Abstract

Municipal solid waste (MSW) management has emerged as probably the most pressing issue many governments nowadays are facing. Traditionally, Waste-to-Energy(WtE) is mostly associated with incineration, but now, with the emergence of the bioeconomy, it embraces a broader definition comprising any processing technique that can generate electricity/heat or produce a waste-derived fuel. Under the ambit of the circular economy many nations are looking for, additional effort must be made to be sure of acquiring the most updated information and paving a sustainable path for managing MSW in such a frame. In this regard, we have undertaken a critical review of various technologies, with their updated progress, involved in the exploitation of MSW as a renewable resource, along with the critical advantages and limitations on energy and material cycling for sustainable MSW management. Incineration, the most widely used method, is nowadays difficult to further apply due to its dubious reputation and social opposition. Meanwhile, to address the organic fraction of MSW which currently is mostly unrecycled and causes disposal issues, the biological approach presents an attractive option. The new emphasis of bioeconomy leads us to understand how environmental biotechnologies should be better connected/integrated for more sustainable MSW management. This article is concluded with advances of future prospects, which can serve as a timely reminder to encourage competent authorities/researchers to work towards further improvement of the present MSW management system.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Background

Unprecedented technological and economic development have shaped the production and consumption characteristics of various kinds of materials. In conjunction with population growth, not only is municipal solid waste (MSW) management nowadays experiencing ever-increasing waste volumes, but is also facing greater complexity and heterogeneity. Now, the aspiration towards more sustainable MSW management necessitates continuous efforts in reviewing different potential technologies for awareness of their updated roles in various applications. Waste-to-energy (WtE) importantly serves as a macro-approach for sustainable MSW management [1], where MSW is already considered as a major significant renewable resource in the twenty-first century [2, 3]. In this regard, WtE incineration is largely adopted in many developed and developing countries [4], and has undergone considerable progressive development, becoming a mature technological option for MSW management. However, considering its implied encouragement of wastefulness, there is no lack of criticism of its effect on the waste management hierarchy, with recycling approaches being much more favored. Moreover, its dubious reputation (due to the potential release of toxic substances and greenhouse gases during combustion [5, 6]) often provokes social opposition or phobia from the general public, making it politically less attractive.

In recent years, the concept of waste biorefinery has been rapidly gaining attention for its potential of producing biofuels and platform chemicals from the organic fraction (e.g., food wastes) of MSW [7, 8]. The scale of energy recovery, significance of material cycling and the implications of boosting a new “bioeconomy” promise to be immense. Although WtE incineration currently offers a convenient option, the long-term success of the circular economy should be the sole means that can ensure that global waste disposal is on an irreversible decline [9]. For this reason, the spectrum of evaluating suitable environmental technologies in sustainable MSW management already spans from merely protecting environmental quality in the past to the point of fulfilling the much more vigorous sustainability pursuits of energy and material cycling. In the current initiative of the circular economy, it is evident that MSW management needs to be focused on the bigger context, embracing a broader definition of WtE technologies that can generate electricity/heat or producing waste-derived fuel under the emergence of the bioeconomy. This new dialogue for the bioeconomy for sustainable MSW management will become much more important than ever before so as to recover resources which go beyond energy recovery and can supplement traditional sources of primary materials. Such a paradigm evolution urges/allows government authorities as well as the involved industries to seek more socially acceptable WtE options and embrace a future MSW management with the greatest green potential.

Successful implementation of more sustainable MSW management will realize better closed loop of materials’ recycling, enlarged renewable energy supply and the preservation of biodiversity and natural ecosystems. This article aims to critically analyze the advantages and drawbacks of traditional thermal WtE technologies and emerging waste biorefinery technologies in this new dialogue on the bioeconomy, where their updated roles on energy/material cycling are examined. This review will help MSW researchers, bioprocess engineers, relevant implementing authorities and policy makers to get a clear picture of the current landscape in sustainable MSW management, and the challenges and opportunities of each WtE technology for their effective application under the emerging bioeconomy.

Sustainable municipal solid waste management

Waste management has been around as a public service since as early as 1751, and it literally covers all polices and exercises required to manage solid, liquid, or gaseous waste, starting from its initial generation to ultimate disposal [10]. Recalling the early development of MSW management, sanitary improvement was on the top priority, but in the last decades, the missions for dealing with increasing MSW were radically transformed—from removal and burying of waste as fast as possible, to the current recycling and even urban mining [11]. Although the missions seem to vary with the development status, the overarching goals of MSW management have been consistent over time, in conserving resources and protecting our environment. The idea of “sustainability” is the core of any countries’ MSW management strategy, with targets to lessen possible environmental loads for generations to come [12].

When waste management plans need to be preliminarily developed or reviewed, the waste management hierarchy often provides general guidelines for methods based on their soundness in regard to sustainability (Fig. 1). As the least preferable option, landfilling has long been the most popular method and remains so in many nations all over the world. Sanitary landfilling can be considered as meticulous disposal of waste on a managed site, catering for the occurrence of biogas recovery and proper leachate treatment [13]. However, from the management perspective, recyclable materials being landfilled cannot attract attention from the general public for positive involvement. Instead, it might promote more wastefulness which is the complete opposite to a closed-loop system that builds on recycling/reuse. Along with land contamination and odor issues, landfill leachate consists of concentrated and recalcitrant substances that can seriously pollute the nearby groundwater aquifers and surfaces. Further, sanitary landfilling in densely populated cities now costs the implementing authorities and citizens far more than in the past [14], and will cost much more with time. Therefore, worldwide efforts on waste minimization have encouraged for years, stressing the significance of municipal recycling against the use of dwindling landfill space, and this advocacy repeatedly enters the political arena in many cities calling for waste recycling.

Sustainable material recycling underpins the principles of the circular economy that European Commission (EU) has been advocating, where materials are retained for as long as possible in integrated waste circulation cycles, through upcycling and optimization of their effective use. On top of saving landfill space, the long-term success of the circular economy enables better diffusion of renewable energy and reduced dependence of imported resources from other countries [15,16,17]. To achieve this, a proper classification system for waste separation is a task of the first importance, and the application of relevant environmental technologies comes next. Commonly known as garbage or trash by the general public, MSW encompasses a broad notion for bulk wastes generated by household, commercial, and industrial activity. The classification can be put in several ways [18], and Table 1 represents a general approach. In many cases, the definitions of MSW do not include sewage sludge, agricultural waste, medical waste and industrial waste. The per-capital MSW generation rate varies across countries. This phenomenon could be briefly accounted for by two reasons: (1) places (usually in well-developed countries) with proper waste reduction policies have established effective waste recycling systems that can exclude the entering of recyclables like food waste, yard waste, metals, packaging materials and plastic bottles into the waste stream [19]; (2) the non-consistent MSW definitions adopted in different waste management policies can also lead to huge deviations. In fact, the EU has also been criticized for unclear MSW definitions [20], where the inconsistencies of the definitions and the uncertainties of the statistical information can result in fragmentation of the internal market, in addition to losing the focus in promoting relevant environmental technologies and polices.

The increasing attention of the circular economy to sustainable MSW management stems from the world aspiration for promoting the transition of energy and material acquisition from more sustainable sources. WtE incineration is a well-known approach and it envisages a structural improvement of national energy systems, in terms of an expanded share of renewable energy through the introduction of MSW as combustion fuel. In the context of the circular economy, the key controversy is its inadequacy to address the sustainability of material cycling in the overall value chain by converting all MSW into ash and flue gas. Particularly, organic waste (especially food waste) accounts for the major fraction of the MSW volume in many places. Regarding the specific potential of biogenic waste for alternative energy/material supplies, the emergence of the bioeconomy is deeply rooted with the circular economy concepts, but with a much stronger emphasis on the use of bioresources to support better sustainability of energy/materials in waste management. The means and focuses of the two technological approaches are clearly different, but one of their common grounds is to attain more sustainable use of the Earth’s finite resources. In later sections of this article, key aspects of the two technological approaches (i.e., thermal WtE and waste biorefinery) on energy/material recovery for sustainable MSW management are discussed.

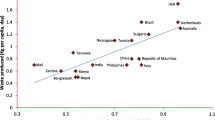

It is noteworthy that technology advancement provides the tools that are essential to facilitate change in sustainable MSW management, and there ought to be a platform for meeting innovation and technology demand. Successful implementation of sustainable MSW management also demands administrative capability, public acceptance, and sufficient financial commitment. In accordance with economic capability, countries are willing to spend about 0.2% and 0.4% of their GDP (gross domestic product) to support sustainable waste management [21]. Though the total financial investment can be similar between countries, there are certainly no uniform waste practices among nations (developed or developing), areas (urban or rural), and different sectors. When trying to attain the goals of waste management, what are always required are tailor-made, regionally adopted, and cost-efficient concepts fitting the various levels and dimensions of social needs. More importantly, they are likely going to be backed by the stakeholders and citizens as ways to solve their existing issues [22,23,24]. Since MSW management involves the whole elements of collection, transport, disposal and treatment of waste, along with regulation and monitoring of the waste management process, there are many intertwined factors which influence this complicated process in regard to more sustainable MSW management.

Thermal waste-to-energy technologies

WtE technologies traditionally cover all thermal processing techniques for generating either heat or fuel gas/oil from MSW. WtE incineration is the most widely applied technique and it basically is the engineered combustion of waste materials at high temperature, with the key outputs of heat and electricity [25]. In comparison, other thermal WtE technologies (including pyrolysis, gasification, and torrefaction) are carried out at a significantly lower temperature and in a less-oxygen environment, involving different reactions and product yields. In general, the moderate temperatures in pyrolysis, with faster heating rates, yield liquid products. The lower temperatures in torrefaction, with long reaction times, primarily produce solid chars. Gasification with the high temperatures and heating rates, promotes the generation of gas products. The standard conditions and synthesized products of various thermal WtE processes are shown in Fig. 2.

WtE incineration

In previous years, incineration was a technological tool primarily used for MSW volume minimization (land saving) and hazardous materials destruction. Associated with its long-time development, incineration is now often accompanied with energy and heat recovery units, and their values and efficiencies have largely improved in application. Denmark and Sweden are the leaders in incineration applications, and in Denmark in 2005, incineration generated nearly 5% of its energy usage and 14% of the entire household heat consumption in their national energy systems [26]. For the purpose of energy generation, MSW incineration has a slightly smaller range of the carbon emission factor (0.04–0.14 kg-CO2/MJ) than that of power plants based on fossil fuel [27]. Per tonne of MSW used for energy generation, about 1.3 tonnes CO2 can be equivalently excluded from the atmosphere if similar quantity of power needs to be generated by fossil-fuel-based power plants. Depending on the MSW composition and combustion technology, the ultimate mass conversion ratios of MSW to the final bottom ash and fly ash are about 10:2.5 and 10:1, respectively, where 75% of the total MSW mass is released by the off gas [28]. Hence, with regard to volume reduction, the effectiveness of incineration is about tenfold. For handling the same MSW quantity, the land requirement for incineration is significantly smaller than the landfilling [29]. Incineration plant, with 30-year working life, calls for less than 100,000 m2 of land for processing one million tonnes of MSW per year, whereas 30 million tonnes of MSW require 300,000 m2 of land for landfilling.

Considering that tremendous amounts of refractory organic and infectious wastes are generated every year, it becomes more important that the high temperature (> 850 °C) during combustion can achieve complete mineralization and transform the wastes into harmless end products. Thus, an advantage of incineration is its efficient destruction of all bacteria, viruses and pharmaceuticals in MSW, preventing these items from entering the natural environment. During incineration, lithophilic substances are concentrated in the bottom ash while atmophilic metals accumulated more in the fly ash [30]. In the past, such ashes were utilized for soil conditioning, but they (especially fly ash) are now paid more attention because of their toxicity [31]. Through applying relevant metal exclusion/immobilization techniques, bottom ash can be transformed into useful construction materials (e.g., for brick making and road construction) [32]. Although bottom ash recycling is deemed feasible, the long-term technical risks (e.g., material strength, heavy metal leaching) and net economic gain are not well known. In contrast, what is known is that the benefits of such recycling towards overall resource conservation are not significant; bottom ash can only substitute 1–2% of main resources of gravel at maximum [33,34,35]. Further, the complete mineralization of the organic fraction in MSW would result in the loss of elements (especially phosphorus) in global nutrient cycles, which is a critical drawback of incineration for material recycling, and in the long run this will be a drain of the world’s resources for certain elements. While bottom ash can be landfilled or perhaps recycled for civil construction, fly ash is much more hazardous, and some latest developments involve extraction of zinc, iron, and copper, etc. by wet chemical extraction and/or electrolysis techniques [36]. However, it remains to be further evaluated if the actual economic and environmental situations can benefit from these new concepts, especially in large-scale applications.

Compared to ashes recycling or combustion processing, flue gas treatment has experienced a higher level of evolution in incineration, and has continually attracted greater attention due to the concerns of toxic pollutants release. MSW can be considered as a heterogeneous ‘fuel’ for combustion, during which the major constituents (such as chlorine and sulphur) would form highly acidic and toxic flue gas. When flue gas is not properly treated, excessive levels of heavy metals and aromatic compounds (including furans and dioxins) are often detected in the environment close to incinerators [37]. These pollutants have been widely considered and written into many emission standards in developed countries. To meet the requirements, the overall incineration investment is often driven beyond the affordability of local authorities. Stricter emission standards will make incineration much more expensive than landfilling, which explain to some extent why the United States stopped expansion of MSW incineration in the late twentieth century, and why the emission standards are sometimes compromised in some developing countries. Challenges arising from public opposition could also be one of major reasons for suspending incineration programs and even the closure of existing MSW plant [38]. Therefore, the high operational costs and potential social opposition of MSW incineration nowadays may make it less economically sustainable and politically attractive in developed countries. As the largest developing countries, China had gone for rapid expansion of MSW incineration over past 15 years, and its total incineration capacity has already become the highest across all nations, and even exceeded the whole of the EU [39, 40]. Zhao et al. [4] reported the issues of incomplete MSW combustion and elevated air pollution in China, where the low energy content and high moisture content of MSW are major difficulties commonly experienced in developing countries [41].

The distinguishing feature of incineration is its robustness in the treatment of heterogeneous waste. In view of its maturity, incineration is now probably the most appropriate transient ‘solution’ for addressing the issue of fast-growing populations with MSW generation. With available land for new landfills becoming more limited in urban settings, it seems unavoidable to further enlarge the capacity or number of incinerators in developing countries. However, it is noteworthy that while we are enjoying the convenience offered by WtE incineration, irreversible consequences result, exhausting the natural environment of material reserves and clean air.

Gasification, pyrolysis, and torrefaction

The advantages of other thermal WtE processes (i.e., gasification, pyrolysis, and torrefaction) over conventional incineration are generally associated with the improved thermochemical transformation efficiency (through different atmosphere and operating temperature conditions) that can reduce flue gas pollution and facilitate the synthesis of recyclable by-products (Fig. 2). During thermal treatment, lower operating temperatures can decrease the chance of alkali volatilization and bed agglomeration [42]. Other than WtE incineration, all other thermal WtE processes are still in the development stage for MSW, and they are much less commercialized in full-scale practice. The features and research progress of the three main types of thermal WtE technologies for MSW are discussed in more detail below.

Gasification is incomplete oxidation with a lesser oxygen content than that needed for full stoichiometric combustion, and there are three major system devices: entrained flow, fuel bed (fixed, moving, rotating) and fluidized bed [43]. Compared to WtE incineration, the partial oxidation is achieved utilizing gasifier agents such as carbon dioxide. As an outcome, the formation of dioxins, NOx and SO2 is more controlled and the total flue gas volume becomes minimal, leading to less expensive gas treatment devices. The minimal flue gas volume also leads to more concentrated contaminants which facilitates more efficient physicochemical treatment that captures fine particulate matter. Gasification is already used for certain MSW categories, including plastic waste, packaging material, and paper waste [44, 45]. However, for mixed MSW, pre-treatment is generally required [46], and one should consider the additional energy consumption of the mechanical biological treatment in the overall energy balance. Fundamentally, gasification/pyrolysis involves parallel and interrelated processes such as fluid dynamics, heat and mass transfer, and complex chemical reactions [47]. In this regard, process modeling is now a major approach that can predict the performance and acquire information for improvement of the energy output. Modeling techniques are based on the principles of material, energy and phase balances, and a wide variety of theoretical and experimental equilibrium models on pyrolysis/gasification have been published. For example, applying Aspen Plus, Ramzan et al. [48] developed a steady-state model to investigate the effect of temperature, water content and equivalent ratio on the energy performance of gasification for general MSW, food waste and poultry waste. It is known that gasification/pyrolysis can be characterized as the two main categories (i.e., allothermal and autothermal). In autothermal gasification, a portion of the feedstock needs to be first partially combusted to initialize the gasification reaction. Recycling of produced syngas to supply energy to make the gasification continuous is one approach [49], but very little work related to modeling the self-sustained gasification process has been reported. In addition, the prediction models are still limited to the discussion of a few operating parameters for the composition and yield of the produced gas, and there is a very scarce adaptability analysis of specific pyrolysis-gasification systems for feeding MSW. All these issues still require a lot of research attention, and they are suitable grounds to further evaluate the efficiency of energy cycling in gasification/pyrolysis of MSW. On the other hand, if compared to WtE incineration, gasification is more complex to operate since it requires one addition step (i.e., syngas conversion) which needs a highly reliable control system since syngas is toxic and potentially explosive. Further, consumption and loss of syngas during the conversion often happens, making its final energy output close to that of WtE incineration plants. Therefore, the complexity in operation and the undermined energy enhancement are critical issues that hinder further application of gasification for MSW.

Pyrolysis is a thermal technique for solid waste treatment in the absence of oxygen but requires higher operating temperatures ranging from 300 to 650 °C, where char and condensable gases are the targeted by-products. The pyrolytic fluid, as a result of volatile gas condensation, can be utilized as a gasoline product after additional upgrading or as building blocks for relevant chemicals’ synthesis [50]. Char is well-known for power generation, soil amendment as long-term carbon sequestration and carbon materials [51]. Char generation from pyrolysis is not a new idea, and it has long been used for synthesizing coke/activated charcoal/biochar from biomass and coal. Although pyrolysis has shown feasibility for many targeted feeds (usually agricultural biomass), considering that MSW is very heterogeneous, the need for comprehensive MSW pretreatment is also the main challenge in application [52]. The composition and yield of oils/gases produced from the pyrolysis of MSW are largely affected by the feedstock, and the operating conditions. For general MSW, the gas yield increases with operating temperature but is still below 1 N m3/kg MSW (about 15 MJ N/m3 calorific value) in most cases [53], and the liquid products consist of a huge water fraction with chemically complex substances. This requires complex wastewater treatment steps before disposal, and these outputs are not satisfactory in terms of energy/material cycling. If aiming to produce oil, plastic waste should be used instead of heterogeneous MSW bulk. Although the char produced from MSW is characterized with a high heating value, a potential resource for solid fuel/material [54], its contamination with toxic organic pollutants and heavy metals requires further critical consideration.

Torrefaction is in fact slower and milder pyrolysis, with operating temperatures from 200 to 350 °C, in which the overall principle lies on moisture evaporation and devolatilization. Compared to pyrolysis, the char by torrefaction usually possesses a higher energy content with increased stability (without undergoing further microbial degradation) [55]. The char can be applied as good-quality fuel for co-firing in combustion, pollutant adsorption in water treatment and soil remediation [56]. Recent research primarily addressed exploration of the char properties after torrefaction of homogeneous biomass. The stricter feedstock requirement probably results in the number of works in MSW torrefaction being relatively trivial when compared with the literature on pyrolysis and gasification.

Bioeconomy and waste biorefinery

The term ‘bioeconomy’ is relatively new, but the basis of the bioeconomy is already in place. From perspective of waste management, bioeconomy considers organic wastes as raw material, transforming them into useful products, in such a manner as crude oil is utilized as a raw material for chemical production. Waste biorefinery leverages a series of biomass conversion processes and process-engineering techniques to produce value-added biofuels/chemicals from biogenic wastes. The higher value of bio-products recovered improves the profitability of waste treatment, and the more efficient production of fuel lowers the reliance on energy from traditional power plant facilities. Therefore, waste biorefinery is a sustainable approach that analogizes today’s petroleum refinery for chemical production (Table 2). According to the European Commission, the bioeconomy currently has a market size of over 2 trillion € and contributes to over 22 million jobs (around 9% of the total EU labor force) across diverse sectors, including agriculture, waste treatment, forestry, food and chemicals production [57,58,59]. Statistically speaking, biogenic waste could potentially contribute up to about 63% of the total share of renewable energy in Europe with a total carbon footprint reduction [60,61,62]. This clear message for current MSW management emphasizes that real exploitation must be paid to those unavoidable organic fractions (especially food waste) which currently go unrecycled, causing disposal issues. These figures also highlight the potential scale of waste biorefinery to the economy of a country, while the opportunities of sector integration and expanded uses of bio-based products are the keys. To promote more sustainable MSW management, anaerobic digestion (AD) and other waste biorefinery techniques now become crucial.

Anaerobic digestion

Biofuels are currently the most visible output of the existing bioeconomy for replacing petroleum refineries. Waste biorefineries are characterized as producing either high-value low-volume or low-value high-volume products from biogenic wastes [63, 64]. In this context, AD has recognized potential to contribute to high-volume biogas production. AD has been around for sanitary purposes for hundreds of years, and it involves a collective microbial degradation process of biodegradable organic matter in the absence of oxygen. The microbial community responsible for biogas production can be briefly classified as either mesophilic (25–37 °C) or thermophilic (50–65 °C), and the conversion rate in AD generally increases with higher operating temperature. The microbial degradation processes in AD are similar to landfills, but AD system results in greater biogas yields within a shorter reaction period. It has been shown that the AD can generate two to four times higher methane yield per tonne of MSW within 3 days than that in 7 years in a landfill [65, 66]. In existing technology, 1 m3 of biogas can be converted into 6.7 kWh of energy [67]. Based on the feedstock type and quality (e.g., biodegradability, nutrient content, inhibition components, etc.) [68,69,70,71,72], different process-engineering techniques (e.g., pretreatment, process configuration, additive dosage) can be applied [73,74,75,76,77,78]. To name one main example, compared to other organic solid wastes, the fast acidification of carbohydrates in food wastes can lead to excessive lowering of pH in AD [79]. The optimum pH for the microbial community in AD is around neutral pH, therefore, AD has long been criticized for its sensitivity to the operating conditions. In this regard, two-phase AD is gaining attention in food waste treatment [80, 81], considering that the physical separation of acidogenesis from methanogenesis enables better system stability, and the methanogenic bioreactor in second phase can largely take up the responsibility for high-rate biogas production [82, 83]. All these process-engineering techniques target the promotion of better energy performance and reliability of AD in organic waste treatment.

In term of material cycling, AD facilitates the solid/liquid separation of organic wastes, finally outputting solid and liquid digestate. Based on the water content in the slurry of the organic wastes, AD systems can be primarily classified into two types: (1) wet (< 5% of total solids) and (2) dry (> 20% of total solids) processes [84]. The volume of liquid digestate from dry AD is much lower than from the wet one, while the nutrients (mainly nitrogen and phosphorus) in the liquid digestate can be further recovered by various biorefinery technologies [85,86,87,88,89,90]. Solid digestate can be used as compost which provides the same value as organic conditioners in land amendment application [91,92,93], lessening the dependence on chemical fertilizers, enhancing soil moisture retention and reducing irrigation requirements [94,95,96,97,98]. Various technologies commonly known as digestate processing exist to refine the digestate quality for subsequent use in agricultural purposes in regard to carbon, nitrogen, phosphorus and some trace elements. The creation of new markets for digestate reuse led to more intense development, and sustainable agriculture coupled with existing organic waste treatment, and the market creation of alternative fertilizer sources for farmers, can give the bioeconomy a huge boost. The opportunities and impacts of positive material flow from waste to resource through AD appear to be enormous, which implies more sustainable material patterns of consumption and production on the global scale. Nevertheless, the current EU legislation discourages the use of AD digestate from heterogeneous waste as a fertilizer, considering that many unwanted substances may potentially appear in AD feedstock. In this regard, to facilitate the beneficial reuse of AD digestate, source separation of food waste from general MSW becomes critical. Recently, many countries have articulated their relevant policy settings on the significance of moving towards a bioeconomy, where food waste management is an important item on their policy agenda.

While the biogas generated in AD is often only considered for electricity generation or even sometimes being directly flared, the value and scope of biogas applications can be largely upgraded by eliminating carbon dioxide and other contaminant gases to provide high-quality biomethane as a substitute for natural gas in various industrial and domestic uses [99,100,101,102,103]. Biogas from AD cannot be only considered alongside as the same arrays with solar or wind power as sustainable energy. The multi-functionality of AD is its clearest strength, underpinning sustainability principles with connections to many innovative waste refinery technologies and sustainable agriculture to solve waste challenges and global nutrients recycling (Fig. 3). As the most mature technology in waste biorefinery, it is clear that AD plants will be the future hub of many possible resource recovery routes in the bioeconomy. Sustainable biogas plant is for the treatment of organic waste, for protection of the environment, and also for production of advanced gaseous biofuels and high-value materials. The full potential of AD has not yet been recognized by many developing, and even developed countries, and developing countries such as Malaysia and Vietnam have just started to recover energy from organic solid wastes, but only on a small scale [104, 105].

From the technological perspective, AD is a fairly mature technology, but research advancement continues in recent years for the sake of exploring better effluent quality and useful connections to other environmental technologies. One common challenge in AD is the long time needed for the methanogenic reaction in biogas production, as it typically takes between 20 and 40 days for each batch cycle and an even longer duration for new system startup [106]. Recent research revealed that direct interspecies electron transfer exists within AD microbial communities and an appropriate dosage of conductive materials (e.g., activated carbon and biochar) in the digester can lead to reduced lag phase, improved organic degradation and enhanced biogas formation rate [107,108,109]. On the other hand, the presence of nitrogenous wastes and high salinity in the feedstock would pose inhibitory effects on the AD processes due to the elevated levels of ammonia and salt [110,111,112], sometimes leading to AD system failure. Compared to mono-digestion (single feedstock for AD), several studies have suggested that the co-digestion of food wastes and bio-solids (e.g., slaughterhouse waste and sewage sludge) can mitigate a certain level of inhibitory effects thereby enhancing the overall biogas production [81, 84, 113,114,115,116,117]. Other benefits of co-digestion include more optimized use of the existing capacity in anaerobic digesters and the generation of more stabilized and nutrient-balanced digestate for the purpose of soil amendment. More technological integration (e.g., granular sludge, hydrothermal liquefaction, microbial fuel cell, and biochar application) will continue to be developed in AD systems [118,119,120,121,122,123,124,125,126]. According to the current research trend, the critical challenge in AD, as well as the bioeconomy is, therefore, to find room for the next wave of innovations that can boost technology and bio-based products to support a more transformative and sustainable waste management of organic fraction in MSW.

Waste valorization

Current waste biorefinery techniques involve mostly single-conversion technology, and green ‘platform chemicals’ or intermediary ‘building blocks’ can be generated from organic wastes using relatively simple biological approaches that have already been established (Fig. 4). To provide more possibilities for valued-added product production and power generation, waste valorization calls for combining conversion technologies in an integrated approach so as to reduce overall costs. Therefore, many modern waste biorefinery technologies often strive to integrate with other processes like AD to realize parallel waste treatment and biotransformation for biofuels and chemicals production. Platform chemicals are not themselves technologies but as partial elements for technical exploration in bioeconomy [127]. Therefore, multiple technologies should be brought together to create interlocked biorefinery process chains from which many other commercial materials can emerge. Considering the number of possible processing techniques in biorefinery process chains, there will be an increasing number of “new” waste valorization models which can be characterized by different combinations of input feedstock, process technologies, platform chemicals and the output bioproducts.

Food waste is a good source for waste valorization in view of its rich nutrient composition of around 50% starch, 40% lipids, and 10% proteins [131]. Prior to bioproducts’ synthesis, a hydrolysis step is necessary to breakdown large molecules of food waste into sugar monomers, fatty acids, amino acids, etc. 31.9 g glucose, 0.28 g FAN, and 0.38 g phosphate recovery was reported from 100 g food waste, which indicated recovery rates of 85%, 40%, and 100% for carbohydrate, total nitrogen, and phosphate, respectively [132]. In many cases, in view of the slow hydrolysis process, an enzyme mixture consisting of cellulase, protease, carbohydrase, and glucoamylase is often required to accelerate the hydrolysis step. Aspergillus oryzae and Aspergillus awamori are known producers of glucoamylases, proteases, and phosphatases [133], and applying them in fungal hydrolysis, it was reported that glucose, free amino nitrogen and phosphate can be recovered from food waste [134]. Similarly, using Halomonas boliviensis, it was reported that polyhydroxyalkanoates can be produced from sugarcane molasses and bakery waste and food waste [135, 136]. Polyhydroxyalkanoates are bio-based polymers that are gaining more attention in the bioeconomy, attributed to their biodegradability and thermoplastic properties similar to petroleum-derived plastics. Bio-based polymers now have a board scope of application, including chiral substrates for drug synthesis and drug delivery, paints, adhesives and medical tissue applications [137,138,139,140]. Other the other hand, the use of solid/liquid effluent from aerobic/anaerobic fermentation of organic waste as bio-fertilizer is also an interesting approach for sustainable waste management [141,142,143,144,145]. Effluent commonly contains many microorganisms which are the function components for bio-fertilizers manufacture. For example, Clostridium and Klebsiella can be responsible for nitrogen fixation, while Bacillus and Pseudomonas can be used for phosphate solubilization [146,147,148,149,150]. Overall, when compared to chemical fertilizers, degraded organic matter and these microorganisms can accelerate the microbial processes in the soil and promote the availability of fertilization nutrients to plants. More importantly, they are inexpensive and renewable sources of plant nutrients, which is crucial for sustainable agriculture. There have been many examples of research and industrial moves towards waste valorization or platform chemicals production from biogenic wastes (Fig. 4). A large number of ‘valorization’ or ‘biorefinery’ publications on food waste or other common organic waste in MSW can be found in the literature [151,152,153,154,155]. Further, numerous research publications indicating the feasibility of resource recovery from homogenous biomass, for example, biofuel residues, crop wastes and sawdust, are also available [156,157,158].

Material recycling from waste is an exciting subject, but the concerns on contaminant detection and rejection happen at all levels of the bioeconomy. Direct utilization of heterogeneous MSW is uncommon and inappropriate for biorefining. Thus, following the idea of the circular economy from the EU it is clear that the development of separate collection structures and recycling capacity should be a top priority. From the technological perspective, without proper waste sorting, the costs for substances-separation can easily transcend the value of the final bio-products [159, 160]. Separation technologies are required to isolate cellulose, antioxidants, amino acids, or any other unwanted substances from the chain of refinery processes. While ordinary distillation can be used for products separation in petroleum refineries, the chemical components recovered from biomass are less volatile. Therefore, more intense waste sorting programs (more than simple isolation of organic fractions from MSW) and the development of appropriate methodologies (e.g., solvent extraction, membrane, reactive adsorption, and chromatography) will have to be prioritized in the bioeconomy (Table 3). Meanwhile, the high chemical oxygen demand, dissolved salts content and micro-pollutant make certain biogenic wastes difficult to be handled by the conventional biological approach. New and more integrated anaerobic treatments for biogas production and material recycling may thereby need to be considered and evaluated [161,162,163,164,165,166,167,168,169,170,171,172,173]. It is firmly believed by the authors that, due to the large volume and heterogeneity of waste produced, from both an economical and technological point of view, the best solution for organic wastes does not always lie in the choice and implementation of a single or typical process technology. However, understanding the benefits and constraints of all these different separation technologies and treatment units will take a considerable effort that already goes far beyond the scope of sustainable MSW management in this article. The clear message here is that the economic pressure (high separation cost and relatively low market price) to valorize wastes is huge; researchers need to carefully consider the financial feasibility of new waste valorization models.

Last but not least, we cannot simply assume that materials are better because they are organic/biogenic, since some biogenic wastes may contain heavy metals, pharmaceutical residues, microbes with antibiotic resistance genes, etc. [174,175,176,177]. Material recycling must be in clean cycles, separating harmful impurities from the recycling resources. The long-term aspiration for waste valorization is, therefore, a ‘superstructure’ with more connected technology integration over wider scales for safe and clean bioproducts. The above discussion highlights that while the potential of biogenic wastes continues to be explored in sustainable MSW management, it is important to consider this emerging trend with a critical attitude, without turning a blind eye to the life-cycle costs and risk management on the hygiene aspects.

Remarks and prospects

The global MSW generation per year is between 1.3 and 1.9 billion tonnes, and it is anticipated to reach 4.2 billion tonnes by 2050 [178]. Sustainable MSW management has emerged to be probably the most pressing issue many governments nowadays are now facing. MSW generation rate is commonly correlated positively to per-capita GDP of a country. Particularly, the MSW generation rates in most developed countries (around 1.00–2.50 kg MSW per capita per day) are much more than those in the developing countries (0.50–1.00 kg MSW per capita per day) [179, 180], where the MSW generation relates to the social and economic prosperity of the country. Hence, on the grounds of economic growth and globalization, it can be deduced that as the individuals of developing countries are gradually switching their lifestyle to those in more developed countries, the MSW generation rate in developing countries will catch up and get close to the rate in developed countries in the coming years. The challenge of MSW management in developing countries is going to be more intense, particularly for those that do not have a planned agenda for responding to substantially larger MSW quantity in future.

Obviously, unless radical changes happen, responsible authorities are not likely to deal with this rapid increase in MSW volume. History has proven the inadequacy of recycling in managing the expanding volumes of MSW, and as a result, the world cannot afford to abandon incineration for now [25]. As the most convenient and robust technology of MSW disposal and energy recovery, however, it is also crucial to understand that the relevance of incineration is not inexhaustible: for one, fundamental opposition to incineration has become rare because of more independent and transparent information that allows to the drawing of more objective conclusions about this technology. Nevertheless, social opposition seems not to stop because of concerns on toxic emissions, which will not be resolved in the short term, regardless of existing technological progress. Second, the costs of incineration are now generally much higher as a result of the advanced flue gas treatment systems and the addition cost from the treatment of bottom ash and fly ash for final disposal. To achieve environmentally and economically sound MSW incineration, a minimum standard for residue treatment and air pollution control is welcome but cutting budgets of incineration is restrained by stricter emission regulations. This is a struggle that many developing economies cannot afford to pay for. Third, incinerating MSW does nothing to alleviate the world shortages on materials and does not move us towards circular economy. Instead, it creates a dependence on MSW as a fuel source as well as the potential encouragement of wastefulness. The idea of countries importing or even competing for MSW as energy sources looks like a huge paradigm shift, but in several places, like Sweden, it is currently the norm. Regarding this phenomenon, the EU emphasized that new incineration plans must consider the risk as to whether sufficient feedstock could be sustained over the coming whole lifespan (20–30 years), without neglecting any opportunities for waste separation and recycling [20, 85].

Traditionally, WtE has been mostly associated with incineration but is now embracing a broader definition with the emergence of the bioeconomy. This article discusses the key thermal and biological WtE technologies in regard to their development progress, focusing on their increasing roles for energy and material cycling in sustainable MSW management. However, this is not an exhaustive review, since unravelling all the detailed principles, optimization techniques and research opportunities on such a wide range of technologies is difficult to achieve in a single article. Instead, this review addresses the critical aspects of energy/material cycling and potential in applications, while the conceptualized role of future AD plant in the bioeconomy is articulated and certain concerns on waste valorization are covered. To promote a better bioeconomy and sustainable MSW management, the idea from the EU is obvious in that the development of separate collection structures and recycling capacity should be top priority. Waste is an environmental problem and also a resource issue. In the coming years, attention to resources recovery from waste streams is going to surpass the initial goal of environment protection in sustainable MSW management. This new dialogue in the bioeconomy will lead us to understand how environmental biotechnologies should be better connected/integrated for processing the organic fraction of MSW and biogenic wastes. The new wave of interest in the bioeconomy would thereby be expected to drive considerable new resource recovery technologies. Researchers are still attempting to determine what needs to be done, and AD technology coupled with many waste biorefinery techniques are clearly a critical component of this journey.

Change history

27 August 2021

A Correction to this paper has been published: https://doi.org/10.1007/s42768-021-00078-9

References

Moya D, Aldás C, López G, Kaparaju P. Municipal solid waste as a valuable renewable energy resource: a worldwide opportunity of energy recovery by using Waste-To-Energy Technologies. Energy Procedia. 2017;134:286–95.

Pour N, Webley PA, Cook PJ. Potential for using municipal solid waste as a resource for bioenergy with carbon capture and storage (BECCS). Int J Greenh Gas Control. 2018;68:1–15.

Di Matteo U, Nastasi B, Albo A, Astiaso Garcia D. Energy contribution of OFMSW (organic fraction of municipal solid waste) to energy-environmental sustainability in urban areas at small scale. Energies. 2017;10(2):229.

Zhao X-G, Jiang G-W, Li A, Li Y. Technology, cost, a performance of waste-to-energy incineration industry in China. Renew Sustain Energy Rev. 2016;55:115–30.

Zhou H, Meng A, Long Y, Li Q, Zhang Y. A review of dioxin-related substances during municipal solid waste incineration. Waste Manag. 2015;36:106–18.

Tozlu A, Özahi E, Abuşoğlu A. Waste to energy technologies for municipal solid waste management in Gaziantep. Renew Sustain Energy Rev. 2016;54:809–15.

Pandey BK, Vyas S, Pandey M, Gaur A. Municipal solid waste to energy conversion methodology as physical, thermal, and biological methods. Curr Sci Perspect. 2016;2:39–46.

Zabaniotou A. Redesigning a bioenergy sector in EU in the transition to circular waste-based bioeconomy—a multidisciplinary review. J Clean Prod. 2018;177:197–206.

Tisserant A, Pauliuk S, Merciai S, Schmidt J, Fry J, Wood R, Tukker A. Solid waste and the circular economy: a global analysis of waste treatment and waste footprints. J Ind Ecol. 2017;21(3):628–40.

Hoornweg D, Bhada-Tata P. What a waste: a global review of solid waste management, vol. 15. Washington, DC: World Bank; 2012. p. 116.

Krook J, Baas L. Getting serious about mining the technosphere: a review of recent landfill mining and urban mining research. J Clean Prod. 2013;55:1–9.

Kurdve M, Shahbazi S, Wendin M, Bengtsson C, Wiktorsson M. Waste flow mapping to improve sustainability of waste management: a case study approach. J Clean Prod. 2015;98:304–15.

Silva TF, Soares PA, Manenti DR, Fonseca A, Saraiva I, Boaventura RA, Vilar VJ. An innovative multistage treatment system for sanitary landfill leachate depuration: studies at pilot-scale. Sci Total Environ. 2017;576:99–117.

Dangi MB, Schoenberger E, Boland JJ. Assessment of environmental policy implementation in solid waste management in Kathmandu, Nepal. Waste Manag Res. 2017;35(6):618–26.

Malinauskaite J, Jouhara H. The trilemma of waste-to-energy: a multi-purpose solution. Energy Policy. 2019;129:636–45.

Saavedra YM, Iritani DR, Pavan AL, Ometto AR. Theoretical contribution of industrial ecology to circular economy. J Clean Prod. 2018;170:1514–22.

Schroeder P, Dewick P, Kusi-Sarpong S, Hofstetter JS. Circular economy and power relations in global value chains: tensions and trade-offs for lower income countries. Resour Conserv Recycl. 2018;136:77–8.

Zhou H, Long Y, Meng A, Li Q, Zhang Y. Classification of municipal solid waste components for thermal conversion in waste-to-energy research. Fuel. 2015;145:151–7.

US EPA. Advancing sustainable materials management: facts and figures. US Environ Prot Agency. 2013;2015:1–16.

Malinauskaite J, Jouhara H, Czajczyńska D, Stanchev P, Katsou E, Rostkowski P, Anguilano L. Municipal solid waste management and waste-to-energy in the context of a circular economy and energy recycling in Europe. Energy. 2017;141:2013–44.

Brunner PH, Fellner J. Setting priorities for waste management strategies in developing countries. Waste Manag Res. 2007;25(3):234–40.

Soltani A, Sadiq R, Hewage K. Selecting sustainable waste-to-energy technologies for municipal solid waste treatment: a game theory approach for group decision-making. J Clean Prod. 2016;113:388–99.

Diaz-Barriga-Fernandez AD, Santibañez-Aguilar JE, Radwan N, Nápoles-Rivera F, El-Halwagi MM, Ponce-Ortega JM. Strategic planning for managing municipal solid wastes with consideration of multiple stakeholders. ACS Sustain Chem Eng. 2017;5(11):10744–62.

Suthar S, Rayal P, Ahada CP. Role of different stakeholders in trading of reusable/recyclable urban solid waste materials: a case study. Sustain Cities Soc. 2016;22:104–15.

Makarichi L, Jutidamrongphan W, Techato KA. The evolution of waste-to-energy incineration: a review. Renew Sustain Energy Rev. 2018;91:812–21.

Bosmans A, Vanderreydt I, Geysen D, Helsen L. The crucial role of Waste-to-Energy technologies in enhanced landfill mining: a technology review. J Clean Prod. 2013;55:10–23.

Astrup TF, Tonini D, Turconi R, Boldrin A. Life cycle assessment of thermal waste-to-energy technologies: review and recommendations. Waste Manag. 2015;37:104–15.

Malindzakova M, Straka M, Rosova A, Kanuchova M, Trebuna P. Modeling the process for incineration of municipal waste. Przem Chem. 2015;94(8):1260–4.

Kumar A, Samadder SR. A review on technological options of waste to energy for effective management of municipal solid waste. Waste Manag. 2017;69:407–22.

Jiao F, Zhang L, Dong Z, Namioka T, Yamada N, Ninomiya Y. Study on the species of heavy metals in MSW incineration fly ash and their leaching behavior. Fuel Process Technol. 2016;152:108–15.

Deng D, Qiao J, Liu M, Kołodyńska D, Zhang M, Dionysiou DD, Ju Y, Ma J, Chang MB. Detoxification of municipal solid waste incinerator (MSWI) fly ash by single-mode microwave (MW) irradiation: addition of urea on the degradation of Dioxin and mechanism. J Hazard Mater. 2019;369:279–89.

Gao X, Yuan B, Yu QL, Brouwers HJH. Characterization and application of municipal solid waste incineration (MSWI) bottom ash and waste granite powder in alkali activated slag. J Clean Prod. 2017;164:410–9.

Birgisdottir H, Pihl KA, Bhander G, Hauschild MZ, Christensen TH. Environmental assessment of roads constructed with and without bottom ash from municipal solid waste incineration. Transp Res Part D Trans Environ. 2006;11(5):358–68.

Xie R, Xu Y, Huang M, Zhu H, Chu F. Assessment of municipal solid waste incineration bottom ash as a potential road material. Road Mater Pavement Des. 2017;18(4):992–8.

Brunner PH, Rechberger H. Waste to energy–key element for sustainable waste management. Waste Manag. 2015;37:3–12.

Haghighi HK, Irannajad M, Fortuny A, Sastre AM. Recovery of germanium from leach solutions of fly ash using solvent extraction with various extractants. Hydrometallurgy. 2018;175:164–9.

Li G, Wu Q, Wang S, Li Z, Liang H, Tang Y, Wang F. The influence of flue gas components and activated carbon injection on mercury capture of municipal solid waste incineration in China. Chem Eng J. 2017;326:561–9.

Jones AM, Harrison RM. Emission of ultrafine particles from the incineration of municipal solid waste: a review. Atmos Environ. 2016;140:519–28.

Lu JW, Zhang S, Hai J, Lei M. Status and perspectives of municipal solid waste incineration in China: a comparison with developed regions. Waste Manag. 2017;69:170–86.

Wang Y, Lai N, Zuo J, Chen G, Du H. Characteristics and trends of research on waste-to-energy incineration: a bibliometric analysis, 1999–2015. Renew Sustain Energy Rev. 2016;66:95–104.

Dong J, Chi Y, Tang Y, Ni M, Nzihou A, Weiss-Hortala E, Huang Q. Effect of operating parameters and moisture content on municipal solid waste pyrolysis and gasification. Energy Fuels. 2016;30(5):3994–4001.

Song G, Qi X, Song W, Lu Q. Slagging characteristics of Zhundong coal during circulating fluidized bed gasification. Energy Fuels. 2016;30(5):3967–74.

Qi T, Lei T, Yan B, Chen G, Li Z, Fatehi H, Bai XS. Biomass steam gasification in bubbling fluidized bed for higher-H2 syngas: CFD simulation with coarse grain model. Int J Hydrog Energy. 2019;44(13):6448–60.

Lopez G, Artetxe M, Amutio M, Alvarez J, Bilbao J, Olazar M. Recent advances in the gasification of waste plastics. A critical overview. Renew Sustain Energy Rev. 2018;82:576–96.

Win MM, Asari M, Hayakawa R, Hosoda H, Yano J, Sakai SI. Characteristics of gas from the fluidized bed gasification of refuse paper and plastic fuel (RPF) and wood biomass. Waste Manag. 2019;87:173–82.

Deng N, Zhang A, Zhang Q, He G, Cui W, Chen G, Song C. Simulation analysis and ternary diagram of municipal solid waste pyrolysis and gasification based on the equilibrium model. Bioresour Technol. 2017;235:371–9.

Schulze S, Nikrityuk P, Abosteif Z, Guhl S, Richter A, Meyer B. Heat and mass transfer within thermogravimetric analyser: from simulation to improved estimation of kinetic data for char gasification. Fuel. 2017;187:338–48.

Ramzan N, Ashraf A, Naveed S, Malik A. Simulation of hybrid biomass gasification using Aspen plus: a comparative performance analysis for food, municipal solid and poultry waste. Biomass Bioenerg. 2011;35(9):3962–9.

Sanlisoy A, Carpinlioglu MO. A review on plasma gasification for solid waste disposal. Int J Hydrog Energy. 2017;42(2):1361–5.

Yang Y, Heaven S, Venetsaneas N, Banks CJ, Bridgwater AV. Slow pyrolysis of organic fraction of municipal solid waste (OFMSW): characterisation of products and screening of the aqueous liquid product for anaerobic digestion. Appl Energy. 2018;213:158–68.

Gopu C, Gao L, Volpe M, Fiori L, Goldfarb JL. Valorizing municipal solid waste: waste to energy and activated carbons for water treatment via pyrolysis. J Anal Appl Pyrol. 2018;133:48–58.

Fang S, Gu W, Chen L, Yu Z, Dai M, Lin Y, Ma X. Ultrasonic pretreatment effects on the co-pyrolysis of municipal solid waste and paper sludge through orthogonal test. Bioresour Technol. 2018;258:5–11.

Chen D, Yin L, Wang H, He P. Reprint of: pyrolysis technologies for municipal solid waste: a review. Waste Manag. 2015;37:116–36.

Sipra AT, Gao N, Sarwar H. Municipal solid waste (MSW) pyrolysis for bio-fuel production: a review of effects of MSW components and catalysts. Fuel Process Technol. 2018;175:131–47.

Stępień P, Białowiec A. Kinetic parameters of torrefaction process of alternative fuel produced from municipal solid waste and characteristic of carbonized refuse derived fuel. Detritus. 2018;3:75–83.

Nobre C, Alves O, Longo A, Vilarinho C, Gonçalves M. Torrefaction and carbonization of refuse derived fuel: char characterization and evaluation of gaseous and liquid emissions. Bioresour Technol. 2019;285:121325.

Kristinsson HG, Jörundsdóttir HÓ. Food in the bioeconomy. Trends Food Sci Technol. 2019;84:4–6.

Koukios E, Monteleone M, Carrondo MJT, Charalambous A, Girio F, Hernández EL, Zabaniotou A. Targeting sustainable bioeconomy: a new development strategy for Southern European countries. The Manifesto of the European Mezzogiorno. J Clean Prod. 2018;172:3931–41.

Viaggi D. Towards an economics of the bioeconomy: four years later. Bio-based Appl Econ J. 2018;5(1050-2018-3671):101–12.

Scarlat N, Fahl F, Dallemand JF. Status and opportunities for energy recovery from municipal solid waste in Europe. Waste Biomass Valoriz. 2018. https://doi.org/10.1007/s12649-018-0297-7.

Zheng Y, Jenkins BM, Kornbluth K, Kendall A, Træholt C. Optimization of a biomass-integrated renewable energy microgrid with demand side management under uncertainty. Appl Energy. 2018;230:836–44.

Rodríguez-Monroy C, Mármol-Acitores G, Nilsson-Cifuentes G. Electricity generation in Chile using non-conventional renewable energy sources—a focus on biomass. Renew Sustain Energy Rev. 2018;81:937–45.

Budzianowski WM. High-value low-volume bioproducts coupled to bioenergies with potential to enhance business development of sustainable biorefineries. Renew Sustain Energy Rev. 2017;70:793–804.

Bender TA, Dabrowski JA, Gagné MR. Homogeneous catalysis for the production of low–volume, high–value chemicals from biomass. Nat Rev Chem. 2018;2:35–46.

Gao A, Tian Z, Wang Z, Wennersten R, Sun Q. Comparison between the technologies for food waste treatment. Energy Procedia. 2017;105:3915–21.

Vigil M, Marey-Pérez MF, Huerta GM, Cabal VÁ. Is phytoremediation without biomass valorization sustainable?—comparative LCA of landfilling vs. anaerobic co-digestion. Sci Total Environ. 2015;505:844–50.

Hasan AM, Ammenberg J. Biogas potential from municipal and agricultural residual biomass for power generation in Hazaribagh, Bangladesh—a strategy to improve the energy system. Renew Energy Focus. 2019;29:14–23.

Safarudin A, Millati R, Taherzadeh MJ, Niklasson C. Inhibition of patchouli oil for anaerobic digestion and enhancement in methane production using reverse membrane bioreactors. Renew Energy. 2018;129:748–53.

Chen L, Tsui TH, Ekama GA, Mackey HR, Hao T, Chen G. Development of biochemical sulfide potential (BSP) test for sulfidogenic biotechnology application. Water Res. 2018;135:231–40.

Meng X, Yu D, Wei Y, Zhang Y, Zhang Q, Wang Z, Wang Y. Endogenous ternary pH buffer system with ammonia-carbonates-VFAs in high solid anaerobic digestion of swine manure: an alternative for alleviating ammonia inhibition? Process Biochem. 2018;69:144–52.

Polizzi C, Alatriste-Mondragón F, Munz G. The role of organic load and ammonia inhibition in anaerobic digestion of tannery fleshing. Water Resources and Industry. 2018;19:25–34.

Rodriguez-Verde I, Regueiro L, Lema JM, Carballa M. Blending based optimisation and pretreatment strategies to enhance anaerobic digestion of poultry manure. Waste Manag. 2018;71:521–31.

Gil A, Siles JA, Martín MA, Chica AF, Estévez-Pastor FS, Toro-Baptista E. Effect of microwave pretreatment on semi-continuous anaerobic digestion of sewage sludge. Renew Energy. 2018;115:917–25.

Yao Y, Bergeron AD, Davaritouchaee M. Methane recovery from anaerobic digestion of urea-pretreated wheat straw. Renew Energy. 2018;115:139–48.

Kor-Bicakci G, Eskicioglu C. c Recent developments on thermal municipal sludge pretreatment technologies for enhanced anaerobic digestion. Renew Sustain Energy Rev. 2018;110:423–43.

Farhat A, Asses N, Ennouri H, Hamdi M, Bouallagui H. Combined effects of thermal pretreatment and increasing organic loading by co-substrate addition for enhancing municipal sewage sludge anaerobic digestion and energy production. Process Saf Environ Prot. 2018;119:14–22.

Qian J, Zhou J, Pei X, Zhang M, Liu Y. Bioactivities and formation/utilization of soluble microbial products (SMP) in the biological sulfate reduction under different conditions. Chemosphere. 2019;221:37–44.

Ye M, Liu J, Ma C, Li YY, Zou L, Qian G, Xu ZP. Improving the stability and efficiency of anaerobic digestion of food waste using additives: a critical review. J Clean Prod. 2018;192:316–26.

Zhou M, Yan B, Wong JW, Zhang Y. Enhanced volatile fatty acids production from anaerobic fermentation of food waste: a mini-review focusing on acidogenic metabolic pathways. Bioresour Technol. 2018;248:68–78.

Yan BH, Selvam A, Wong JW. Innovative method for increased methane recovery from two-phase anaerobic digestion of food waste through reutilization of acidogenic off-gas in methanogenic reactor. Bioresour Technol. 2016;217:3–9.

Mehariya S, Patel AK, Obulisamy PK, Punniyakotti E, Wong JW. Co-digestion of food waste and sewage sludge for methane production: current status and perspective. Bioresour Technol. 2018;265:519–31.

Tsui TH, Ekama GA, Chen GH. Quantitative characterization and analysis of granule transformations: role of intermittent gas sparging in a super high-rate anaerobic system. Water Res. 2018;139:177–86.

Tsui TH, Chen L, Hao T, Chen GH. A super high-rate sulfidogenic system for saline sewage treatment. Water Res. 2016;104:147–55.

Karthikeyan OP, Trably E, Mehariya S, Bernet N, Wong JW, Carrere H. Pretreatment of food waste for methane and hydrogen recovery: a review. Bioresour Technol. 2018;249:1025–39.

Di Maria F, Barratta M, Bianconi F, Placidi P, Passeri D. Solid anaerobic digestion batch with liquid digestate recirculation and wet anaerobic digestion of organic waste: comparison of system performances and identification of microbial guilds. Waste Manag. 2017;59:172–80.

Stiles WA, Styles D, Chapman SP, Esteves S, Bywater A, Melville L, Chaloner T. Using microalgae in the circular economy to valorise anaerobic digestate: challenges and opportunities. Bioresour Technol. 2018;267:732–42.

Kocatürk-Schumacher NP, Zwart K, Bruun S, Stoumann Jensen L, Sørensen H, Brussaard L. Recovery of nutrients from the liquid fraction of digestate: use of enriched zeolite and biochar as nitrogen fertilizers. J Plant Nutr Soil Sci. 2018;182:187–95.

Tambone F, Orzi V, Zilio M, Adani F. Measuring the organic amendment properties of the liquid fraction of digestate. Waste Manag. 2019;88:21–7.

Montero E, Olguín EJ, De Philippis R, Reverchon F. Mixotrophic cultivation of Chlorococcum sp. under non-controlled conditions using a digestate from pig manure within a biorefinery. J Appl Phycol. 2018;30(5):2847–57.

Somers MH, Azman S, Sigurnjak I, Ghyselbrecht K, Meers E, Meesschaert B, Appels L. Effect of digestate disintegration on anaerobic digestion of organic waste. Bioresour Technol. 2018;8:568–76.

Pappalardo G, Selvaggi R, Bracco S, Chinnici G, Pecorino B. Factors affecting purchasing process of digestate: evidence from an economic experiment on Sicilian farmers’ willingness to pay. Agric Food Econ. 2018;6(1):16.

Borowski S, Boniecki P, Kubacki P, Czyżowska A. Food waste co-digestion with slaughterhouse waste and sewage sludge: digestate conditioning and supernatant quality. Waste Manag. 2018;24:158–67.

Logan M, Visvanathan C. Management strategies for anaerobic digestate of organic fraction of municipal solid waste: current status and future prospects. Waste Manag Res. 2019;37(1_suppl):27–39.

Tsai WT, Fang YY, Cheng PH, Lin YQ. Characterization of mesoporous biochar produced from biogas digestate implemented in an anaerobic process of large-scale hog farm. Biomass Convers Biorefinery. 2018;8(4):945–51.

Beck-Broichsitter S, Fleige H, Horn R. Compost quality and its function as a soil conditioner of recultivation layers–a critical review. Int Agrophys. 2018;32(1):11–8.

Elbashier MM, Shao X, Tingting C, Ali AA. Effects of anaerobic digestate on Chinese melon (Cucumis melo L.) yield components, soil properties, and microbial communities under saline irrigation condition. Commun Soil Sci Plant Anal. 2018;49(19):2446–55.

Sánchez-Rodríguez AR, Carswell AM, Shaw R, Hunt J, Saunders K, Cotton J, Misselbrook TH. Advanced processing of food waste based digestate for mitigating nitrogen losses in a winter wheat crop. Front Sustain Food Syst. 2018;2:35.

Andersen L, Lamp A, Dieckmann C, Baetge S, Schmidt LM, Kaltschmitt M. Biogas plants as key units of biorefinery concepts: options and their assessment. J Biotechnol. 2018;283:130–9.

Angelidaki I, Treu L, Tsapekos P, Luo G, Campanaro S, Wenzel H, Kougias PG. Biogas upgrading and utilization: current status and perspectives. Biotechnol Adv. 2018;36(2):452–66.

Omar B, Abou-Shanab R, El-Gammal M, Fotidis IA, Kougias PG, Zhang Y, Angelidaki I. Simultaneous biogas upgrading and biochemicals production using anaerobic bacterial mixed cultures. Water Res. 2018;142:86–95.

Vo TT, Wall DM, Ring D, Rajendran K, Murphy JD. Techno-economic analysis of biogas upgrading via amine scrubber, carbon capture and ex situ methanation. Appl Energy. 2018;212:1191–202.

Srinuanpan S, Cheirsilp B, Boonsawang P, Prasertsan P. Immobilized oleaginous microalgae as effective two-phase purify unit for biogas and anaerobic digester effluent coupling with lipid production. Bioresour Technol. 2019;281:149–57.

Sahota S, Shah G, Ghosh P, Kapoor R, Sengupta S, Singh P, Thakur IS. Review of trends in biogas upgradation technologies and future perspectives. Bioresour Technol Rep. 2018;1:79–88.

Roubík H, Mazancová J, Le Dinh P, Van Dinh D, Banout J. Biogas quality across small-scale biogas plants: a case of central Vietnam. Energies. 2018;11(7):1794.

Morgan HM Jr, Xie W, Liang J, Mao H, Lei H, Ruan R, Bu Q. A techno-economic evaluation of anaerobic biogas producing systems in developing countries. Bioresour Technol. 2018;250:910–21.

Stan C, Collaguazo G, Streche C, Apostol T, Cocarta D. Pilot-scale anaerobic co-digestion of the OFMSW: improving biogas production and startup. Sustainability. 2018;10(6):1939.

Baek G, Kim J, Kim J, Lee C. Role and potential of direct interspecies electron transfer in anaerobic digestion. Energies. 2018;11(1):107.

Park JH, Kang HJ, Park KH, Park HD. Direct interspecies electron transfer via conductive materials: a perspective for anaerobic digestion applications. Bioresour Technol. 2018;254:300–11.

Wang T, Zhang D, Dai L, Dong B, Dai X. Magnetite triggering enhanced direct interspecies electron transfer: a scavenger for the blockage of electron transfer in anaerobic digestion of high-solids sewage sludge. Environ Sci Technol. 2018;52(12):7160–9.

Gao Y, Fang Z, Liang P, Zhang X, Qiu Y, Kimura K, Huang X. Anaerobic digestion performance of concentrated municipal sewage by forward osmosis membrane: focus on the impact of salt and ammonia nitrogen. Bioresour Technol. 2019;276:204–10.

Li J, Shi W, Jiang C, Bai L, Wang T, Yu J, Ruan W. Evaluation of potassium as promoter on anaerobic digestion of saline organic wastewater. Bioresour Technol. 2018;266:68–74.

Akindele AA, Sartaj M. The toxicity effects of ammonia on anaerobic digestion of organic fraction of municipal solid waste. Waste Manag. 2018;71:757–66.

Ma C, Liu J, Ye M, Zou L, Qian G, Li YY. Towards utmost bioenergy conversion efficiency of food waste: pretreatment, co-digestion, and reactor type. Renew Sustain Energy Rev. 2018;90:700–9.

Tyagi VK, Fdez-Güelfo LA, Zhou Y, Álvarez-Gallego CJ, Garcia LR, Ng WJ. Anaerobic co-digestion of organic fraction of municipal solid waste (OFMSW): progress and challenges. Renew Sustain Energy Rev. 2018;93:380–99.

Salama ES, Saha S, Kurade MB, Dev S, Chang SW, Jeon BH. Recent trends in anaerobic co-digestion: fat, oil, and grease (FOG) for enhanced biomethanation. Prog Energy Combust Sci. 2019;70:22–42.

Rodríguez-Abalde Á, Guivernau M, Prenafeta-Boldú FX, Flotats X, Fernández B. Characterization of microbial community dynamics during the anaerobic co-digestion of thermally pre-treated slaughterhouse wastes with glycerin addition. Bioprocess Biosyst Eng. 2019;42(7):1175.

Siddique MNI, Wahid ZA. Achievements and perspectives of anaerobic co-digestion: a review. J Clean Prod. 2018;194:359–71.

Tsui TH, Hao T, Chen GH. Gas-enhanced operation and stepwise organic stressing as a new alternative in realising successful sludge granulation in high-rate anaerobic bioreactor for wastewater treatment. HKIE Trans. 2016;23(4):222–9.

Wang B, Wu D, Ekama GA, Tsui TH, Jiang F, Chen GH. Characterization of a new continuous gas-mixing sulfidogenic anaerobic bioreactor: hydrodynamics and sludge granulation. Water Res. 2018;135:251–61.

Kang X, Zhang Y, Song B, Sun Y, Li L, He Y, Yuan Z. The effect of mechanical pretreatment on the anaerobic digestion of Hybrid Pennisetum. Fuel. 2019;252:469–74.

Song B, Buendia-Kandia F, Yu Y, Dufour A, Wu H. Importance of lignin removal in enhancing biomass hydrolysis in hot-compressed water. Bioresour Technol. 2019;288:121522.

Wu H, Yin Z, Quan Y, Fang Y, Yin C. Removal of methyl acrylate by ceramic-packed biotrickling filter and their response to bacterial community. Bioresour Technol. 2016;209:237–45.

Si B, Yang L, Zhou X, Watson J, Tommaso G, Chen WT, Zhang Y. Anaerobic conversion of the hydrothermal liquefaction aqueous phase: fate of organics and intensification with granule activated carbon/ozone pretreatment. Green Chem. 2019;21(6):1305–18.

Fernandez S, Srinivas K, Schmidt AJ, Swita MS, Ahring BK. Anaerobic digestion of organic fraction from hydrothermal liquefied algae wastewater byproduct. Bioresour Technol. 2018;247:250–8.

Yao Y, Zhang Y, Gao B, Chen R, Wu F. Removal of sulfamethoxazole (SMX) and sulfapyridine (SPY) from aqueous solutions by biochars derived from anaerobically digested bagasse. Environ Sci Pollut Res. 2018;25(26):25659–67.

Luz FC, Cordiner S, Manni A, Mulone V, Rocco V. Biochar characteristics and early applications in anaerobic digestion—a review. J Environ Chem Eng. 2018;6(2):2892–909.

O’Callaghan K. Technologies for the utilisation of biogenic waste in the bioeconomy. Food Chem. 2016;198:2–11.

Menon V, Rao M. Trends in bioconversion of lignocellulose: biofuels, platform chemicals & biorefinery concept. Prog Energy Combust Sci. 2012;38(4):522–50.

Fernando S, Adhikari S, Chandrapal C, Murali N. Biorefineries: current status, challenges, and future direction. Energy Fuels. 2006;20(4):1727–37.

Kamm B, Gruber PR, Kamm M. Biorefineries-industrial processes and products, vol. 1. New York: Wiley; 2006.

Pleissner D, Lin CSK. Valorisation of food waste in biotechnological processes. Sustain Chem Process. 2013;1(1):21.

Pleissner D, Lam WC, Sun Z, Lin CSK. Food waste as nutrient source in heterotrophic microalgae cultivation. Bioresour Technol. 2013;137:139–46.

Shin HY, Kim SM, Lee JH, Lim ST. Solid-state fermentation of black rice bran with Aspergillus awamori and Aspergillus oryzae: effects on phenolic acid composition and antioxidant activity of bran extracts. Food Chem. 2019;272:235–41.

Dessie W, Zhang W, Xin F, Dong W, Zhang M, Ma J, Jiang M. Succinic acid production from fruit and vegetable wastes hydrolyzed by on-site enzyme mixtures through solid state fermentation. Bioresour Technol. 2018;247:1177–80.

Stanley A, Kumar HP, Mutturi S, Vijayendra SN. Fed-batch strategies for production of PHA using a native isolate of Halomonas venusta KT832796 strain. Appl Biochem Biotechnol. 2018;184(3):935–52.

Chen X, Yu L, Qiao G, Chen GQ. Reprogramming Halomonas for industrial production of chemicals. J Ind Microbiol Biotechnol. 2018;45(7):545–54.

Johnston B, Kowalczuk M, Hill D, Tchuenbou-Magaia F, Jonah I, Radecka I. From trash to treasure–turning plastic waste into biodegradable polymers using bacteria. Access Microbiol. 2019;1(1A). https://doi.org/10.1099/acmi.ac2019.po0462.

Rodriguez-Perez S, Serrano A, Pantión AA, Alonso-Fariñas B. Challenges of scaling-up PHA production from waste streams. A review. J Environ Manag. 2018;205:215–30.

Witko T, Guzik M, Sofińska K, Stepien K, Podobinska K. Novel biocompatible polymers for biomedical applications. Biophys J. 2018;114(3):363a.

Bhatia SK, Wadhwa P, Bhatia RK, Patel SKS, Yang YH. Strategy for biosynthesis of polyhydroxyalkonates polymers/copolymers and their application in drug delivery. In: Biotechnological applications of polyhydroxyalkanoates. Springer, Singapore, 2019. p. 13–34.

Zhou Y, Selvam A, Wong JW. Chinese medicinal herbal residues as a bulking agent for food waste composting. Bioresour Technol. 2018;249:182–8.

Asses N, Farhat W, Hamdi M, Bouallagui H. Large scale composting of poultry slaughterhouse processing waste: microbial removal and agricultural biofertilizer application. Process Saf Environ Prot. 2019;124:128–36.

Styles D, Adams P, Thelin G, Vaneeckhaute C, Chadwick D, Withers PJ. Life cycle assessment of biofertilizer production and use compared with conventional liquid digestate management. Environ Sci Technol. 2018;52(13):7468–76.

Aghbashlo M, Tabatabaei M, Soltanian S, Ghanavati H. Biopower and biofertilizer production from organic municipal solid waste: an exergoenvironmental analysis. Renew Energy. 2019;143:64–76.

Paul S, Dutta A, Defersha F. Mechanical and alkaline hydrothermal treated corn residue conversion into bioenergy and biofertilizer: a resource recovery concept. Energies. 2018;11(3):516.

Smitha GR, Basak BB, Thondaiman V, Saha A. Nutrient management through organics, bio-fertilizers and crop residues improves growth, yield and quality of sacred basil (Ocimum sanctum Linn). Ind Crops Prod. 2019;128:599–606.

Sharma S, Rana VS, Kumari M, Mishra P. Biofertilizers: boon for fruit production. J Pharmacogn Phytochem. 2018;7(5):3244–7.

Walsh JJ, Jones DL, Chadwick DR, Williams AP. Repeated application of anaerobic digestate, undigested cattle slurry and inorganic fertilizer N: impacts on pasture yield and quality. Grass Forage Sci. 2018;73(3):758–63.

Stamenković S, Beškoski V, Karabegović I, Lazić M, Nikolić N. Microbial fertilizers: a comprehensive review of current findings and future perspectives. Span J Agric Res. 2018;16(1):1–18.

Qi G, Pan Z, Sugawa Y, Andriamanohiarisoamanana FJ, Yamashiro T, Iwasaki M, Umetsu K. Comparative fertilizer properties of digestates from mesophilic and thermophilic anaerobic digestion of dairy manure: focusing on plant growth promoting bacteria (PGPB) and environmental risk. J Mater Cycles Waste Manag. 2018;20(3):1448–57.

Jiang Y, May HD, Lu L, Liang P, Huang X, Ren ZJ. Carbon dioxide and organic waste valorization by microbial electrosynthesis and electro-fermentation. Water Res. 2018;149:42–55.

Zabaniotou A, Kamaterou P. Food waste valorization advocating circular bioeconomy-a critical review of potentialities and perspectives of spent coffee grounds biorefinery. J Clean Prod. 2018;211:1553–66.

Kannah RY, Velu C, Banu JR, Heimann K, Karthikeyan OP. Food waste valorization by microalgae. In: Waste to wealth. Springer, Singapore, 2018. p. 319–342.

Sarkar O, Butti SK, Mohan SV. Acidogenic biorefinery: food waste valorization to biogas and platform chemicals. In: Waste biorefinery: potential and perspectives, 2018, p. 203.

Brunklaus B, Rex E, Carlsson E, Berlin J. The future of Swedish food waste: an environmental assessment of existing and prospective valorization techniques. J Clean Prod. 2018;202:1–10.

Siciliano A, Limonti C, Mehariya S, Molino A, Calabrò V. Biofuel production and phosphorus recovery through an integrated treatment of agro-industrial waste. Sustainability. 2018;11(1):1–17.

Paul S, Dutta A. Challenges and opportunities of lignocellulosic biomass for anaerobic digestion. Resour Conserv Recycl. 2018;130:164–74.

Kuznetsov BN, Sudakova IG, Garyntseva NV, Levdansky VA, Ivanchenko NM, Pestunov AV, Pinel C. Green biorefinery of larch wood biomass to obtain the bioactive compounds, functional polymers and nanoporous materials. Wood Sci Technol. 2018;52(5):1377–94.

Ashokkumar V, Chen WH, Ngamcharussrivichai C, Agila E, Ani FN. Potential of sustainable bioenergy production from Synechocystis sp cultivated in wastewater at large scale—a low cost biorefinery approach. Energy Convers Manag. 2019;186:188–99.