Abstract

Loess is a large-scale deposit which is easy to mine and widely distributed on the epipedon. The clay fraction of loess, also known as ‘loessial clay’, is a very important component of loess which affects its properties and performance. From a ‘materials’ perspective, the clay fraction of loess has been ignored. Recently, loess particles have attracted interest because of their potential applications. The focus in the current review is on the methods of modifying loess particles and their application as functional materials. The major components of loess particles are clays, calcite, and quartz, with the clays including kaolinite, illite, montmorillonite, and chlorite. Loess has a range of particle sizes, types, and dispersibilities. The particles agglomerate readily, mainly because cementation occurs readily in the clay fraction. Loess particles can be modified and their properties can be improved by compaction, separation, purification, acidification, calcination, surfactant modification, geopolymerization, and polymer modification. Loess-based functional materials have been used as sorbents, eco-friendly superabsorbents, soil and water conservation materials, humidity-regulating materials, and building materials. Separated and purified loess particles can adsorb metal ions and harmful elements directly. Surfactant-modified loess particles can remove organic compounds effectively. After modification with polymers, loess particles exhibit greater capacity for the removal of environmental pollutants such as harmful metal ions and dyes. As a superabsorbent, modified loess shows excellent thermal stability and swelling behavior. Calcined loess could be utilized as an energy-saving building material with good humidity-regulating performance, and geological polymerization has further expanded the scope of applications of loess in architecture. In summary, loess-based functional materials, which are inexpensive and ecologically friendly, deserve more attention and further development.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

The term loess, meaning loose, was first used by von Leonhard (1823). In China, the properties of loess were understood >2000 years ago (Liu et al. 1985) when loess was referred to as ‘Huangtu’. Loess was defined by Pecsi (1990) as "a loose deposit with coarse silt predominant in grain size, unstratified, porous, permeable, stable in steep walls, easily erodible by water, 'structured light loam' of pale yellow color due to finely dispersed limonite (iron hydroxides), quartz as main mineral constituent (40–80%), subordinate feldspar content, variable amounts of clay minerals (5–20%), and carbonates (1–20%)." From a mineralogical perspective, loess, distributed mainly in the relatively dry mid-latitudes of the world which account for >10% of the global land area (Wang et al. 2018), is a typical granular inorganic deposit, composed predominantly of silt-sized particles in which quartz is the main mineral component, followed by silicoaluminate minerals such as clay minerals which have great influence on the properties of loess, and non-silicoaluminate minerals such as carbonates.

Loess was investigated by geologists and pedologists who focused mainly on its geological origin (Zhu 1991; Gong et al. 2015; Deng et al. 2019), distribution (Nie et al. 2015; Zhang et al. 2018), composition, and properties (Smalley 1995; Gong et al. 2016). Loess contains clay minerals which have a range of particle sizes, are of multiple types, and possess various dispersibilities. Loess particles agglomerate readily because cementation of clay occurs readily. The clay fraction of loess, referred to as ‘loessial clay’ or ‘clayey loess’, is, therefore, a very important component of loess because it affects the properties of the loess, including its collapsibility, swelling, and absorptivity. Historically, loessial clay has been mostly ignored for materials applications because its composition is complex. In recent decades, based on the research progress in nanomaterials and clays, the clay fraction of loess has received increasing attention because of its potential applications in the field of materials science. Recently, loess has been used in the manufacture of functional materials because it is widespread and an inexpensive natural inorganic material. The properties of loess can be improved significantly by effective modifications. The purpose of the present review was to summarize the classification, composition, and properties of loess particles; to describe the modification, preparation, and application of loess-based materials, and to explore the current research status and challenges of loess as a material in the hope of making suggestions for the further development of loess materials.

CLASSIFICATION, DISTRIBUTION, COMPOSITION, AND PHYSICOCHEMICAL PROPERTIES OF LOESS

Classification and Distribution

Loess can be classified from various perspectives. Using the geological and geographical classification, loess has been divided into plateau, intermontane basin, valley plain, anteriorly marginal zone, and high-mountain slope types. In genetic classification, loess can be divided into eluvial, slope, alluvial, eluvial-slope, slope-alluvial, alluvial-diluvial, eolian product, and glacial accumulation types (Zhang 1963). Both of these classifications are used frequently in the geological field. Loess can also be classified in terms of collapsibility (I), plasticity index (PI) (II), and particle size (III) (Fig. 1).

-

(I)

Loess has been divided into collapsible and non-collapsible types. The difference is the amount of soil subsidence due to water erosion (Fig. 1) (Derbyshire et al. 1995; Nouaouria et al. 2008). Collapsible loess refers to a special soil that is prone to subsidence deformation due to structural changes after water erosion (Derbyshire et al. 1995).

-

(II)

Soil is often classified by PI because it is an important characteristic that distinguishes clayey soils from sandy soils (Guggenheim and Martin 1995). The PI can reflect the grain size, mineral composition, and plasticity of soil. The larger the PI, the smaller the loess particle size, the larger the specific surface area, and the greater the clay content (Moreno-Maroto and Alonso-Azcárate 2018). The clay components are dominant in loess when PI > 20, while the amounts of sand and gravel are dominant when PI < 6 (Zhu 1995).

-

(III)

The size of most loess particles (LoPs) is between 0.01 and 50 μm, and only a small proportion of loess particles are outside this range. Loess particles may be divided into large loess particles (LLoPs), medium loess particles (MLoPs), and small loess particles (SLoPs) (Yan et al. 2020), and could be separated by a simple physical sedimentation method with particle sizes of 20–50, 10–20, and 0.01–10 μm, respectively. The SLoPs contain large amounts of clay, such as illite, kaolinite, montmorillonite, and chlorite.

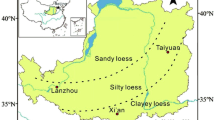

Loess is distributed widely around the world, covering an area of 1.3×107 km2 and comprises ~10% of the earth's land surface, including sections of central Asia, central Europe, the northwestern and central United States, Alaska, and South America (Porter 2007; Rousseau et al. 2007; Roberts et al. 2013). Extensive loess deposits appear to be a phenomenon of the Quaternary (Smalley 1966) and show a clear spatial relationship with areas of Pleistocene continental glaciation. Such deposits have been referred to as ‘glacial’ loess, ‘ice sheet’ loess, or ‘periglacial’ loess. Relatively restricted deposits of loess also occurred on the margins of some deserts in the form of “peridesert loess” (Smalley and Vita-Finzi 1968). Northwest China contains the largest loess plateau in the world with a thickness of >300 m near the city of Lanzhou in Gansu Province (Derbyshire 1983). The most extensive loess deposit (with an area of 6.2×105 km2) (Derbyshire et al. 1998) occurs in the Loess Plateau in China, referred to as “Huangtu Gaoyuan” in Chinese (Fig. 2) (Sun 2002; Zhao et al. 2016).

Composition

The composition of loess is complex and made up primarily of clay minerals, such as illite, kaolinite, smectite (montmorillonite), and chlorite, and non-clay minerals such as quartz, mica, calcite, and feldspar (Yi et al. 2017). Many kinds of loess clay particles exist with sizes of <4 μm (Deng et al. 2010). Taking a global perspective, loess displays significant natural variation in terms of thickness, grain size, color, mineralogy, geochemical composition, geotechnical characteristics, and morphology (Pye 1995). With the development of analytical technology, many methods have been used to study loess minerals qualitatively and quantitatively. Illite was found (Nouaouria et al. 2008) to be the primary clay mineral. Loess in the lower Mississippi Valley of the United States was found (Pye and Johnson 1988) to contain clay minerals illite, illite-smectite, kaolinite, and chlorite, and non-clay minerals quartz, calcite, and feldspars. Other loess formations, such as those in the Negev Desert of Israel, also contain illite, smectite, quartz, and calcite (Herut et al. 1999). In the Loess Plateau of China, the loessial clay minerals are mainly illite (Tang et al. 2008a, 2008b; Li et al. 2009a), consistent with compositions from other regions (Nouaouria et al. 2008). Other clay minerals present vary with the area (Iannuccelli et al. 2016).

The main clay-mineral assemblages in loess in various regions of the world are summarized in Table 1. In China, the clay-mineral compositions and properties of loess have been well studied. The clay mineral assemblages had obvious zonal characteristics (Shi et al. 2005). A comparative analysis of the composition based on XRD and the spatial distribution of clay minerals in five loess profiles (points) at various latitudes and climatic zones in China was done by Shi et al. (2005). From northwest to southeast China, the clay-mineral compositions change considerably with decreasing latitude. Though the compositions and morphologies are complex, the loess soil texture was suggested by Zhao et al. (2016) to be almost “homogeneous” across the Loess Plateau (LP) in China. But this “homogeneous soil texture" is not necessarily available in other locations around the world, e.g. in the Pannonia region of Croatia (Rubinic et al. 2014). It was also found that sand, silt, and clay contents varied slightly with increasing soil depths in the 0–500 cm soil layer (Zhao et al. 2016).

Structural elements in loess are conditioned by various physical-chemical processes which take place in the source areas, when the material is transported, and during its deposition and accumulation, and are related to the geological development and the paleogeographic/environmental conditions (Johnson and Willey 2000; Jiang et al. 2014). Because of the way it is generated, loess exhibits a complex grain-size distribution, macro-pores, and root-like channels (Chen et al. 2010). The basic unit in loess soils was found by Minervin and Komissarova (1979) to be the aggregate (0.01–0.1 mm), which has the shape of a concentric ellipsoidal globule. Clay minerals, followed by carbonate and salt, play a key role in the contact between structural elements in loess. The loess structure is conditioned by the clay content, because of the surface molecular forces. Having studied the microstructure of loess in central Spain, the loess was found (Garcia Gimenez et al. 2012) to consist of fine-sized aggregates accompanied by silts with small sand contents and variable clay contents which rarely surpass 30%.

Physicochemical Properties

The composition of the clay fraction in loess is complex. Clay minerals were found (Liu 1965) to affect the physical, chemical, and hydrologic properties of loess. These properties include strength, expansibility, permeability coefficient, plastic limit, liquid limit, and viscosity coefficient. The surface energies of clay minerals are very significant. Different clay minerals possess different surface energies and water-adsorbing abilities. Loess properties are often different, therefore.

From the viewpoints of geology and edaphology (Rollins and Rogers 1994; Gillijns et al. 2005; Wang et al. 2017), loess has a metastable structure, and can be collapsed by water. When loess is soaked with water under pressure, cementation between particles is lost, which is the main cause of collapsibility. The cement in sand loess was found (Zhang and Qu 2005) to be mainly clay minerals which attached to the surface of skeleton particles such as clastic particles or aggregates. The cation exchange capacity (CEC) of soils and clays is linked to their physical and mineral properties. The CEC of soils and clays can be determined rapidly by methylene blue exchange (Wang et al. 1996). The CEC of loess varies greatly among samples from different locations because of the different loess contents or types (Table 2). In addition, pH has an effect on the CEC because the dissociation of hydroxyl groups on the surface of clay particles was affected by the pH value of the medium. When the pH of the medium decreases, the negative charge on the surface of clay particles also decreases, and that, in turn, decreases the CEC (Coleman and Harward 1953).

METHODS OF MODIFICATION AND FUNCTIONALIZATION

Based on their special composition and physical-chemical properties, loess particles may be used for preparing functional materials, and a number of methods and technologies have been tested for the modification and functionalization of loess particles.

Separation and Purification of Loess Particles

Because of the complex composition of natural loess, it is still not used widely as a ‘material.’ Effective separation of the mineral components of loess poses a significant challenge.

In most cases, loess particles are separated by size before modification. Generally, loess particles within a specific size range are separated by the sedimentation method (Fan et al. 2017) or the suspension method (Yin et al. 2019). LoPs can be separated into three types and clay is the main component in SLoPs (~0.01–10 μm). Not surprisingly, SLoP was found (Meunier 2006) to contain significant quantities of clay minerals, with sizes ranging from a few micrometers to nanometers.

During determination of soil texture or separation of different particle size fractions of soil, hydrogen peroxide (H2O2) was used to remove organic matter (OM) (Martin 1954; Anderson, 1961), which was summarized by Taubner et al. (2009) and Zhang et al. (2017). This method has also been used to remove OM from the loess when studying the sorption behavior and mechanism of Pb(II) on Chinese loess (Li et al. 2009).

Acidification

Acidification is an effective way of improving the surface properties of clay minerals (Rampazzo and Blum 1991; Warren et al. 1992) as it can remove carbonates. For loess, acid activation with HCl solution could enlarge channels in loess particles as it can facilitate the disintegration of loess aggregates and eliminate carbonate and other impurities (Eren and Afsin 2007; Frini-Srasra and Srasra 2010). More clay minerals are exposed on the surface of loess (Yang et al. 2010), and the porosity and number of active centers are increased. After washing thoroughly with water, the protons are removed from the acid. Acid treatment can increase considerably the number of silanol groups on the surfaces of clay minerals, which improves their adsorptivities or catalytic properties (Lenarda et al. 2007; Yan et al. 2020).

The exposed hydroxyl groups can participate in various reactions resulting in surface modification and improved properties for the loess particles (Lu et al. 2017). The acid concentration should be moderate because silicate minerals can dissolve in very acidic solutions (Rampazzo and Blum 1991; Warren et al. 1992; Breen et al. 1995; Mu and Wang 2016).

Calcination

During calcination, most organic matter (OM), adsorbed water, interlayer water, and structural water are lost easily, which changes the adsorption capacity of the loess. This reduces water films during adsorption of pollutants, and accelerates the diffusion of adsorbate molecules because the water film is formed by the adsorbed water, which is removed in the calcining process. The removal of water and the creation of more pores accelerate the diffusion and fluidity of adsorbed molecules (Wang et al. 2014). Loess that was oven dried at 105°C for 24 h to remove bulk water was effective at removing Zn(II) from aqueous solutions (Tang et al. 2008a). After high-temperature calcination, water and most OM are lost, while the clay component and partial CaCO3 are decomposed. The specific surface area of the loess decreases and the particle sizes increase due to the agglomeration and bonding of the calcinated loess, which is caused by crosslinking reactions involving hydroxyl groups (Tang et al. 2009a; Trivedi et al. 2001; Nachtegaal and Sparks 2004).

Geopolymerization

Loess can be treated with soil stabilizers, such as ordinary portland cement (OPC) or lime (Arrua et al. 2012; Metelkova et al. 2012; Pei et al. 2015). Synthesis of conventional stabilizers consumes much energy and emits CO2, however. Geopolymers offer (Liu et al. 2016) a promising alternative to OPC because they can be synthesized from a variety of low-cost materials or industrial wastes such as metakaolin, fly ash, rice husk ash, and furnace slag (Cristelo et al. 2012; Posi et al. 2013; Zhang et al. 2013a; Deb et al. 2014).

Geopolymers are amorphous aluminosilicate-based polymers formed by alkaline activation of alumina-containing and silica-containing materials, a polycondensation process in which the tetrahedral silica (SiO4) and alumina (AlO4) are linked with one another through shared oxygen atoms (Majidi 2009). The raw materials are mainly rock-forming minerals of geological origin. Geopolymerization is a chemical process that rapidly transforms partially or totally amorphous aluminosilicate sources into three-dimensional polymeric networks (Duxson et al. 2007; Zhang et al. 2013a). Under strong alkaline conditions, aluminosilicates dissolve rapidly to release SiO4 and AlO4 tetrahedral units, and the polycondensation process is promoted (Davidovits 1994; Yip et al. 2005; Liew et al. 2016). The general formula of a geopolymer can be expressed as (Na,K)n[–(SiO2)q–AlO2–]n, where n represents the degree of polycondensation and q is the Si/Al ratio.

Loess was found by Mawulé Dassekpo et al. (2017) to consist essentially of silicon and aluminum. Both amorphous and crystalline materials are present in loess. Sodium silicate (Na2SiO3) solution and sodium hydroxide (NaOH) in pellet form have been used as alkali activators to break the original Si–O–Si and Si–O–Al bonds in loess. The broken bonds can be reformed, and subsequently create three-dimensional polymeric networks.

Modification by Surfactants

Loess particles can be modified with cationic, anionic, or anion-cation surfactants. The surfactant molecules are adsorbed on the surface or inserted into gaps in loess particles via ion exchange, ion-pair adsorption, and/or hydrophobic bonding. After modification by surfactants, the hydrophilicity of the modified loess changes and adsorptivity improves.

Using cationic surfactants, such as salts of organic quaternary ammonium ions [(CH3)3NR]+, the native exchangeable cations (H+ or Ca2+) in loess particles are replaced by the organic cations. Loess can be modified according to Chen et al. (2002) with hexadecyltrimethylammonium bromide (HDTMA+Br–), a typical cationic surfactant (Zhou et al. 2002; Wu et al. 2012), or with anionic surfactants such as sodium dodethylbenzene sulfonate (SDBS). Loess was treated (Meng et al. 2008) with the amphoteric modifier, duodalkylbetaine (BS-12). After modification, its adsorptivity toward contaminants was greatly enhanced.

Polymer Modification

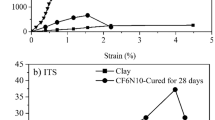

Surface modification of clay minerals is critical for the fabrication of new functional materials. The aforementioned surfactants have been used as organic agents for modifying loess. Most organics cause secondary pollution because they are easily lost during use, however. The synthesis of loess-based polymers via in situ polymerization was first reported by He et al. (2012). The polymer modification of loess particles has been the subject of more attention because polymers are easily functionalized and not subject to facile migration.

Many common functional monomers, such as acrylic acid (AA), hydroxyethyl methacrylate (HEMA), acrylamide (AM), sodium p-styrene sulfonate, and methyl methacrylate (MMA), can be used in polymerization to produce functional polymer-modified loess, according to Wang et al. (2015a). Various biocompatible monomers, such as itaconic acid (IA) and N-vinyl-2-pyrrolidone (NVP), are also used as functional monomers, for the creation of biocompatible polymer composite adsorbents (Shen et al. 2018). Biopolymers, such as chitosan (CS), sodium alginate, guar gum (GG), and xanthan gum (XG), have also been used to modify loess. Xanthan gum-g-poly(AA)/loess (XG-g-PAA/ loess) was synthesized successfully in aqueous solution by Feng et al. (2014). Loess was modified with cetyltrimethylammonium bromide (CTAB) (Wang et al. 2013) to create a structure that exhibited modified surface properties and increased the hydrophobicity of silicates, thereby changing the adhesion and dispersing performances of the loess in the polymer matrix. A superabsorbent composite, NaAlg-g-PAA/organo-loess, was prepared by Ma et al. (2015b) in which AA was grafted onto a sodium alginate (NaAlg) backbone in the presence of organo-loess.

Based on experience (Lu et al. 2017; Shen et al. 2018), typical modification reactions are as follows: first, the copolymers were reacted with loess using in situ polymerization, which formed loess copolymer composites (Fig. 3); second, a polymer was grafted onto natural polymers and reacted with loess (Fig. 4); and third, after surface modification with active monomers, the copolymer was grafted and formed a loess surface with a grafted copolymer (Fig. 5).

APPLICATION OF LOESS-BASED FUNCTIONAL MATERIALS

In ancient China, loess was used as a drug ingredient because it exhibited known medicinal properties in healthcare applications (Bae and Bae 2018; Lee 2018). For example, “Huangdi's Classic on Medicine,” a famous medical document of ancient China, recommended loess particles for detoxification. Few reports exist on the mechanisms of detoxification, however. Since the last century, the importance of loess in agriculture has been investigated (Catt 2001; Chen et al. 2007a, b; Fan 2015). Study of loess and the loess clay fraction in the field of functional materials has been inadequate because of the complexity of the material.

Recently, based on the research progress in nanomaterials, clays, and functional materials, clay particles from loess have been shown to be useful in preparing functional materials (He et al. 2012; Ma et al. 2015a, b).

Loess-based Adsorbing Materials

Because of its small particle size, large specific surface area, and the numerous hydroxyl groups (Si–OH) on its surface, the clay fraction of loess exhibits excellent adsorption performance. According to Wang et al. (2014), loess and modified loess can be used as low-cost and eco-friendly adsorbents for removing metal ions or organic compounds. These applications include uses in the food, medicine, and chemical industries, and in water-treatment processes.

Adsorption of Metal Ions

As an inexpensive raw material, loess has been used to remove heavy-metal ions such as Pb, Cu, Co, Zn, Ni, Fe, Mn, Hg, Cr, Cd, and Tl from aqueous solutions (Punrattanasin and Sariem 2015; Wang et al. 2015a), which could reduce greatly the cost of sewage treatment. Work by Tang et al. (2008a) found that loess, after oven drying at 105°C for 24 h to remove bulk water, was effective at removing Zn(II) from aqueous solutions, and that kaolinite and goethite were the major clays responsible for removal of Zn(II). After high-temperature calcination, the adsorption of Zn(II) on the calcined loess implied an ion exchange of the solute with calcite and goethite (Tang et al. 2009b). The ion-exchange reaction between calcite and Zn(II) is written as:

The goethite component was active for Zn(II) adsorption (Trivedi et al. 2001; Nachtegaal and Sparks 2004), and Zn(II) can form a complex with Fe-OH groups as follows:

Modified loess was proven to be effective in removing Cd(II) from landfill leachate (Yang et al. 2012), and its adsorption capacity for Cd(II) was determined to be 7.08 mg g–1. The adsorption of Pb(II) by loess and modified loess adsorbents has also been investigated. The differences in loess samples from various locations and subject to various modification technologies are compared, and their adsorption mechanisms are summarized (Table 3). The adsorption capacities of the loess particles varied with location, depth, pretreatment, and modification technologies. Red loess is found mainly in the south of China and contains more clay minerals than in the north of China. For aggregated globule loess particles, the hydrogen peroxide to remove OM breaks the aggregation state and exposes the surfaces of the clay minerals, which promotes greater ion adsorption. The adsorptivity of loess is also improved significantly by polymer modification. Clay minerals with effective diameter <1 μm (EDCM) extracted from various loessial soils showed a high capacity for Pb(II) sorption from aqueous solutions based on their large surface area, organic-matter content, mineralogical composition, and abundance of active functional groups. This means that loess-based adsorption materials are excellent candidates for the adsorption of heavy-metal ions and may help in assessing their potential risks in vulnerable ecosystems.

The adsorptivity by loess of radioactive elements, such as Am(III), 238Pu, 237Np, 134Cs, 60Co, Ce(III), and 85Sr, has also been studied (Huo et al. 2013). The CaCO3 and OM in loess were the main sites for the adsorption of Am(III). Carbonate also played an important role in the adsorption of 237Np.

Loess could be used as an adsorbent for the recovery of Li+ according to Kim et al. (2017) Loess exhibited greater selectivity for Li+ than for other cations (Ca2+, Mg2+, K+, and Na+) in seawater, and it is inexpensive.

Adsorption of Organics

Surfactant-modified loess was used to remove organic compounds. For example, after modification with hexadecyltrimethylammonium bromide (HDTMA+Br–), a typical cationic surfactant, loess adsorbed effectively organic compounds such as toluene (Zhan et al. 2005), 2,4-dichlorophenol, phenanthrene, and naphthalene (Zhou et al. 2002; Wu et al. 2012). The effectiveness of removal of organics was greater for loess treated with ionizable organic compounds, such as p-nitroaniline, benzoic acid (BA), 2,4-dinitrophenol (DNP) (Zhou et al. 2002), or chlorobenzene (Chen and Zhu 2006). The adsorption of aromatic anions on HDTMA-modified loess also increased significantly (Zhou et al. 2003). When multiple compounds existed simultaneously in the soil, competitive adsorption of the aromatic anions was observed (Zhou et al. 2003).

Following modification with anion-cation surfactants, the adsorptivity of loess for aqueous-phase neutral organic compounds (NOCs) (e.g. toluene) was enhanced. After modification with anionic surfactants, the hydrophilicity of the loess soil increased, but the adsorptivities for hydrophobic organic contaminants decreased. With modification using amphoteric agents, loess could adsorb hydrophilic and hydrophobic organic pollutants simultaneously (Chen et al. 2002). The modification of loess could decrease significantly the antagonistic effects of organic pollutants (phenol) if the loess was treated with the amphoteric modifier duodalkylbetaine (Meng et al. 2008).

Loess has the ability to remove pharmaceutical compounds and fungicides. The adsorption of tetracycline on loess surfaces decreased gradually with increasing natural cation concentration in solution (Wu et al. 2008). The adsorption capacity of loess could be improved by adding organic modifiers (Filipe et al. 2010). Cationic surfactant-modified loess could be used to adsorb antibiotic pharmaceutical compounds, according to Thiele (2000). Modified loess had a greater ability to adsorb bensulfuron-methyl than did the unmodified version. For example, loess-based nanocomposite adsorbent was used to remove malachite green (MG) dye from wastewater, and a removal percentage of 80% was achieved (Heydartaemeh et al. 2017). Loess-based copolymer composites (L/CoPolym) (Wang et al. 2015b) and loess surface-grafted copolymers (Lu et al. 2017) showed large adsorptivities for removing basic fuchsin in aqueous solution, with removal rates of 98.2 and 98.4%, respectively.

Other Environmental Pollution Treatments

Loess has been used to prevent acid-mine drainage and to control heavy-metal contamination within in situ treatment systems. This was important because acid-mine drainage is very acidic, contains sulfates and metals, and constitutes a serious environmental problem in coal-mining areas in developing countries (Ma et al. 2012). Results from Zhao et al. (2012) indicated that loess raised the pH of the coal acid waste significantly and removed some of the SO42– minerals. Loess was also used for removing pollutants found in landfill leachate. For example, NH4+-N, a significant pollutant, could be removed effectively by loess (Xie et al. 2017), with an adsorptivity of 72.30 mg g–1 (predicted by the Langmuir model).

In natural water bodies, phosphates (HPO42–and H2PO4–) are the dominant form of P in nutrient pollution. The adsorption affinity of phosphate for modified and unmodified loess specimens with metal ions (ZnII, CuII, and PbII) was explored by Li et al. (2009b). Adsorptivities of phosphorus for the three adsorbents were >35, >19.4, and >71.8 mg g–1, respectively, while that for the original loess was >3.32 mg g–1. The removal rate for total phosphorus (TP) in municipal wastewater was 93.1% (Park and Jung 2011), using loess with a particle size of ≤45 μm. Three inexpensive substrates, including loess, cinder, and limestone, were used by Guan et al. (2009) to construct a wetland. They found that the average TP-removal rate was 41%. In addition to pore adsorption, chemical adsorption such as hydrogen bonding due to the large amount of clay in loess of particle size ≤45 μm was observed. This was also demonstrated by the adsorption process conforming to a pseudo-second order kinetics model. Work by Drizo et al. (1999) considered integrated multiple effects in TP removal, such as adsorption, precipitation, and growth of microorganisms. Loess could remove As from aqueous solutions, according to Rukh et al. (2017).

In summary, loess has been used widely as an adsorption and separation material for removing metal ions or organic compounds. The material is economical and environmentally friendly and is proven to be appropriate for the treatment of wastewater and landfill leachate.

Superadsorbent Composites for Water-retaining Materials

Superadsorbents, water-adsorbing and retaining materials, are used widely in fields such as drug delivery, agriculture, hygiene products, and wastewater treatment. Loess content was found by Chen and Peng (2018) to affect the swelling and water-retention capabilities because of the presence of many hydroxyl groups on the surfaces of loess particles. The lattice of the clay crystallite is, typically, disrupted at the edges, and a broken bond surface is exposed. Additional polar sites at the broken edges are mainly the octahedral Al–OH and tetrahedral Si–OH groups, which improve the swelling properties and reduce the cost of superadsorbents. For example, a superadsorbent composite, NaAlg-g-PAA/organo-loess, exhibited significant swelling properties (Ma et al. 2015b). Its maximum equilibrium water adsorption rates (when incorporated with 10 wt.% organo-loess) in distilled water and 0.9 wt.% NaCl aqueous solution were 656 and 69 g g–1, respectively. The use of organo-loess clearly improves the swelling properties and reduces the cost as a result of the increased quantity of loess in the superadsorbent. In superadsorbents, the addition of loess is conducive to expansion because of the following two points: first, the loess-based superadsorbent is porous with an increased specific surface area, which is conducive to contact with water and promotes the swelling of the polymer; and second, the small particles of clay (such as illite, kaolinite, montmorillonite) in loess exhibit good hydrophilicities, which enables them to swell in water.

Superadsorbent materials can also alleviate the pressure caused by water shortage and change the process of rainfall runoff. A low-cost and environmentally friendly GG-g-PAA/loess composite was prepared by Ma et al. (2015a) for chemical sand-fixing. The sand-fixing results imply that it has significant potential for the control of desertification, with a comprehensive array of benefits (soil-erosion prevention, redistribution of soil water and temperature, maintenance of fertility, and synergy between superabsorbent polymers and plants), thereby ensuring socioeconomic and ecological sustainabilities in dryland systems (Cao et al. 2017).

Humidity-Regulating Materials

The calcination of loess results in a tough mesoporous material synthesized without additives, and tobermorite formation was found to exert a positive effect on strength and porosity (Zhang et al. 2013b). In addition, mesopores exerted a positive influence on the humidity-regulating performance of the material derived from loess (Fig. 6) (Zhang et al. 2013b). In order to confirm the effect of the pore dimensions on humidity regulation, Lan et al. (2017) observed that the effective humidity-regulating performance of materials depends heavily on their pore dimensions (3.5–7.1 nm) (Fig. 7). From the reported results, the self-regulating humidity performance could be improved by decreasing the pore dimensions of the loess.

a Mesopore-size distribution curves calculated by the Barrett-Joyner-Halenda equation using N2 gas desorption isotherms for RL (squares), CL (triangles), and HCL (circles); b weight changes of RL (squares), CL (triangles), HCL (circles), and common brick (pentagons) during the measurement period at 33−75% relative humidity (RH) at 25°C for 48 h. [RL: raw loess, CL: calcined loess, HCL: hydrothermally synthesized calcined loess] (Zhang et al. 2013b)

a Pore-size distributions of the materials with various average pore diameters; and b water-vapor adsorption/desorption capabilities of materials (S1–S7) measured at RH values of 33% and 75% at 25°C for 48 h (Lan et al. 2017)

Building Materials

Loess has been used as a building material and a study by Lu et al. (2010) found that the effective regulation of humidity might result in energy savings. Loess cannot be used directly as a building material, however, because of its limitations in terms of strength, durability, and workability. To develop green materials for civil engineering applications, Liu et al. (2016) used loess for preparing geopolymers. Those authors found that it has potential applications in loess soil stabilization, such as for the subgrade, subbase, or base in pavements.

A loess paste was prepared (by means of geopolymerization of loess in alkali solutions – a new binding material) and tested by Kim et al. (2011). The potential use of loess to activate a geopolymerization reaction was investigated by Mawulé et al. (2017) who identified optimal ratios for a combination of fly ash with loess in the development of a new geopolymer material, and provided a green alternative to Portland cement, with considerable economic savings. In addition, the small clay content in most loess deposits was suggested by Smalley and Markovic (2019) to make loess an ideal material for brick production. Loess could also be made into loess-solidified compacted brick (Lv et al. 2019) and could be used in eco-friendly composite panels for buildings (Yoo and Cho 2019) and to fabricate artificial marble (Chung et al. 2011). These characteristics suggest potential for loess-geopolymers in civil engineering applications.

CHALLENGES AND FUTURE PERSPECTIVES

Although loess has a long history of research, limited studies have been performed on loess particles for materials applications. Overcoming the following challenges is, therefore, imperative for the efficient use of loess materials:

-

Loess particles are a kind of granular material, in which the clay fraction has multi-scale, multi-type, and multi-dispersion characteristics, unlike ordinary clay minerals. The particle sizes range from a few micrometers to nanometers. To date, relatively few systematic studies of the clay fraction of loess have been carried out, e.g. its composition and distribution are not understood clearly. Further research and development of clay resources from loess are needed.

-

Loess contains a variety of mineral components. In practical applications, the identification of the mineral that plays the key role in loess particles needs to be determined.

-

In loess particles, the relationship between its composition, structure, particle size and function, and the effective use of this synergy in applications need to be studied.

-

Simple and effective green separation methods need to be explored.

CONCLUSIONS

Loess particles have a range of particle sizes, types, and various dispersibilities. In loess particles, the major components of the clay fraction are illite, kaolinite, montmorillonite, and chlorite. Cementation of the clay fraction is straightforward, which affects its properties, such as collapsibility, swelling, and adsorptivity. Following separation and purification, loess particles can be modified by physical or chemical methods, such as acidification, calcination, geopolymerization, or treatment with surfactants or polymers, which produce loess-based functional materials. These can be used as adsorbents, eco-friendly superabsorbents, soil and water conservation materials, humidity self-regulating materials, and building materials, and the clay fraction plays a very important role in these functional materials. In summary, loess-based functional materials, which are inexpensive and eco-friendly, deserve more attention and further development.

References

Anderson, J. U. (1961). An improved pretreatment for mineralogical analysis of samples containing organic matter. Clays and Clay Minerals, 10, 380–388.

Arrua, P., Aiassa, G., & Eberhardt, M. (2012). Loess soil stabilized with cement for civil engineering applications. International Journal of Earth Sciences Engineering, 5, 10–17.

Bae, J. S. & Bae, J. M. (2018). Manufacturing method of environmentally friendly loess board. Korea, KR 1859442 B1 20180523.

Breen, C., Madejová, J., & Komadel P. (1995). Correlation of catalytic activity with infrared, Si MAS NMR and acidity data for acid-treated fine fractions of montmorillonites. Pp. 202–203 in: Clay and Clay Material Sciences , Proceedings Euroclay’95, Leuwen (A. Elsen, P. Grobet, M. Keung, H. Lehman, R. Schoonheydt, and H. Toufar, editors). Springer.

Cao, Y. B., Wang, B. T., Guo, H. Y., Xiao, H. J., & Wei, J. J. (2017). The effect of super absorbent polymers on soil and water conservation on the terraces of the loess plateau. Ecological Engineering, 102, 270–279.

Catt, J. A. (2001). The agricultural importance of loess. Earth-Science Reviews, 54, 213–229.

Chen, C. H., & Zhu, K. (2006). Effects of CTMAB on adsorption of chlorobenzene onto loess soil. Journal of Lanzhou Jiaotong University, 25(6), 112–115.

Chen, X. M., & Peng, Y. J. (2018). Managing clay minerals in froth flotation—A critical review. Mineral Processing and Extractive Metallurgy Review, 39, 289–307.

Chen, H., Yang, R. Q., Zhu, K., Zhou, W. J., & Jiang, M. (2002). Attenuating toluene mobility in loess soil modified with anion-cation surfactants. Journal of Hazardous Materials, 94, 191–201.

Chen, L. D., Wei, W., Fu, B. J., & Lu, Y. H. (2007a). Soil and water conservation on the Loess Plateau in China: Review and perspective. Progress in Physical Geography – Earth and Environment, 31, 389–403.

Chen, H., Zhao, Y. G., & Wang, A. Q. (2007b). Removal of Cu(II) from aqueous solution by adsorption onto acid-activated palygorskite. Journal of Hazardous Materials, 149, 346–354.

Chen, T. H., Xie, Q. Q., Xu, H. F., Chen, J., Ji, J. F., Lu, H. Y., & Balsam, W. (2010). Characteristics and formation mechanism of pedogenic hematite in quaternary Chinese loess and paleosols. Catena, 81, 217–225.

Chung, D. C., Rha, D. C., & Park, E. S. (2011). Composite solid surface article containing loess, US 7875668B2, 20110125.

Coleman, N., & Harward, M. E. (1953). The heats of neutralization of acid clays and cation-exchange resins. Journal of the American Chemical Society, 75, 6045–6046.

Cristelo, N., Glendinning, S., Fernandes, L., & Pinto, A. T. (2012). Effect of calcium content on soil stabilisation with alkaline activation. Construction and Building Materials, 29, 167–174.

Davidovits J., (1994). High-alkali cements for 21st century concretes. Pp. 383–398 in: Concrete Technology, Past, Present and Future (P.K. Metha, editor). Farmington Hills: American Concrete Institute, 144.

Deb, P. S., Nath, P., & Sarker, P. K. (2014). The effects of ground granulated blast-furnace slag blending with fly ash and activator content on the workability and strength properties of geopolymer concrete cured at ambient temperature. Materials & Design, 62, 32–39.

Deng, J., Wang, L. M., Zhang, Z. Z., & Bing, H. (2010). Microstructure characteristics and forming environment of late Quaternary Period loess in the Loess Plateau of China. Environmental Earth Sciences, 59, 1807–1817.

Deng, C., Hao, Q., Guo, Z., & Zhu, R. (2019). Quaternary integrative stratigraphy and timescale of China. Science China-Earth Sciences, 62, 324–348.

Derbyshire, E. (1983). Origin and characteristics of some Chinese loess at two locations in China. Developments in Sedimentology, 38, 69–90.

Derbyshire, E., Meng, X., & Kemp, R. A. (1998). Provenance, transport and characteristics of modern aeolian dust in western Gansu Province, China, and interpretation of the Quaternary loess record. Journal of Arid Environments, 39, 497–516.

Derbyshire, E., Meng, X. M., Wang, J. T., Zhou, Z. Q., & Li, B. X. (1995). Collapse loess on the loess plateau of China. Genesis and Properties of Collapsible Soils, 267–293.

Drewnik, M., Skiba, M., Szymanski, W., & Zyla, M. (2014). Mineral composition vs. soil forming processes in loess soils – A case study from Kraków (Southern Poland). Catena, 119, 166–173.

Drizo, A., Frost, C. A., Grace, J., & Smith, K. A. (1999). Physico-chemical screening of phosphate-removing substrates for use in constructed wetland systems. Water Research, 33, 3595–3602.

Duxson, P., Fernández-Jiménez, A., Provis, J. L., Lukey, G. C., Palomo, A., & Van Deventer, J. S. J. (2007). Geopolymer technology: The current state of the art. Journal of Materials Science, 42, 2917–2933.

Eren, E., & Afsin, B. (2007). Investigation of a basic dye adsorption from aqueous solution onto raw and pre-treated sepiolite surfaces. Dyes and Pigments, 73, 162–167.

Fan, X. L. (2015). Soil water, fertility and sustainable agricultural production in arid and semiarid regions on the Loess Plateau. Journal of Plant Nutrition and Soil Science, 163, 107–113.

Fan, C. H., Du, B., Zhang, Y. C., Ding, S. L., Gao, Y. L., & Chang, M. (2017). Adsorption of lead on organo-mineral complexes isolated from loess in Northwestern China. Journal of Geochemical Exploration, 176, 50–56.

Feng, E. K., Ma, G. F., Wu, Y. J., Wang, H. P., & Lei, Z. Q. (2014). Preparation and properties of organic-inorganic composite superabsorbent based on xanthan gum and loess. Carbohydrate Polymers, 111, 463–468.

Filipe, O. M. S., Vidal, M. M., Scherer, H. W., Schneider, R. J., Duarte, A. C., Esteves, V. I., & Santos, E. B. H. (2010). Effect of long term organic amendments on adsorption-desorption of thiram onto a luvisol soil derived from loess. Chemosphere, 80, 293–300.

Frini-Srasra, N., & Srasra, E. (2010). Acid treatment of south Tunisian palygorskite: removal of Cd(II) from aqueous and phosphoric acid solutions. Desalination, 250, 26–34.

García Gimenez, R., Vigil de la Villa Mencía, R., & Gonzalez Martín, J. A. (2012). Characterization of loess in central Spain: a microstructural study. Environmental Earth Sciences, 65, 2125–2137.

Gillijns, K., Poesen, J., & Deckers, J. (2005). On the characteristics and origin of closed depressions in loess-derived soils in Europe — a case study from central Belgium. Catena, 60, 43–58.

Godderis, Y., Williams, J. Z., Schott, J., Pollard, D., & Brantley, S. L. (2010). Time evolution of the mineralogical composition of Mississippi Valley loess over the last 10 kyr: Climate and geochemical modeling. Geochimica et Cosmochimica Acta, 74, 6357–6374.

Gong, H., Zhang, R., Yue, L., Zhang, Y., & Li, J. (2015). Magnetic fabric from red clay sediments in the Chinese Loess Plateau. Scientific Reports, 5, 9706.

Gong, H., Nie, J., Wang, Z., Peng, W., Zhang, R., & Zhang, Y. A. (2016). Comparison of zircon U-Pb age results of the Red Clay sequence on the central Chinese Loess Plateau. Scientific Reports, 6, 29642.

Guan, B. H., Yao, X., Jiang, J. H., Tian, Z. Q., An, S. Q., Gu, B. H., & Cai, Y. (2009). Phosphorus removal ability of three inexpensive substrates: Physicochemical properties and application. Ecological Engineering, 35, 576–581.

Guggenheim, S., & Martin, R. T. (1995). Definition of clay and clay mineral: joint report of the AIPEA nomenclature and CMS nomenclature committees. Clays and Clay Minerals, 43, 255–256.

He, Y. F., Zhang, L., Wang, R. M., Li, H. R., & Wang, Y. (2012). Loess clay based copolymer for removing Pb(II) ions. Journal of Hazardous Materials, 227–228, 334–340.

Herut, B., Zohary, T., Robarts, R. D., & Kress, N. (1999). Adsorption of dissolved phosphate onto loess particles in surface and deep eastern Mediterranean water. Marine Chemistry, 64, 253–265.

Heydartaemeh, M. R., Aslani, S., & Doulati, A. F. (2017). Loess soil nanoparticles as a novel adsorbent for adsorption of green malachite dye. Journal of Chromatography & Separation Techniques, 8, 2157–7064.

Huo, L. J., Qian, T. W., Hao, J. T., & Zhao, D. Y. (2013). Sorption and retardation of strontium in saturated Chinese loess: experimental results and model analysis. Journal of Environmental Radioactivity, 116, 19–27.

Iannuccelli, V., Maretti, E., Sacchetti, F., Romagnoli, M., Bellini, A., Truzzi, E., Miselli, P., & Leo, E. (2016). Characterization of natural clays from Italian deposits with focus on elemental composition and exchange estimated by EDX analysis: potential pharmaceutical and cosmetic uses. Clays and Clay Minerals, 64, 719–731.

Jiang, M. J., Zhan, F. G., Hu, H. J., Cui, Y. J., & Peng, J. B. (2014). Structural characterization of natural loess and remolded loess under triaxial tests. Engineering Geology, 181, 249–260.

Johnson, W. C., & Willey, K. L. (2000). Isotopic and rock magnetic expression of environmental change at the Pleistocene-Holocene transition in the central Great Plains. Quaternary International, 67, 89–106.

Karathanasis, A. D., & Colrick, P. A. (1991). Soil formation on loess/sandstone toposequences in west-central Kentucky: morphology and physicochemical properties. Soil Science, 152, 14–24.

Kim, B., Choi, H., Kang, K., & Yi, C. (2011). Characteristics of natural loess (hwangtoh) paste subjected to geopolymerization. Journal of the Korea Concrete Institute, 23, 121–127.

Kim, D., Choi, J. H., Hong, Y. P., & Ryoo, K. S. (2017). Use of loess as adsorbent for recovery of Li+ from seawater. Bulletin of the Korean Chemical Society, 38, 5–11.

Lan, H. R., Jing, Z. Z., Li, J., Miao, J. J., & Chen, Y. Q. (2017). Influence of pore dimensions of materials on humidity self-regulating performances. Materials Letters, 204, 23–26.

Lee, J. H. (2018). Method for manufacturing functional yellow clay board containing red ginseng ingredient beneficial for human body. Korea, KR 1850750 B1 20180531.

Lenarda, M., Storaro, L., Talon, A., Moretti, E., & Riello, P. (2007). Solid acid catalysts from clays: preparation of mesoporous catalysts by chemical activation of metakaolin under acid conditions. Journal of Colloid and Interface Science, 311, 537–543.

von Leonhard, C. C. (1823). Ungleichartige Gesteine (pp. 356–359). Sbst. Rezension.

Li, Z., Tang, Z., Chen, X. W., & Y. M., & Wang, Y. (2009a). Sorption behavior and mechanism of Pb(II) on Chinese loess. Journal of Environmental Engineering, 135, 58–67.

Li, Z., Tang, Z., Chen, X. W., & Wang, Y. (2009b). Behaviour and mechanism of enhanced phosphate sorption on loess modified with metals: equilibrium study. Journal of Chemical Technology and Biotechnology, 84, 595–603.

Liew, Y. M., Heah, C. Y., Mohd, M. A. B., & Kamarudin, H. (2016). Structure and properties of clay-based geopolymer cements: a review. Progress in Materials Science, 83, 595–629.

Liu, D. S. (1965). Loess deposits in China (pp. 143–150). Science Press.

Liu, D. S., An, Z. S., & Yuan, B. Y. (1985). Loess and dust in China. Quaternary Studies in China, 6, 113–125.

Liu, Z., Cai, C. S., Liu, F. Y., & Fan, F. H. (2016). Feasibility study of loess stabilization with fly ash-based geopolymer. Journal of Materials in Civil Engineering, 28, 04016003.

Lu, L., Jing, Z., Wang, Z., Pan, X., & Ishida, E. H. (2010). Hydrothermal synthesis of loessial mesoporous materials. AIP Conference Proceedings, 1251, 308–311.

Lu, T. J., Wang, L., He, Y. F., Chen, J., & Wang, R. M. (2017). Loess surface grafted functional copolymer for removing basic fuchsin. RSC Advances, 7, 18379–18383.

Lv, Q. F., Xiang, J. R., He, J. F., Yu, J. J., Li, C. C., Pan, S. J., & Wang, Z. H. (2019) Preparation of loess solidified compacted brick. Patent of China. CN 109320147 A 20190212.

Ma, B. G., Wang, H. Y., Gao, R., & Li, S. L. (2012). Effect of loess for preventing contamination of acid mine drainage from coal waste. Journal of Coal Science and Engineering, 18, 302–306.

Ma, G. F., Feng, E. K., Ran, F. T., Dong, Z. B., & Lei, Z. Q. (2015a). Preparation and sand-fixing property of a novel and eco-friendly organic-inorganic composite. Polymer-Plastics Technology and Engineering, 54, 703–710.

Ma, G. F., Ran, F. T., Yang, Q., Feng, E. K., & Lei, Z. Q. (2015b). Eco-friendly superabsorbent composite based on sodium alginate and organo-loess with high swelling properties. RSC Advances, 5, 53819–53828.

Majidi, B. (2009). Geopolymer technology, from fundamentals to advanced applications: A review. Advanced Materials Technologies, 24, 79–87.

Martin, R. T. (1954). Calcium oxalate formation in soil from hydrogen peroxide treatment. Soil Science, 77, 143–145.

Mawulé Dassekpo, J. B., Zha, X. X., & Zhan, J. P. (2017). Synthesis reaction and compressive strength behavior of loess-fly ash based geopolymers for the development of sustainable green materials. Construction and Building Materials, 141, 491–500.

Meng, Z. F., Zhang, Y. P., & Zhang, Z. Q. (2008). Simultaneous adsorption of phenol and cadmium on amphoteric modified soil. Journal of Hazardous Materials, 159, 492–498.

Metelkova, Z., Bohac, J., Prikryl, R., & Sedlarova, I. (2012). Maturation of loess treated with variable lime admixture: Pore space textural evolution and related phase changes. Applied Clay Science, 61, 37–43.

Meunier, A. (2006). Why are clay minerals small? Clay Minerals, 41, 551–566.

Minervin, A. V., & Komissarova, N. N. (1979). The structural and textural development of subsiding loess soils of the Minusinks intermontane depression. Engineering Geology, 2, 1–10.

Moreno-Maroto, J. M., & Alonso-Azcárate, J. (2018). What is clay? A new definition of “clay” based on plasticity and its impact on the most widespread soil classification systems. Applied Clay Science, 161, 57–63.

Mu, B., & Wang, A. Q. (2016). Adsorption of dyes onto palygorskite and its composites: A review. Journal of Environmental Chemical Engineering, 4, 1274–1294.

Nachtegaal, M., & Sparks, D. L. (2004). Effect of iron oxide coatings on zinc sorption mechanisms at the clay-mineral/water interface. Journal of Colloid and Interface Science, 276, 13–23.

Nie, J. S., Stevens, T., Rittner, M., Stockli, D., Garzanti, E., Limonta, M., Bird, A., Andò, S., Vermeesch, P., Saylor, J., Lu, H. Y., Breecker, D., Hu, X. F., Liu, S. P., Resentini, A., Vezzoli, G., Peng, W. B., Carter, A., Ji, S. C., & Pan, B. T. (2015). Loess plateau storage of Northeastern Tibetan Plateau-derived Yellow River sediment. Nature Communication, 6, 8511.

Nouaouria, M. S., Guenfoud, M., & Lafifi, B. (2008). Engineering properties of loess in Algeria. Engineering Geology, 99, 85–90.

Park, J. H., & Jung, D. I. (2011). Removal of total phosphorus (TP) from municipal wastewater using loess. Desalination, 269, 104–110.

Pecsi, M. (1990). Loess is not just accumulation of airborne dust. Quaternary International, 7, 1–21.

Pei, X. J., Zhang, F. Y., Wu, W. J., & Liang, S. Y. (2015). Physicochemical and index properties of loess stabilized with lime and fly ash piles. Applied Clay Science, 114, 77–84.

Porter, S. C. (2007). Loess records: China. Pp. 1439–1440 in: Encyclopedia of Quaternary Science (A. E. Scott, editor). Elsevier, UK.

Posi, P., Teerachanwit, C., Tanutong, C., Limkamoltip, S., Lertnimoolchai, S., Sata, V., & Chindaprasirt, P. (2013). Lightweight geopolymer concrete containing aggregate from recycle lightweight block. Materials & Design, 52, 580–586.

Pospisilova, L., Uhlk, P., Mensik, L., Hlisnikovsky, L., Eichmeier, A., Horakova, E., & Vlcek, V. (2020). Clay mineralogical composition and chemical properties of Haplic Luvisol developed on loess in the Protected Landscape Area Litovelské Pomoraví. European Journal of Soil Science, 1–15. https://doi.org/10.1111/ejss.13041.

Punrattanasin, P., & Sariem, P. (2015). Adsorption of copper, zinc, and nickel using loess as adsorbent by column studies. Polish Journal of Environmental Studies, 24, 1259–1266.

Pye, K. (1995). The nature, origin and accumulation of loess. Quaternary Science Reviews, 14, 653–667.

Pye, K., & Johnson, R. (1988). Stratigraphy, geochemistry and thermoluminescence ages of Lower Mississippi Valley Loess. Earth Surface Processes and Landforms, 13, 103–124.

Rampazzo, N. & Blum, W.E.H. (1991). Decrease of layer charge in 2:1 clay minerals through soil acidification, Malatya-Hekimhan province, Eastern Turkey. pp. 863–864 in: Proceedings 7th Euroclay Conference.

Roberts, H. M., Muhs, D. R., & Bettis, E. A. (2013). Loess records| North America. pp. 60–628 in: Encyclopedia of Quaternary Science. Elsevier, Amsterdam.

Rollins, K. M., & Rogers, G. W. (1994). Mitigation measures for small structures on collapsible alluvial soils. Journal of Geotechnical Engineering, 120, 1533–1553.

Rousseau, D. D., Derbyshire, E., Antoine, P., & Hatté, C. (2007). Loess records: Europe, Pp. 1440–1456 in: Encyclopedia of Quaternary Science (S.A. Elias, editor). Elsevier.

Rubinic, V., Durn, G., sHusnjak, S., & Tadej, N. (2014). Composition, properties and formation of Pseudogley on loess along a precipitation gradient in the Pannonian region of Croatia. Catena, 113, 138–149.

Rukh, S., Akhtar, M. S., Mehmood, A., Hassan, S., Khan, K. S., Naqvi, S. M. S., & Imran, M. (2017). Arsenate and arsenite adsorption in relation with chemical properties of alluvial and loess soils. Journal of the Serbian Chemical Society, 82, 943–954.

Shen, Y., Wang, Q. Q., Wang, Y., He, Y. F., Song, P. F., & Wang, R. M. (2018). Itaconic copolymer modified loess for high-efficiently removing copper ions from wastewater. Journal of Dispersion Science and Technology, 40, 794–801.

Shi, Y. X., Dai, X. R., Song, Z. G., Zhang, W. G., & Wang, L. Q. (2005). Characteristics of clay mineral assem blages and their spatial distribution of Chinese loess in different clmiatic zones. Acta Sedimentation Sinica, 23, 690–695.

Smalley, I. J. (1966). The properties of glacial loess and the formation of loess deposits. Journal of Sedimentary Petrology, 36, 669–676.

Smalley, I. J. (1995). Making the material: The formation of silt sized primary mineral particles for loess deposits. Quaternary Science Reviews, 14, 645–651.

Smalley, I., & Markovic, S. B. (2019). Controls on the nature of loess particles and the formation of loess deposits. Quaternary International, 502, 160–164.

Smalley, I. J., & Vita-Finzi, C. (1968). The formation of fine particles in sandy deserts and the nature of desert' loess. Journal of Sedimentary Petrology, 38, 766–774.

Sun, J. M. (2002). Provenance of loess material and formation of loess deposits on the Chinese Loess Plateau. Earth and Planetary Science Letters, 203, 845–859.

Tang, X. W., Li, Z. Z., & Chen, Y. M. (2008a). Behaviour and mechanism of Zn(II) adsorption on Chinese loess at dilute slurry concentrations. Journal of Chemical Technology and Biotechnology, 83, 673–682.

Tang, X. W., Zhen, Z. L. I., Chen, Y. M., & Wang, Y. (2008b). Removal of Cu(II) from aqueous solution by adsorption on Chinese quaternary loess: kinetics and equilibrium studies. Environmental Letters, 43, 779–791.

Tang, X., Li, Z., Chen, Y., & Wang, Z. (2009a). Removal of Zn(II) from aqueous solution with natural Chinese loess: Behaviors and affecting factors. Desalination, 249, 49–57.

Tang, X. W., Li, Z. Z., & Chen, Y. M. (2009b). Adsorption behavior of Zn(II) on calcinated Chinese loess. Journal of Hazardous Materials, 161, 824–834.

Taubner, H., Roth, B., & Tippkotter, R. (2009). Determination of soil texture: Comparison of the sedimentation method and the laser-diffraction analysis. Journal of Plant Nutrition and Soil Science, 172, 161–171.

Thiele, S. (2000). Adsorption of the antibiotic pharmaceutical compound sulfapyridine by a long-term differently fertilized loess chernozem. Journal of Plant Nutrition and Soil Science, 163, 589–594.

Trivedi, P., Axe, L., & Tyson, T. A. (2001). An analysis of zinc sorption to amorphous versus crystalline iron oxides using XAS. Journal of Colloid and Interface Science, 244, 230–238.

Wang, M. K., Wang, S. L., & Wang, W. M. (1996). Rapid estimation of cation-exchange capacities of soils and clays with methylene blue exchange. Soil Science Society of America Journal, 60, 138–141.

Wang, J. T., Wang, Q., Zheng, Y. A., & Wang, A. Q. (2013). Synthesis and oil absorption of poly (butylmethacrylate)/organo-attapulgite nanocomposite by suspended emulsion polymerization. Polymer Composites, 34, 274–281.

Wang, Y., He, Y. F., Wang, L., Huang, Y. J., & Wang, R. M. (2014). Application in wastewater treatment of loess clay and its modification. Technology of Water Treatment, 40, 16–21.

Wang, L., He, W. J., He, Y. F., Li, H., & Wang, R. M. (2015a). Loess based copolymer composite for removing basic fuchsin. Key Engineering Materials, 633, 165–168.

Wang, Y., Tang, X. W., & Wang, H. Y. (2015b). Characteristics and mechanisms of Ni(II) removal from aqueous solution by Chinese loess. Journal of Central South University, 22, 4184–4192.

Wang, Z. C., Xie, Y. L., Qiu, J. L., Zhang, Y. W., & Fan, H. B. (2017). Field experiment on soaking characteristics of collapsible loess. Advances in Materials Science and Engineering, 1–17.

Wang, X. Y., Lu, H. Y., Zhang, H. Z., Wu, J., Hou, X. X., Fu, Y., & Geng, J. Y. (2018). Distribution, provenance, and onset of the Xiashu loess in southeast China with paleoclimatic implications. Journal of Asian Earth Sciences, 155, 180–187.

Warren, C. J., Dudas, M. J., & Abboud, S. A. (1992). Effects of acidification on the chemical composition and layer charge of smectite from calcareous till. Geoderma, 40, 731–739.

Wu, T. X., Zhou, M., Guo, H. D., Duan, H., & Chen, H. (2008). Adsorption of tetracycline on loess soils. Acta Scientiae Circumstantiae, 28, 2311–2314.

Wu, Y. G., Zhang, X. Y., Hu, S. H., & Lu, C. (2012). Jointed effects of inorganic salts and sodium dodecylbenzene sulfonate (SDBS) on sorption and adsorption of phenanthrene in loess soils. Journal of China University of Geosciences, 37, 319–325.

Xie, H. J., Wang, S. Y., Qiu, Z. H., & Jiang, J. Q. (2017). Adsorption of NH4+-N on Chinese loess: Non-equilibrium and equilibrium investigations. Journal of Environmental Management, 202, 46–54.

Xing, S. T., Zhao, M. Q., & Ma, Z. C. (2011). Removal of heavy metal ions from aqueous solution using red loess as an adsorbent. Journal of Environmental Sciences, 23, 1497–1502.

Yan, H. Y., Wang, Q. Q., He, Y. F., Shen, Y., Song, P. F., & Wang, R. M. (2020). Loess particles loaded petaloid Bi2S3 nanowires for highly efficient photodegradation of dyes under sunlight. Indian Journal of Chemistry, 59A, 1442–1448.

Yang, H. M., Tang, A. D., Ouyang, J., Li, M., & Mann, S. (2010). From natural attapulgite to mesoporous materials: methodology, characterization and structural evolution. Journal of Physical Chemistry B, 114, 2390–2398.

Yang, Q. L., Zhang, J. L., Yang, Q., Yu, Y. X., & Yang, G. (2012). Behavior and mechanism of Cd(II) adsorption on loess modified clay liner. Desalination and Water Treatment, 39, 10–20.

Yi, Z. Z., Huang, L., Liu, F., Kuang, W. M., Ling, F. Q., & Zhu, J. (2017). The properties of clay minerals in soil particles from two Ultisols, China. Clays and Clay Minerals, 65, 273–285.

Yin, X. Q., Yu, L., Luo, X. H., Zhang, Z., Sun, H. M., Mosa, A. A., & Wang, N. (2019). Sorption of Pb (II). onto < 1 μm effective diameter clay minerals extracted from different soils of the Loess Plateau, China. Geoderma, 337, 1058–1066.

Yip, C. K., Lukey, G. C., & Deventer, J. S. J. V. (2005). The coexistence of geopolymeric gel and calcium silicate hydrate at the early stage of alkaline activation. Cement and Concrete Research, 35, 1688–1697.

Yoo, S. B. & Cho, M. H. (2019). Eco-friendly composite panel using an eco-friendly material for building. Patent of Korea, KR 1939707 B1 20190117.

Zhan, H. Y., Jiang, Y. F., Yuan, J. M., & Chen, H. (2005). Sorption kinetics of naphthalene and phenanthrene to loess soils. Environmental Science & Technology, 28, 10–11.

Zhang, Z. H. (1963). The theoretical basis of loess classification in China. Georeview, 21, 12–14.

Zhang, Y. S., & Qu, Y. X. (2005). Cement of sand loess and their cementation in north Shaanxi and west Shanxi. Journal of Engineering Geology (China), 13, 18–28.

Zhang, M., Guo, H., El-Korchi, T., Zhang, G., & Tao, M. (2013a). Experimental feasibility study of geopolymer as the next-generation soil stabilizer. Construction and Building Materials, 47, 1468–1478.

Zhang, Y., Jing, Z. Z., Fan, X. W., Fan, J. J., Lu, L., & Ishida, E. H. (2013b). Hydrothermal synthesis of humidity-regulating material from calcined loess. Industrial & Engineering Chemistry Research, 52, 4779–4786.

Zhang, Z. Y., Huang, L., Liu, F., Wang, M. K., Fu, Q. L., & Zhu, J. (2017). The properties of clay minerals in soil particles from two Ultisols, China. Clays and Clay Minerals, 65, 273–285.

Zhang, Z. K., Li, G. J., Yan, H., & An, Z. S. (2018). Microcodium in Chinese loess as a recorder for the oxygen isotopic composition of monsoonal rainwater. Quaternary International, 464(B), 364–369.

Zhao, Z. H., Wu, S. Z., & Chen, Y. S. (2012). Experimental study on the disposal of coal acid mine drainage with loess. Geotechnical Investigation & Surveying, 5, 38–41.

Zhao, C. L., Shao, M. A., Jia, X. X., & Zhang, C. C. (2016). Particle size distribution of soils (0–500 cm). in the Loess Plateau, China. Geoderma Regional, 7, 251–258.

Zhou, W. J., Yang, R. Q., Jiang, M., Zhan, H. Y., Chen, H., & Liu, G. G. (2002). Effect of surfactant on sorption behavior of 2,4-dichlorophenol in loess soils. China Environmental Science, 22, 316–319.

Zhou, W. J., Zhu, K., Zhan, H. Y., Jiang, M., & Chen, H. (2003). Sorption behaviors of aromatic anions on loess soil modified with cationic surfactant. Journal of Hazardous Materials, B100, 209–218.

Zhu, X. M. (1991). The formation of loess plateau and its harnessing measures. Bulletin of Soil and Water Conservation, 11, 1–8.

Zhu, M. R. (1995). Plastic index classification of loess foundation. Journal of Northwest Institute of Architecture Engineering, 1, 6–8.

Acknowledgments

This study was supported by the National Natural Science Foundation of China (Grant No. 21865030) and Gansu International Sci & Techn Coop-Base for Water-retention Functional Materials.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Funding

Funding sources are as stated in the Acknowledgments.

Additional information

(Received 7 July 2020; revised 9 March 2021; AE: Yuji Arai)

Rights and permissions

About this article

Cite this article

Shen, Y., Yan, H., Wang, R. et al. Review: Progress with Functional Materials Based on Loess Particles. Clays Clay Miner. 69, 301–314 (2021). https://doi.org/10.1007/s42860-021-00123-y

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42860-021-00123-y