Abstract

Highly stretchable strain sensors with high sensitivity, wide sensing range, and high durability have broader application prospects in the fields of wearable sensors, electronic skin, and soft robots. However, it is still challenging to fabricate strain sensors with high sensitivity, wide working range, excellent durability, and antibacterial properties. Herein, a highly stretchable and porous thermoplastic polyurethane/carbon nanotube@silver nanoparticles (TPU/CNT@AgNPs) strain sensor was facilely prepared by electrospinning combined with dip coating CNT and reduction of AgNO3. The TPU/CNT@AgNPs strain sensor exhibited high sensitivity (the maximum gauge factor of 930), favorable conductivity (539.7 S m−1), wide sensing range (0.1 ~ 500% strain), a fast response time (100 ms at 1% strain), high dynamic response performance (2400 mm/min), air permeability, and antibacterial activity, due to the synergetic effect of the multi-conductive network between CNT and AgNPs. Benefiting from the in situ generated AgNPs and the π–π interaction between the benzene ring structure of TPU and CNT, the TPU/CNT@AgNPs strain sensor exhibited excellent durability (1400 cycles for 200% strain) and could work even after being immersed in harsh conditions (acidic and alkaline solution). Besides, the strain sensor can be successfully employed in monitoring human motion from tiny pulse beats to large bending movements of fingers, wrists, and knees. This work provides a feasible approach to preparing a strain sensor with outstanding overall performance, which has a perspective and alluring application in the realm of wearable electronics.

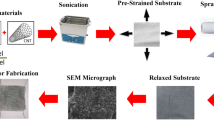

Graphical Abstract

Highly stretchable TPU/CNT@AgNPs strain sensor with high sensitivity was prepared by dipping CNT and AgNPs reduction on electrospun TPU mat.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

With the continuous development of information technology and flexible materials [1,2,3], numerous lightweight and easy-to-wear flexible strain sensors have emerged, which can detect the daily movement status of the human by converting environmental stimuli into visualized electrical signals [4,5,6]. According to the working mechanism, flexible strain sensors can be divided into three categories: piezoelectric [7, 8], capacitive [9, 10], and resistive [11,12,13,14,15,16,17]. Among them, resistive-based ss1ensors have attracted extensive research due to their high sensitivity, fast dynamic response rate, convenient signal acquisition, and facile assembly process, which are widely used in real-time motion detection and continuous health monitoring [18], flexible electronic skin [19, 20], speech recognition [21], and soft robotics [22]. To better meet the applications in the above fields, resistive strain sensors put forward high requirements for flexible strain sensors in terms of stretchability, sensitivity (gauge factor (GF)), conductivity, working range, durability, lightweight, and antibacterial performance.

Among the many flexible materials, thermoplastic polyurethane (TPU) is a common stretchable material with high elasticity and high ductility, as well as outstanding high tensile strength, toughness, and age resistance [23, 24]. These properties make it an ideal material for fabricating flexible sensors [25, 26]. In recent years, conductive carbon materials have been widely utilized in a variety of fields [27,28,29,30,31], and researchers have employed a variety of approaches to incorporate carbon-based conductive materials into TPU materials in order to fabricate TPU-based flexible resistance strain sensors. For example, Lü et al. [32] used the freeze-drying method to make a TPU foam and then coated it on oxidized graphene oxide (GO) and chemically reduced it to fabricate a strain sensor, which demonstrated outstanding flexibility (Young’s modulus: 137 kPa), ultra-high compressibility (up to 90%), and high compressive strength (> 1.94 MPa). Dong et al. [26] fabricated MXene/CNT/TPU composite strain sensors with high sensitivity through a vacuum filtration process. Chen et al. [33] developed a TPU/polydopamine/MXene conductive syntactic foam pressure sensor with a fast response time (40 ms) and a wide working range (10 Pa ~ 122 kPa) by the combination of directional freezing and dip coating. However, it is difficult to prepare lightweight, porous, and thin strain sensors for users to wear using the above-mentioned preparation method.

Electrospinning is an effective, facile, and scalable approach for preparing micro-nano fiber membranes, which are widely employed in medical devices, filters, and flexible electronic devices [34, 35]. Electrospinning fibers have numerous advantages, including a large specific surface area, high porosity, a small diameter, lightweight, and favorable mechanical flexibility, which make them ideal basic materials for functional nanocomposite. Specifically, TPU is easily electrospun into fibrous membranes with excellent stretchability, flexibility, and mechanical strength [36]. In general, conductive polymer fibers are made by high-voltage electrostatic spraying of polymer solutions containing conductive nanofiller [37]. To prepare composite material with high conductivity, substantial nano-conductive fillers must be incorporated. Nevertheless, a high concentration of nano-fillers raises the viscosity of the electrospinning solution and facilitates needle blockage, making electrospinning more difficult [38]. In addition, the direct mixing method of conductive fillers would diminish the tensile properties and resilience of TPU fibers.

Recently, flexible strain sensors have been fabricated by coating conductive material on the electrospun nanofiber membranes using the ultrasonic method. For instance, Wang and co-workers [39] developed a highly stretchable strain sensor by coating CNT onto the electrospun TPU nanofiber surface using the ultrasound approach. The as-prepared strain sensor with CNT conductive network exhibited relatively low sensitivity (GF = 0.194), owing to the fact that the high aspect ratio CNT had no significant slippage and maintained good interconnection during initial stretching, resulting in no obvious change in resistance. Meanwhile, it is reported that the introduction of silver nanowires (AgNWs) into strain sensors can significantly improve sensitivity. Wang et al. [40] and Lu et al. [41]. prepared flexible strain sensors with high sensitivity by directly depositing a layer of AgNWs film on the electrospun fiber membranes using the filtration method. As-prepared strain sensors achieved high sensitivity due to the rapid crack propagation of AgNWs during the stretching process, which resulted in an exponential increase in sensor resistance, hence significantly enhancing the sensor sensitivity. However, applying high strain to this type of sensor leads to permanent breakage of AgNWs connections, causing an irreversible change in resistance. And high-strain loading can also cause the peel-off of AgNWs from the flexible substrate, limiting the working range of the flexible strain sensor [42]. It remains a significant challenge to fabricate a flexible strain sensor with both high sensitivity and a wide sensing range.

Herein, we successfully fabricated porous flexible TPU/CNT@AgNPs fiber membranes with double conductive networks for strain sensors by a facile impregnation and reduction process, based on porous electrospun TPU membranes as the skeleton. The TPU/CNT@AgNPs strain sensor exhibited quick response, high sensitivity, a wide sensing range, and long-term durability owing to the synergistic effect of CNT and AgNPs. The CNT and AgNPs can wrap the fiber surface without compromising the mechanical capabilities of the TPU membranes, allowing the constructed TPU/CNT@AgNPs sensor to rely on the superior stretchability of TPU to withstand the enormous strain required for human movement monitoring. In addition, the sensor demonstrated good antibacterial activity, breathability, flush resistance, and acid–base resistance. Most importantly, the TPU/CNT@AgNPs strain sensor can accurately monitor human motions, including subtle pulse and large bending movements, demonstrating great potential application in multifunctional intelligent wearable sensors.

2 Experimental section

2.1 Materials

Thermoplastic polyurethane (TPU, Elastollan® 1185A) was purchased from BASF. Tetrahydrofuran (THF, Purity ≥ 99.5%) and L-ascorbic acid (LAA) were purchased from Sinopharm Chemical Reagent Co., Ltd. N, N-dimethylformamide (DMF, purity ≥ 99.5%) was supplied from Zhiyuan Chemical Reagent Co., Ltd. Silver nitrate solution (SNS, AgNO3, 0.100 mol/L) was purchased from Macklin Biochemical Co., Ltd. Multiwalled carbon nanotubes (CNT) aqueous dispersion (CNT content is about 10 wt.%) were purchased from XFNANO Materials Tech Co., Ltd.

2.2 Preparation of electrospinning TPU fiber membrane

Firstly, TPU pellets were dried in an oven at 80 °C for 24 h to remove moisture. Then, spinning precursor solutions with various TPU mass ratios (16 wt.%, 18 wt.%, 20 wt.%, 22 wt.%, and 24 wt.%) were prepared by dissolving TPU pellets in a combination of DMF and THF (mass ratio of 1:2) and subsequently stirred for 12 h at room temperature. After statically placing for a period of time, the above TPU solutions were used for electrospinning to obtain TPU nanofiber membranes. The spinning temperature and the distance between electrodes and the roller collector speed were fixed at 25 °C, 15 cm, and 250 rpm, respectively. The variable electrospinning parameters were voltages (8 kV, 10 kV, 12 kV, and 13.5 kV) and solution flow rates (0.1 mL/h, 0.5 mL/h, 1 mL/h, 1.5 mL/h, and 2 mL/h).

2.3 Preparation of precursor TPU/CNT nanocomposite membrane

Firstly, CNT aqueous dispersion (CNAD) was diluted by deionized water into different concentrations (0.5 wt.%, 1 wt.%, 3 wt.%, and 5 wt.%). Then, the TPU nanofiber membrane obtained above was tailored to the size of 1 cm × 4 cm and dipped in CNT aqueous dispersion with different concentrations for 10 min, separately. After that, the obtained TPU/CNT nanofiber membranes with different CNT contents were dried in the oven at 60 °C for 30 min and denoted as TPU/0.5CNT, TPU/1CNT, TPU/3CNT, and TPU/5CNT, respectively.

2.4 Preparation of TPU/CNT@AgNPs sensor

The obtained TPU/CNT membranes were put into SNS (0.100 mol/L) for 120 min to absorb silver ions and vacuum dried at 50 °C for 10 min, and then dipped into the different concentration LAA solutions (1 g/L, 10 g/L, 20 g/L, 30 g/L, and 40 g/L). After reduction by LAA, silver ions can be reduced to silver nanoparticles and attached to TPU/CNT membranes. Subsequently, the obtained TPU/CNT@AgNPs nanofiber membranes were rinsed with deionized water to remove the residual LAA solution and then dried under vacuum at 50° for 20 min. By repeating the above steps, TPU/CNT@AgNPs nanofiber membranes with different reduction times were prepared and denoted as TPU/3CNT@AgNPs-x (x representing silver ion reduction times).

2.5 Characterizations

The surface morphology of nanofiber membranes was observed by field emission scanning electron microscopy (SEM, Novaanskem 450, USA). The fiber diameter was measured via Image Pro Plus software by taking 100 fibers. Elemental composition, content, and distribution of TPU/CNT@AgNPs were analyzed by energy dispersive spectroscopy (EDS, Oxford Instruments, UK). Thermal stability was investigated by a thermogravimetric analysis instrument (TG209F1 Libra, Germany). The X-ray diffraction pattern was obtained by an X-ray diffractometer (XRD, Bruker D8, Germany) in the range of 10–70° and a step interval of 4°/min. Fourier transform infrared spectroscopy (FTIR) measurements were performed using a Bruker Tensor 27 instrument. Mechanical properties were measured by a universal testing machine (UTM2102, China). The electrical signal of the strain sensor was recorded by LCR Tester (TH2830, China). All the current–voltage (I–V) characteristic curves were carried out on an electrochemical workstation (CHI 760E, USA).

The air permeability of TPU/CNT@AgNPs was carried out in a homemade apparatus consisting of a straight-necked test tube with a hollow bottom and a double-necked conical flask. The TPU/CNT@AgNPs membrane was clamped between the straight-necked test tube and the flask. Approximately 100 mL of deionized water stained with Prussian Blue was poured from the top of the straight-necked test tube, ensuring that the liquid does not overflow from the clamp. The double-necked conical flask was injected with air using an injector, and the gas would flow through the film, causing the water in the test tube with a straight neck to create air bubbles. By observing bubbles, the air permeability of a TPU/3CNT@AgNPs membrane was examined. Wearing the TPU/CNT@AgNPs membrane as a wearable sensor for monitoring human motion had obtained the informed and signed consent of the first author of the article. The sensing performance of resistive sensors was characterized by the relative resistance change (ΔR/R0), which was evaluated by Eq. (1):

where R0 is the initial resistance and ΔR represents the changed resistance.

The sensor sensitivity named gauge factor (GF) was calculated by Eq. (2):

where ε is the ratio of the stretched length to the original length.

The antibacterial properties of the TPU/3CNT@AgNPs sensor were investigated by the inhibition zone method using Staphylococcus aureus (S. aureus, CMCC(B)26,003) and Escherichia coli (E. coli, ATCC 25,922). The S. aureus and E. coli were cultured in an air bath shaker at 30 °C, respectively. The bacteria were diluted to a concentration of 106 CFU/mL using LB solution. After 12 h, the resulting bacterial suspension was prepared and 50 μL suspensions were dropwise added onto the plates of LB agar. After that, the TPU/3CNT@AgNPs-4 membrane with a diameter of about 7 mm and the corresponding blank sample was placed on the agar plate in a 30 °C incubator, and after 12 h of incubation, the bacterial growth was observed. These tests had been conducted in three independent repeats.

3 Results and discussion

3.1 Optimization for the preparation of TPU/CNT@AgNPs membrane

The facile preparation route of the TPU/CNT@AgNPs strain sensor is illustrated in Fig. 1, which contains the electrospinning and step-by-step dipping and reduction processes. In Fig. S1, the suspension of CNT, AgNO3, and LAA prepared remained homogeneous after standing for 24 h, indicating that CNT, AgNO3, and LAA could be stably dispersed in an aqueous solution. By adjusting the electrospinning solution concentration, voltage, and flow rate, the electrospinning conditions of the neat TPU nanofiber membrane were determined. It can be seen that as the polymer solution concentration increased, the diameter of TPU fibers increased (Fig. S2). Increasing the voltage initially changed the distribution of fiber diameter from uneven to uniform, and when the voltage reached a certain value, the diameter distribution became non-uniform again (Fig. S3). Similarly, fiber diameter gradually increased with increasing flow rate and becomes uniform after reaching a certain value of the flow rate (Fig. S4). Based on the above results, the concentration, voltage, and flow rate of the spinning solution were fixed at 22 wt.%, 12 kV, and 1.5 mL/h, respectively. Finally, the resultant TPU nanofiber membranes with a thickness of 0.25 ± 0.02 mm were used as the mat.

Subsequently, the precursor TPU/CNT nanofiber membranes with varied CNT loading were fabricated by dipping TPU nanofiber membranes in CNT aqueous dispersion (CNAD) with different CNT concentrations. The obtained samples were defined as TPU/xCNT (x representing the mass ratio of CNT in CNAD). The detailed composition of TPU/CNT nanofiber membranes is shown in Table S1. A few CNTs were adsorbed on the fiber surface when the membranes were low-concentration CNAD (Fig. S5a and S5b). As shown in Fig. S5c, the fiber surface was covered with a large number of CNT when the CNAD concentration is 3 wt.%. When CNAD concentration further increased to 5 wt.%, the pores between fibers were gradually covered by dense CNT (Fig. S5d). Moreover, the conductivity of TPU/CNT nanofiber membranes did not increase significantly when the concentration of CNAD exceeded 3 wt.% (Fig. S6), indicating that 3 wt.% was the optimal concentration of CNAD. Therefore, TPU/3CNT nanofiber membrane was selected as the precursor for the next preparation of the strain sensor.

Figure S7 shows the morphology of TPU/3CNT@AgNPs nanofiber membranes with different LAA reducing agent concentrations (1 g/L, 10 g/L, 20 g/L, 30 g/L, and 40 g/L). It was obvious that the color of the membrane gradually turned white with increasing LAA concentration, indicating the enhanced reduction of AgNPs on the TPU/3CNT membrane surface. When the concentrations of the LAA reducing agent were 1 g/L and 10 g/L, only a small amount of AgNPs was reduced on the fiber surface (Fig. S7a3 and S7b3). The reduced AgNPs on the TPU/3CNT fiber surface gradually increased with increasing LAA concentration and the fiber surface was densely covered with relatively uniform AgNPs (Fig. S7c3 and S7d3). The distribution of AgNPs on the fiber surface was not significantly changed as the LAA concentration further increased to 40 g/L (Fig. S7e3), indicating that the LAA concentration has reached saturation at 30 g/L. Therefore, 30 g/L was chosen as the concentration of LAA reducing agent for the following studies. Figure S8 depicts the morphologies of TPU/3CNT@AgNPs nanofiber membranes with different silver ion reduction times. When the number of reductions was increased to the fifth time, AgNPs completely covered the surface of the fibers. With increasing reduction times, the conductivity of TPU/3CNT/AgNPs membranes improved from 32.8 to 539.7 S/m (Fig. S9), indicating that AgNPs coating on the surface of TPU/3CNT fibers can enhance the conductivity further. The conductivity of TPU/3CNT/AgNPs is better than most of the electrospun membranes previously reported in the literature (Table S2). Notably, when the times of reduction increased to 4, the conductivity of TPU/3CNT@AgNPs tended to be steady. Therefore, TPU/3CNT@AgNPs-4 was selected for subsequent experiments. In addition, the good linearity of the I-V characteristic curve demonstrated TPU/3CNT@AgNPs-4 sensor compound Ohm’s law (Fig. S10).

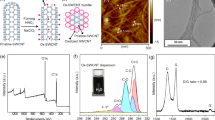

3.2 Morphology and structure characterization of TPU/3CNT@AgNPs-4 membrane

Figure 2 shows the SEM and digital images of TPU, TPU/3CNT, and TPU/3CNT@AgNPs-4 nanofiber membranes, respectively. Neat TPU nanofiber membrane shows a smooth surface and uniform diameter (Fig. 2a2). The CNT coating on the fiber surface can be clearly seen in Fig. 2b2. Dense AgNPs were successfully reduced on TPU/3CNT membrane and evenly distributed on the fiber surface (Fig. 2c2). In addition, CNT was interweaved and covered with partial AgNPs. The EDS spectra and elemental mapping images demonstrated that TPU/3CNT@AgNPs-4 contained C, Ag, O, and little N elements, and the relative weight ratios of C, Ag, and O are 84.3 wt. %, 12.7 wt.%, and 3 wt.%, respectively (Fig. 2d), which also were confirmed in EDX spectroscopy (Fig. S11). Figure 2a3–c3 demonstrated that all three kinds of membranes exhibited sufficient flexibility and were robust to be knotted and twisted. Figures S12 and S13 show the XRD pattern and TGA curve of pure TPU, TPU/3CNT, and TPU/3CNT@AgNPs-4 membranes, respectively, which proves that the CNT and AgNPs were successfully coated on the neat TPU nanofiber membranes by dipping coating and 4 times reduction of AgNO3. FTIR spectrum indicates that no new chemical groups are generated on the surface of TPU/3CNT@AgNPs-4 membrane after dipping CNT and reducing AgNPs (Fig. S14).

3.3 Mechanical performance of TPU/3CNT@AgNPs-4

Stretchability is an important parameter to evaluate the mechanical properties of flexible sensors [43]. The TPU/3CNT@AgNPs-4 membrane exhibited superior stretchability and could recover to its original shape after a large deformation (Fig. 3a). The mechanical properties of the TPU/3CNT@AgNPs-4 membrane were evaluated quantitatively through tensile tests. Figure 3b and c reveal the typical stress–strain curve and histogram of tensile stress and Young’s modulus as well as elongation at the break of TPU, TPU/3CNT, and TPU/3CNT@AgNPs-4 membranes. Coating CNT and reducing AgNPs on the TPU fiber surface did not significantly deteriorate the mechanical properties, and TPU/3CNT@AgNPs-4 exhibited an excellent tensile strength of 3.03 MPa and a high stretchability of 515%. Figure 3d shows the multiple cyclic stretching curves of the TPU/3CNT@AgNPs-4 sensor under 10%, 30%, 50%, 100%, and 200% strain, respectively. The tensile stress increased as the strain increased, and at a large strain of 200%, the tensile stress responded steadily during the cyclic stretch-releasing process. Each stretched hysteresis loop was substantially coincident with the other under 500 cycles of 100% strain stretching (Fig. 3e), demonstrating that TPU/3CNT@AgNPs-4 has excellent fatigue resistance. And after 500 cycles of 100% strain stretching, the retention of max stress remained at approximately 85%, and the residual strain was below 20% (Fig. 3f), further demonstrating the excellent durability and shape-recovery ability.

a Physical images of TPU/3CNT@AgNPs-4 sensor before and during stretching. b and c Stress–strain curve and histogram of tensile property for neat TPU, TPU/3CNT, and TPU/3CNT@AgNPs-4 membranes. d Tensile stress of TPU/3CNT@AgNPs-4 membranes as a function of time under 10%, 30%, 50%, 100%, and 200% strain, respectively. e Hysteresis loops for the 1st, 30th, 50th, 100th, 300th, and 500th cycles of TPU/3CNT@AgNPs-4 membranes. f Residual strain and retention of max stress after 500 cycles of 100% strain stretching

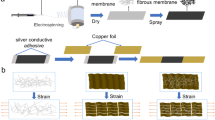

3.4 Sensing performance of TPU/3CNT@AgNPs-4 membrane

It is understandable that the electrical resistance variation of the strain sensor is mainly induced by structural changes, resulting from the change in contact between conductive particles under stretching. Here, a simplified flexible strain sensor prototype was assembled (Fig. S15a). As shown in Fig. S15b–d and Video S1, the strain sensor device without external tensile was electrically connected, resulting in the bright yellow of the LED. The brightness of LED light gradually weakened with the increased external tension, which indicated that TPU/3CNT@AgNPs-4 sensor has great potential for fabricating wearable and durable strain sensor devices. The resistance value of the TPU/3CNT@AgNPs-4 strain sensor remained steady for 30 days at room temperature (Fig. S16), exhibiting high stability of the sensor. The gauge factor (GF) is a key parameter for evaluating the sensitivity of the flexible sensor, which is obtained by calculating the slope of relative resistance change (ΔR/R0) vs. strain curve. As shown in Fig. 4a, compared with TPU/3CNT, the sensitivity of TPU/3CNT@AgNPs-4 has been greatly improved, exhibiting a 44 high GF in the strain range of 0–50%, which outperformed most of the previously reported high-sensitivity flexible strain sensors [44,45,46]. The strain range of 0–50% is the most working range for detecting human motions, and the high sensitivity of the sensor is conducive to improving the lower limit of detection to monitor small strain motion (e.g., speech recognition, pulse). By further increasing the strain, the GF of TPU/3CNT@AgNPs-4 gradually increased to 930 in the range of 400–500% strain.

a The ΔR/R0 of the TPU/3CNT@AgNPs-4 sensor as a function of strain. b Schematic diagram of sensing mechanism of the TPU/3CNT@AgNPs-4 based strain sensor. c Comparison of tensile strains and maximum GF with other strain sensors reported previously [20, 39, 41, 44, 46,47,48,49,50,51,52,53,54]. d and e ΔR/R0 curves under different tensile strains (0.1–10% strain). f ΔR/R0 curves under five different tensile rates (45, 90, 135, 180, and 2400 mm/min) at 50% strain. g ΔR/R0 curves under 1400 cycles stretch at 200% strain. h Response time of the sensor the under a cyclic strain of 1% at a tensile rate of 500 mm/min

Figure 4b depicts the schematic illustration of the sensing mechanism for the TPU/3CNT@AgNPs-4 strain sensor. The architecture of the TPU/3CNT@AgNPs-4 sensor’s bilayer conductive network topology contributes to its sensitivity. In small strains, the AgNPs on the fiber surface contact each other and form a dense conductive network, which plays a major role in the electrical conduction process compared with CNT. Electrons are transferred on the fiber surface and between adjacent fibers mainly through the conductive network of AgNPs. After preliminary stretching, TPU/3CNT@AgNPs nanofiber becomes longer and thinner, the distance between conductive particles on the fiber surface expands, and the dense conductive networks dominated by “point to point” conduction originally composed of AgNPs begin to be destroyed. The newly formed conductive network is mainly composed of CNT to CNT “wire to wire” mode or CNT to AgNPs “wire to point” mode, resulting in increased resistance (the resistance of Ag is much smaller than that of CNT). However, since the distance between conductive networks on the adjacent fibers has not exceeded the limited transition distance of electron transfer, electrons can still transfer between fibers. With further stretching of the TPU/3CNT@AgNPs membrane, a large number of AgNPs conductive networks on the surface of the fiber are disconnected, and electrons can only be transferred through a small number of conductive networks. At high strain, the TPU/3CNT@AgNPs membrane demonstrates a greater variance in resistance with the same strain change; as a result, the sensitivity of the TPU/3CNT@AgNPs membrane increases with strain.

The SEM images of the TPU/3CNT@AgNPs film under different deformation processes more realistically show the dynamic structural changes of the TPU/3CNT@AgNPs (Fig. S17). As shown in Fig. 4c and Table S2, TPU/3CNT@AgNPs-4 exhibited excellent sensitivity compared to the flexible strain sensors reported in previous literature, respectively [20, 39, 41, 44, 46,47,48,49,50,51,52,53,54]. The ΔR/R0 signals of the TPU/3CNT@AgNPs sensor under different tensile strains in the range of 0.1–10% exhibited nearly identical waveforms (Fig. 4d and e), indicating that the sensor has a high degree of stability and an extremely low detection limit, allowing it to monitor strains as small as 0.1%. In addition, as the tensile strain increased, the value of ΔR/R0 also gradually increased, indicating that the strain sensor has wide sensing range. Figure 4f displays ΔR/R0 curves of the TPU/3CNT@AgNPs-4 strain sensor under five different stretching rates (45, 90, 135, 180, and 2400 mm/min) at 50% strain. The TPU/3CNT@AgNPs strain sensor generated stable and repetitive ΔR/R0 signals when repeatedly stretched at a normal rate of 45 mm/min and an ultra-fast rate of 2400 mm/min, owing to the high resilience of the TPU/3CNT@AgNPs-4 sensor. Figure 4g depicts the highly repeatable ΔR/R0 signals of the strain sensor toward 1400 cycle stretches at 200% strain. The partial enlargement image captured from the last 200 s of the ΔR/R0 signals shows that the sensor almost has the same response compared with the initial 200 s, demonstrating the ultra-durable sensing performance of TPU/3CNT@AgNPs-4. As depicted in Fig. 4h, the response and recovery times of the TPU/3CNT@AgNPs-4 sensor were 100 ms and 150 ms, respectively, indicating that the sensor has application potential for detecting quick motions such as fast running.

3.5 Applications of TPU/3CNT@AgNPs-4 strain sensor in monitoring human motions

The above characterizations and analyses demonstrate that the TPU/3CNT@AgNPs-4 strain sensor has high sensitivity, wide sensing range, and excellent stability and durability as well as great potential in human motion monitoring from tiny to large movement. The strain sensor can be lightly and flexibly attached to the human body. The waveforms of a triple-humped waveform, including the percussion (P) wave, tidal (T) wave, and dicrotic (D) wave, were clearly distinguished (Fig. 5a), which demonstrates that the strain sensor can detect human tiny movements. Besides, the sensor can also distinguish words with different syllables and record the current changes (Fig. 5c). For example, the ΔR/R0 signal exhibited only one peak for the single-syllable word “FOUR,” whereas it exhibited two peaks for the two-syllable word “LUCKY.” The three-syllable word “study” also displayed three peaks. The regular vibration of Adam’s apple can be monitored by the sensor when drinking water (Fig. 5d). The above demonstrations indicate that the sensor has the ability to distinguish different signals from weak throat vibrations, showing great potential for speech recognition. Figure 5e depicts that the sensor can accurately convey the frequency of wrist bending. In Fig. 5f, the elbow performs two different degrees of flexion and the motions can be clearly monitored and distinguished by the sensor, which demonstrates that the sensor can be used to identify the intensity of human movement. When the sensor is attached to the index finger, the sensor presents a periodic and stable resistance response with the bending action of the finger (Fig. 5g). And the sensor can also be used to detect the large motions of bending and straightening of the knee (Fig. 5h). Based on the above results, the TPU/3CNT@AgNPs-4 strain sensor’s high sensitivity and wide working range would make it a promising candidate for use as electronic skins for real-time human motion and health monitoring.

Applications of the TPU/3CNT@AgNPs-4 strain sensor for human motion detection from tiny to large movement. a The relative resistance changes of the TPU/3CNT@AgNPs-4 strain sensor for monitoring pulse. b Schematic diagram of the TPU/3CNT@AgNPs-4 strain sensor for monitoring human motion. The relative resistance changes of the TPU/3CNT@AgNPs-4 stain sensor for monitoring c pronunciation of words with different syllables, d Adam’s apple vibration caused by drinking water, e wrist bending, f elbow bending, g finger bending, and h knee bending

3.6 Antibacterial activity, durability, and breathability of TPU/3CNT@AgNPs-4 strain sensor

If the wearable strain sensor has antibacterial properties, it would be of great benefit to human health to prevent bacteria from being nourished by sweat during prolonged use. The antibacterial effect of neat TPU, TPU/3CNT, and TPU/3CNT@AgNPs-4 membranes was measured using Staphylococcus aureus (S. aureus) and Escherichia coli (E. coli) as representative bacteria (Fig. 6a and b). There was no antibacterial zone around the pure TPU, and the antibacterial zone appeared after the TPU was coated with CNT and AgNPs. In Fig. 6c, the diameter of the inhibition zone was measured quantitatively. The diameter of bacteriostatic zoner was 2.8 mm for S. aureus and 1.4 mm for E. coli around TPU/3CNT, respectively. After reducing AgNPs on the TPU/3CNT surface, the antibacterial zoner diameter of the TPU/3CNT@AgNPs-4 membrane obviously increased to 4.2 and 2.3 mm for S. aureus and E. coli, respectively. As anticipated, the incorporation of CNT confers significant antibacterial function to the TPU/3CNT@AgNPs-4 sensor, and the antibacterial effect is further enhanced by the addition of AgNPs [55,56,57], certifying that the TPU/3CNT@AgNPs-4 sensor has great potential as a flexible antibacterial sensor.

Antibacterial activity of TPU, TPU/3CNT, and TPU/3CNT@AgNPs-4 membranes: a S. aureus. b E. coli. c Corresponding diameters of inhibition-zone for S. aureus and E. coli. d Physical pictures of TPU/3CNT@AgNPs strain sensor immersed in different mediums for 24 h and dried. e ΔR/R0 curve of TPU/3CNT@AgNPs sensor at 50% strain after 24 h immersion. f and g ΔR/R0 curve of TPU/3CNT@AgNPs sensor under different strains after immersing in acidic and alkaline solution for 120 min, respectively. h Air permeability of TPU/3CNT@AgNPs-4 sensor

Besides, the durability of the sensor is also a key parameter for its long-term use. Water resistance is an important indicator of durability [58, 59], and often the sensor will be corroded by acidic sweat or beverages when worn by the user. The durability of TPU/3CNT@AgNPs-4 was evaluated by soaking in different liquids, such as alcohol, sprite, tea, sports drink, and orange juice for 24 h (Fig. 6d). There was no obvious change in the color of the liquid, indicating that the CNTs and AgNPs have not been flaked off from the surface of TPU/3CNT@AgNPs-4. After drying, TPU/3CNT@AgNPs-4 maintained the original sensing performance and output stable ΔR/R0 signals under 50% strain after drying (Fig. 6e). Moreover, after 2 h of immersion in an acidic solution (pH: 4.52) configured by potassium hydrogen phthalate, the TPU/3CNT@AgNPs-4 sensor output stable ΔR/R0 signals are at 50% and 100% strains during cyclic stretching (Fig. 6f). We further evaluated the alkali resistance of the sensor by immersing it for 2 h in an alkaline solution (pH: 9.69) containing sodium tetraborate (Fig. 6g). The sensor maintained a favorable sensing performance, producing extremely stable ΔR/R0 signals. The high durability of TPU/3CNT@AgNPs-4 sensor may be due to the π–π interaction between the benzene ring structure of TPU and CNTs, resulting in a tight coating of CNTs on the fiber surface of TPU [60]. Benefiting from the porosity of electrospinning and precise regulation of conductive coating, the TPU/3CNT@AgNPs-4 stain sensor exhibited high air permeability (Fig. 6h), which can provide a more comfortable experience for users.

4 Conclusion

A mechanically robust TPU/3CNT@AgNPs-4 strain sensor with excellent stretchability, high sensitivity, wide sensing range, good stability, ultra-durability, superior antibacterial activity, air permeability, and flush resistance was successfully developed by dipping CNT and in situ reduction of AgNPs on the surface electrospun TPU nanofiber membrane. The introduction of AgNPs enhanced the conductivity, sensitivity, and antibacterial properties of the sensor. Consequently, the TPU/3CNT@AgNPs-4 sensor exhibited good electromechanical behaviors, including ultrahigh dynamic monitoring rate (2400 mm/min), high sensitivity (GF = 930), fast response speed (100 ms at 1% strain), and excellent stability (~ 1400 cycles at 200% strain). It also possessed a highly dependable and wide detection capability for an ultra-low strain of 0.1% and a large strain of 500%. Meanwhile, the TPU/3CNT@AgNPs-4 sensor is ideal for complicated situations and can function normally after soaking in an acid–base solution. We believe that this research can inspire future work on the fabrication of wearable strain sensors that incorporate the benefits of conducting mediums and polymer matrices as well as their preparation methods of electrospinning, thereby allowing them to be used in wearable electronics, health monitoring equipment, and speech recognition systems.

Data availability

The TPU/3CNT@AgNPs-4 stain sensor is breathable, and when worn on the skin, it can provide a breathable environment for the skin and improve comfort. This is just a subjective guess without actual measurement.

References

Gao S, Zhao X, Fu Q, Zhang T, Zhu J, Hou F, Ni J, Zhu C, Li T, Wang Y, Murugadoss V, Mersal GAM, Ibrahim MM, El-Bahy ZM, Huang M, Guo Z (2022) Highly transmitted silver nanowires-SWCNTs conductive flexible film by nested density structure and aluminum-doped zinc oxide capping layer for flexible amorphous silicon solar cells. J Mater Sci Technol 126:152–160. https://doi.org/10.1016/j.jmst.2022.03.012

Wang W, Yi L, Zheng Y, Lu J, Jiang A, Wang D (2023) Photochromic and mechanochromic cotton fabric for flexible rewritable media based on acrylate latex with spiropyran cross-linker. Compos Commun 37:101455. https://doi.org/10.1016/j.coco.2022.101455

Zhu H, Hu W, Zhao S, Zhang X, Pei L, Zhao G, Wang Z (2020) Flexible and thermally stable superhydrophobic surface with excellent anti-corrosion behavior. J Mater Sci 55(5):2215–2225. https://doi.org/10.1007/s10853-019-04050-1

Lin M, Zheng Z, Yang L, Luo M, Fu L, Lin B, Xu C (2022) A high-performance, sensitive, wearable multifunctional sensor based on rubber/CNT for human motion and skin temperature detection. Adv Mater 34(1):2107309. https://doi.org/10.1002/adma.202107309

Wu W, Ren Y, Jiang T, Hou L, Zhou J, Jiang H (2022) Anti-drying, transparent, ion-conducting, and tough organohydrogels for wearable multifunctional human–machine interfaces. Chem Eng J 430:132635. https://doi.org/10.1016/j.cej.2021.132635

Chen G, Xiao X, Zhao X, Tat T, Bick M, Chen J (2022) Electronic textiles for wearable point-of-care systems. Chem Rev 122(3):3259–3291. https://doi.org/10.1021/acs.chemrev.1c00502

Zhang X, Wang Y, Gao X, Ji Y, Qian F, Fan J, Wang H, Qiu L, Li W, Yang H (2021) High-temperature and flexible piezoelectric sensors for lamb-wave-based structural health monitoring. ACS Appl Mater Interfaces 13(40):47764–47772. https://doi.org/10.1021/acsami.1c13704

Xu Z, Wan X, Mo X, Lin S, Chen S, Chen J, Pan Y, Zhang H, Jin H, Duan J, Huang L, Huang L-B, Xie J, Yi F, Hu B, Zhou J (2021) Electrostatic assembly of laminated transparent piezoelectrets for epidermal and implantable electronics. Nano Energy 89:106450. https://doi.org/10.1016/j.nanoen.2021.106450

Ha KH, Zhang W, Jang H, Kang S, Wang L, Tan P, Hwang H, Lu N (2021) Highly sensitive capacitive pressure sensors over a wide pressure range enabled by the hybrid responses of a highly porous nanocomposite. Adv Mater 33(48):2103320. https://doi.org/10.1002/adma.202103320

Hwang J, Kim Y, Yang H, Oh JH (2021) Fabrication of hierarchically porous structured PDMS composites and their application as a flexible capacitive pressure sensor. Compos Part B: Eng 211:108607. https://doi.org/10.1016/j.compositesb.2021.108607

Xie W, Yao F, Gu H, Du A, Lei Q, Naik N, Guo Z (2022) Magnetoresistive and piezoresistive polyaniline nanoarrays in-situ polymerized surrounding magnetic graphene aerogel. Adv Compos Hybrid Mater 5(2):1003–1016. https://doi.org/10.1007/s42114-021-00413-y

Ji X, Zhong Y, Li C, Chu J, Wang H, Xing Z, Niu T, Zhang Z, Du A (2021) Nanoporous carbon aerogels for laser-printed wearable sensors. ACS Appl Nano Mater 4(7):6796–6804. https://doi.org/10.1021/acsanm.1c00858

Chen A, Wang C, Abu Ali OA, Mahmoud SF, Shi Y, Ji Y, Algadi H, El-Bahy SM, Huang M, Guo Z, Cui D, Wei H (2022) MXene@nitrogen-doped carbon films for supercapacitor and piezoresistive sensing applications. Compos Part A: Appl S 163:107174. https://doi.org/10.1016/j.compositesa.2022.107174

Kong D, El-Bahy ZM, Algadi H, Li T, El-Bahy SM, Nassan MA, Li J, Faheim AA, Li A, Xu C, Huang M, Cui D, Wei H (2022) Highly sensitive strain sensors with wide operation range from strong MXene-composited polyvinyl alcohol/sodium carboxymethylcellulose double network hydrogel. Adv Compos Hybrid Mater 5(3):1976–1987. https://doi.org/10.1007/s42114-022-00531-1

Wu Y, Wu J, Lin Y, Liu J, Pan X, He X, Bi K, Lei M (2022) Melamine sponge skeleton loaded organic conductors for mechanical sensors with high sensitivity and high resolution. Adv Compos Hybrid Mater 6(1):4. https://doi.org/10.1007/s42114-022-00581-5

Chang X, Chen L, Chen J, Zhu Y, Guo Z (2021) Advances in transparent and stretchable strain sensors. Adv Compos Hybrid Mater 4(3):435–450. https://doi.org/10.1007/s42114-021-00292-3

Hu M, Gao Y, Jiang Y, Zeng H, Zeng S, Zhu M, Xu G, Sun L (2021) High-performance strain sensors based on bilayer carbon black/PDMS hybrids. Adv Compos Hybrid Mater 4(3):514–520. https://doi.org/10.1007/s42114-021-00226-z

Mishra S, Mohanty S, Ramadoss A (2022) Functionality of flexible pressure sensors in cardiovascular health monitoring: a review. ACS Sens 7(9):2495–2520. https://doi.org/10.1021/acssensors.2c00942

Cao M, Su J, Fan S, Qiu H, Su D, Li L (2021) Wearable piezoresistive pressure sensors based on 3D graphene. Chem Eng J 406:126777. https://doi.org/10.1016/j.cej.2020.126777

Zhao Y, Ren M, Shang Y, Li J, Wang S, Zhai W, Zheng G, Dai K, Liu C, Shen C (2020) Ultra-sensitive and durable strain sensor with sandwich structure and excellent anti-interference ability for wearable electronic skins. Compos Sci Technol 200:108448. https://doi.org/10.1016/j.compscitech.2020.108448

Tian G, Zhan L, Deng J, Liu H, Li J, Ma J, Jin X, Ke Q, Huang C (2021) ACS Appl Mater Interfaces Coating of multi-wall carbon nanotubes (MWCNTs) on three-dimensional, bicomponent nonwovens as wearable and high-performance piezoresistive sensors. Chem Eng J 425:130682. https://doi.org/10.1016/j.cej.2021.130682

Hu X, Yang F, Wu M, Sui Y, Guo D, Li M, Kang Z, Sun J, Liu J (2021) A super-stretchable and highly sensitive carbon nanotube capacitive strain sensor for wearable applications and soft robotics. Adv Mater Technol 7(3):2100769. https://doi.org/10.1002/admt.202100769

Duan L, D'Hooge DR, Cardon L (2020) Recent progress on flexible and stretchable piezoresistive strain sensors: from design to application. Prog Mater Sci 114:100617. https://doi.org/10.1016/j.pmatsci.2019.100617

Wang H, Peng X, Liu F, Song X, Wang H, Geng L, Huang A (2022) Facile preparation of super lightweight and highly elastic thermoplastic polyurethane bead blend foam with microporous segregated network structure for good interfacial adhesion. J Supercrit Fluid 184:105568. https://doi.org/10.1016/j.supflu.2022.105568

Li Q, Yin R, Zhang D, Liu H, Chen X, Zheng Y, Guo Z, Liu C, Shen C (2020) Flexible conductive MXene/cellulose nanocrystal coated nonwoven fabrics for tunable wearable strain/pressure sensors. J Mater Chem A 8(40):21131–21141. https://doi.org/10.1039/D0TA07832H

Dong H, Sun J, Liu X, Jiang X, Lu S (2022) Highly sensitive and stretchable MXene/CNTs/TPU composite strain sensor with bilayer conductive structure for human motion detection. ACS Appl Mater Interfaces 14(13):15504–15516. https://doi.org/10.1021/acsami.1c23567

Yang J, Cui N, Lu J, Han D, Shen J, Zhang Z, Qin L, Zhou B, Du A (2022) A facile and versatile post-treatment method to efficiently functionalize 3D-printed carbon aerogels via introducing tailored metal elements. ACS Appl Energy Mater 5(10):11970–11976. https://doi.org/10.1021/acsaem.2c02481

Li F, Li Q, Kimura H, Xie X, Zhang X, Wu N, Sun X, Xu BB, Algadi H, Pashameah RA, Alanazi AK, Alzahrani E, Li H, Du W, Guo Z, Hou C (2023) Morphology controllable urchin-shaped bimetallic nickel-cobalt oxide/carbon composites with enhanced electromagnetic wave absorption performance. J Mater Sci Technol 148:250–259. https://doi.org/10.1016/j.jmst.2022.12.003

Hou C, Yang W, Kimura H, Xie X, Zhang X, Sun X, Yu Z, Yang X, Zhang Y, Wang B, Xu BB, Sridhar D, Algadi H, Guo Z, Du W (2023) Boosted lithium storage performance by local build-in electric field derived by oxygen vacancies in 3D holey N-doped carbon structure decorated with molybdenum dioxide. J Mater Sci Technol 142:185–195. https://doi.org/10.1016/j.jmst.2022.10.007

Mu Q, Liu R, Kimura H, Li J, Jiang H, Zhang X, Yu Z, Sun X, Algadi H, Guo Z, Du W, Hou C (2022) Supramolecular self-assembly synthesis of hemoglobin-like amorphous CoP@N, P-doped carbon composites enable ultralong stable cycling under high-current density for lithium-ion battery anodes. Adv Compos Hybrid Mater 6(1):23. https://doi.org/10.1007/s42114-022-00607-y

Yang W, Peng D, Kimura H, Zhang X, Sun X, Pashameah RA, Alzahrani E, Wang B, Guo Z, Du W, Hou C (2022) Honeycomb-like nitrogen-doped porous carbon decorated with Co3O4 nanoparticles for superior electrochemical performance pseudo-capacitive lithium storage and supercapacitors. Adv Compos Hybrid Mater 5(4):3146–3157. https://doi.org/10.1007/s42114-022-00556-6

Lü X, Yu T, Meng F, Bao W (2021) Wide-range and high-stability flexible conductive graphene/thermoplastic polyurethane foam for piezoresistive sensor applications. Adv Mater Technol 6(10):2100248. https://doi.org/10.1002/admt.202100248

Chen Q, Gao Q, Wang X, Schubert DW, Liu X (2022) Flexible, conductive, and anisotropic thermoplastic polyurethane/polydopamine /MXene foam for piezoresistive sensors and motion monitoring. Compos Part A: Appl S 155:106838. https://doi.org/10.1016/j.compositesa.2022.106838

Huang A, Liu F, Cui Z, Wang H, Song X, Geng L, Wang H, Peng X (2021) Novel PTFE/CNT composite nanofiber membranes with enhanced mechanical, crystalline, conductive, and dielectric properties fabricated by emulsion electrospinning and sintering. Compos Sci Technol 214:108980. https://doi.org/10.1016/j.compscitech.2021.108980

Wang M, Ma C, Uzabakiriho PC, Chen X, Chen Z, Cheng Y, Wang Z, Zhao G (2021) Stencil printing of liquid metal upon electrospun nanofibers enables high-performance flexible electronics. ACS Nano 15(12):19364–19376. https://doi.org/10.1021/acsnano.1c05762

Ren M, Zhou Y, Wang Y, Zheng G, Dai K, Liu C, Shen C (2019) Highly stretchable and durable strain sensor based on carbon nanotubes decorated thermoplastic polyurethane fibrous network with aligned wave-like structure. Chem Eng J 360:762–777. https://doi.org/10.1016/j.cej.2018.12.025

Wang X, Xue R, Li M, Guo X, Liu B, Xu W, Wang Z, Liu Y, Wang G (2022) Strain and stress sensing properties of the MWCNT/TPU nanofiber film. Surf Interfaces 32:102132. https://doi.org/10.1016/j.surfin.2022.102132

Tang J, Wu Y, Ma S, Yan T, Pan Z (2022) Flexible strain sensor based on CNT/TPU composite nanofiber yarn for smart sports bandage. Compos Part B: Eng 232:109605. https://doi.org/10.1016/j.compositesb.2021.109605

Wang L, Chen Y, Lin L, Wang H, Huang X, Xue H, Gao J (2019) Highly stretchable, anti-corrosive and wearable strain sensors based on the PDMS/CNTs decorated elastomer nanofiber composite. Chem Eng J 362:89–98. https://doi.org/10.1016/j.cej.2019.01.014

Wang W, Ma Y, Wang T, Ding K, Zhao W, Jiao L, Shu D, Li C, Hua F, Jiang H, Tong S, Yang S, Ni Y, Cheng B (2022) Double-layered conductive network design of flexible strain sensors for high sensitivity and wide working range. ACS Appl Mater Interfaces 14(32):36611–36621. https://doi.org/10.1021/acsami.2c08285

Lu L, Wei X, Zhang Y, Zheng G, Dai K, Liu C, Shen C (2017) A flexible and self-formed sandwich structure strain sensor based on AgNW decorated electrospun fibrous mats with excellent sensing capability and good oxidation inhibition properties. J Mater Chem C 5(28):7035–7042. https://doi.org/10.1039/c7tc02429k

Sharma N, Nair NM, Nagasarvari G, Ray D, Swaminathan P (2022) A review of silver nanowire-based composites for flexible electronic applications. Flexible Printed Electron 7(1):014009. https://doi.org/10.1088/2058-8585/ac5214

Shi Y, Jiang J, Ye H, Sheng Y, Zhou Y, Foong SY, Sonne C, Chong WWF, Lam SS, Xie Y, Li J, Ge S (2023) Transforming municipal cotton waste into a multilayer fibre biocomposite with high strength. Environ Res 218:114967. https://doi.org/10.1016/j.envres.2022.114967

Li Y, Zhou B, Zheng G, Liu X, Li T, Yan C, Cheng C, Dai K, Liu C, Shen C, Guo Z (2018) Continuously prepared highly conductive and stretchable SWNT/MWNT synergistically composited electrospun thermoplastic polyurethane yarns for wearable sensing. J Mater Chem C 6(9):2258–2269. https://doi.org/10.1039/c7tc04959e

Ma J, Wang P, Chen H, Bao S, Chen W, Lu H (2019) Highly sensitive and large-range strain sensor with a self-compensated two-order structure for human motion detection. ACS Appl Mater Interfaces 11(8):8527–8536. https://doi.org/10.1021/acsami.8b20902

Wang C, Li X, Gao E, Jian M, Xia K, Wang Q, Xu Z, Ren T, Zhang Y (2016) Carbonized silk fabric for ultrastretchable, highly sensitive, and wearable strain sensors. Adv Mater 28(31):6640–6648. https://doi.org/10.1002/adma.201601572

Pan W, Wang J, Li YP, Sun XB, Wang JP, Wang XX, Zhang J, You HD, Yu GF, Long YZ (2020) Facile preparation of highly stretchable TPU/Ag nanowire strain sensor with spring-like configuration. Polymers-Basel 12(2):339. https://doi.org/10.3390/polym12020339

Guo T, Li C, Yang J, Wang P, Yue J, Huang X, Wang J, Tang X-Z (2020) Holey, anti-impact and resilient thermoplastic urethane/carbon nanotubes fabricated by a low-cost “vapor induced phase separation” strategy for the detection of human motions. Compos Part A: Appl S 136:105974. https://doi.org/10.1016/j.compositesa.2020.105974

Li Z-Y, Zhai W, Yu Y-F, Li G-J, Zhan P-F, Xu J-W, Zheng G-Q, Dai K, Liu C-T, Shen C-Y (2020) An ultrasensitive, durable and stretchable strain sensor with crack-wrinkle structure for human motion monitoring. Chin J Polym Sci 39(3):316–326. https://doi.org/10.1007/s10118-021-2500-8

Li H, Chen J, Chang X, Xu Y, Zhao G, Zhu Y, Li Y (2021) A highly stretchable strain sensor with both an ultralow detection limit and an ultrawide sensing range. J Mater Chem A 9(3):1795–1802. https://doi.org/10.1039/d0ta10990h

Mohammed AM, Maddipatla D, Narakathu BB, Chlaihawi AA, Emamian S, Janabi F, Bazuin BJ, Atashbar MZ (2018) Printed strain sensor based on silver nanowire/silver flake composite on flexible and stretchable TPU substrate. Sensor Actuat A: Phys 274:109–115. https://doi.org/10.1016/j.sna.2018.03.003

Zhou J, Xu X, Xin Y, Lubineau G (2018) Coaxial thermoplastic elastomer-wrapped carbon nanotube fibers for deformable and wearable strain sensors. Adv Funct Mater 28(16):1705591. https://doi.org/10.1002/adfm.201705591

Shi X, Wang H, Xie X, Xue Q, Zhang J, Kang S, Wang C, Liang J, Chen Y (2019) Bioinspired ultrasensitive and stretchable MXene-based strain sensor via nacre-mimetic microscale “Brick-and-Mortar” architecture. ACS Nano 13(1):649–659. https://doi.org/10.1021/acsnano.8b07805

Wang Y, Li W, Zhou Y, Jiang L, Ma J, Chen S, Jerrams S, Zhou F (2020) Fabrication of high-performance wearable strain sensors by using CNTs-coated electrospun polyurethane nanofibers. J Mater Sci 55(26):12592–12606. https://doi.org/10.1007/s10853-020-04852-8

Wang H, Wang M, Xu X, Gao P, Xu Z, Zhang Q, Li H, Yan A, Kao RY, Sun H (2021) Multi-target mode of action of silver against Staphylococcus aureus endows it with capability to combat antibiotic resistance. Nat Commun 12(1):3331. https://doi.org/10.1038/s41467-021-23659-y

Mao C, Xiang Y, Liu X, Cui Z, Yang X, Yeung KWK, Pan H, Wang X, Chu PK, Wu S (2017) Photo-inspired antibacterial activity and wound healing acceleration by hydrogel embedded with Ag/Ag@AgCl/ZnO nanostructures. ACS Nano 11(9):9010–9021. https://doi.org/10.1021/acsnano.7b03513

Zhao J, Haowei M, Saberi A, Heydari Z, Baltatu MS (2022) Carbon nanotube (CNT) encapsulated magnesium-based nanocomposites to improve mechanical, degradation and antibacterial performances for biomedical device applications. Coatings 12(10):1589. https://doi.org/10.3390/coatings12101589

Ge S, Ma NL, Jiang S, Ok YS, Lam SS, Li C, Shi SQ, Nie X, Qiu Y, Li D, Wu Q, Tsang DCW, Peng W, Sonne C (2020) Processed bamboo as a novel formaldehyde-free high-performance furniture biocomposite. ACS Appl Mater Interfaces 12(27):30824–30832. https://doi.org/10.1021/acsami.0c07448

Ge S, Ouyang H, Ye H, Shi Y, Sheng Y, Peng W (2023) High-performance and environmentally friendly acrylonitrile butadiene styrene/wood composite for versatile applications in furniture and construction. Adv Compos Hybrid Mater 6(1):44. https://doi.org/10.1007/s42114-023-00628-1

Cheng H, Wang B, Yang K, Yang YQ, Wang C (2021) A high-performance piezoresistive sensor based on poly (styrene-co-methacrylic acid)@polypyrrole microspheres/graphene-decorated TPU electrospun membrane for human motion detection. Chem Eng J 426:131152. https://doi.org/10.1016/j.cej.2021.131152

Funding

This work was supported by National Natural Science Foundation of China (No. 52203034 and 52273032), Natural Science Foundation of Fujian Province (2020J05190 and 2020J02007), Major Science and Technology Project of Fuzhou City (2021-ZD-285), and Scientific Research Foundation of Fujian University of Technology (GY-Z19048, GY-Z21014, and GY-Z17073).

Author information

Authors and Affiliations

Contributions

An Huang: investigation, resources, validation, and writing—review and editing. Yu Guo: investigation, data curation, validation, and writing—original draft. Yiwei Zhu: methodology and data curation. Tingjie Chen: methodology and formal analysis. Zhenyu Yang: investigation and software. Yao Song: investigation and software. Priyanka Wasnik: writing—original draft and format checking. Handong Li: data analysis. Shuqiang Peng: conceptualization, methodology, and writing—review and editing. Zhanhu Guo: supervision and writing—original draft. Xiangfang Peng: supervision, methodology, conceptualization, and funding acquisition.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file2 (MP4 9016 KB)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, A., Guo, Y., Zhu, Y. et al. Durable washable wearable antibacterial thermoplastic polyurethane/carbon nanotube@silver nanoparticles electrospun membrane strain sensors by multi-conductive network. Adv Compos Hybrid Mater 6, 101 (2023). https://doi.org/10.1007/s42114-023-00684-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42114-023-00684-7