Abstract

A procedure for selective recovery of uranium from a hydrous oxide cake produced after alkali breakdown of Rosetta monazite mineral concentrate was proposed. This procedure was based on using urea as a leaching and chelating agent. The proposed procedure involved selective leaching of uranium (98%) using 150 g/L urea within 5 h agitation time, 400 rpm agitation speed at 25 °C and solid/liquid (S/L) ratio of 1/4 (weight/volume), leaving behind thorium (Th) and rare earth elements (REEs) content. Kinetics of leaching process as well as reaction mechanism between urea and uranium has been discussed. The results show that the predominant dissolution mechanism of uranium was chemically controlled and the apparent activation energy was 45.103 kJ/mole. The work was then shifted to separate Th selectively from the combined Th–REEs hydroxide cake via alkali dissolution of Th using a mixed weight of 3/1 Na2CO3/NaHCO3 in a total concentration of 150 g/L. Finally, a tentative flow-sheet for selective recovery of U, Th and REEs from the studied hydrous oxide cake was presented.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Monazite is a rare earth phosphate mineral, which constitutes one of the main sources of rare earth metals (RE and/or REEs). It also contains thorium and uranium in significant concentration; thus, monazite is considered as one of the non-conventional uranium resources. Monazite concentrate commonly contains 24–29% of phosphate (P2O5), 55–60% rare earth metal oxides, 5–10% thorium oxide (ThO2) and 0.2–0.4% uranium oxide (U3O8) [1]. Due to its extreme stability, monazite concentrate can be leached either by sulfuric acid or by sodium hydroxide at elevated temperature to decompose the orthophosphate lattice. Sodium hydroxide treatment is preferred in most commercial extraction plants because it is better to separate phosphate from the rare earth [2, 3]. The chemical reactions of both acidic and alkaline monazite processing are represented by the following equations:

Several methods are used for industrial processing of monazite to extract uranium, thorium and REEs from monazite sands [4]. The alkali process was proffered for monazite treatment in the different plants established in Malaysia, France and the US [5, 6]. Some workers treated the monazite using 70% NaOH under pressure for 2 h at 150 °C to produce insoluble REEs and Th hydroxides for subsequent processing [7].

Recently, Amer et al. [8] have suggested an alternative procedure for processing of monazite mineral concentrate. This procedure was based on recovering uranium, thorium and rare earths using oxalate precipitation. In a sulphate solution containing 0.147 g/L U, 2.51 g/L Th and 23.93 g/L RE, 98% of thorium and 99% of rare earths were precipitated at pH 0.7 and 60 °C, while uranium remained in the solution. Thorium oxalate precipitate was subsequently selectively dissolved in a solution containing 150 g/L Na2CO3 and NaHCO3 in a ratio of 3:1 at 75 °C. It was proved that thorium could form a soluble complex with carbonate via the reaction shown in Eq. (3):

Also, Amer et al. [9] have investigated an innovative procedure for a selective recovery of REEs from a hydrous oxide cake of Rosetta monazite mineral concentrate after alkali breakdown. This procedure was based on the selective dissolution of REEs from a hydrous oxide cake using ammonium sulfate solution. On the other hand, the subsequent recoveries of the other two associated metal values namely; U and Th have been achieved by selective carbonate dissolution for U followed by acidic leaching for both Th and the remained heavy REEs.

On the other hand, in the field of developing new interesting extractants for U recoveries, urea as a leaching agent offers several advantages over the classically used reagents especially with respect to the harmless nature of their degradation products and the possibility to burn; a matter which would reduce volume of secondary waste.

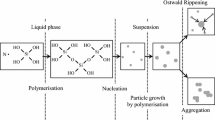

In this context, it can be stated that uranium was complexed with urea as urea uranate complex [(H2O·UO3·2CO (NH2)2]. The latter was obtained for the first time by Gentile et al. [10]. In this regard, it might be interesting to refer to the application of amide and di-amide as promising extracting agents in the back end of the nuclear fuel cycle [11]. In the latter, the advantage of N,N-dialkyl aliphatic amides over organo-phosphorous compounds have been identified [12]. Accordingly, urea usually coordinates as a monodentate ligand through the oxygen atom, forming a C=O···M angle considerably smaller than 180°, in accordance with the O atom (A) (Fig. 1) [13]. The rare N, O-bidentate coordination mode (B) has been found in a very limited number of cases [14].

(after Tian et al. [13])

Suggested mechanism

There were many efforts to study the interaction between the doubly charged uranyl cation and water molecules which could result in a hydration sphere. The hydration sphere is composed of a first hydration shell with water molecules coordinated directly to the uranyl ion in the equatorial plane (about five water molecules), and a second hydration shell with a second group of water molecules associated through hydrogen bonding with the water molecules in the first hydration shell (about ten water molecules [15, 16]. Correlation studies further stated that under different pH conditions, the coordination environment and the species of the uranyl ion could be changed, for example, [UO2(H2O)5]2+ at lower pH (pH 0–3) [17, 18] dimer [(UO2)2(OH)2(H2O)6]2+ and trimer [(UO2)3(O)(OH)3(H2O)6]+ as the pH increases to about 4 [19, 20], and [UO2(OH)4]2−·(H2O) or [UO2 (OH)5]3− in a highly alkaline solution (about pH = 12). The urea ligand possesses double bond oxygen atoms with structural nitrogen atoms which are also regarded as excellent donor atoms to uranium [21,22,23].

In this context, El-Sheikh et al. [24] have proven a selective leaching of uranium from the poly-mineralized carbonate-rich latosol ore material of Abu Thor locality of southwestern Sinai, Egypt using urea. The optimum leaching conditions have been determined using an ore ground to − 60 mesh size (0.250 mm), a urea solutions of 60 g/L concentration for 90 min in S/L ratio of 1/5. Under these conditions, uranium leaching efficiency was found to attain up to 97.5%.

In the present work, urea was considered as a selective non-conventional and economic leaching agent for uranium dissolution from a hydrous oxide cake produced after alkali breakdown of Rosetta monazite mineral concentrate. This was followed by a selective separation of either Th and REEs from the remaining combined Th–REEs cake according to the work of Amer et al. [9].

2 Experimental

2.1 Material Preparation

In order to have a hydrous oxide cake, 500 g from the provided monazite mineral concentrate (90% purity) was ground to − 300 mesh size and then digested in 40% NaOH with S/L ratio of 1/1.5 for 4 h stirring time at 140 °C. The filtrate was subjected to sodium phosphate crystallization as a by-product at 60 °C. On the other hand, the obtained hydrous oxide cake was washed and dried at 110 °C before applying a selective leaching of uranium using urea. The two remaining metal values namely; Th and REEs were then selectively leached using alkaline leaching with NaCO3/NaHCO3 mixture according to the work of Amer et al. [8, 9].

3 Processing Procedures

3.1 Selective Leaching of Uranium

The hydrous oxide cake under consideration was subjected to a selective leaching of uranium using urea as a leaching agent. This process has been performed via batch technique by mixing a hydrous oxide cake with a suitable volume of urea of various concentrations. The slurry was then agitated (400 rpm) for a fixed time at a certain temperature. After that, the treated slurry was filtered and the residue left behind was thoroughly washed. Both of filtrate and washings were made up to volume before analyses.

3.2 Selective Dissolution of Thorium from the Combined Th–REEs Cake

According to Amer et al. [9], thorium was selectively dissolved from the free uranium hydrous oxide cake by mixing with 3/1 of Na2CO3/Na HCO3 solution in a total concentration of 150 g/L at solid/liquid ratio of 1/6 for 2 h at 75 °C.

4 Analytical Procedures

The hydrous oxide cake was analyzed for determination of its chemical composition using prism ICP-OES, Teledyne technologies (Inductively Coupled Plasma Optical Emission Spectrometer). Meanwhile, thorium and REEs (in terms of La) were spectrometrically determined by the chromogenic reagent, Arsenazo-III [25]. Uranium in the different aqueous stream solutions as well as in the obtained concentrate was determined by the oxidimetric titration method against ammonium metavanadate after its reduction [26]. On the other hand, the final obtained concentrates of U, Th and REEs have semi-qualitatively been determined using ESEM-EDAX technique (Environmental Scanning Electron Microscopy/Energy Dispersive X-ray Spectroscopy, Philips XL 30) together with wet chemical analyses. Infra-red spectra of urea before and after reaction with uranium were obtained using Book Company, New York Spectrometer. Each sample was determined using KBr disk.

5 Results and Discussion

5.1 Material Characteristics

According to Table 1 of Amer et al. [9], chemical composition of the working Rosetta monazite mineral concentrate assays: RE2O3 (rare earth oxides) of more than 57%, P2O5 27.35% while ThO2 and U3O8 attained 6.13% and 0.35%, respectively. Besides, relatively low contents of Fe2O3, SiO2 and TiO2 reaching about 3.00, 2.80 and 2.08%, respectively were also reported.

In the present work, chemical composition of the prepared hydrous oxide cake has revealed the assay of 0.346% for U3O8, 5.89% for ThO2 and 56.18% for the RE2O3 as their alkali dissolution within efficiencies of 99.0, 96.1 and 97.2%, respectively.

5.2 Selective Uranium Dissolution

The dissolution of uranium selected from the studied hydrous oxide cake of Rosetta monazite mineral concentrate using urea was applied. The main applicable leaching conditions for recovering U content include effect of; urea concentration, agitation time, temperature, and S/L ratio. Each experiment was performed upon 5 g portion from the studied hydrous oxide cake.

5.3 Effect of Urea Concentration

The effect of urea concentration upon uranium dissolution efficiency from hydrous oxide cake was studied between 50 and 250 g/L. The other leaching conditions were fixed at solid–liquid (S/L) ratio of 1/4 and 3 h agitation time within agitation speed of 400 rpm at 25 °C.

From Table 2, it can be concluded that by increasing urea concentration from 50 to 150 g/L uranium dissolution efficiency increased from 50 to 85%. On the other hand, increasing urea concentration to 200 and 250 g/L have resulted in a progressive decrease in uranium dissolution efficiency down to only 75% at 250 g urea/L. This may actually be due to the polymerization of urea molecules at high concentration values. However, biuret may be formed when two molecules of urea combine with the loss of a molecule of ammonia [27]:

Thus, it can be stated that the optimum concentration of urea solution was 150 g/L. It is worthy to mention herein that, neither Th nor REEs have been affected to any extent by increasing urea concentration.

5.4 Effect of Agitation Time

A series of leaching experiments were done using 150 g/L of urea to study the effect of different agitation time upon U dissolution efficiency at the fixed conditions of; agitation speed 400 rpm, 25 °C and 1:4 S/L ratio. The obtained results indicate that increasing agitation time from 1 to 5 h has resulted in improving the leaching efficiency of U from 40 to 98%, Table 3. Therefore, it can be concluded that 5 h is adequate to almost complete selective leaching of U using 150 g/L of urea. In this context, it is also noticed that REEs and Th contents of the studied hydrous cake were not affected even when the leaching time was increased to more than 5 h.

5.5 Effect of Leaching Temperature

The effect of temperature upon U leaching efficiency was studied between the ranges from 25 to 85 °C. The other leaching conditions were fixed at 150 g/L of urea, 5 h agitation time within agitation speed of 400 rpm and S/L ratio of 1:4. Under these conditions, the obtained dissolution efficiency can be illustrated from Table 4 which indicated that increasing leaching temperature has resulted in an adverse effect upon U dissolution efficiency. This may be due to urea polymerization or degradation by increasing pulp temperature. However, isocyanic acid may be produced from the thermal decomposition of ammonium cyanate as a result of degradation of urea [27]:

Accordingly, 25 °C is the optimum leaching temperature in which U dissolution efficiency attained 98%. Also, REEs and Th dissolution was not affected by any increase in the leaching temperature.

5.6 Effect of the Solid/Liquid Ratio

The effect of solid/liquid ratio upon U leaching efficiency was studied between 1/1 and 1/5 at fixed conditions of 25 °C, 150 g/L urea concentration and 5 h agitation time within agitation speed of 400 rpm. From the obtained results, as shown in Table 5, it can be concluded that beyond S/L ratio of 1/4, only a slight steady increase in the leaching efficiency of uranium has been achieved. Accordingly, a solid/liquid ratio of 1/4 would be considered as the optimum one at which the leaching efficiency of uranium attained 98%. In this regard, it is noticed that REEs and Th contents of the studied hydrous oxide cake were not affected even when decreasing the S/L ratio to 1/5.

From the foregoing study, it can be stated that the optimum leaching conditions for dissolving 98% of the U content using urea are as following:

Urea concentration: 150 g/L.

Leaching time: 5 h.

Leaching temperature: 25 °C.

Solid/liquid ratio: 1:4.

pH: 4.5 [28].

Agitation speed: 400 rpm

6 Kinetics of Leaching Process

6.1 Effect of Leaching Time on the Dissolution of Uranium at Different Temperatures

Leaching of uranium from the studied hydrous oxide cake was carried out at optimum conditions in the presence of 150 g/L of urea, solid/liquid ratio 1:4 at a temperature range between 25 and 85 °C. Figure 2 shows that the leachability of uranium increases gradually by increasing of time. The maximum leachability was found at 25 °C and after leaching time of 300 min.

6.2 Application of Leaching Kinetic Models

The un-reacted shrinking-core model is the most commonly used mathematical model to describe the heterogeneous reactions like mineral leaching from ores. In the solid–liquid phase reactions, the rate of reaction is controlled by the following steps: liquid-film diffusion (mass transfer), solid or product layer diffusion, and surface reaction or chemical reaction. One or more of these factors might control the rate of the reaction [29]. Amongst the three controlling mechanisms, the liquid-film diffusion resistance is eliminated or minimized by effective stirring.

In order to determine the type of leaching mechanism prevalent for uranium, some reaction models were investigated to find which kinetic equation can fit the reaction isotherms. The results were analyzed by using the following kinetic rate equations.

Reaction rate expression controlled by the surface chemical reaction:

Kc is the rate constant (/min) for chemical reaction. x is the fraction of recovery.

Reaction rate expression controlled by the diffusion through the ash or product layer:

where Kd is the rate constant (/min) for diffusion through the product layer.

The results of calculating 1 − (1 − x)1/3 at different leaching times and temperatures are shown in Table 6. Figures 3 and 4 show the result of plotting 1 − (1 − x)1/3 and 1 − 3(1 − x)2/3 + 2(1 − x) as a function of time at different leaching temperatures. The values of the reaction rate constants K were determined from the slope (x factor) of the straight line of the relation between kinetic model and time.

The R2 values mean the extent of fitting between the experimental data and the predicted one. The best fit has R2 of nearly 1.0. The kc values varied in the rage of 0.00025–0.0048/min while the kd were between 0.0023 and 0.00004/min. The R2 values for kc were 0.9808–0.9319 while for kd it was in the range of 0.9021–0.94502. Based on the R2 values, it can be inferred that the predominant dissolution mechanism of uranium from the monazite hydrous oxide cake is chemically controlled only.

6.3 Calculation of the Activation Energy

The relation between the logarithmic values of the reaction rate constants Kc and the reciprocal of the absolute leaching temperatures are shown in Table 7. The logarithmic values of these reactions rate constants were plotted against the reciprocal of the absolute reduction temperature according to the Arrhenius equation shown in Fig. 5.

The activation energy of the reaction can be calculated using the following equation:

where K is a reaction rate constant, recovery (conversion fraction) in /min, A is the frequency factor, constant/min, Ea is the apparent activation energy kJ/mol. Rg is the universal gas constant = 8.314 J/k/mol. T is the reaction temperature “k”.

From Fig. 5, the activation energy (Ea) was calculated as follows:

For reaction rate expression controlled by the chemical.Equation, \({\text{y}} = - 5424.4{\text{x}} + 10.2242\)

Ea = [− 5424.4 * − 8.314] = 450,985 J/mol = 45 kJ/mol

The apparent activation energy (Ea) was calculated from the slope of straight line obtained to be 45 kJ/mole for chemical controlled reaction models. Based on the Ea values, it can be inferred that the predominant dissolution mechanism of uranium from the monazite hydrous oxide cake is chemically controlled only. In this context, according to Crundwell [30] the activation energy for diffusion-controlled reactions is below 20 kJ/mol and it is above 40 kJ/mol for chemical controlled reactions.

7 Reaction Mechanism Between Urea and Uranium

Fourier transform infrared spectrometer characterization (FTIR) spectra are a useful tool to identify molecular to functional groups of the organic compounds. In the present work, the band observed at 3446/cm in spectra indicates the presence of N–H (primary amine) and 1686/cm for C=O while peak value at 1618/cm attributed to N–H bending. Also, C–N intense absorption bands appeared at 1463/cm. Finally, from the IR of reacted urea it can be stated that it is affected only at C=O which is shifted to 1605/cm Fig. 6.

From these results, it can be concluded that urea is a very weak base with a relatively high permanent dipole moment and hence electrolytically conducting in its aqueous solution. This electrolytic behavior can be well understood by a zwitter ion structure. Urea mostly exists as a zwitter ion NH2+:C(NH2)O_ and the following resonating hybrid structure were suggested [31, 32]:

Accordingly, if we have more urea molecules in solution, the UO22+ will pose more repulsion from −NH2+ and this repulsion is low at lower urea concentrations. Furthermore, intermolecular interactions (Van der Waals force and hydrogen bonding) getting stronger with increasing the number of urea molecules and hence the solution deviates from ideality (i.e. in concentrated liquids, ions are not randomly distributed as we see in the case of ideal solutions).

Urea complexation with uranyl ions can be written as:

We expect that urea is coordinated to U (VI) via the lone pair of electron at the oxygen atom of the carbonyl group (> C=O: → U) [33]. Also, with respect to U (VI) shows the distribution of U specious in relatively high urea concentrations [28]. According to this author, each set of urea concentrations behaves differently when interacting with a 5 × 10−5 M uranyl solution in a medium of pH 4.5 at room temperature Fig. 7.

(after Osman [28])

Distribution of uranium species in aqueous urea solution

8 Recovery of the Study Valuable Metals

8.1 Recovery of Uranium

For recovering uranium from the studied monazite hydrous oxide cake, a pregnant solution was prepared by applying the above mentioned optimum leaching conditions upon 500 g of the provided cake which has revealed the assay of 0.428 g/L of uranium with leaching efficiency of 98%. The latter is suitable for applying a direct precipitation technique to recover U, but the problem lies in the formation of gelatinous material at pH around 5 and/or 12. So, to avoid this problem, the uranium–urea solution would be firstly evaporated till crystallization. The crystalline precipitate was then dissolved in dilute sulfuric acid to convert uranyl urate complex to the uranyl sulfate one. The latter solution was then subjected to pH adjustment at pH 5.5–7 using NH4OH solution to precipitate uranium as ammonium di-uranate according to the following equation:

The precipitated ammonium di-uranate was properly filtered, washed and dried before being ascertained by the qualitative ESEM analysis as shown in Fig. 8. On the other hand, the quantitative chemical analysis of the obtained pure uranium concentrate revealed a U content of about 76%.

8.2 Recovery of Th and REEs

According to Amer et al. [9], Th could be recovered from its combined REEs by alkali treatment of the working hydrous oxide cake using a mixed weight of 3/1 Na2CO3/NaHCO3 in total concentration of 150 g/L at solid/liquid ratio of 1/6 for 2 h at 75 °C. Analysis of the prepared thorium solution was found to be free from any of REEs while its Th content assayed 0.5 g Th/L. Acidification of the latter using diluted HCl to pH 2.3 resulted in the precipitation of Th hydroxide which was filtered, washed, dried and calcined to have ThO2 (Fig. 9). On the other hand, REEs concentrate left behind was calcinated and proven by ESEM-EDAX analysis (Fig. 10). Finally, the mentioned procedure was proposed in working flow-sheet Fig. 11.

9 Conclusions

A new procedure has been developed for a selective recovery of uranium from a hydrous oxide cake of Egyptian monazite mineral concentrate. This procedure involved selective leaching of uranium using 150 g/L urea, 5 h agitation time within agitation speed of 400 rpm at 25 °C and S/L ratio of 1/4, leaving behind Th and REEs content. Kinetics of the leaching process as well as the reaction mechanism between urea and uranium has been proved as chemically controlled and the calculated apparent activation energy was 45.103 kJ/mol. From the obtained results, it can be concluded that urea offers several advantages over the classically used reagents especially with respect to the harmless nature of their degradation products and the possibility to burn; a matter which would reduce volume of secondary waste.

On the other hand, to separate Th selectively from the combined Th–REEs hydroxide, Th was dissolved via alkaline leaching using mixed weight of 3/1 Na2CO3/Na HCO3 in total concentration of 150 g/L, solid/liquid ratio of 1/6 for 2 h at 75 °C.

Finally, proper analyses of the obtained concentrates of U, Th and REEs have revealed the potential of applying the mentioned procedure.

References

Gupta CK, Mukherjee TK (1990) Hydrometallurgy in extraction process. Lib Congress 1:90–1561 (ISBN 0-8493-6804. Printed by United States)

Alex P, Suri AK, Gupta CK (1998) Processing of xenotime concentrate. Hydrometallurgy 50:331–338

Xie F, An Zhang T, Dreisinger D, Doyle F (2014) A critical review on solvent extraction of rare earths from aqueous solutions. Miner Eng 56:10–28

Brisson VL, Zhuang WQ, Alvarez-Cohen L (2016) Bioleaching of rare earth elements from monazite sand. Biotechnol Bioeng 113:339–348

Gupta CK, Krishnamurthy N (2005) Extractive metallurgy of rare earths. CRC Press, NY

De Rohden C, Seine N, Peltier M (1950) Treatment of monazite. US 2783125A

Hart K, Levins DM (1988) Management of wastes from the processing of rare earth minerals [online]. In: Chemeca 88 (16th: 1988: Sydney, NSW). Chemeca 88: Australia’s Bicentennial International Conference for the Process Industries; Preprints of Papers. Barton, ACT: Institution of Engineers, Australia, 1988: 82–88. National conference publication (Institution of Engineers, Australia); no. 88/16. https://search.informit.com.au/documentSummary;dn=844874222508066;res=IELENG>. Accessed 08 Mar 18 (ISBN: 0858254093)

Amer TE, El-Sheikh EM, Gado MA, Abu-Khoziem HA, Zaki SA (2018) Selective recovery of lanthanides, uranium and thorium from Rosetta monazite mineral concentrate. Sep Sci Technol 53(10):1522–1530

Amer TE, Abdella WM, Wahab GM, El-Sheikh EM (2013) A suggested alternative procedure for processing of monazite mineral concentrate. Int J Miner Process 125:106–111

Gentile PS, Talley LH, Collopy TJ (1959) The chemistry of uranyl nitrate–hydroxide–urea systems. J Inorg Nucl Chem 10(1–2):110–113

Manchanda VK, Pathak PN (2004) Amides and diamides as promising extractants in the back end of the nuclear fuel cycle: an overview. Sep Purif Technol 35:85–103

Jr Siddall (1960) Effects of structure of N,N-disubstituted amides on the extraction of actinide and zirconium nitrates and of nitric acid. J Phys Chem 64:1863–1866

Tian Y, Fu J, Zhang Y, Cao K, Bai C, Wang D, Li S, Xue Y, Ma L, Zheng C (2015) Ligand-exchange mechanism: new insight into solid-phase extraction of uranium based on a combined experimental and theoretical study. Phys Chem Chem Phys 17:7214–7223

Gentile JR, Roden AH, Klein RD (1972) An analysis-of-variance model for the intrasubject replication design. J Appl Behav Anal 5:193–198

Nichols P, Bylaska EJ, Schenter GK, de Jong W (2008) Equatorial and apical solvent shells of the UO2 2+ ion. J Chem Phys A 128:124507

Shamov GA, Schreckenbach G (2005) Density functional studies of actinyl aquo complexes studied using small-core effective core potentials and a scalar four-component relativistic method. J Phys Chem A 109(48):10961–10974

Nguyen-Trung C, Palmer DA, Begun GM, Peiffert C, Mesmer RE (2000) Aqueous uranyl complexes 1. raman spectroscopic study of the hydrolysis of uranyl(VI) in solutions of trifluoro methane sulfonic acid and/or tetra-methyl ammonium Hydroxide at 25 °C and 0.1 Mpa. J Sol Chem 29:101–129

Clark DL, Conradson SD, Donohoe RJ, Keogh DW, Morris DE, Palmer PD, Rogers RD, Tait CD (1999) Chemical speciation of the uranyl ion under highly alkaline conditions. Synthesis, structures, and oxo ligand exchange dynamics. Inorg Chem 38(7):1456–1466

Tsushima S, Rossberg A, Ikeda A, Muller K, Scheinost AC (2007) Stoichiometry and structure of uranyl(VI) hydroxo dimer and trimer complexes in aqueous solution. Inorg Chem 46(25):10819–10826

Oda Y, Aoshima A (2002) Ab initio quantum chemical study on charge distribution and molecular structure of uranyl (VI) species with Raman Frequency. J Nucl Sci Technol 39(6):647–654

Soderholm L, Skanthakumar S, Neuefeind J (2005) Determination of actinide speciation in solution using high-energy X-ray scattering. Anal Bioanal Chem 383(1):48–55

Wahlgren U, Moll H, Grenthe I, Schimmelpfennig B, Maron L, Vallet V, Gropen O (1999) Structure of uranium(VI) in strong alkaline solutions: a combined theoretical and experimental investigation. J Phys Chem A 103(41):8257–8264

Neuefeind J, Soderholm L, Skanthakumar S (2004) Experimental coordination environment of uranyl(VI) in aqueous solution. J Phys Chem A 108(14):2733–2739

El-Sheikh EM, Ali SA, Ghazala RA, Abdelwarith A, Salem F (2015) Leaching characteristics of uranium and copper from their mineralization in the carbonate rich latosol of Abu Thor locality, SW Sinai, Egypt. Isotop Radiat Res 47(2):231–246

Merczenko Z (1986) Separation and spectrophotometric determination of elements. Harwood, New York, p 708

Mathew KJ, Bürger S, Ogt SV, Mason PM, Narayanan UI (2009) Uranium assay determination using Davies and Gray titration Proceedings of The Eighth International Conference on Methods and Applications of Radio analytical Chemistry (Marc VIII) Kailua-Kona, Hawaii, 5

Osman AA (2014) Investigation of uranium binding forms in environmentally relevant waters and bio-fluids. Ph.D, thesis, im Institut für Ressourcenökologie, Helmholtz-Zentrum Dresden-Rossendorf e.V. angefertigt, p 120

Levenspiel O (1999) Chemical reaction engineering. Wiley, New York, Chichester, Weinheim, Brisbane, Toronto, p 684

Crundwell FK (2013) The dissolution and leaching of minerals. Mechanisms, myths and misunderstandings. Hydrometallurgy 139:132–148

Harris JO, Robson AH (1948) Structure of urea. Nature 161:98

Venkatesan VK, Suryanarayana CV (1956) Conductance and other physical properties of urea solutions. J Phys Chem 60:775–776

Van Staveren CJ, Fenton DE, Reinhoudt DN, Van Eerden J, Harkema S (1987) Complexation of Urea and UO2 2+ in a Schiff Base Macrocycle: a Mimic of an Enzyme Binding Site. J Am Chem Soc 109:3456–3458

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Amer, T.A., El-Sheikh, E.M., Hassanin, M.A. et al. Processing of Monazite Mineral Concentrate for Selective Recovery of Uranium. Chemistry Africa 2, 123–134 (2019). https://doi.org/10.1007/s42250-018-00037-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42250-018-00037-8