Abstract

Fiber materials are promising for electrocatalysis applications due to their structural features including high surface area, controllable chemical compositions, and abundant composite forms. In the past decade, considerable research efforts have been devoted to construct advanced fiber materials possessing conductive network (to facilitate efficient electron transport) and large specific surface area (to support massive catalytically active sites) to boost electrocatalysis performance. Herein, we focused on recent advances in fiber-based electrocatalyst with enhanced electrocatalytic activity. Moreover, the synthesis, structure, and properties of fiber materials and their applications in hydrogen evolution reaction, oxygen evolution reaction, oxygen reduction reaction, carbon dioxide reduction reaction, and nitrogen reduction reaction are discussed. Finally, the research challenges and future prospects of fiber materials in electrocatalysis applications are proposed.

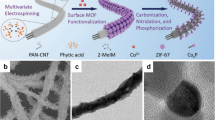

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The rapid depletion of fossil fuels and associated environmental concerns have stimulated significant efforts to develop efficient energy conversion technologies [1,2,3,4]. Electrocatalytic reactions, including hydrogen evolution reaction (HER), oxygen evolution reaction (OER), oxygen reduction reaction (ORR), carbon dioxide reduction reaction (CO2RR), and nitrogen reduction reaction (NRR), are the core of the clean and renewable energy technologies [5, 6]. However, the use of these technologies is severely impeded by the sluggish kinetics of the electrocatalysis processes [7]. It is highly desirable to develop high-efficiency and durable catalysts to promote these electrochemical reactions. Till now, precious metals and nonprecious transition metals, as well as their compounds (e.g., oxides, nitrides, sulfides, phosphides, and carbides), have been widely used as efficient electrocatalysts for energy conversion [8,9,10]. In addition to composition control, the structural modulation of the electrocatalysts is also important, especially for the complicated multi-step or multi-product electrocatalytic reactions that are highly dependent on chemical and electronic structures.

Fiber materials, are potent electrocatalysts, due to their unique features such as high specific surface area, tunable chemical components, and controllable architectures [11]. As summarized in Fig. 1, publications and citations of fiber electrocatalysts have increased steadily in the past decades. Numerous structural engineering strategies have been applied to fabricate advanced fiber-based catalysts with exceptional electrocatalytic properties [12, 13]. Figure 2 illustrates the fundamentals of fiber materials for electrocatalysis, including structural features, synthesis approaches, structural engineering, and composite structure. The conductive network is beneficial for the rapid mass/electron transport in electrodes, therefore, the fabrication of fiber-based electrocatalysts generally accompanies the carbonization of polymer fibers. The catalytic activities of carbon fiber have been demonstrated to be induced by doping with defective or heteroatoms (e.g., N, B, S, P, O, F). They play an important role in manipulating charge distribution of the carbon fiber matrix [14, 15]. In addition to enhance the intrinsic catalytic activity of the fiber matrix, the carbon fiber can also serve as a substrate for catalytically active materials (single atoms, metals and their compounds) to improve the overall catalytic activity of the composite fibers [16, 17]. Increasing the intrinsic activity of each active site and the number of active sites of the fiber materials have been proven as effective strategies to enhance the efficiency of fiber-based electrocatalysts [18, 19]. The former could be achieved by morphology engineering, size control, interface modification, and electronic structure manipulation of catalytically active materials; the latter is mainly based on increasing the specific surface area of fiber matrix to support massive catalytically active sites, such as reducing the diameter of the fiber to the nanoscale and constructing mesoporous 3D framework.

Statistics of publications and citations of fiber electrocatalysts from 2011 to 2021 by putting the search formula TS = (fiber AND “hydrogen evolution reaction” OR “oxygen evolution reaction” OR “oxygen reduction reaction” OR “carbon dioxide reduction reaction” OR “nitrogen reduction reaction”), using the website Web of Science accessed through: https://webofknowledge.com/ on 7 Dec. 2021

Considering the great potential of using fiber materials in electrocatalysis, a concise updated overview of this rapidly developing area is required. In this review, we briefly discuss the design concepts and fabrication methods of fiber-based electrocatalysts, followed by the major applications of fiber materials in the areas of electrocatalysis. Particularly, the fundamental relationships between the structure and properties are highlighted to provide creative insight on the construction of high-performance fiber-based electrocatalysts. Finally, we point out the current challenges and future prospects for fiber-based electrocatalysts development.

Fundamentals of Fiber-Based Electrocatalysts

Fiber materials are featured with tailorable morphology and structure, large specific surface area, and interconnected conductive networks, all of which are highly correlated to electrocatalytic activity. The high activity of catalyst during a catalytic reaction relies on increasing the activity of fiber matrix or exposing more catalytically active sites. The activity of fiber matrix can be induced by heteroatoms doping or the introduction of active components (single atoms, metals and their compounds), while constructing 3D mesoporous structure increases the specific surface area of fiber matrix to support more active sites. Based on these structural characteristics, numerous approaches have been developed for activating those fiber materials for electrocatalysis.

Fiber Materials Directly as Active Species

Inorganic fiber materials such as TiO2 fiber can contribute significantly to the catalytic performance due to their intrinsic electrocatalytic activity. For instance, the TiO2 fiber can be obtained by electrospinning a mixture solution of poly (vinyl pyrrolidone) and titanium isopropoxide, followed by calcination in air to remove the organic component [20]. The resulting abundant mesopores in fiber matrix are advantageous to the electrolyte permeation.

Carbon fiber catalysts with low-cost were discovered to be a promising catalyst when compared to metal-based fiber. The catalytic activities of these catalysts have been induced by doping. Heteroatom doping can induce the charge redistribution in the carbon fiber, which is beneficial in facilitating the chemisorption of reactants/products during catalytic process [21, 22]. Doping heteroatoms into carbon fibers frameworks can be accomplished in two ways: in-situ synthesis and post-processing. For in-situ doping heteroatoms during the synthesis process of fibers, the heteroatom-containing precursor is generally mixed with carbon sources followed by carbonization. The post-processing doping can be achieved by pyrolyzing the heteroatom-containing chemical reagents or gases. For example, Wang et al. reported a scalable strategy for in-situ doping the N, F, and B atoms into carbon fibers via electrospinning and subsequent thermal treatment, in which the polyacrylonitrile (PAN) and ammonium tetrafluoroborate were used as the precursor for carbon fiber and N, F, B resource, respectively (Fig. 3a) [23]. Each active site in ORR processes is a complex or union of heteroatoms and carbon atoms around defects or vacancies, leading to higher activity via efficient 4e− transfer mechanism. Zhao and co-workers demonstrated N, S co-doped porous carbon cloth (CC) using post-processing method (Fig. 3b) [24]. In this case, sulfur was incorporated into CC through hydrothermal treatment with thiourea, followed by pyrolysis with benzyl disulfide, and finally the NH3 plasma treatment was performed to further dope N into S-doped CC. The N, S dual-doping leads to asymmetrical spin and charge density, resulting in a synergistic effect to enhance electrocatalytic activity. All in all, although pure fiber is electrochemically inactive, doping with heteroatoms without loading other active materials can induce excellent electrochemical activities.

a Schematic illustration of the preparation process of the N, F, and B ternary doped carbon fibers. Reproduced with permission [23]. Copyright 2018, Wiley–VCH. b Schematic illustration for the preparation of N, S-CC by three-step in situ activation process. Reproduced with permission [24]. Copyright 2018, Wiley–VCH. c FESEM and d TEM images of as-prepared Ni2P@NPCNF. e Illustration of the enhanced HER process over Ni2P@NPCNFs. Reproduced with permission [33]. Copyright 2018, Wiley–VCH. f SEM images of CC@ZnO-1, CC@ZnO-2, and CC@ZnO-3. Reproduced with permission [36]. Copyright 2019, Wiley–VCH

Fiber Materials as Catalyst Support

Fiber materials are commonly used as a desirable catalyst support because they provide interconnected conductive networks, continuous electron transfer pathways, and large surface area for loading catalytically active species [25]. Due to the simple preparation, easy-to-control composition and morphology, electrospinning has been established as the most promising methods for the fabrication of fiber catalysts [26,27,28]. A wide variety of catalytically active materials, comprising noble metals, transition metals and their alloys, oxides, chalcogenides, carbides, and phosphides, could be composited with fiber matrix to facilitate rapid mass/electron transport and prevent the agglomeration of active materials [29,30,31,32]. For instance, by electrospinning and following controllable pyrolyzed reduction, the ultrafine nickel phosphides embedded N-doped porous carbon nanofibers could be easily synthesized (Fig. 3c–e) [33]. Using the same method, a series of pea-like metal phosphides embedded composite fibers can be successfully fabricated.

Moreover, various post-treatment strategies, including surface deposition, interfacial growth, dip-coating, plasma treatment, and anodic oxidation technique have been devised to endow fiber matrix with some unique interface properties and enhanced catalytic activity [34, 35]. Surface deposition and dip-coating makes it possible to load active materials with controlled layer and morphology. Interfacial growth is a straightforward method to grow active materials with rational controlled composition, size, morphology, and structure. Wang et al. successfully synthesized hierarchical ZnO arrays on carbon cloth by a facile hydrothermal reaction, the ZnO arrays with single-rod, cluster and tetrapod-shaped can be obtained by using different zinc sources (Fig. 3f) [36]. The Hu group synthesized a series of multicomponent nanoparticles with different composition, size, and phase on carbon nanofibers by optimizing the carbothermal shock parameters such as substrate, temperature, shock duration, and heating/cooling rate [37]. Furthermore, in-situ growth of active materials on flexible substrates, such as carbon cloths (CC), flexible films, and metal foams is an effective approach to facilitate the electron transfer between the active sites and current collector.

Design Strategies of Advanced Fiber Electrocatalysts

It is well known fact that the high activity of electrocatalyst relies on increasing the intrinsic activity or exposing more reactive sites [38, 39]. In terms of the intrinsic catalytic activity of the active species, doping heteroatoms, introducing oxygen vacancy, and constructing 3D porous architectures could expose more active sites to accelerate the electrocatalytic reactions [40, 41]. Qiao et al. reported the design of NiO nanorod arrays that were in-situ fabricated on carbon fiber paper via a facile cation exchange methodology, and the amounts of O-vacancies on the surface of NiO nanorods could be turned by controlling the cation exchange temperature [42]. Based on the experimental studies and density functional theory calculations, they demonstrated that the O-vacancy engineering assures a rapid electron transfer and promote their catalytic activity and durability. In addition to introducing oxygen vacancy, heteroatom doping could also facilitate the charge redistribution and chemisorption of reactants/products [14].

The catalytic activity can also be improved by constructing porous carbon fiber networks, as the hierarchical porous framework can provide a large specific surface area to support more catalytically active species. In this regard, electrospinning has been considered as a practical approach to construct meso- and macropores in fiber matrix. The Yu group synthesized a novel hierarchical fiber catalyst by electrospinning bimetallic zeolitic imidazolate framework (ZIFs) precursors and carrying polymers followed by pyrolysis process [43]. This hierarchical porous structure plays a vital role in boosting catalytic activity by improving the exposure of active sites and accelerating mass/electron transfer.

Fiber-Based Catalysts for Electrocatalysis Applications

Fiber materials possess large electrochemical active surface areas and high electron/mass diffusion rates, making them potent for the application in the field of electrochemical catalysis. The type, amount, and dispersion of the active species can be easily turned to optimize the catalytic activity of fiber-based catalysts. This section focuses on the application of fiber-based materials as electrocatalysts, based on synthesis-structure–property principles, including HER, OER, ORR, CO2RR, and NRR.

Fiber-Based Electrocatalysts for HER

Hydrogen (H2) has gained attention as a sustainable, clean, and renewable energy resource. The electrocatalytic water splitting via the hydrogen evolution reaction (HER) represents a cost-effective and efficient method to produce H2 [44, 45]. Although noble-metals such as Pt, IrO2 are regarded as the most active catalysts for HER, their high cost and limited abundance impede large-scale implementation. In this context, cost-effective electrocatalysts derived from carbon fibers have emerged to be a possible alternative to noble metals. Owing to the excellent conductivity and corrosion resistance, transition metal carbide, nitride, sulfide, selenide, phosphide, and alloys have been identified as promising HER catalysts [46, 47]. For fiber-based electrocatalysts for HER, the optimization of electrochemical performance can be realized by altering the composite structure or electronic properties of fiber matrix and active metal species. Density functional theory (DFT) calculations have demonstrated that doping of the carbon fiber skeleton with N, B, S, P atoms could reduce the Gibbs free-energy of the hydrogen adsorption (∆GH*) to enhance the HER activity [48]. Apart from the structural modification of fiber matrix, tuning active metal species by doping with non-noble-metal cation and anion could also achieve optimized catalytic performance.

Electrospinning and subsequent pyrolysis have been widely developed to prepare efficient HER electrocatalysts, for example, ultrafine bimetallic Ni2−xCoxP nanoparticles embedded N-doped carbon nanofibers (Ni2−xCoxP/N–C NFs) are fabricated as electrode material for pH-universal HER (Fig. 4a, b) [49]. Owing to the 1D hierarchical nanostructures (fully expose active sites and facilitate charge transfer) and alloy Ni2-xCoxP nanoparticle (fulfil electronic modulation on active sites), the Ni2−xCoxP/N–C NFs exhibited optimized HER performance in acidic, neutral, and alkaline electrolytes (Fig. 4c). In addition to directly incorporating active species in fiber matrix via electrospinning, the carbon fiber can also serve as a conductive support to load catalytically active species. Common conductive supports are mainly focused on electrospun fibers, commercial carbon fiber papers (CFP), and carbon cloth (CC). Featuring with mechanical strength and flexibility, CFP and CC can be directly employed as a self-supported electrode to avoid the use of binders, thereby facilitating efficient electron transfer [50]. For instance, Zhang and colleagues have directly grown Mo-precursor nanowire arrays (NWAs) on CFP through the solvothermal reaction, followed by thermal treatment under different gas atmosphere led to the formation of a series of molybdenum-based compounds (MoP, MoS2, Mo2C, MoN, and MoO2) [51]. As shown in Fig. 4d–f, the length and diameters of the MoP nanowires on CFP are ~ 9 µm and 50–150 nm, respectively, which were composed of closely interconnected MoP nanocrystals with rich nanopores. The HER activities were evaluated in 0.5 M H2SO4, 1.0 M PBS, and 1.0 M KOH electrolytes, respectively. The fabricated MoP NWAs/CFP exhibit a high alkaline HER activity with a low overpotential of 52 mV at a current density of 10 mA cm−2, which is comparable with that of the Pt electrodes (Fig. 4 g, h). Besides the catalytic activity, the durability is another essential factor for HER. Liu and co-workers have confirmed that N, P dual-doped carbon coatings on active species not only prevent the aggregation of nanoparticles, but also facilitate the charge/mass transportation [52]. The polarization curve of obtained electrode displays a negligible degradation after 3000 continuous CV cycles.

a SEM and b TEM images of the Ni0.67Co1.33P/N–C NFs. c illustration of interfacial charge transfer in Ni2-xCoxP/N–C NFs. Reproduced with permission [49]. Copyright 2019, Elsevier. d, e SEM and f TEM images of MoP NWAs/CFP. g Polarization curves and h Tafel plots of MoXn NWAs/CFP and Pt electrodes recorded in 1.0 M KOH. Reproduced with permission [51]. Copyright 2018, Wiley–VCH

Recently, a series of in-situ characterization techniques, including liquid-phase transmission electron microscopy, in-situ X-ray absorption spectroscopy, and in-situ Raman spectroscopy has been developed to reveal the intermediate information during catalytic process. The P-substituted CoSe2 nanowires covered CC electrode was prepared by Zhu and co-workers [53]. They use the sequential in situ STEM images of the catalyst after immersing in the alkaline electrolyte to explore the real catalytically reactive species. After contacting with the alkaline electrolyte, the CoSe1.26P1.42 transformed into Co(OH)2, confirming that P-substituted CoSe2 catalyst acting as the “pre-catalyst” rather than the real reactive species.

Fiber-Based Electrocatalysts for OER

Many energy conversion systems, such as water splitting and metal-air batteries, rely on OER reaction. However, OER is a four-electron coupled reaction that often suffers from sluggish kinetics and high overpotential, limiting its energy conversion efficiency [54, 55]. Due to the low element abundance of currently available commercialized RuO2 and IrO2 catalysts, transition metals and their compounds have drawn extensive attention over the past few years [56]. Since the bare metal catalysts are prone to be eroded and aggregated with each other during electrochemical reactions, efficient solid catalyst supports are required to stabilize catalytically materials. Benefiting from the high electrical contact area and interconnected electron-transfer pathways, fiber materials have received increasing interest as promising supports to load catalytically active sites [57]. Electrospinning is considered as a convenient method for the fabrication of 1D nanostructures with large specific surface areas and controlled morphology [58]. Recently, it has been demonstrated that NiFe alloy nanoparticles embedded N-doped carbon nanofibers, developed by electrospinning and subsequent heat treatment, exhibited remarkably enhanced OER performance with a low overpotential of 294 mV at a current density of 10 mA cm−2 in alkaline solution [59]. Further modification of the fiber matrix by constructing porous network could provide more exposed catalytic sites. Zhao and colleagues proposed an in-situ growth strategy to synthesis zeolitic imidazolate frameworks (ZIFs)/polyacrylonitrile (PAN) core/shell fiber (PAN@ZIFs) [60]. The following high-temperature pyrolysis could convert PAN@ZIFs to heteroatom-doped carbon fiber, thereby providing continuous conductive nanoporous network as well as highly exposed active sites. From Fig. 5a–c, it can be observed that the small size of ZIF-67 tends to form a uniform and dense coating on the whole fiber. TEM images in Fig. 5d, e proved that the metal particles existed in the interior of CNF@Zn/CoNC with graphitic shell scattered around fiber surface. The CNF@Zn/CoNC displays the most negative potential (1.70 V vs RHE) at current density of 10 mA cm−2, which is attributed to the core–shell structure with abundant multiactive sites facilitateing fast electron/ions transport (Fig. 5f).

a Schematic illustration of morphology evolution in PAN@ZIF-67 fiber. SEM images of b PAN@ZIF-67–400 fiber and c PAN@ZIF-67–80 fiber. d TEM and e HRTEM images of CNF@Zn/CoNC. f LSV curves of CNF@ZnNC, CNF@Zn/CoNC, CNF@CoNC, and 30 wt% Pt/C for OER. Reproduced with permission [60]. Copyright 2018, Wiley–VCH

Active materials directly grown on conductive substrates as binder-free electrode have many intrinsic advantages over powdery forms conglutinated electrode, such as highly exposed active sites, reduced contact resistance, and sufficient accessibility of reactants and products. For instance, a facile “impregnation-carbonization-acidification” strategy was proposed to grow a class of single-atom-anchored (including cobalt and nickel single atoms) monolith on carbon nanofibers (Co SA@NCF/CNF) as binder-free OER electrocatalysts [61]. The obtained Co SA@NCF/CNF shows excellent flexibility, which can be directly used as flexible electrodes. The Co SA@NCF/CNF film is composed of uniformly interconnected microfibers, and the carbon flakes with open mesopores uniformly cover the carbon nanofibers. Due to the optimized active sites and hierarchically porous structure, the binder-free Co SA@NCF/CNF exhibits excellent OER activity and durability in alkaline medium. Furthermore, the composition, morphology, and structure of the active materials on conductive substrates can be rationally controlled through surface modification methods, such as anodic oxidation, surface coating, elements doping, and so on [62, 63]. A novel 3D hierarchical structure with iron-substituted CoOOH porous nanosheet arrays grown on carbon fiber cloth (Fe0.33Co0.67OOH PNSs/CFC) was synthesized by electrodeposition and subsequent in-situ anodic oxidation (Fig. 6a) [64]. As shown in Fig. 6b–d, the obtained Fe0.33Co0.67OOH PNSs/CFC hierarchical arrays is composed of rough porous nanosheets with a thickness of about 5 nm. The partial CoO6 octahedral structures in CoOOH could be substituted by FeO6 octahedrons during the anodic oxidation process (Fig. 6e), and the DFT calculation reveals that FeO6 octahedron possesses more active sites for OER. Besides, using a facile hydrothermal method, the vertically crossed CuCo nanosheet precursors grown on CF were synthesized [65]. The following calcination process in the NH3 atmosphere leads to the formation of N-doped carbon layer surrounding the nanosheets. The specific surface area significantly increased after thermal annealing, which is favorable for providing facile electrolyte accessibility and additional active sites.

a Illustration of the fabrication of FexCo1−xOOH PNSAs/CFC. b, c SEM images and d TEM image of Fe0.33Co0.67OOH PNSs/CFC. e The structural transformation from α-Co(OH)2 to Fe0.33Co0.67OOH. Reproduced with permission. [64]. Copyright 2018, Wiley–VCH

Fiber-Based Electrocatalysts for ORR

The ORR is a core reaction for rechargeable metal-air batteries and fuel cells [66]. Exploring non-precious metal catalysts with sufficient activity and durability to replace Pt or Pt-based catalysts has been a challenge for large scale production and practical applications [67, 68]. In the past few years, metal–organic frameworks (MOFs), transition-metal carbides/nitrides/sulfides/alloys, metal-free heteroatom-doped carbon, and metal-nitrogen-carbon (M–N–C) catalysts have attracted great attention as electrocatalysts for ORR. The ORR can proceed through the two-step 2e− pathway or the 4e− reduction pathway in both acid and alkaline media, where the 4e− pathway is more desirable for efficient ORR electrocatalysis. The ORR activity of cathode is strongly influenced by the chemical, structural, and transport properties of the active material.

Recently, atomically dispersed and nitrogen-coordinated single metal sites embedded in carbon (denoted as M–N–C) has been widely investigated as the non-precious metal catalysts for the ORR [69]. Among the numerous studied precursors, MOFs constructed by metal ions and organic ligands are effective in creating atomically dispersed M–N4 sites embedded in defect-rich carbon matrix. 1D MOF-derived nanofibers with hierarchically porous architecture can be easily produced via electrospinning and thermal treatments, which is conducive to exposing more accessible active sites and facilitating mass/electron transport. Using the electrospinning technique, He et al. prepared an interconnected hierarchical fibrous architecture to maximize the utilization of CoN4 sites for highly active M–N–C cathodes [70]. The obtained nanofiber catalyst shows a porous fibrous morphology and hierarchical structure, thus facilitating the mass transfer of reactants (O2 and H+) and product (H2O). However, these fibrous catalysts synthesized via in-situ electrospinning mainly possess microporous structures, the fabrication of CNFs with open-mesoporous and interconnected structure is quite challenging. Inspired by fibrous string structures of bufo-spawn, Chen and co-workers prepared the atomic Fe–Nx sites coupled open-mesoporous N-doped-carbon nanofibers (OM-NCNF-FeNx) by fabricating open-mesoporous nanofibers and then coupling atomic Fe–Nx catalytic sites (Fig. 7a) [71]. Figure 7b, c clearly reveal the OM-NCNF-FeNx consist of abundant irregular open mesopores and fully interconnected structures. When compared with the other types of CNF catalysts, the OM-NCNF-FeNx shows comparable or better ORR performance (E0 = 0.905 V and E1/2 = 0.836 V) (Fig. 7d).

a Schematic representations of the synthesis of atomic Fe-Nx sites coupled open-mesoporous N-doped-carbon nanofibers (OM-NCNF-FeNx). b SEM and c TEM images of the OM-NCNF-FeNx nanofiber. d ORR polarization curves for nanofibers catalysts in 0.1 M KOH. Reproduced with permission [71]. Copyright 2018, Wiley–VCH

Furthermore, by anchoring ultrasmall TMO nanocrystals on conductive carbon fiber supports, electrocatalytic performance could be dramatically improved [72]. Because of the poor electronic conductivity and low surface area, the electrocatalytic activity of pure bulk TMOs is far less than expectated. In this regard, regulating defects (doping heteroatoms and introducing oxygen vacancies) in nanocomposites is an effective approach to manipulate the chemical activities of TMOs. For instance, Yang and co-workers proposed a controllable N-doping strategy to improve the ORR catalytic activity of Co3O4 on CC [73]. The DFT calculations and experimental results reveal that the N doping could significantly improve the electronic conductivity and O2 adsorption capability of Co3O4, thereby facilitating the ORR process (Fig. 8a). Moreover, oxygen vacancies could serve as electron donors to enhance the electrical conductivity and alter the surface electronic structures, thus enhancing the number of active sites and the catalytic activity. It has been reported that a Kirkendall diffusion process could induce the generation of oxygen vacancy in Co3O4 hollow particles (Fig. 8b), this synthetic approach may also be extended to other oxides, selenides and sulfides with similar structures to produce vacancies [74]. The obtained fiber catalyst shows the highest ORR half-wave potential of 0.834 V, which is in good agreement with its high ORR electron transfer number of about 4.0 (Fig. 8c, d).

a Calculated structures and O2-adsorption energies (ΔEad) of the undoped and N-doped Co3O4 (110) surfaces. Reproduced with permission [73]. Copyright 2017, Wiley–VCH. b Illustration of the evolution of Co particles into hollow Co3O4 particles with the formation of oxygen vacancies during the oxidation process. c ORR polarization curves. d K-L plots of Co3O4−x HoNPs@HPNCS-60. Inset: the corresponding LSV curves. Reproduced with permission [74]. Copyright 2019, Wiley–VCH

Fiber-Based Electrocatalysts for CO2RR

The excessive combustion of fossil fuels has led to a significant increase of CO2 emission. The accumulation of CO2 in atmosphere greatly contributes to the global warming and climate deterioration [75]. The electrochemical CO2 reduction reaction (CO2RR) allows one to convert CO2 into valuable products including methane, formic acid, carbon monoxide (CO), etc., thus reducing the carbon footprint [76]. However, the thermodynamically stable and kinetically inert nature of CO2, as well as the competing reaction of HER, greatly hinder the large-scale application of the CO2RR. It is important to explore low-cost and abundant electrocatalysts that allow for the efficient CO2 reduction while minimizing the hydrogen production. The electrocatalysts for CO2RR can be divided into three categories: producing formic acid (Sn, Pb, Bi), producing CO (Au, Ag, Zn), and producing a range of higher order hydrocarbons (Cu) [77]. Fiber materials have been used as an effective support for metal nanoparticles owing to their large specific surface area and conductive interconnected network, affording a metal-support synergy to optimize catalytic activity.

Cu is the only recognized CO2RR electrocatalysts catalyzing the generation of a series of hydrocarbons or alcohols in aqueous solutions. Since Cu-based electrocatalysts usually generate a variety of gaseous and liquid phase products, it is necessary to reasonably control the catalytic selectivity of CO2RR to obtain target product. Using electrospinning technology, a through-hole carbon nanofibers with abundant and homogeneously distributed Cu single atoms (CuSAs/TCNFs) was designed for efficient electrochemical CO2RR [78]. The CuSAs/TCNFs form a hierarchical interconnected network with a diameter of 700 nm, and no clusters or nanoparticles can be found in HR-TEM image (Fig. 9a). Due to the synergistic effect of the through-hole carbon structure and abundant isolated Cu active sites, the CuSAs/TCNFs exhibits a high Faradaic efficiency (methanol) of 44% (Fig. 9b, d). According to the DFT calculations in Fig. 9c, the Cu–N4 structure demonstrates a favorable free energy (1.17 eV) for rate-determining step, so that the as-generated COOH* intermediate can be easily converted to a CO* species. Researchers also found that the introduction of Cu atoms in nickel-copper alloy could effectively tune the d-band electron configuration, leading to a moderate hydrogen adsorption and optimal HER activity [79]. The obtained self-standing array structured electrode (atomically dispersed Ni anchored N-doped carbon nanotube array with nickel-copper alloy encapsulation on CFP) possesses high Faradic efficiency toward CO formation.

a HR-TEM images of CuSAs/TCNFs. b Illustration of CO2 diffusion on CuSAs/CNFs and CuSAs/TCNFs. c Free energy diagram of CO2 to CO on pyridine N, Ni-N4, and Cu-N4 structure. d Faradaic efficiencies of all products at CuSAs/TCNFs. Reproduced with permission [78]. Copyright 2019, American Chemical Society

Different from Cu-based electrocatalyst, metallic Bi and Bi2O3 catalysts have been demonstrated to show high selectivity for formate production. The activity for formate production of Bi-based catalysts can be enhanced by Bi alloying and structural engineering. Using a scalable hot-aerosol synthesis strategy, Tricoli et. al. proposed the tunable design of 3D fractal structured Bi2O3 (f-Bi2O3) on porous carbon fiber paper [80]. Even though the selectivity trends of f-Bi2O3 and Bi2O3 toward formate generation are similar, the higher exposure of roughened β-phase Bi2O3/Bi edges would entail an improved diffusion of CO2 reactants and products, resulting in higher jHCOO− (− 20.9 mA cm−2).

Fiber-Based Electrocatalysts for NRR

Electrochemical conversion of nitrogen (N2) to ammonia gas (NH3) was treated as one of the significant industrial processes because of the high efficiency and abundant reaction resources [81, 82]. This strategy is expected to replace conventional Haber–Bosch process which consumes great amount of energy consumption and a significant amount of carbon dioxide (CO2) released. However, when compared with industrial production, electrochemical NRR suffers from unsatisfactory ammonia production and poor Faraday efficiency (FE) [83]. Over the past few decades, numerous structural engineering strategies have developed to enhance intrinsic activity of the electrocatalyst or introduce extra active sites to improve the efficiency and ammonia production rate of N2 reduction reaction [84]. Apart from optimizing catalytic performance of NRR, strengthening the suppression of HER is also necessary due to the fierce competition between NRR and HER. Studies have revealed that by selecting, designing, and engineering electrocatalysts, the transfer of protons from the electrolyte to the catalyst can be slowed down, thereby alleviating the inhibitory effect of HER on NRR [85].

Recent reports have emphasized the importance of structural engineering (defect engineering, surface orientation and amorphization) for N2 adsorption and activation. Although structural defects are beneficial to the NRR process, they inevitably reduce electronic conductivity. It has been proved that dispersing active materials with abundant defects on conducting fiber supports is ideal for NRR applications. Peng and co-workers reported N-defective carbon nitride grown on carbon paper as a highly selective NRR electrocatalyst [86]. They confirmed that the dinitrogen molecules are preferably chemically adsorbed on the C=N−C N2C vacancy site via an end-on mode, whereas unpaired electrons in carbon nitride can be reversely donated to the adsorbed nitrogen molecule and promote N2 reduction. Furthermore, introducing oxygen vacancies could increase the ability to capture electrons as well as adjust the band structure, which is conducive to promoting the electrocatalytic NRR performance. For example, the amorphous Bi4V2O11 contains significant oxygen vacancies and has been used as the active material for electrocatalytic NRR (Fig. 10a) [87]. The obtained noble-metal-free Bi4V2O11/CeO2 hybrid with an amorphous phase (BVC-A) possesses hollow nanofibrous morphology with a diameter of about 60 nm, in which the CeO2 nanocrystals are well-dispersed in the BVC-A nanofibers (Fig. 10b, c). As illustrated in Fig. 10d, the Bi4V2O11/CeO2 forms a type I band alignment, which is beneficial in facilitating the interfacial electrons transfer from CeO2 to Bi4V2O11 (Fig. 10e).

a Illustration of the fabrication of BVC-A and BVC-C NRR electrocatalysts. b SEM and c HRTEM images of BVC-A. d Band alignment of Bi4V2O11 and CeO2. e Illustration of interfacial charge transfer in BVC-A. Reproduced with permission [87]. Copyright 2018, Wiley–VCH. SEM images of f TiO2 nanofibrous membrane and g C@CoS@TiO2 nanofibrous membrane. h Ammonia yields and Faradaic efficiencies of a C@CoS@TiO2 nanofibrous membrane at different potentials. Reproduced with permission [20]. Copyright 2019, Wiley–VCH

Actually, the present transition-metal electrocatalysts still suffer from low activity and Faradaic efficiency due to poor interfacial reaction kinetics. It is reported that the interface engineering through constructing heterojunction will facilitate charge transfer, leading to fast reaction kinetics at the heterointerface. Guo et al. developed a self-standing FeS@MoS2/CFC hybrid NRR electrode through a one-step hydrothermal method [88]. The unique synergy between Fe and Mo facilitates an optimized artificial NRR system through imitating the composition of natural enzymes such as FeMo-nitrogenases. Compared to inactive carbonaceous matrices, the researchers found that the TiO2 nanofibrous membrane made a significant contribution to the NRR performance owing to its intrinsic catalytic activity [20]. Particularly, an interface-engineered heterojunction was developed, in which the CoS nanosheets anchored on TiO2 nanofibrous membrane (Fig. 10f, g). The TiO2 nanofibrous membrane could prevent agglomeration of CoS nanosheets, and the intimate coupling between CoS and TiO2 facilitates the charge transfer at the heterogeneous interface. As shown in Fig. 10 h, the obtained electrocatalyst provides high ammonia yield and Faradaic efficiency of 8.09 × 10–10 mol s−1 cm−2 and 28.6%, respectively.

Summary

According to the locational relationships between electrocatalytically active materials and fiber matrix, most of fiber electrocatalysts can be divided into two types based on recent research: (1) supported electrocatalysts and (2) embedded electrocatalysts. Because the supported active materials are completely exposed in supported electrocatalysts, the high resistance to chemical attack, as well as the robust conjugation of fiber matrix and supported material, is the key to enhance catalytic activity. While for embedded electrocatalysts, interconnected porous structure is advantageous for the sufficient exposure of active sites and the mass transfer. Furthermore, for different electrocatalytic applications, the active material should be cautiously selected according to the difference of the catalytic reactions. For HER, OER, and ORR, the adaptability of the catalysts under different pH values is necessary because the metal species are sensitive to the pH of the electrolyte. The interface structure should be reasonably designed to adapt different reaction medium. Till now, metals are the most investigated electrocatalysts for heterogeneous CO2RR, hybrid catalyst might represent the future orientation for catalyst design. Further investigations on fiber-based CO2RR catalysts should be performed to understand the structure-performance relationships. Since the intense HER competition significantly limits Faradaic efficiency of NRR, the morphology, crystal phase, and composite structure of the fiber catalyst should be well designed to reduce the HER selectivity and increase the ammonia yield.

Conclusions and Perspectives

We have reviewed the recent progress of fiber materials for electrocatalysis applications. The unique traits of fiber materials have been summarized while various design strategies for optimize electrocatalytic activity were highlighted. Their applications in five representative electrocatalysis reactions including HER, OER, ORR, CO2RR, and NRR, were reviewed by organizing and comparing the electrochemical performance of different fiber-based electrocatalysts. Although current results of fiber-based electrocatalyst are inspiring, following issues still need to be addressed before their practical applications.

First, increasing the intrinsic activity of active species would improve the catalytic efficiency of fiber catalysts. In the past few decades, the catalytic properties of fiber-based electrocatalysts have been significantly enhanced by engineering the electronic structure within catalytically active materials (e.g. defect engineering, element doping, and construction of heterojunction). Despite the fact that some studies have been conducted to reveal the correlations between bonding configuration and catalytic activity, the chemical nature of catalysts and actual reaction mechanism are still unclear. Future research should concentrate on precisely controlling the content, location, and distribution of dopants, in order to gain a basic understanding of the doping induced charge transfer and associated electrochemical property changes. Moreover, numerous structural modification methods for active components like particle size reduction, hierarchically porous architecture construction, and crystalline structure optimization, can be combined with electronic engineering to improve the intrinsic activity of active species.

Second, the structural engineering of fiber matrix allows for anchoring more reactive sites. Despite the fact that fiber material has a relatively high specific surface area, simply electrospinning a mixture of organic precursor and active species may cause insufficient exposure of the active site. Constructing a 3D porous hierarchical fibrous architecture through electrospinning helps maximize the utilization of active species, and plays a vital role in boosting the catalytic performance by providing facile electron diffusion pathway and facilitating the efficient mass transport. However, the active species in hierarchical structures are currently limited to specific compositions like single atoms, and it is critical to expand it to other systems. For the loading of active materials on the fiber surface through post-treatment, high specific surface area of fiber matrix is a premise to load more active sites, it is of great significance to rationally balance the loadings and specific surface area to achieve high specific activity and mass activity.

Finally, because the conventional electrode fabrication results in poor electron transfer between catalysts and current collector, thus fiber catalysts without additive must be constructed to directly act as a freestanding electrode to enhance catalytic activity and durability. Currently, the processing methods of surface modification on fiber support mainly include solvothermal, electrodeposition, and chemical treatments. However, all these technologies are suffered from the difficulty of uniformly distribution of active components. Developing an easy-to-synthesize method to evenly loading active materials and enhance their interaction with fiber support helps to optimize the electronic structure at the surface and consequently improving catalytic activity.

In addition to conventional electrocatalytic applications mentioned above, fiber materials have been expanding rapidly to various catalytic reactions such as oxidation reactions, reduction of various organic chemicals, and organic electrochemical transformations. We are confident that fiber materials with exceptional properties will continue to play an indispensable role in the development of electrocatalysis applications.

References

Zhang Z, Wu X, Kou Z, Song N, Nie G, Wang C, Verpoort F, Mu S. Rational design of electrospun nanofiber-typed electrocatalysts for water splitting: a review. Chem Eng J 2022;428:131133.

Wang Y, Su H, He Y, Li L, Zhu S, Shen H, Xie P, Fu X, Zhou G, Feng C, Zhao D, Xiao F, Zhu X, Zeng Y, Shao M, Chen S, Wu G, Zeng J, Wang C. Advanced electrocatalysts with single-metal-atom active sites. Chem Rev 2020;120:12217.

Tao L, Wang Y, Zou Y, Zhang N, Zhang Y, Wu Y, Wang Y, Chen R, Wang S. Charge transfer modulated activity of carbon-based electrocatalysts. Adv Energy Mater 2020;10:1901227.

Chen J, Wu J, Sherrell PC, Chen J, Wang H, Zhang W-X, Yang J. How to build a microplastics-free environment: strategies for microplastics degradation and plastics recycling. Adv Sci 2022. https://doi.org/10.1002/advs.202103764 .

Huang Z-F, Wang J, Peng Y, Jung C-Y, Fisher A, Wang X. Design of efficient bifunctional oxygen reduction/evolution electrocatalyst: recent advances and perspectives. Adv Energy Mater 2017;7:1700544.

Wang H-F, Tang C, Zhang Q. A review of precious-metal-free bifunctional oxygen electrocatalysts: rational design and applications in zn−air batteries. Adv Funct Mater 2018;28:1803329.

Tiwari JN, Sultan S, Myung CW, Yoon T, Li N, Ha M, Harzandi AM, Park HJ, Kim DY, Chandrasekaran SS, Lee WG, Vij V, Kang H, Shin TJ, Shin HS, Lee G, Lee Z, Kim KS. Multicomponent electrocatalyst with ultralow Pt loading and high hydrogen evolution activity. Nat Energy 2018;3:773.

Wang Z-L, Xu D, Xu J-J, Zhang X-B. Oxygen electrocatalysts in metal–air batteries: from aqueous to nonaqueous electrolytes. Chem Soc Rev 2014;43:7746.

Chen X, Yang J, Cao Y, Kong L, Huang J. Design principles for tungsten oxide electrocatalysts for water splitting. ChemElectroChem 2021;8:4427.

Miao M, Pan J, He T, Yan Y, Xia BY, Wang X. Molybdenum carbide-based electrocatalysts for hydrogen evolution reaction. Chem Eur J. 2017;23:10947.

Liu T, Li P, Yao N, Cheng G, Chen S, Luo W, Yin Y. CoP-doped MOF-based electrocatalyst for pH-Universal hydrogen evolution reaction. Angew Chem Int Ed 2019;58:4679.

Kong D, Wang H, Lu Z, Cui Y. CoSe2 nanoparticles grown on carbon fiber paper: an efficient and stable electrocatalyst for hydrogen evolution reaction. J Am Chem Soc 2014;136:4897.

Xue J, Wu T, Dai Y, Xia Y. Electrospinning and electrospun nanofibers: methods, materials, and applications. Chem Rev 2019;119:5298.

Paul R, Zhu L, Chen H, Qu J, Dai L. Recent advances in carbon-based metal-free electrocatalysts. Adv Mater 2019;31:1806403.

Yang L, Shui J, Du L, Shao Y, Liu J, Dai L, Hu Z. Carbon-based metal-free ORR electrocatalysts for fuel cells: past, present, and future. Adv Mater 2019;31:1804799.

Cheng N, Ren L, Xu X, Du Y, Dou SX. Recent development of zeolitic imidazolate frameworks (ZIFs) derived porous carbon based materials as electrocatalysts. Adv Energy Mater 2018;8:1801257.

Lan Y, Chen J, Zhang H, Zhang W-X, Yang J. Fe/Fe3C nanoparticle-decorated N-doped carbon nanofibers for improving the nitrogen selectivity of electrocatalytic nitrate reduction. J Mater Chem A 2020;8:15853.

Tang C, Wang H-F, Zhang Q. Multiscale principles to boost reactivity in gas-involving energy electrocatalysis. Acc Chem Res 2018;51:881.

Sultan S, Tiwari JN, Singh AN, Zhumagali S, Ha M, Myung CW, Thangavel P, Kim KS. Single atoms and clusters based nanomaterials for hydrogen evolution, oxygen evolution reactions, and full water splitting. Adv Energy Mater 2019;9:1900624.

Liu Y-T, Chen X, Yu J, Ding B. Carbon-nanoplated CoS@TiO2 nanofibrous membrane: an interface-engineered heterojunction for high-efficiency electrocatalytic nitrogen reduction. Angew Chem Int Ed 2019;58:18903.

Dai L, Xue Y, Qu L, Choi H-J, Baek J-B. Metal-free catalysts for oxygen reduction reaction. Chem Rev 2015;115:4823.

Zhang F-Z, Ma Y-Y, Jiang M-M, Luo W, Yang J-P. Boron heteroatom-doped silicon–carbon peanut-like composites enables long life lithium-ion batteries. Rare Met 2021. https://doi.org/10.1007/s12598-021-01741-0 .

Wang L, Wang Y, Wu M, Wei Z, Cui C, Mao M, Zhang J, Han X, Liu Q, Ma J. Nitrogen, fluorine, and boron ternary doped carbon fibers as cathode electrocatalysts for zinc-air batteries. Small 2018;14:1800737.

Zhao Z, Yuan Z, Fang Z, Jian J, Li J, Yang M, Mo C, Zhang Y, Hu X, Li P, Wang S, Hong W, Zheng Z, Ouyang G, Chen X, Yu D. In situ activating strategy to significantly boost oxygen electrocatalysis of commercial carbon cloth for flexible and rechargeable Zn-air batteries. Adv Sci 2018;5:1800760.

Lu X, Li M, Wang H, Wang C. Advanced electrospun nanomaterials for highly efficient electrocatalysis. Inorg Chem Front 2019;6:3012.

Wu J, Wang N, Zhao Y, Jiang L. Electrospinning of multilevel structured functional micro-/nanofibers and their applications. J Mater Chem A 2013;1:7290.

Lan Y, Luo H, Ma Y, Hua Y, Liao T, Yang J. Synergy between copper and iron sites inside carbon nanofibers for superior electrocatalytic denitrification. Nanoscale 2021;13:10108.

Chen J, Wu J, Wang H, Yang J. Research prospect of fibrous microplastics removal in aquatic environment. J Text Res 2021;42:18.

Liao H, Fisher A, Xu ZJ. Surface segregation in bimetallic nanoparticles: a critical issue in electrocatalyst engineering. Small 2015;11:3221.

Cai X, Zhang C, Zhang S, Fang Y, Zou D. Application of carbon fibers to flexible, miniaturized wire/fiber-shaped energy conversion and storage devices. J Mater Chem A 2017;5:2444.

Dinh KN, Liang Q, Du C-F, Zhao J, Tok AIY, Mao H, Yan Q. Nanostructured metallic transition metal carbides, nitrides, phosphides, and borides for energy storage and conversion. Nano Today 2019;25:99.

Su L, Zhang F, Wang L, Fang X, Jiang W, Yang J. Flexible electrocatalysts: interfacial-assembly of iron nanoparticles for nitrate reduction. Chem Commun 2021;57:6740.

Wang M-Q, Ye C, Liu H, Xu M, Bao S-J. Nanosized metal phosphides embedded in nitrogen-doped porous carbon nanofibers for enhanced hydrogen evolution at all pH values. Angew Chem Int Ed 2018;57:1963.

Zhang F, Sherrell PC, Luo W, Chen J, Li W, Yang J, Zhu M. Organic/inorganic hybrid fibers: controllable architectures for electrochemical energy applications. Adv Sci 2021;8:2102859.

Kale MB, Borse RA, Gomaa Abdelkader MA, Wang Y. Electrocatalysts by electrodeposition: recent advances, synthesis methods, and applications in energy conversion. Adv Funct Mater. 2021;31:2101313.

Wang L, Li X, Li Q, Yu X, Zhao Y, Zhang J, Wang M, Che R. Oriented polarization tuning broadband absorption from flexible hierarchical ZnO arrays vertically supported on carbon cloth. Small 2019;15:1900900.

Yao Y, Huang Z, Xie P, Lacey Steven D, Jacob Rohit J, Xie H, Chen F, Nie A, Pu T, Rehwoldt M, Yu D, Zachariah Michael R, Wang C, Shahbazian-Yassar R, Li J, Hu L. Carbothermal shock synthesis of high-entropy-alloy nanoparticles. Science 2018;359:1489.

Cai B, Eychmüller A. Promoting electrocatalysis upon aerogels. Adv Mater 2019;31:1804881.

Zhou D, Chen J, Wu J, Yang J, Wang H. Biodegradation and catalytic-chemical degradation strategies to mitigate microplastic pollution. Sustain Mater Techno. 2021;28:e00251.

Ling T, Zhang T, Ge B, Han L, Zheng L, Lin F, Xu Z, Hu W-B, Du X-W, Davey K, Qiao S-Z. Well-dispersed nickel- and zinc-tailored electronic structure of a transition metal oxide for highly active alkaline hydrogen evolution reaction. Adv Mater 2019;31:1807771.

Ji D, Sun J, Tian L, Chinnappan A, Zhang T, Jayathilaka WADM, Gosh R, Baskar C, Zhang Q, Ramakrishna S. Engineering of the heterointerface of porous carbon nanofiber-supported nickel and manganese oxide nanoparticle for highly efficient bifunctional oxygen catalysis. Adv Funct Mater 2020;30:1910568.

Zhang T, Wu M-Y, Yan D-Y, Mao J, Liu H, Hu W-B, Du X-W, Ling T, Qiao S-Z. Engineering oxygen vacancy on NiO nanorod arrays for alkaline hydrogen evolution. Nano Energy 2018;43:103.

Zhang C-L, Lu B-R, Cao F-H, Wu Z-Y, Zhang W, Cong H-P, Yu S-H. Electrospun metal-organic framework nanoparticle fibers and their derived electrocatalysts for oxygen reduction reaction. Nano Energy 2019;55:226.

Li Y, Sun Y, Qin Y, Zhang W, Wang L, Luo M, Yang H, Guo S. Recent advances on water-splitting electrocatalysis mediated by noble-metal-based nanostructured materials. Adv Energy Mater 2020;10:1903120.

Fang Z, Peng L, Qian Y, Zhang X, Xie Y, Cha JJ, Yu G. Dual tuning of Ni–Co–A (A = P, Se, O) nanosheets by anion substitution and holey engineering for efficient hydrogen evolution. J Am Chem Soc 2018;140:5241.

Vij V, Sultan S, Harzandi AM, Meena A, Tiwari JN, Lee W-G, Yoon T, Kim KS. Nickel-based electrocatalysts for energy-related applications: oxygen reduction, oxygen evolution, and hydrogen evolution reactions. ACS Catal 2017;7:7196.

Chen Y-Y, Zhang Y, Jiang W-J, Zhang X, Dai Z, Wan L-J, Hu J-S. Pomegranate-like N, P-Doped Mo2C@C nanospheres as highly active electrocatalysts for alkaline hydrogen evolution. ACS Nano 2016;10:8851.

Jiao Y, Zheng Y, Davey K, Qiao S-Z. Activity origin and catalyst design principles for electrocatalytic hydrogen evolution on heteroatom-doped graphene. Nat Energy 2016;1:16130.

Mo Q, Zhang W, He L, Yu X, Gao Q. Bimetallic Ni2-xCoxP/N-doped carbon nanofibers: solid-solution-alloy engineering toward efficient hydrogen evolution. Appl Catal B: Environ 2019;244:620.

Sun H, Yan Z, Liu F, Xu W, Cheng F, Chen J. Self-supported transition-metal-based electrocatalysts for hydrogen and oxygen evolution. Adv Mater 2020;32:1806326.

Zhang X, Zhou F, Pan W, Liang Y, Wang R. General construction of molybdenum-based nanowire arrays for pH-universal hydrogen evolution electrocatalysis. Adv Funct Mater 2018;28:1804600.

Liu B, Li H, Cao B, Jiang J, Gao R, Zhang J. Few layered N, P dual-doped carbon-encapsulated ultrafine MoP nanocrystal/MoP cluster hybrids on carbon cloth: an ultrahigh active and durable 3D self-supported integrated electrode for hydrogen evolution reaction in a wide pH range. Adv Funct Mater 2018;28:1801527.

Zhu Y, Chen H-C, Hsu C-S, Lin T-S, Chang C-J, Chang S-C, Tsai L-D, Chen HM. Operando unraveling of the structural and chemical stability of p-substituted CoSe2 electrocatalysts toward hydrogen and oxygen evolution reactions in alkaline electrolyte. ACS Energy Lett 2019;4:987.

Xia C, Jiang Q, Zhao C, Hedhili MN, Alshareef HN. Selenide-based electrocatalysts and scaffolds for water oxidation applications. Adv Mater 2016;28:77.

Suntivich J, May Kevin J, Gasteiger Hubert A, Goodenough John B, Shao-Horn YA. Perovskite oxide optimized for oxygen evolution catalysis from molecular orbital principles. Science 2011;334:1383.

Chen P, Xu K, Fang Z, Tong Y, Wu J, Lu X, Peng X, Ding H, Wu C, Xie Y. Metallic Co4N porous nanowire arrays activated by surface oxidation as electrocatalysts for the oxygen evolution reaction. Angew Chem Int Ed 2015;54:14710.

Cao X, Wang T, Jiao L. Transition-metal (Fe Co, and Ni)-based nanofiber electrocatalysts for water splitting. Adv Fiber Mater 2021;3:210.

Nie G, Zhao X, Luan Y, Jiang J, Kou Z, Wang J. Key issues facing electrospun carbon nanofibers in energy applications: on-going approaches and challenges. Nanoscale 2020;12:13225.

Wei P, Sun X, Liang Q, Li X, He Z, Hu X, Zhang J, Wang M, Li Q, Yang H, Han J, Huang Y. Enhanced oxygen evolution reaction activity by encapsulating NiFe alloy nanoparticles in nitrogen-doped carbon nanofibers. ACS Appl Mater Interfaces 2020;12:31503.

Zhao Y, Lai Q, Zhu J, Zhong J, Tang Z, Luo Y, Liang Y. Controllable construction of core-shell Polymer@Zeolitic imidazolate frameworks fiber derived heteroatom-doped carbon nanofiber network for efficient oxygen electrocatalysis. Small 2018;14:1704207.

Ji D, Fan L, Li L, Peng S, Yu D, Song J, Ramakrishna S, Guo S. Atomically transition metals on self-supported porous carbon flake arrays as binder-free air cathode for wearable zinc−air batteries. Adv Mater 2019;31:1808267.

Bae S-H, Kim J-E, Randriamahazaka H, Moon S-Y, Park J-Y, Oh I-K. Seamlessly conductive 3D nanoarchitecture of core-shell Ni-Co nanowire network for highly efficient oxygen evolution. Adv Energy Mater 2017;7:1601492.

Li X, Wang Y, Wang J, Da Y, Zhang J, Li L, Zhong C, Deng Y, Han X, Hu W. Sequential electrodeposition of bifunctional catalytically active structures in MoO3/Ni–NiO composite electrocatalysts for selective hydrogen and oxygen evolution. Adv Mater 2020;32:2003414.

Ye S-H, Shi Z-X, Feng J-X, Tong Y-X, Li G-R. Activating CoOOH porous nanosheet arrays by partial iron substitution for efficient oxygen evolution reaction. Angew Chem Int Ed 2018;57:2672.

Zheng J, Chen X, Zhong X, Li S, Liu T, Zhuang G, Li X, Deng S, Mei D, Wang J-G. Hierarchical porous NC@CuCo nitride nanosheet networks: highly efficient bifunctional electrocatalyst for overall water splitting and selective electrooxidation of benzyl alcohol. Adv Funct Mater 2017;27:1704169.

Ni B, Ouyang C, Xu X, Zhuang J, Wang X. Modifying commercial carbon with trace amounts of ZIF to prepare derivatives with superior ORR activities. Adv Mater 2017;29:1701354.

Xia Z, An L, Chen P, Xia D. Non-Pt nanostructured catalysts for oxygen reduction reaction: synthesis, catalytic activity and its key factors. Adv Energy Mater 2016;6:1600458.

Cao X, Deng J, Pan K. Electrospinning janus type CoOx/C nanofibers as electrocatalysts for oxygen reduction reaction. Adv Fiber Mater 2020;2:85.

Liu S, Wang Z, Zhou S, Yu F, Yu M, Chiang C-Y, Zhou W, Zhao J, Qiu J. Metal–organic-framework-derived hybrid carbon nanocages as a bifunctional electrocatalyst for oxygen reduction and evolution. Adv Mater 2017;29:1700874.

He Y, Guo H, Hwang S, Yang X, He Z, Braaten J, Karakalos S, Shan W, Wang M, Zhou H, Feng Z, More KL, Wang G, Su D, Cullen DA, Fei L, Litster S, Wu G. Single cobalt sites dispersed in hierarchically porous nanofiber networks for durable and high-power PGM-free cathodes in fuel cells. Adv Mater 2020;32:2003577.

Cheng C, Li S, Xia Y, Ma L, Nie C, Roth C, Thomas A, Haag R. Atomic Fe–Nx coupled open-mesoporous carbon nanofibers for efficient and bioadaptable oxygen electrode in Mg–Air batteries. Adv Mater 2018;30:1802669.

Wu G, More Karren L, Johnston Christina M, Zelenay P. High-performance electrocatalysts for oxygen reduction derived from polyaniline, iron, and cobalt. Science 2011;332:443.

Yu M, Wang Z, Hou C, Wang Z, Liang C, Zhao C, Tong Y, Lu X, Yang S. Nitrogen-doped Co3O4 mesoporous nanowire arrays as an additive-free air-cathode for flexible solid-state zinc-air batteries. Adv Mater 2017;29:1602868.

Ji D, Fan L, Tao L, Sun Y, Li M, Yang G, Tran TQ, Ramakrishna S, Guo S. The kirkendall effect for engineering oxygen vacancy of hollow Co3O4 nanoparticles toward high-performance portable zinc-air batteries. Angew Chem Int Ed 2019;58:13840.

Kondratenko EV, Mul G, Baltrusaitis J, Larrazábal GO, Pérez-Ramírez J. Status and perspectives of CO2 conversion into fuels and chemicals by catalytic, photocatalytic and electrocatalytic processes. Energy Environ Sci 2013;6:3112.

Vasileff A, Zheng Y, Qiao SZ. Carbon solving carbon’s problems: recent progress of nanostructured carbon-based catalysts for the electrochemical reduction of CO2. Adv Energy Mater 2017;7:1700759.

Li M, Ma Y, Chen J, Lawrence R, Luo W, Sacchi M, Jiang W, Yang J. Residual chlorine induced cationic active species on a porous copper electrocatalyst for highly stable electrochemical CO2 reduction to C2+. Angew Chem Int Ed 2021;60:11487.

Yang H, Wu Y, Li G, Lin Q, Hu Q, Zhang Q, Liu J, He C. Scalable production of efficient single-atom copper decorated carbon membranes for CO2 electroreduction to methanol. J Am Chem Soc 2019;141:12717.

Zhang T, Han X, Yang H, Han A, Hu E, Li Y, Yang X-Q, Wang L, Liu J, Liu B. Atomically dispersed nickel(I) on an alloy-encapsulated nitrogen-doped carbon nanotube array for high-performance electrochemical CO2 reduction reaction. Angew Chem Int Ed. 2020;59:12055.

Tran-Phu T, Daiyan R, Fusco Z, Ma Z, Amal R, Tricoli A. Nanostructured β-Bi2O3 fractals on carbon fibers for highly selective CO2 electroreduction to formate. Adv Funct Mater 2020;30:1906478.

Zhao X, Hu G, Chen G-F, Zhang H, Zhang S, Wang H. Comprehensive understanding of the thriving ambient electrochemical nitrogen reduction reaction. Adv Mater 2021;33:2007650.

Xu H, Wu J, Luo W, Li Q, Zhang W, Yang J. Dendritic cell-inspired designed architectures toward highly efficient electrocatalysts for nitrate reduction reaction. Small 2020;16:2001775.

Guo W, Zhang K, Liang Z, Zou R, Xu Q. Electrochemical nitrogen fixation and utilization: theories, advanced catalyst materials and system design. Chem Soc Rev 2019;48:5658.

Zhang T, Zong W, Ouyang Y, Wu Y, Miao Y-E, Liu T. Carbon fiber supported binary metal sulfide catalysts with multi-dimensional structures for electrocatalytic nitrogen reduction reactions over a wide pH range. Adv Fiber Mater 2021;3:229.

Chen X, Guo Y, Du X, Zeng Y, Chu J, Gong C, Huang J, Fan C, Wang X, Xiong J. Atomic structure modification for electrochemical nitrogen reduction to ammonia. Adv Energy Mater 2020;10:1903172.

Peng G, Wu J, Wang M, Niklas J, Zhou H, Liu C. Nitrogen-defective polymeric carbon nitride nanolayer enabled efficient electrocatalytic nitrogen reduction with high faradaic efficiency. Nano Lett 2020;20:2879.

Lv C, Yan C, Chen G, Ding Y, Sun J, Zhou Y, Yu G. An amorphous noble-metal-free electrocatalyst that enables nitrogen fixation under ambient conditions. Angew Chem Int Ed 2018;57:6073.

Guo Y, Yao Z, Timmer BJJ, Sheng X, Fan L, Li Y, Zhang F, Sun L. Boosting nitrogen reduction reaction by bio-inspired FeMoS containing hybrid electrocatalyst over a wide pH range. Nano Energy 2019;62:282.

Acknowledgements

This work was supported by the Fundamental Research Funds for the Central Universities (2232021A-02), Shanghai Committee of Science and Technology, China (No. 21ZR1480000), National Natural Science Foundation of China (No. 52122312, No. 52172291), State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, Donghua University.

Funding

The funding has been received from Fundamental Research Funds for the Central Universities with Grant no. 2232021A-02; Shanghai Committee of Science and Technology, China with Grant No. 21ZR1480000; National Natural Science Foundation of China with Grant Nos. 52122312, 52172291.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflicts of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, F., Chen, J. & Yang, J. Fiber Materials for Electrocatalysis Applications. Adv. Fiber Mater. 4, 720–735 (2022). https://doi.org/10.1007/s42765-022-00146-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42765-022-00146-7