Experimental results

In accordance with the defined aim of this research and applied experimental design, xanthan production was firstly carried out on commercial glycerol-based media in order to examine the individual and interactive effects of medium ingredients on the bioprocess success and to define its optimal composition. The results of the experiments performed are presented in Table 1.

At the end of the bioprocess, the xanthan concentration in the cultivation broths was in the range of 7.98–12.94 g/L (Table 1), where the best result was obtained on media with a glycerol content of 30.00 g/L and equal amounts of organic and inorganic nitrogen sources (0.60 g/L). The crucial factor for xanthan production is an adequate concentration of carbon source in the medium, due to its importance in both the cultivation and biosynthesis stages. Unlike carbon, nitrogen is a nutrient which plays a role only in bacterium growth. This study involved the use of ammonium-nitrate as inorganic nitrogen source and peptone as a complex organic nitrogen source rich in microelements, which are also important for xanthan production. However, according to research reported by Cadmus and Knutson (1983), the organic nitrogen source has a negative impact to xanthan biosynthesis since it does not stimulate production of high-pyruvate polysaccharides. As a possible way to overcome this disadvantage, they suggested the substitution of the organic nitrogen source with an inorganic one. On the other hand, the results of this study clearly indicate the necessity of using both an organic and an inorganic nitrogen source (Table 1). Additionally, it is important to note that the lowest amount of xanthan was separated from the medium that contained only glycerol. This result is a consequence of nitrogen deficiency and indicates the importance of an adequate C/N ratio in the cultivation medium. According to the results of previous research, a high C/N ratio is necessary for successful conversion of the carbon source to the desired biopolymer (Palaniraj and Jayaraman 2011).

The possibility of application of less expensive substrates for xanthan production has been investigated in other studies. According to Brandão et al. (2013) glycerol is an excellent carbon source that could stimulate microbial polysaccharide production. Comparing the results obtained by using conventional and alternative glycerol-based media, it was suggested that glycerol chemical structure affects the pathway of xanthan biosynthesis. Moreover, the use of crude glycerol, which is rich in microelements, can increase the bioprocess efficiency if the producing strain is isolated from the environment. The xanthan yield presented in this study is somewhat higher than the values listed in this publication.

Besides the xanthan concentration in the cultivation broths at the end of the bioprocess, Table 1 summarizes the values of the molecular weight of the separated biopolymer and the residual contents of carbon and nitrogen. Molecular weight was determined in order to define the quality of the produced xanthan. The highest values of this parameter were obtained in the experiments where the media with the lowest examined glycerol concentrations were used, and vice versa indicating that an increase of the carbon source content in the cultivation medium negatively affects the xanthan quality. Also, it can be noted that the values of the molecular weight are in expected ranges for such a level of biopolymer purity and in agreement with a previous study (Rončević et al. 2014).

Detection of the residual nutrients content is very important from both an economic and environmental viewpoint of biotechnological production. Unutilised nutrients which remain in the cultivation medium after the bioprocess can cause problems with the product separation and purification, and also represent contaminants in any effluents generated that must be removed before discharge into the environment. The residual glycerol content was in the range of 4.14–29.74 g/L and indicates that the lowest reduction of the carbon source occurs in the media with the highest examined initial concentration of this nutrient (Table 1). When it comes to nitrogen content, it is also very important to carefully choose the appropriate initial concentration. The residual content of this nutrient was in the range of 0.12–1.65 g/L (Table 1), with the exception of the medium without the initial addition of nitrogen. Although residual nitrogen concentration is significantly lower compared to unutilised carbon source, it can be very harmful and cause diverse negative impacts on ecosystems (Yamashita and Yamamoto-Ikemoto 2014).

Statistical analysis and mathematical modelling

RSM is a powerful tool for efficient identification of individual and interactive effects of variables on indicators of process efficacy, and for determination of the optimal conditions for a multivariable system (Bas and Boyaci 2007). For the responses selected in this study (Table 1), second-degree polynomial models were established to evaluate and quantify the influence of the examined variables. The results of statistical analyses and mathematical modelling are given in Tables 2 and 3.

The statistical analyses of the modelled responses were performed in the form of analysis of variance (ANOVA). ANOVA is important for determining the adequacy and significance of the quadratic models. The analyses were done by means of Fisher’s F test. Generally, the F value with a low p value indicates high significance of the regression model. ANOVA summary results presented in Table 2 indicate that the obtained models were statistically significant (p < 0.01) at the 99% confidence level.

Alternatively, the fitting of the experimental data to the regression model was checked and suitably explained by the coefficient of determination (R2). Relatively high values of the determination coefficient obtained for all responses (Table 2) indicate a good fit of experimental results to the second-degree polynomial model. This means that only a small percentage of the variations in the analysed data could not be explained by the defined mathematical models.

The application of RSM to experimental data (Table 1) resulted in generation of regression equations, which are empirical relationships between the selected responses and the factors varied. The coefficients of the regression equations and their significance are presented in Table 3. A positive sign in the values of the linear and quadratic coefficients in the regression equations points to a direct relationship, while a negative sign of these coefficients indicates an inverse relationship between the variables. On the other hand, a positive sign of the interaction coefficients refers to a synergistic effect of certain factors, but if these coefficients are negative their antagonistic effect on the analysed response is evident.

The statistical significance of each coefficient was determined by p values, that also indicated the interaction strength between each independent variable. The results of the regression analysis, i.e., p values for all the linear, quadratic and interaction effects of the varied factors on selected responses, are given in Table 3. The p value is used to assess the statistical significance for each of the regression equation coefficients. The coefficients of the regression equations are highly significant, with a confidence level of 99%, if their p values are less than 0.01. Statistically significant coefficients, with a confidence level of 95%, have p values less than 0.05. These values are marked in the table.

The regression equations can be graphically presented by response surface plots, which provide a visual interpretation of the interaction between two factors and facilitate the location of the optimal experimental conditions. Considering that the biopolymer concentration in the medium at the end of the bioprocess is the most significant response in xanthan production, these dimensional plots were generated to understand the interactions of the examined medium ingredients and to determine their optimal values to achieve the maximal xanthan biosynthesis (Figs. 1, 2 and 3). The graphs presented in Figs. 1, 2 and 3 represent the effects of two factors on the selected response while the third was maintained at the central value of the applied experimental design.

The effects of the initial contents of the carbon and organic nitrogen sources on the xanthan concentration in the medium with constant content of inorganic nitrogen source (0.6 g/L) are shown in Fig. 1.

The generated plot (Fig. 1) indicates that the initial glycerol content has almost no influence on xanthan production under the applied experimental conditions for all examined peptone content. It is evident that a significant increase in the initial carbon source content leads to a minimal increase in the biopolymer concentration in the media at the end of cultivation. On the other hand, the increase of the initial content of organic nitrogen source up to 0.6–0.8 g/L has a positive effect on xanthan biosynthesis. However, the values of the observed response show a noticeable decrease with higher peptone content in the cultivation medium. This can be explained by the fact that xanthan is a secondary metabolite of the genus Xanthomonas; thus, an earlier onset of the stationary phase, during which the products of the secondary metabolism are synthesized, is often achieved by limiting the nitrogen concentration in the production medium (García-Ochoa et al. 2000). So, it is proven that the definition of the optimal carbon to organic nitrogen ratio is a critical step in formulation of the medium composition for xanthan production and greatly affects the success of the performed bioprocess (Becker et al. 1998).

Figure 2 illustrates the effects of the initial contents of carbon and inorganic nitrogen sources on the xanthan concentration in the medium with constant content of organic nitrogen source (0.6 g/L).

As in the previous case, graphically presented results (Fig. 2) suggest that xanthan production depends mainly on the initial content of the nitrogen source, while the impact of the carbon source used is almost insignificant. Therefore, the organic and inorganic nitrogen sources are the most important medium ingredients for xanthan biosynthesis under the applied experimental conditions. This is also confirmed by the p values for the linear (p = 0.011 for peptone and p = 0.003 for ammonium-nitrate content) and quadratic (p = 0.006 for peptone and p = 0.003 for ammonium-nitrate content) coefficients of these components in the mathematical model for xanthan concentration in the cultivation medium (Table 3).

Figure 3 shows the effects of initial organic and inorganic nitrogen source content on the xanthan production on glycerol-based medium with an initial carbon source of 30.0 g/L.

From the response surface plot represented in Fig. 3, it can be seen that a change of the initial content of ammonium-nitrate has a greater impact on the xanthan concentration in cultivation medium if the initial peptone content is 0.0–0.4 g/L. Therefore, the selected response is intensified with increasing inorganic nitrogen content at low values of organic nitrogen, and vice versa. An antagonistic effect of these factors on xanthan biosynthesis is also confirmed by the negative value of the interaction coefficient for peptone and ammonium-nitrate content (b23 = − 3.014) given in Table 3. At an initial content of organic nitrogen source of 0.6–1.2 g/L, regardless of the inorganic nitrogen source content in the medium, xanthan production is almost equally expressed.

According to all of the response surface plots presented in Figs. 1, 2 and 3 the maximal values of the selected response were obtained if the variables had the middle values of the examined range. Consequently, a maximal xanthan concentration is obtained in a medium with initial glycerol content of 30–40 g/L and initial peptone and ammonium-nitrate contents of 0.4–0.8 g/L. Additionally, it can be observed that xanthan production was significantly reduced in the media with low nitrogen content, while this nutrient in excess limits the biopolymer synthesis. Thus, the increase of all nutrients is followed by an increase in xanthan concentration up to a maximal value, after which it decreases gradually. Evidently, the definition of an adequate carbon to nitrogen ratio, as well as organic to inorganic nitrogen source ratio, is important to stimulate xanthan biosynthesis and to improve bioprocess efficacy.

Optimisation of glycerol-based medium composition

The final purpose of using response surface methodology is the optimisation of the examined process. To optimise the process with two or more selected responses, it is recommended to use the concept of a desirability function. This approach combines multiple responses into one response called the overall desirability function by choice of a value from 0 (one or more characteristics are unacceptable) to 1 (all process characteristics are on target) (Ferreira et al. 2007). In this research, the concept of a desirability function was used to optimise the initial contents of carbon and organic and inorganic nitrogen sources in the glycerol-based medium for xanthan production. Two optimisation sets were considered and the results obtained are presented in Table 4.

If the only goal of optimisation is to achieve maximal xanthan concentration in the medium at the end of the bioprocess (first set, Table 4), the overall desirability function has a maximal value (1.00) for the initial contents of glycerol, peptone and ammonium-nitrate of 32.96 g/L, 0.55 g/L and 0.73 g/L, respectively. By using a medium with such nutrients contents, the model predicts the generation of a cultivation broth with 12.95 g/L of xanthan characterised by a molecular weight of 2.14·105 g/moL. The predicted residual contents of glycerol and total nitrogen compounds are 15.86 g/L and 0.73 g/L, respectively.

When defining the medium composition it must be taken into account that the bioprocess efficiency is improved if the residual nutrient content is minimal, because the unused nutrients represent losses from an economic viewpoint due to high market prices of medium ingredients and high cost of effluent processing prior to release into the environment. Therefore, in the second optimisation set (Table 4), in addition to achieving the maximal xanthan accumulation, the minimal residual contents of analysed nutrients were selected as individual desirability functions. According to the model predictions for the highest value of the overall desirability function (0.85) the optimal values of the initial contents of glycerol, peptone and ammonium-nitrate are 15.86 g/L, 0.18 g/L and 0.67 g/L, respectively. The predicted value of xanthan concentration is 11.76 g/L and its molecular weight is 3.31·105 g/moL, while the residual nutrients contents are 4.16 g/L and 0.30 g/L for glycerol and total nitrogen, respectively.

Comparing the optimisation results given in Table 4, it is evident that the use of the cultivation medium proposed in the second set can reduce the costs of medium preparation and waste treatment. This is corroborated by the potential reduction of initial contents of glycerol, peptone and ammonium-nitrate by 51.88%, 72.73% and 8.22%, respectively, as well as the huge reduction of the residual contents of glycerol and total nitrogen by 73.77% and 58.90%, respectively. However, a decrease of the xanthan concentration by only 9.19% was predicted, while the significant change in the biopolymer quality was noted which is confirmed by a 35.35% higher value of the molecular weight. The optimisation results represent reliable data for further investigation aimed to improve xanthan production in glycerol-based cultivation medium.

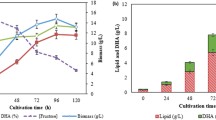

Validation of the optimisation model and possibility of crude glycerol utilisation

Finally, in order to validate the developed optimisation model (second set in Table 4), xanthan production in commercial glycerol-based medium with optimal composition was carried out in triplicate. The results are given in Table 5 and indicate that the data are in excellent accord with the predicted values for all modelled responses.

In addition to these confirmation experiments, another investigation was performed to examine the possibility of xanthan production in crude glycerol-based medium and to evaluate the bioprocess success. For this purpose, a cultivation medium of optimal formulation (second set in Table 4) was prepared with crude glycerol as the sole carbon source. The xanthan biosynthesis was carried out simultaneously under the previously applied experimental conditions in triplicate. Results obtained by analysing the media at the end of the bioprocess are shown in Table 5. Based on the data presented, it can be seen that the values of xanthan concentration and its molecular weight are much lower than those obtained when commercial glycerol is applied, while the contents of residual glycerol and total nitrogen are higher. The possible explanation for this situation is the presence of different impurities in crude glycerol generated during biodiesel manufacture from waste oil. A similar observation was noted in research conducted by Gondim et al. (2019).

Since the growth of Xanthomonas campestris cells and synthesis of biopolymer depend on various factors (García-Ochoa et al. 2000), future considerations aimed to improve xanthan production in crude glycerol-based medium should include optimisation of process parameter values. Among these, the most significant are parameters responsible for dissolved oxygen concentration (Rončević et al. 2019b). So, new series of experiments should be performed to define the optimal temperature, pH value, aeration rate, agitation speed and cultivation time for both bioprocess stages, i.e., inoculum preparation and biopolymer synthesis. Another solution to increase xanthan yield is the application of novel producing strains that tolerate high concentrations of various inhibitors.

Conclusions

Response surface methodology combined with Box-Behnken design and a desirability function approach was found to be an effective tool for optimisation of glycerol-based medium for xanthan production. The results obtained suggest that commercial glycerol represents an appropriate replacement for traditionally used carbon sources responsible for both quantity and quality of the biopolymer. Additionally, it is proven that commercial glycerol can be substituted with crude glycerol generated by a biodiesel industry, as a cheap alternative substrate. However, further research needs to be undertaken in order to determine the optimal process parameters for xanthan biosynthesis and to examine the success of application of novel producing strains. The utilisation of crude glycerol for biotechnological xanthan production could contribute significantly to solving ecological problems caused by discharge of effluents in the environment without adequate treatment.

References

Alves VD, Freitas F, Costa N, Carvalheira M, Oliveira R, Gonçalves MP, Reis MAM (2010) Effect of temperature on the dynamic and steady-shear rheology of a new microbial extracellular polysaccharide produced from glycerol byproduct. Carbohydr Polym 79(4):981–988

Alves VD, Ferreira AR, Costa N, Freitas F, Reis MAM, Coelhoso IM (2011) Characterization of biodegradable films from the extracellular polysaccharide produced by Pseudomonas oleovorans grown on glycerol byproduct. Carbohyd Polym 83(4):1582–1590

Assis DJ, Brandão LV, de Souza Costa LA, Figueiredo TVB, Sousa LS, Padilha FF, Druzian JI (2014) A study of the effects of aeration and agitation on the properties and production of xanthan gum from crude glycerin derived from biodiesel using the response surface methodology. Appl Biochem Biotechnol 172(5):2769–2785

Ayyalusamy S, Mishra S (2018) Optimization of preparation conditions for activated carbons from polyethylene terephthalate using response surface methodology. Braz J Chem Eng 35(3):1105–1116

Bajić BŽ, Vučurović DG, Dodić SN, Rončević ZZ, Grahovac JA, Dodić JM (2017) The biotechnological production of xanthan on vegetable oil industry wastewaters Part I: modelling and optimization. Chem Ind Chem Eng Quart 23(3):329–339

Bas D, Boyaci IH (2007) Modeling and optimization I: Usability of response surface methodology. J Food Eng 78(3):836–845

Becker A, Katzen F, Puhler A, Ielpi L (1998) Xanthan gum biosynthesis and application: a biochemical/genetic perspective. Appl Microbiol Biotechnol 50(2):145–152

Brandão LV, Assis DJ, López JA, Espiridião MCA, Echevarria EM, Druzian JI (2013) Bioconversion from crude glycerin by Xanthomonas campestris 2103: xanthan production and characterization. Braz J Chem Eng 30(4):737–746

Cadmus MC, Knutson Jr CA (1983) Production of high-pyruvate xanthan gum on synthetic medium. United States Patent, US-4394447-A

Carignatto CRR, Oliveira MKS, de Lima VMG, de Oliva NP (2011) New culture medium to Xanthan production by Xanthomonas campestris pv. campestris. Indian J Microbiol 51(3):283–288

Fan X, Burton R, Zhou Y (2010) Glycerol (Byproduct of Biodiesel Production) as a source for fuels and chemicals—mini review. Open Fuels Energy Sci J 3(1):17–22

Ferreira SLC, Bruns RE, Ferreira HS, Matos GD, David JM, Brandão GC, da Silva EGP, Portugal LA, dos Reis PS, Souza AS, dos Santos WNL (2007) Box-Behnken design: an alternative for the optimization of analytical methods. Anal Chim Acta 597(2):179–186

Flahive JJ III, Foufopoulos A, Etzel MR (1994) Alcohol precipitation of xanthan gum from pure solutions and fermentation broths. Sep Sci Technol 29(13):1673–1687

Freitas F, Alves VD, Pais J, Costa N, Oliveira C, Mafra L, Hilliou L, Oliveira R, Reis MAM (2009) Characterization of an extracellular polysaccharide produced by a Pseudomonas strain grown on glycerol. Biores Technol 100(2):859–865

Freitas F, Alves VD, Pais J, Carvalheira M, Costa N, Oliveira R, Reis MAM (2010) Production of a new exopolysaccharide (EPS) by Pseudomonas oleovorans NRRL B-14682 grown on glycerol. Process Biochem 45(3):297–305

Freitas F, Alves VD, Reis MAM (2011) Advances in bacterial exopolysaccharides: from production to biotechnological applications. Trends Biotechnol 29(8):388–398

García-Ochoa F, Santos VE, Casas JA, Gómez E (2000) Xanthan gum: production, recovery, and properties. Biotechnol Adv 18(7):549–5479

Giavasis I (2013) Production of microbial polysaccharides for use in food. In: McNeil B, Archer D, Giavasis I, Harvey L (eds) Microbial production of food ingredients, enzymes and nutraceuticals. Woodhead Publishing, Oxford

Gondim TS, Pereira RG, Fiaux SB (2019) Xanthan gum production by Xanthomonas axonopodis pv. mangiferaeindicae from glycerin of biodiesel in different media and addition of glucose, Acta Scientiarum. Biol Sci 41(1):1–8

Grahovac J, Grahovac M, Dodić J, Bajić B, Balaž J (2014) Optimization of cultivation medium for enhanced production of antifungal metabolites by Streptomyces hygroscopicus. Crop Prot 65(1):143–142

Hejna A, Kosmela P, Formela K, Piszczyk L, Haponiuk JT (2016) Potential applications of crude glycerol in polymer technology—current state and perspectives. Renew Sustain Energy Rev 66(1):449–475

Helrich K (1990) Official methods of analysis of the association of official analytical chemists, Fifteenth edn. Association of Official Analytical Chemists, Arlingron

Ibrahim HM, Elkhidir EE (2011) Response surface method as an efficient tool for medium optimisation. Trends Appl Sci Res 6(2):121–129

Konstantinović SS, Danilović BR, Ćirić JT, Ilić SB, Savić DS, Veljković VB (2016) Valorization of crude glycerol from biodiesel production. Chem Ind Chem Eng Quart 22(4):461–489

Li P, Li T, Zeng Y, Li X, Jiang X, Wang Y, Xie T, Zhang Y (2016) Biosynthesis of xanthan gum by Xanthomonas campestris LRELP-1 using kitchen waste as the sole substrate. Carbohyd Polym 151(1):684–691

Milas M, Rinaudo M, Tinland B (1985) The viscosity dependence on concentration, molecular weight and shear rate of xanthan solutions. Polym Bull 14(2):157–164

Moita R, Freches A, Lemos PC (2014) Crude glycerol as feedstock for polyhydroxyalkanoates production by mixed microbial cultures. Water Res 58(1):9–20

Palaniraj A, Jayaraman V (2011) Production, recovery and applications of xanthan gum by Xanthomonas campestris. J Food Eng 106(1):1–12

Pan C, Tan GYA, Ge L, Chen CL, Wang JY (2019) Two-stage microbial conversion of crude glycerol to 1,3-propanediol and polyhydroxyalkanoates after pretreatment. J Environ Manag 232(1):615–624

Quispe CAG, Corornado CJR, Carvalho JA Jr (2013) Glycerol: production, consumption, prices, characterization and new trends in combustion. Renew Sustain Energy Rev 27(1):475–493

Rahim MHA, Hasan H, Lim EJ, Samrani PK, Abbas A (2019) Pretreatment strategies to improve crude glycerol utilisation and metabolite production by Aspergillus terreus. Int J Chem Eng 2019(1):1–6

Rončević ZZ, Bajić BŽ, Grahovac JA, Dodić SN, Dodić JM (2014) Effect of the initial glycerol concentration in the medium on the xanthan biosynthesis. Acta Period Technol 45(1):239–246

Rončević Z, Bajić B, Dodić S, Grahovac J, Pajović-Šćepanović R, Dodić J (2019a) Optimization of bioethanol production from soybean molasses using different strains of Saccharomyces cerevisiae. Hemijska Industrija 73(1):1–12

Rončević Z, Grahovac J, Dodić S, Vučurović D, Dodić J (2019b) Utilisation of winery wastewater for xanthanproduction in stirred tank bioreactor: bioprocess modelling and optimisation. Food Bioprod Process 117(1):113–125

Rosalam S, England R (2006) Review of xanthan gum production from unmodified starches by Xanthomonas comprestris sp. Enzyme Microb Technol 39(2):197–207

Samul D, Leja K, Grajek W (2014) Impurities of crude glycerol and their effect on metabolite production. Ann Microbiol 64(1):891–898

Sutherland IW (2001) Microbial polysaccharides from Gram-negative bacteria. Int Dairy J 11(9):663–674

Tan HW, Abdul Aziz AR, Aroua MK (2013) Glycerol production and its applications as a raw material: a review. Renew Sustain Energy Rev 27(1):118–127

Thapa LP, Lee SJ, Yoo HY, Choi HS, Park C, Kim SW (2013) Development of glycerol-utilizing Escherichia coli strain for the production of bioethanol. Enzyme Microb Technol 53(3):206–215

Yamashita T, Yamamoto-Ikemoto R (2014) Nitrogen and phosphorus removal from wastewater treatment plant effluent via bacterial sulfate reduction in an anoxic bioreactor packed with wood and iron. Int J Environ Res Public Health 11(9):9835–9853

Yazdani SS, Gonzalez R (2007) Anaerobic fermentation of glycerol: a path to economic viability for the biofuels industry. Curr Opin Biotechnol 18(3):213–219

Acknowledgements

This study is the result of the research conducted within the projects TR 31002 and 451-03-68/2020-14/200134 funded by the Ministry of Education, Science and Technological Development of the Republic of Serbia.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rončević, Z., Bajić, B., Vlajkov, V. et al. Optimisation of xanthan production on glycerol-based medium using response surface methodology. Braz. J. Chem. Eng. 37, 617–627 (2020). https://doi.org/10.1007/s43153-020-00062-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43153-020-00062-6