Abstract

The Congo red (CR) desorption, from two dye-loaded agricultural solid wastes such as Argan nutshell (ArS) and Almond shell (AmS), was evaluated in this study. The adsorbents were characterized by FTIR and SEM analyzes. Process optimization was conducted using Response Surface Methodology (RSM) feature central composite design (CCD). At optimum conditions (CR-adsorbent dose = 16 g L− 1, pH = 4, contact time = 50 min, NaOH concentration = 0.1 M, temperature = 23 ± 1 °C), the CR adsorption values were found to be 98.15% and 98.43%, respectively, for CR-ArS and CR-AmS. Further, a good agreement was found between the experimental results and those predicted by the pseudo-second-order kinetic model. CR desorption efficiencies of 98.45% for CR-ArS, and 98.86% for CR-AmS, were obtained from the CCD-RSM study. Such efficiency values of the CR desorption were reached under optimized conditions of CR-adsorbent dose, contact time, and NaOH concentration: 13 g L–1, 35 min, and 0.07 M for CR-ArS and 12.4 g L–1, 32 min, and 0.06 M for CR-AmS. Furthermore, the ArS and AmS adsorbents showed good regeneration and reusability. The overall data indicate that agricultural solid wastes such as Argan nutshell and Almond shell are suitable adsorbents for wastewater treatment.

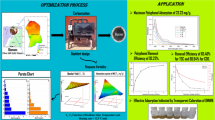

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The annual estimated worldwide dye production is around 7 × 105 tons [1]. The dyeing process usually releases 15% of used dyes into the nearest aquatic system affecting water-dwelling flora and fauna [2,3,4]. Azo dyes are named on the account of their chemical configuration and containing countless (–N=N–) azo groups [5, 6]. Azo complexes are the most widely used colorants, particularly Congo red (CR) which is used in numerous trades such as textile, leather, plastic, foods industry, medical industry, paper, and printing [7, 8]. The CR interacts with water ecosystem, induces physicochemical (temperature, salinity and pH), and changes and disrupts various biological parameters [9]. The CR is difficult to separate from wastewater, due to its good solubility in water and degradation-resistant property [10, 11]. The discharge of dyes in the water environment causes severe problems for aquatic organisms and human health. It should be noted that dyes are toxic, carcinogenic, mutagenic, and allergenic [12,13,14]. Further, dyes with concentration levels lower than 1 mg L− 1 are easily observed and they can easily prevent several biological processes [15]. The color of textile effluents exacerbates this problem, mainly due to their biodegradable properties [16].

Consequently, it is necessary to eliminate the effluent containing dyes before mixing them with unpolluted natural water. Thus, the already developed physiochemical technologies like adsorption on activated carbon, oxidation, coagulation, precipitation, filtration, electrochemical, etc. [17] have been used to process taint water. But these processes are not reliable as they could not remove the color to an acceptable level. They also have high-cost investment, low selectivity, and difficulty in regeneration, making them unfit for the dye removal [18]. Adsorption has been advocated as a highly efficient process for the removal of inorganic and organic pollutants from wastewater based on its efficiency, simplicity, design flexibility, and cost-effectiveness [19, 20].

Agricultural solid wastes have gained tremendous interest for their potential to remove contaminants from aqueous solutions, their reuse as fertilizer, and their conversion to biofuel [21]. Using agricultural solid waste-based adsorbents, as an alternative, has several advantages, including low cost, high degradability, high regeneration ability, and porous structures and functional groups that lead to high adsorption activity [22, 23]. Furthermore, using these adsorbents for wastewater treatment is a long-term solution for lowering the accumulation of agricultural wastes [24]. Among these agricultural solid wastes, Argan nutshell (ArS) and Almond shell (AmS), are available and abundant in Morocco. The ArS and AmS were excellent potential adsorbents to remove dyes from wastewaters [25, 26] and were rapid to remove cationic dyes (10 min) compared to anionic dyes (60 min) following a second-order kinetic model [27, 28]. The ArS and AmS are porous structures (porosity over 85%) and have a density equal to (0.5‒1 kg L− 1) [26]. This shell type is recognized with its porous structure and its large surface, making the adsorption process feasible [27]. Over the recent decades, Argan nutshell and Almond shell have been used to adsorb various pollutants such as heavy metals [29], humic acid [30], and dyes [25].

The present work was carried out to investigate the desorption efficiency of Congo red from dye covered Argan nutshell (ArS) and Almond shell (AmS) adsorbents, by using sodium hydroxide (NaOH). Fourier Transform Infra-Red (FTIR) spectroscopy and Scanning Electron Microscopy (SEM) were used to identify the surface functional groups and the surface morphologies of the two adsorbents. Further, various parameters affecting the dye desorption process such as the CR-adsorbent dose, the contact time, and the NaOH concentration, were investigated. The kinetic desorption models (pseudo-first-order and pseudo-second-order) were also conducted. Firstly, the desorption of CR was optimized by the response surface methodology (RSM) integrated central composite design (CCD). Possible mechanisms of ArS and AmS adsorption and desorption of CR are then proposed based on the RSM-CCD results. Finally, the potential reusability of ArS and AmS adsorbents to remove the CR from wastewater were also evaluated.

2 Experimental

2.1 Chemicals

Congo red (CR), hydrochloric acid (HCl), and sodium hydroxide (NaOH) have been purchased from Sigma-Aldrich and have analytical quality. The water solubility of the used CR dye is 6.97 g L− 1.

2.2 ArS and AmS Preparation and Characterization

The Argan nut and Almond shells were washed with distilled water to remove surface impurities and dust particles. Then, the washed biomaterials were placed in an oven at 105 °C for 24 h, thereafter they were grinded on a laboratory mill Retsch SM10 and they were sieved to 50–100 μm on a laboratory sieve. In the final step, the sieved shells particles were placed in a 1% HCl solution for 24 h and then washed several times with distilled water to eliminate dust particles and other impurities trapped in the shell pores. The analysis of the biomaterials by FTIR spectroscopy (FTIR, Jasco 4100) was carried out in order to identify the different chemical functions of the molecules present on the shells surfaces. The surface textures of ArS and AmS were analyzed by scanning electron microscopy (SEM, SUPRA 40 VP). The point of zero charge (PZC) values of ArS and AmS have been determined as reported elsewhere by El Messaoudi et al. [9].

2.3 Adsorption Tests

To study the adsorption process, 0.8 g of ArS or AmS was first added to a 50 mL of CR solution at a concentration of 100 mg L–1 in an Erlenmeyer flask glass (250 mL). The solution pH was adjusted at 4 by using 0.1 M NaOH or HCl aqueous solutions. The mixture was agitated at 170 rpm at 23 ± 1 °C and pH = 4 for 60 min. Samples were taken at regular intervals to measure the absorbance of the supernatant solution using a visible UV spectrophotometer (2300/Techcomp), at wavelength (λmax = 498 nm) of Congo red maximum absorbance. Equation (1) was employed to determine the amounts of the CR adsorbed qe,a (mg g− 1) on the ArS or AmS. In addition, the adsorption efficiency of each adsorbent was calculated using Eq. (2).

where C0 (mg L− 1) refers to the initial concentration of CR, Ce (mg L− 1) is the concentration at the equilibrium of CR, V (L) is the solution volume, and W (g) is the amount of adsorbent.

2.4 Desorption Experiments

After test adsorption, the CR-loaded adsorbent was dried at 80 °C for 24 h. Then 0.8 g of the dried CR-loaded adsorbent was added to 50 mL of 0.1 M NaOH aqueous solution. The resulted mixture was stirred at 150 rpm at 23 ± 1 °C for 50 min. The filtrate from each sample was then collected and centrifuged for 5 min at 3000 rpm, and the clear supernatant was used to examine desorption efficiency by spectrophotometry. The amount of CR desorbed qe,d (mg g− 1) and CR desorption efficiency (%) were calculated using Eqs. (3) and (4), respectively:

where Cd (mg L− 1) refers to the desorbed concentration of CR.

2.5 CR Desorption Analyzes by CCD and RSM Methods

In this study, contact time (X1), NaOH concentration (X2), and CR-adsorbent dose (X3), were considered as input variables, and CR desorption efficiency was regarded as the response variable. Design-Expert version 12.0.3 software and the CCD approach were employed to design the experiments and investigate the effect of input variables on response variables. RSM is a statistical method used to perform experiment analysis, modeling, and process optimization [31]. The ranges of the considered variables and the corresponding observed responses are summarized in Table 1. In RSM, the most complex model is the quadratic model, which includes the relationship between response and independent variables (‒α, ‒1, 0, 1, and + α). The quadratic model is expressed by Eq. (5) [32, 33]:

where D (%) refers to the CR desorption efficiency.

3 Results and Discussion

3.1 FTIR and SEM Analyzes

To elucidate the interaction of functional groups of ArS and AmS with the CR dye molecules. FTIR analysis was carried out. The FTIR spectra of ArS, CR-ArS, AmS, and CR-AmS are shown in Fig. 1a,b, respectively. The broad bands at around 3332, 3345, 2924, and 2915 cm− 1 are assigned to a −O−H group [34, 35] and −C−H [36,37,38] stretching, respectively. The peaks at 1718 and 1630 cm− 1 for ArS and 1743 and 1626 cm− 1 for AmS represent stretching vibrations of –C=O of esters and acids [39, 40] and aromatic –C=C [41], respectively. The peaks at 1442, 1254, and 1020 cm− 1 for ArS and 1454, 1245, and 1021 cm− 1 for AmS are attributed to aliphatic –C–O–C, –C–O–H, –C–O stretching, respectively [42,43,44]. These results confirm the presence of ‒OH, C=O, and ‒C‒O functional groups [27, 28, 45]. After adsorption of CR (CR-ArS and CR-AmS), the band intensity of ‒O‒H, ‒C=O, and ‒C‒O stretching vibrations are considerably reduced along with a slight shifting of bands to lower frequencies, indicating an interaction between CR molecules and functional groups on ArS and AmS probably involving hydrogen bonding, which authenticates the adsorption process [46].

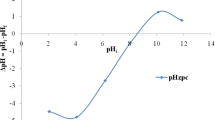

Argan nutshells and Almond shells were analyzed by scanning electron microscopy to scrutinize their morphologies. Thus, SEM images of ArS and AmS are depicted in Fig. 2a, b and they show the surface texture of the biomaterials. It can be seen that ArS and AmS have heterogeneous surfaces, irregular forms, they are porous, and they contain micropores (50–100 μm). The nature of surface charge depends on the adsorbent PZC values, which are 5.2 and 5.7, respectively, for Argan nutshell Almond shell [27, 28].

3.2 Desorption

3.2.1 Dye-Adsorbent Dose Effect

An important factor related to the desorption process is the dye-adsorbent dosage. In Fig. 3, when the following parameters are kept constant (NaOH concentration = 0.5 M, contact time = 120 min, temperature = 23 ± 1 °C), it is shown that by increasing the CR-adsorbent dosage from 4 to 16 g L− 1, the desorption of CR from CR-ArS and CR-AmS increased from 88.53% to 98.08% and from 87.61% to 98.43%, respectively. In fact, increasing the adsorbent dosage, in a specific volume of liquid, increases the number of available sites, improving the probability of repulsion between CR molecules dye and ArS and AmS [47]. However, we observe a decrease in CR desorption after a CR-adsorbent dosage of 16 g L− 1 due to the decrease in the active desorption sites on the adsorbent surface [48].

3.2.2 Desorption Kinetics

According to the results illustrated in Fig. 4, it can be seen that increasing the contact time from 0 to 50 min leads to improving the CR desorption from the adsorbent. The possible reason for this improvement is the increased probability with contact time of the CR dye molecules repulsion from the adsorbent surface [9]. However, the decreased desorption efficiency was observed with further contact time. The lower CR desorption rate at higher contact times may result from the decrease of the desorption active sites, since they are available mainly at the beginning of the desorption process [11]. The desorption sites decrease with increasing contact time and lead to the reduction of the desorption efficiency [49].

The pseudo-first-order and pseudo-second-order models are two well-known models for evaluating the desorption kinetics of CR from CR-ArS and CR-AmS. The Pseudo-first-order model is expressed by the following Eq. (6) and the pseudo-second-order model is given by the following Eq. (7) [19, 36, 50].

with qe,d (mg g− 1) is the quantity desorbed at equilibrium, qt,d (mg g− 1) is the quantity desorbed at time t (mg/g), t(min) is the contact time, K1 (min− 1) as constant for pseudo-first-order rate and K2 (g mg− 1 min− 1) refers to pseudo-second-order. The constants and parameters for kinetic models are presented in Table 2. From Table 2, the correlation coefficients show that the pseudo-second-order model is the one that best describes the desorption process of CR from ArS and AmS. In this case, correlation coefficients very close to 1 are obtained. The analysis of the kinetic data is in good agreement with those of the literature, which indicates that the desorption of CR was best fitted pseudo-second-order model [51].

3.2.3 Effect of NaOH Concentration

The variation of CR desorption efficiency based on the concentration of NaOH solution is shown in Fig. 5. According to the results, it can be found that increasing the NaOH concentration from 0.01 to 0.1 M leads to lower desorption efficiency of CR from CR-ArS and CR-AmS. Such behaviors may result from the fact that the adsorbent has a specific and limited number [52] of desorption sites which are more available at low NaOH concentrations, leading to increased values of the desorption efficiency [53]. Increasing the NaOH concentration leads to lower desorption sites [54]. Similar decreases in the desorption efficiency by increasing the NaOH concentration of NaOH, were also observed by others authors, Amran et al. [55]; Munagapati et al. [56], and Khanjani et al. [57].

3.3 Optimization analysis of CR desorption

The predicated CR desorption efficiencies from CR-ArS and CR-AmS were obtained by the developed model given below, respectively:

where D (%) is the CR desorption efficiency, X1 is the contact time, X2 is the NaOH concentration, X3 is the CR-adsorbent dose, X1 X 2 is the interaction between contact time and NaOH concentration, X1 X 3 is the interaction between contact time and CR-adsorbent dose, and X2X 3 is the interaction between NaOH concentration and CR-adsorbent dose. The results obtained are presented in Table 3 for CR-ArS and in Table 4 for CR-AmS. The regression analysis showed that the effect of linear terms on CR desorption efficiency was from highest to lowest as X1, X2, and X3 [31]. In addition, the impact coefficients of interaction terms from highest to lowest were found to be X1X3, X2 X 3, and X1 X 2, respectively; their effect was negative, positive, and positive, respectively. The effect of quartic terms from highest to lowest was related to X32, X22, and X12, which have a positive, negative, and negative impact. According to the statistical analysis, some regression components, including X1X 2, X32, X22, and X12 had a non-significant effect (p-value > 0.05), while the other components, especially X1, X2, and X3 had a significant impact (p-value < 0.05) [18]. Based on the obtained coefficients (obtained coefficient) and given the positive or negative effects of the independent variables, the final regression model related to CR-ArS and CR-AmS is presented in Tables 3 and 4, respectively. The values of adequate precision (> 4) and R2 (> 95%) obtained for the regression models indicated the high accuracy of the accepted models [31].

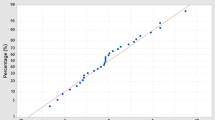

The predicted versus actual values and the mutual effects of the three experimental parameters (contact time, NaOH concentration, and CR-adsorbent dose) on CR desorption from CR-ArS and CR-AmS were analyzed using the 3D response surface, as presented in Figs. 6 and 7, respectively. The experimental values for the responses were in good agreement with the amounts predicted by the RSM model. The predicted values obtained were closer to the experimental values, as shown by the high R2-value [58, 59]. The desorption of CR was 98.45% for CR-ArS and 98.86% for CR-AmS obtained using CCD-RSM optimization. The minimum amount of the above parameters should be 13 g L− 1, 35 min, and 0.07 M for CR-ArS and 12.4 g L− 1, 32 min, and 0.06 M for CR-AmS Figs. 6 and 7 illustrate the dimensional response surfaces that show the effects of the significant variables (contact time, NaOH concentration, and CR-adsorbent dose).

3.4 Adsorption and Desorption Mechanisms of CR

Based on the FTIR analysis of ArS and AmS, we proposed CR adsorption and desorption mechanisms from the surface of CR-ArS and CR-AmS (Fig. 8) at pH = 4. The binding between Congo red, and the OH, –COOH and SO3− surface groups of Argan nut and Almond shells, occurs mainly by attraction electrostatic, hydrogen bond, and Van der Waals bond. The following reaction illustrates the proposed mechanism [47, 60]. The desorption breaks these interactions between the CR molecules and the adsorbent surface upon the addition of NaOH.

3.5 Recyclability of ArS and AmS

The adsorbent regeneration is necessary to make the sorption process economical and applicable at large scale [33, 49]. The assessment of the recycling efficiencies of ArS and AmS, for the CR molecules removal, upon the NaOH addition, at a concentration of 0.1 M, were carried out and the results are depicted in Fig. 9. Hence, after six cycles, The CR adsorption efficiency gradually decreased from 88.37 to 71.26% for ArS and from 85.06 to 69.71% for AmS. Similarly, other anionic dyes can also realize batch adsorption and desorption [61]. To locate our materials, we have grouped in Table 5 the regeneration and reusability of some adsorbents which were used to remove CR. As can be observed in Table 5, our bio adsorbents Argan and Almond shells are among the efficient adsorbents, proving that they are suitable for the CR molecules removal from wastewater.

4 Conclusions

The present investigation has provided an insight into the adsorption efficiency of the Argan nutshell and Almond shell, as exceptional bio sorbents, for Congo red removal from aqueous solutions. After the adsorption process, the desorption of CR from the dye-loaded adsorbents were studied. In addition, the desorption efficiency of the CR dye was monitored under the optimal conditions (CR-adsorbent dose, contact time, and NaOH concentration). To achieve CR desorption efficiencies over 98% by CR-ArS and CR-AmS, the minimum of the CR-adsorbent dose, the contact time and the NaOH concentration should be 16 g L− 1, 50 min, and 0.1 M, respectively. From the comparison of the experimental results to the desorption kinetic models, it was found that the CR desorption data were best fitted to the pseudo-second-order kinetic model. Hence, CR desorption efficiencies of 98.45% and 98.86% were obtained, respectively, for CR-ArS and CR-AmS, by using CCD-RSM optimization, and the minimum amount of the above parameters should be 13 g L− 1, 35 min, and 0.07 M for CR-ArS and 12.4 g L− 1, 32 min, and 0.06 M for CR-AmS. A reusability study in six cycles confirmed the efficacy of Argan nutshell and Almond shell to remove Congo red from aqueous solutions. The above results are advantageous for developing economically viable and eco-friendly techniques for the remediation of wide variety of pollutants.

References

Chowdhury MF, Khandaker S, Sarker F et al (2020) Current treatment technologies and mechanisms for removal of indigo carmine dyes from wastewater: a review. J Mol Liq 318:114061. https://doi.org/10.1016/J.MOLLIQ.2020.114061

Yeamin M, Islam MMB, Chowdhury AN, Awual MR (2021) Efficient encapsulation of toxic dyes from wastewater using several biodegradable natural polymers and their composites. J Clean Prod 291:125920. https://doi.org/10.1016/J.JCLEPRO.2021.125920

Bounaas M, Bouguettoucha A, Chebli D et al (2021) Role of the wild carob as biosorbent and as precursor of a new high-surface-area activated carbon for the adsorption of methylene blue. Arab J Sci Eng 46:325–341. https://doi.org/10.1007/s13369-020-04739-5

Benjelloun M, Miyah Y, Bouslamti R et al (2022) The fast-efficient adsorption process of the toxic dye onto shells powders of walnut and peanut: experiments, equilibrium, thermodynamic, and regeneration studies. Chem Africa 2022:1–19. https://doi.org/10.1007/S42250-022-00328-1

Dbik A, Bentahar S, El Khomri M et al (2020) Adsorption of Congo red dye from aqueous solutions using tunics of the corm of the saffron. In: Materials today: proceedings

Benkhaya S, M’rabet S, El Harfi A (2020) Classifications, properties, recent synthesis and applications of azo dyes. Heliyon. https://doi.org/10.1016/J.HELIYON.2020.E03271

Kumar A, Dixit U, Singh K et al (2021) Structure and properties of dyes and pigments. https://doi.org/10.5772/INTECHOPEN.97104

Rane A, Joshi SJ (2021) Biodecolorization and biodegradation of dyes: a review. Open Biotechnol J 15:97–108. https://doi.org/10.2174/1874070702115010097

El Messaoudi N, El Khomri M, Chlif N et al (2021) Desorption of Congo red from dye-loaded Phoenix dactylifera date stones and Ziziphus lotus jujube shells. Groundw Sustain Dev 12:100552. https://doi.org/10.1016/j.gsd.2021.100552

Singh S, Perween S, Ranjan A (2021) Dramatic enhancement in adsorption of congo red dye in polymer-nanoparticle composite of polyaniline-zinc titanate. J Environ Chem Eng 9:105149. https://doi.org/10.1016/J.JECE.2021.105149

El Messaoudi N, El Khomri M, Dbik A et al (2016) Biosorption of Congo red in a fixed-bed column from aqueous solution using jujube shell: experimental and mathematical modeling. J Environ Chem Eng 4:3848–3855. https://doi.org/10.1016/j.jece.2016.08.027

Islam A, Teo SH, Taufiq-Yap YH et al (2021) Step towards the sustainable toxic dyes removal and recycling from aqueous solution-a comprehensive review. Resour Conserv Recycl 175:105849. https://doi.org/10.1016/J.RESCONREC.2021.105849

Ali S, Jan FA, Ullah R et al (2022) Kinetic and thermodynamic study of the photo catalytic degradation of methylene blue (MB) in aqueous solution using cadmium sulphide (CdS) nanocatalysts. Chem Afr 2022:1–12. https://doi.org/10.1007/S42250-022-00327-2

El Messaoudi N, El Khomri M, Chegini ZG et al (2022) Desorption of crystal violet from alkali-treated agricultural material waste: an experimental study, kinetic, equilibrium and thermodynamic modeling. Pigment Resin Technol 51:309–319. https://doi.org/10.1108/PRT-02-2021-0019/FULL/XML

Ledakowicz S, Pázdzior K (2021) Recent achievements in dyes removal focused on advanced oxidation processes integrated with biological methods. Molecules. https://doi.org/10.3390/MOLECULES26040870

Lin L, Zhu W, Zhang C et al (2021) Combination of wet fixation and drying treatments to improve dye fixation onto spray-dyed cotton fabric. Sci Rep 111(11):1–15. https://doi.org/10.1038/s41598-021-94885-z

Hasan MM, Shenashen MA, Hasan MN et al (2021) Natural biodegradable polymeric bioadsorbents for efficient cationic dye encapsulation from wastewater. J Mol Liq 323:114587. https://doi.org/10.1016/J.MOLLIQ.2020.114587

El Messaoudi N, El Khomri M, Chegini ZG et al (2021) Dye removal from aqueous solution using nanocomposite synthesized from oxalic acid-modified agricultural solid waste and ZnFe2O4 nanoparticles. Nanotechnol Environ Eng 71(7):1–15. https://doi.org/10.1007/S41204-021-00173-6

El Mouden A, El Guerraf A, El Messaoudi N et al (2022) Date stone functionalized with 3-aminopropyltriethoxysilane as a potential biosorbent for heavy metal ions removal from aqueous solution. Chem Afr 2022:1–15. https://doi.org/10.1007/S42250-022-00350-3

Suzaimi ND, Goh PS, Malek NANN et al (2020) Enhancing the performance of porous rice husk silica through branched polyethyleneimine grafting for phosphate adsorption. Arab J Chem 13:6682–6695. https://doi.org/10.1016/J.ARABJC.2020.06.023

Redondo-Gómez C, Quesada MR, Astúa SV et al (2020) Biorefinery of biomass of agro-industrial banana waste to obtain high-value biopolymers. Molecules. https://doi.org/10.3390/MOLECULES25173829

Karić N, Maia AS, Teodorović A et al (2022) Bio-waste valorisation: agricultural wastes as biosorbents for removal of (in)organic pollutants in wastewater treatment. Chem Eng J Adv 9:100239. https://doi.org/10.1016/J.CEJA.2021.100239

El Messaoudi N, El Khomri M, Dbik A et al (2017) Selective and competitive removal of dyes from binary and ternary systems in aqueous solutions by pretreated jujube shell (Zizyphus lotus). J Dispers Sci Technol 38:1168–1174. https://doi.org/10.1080/01932691.2016.1228070

Kwikima MM, Mateso S, Chebude Y (2021) Potentials of agricultural wastes as the ultimate alternative adsorbent for cadmium removal from wastewater. A review. Sci Afr 13:e00934. https://doi.org/10.1016/J.SCIAF.2021.E00934

El Khomri M, El Messaoudi N, Dbik A et al (2020) Efficient adsorbent derived from Argania Spinosa for the adsorption of cationic dye: Kinetics, mechanism, isotherm and thermodynamic study. Surf Interfaces 20:100601. https://doi.org/10.1016/j.surfin.2020.100601

El Khomri M, El Messaoudi N, Dbik A et al (2021) Regeneration of argan nutshell and almond shell using HNO3 for their reusability to remove cationic dye from aqueous solution. Chem Eng Commun. https://doi.org/10.1080/00986445.2021.1963960

El Khomri M, El Messaoudi N, Dbik A et al (2021) Removal of Congo red from aqueous solution in single and binary mixture systems using Argan nutshell wood. Pigment Resin Technol. https://doi.org/10.1108/PRT-04-2021-0045/FULL/XML

Khomri M, El Messaoudi MN, El Dbik A et al (2022) Organic Dyes adsorption on the almond shell (prunus dulcis) as agricultural solid waste from aqueous solution in single and binary mixture systems. Biointerface Res Appl Chem 12:2022–2040.

Qamouche K, Chetaine A, El Yahyaoui A et al (2021) Uranium and other heavy metal sorption from Moroccan phosphoric acid with argan nutshell sawdust. Min Eng 171:107085. https://doi.org/10.1016/J.MINENG.2021.107085

Melhaoui R, Miyah Y, Kodad S et al (2021) On the suitability of almond shells for the manufacture of a natural low-cost bioadsorbent to remove brilliant green: kinetics and equilibrium isotherms study. Sci World J. https://doi.org/10.1155/2021/6659902

El Messaoudi N, El Khomri M, Fernine Y et al (2022) Hydrothermally engineered Eriobotrya japonica leaves/MgO nanocomposites with potential applications in wastewater treatment. Groundw Sustain Dev 16:100728. https://doi.org/10.1016/J.GSD.2022.100728

Jawad AH, Malek NNA, Abdulhameed AS, Razuan R (2020) Synthesis of magnetic chitosan-fly ash/Fe3O4 composite for adsorption of reactive orange 16 dye: optimization by Box–Behnken design. J Polym Environ 28:1068–1082. https://doi.org/10.1007/s10924-020-01669-z

El Messaoudi N, El Khomri M, Ablouh EH et al (2022) Biosynthesis of SiO2 nanoparticles using extract of Nerium oleander leaves for the removal of tetracycline antibiotic. Chemosphere 287:132453. https://doi.org/10.1016/J.CHEMOSPHERE.2021.132453

Salomón YLdO, Georgin J, Franco DSP et al (2020) Powdered biosorbent from pecan pericarp (Carya illinoensis) as an efficient material to uptake methyl violet 2B from effluents in batch and column operations. Adv Powder Technol 31:2843–2852. https://doi.org/10.1016/j.apt.2020.05.004

Shakoor S, Nasar A (2019) Utilization of Cucumis sativus peel as an eco-friendly biosorbent for the confiscation of crystal violet dye from artificially contaminated wastewater. Anal Chem Lett 9:1–19. https://doi.org/10.1080/22297928.2019.1588162

El Messaoudi N, Dbik A, El Khomri M et al (2017) Date stones of Phoenix dactylifera and jujube shells of Ziziphus lotus as potential biosorbents for anionic dye removal. Int J Phytoremediation 19:1047–1052. https://doi.org/10.1080/15226514.2017.1319331

Siengchum T, Isenberg M, Chuang SSC (2013) Fast pyrolysis of coconut biomass-an FTIR study. Fuel 105:559–565. https://doi.org/10.1016/j.fuel.2012.09.039

Loulidi I, Boukhlifi F, Ouchabi M et al (2020) Adsorption of crystal violet onto an agricultural waste residue: kinetics, isotherm, thermodynamics, and mechanism of adsorption. Sci World J. https://doi.org/10.1155/2020/5873521

Jawad AH, Abdulhameed AS (2020) Statistical modeling of methylene blue dye adsorption by high surface area mesoporous activated carbon from bamboo chip using KOH-assisted thermal activation. Energy Ecol Environ 5:456–469. https://doi.org/10.1007/s40974-020-00177-z

Surip SN, Abdulhameed AS, Garba ZN et al (2020) H2SO4-treated Malaysian low rank coal for methylene blue dye decolourization and cod reduction: optimization of adsorption and mechanism study. Surf Interfaces 21:100641. https://doi.org/10.1016/j.surfin.2020.100641

El Messaoudi N, El Khomri M, Bentahar S et al (2016) Evaluation of performance of chemically treated date stones: application for the removal of cationic dyes from aqueous solutions. J Taiwan Inst Chem Eng 67:244–253. https://doi.org/10.1016/j.jtice.2016.07.024

Feng NC, Guo XY (2012) Characterization of adsorptive capacity and mechanisms on adsorption of copper, lead and zinc by modified orange peel. Trans Nonferrous Met Soc China (English Ed) 22:1224–1231. https://doi.org/10.1016/S1003-6326(11)61309-5

Singh J, Ali A, Jaswal VS, Prakash V (2015) Desalination of Cd2 + and Pb2 + from paint industrial wastewater by Aspergillus niger decomposed Citrus limetta peel powder. Int J Environ Sci Technol 12:2523–2532. https://doi.org/10.1007/s13762-014-0620-1

Vargas VH, Paveglio RR, de Pauletto P et al (2020) Sisal fiber as an alternative and cost-effective adsorbent for the removal of methylene blue and reactive black 5 dyes from aqueous solutions. Chem Eng Commun 207:523–536. https://doi.org/10.1080/00986445.2019.1605362

El Messaoudi N, El Khomri M, Dabagh A et al (2021) Synthesis of a novel nanocomposite based on date stones/CuFe2O4 nanoparticles for eliminating cationic and anionic dyes from aqueous solution. Int J Environ Stud. https://doi.org/10.1080/00207233.2021.1929469

Shahrin EWES, Narudin NAH, Shahri NNM et al (2022) Adsorption behavior and dynamic interactions of anionic acid blue 25 on agricultural waste. Molecules 27:1718. https://doi.org/10.3390/MOLECULES27051718

El Messaoudi N, El Khomri M, Goodarzvand Chegini Z et al (2021) Desorption study and reusability of raw and H2SO4 modified jujube shells (Zizyphus lotus) for the methylene blue adsorption. Int J Environ Anal Chem. https://doi.org/10.1080/03067319.2021.1912338

Mondal NK, Kar S (2018) Potentiality of banana peel for removal of Congo red dye from aqueous solution: isotherm, kinetics and thermodynamics studies. Appl Water Sci 8:157. https://doi.org/10.1007/s13201-018-0811-x

Bhatti HN, Safa Y, Yakout SM et al (2020) Efficient removal of dyes using carboxymethyl cellulose/alginate/polyvinyl alcohol/rice husk composite: adsorption/desorption, kinetics and recycling studies. Int J Biol Macromol 150:861–870. https://doi.org/10.1016/J.IJBIOMAC.2020.02.093

Dbik A, El Messaoudi N, Lacherai A (2014) Valorisation of wood dates stones of a variety of palm tree of Tinghir region (Morocco): application to eliminate methylene blue. J Mater Environ Sci 5:2510–2514

Zhu C, Xia Y, Zai Y et al (2019) Adsorption and desorption behaviors of HPEI and thermoresponsive HPEI based gels on anionic and cationic dyes. Chem Eng J 369:863–873. https://doi.org/10.1016/J.CEJ.2019.03.169

Li Q, Wang M, Yuan X et al (2019) Study on the adsorption and desorption performance of magnetic resin for Congo red. Environ Technol (UK). https://doi.org/10.1080/09593330.2019.1673830

Ruan CQ, Strømme M, Lindh J (2018) Preparation of porous 2,3-dialdehyde cellulose beads crosslinked with chitosan and their application in adsorption of Congo red dye. Carbohydr Polym 181:200–207. https://doi.org/10.1016/J.CARBPOL.2017.10.072

Jain R, Sikarwar S (2014) Adsorption and desorption studies of Congo red using low-cost adsorbent: activated de-oiled mustard. Desalin Water Treat 52:7400–7411. https://doi.org/10.1080/19443994.2013.837004

Amran F, Zaini MAA (2021) Sodium hydroxide-activated Casuarina empty fruit: Isotherm, kinetics and thermodynamics of methylene blue and congo red adsorption. Environ Technol Innov 23:101727. https://doi.org/10.1016/J.ETI.2021.101727

Munagapati VS, Kim DS (2016) Adsorption of anionic azo dye Congo Red from aqueous solution by Cationic Modified Orange Peel Powder. J Mol Liq 220:540–548. https://doi.org/10.1016/J.MOLLIQ.2016.04.119

Khanjani S, Morsali A (2014) Ultrasound-promoted coating of MOF-5 on silk fiber and study of adsorptive removal and recovery of hazardous anionic dye “congo red”. Ultrason Sonochem 21:1424–1429. https://doi.org/10.1016/J.ULTSONCH.2013.12.012

Chakraborty D, Gupta G, Kaur B (2016) Metabolic engineering of E. coli top 10 for production of vanillin through FA catabolic pathway and bioprocess optimization using RSM. Protein Expr Purif 128:123–133. https://doi.org/10.1016/j.pep.2016.08.015

Nitnithiphrut P, Pimsri R, Seithtanabutara V (2017) RSM optimization for the production of activated carbons from para-wood residue. Key Engineering Materials. Trans Tech Publications Ltd, pp 100–104

Jawad AH, Abdulhameed AS, Mastuli MS (2020) Acid-factionalized biomass material for methylene blue dye removal: a comprehensive adsorption and mechanism study. J Taibah Univ Sci 14:305–313. https://doi.org/10.1080/16583655.2020.1736767

Hu X, Yan L, Wang Y, Xu M (2020) Freeze-thaw as a route to build manageable polysaccharide cryogel for deep cleaning of crystal violet. Chem Eng J 396:125354. https://doi.org/10.1016/j.cej.2020.125354

Si J, Yuan TQ, Cui BK (2015) Exploring strategies for adsorption of azo dye Congo Red using free and immobilized biomasses of Trametes pubescens. Ann Microbiol 65:411–421. https://doi.org/10.1007/s13213-014-0874-3

Sarim KM, Kukreja K, Shah I, Choudhary CK (2019) Biosorption of direct textile dye Congo red by Bacillus subtilis HAU-KK01. Bioremediat J 23:185–195. https://doi.org/10.1080/10889868.2019.1641466

Zhang R, Zhang J, Zhang X et al (2014) Adsorption of Congo red from aqueous solutions using cationic surfactant modified wheat straw in batch mode: kinetic and equilibrium study. J Taiwan Inst Chem Eng 45:2578–2583. https://doi.org/10.1016/j.jtice.2014.06.009

Acemioǧlu B (2004) Adsorption of Congo red from aqueous solution onto calcium-rich fly ash. J Colloid Interface Sci 274:371–379. https://doi.org/10.1016/j.jcis.2004.03.019

Bensalah H, Bekheet MF, Younssi SA et al (2017) Removal of cationic and anionic textile dyes with Moroccan natural phosphate. J Environ Chem Eng 5:2189–2199. https://doi.org/10.1016/j.jece.2017.04.021

Elwakeel KZ, Elgarahy AM, Elshoubaky GA, Mohammad SH (2020) Microwave assist sorption of crystal violet and Congo red dyes onto amphoteric sorbent based on upcycled sepia shells 03 chemical sciences 0306 physical chemistry (incl. structural). J Environ Heal Sci Eng 18:35–50. https://doi.org/10.1007/s40201-019-00435-1

Author information

Authors and Affiliations

Ethics declarations

Conflict of interest

The authors declare no conflict interests.

Rights and permissions

About this article

Cite this article

El Khomri, M., El Messaoudi, N., Dbik, A. et al. Optimization Based on Response Surface Methodology of Anionic Dye Desorption From Two Agricultural Solid Wastes. Chemistry Africa 5, 1083–1095 (2022). https://doi.org/10.1007/s42250-022-00395-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42250-022-00395-4