Abstract

The Mn-doped CCTO (CaCu3Ti(4−x)MnxO12 system x = 0.25, 0.50 and 1.00) ceramic has been synthesized by using metal nitrates and solid TiO2 powder sintered at 1223 K for 8 h. The crystal phase of CCTMO was confirmed by the XRD at 1223 K for 8 h. The phase-structure, as well as microstructure, was examined by XRD and SEM, respectively. The SEM micrograph revealed the effect of Mn concentration on grain size and grain formation. The bright-field TEM image of the system confirmed the particle size in the range of 22–30 nm. The stoichiometry and purity of synthesized material were observed by EDX. The investigated dielectric permittivity and tangent loss were found to be 150 and 0.6, respectively, at room temperature (10 kHz), which may be used in electronic devices.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

An unusual and promising perovskite oxide CaCu3T4O12 (CCTO) was recently found at extraordinarily high dielectric permittivity at room temperature in the range of 104–106, which is frequency independent and possesses good temperature stability over a broad temperature range from 100 to 800 K [1,2,3]. The temperature dependency and high dielectric constant of CCTO have attracted much of the attention of scientists. Such special physical behavior and being Ba/Pb free make it a promising application for microelectronics devices, such as an actual application of CCTO perovskites in the modern electronic devices; but the main problems of this type of ceramic material is its high tangent loss and large linkage current. The CCTO ceramic has been combined in a 1:3 ratio of A-site-ordered perovskite A1Cu3Ti4O12 with space group Im3, containing octahedral Ti-site of TiO6 and was also combined with A-site of Cu square-planar [1, 4, 5]. The extrinsic origin relaxation resulting from contact effect, spatial inhomogeneity and the internal barrier layer capacitor mechanism (IBLC) is frequently accepted to be the cause of the colossal dielectric constant (CDC); and intrinsic relaxation for colossal dielectric constant is also active which is responsible for electrical behavior of CaCu3Ti4O12 (CCTO), depending on their synthesis route [6,7,8]. Previous researches on CCTO recommended that the local dipoles induced by doping on Ti-site could be responsible for the high dielectric constant [9]. Scientists across the globe carried out an extensive study over the mechanism of dependable high dielectric constant (ɛr) of CCTO but have not reached a definitive conclusion. The internal boundary layer capacitor (IBLC) mechanism explained the high dielectric constant in CCTO ceramics [10,11,12]. According to IBLC theory, in CCTO ceramic, the dielectric variation is produced from the semiconducting grains and insulating grains boundary (GB). Therefore, the variation on microstructure can explain up to a good extent by studying the dielectric properties [13, 14]. Recently, researches revealed that the mixed metal-valent structure (e.g., Ti3+/Ti4+, Fe2+/Fe3+, Cu+/Cu2+, Mn3+/Mn4+ and so on) interrelated ordinary behavior of CDC materials [15, 16], which might directly affect the dielectrical behavior of CCTO ceramics. In this way, the different compositions of Mn-doping in CCTO change the grain boundary and also produce a large effect on dielectric behaviors [14]. The microstructure of CCTO ceramic also changes considerably with a small variation in sintering temperature due to irregular grain growth behavior of Mn-doped ceramics [16, 18]. The metal ion doping in CCTO was found to be a good method that strongly controls microstructure, particle size, electrical properties of grains (semiconducting/insulating behaviors) and grain boundaries (dielectric constant, thickness and resistance) [19]. On the basis of structural investigation, the part TiO6 octahedra are sufficient to produce local distortions, which is effectively responsible for the pure ferroelectric properties of CCTO ceramic. In fact, the ferroelectric behavior was observed in CCTO in a broad temperature range. Furthermore, in comparison with other isostructural compounds, only the CCTO has possessed high dielectric constant [20, 21].

CCTO was synthesized by solid-state method from the metal oxide at high temperature. This method needed a long reaction time, high calcination and sintering temperature. In addition, some other secondary phases (CuO, TiO2 and Cu2TiO3) may also come out during synthesis [22, 23]. On the other hand, synthesis by a chemical solution process such as sol–gel using metal alkoxide gives intimate and uniform mixing of the metal ion at the atomic scale. In this route, titanium isopropoxide Ti(OR)4 is very costly. So, we have synthesized CaCu3Ti(4−x)MnxO12 by a semi-wet route and reported their comparative studies of synthesis, microstructure, dielectric and ferroelectric properties. In this method, metal nitrates have been used in powder form instead of using costly titanium isopropoxide.

The CCTMO was calcined as well as sintered at 973 K and 1223 K, respectively, for 8 h. The results confirmed that the Mn-doping can make the dielectric constant decrease with increasing Mn concentration about two orders of magnitude (from 104–102) [21, 24]. These procedures possess the advantage to refine permittivity, dielectric loss and the ferromagnetic response of Mn-doped CCTO ceramics.

2 Experimental details

2.1 Materials and synthesis

CCTMO was synthesized through a semi-wet route. In this method, chemicals calcium nitrate Ca(NO3)2·4H2O (98% Merck, India), copper nitrate Cu(NO3)2·3H2O (99% Merck, India), manganese acetate Mn(CH3COO)2·4H2O (99% Merck, India) and titanium oxide TiO2 (99% Merck, India), were taken in stoichiometric amounts in molar ratio. The solution of Ca(NO3)2·4H2O, Cu (NO3)2·3H2O, and Mn(CH3COO)2·4H2O was prepared in distilled water. All the solutions were mixed together in a beaker, and a stoichiometric amount of solid TiO2 was added in solution. The calculated amount of citric acid (99.5%, Merck India) equivalent to metal ions was dissolved in distilled water and mixed with the solution. The resulting solution was heated on a hot-plate magnetic stirrer at 348–353 K to evaporate water and allows for self-ignition. A fluffy mass of CCTMO powders was obtained after the removal of a lot of gases. Citric acid was used as a complexing agent that acts as fuel in the ignition step. The resulting CCTMO powder was ground with the help of agate and mortar to make a fine powder. The powder was calcined at 1073 K for 6 h. Calcined powder was used to make cylindrical pellets using 2% PVA as a binder on applying 3 tons of pressure using hydraulic pressure for 90 s. Finally, the CCTMO pellets were sintered at 1373 K for 8 h.

2.2 Characterization

The crystalline phase of CCTMO ceramic-sintered sample was identified by X-ray diffractometer (Rigaku miniflex 600, Japan) applying Cu-kα radiation with wavelength 1.5418 Å. The microstructure and elemental composition were confirmed by scanning electron microscope (ZEISS; model EVO18 research, Germany) attached with an energy-dispersive X-ray (EDX) analyzer (Oxford instrument, USA). The particle size was examined by a high-resolution transmission electron microscope (HR-TEM, Technai G2 20 S-Twin). For HR-TEM characterization, the sample was dispersed in acetone and sonicated for 2 h. This suspension was deposited on a carbon-coated copper grid and dried in oven for 4 h. The thickness and surface morphology were analyzed using atomic force microscopy (NTEGRA Prima, Germany). The dielectric data of silver-coated cylindrical pellets were examined by LCR meter (PSM1735, NumetriQN4L, UK). The ferroelectric behaviors of sintered CCTMO ceramics were measured by the ferroelectric tracer (automatic P–E loop tracer, Marin India).

3 Results and discussion

3.1 Microstructure studies

The X-ray diffraction pattern of CaCu3Ti4−xMnxO12 (x = 0.25, 0.50 and 1.00) ceramics powder sintered at 1223 K for 8 h is shown in Fig. 1. It illustrates the presence of CCTO as a major phase along with the minor phase of TiO2. The diffraction patterns are correctly matched with JCPDS (card no. 21-0140), which confirms the presence of the major phase formation of CCTO with the minor secondary phase with JCPDS (card no. 46-1238) of TiO2 [23]. The structure of the CCTO sample does not change after Mn-doping sintered at 1223 K for 8 h, and it remains cubical in all compositions of Mn-doped CCTO samples. The crystallite size (D) of CCTMO was calculated by using the Debye–Scherrer formula, which is represented as follows in eq. (1).

where D is crystallite size, k is constant equal to 0.89, λ is a wavelength of X-ray, θ is the Bragg diffraction angle and β is the full width at half maximum (FWHM) in radians. For the calculation of the correct value of crystallite size, the line broadening due to instrumental effect was eliminated by using a standard sample (silicon wafer) for XRD data. The average crystalline size of CCTMO was calculated as 16 nm, 40 nm and 32 nm at different Mn-doping concentrations x = 0.25, 0.50, and 1.00 (CaCu3Ti4−xMnxO12), respectively. The lattice parameter increases with an increased doping concentration of Mn in CCTO due to increases in density.

Figure 2 illustrates the bright-field TEM images (a, b and c) along with the corresponding SEAD pattern (d, e and f) of CaCu3Ti4−xMnxO12 ceramics with (x = 0.25, 0.50 and 1.00) sintered at 1223 K for 8 h. The observed particle size measured by TEM was found to be 23 ± 10 nm, 31 ± 10 nm and 24 ± 10 nm at a different doping concentration of Mn (x = 0.25, 0.50 and 1.00) in CaCu3Ti4−xMnxO12 ceramic. The particle size calculated by TEM is close to crystallite size observed by X-ray diffraction. Figure 2(d, e and f) shows the selected area diffraction (SAED) pattern, which confirms that the free-standing crystal shows the single crystal in nature [25].

Figure 3a–c presents the SEM micrograph of CaCu3Ti4−xMnxO (x = 0.25, 0.50 and 1.00) ceramics sample sintered at 1223 K for 8 h. The doping of Mn in CCTO greatly affects the microstructures [11]. The microstructural progress showed a relatively different behavior according to the doped Mn content. The average grain size of CCTMO ceramic at low doped Mn content (x = 0.25) has been observed at 1.90 µm. The average grain size of CCTMO at high Mn-doped (x = 0.50 and 1.00) content has been observed as 1.57 µm and 1.78 µm, respectively. The grain size uniformly increases with increasing Mn compositions. The increase in grain size with increasing Mn concentration may be due to enlarged grain boundary mobility [12]. Figure 3d–f presents the EDX spectra of CCTMO ceramic sintered at 1223 K for 8 h, which confirms the presence of Ca, Cu, Mn, Ti and O elements. The atomic percentage of Ca, Cu, Mn, Ti, and O elements is shown in Table 1 with different compositions confirming the stoichiometry and purity of CCTMO ceramic materials.

Figure 4a depicts 2D atomic force micrograph (AFM) of CaCu3Ti4−xMnxO12 (x = 1.00) ceramic sintered at 1223 K for 8 h. The 2D micrograph illustrates the bimodal structures of grains separated from the grain boundary [26]. The average roughness (Ra) and root mean square roughness (Rq) were found to be 72 nm and 90 nm, respectively, on a scanned area 20 µm × 20 µm. The maximum peak valley depth (Rv) of a 2D structure is found to be 241 µm. Figure 4b shows the distribution of the particles observed in the 3D structure. Figure 4c presents the histogram of grain size, in which the majority of grains are obtained in the range of 1.0–1.4 µm. The average grain size estimated by a 2D micrograph was found to be 1.2 µm out of 191 gains, as shown in Fig. 4c, which is supported by SEM investigation.

3.2 Dielectric studies

The frequency-dependent dielectric constant (ɛr) at room temperature is shown in Fig. 5. The dielectric permittivity (ɛr) decreases with increasing frequency. The value of dielectric constant (ɛr) at room temperature at 10 kHz was found to be 148, 122 and 105 for CaCu3Ti4−xMnxO12 (x = 0.25, 0.50 and 1.00) ceramic samples sintered at 1223 K for 8 h. Figure 6 shows the tangent loss (tan δ) against frequency at room temperature (10 kHz). The tangent loss (tan δ) of CaCu3Ti4−xMnxO12 (x = 0.25, 0.50 and 1.00) ceramic was found to be 0.4, 0.3 and 0.6 at 10 kHz. The tangent loss in Mn-doped CCTO was found to be 0.5 at 10 kHz for all measured compositions [27, 28]. These effects create semiconducting grains and insulating boundaries as published in many ceramic oxides by using the IBLC mechanism in different CCTMO compositions [29]. The tangent loss curves observed in the Mn-doped CCTO are due to thermally activated relaxation [30].

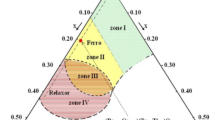

Figure 7 depicts that the polarization against the electric field P–E hysteresis loop of different compositions of Mn-doped CCTO ceramic was detected at room temperature (313 K). This calculation was carried out at a frequency of 150 Hz. With the increasing temperature, the nature of the loop has been changed which becomes slimmer. This property of the P–E loop shows the evolution process to relaxor ferroelectrics [31]. At the given electric field, resultant remnant polarization (Pr) increases with increasing Mn concentration in CCTO samples. The measured value of remnant polarization (Pr) for CaCu3T(4−x)MnxO12 ceramic with compositions x = 0.25, 0.50 and 1.00 is 0.259, 0.258 and 0.427 µC/cm2 at 1223 K for 8 h. On the applying, high electric field saturation was not found in the P–E hystersis loop for CaCu3Ti(4−x) Mnx O12 ceramicx (x= 0.25, 0.50 and 1.00) at room temperature. The absence of saturation polarization is due to the resistor joint in parallel, indicating the lossy capacitor nature of the materials [32].

4 Conclusions

CaCu3T(4−x)MnxO12 (x = 0.25, 0.50 and 1.00) was successfully synthesized by semi-wet route. Solid TiO2 powder and metal nitrates are used in the preparation of CCTMO. The major phase as CCTO along with the minor phase of TiO2 was confirmed by XRD sintered at 1223 K for 8 h. The SEM micrograph shows the clear grain and grain boundaries with an average grain size in the range of 1–2 µm. The particle size was measured by the TEM technique. The dielectric constant decreases with increasing Mn concentration in CCTMO ceramic. The measured tangent loss decreases with increasing frequency. The stoichiometry and purity of CCTMO ceramic were confirmed by the EDX analysis.

References

Thomas AK, Abraham K, Thomas J, Saban KV (2017) Electrical and dielectric behaviour of Na0.5La0.25Sm0.25Cu3Ti4O12 ceramics investigated by impedance and modulus spectroscopy. J Asian Ceram 5:56–61

Gavrilyachenko VG, Kabirov YV, Panchenko EM, Sitalo EI, Gavrilyachenko TV, Milov EV, Lyanguzov NV (2013) Specific features of the dielectric spectrum of CaCu3Ti4O12 in the low-frequency range. Phys Solid State 55:1651–1654

Jesurani S, Kanagesan S, Velmurugan R, Thirupathi C, Sivakumar M, Kalaivani T (2011) Nanoparticles of the giant dielectric material, calcium copper titanate from a sol–gel technique. Mater Lett 65:3305–3308

Schmidt R, Stennett MC, Hyatt NC, PokornY J, Prado-Gonjal J, Li M, Sinclair DC (2012) Effects of sintering temperature on the internal barrier layer capacitor (IBLC) structure in CaCu3Ti4O12 (CCTO) ceramics. J Eur Ceram Soc 32:3313–3323

Aliabadi TN, Alizadeh P (2019) Microstructure and dielectric properties of CCTO glass-ceramic prepared by the melt-quenching method. Ceram Int 45(15):19316–19322

Riquet G, Marinel S, Bréard Y, Harnois C (2019) Sintering mechanism and grain growth in CaCu3Ti4O12 ceramics. Ceram Int 45:9185–9191

Kim BK, Lee HS, Lee JW, Lee SE, Cho YS (2010) Dielectric and grain-boundary characteristics of hot pressed CaCu3Ti4O12. J Am Ceram Soc 93:2419–2422

Thongbai P, Putasaeng B, Yamwong T, Maensiri S (2012) Modified giant dielectric properties of samarium doped CaCu3Ti4O12 ceramics. Mater Res Bull 47:2257–2263

Fan J, Leng S, Cao Z, He W, Gao Y, Liu J, Li G (2019) Colossal permittivity of Sb and Ga co-doped rutile TiO2 ceramics. Ceram Int 45:1001–1010

Li M, Sinclair DC, West AR (2011) Extrinsic origins of the apparent relaxorlike behavior in CaCu3Ti4O12 ceramics at high temperatures: a cautionary tale. J Appl Phys 109:084106

Singh L, Rai US, Mandal KD (2012) Influence of Zn-doping on microstructures and dielectric properties in CaCu3Ti4O12 ceramic synthesised by semi-wet route. Adv Appl Ceram 111:374–380

Senda S, Rhouma S, Torkani E, Megriche A, Autret C (2017) Effect of nickel substitution on electrical and microstructural properties of CaCu3Ti4O12 ceramic. J Alloys Compd 698:152–158

Kim KM, Lee JH, Lee KM, Kim DY, Riu DH, Lee SB (2008) Microstructural evolution and dielectric properties of Cu-deficient and Cu-excess CaCu3Ti4O12 ceramics. Bull Mater Sci 43:284–291

Amaral F, Valente MA, Costa LC (2010) Dielectric properties of CaCu3Ti4O12 (CCTO) doped with GeO2. J Non-Cryst Solids 356:822–827

Sun X, Wang C, Wang G, Lei C, Li T, Liu L (2013) Low-temperature dielectric relaxations associated with mixed-valent structure in Na0.5Bi0.5Cu3Ti4O12. J Am Ceram Soc 96:1497–1503

Sun X, Wang C, Wang G, Lei C, Li T, Liu L (2013) Low-temperature relaxations associated with mixed-valent structure in Sr2TiMnO6. J Am Ceram Soc 96:513–518

Kim KM, Kim SJ, Lee JH, Kim DY (2007) Microstructural evolution and dielectric properties of SiO2-doped CaCu3Ti4O12 ceramics. J Eur Ceram Soc 27:3991–3995

Kawrani S, Boulos M, Cornu D, Bechelany M (2019) From synthesis to applications: copper calcium titanate (CCTO) and its magnetic and photocatalytic properties. Chem Open 8:922–950

Kashyap R, Thakur OP, Tandon RP (2012) Study of structural, dielectric and electrical conduction behaviour of Gd substituted CaCu3Ti4O12 ceramics. Ceram Int 38:3029–3037

Kumari R, Ahlawat N, Agarwal A, Sanghi S, Sindhu M, Rani S (2018) Effect of doping of alkaline metal ions on structural and electrical properties of Bi0.8M0.2FeO3-modified Na0.5Bi0.5TiO3 ceramics (M = Ca, Sr, and Ba). J Alloys Compd 747:712–720

Li M, Chen XL, Zhang DF, Wang WY, Wang WJ (2010) Humidity sensitive properties of pure and Mg-doped CaCu3Ti4O12. Sens Actuators B Chem 147:447–452

Lin YH, Deng W, Xu W, Liu Y, Chen D, Zhang X, Nan CW (2012) Abnormal dielectric behaviors in Mn-doped CaCu3Ti4O12 ceramics and their response mechanism. Mater Sci Eng, B 177:1773–1776

Cai J, Lin YH, Cheng B, Nan CW, He J, Wu Y, Chen X (2007) Dielectric and nonlinear electrical behaviors observed in Mn-doped Ca Cu3Ti4O12 ceramic. Appl Phys Lett 91:252905

Wang C, Ni W, Zhang D, Sun X, Wang J, Li H, Zhang N (2016) Dielectric properties of pure and Mn-doped CaCu3Ti4O12 ceramics over a wide temperature range. J Electroceram 36:46–57

Mandal KD, Rai AK, Kumar D, Parkash O (2009) Dielectric properties of the Ca1−xLaxCu3Ti4−xCoxO12 system (x = 0.10, 0.20 and 0.30) synthesized by semi-wet route. J Alloys Compd 10(478):771–776

Kim HE, Choi SM, Hong YW (2014) Improved dielectric properties of the CaCu3Ti4O12 composites using BaTiO3-coated powder as precursor. J Alloys Compd 610:594–599

Gautam P, Khare A, Sharma S, Singh NB, Mandal KD (2016) Characterization of Bi2/3Cu3Ti4O12 ceramics synthesized by semi-wet route. Prog Nat Sci Mater 26:567–571

Jia R, Zhao X, Li J, Tang X (2014) Colossal breakdown electric field and dielectric response of Al-doped CaCu3Ti4O12 ceramics. Mater Sci Eng, B 185:79–85

Sun DL, Wu AY, Yin ST (2008) Structure, properties, and impedance spectroscopy of CaCu3Ti4O12 ceramics prepared by sol–gel process. J Am Ceram Soc 91:169–173

Wu X, Huang K, Yuan L, Feng S (2018) Fabrication of ultralong perovskite structure nanotubes. RSC Adv 8:367–373

Huang CJ, Li K, Wu SY, Zhu XL, Chen XM (2015) Variation of ferroelectric hysteresis loop with temperature in (SrxBa1−x)Nb2O6 unfilled tungsten bronze ceramics. J Mater 1:146–152

Yadava SS, Singh L, Sharma S, Mandal KD, Singh NB (2016) Effect of temperature on the dielectric and ferroelectric properties of a nanocrystalline hexagonal Ba4YMn3O11.5−δ ceramic synthesized by a chemical route. RSC Adv 6:68247–68253

Acknowledgements

The author would like to thank the in-charge of the central instrument facility centre (CIFC), IIT (BHU), Varanasi, for SEM, TEM and AFM facilities. One of the authors Santosh Pandey is grateful to IIT (BHU) for financial support for teaching assistantship.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest among the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pandey, S., Mandal, K.D. Investigation of microstructure, ferroelectric and dielectric behavior of CaCu3Ti(4−x)MnxO12 perovskites synthesized through semi-wet route. SN Appl. Sci. 1, 1738 (2019). https://doi.org/10.1007/s42452-019-1647-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-1647-1