Abstract

With the need for artificial intelligence and distributed energy, to power all electronics and sensors is becoming a major challenge. A triboelectric nanogenerator (TENG) is a technology that harvests environmental energy and converts it into electrical energy, which can convert ambient energy into electrical energy through a coupling of triboelectrification and electrostatic induction. It is considered a reliable alternative to centralized power supply, which can make up for the shortcomings of traditional power generation technology. Here, this review introduces four different TENG, especially the fabrication methods and applications, including (1) TENG-based self-powered sensors, (2) TENG for biomedicine, (3) TENG for Internet of things (IoTs), and (4) TENG for blue energy harvesting. Meanwhile, the fabrication methods and characteristics of four different TENG are discussed and introduced in detail respectively, and the emerging applications’ prospects of different TENG are also introduced. This review is not only introducing the current application directions and fabrication methods of TENG, but also providing guidance for the future development of TENG.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

With the continuous development of artificial intelligence in the Internet age, many portable and distributed wireless electronic devices are used in lots of fields [1,2,3]. In the application of network information and artificial intelligence, a large number of smart electronic devices are required, and the electric energy consumption of all these devices has become a serious problem. Traditional mobile devices, as well as a large number of electrical appliances, are powered by chemical batteries and capacitors. However, due to the defects of traditional power supply equipment such as unsustainable charging time and uncertainty, it cannot supply power to equipment anytime and anywhere. In addition, chemical batteries also lead to serious pollution problems, and the pollution problems become more and more serious with the passage of time. Therefore, people need a durable and convenient energy harvesting technology that can convert various energies in the surrounding environment into electrical energy to fill the gap of conventional battery technology [4, 5]. On this basis, a series of technologies for converting environmental energy into electrical energy have been developed, including solar cells (SC) [6], electromagnetic generators (EMGs) [7], biofuel cells, and thermoelectric generators. Some distributed energy resources have not been utilized due to the shortcomings of current power generation technologies, but they exist widely in the world and are easier to obtain than traditional power generation technologies. Since 2012, the TENG power generation technology proposed by Zhonglin Wang’s research group has been widely regarded as an effective power generation technology for environmental energy harvesting [6,7,8]. In addition to collecting mechanical energy such as human vibration and motion energy, TENG can also collect wind energy, wave energy, solar energy, thermal energy, etc., and convert these energies into electrical energy to power electronic devices. In the past decade, the research of TENG has been expanded in various fields, and TENG has many unprecedented advantages over traditional chemical batteries, including light weight, low cost, simple fabrication process, and high power density. In the natural ecology, wind energy, ocean energy, geothermal energy, solar energy, biomass energy, and other energy sources widely exist in the ecological environment, and these energy sources are gradually being developed and utilized by people. All eco-friendly energy can realize clean and energy-efficient distributed energy network for TENG [9, 10]. These sustainable charging sources based on TENG technology are beneficial to the innovation of wireless sensing devices and become feasible options for extending the lifespan of future information networks [11]. In addition, the TENG energy-harvesting device can be arranged as an energy-harvesting group device and distributed in different scenarios, and it can also adapt to harsh environments, including areas that are not easily accessible by conventional energy harvesting [12,13,14]. Therefore, TENG converts energy such as mechanical energy in the environment into electrical energy and solves the problem of power supply for distributed equipment, bringing an unprecedented effective solution to the problem of power supply for electronic equipment in the age of artificial intelligence and data.

The emergence of nanogenerators (NGs) makes the recycling of mechanical energy possible and the theoretical origins of NGs were discovered, which are practical techniques. The theoretical basis of TENG is based on the second term of Maxwell's displacement current equation for research [15,16,17]. The TENG device has a simple structure, does not require complex technical investment, can convert environmental energy into electrical energy at low cost, and has broad practical application prospects in industry. According to the material composition, structural characteristics, and working mechanism, nano-piezoelectric generators are mainly divided into piezoelectric nanogenerators (PENGs) [18], TENG, and thermoelectric nanogenerators. PENGs convert the stress inside the material into electrical energy by the piezoelectric effect, while TENG utilizes contact electrification (CE) and electrostatic inductive coupling effects to efficiently convert various types of mechanical energy. Pyroelectric NGs convert periodically fluctuating thermal energy into electrical energy by the pyroelectric effect. Due to its light weight, low cost, environmental friendliness, and good universality, TENG has attracted extensive research interest and is considered to be an effective tool for mechanical energy harvesting.

The working principle of TENG is based on the coupling of triboelectrification and electrostatic induction, which uses the electrical energy generated by the friction of the dielectric material as the triboelectric electrode and the metal material of the sensing electrode to power the device through free charge movement. Under the action of external force, different materials have different electron gain and loss capabilities, so that electrons are transferred between different materials during the friction process. If the triboelectrode material is attached to the back of the sensing electrode, for example, fluorinated ethylene propylene (FEP) is attached to the back of copper, the sensing electrode material will induce the opposite charge. When the contact of two different friction electrodes is separated, a potential difference is generated under the action of electrostatic force, and the potential difference drives electrons to flow between the positive and negative sensing electrodes. The contact and separation of the material cycle generates alternating current, which converts mechanical energy into electrical energy. Currently, TENG can be divided into four basic working modes: vertical contact-separation, horizontal sliding, single-electrode, and independent-layer modes (Fig. 1). Based on these four working modes, TENG has various construction structures and modes, which are applied in different scenarios and collect energy from the environment through different forms. The vertical contact-separation model is the earliest model of TENG since 2015, and its triboelectrodes are constructed in two styles: conductor to dielectric and dielectric to dielectric. It is composed of polyimide and polyester (PET) film and polyimide film (Kapton) [19, 20], and the back is coated with electrodes. There are uneven protruding parts on the polymer surface, and the protruding parts are sheared and damaged with increasing friction, plus there will be thermal effects in the contact area after friction. In this region, the polymer plasticizes and melts, causing the polymer chains to break and crack. In the cold state, the polymer is easily broken to generate free radicals. Free radicals and particles formed by polymer dissociation are energetic, unstable, and short-lived, and these reactive particles are easily mobile. In the contact friction area between FEP and Kapton, the carbon–carbon bond and carbon–fluorine bond of the triboelectrode material are homolytically cleaved to generate a large number of carbon–carbon radicals and fluorine-carbon radicals, and the free radicals affect the electric dipole moment distribution. When there is no external force on the tribodielectric material, the electric dipole moment of the dielectric material is independent and neutral, and no charge will be generated if there is no potential difference between the two electrons. However, because FEP is easy to be negatively charged, Kapton is easy to be positively charged, and electrons are transferred from the hydrocarbon group to the fluorocarbon group during the crosslinking process, forming positively charged hydrocarbon chains and negatively charged fluorocarbon chains, so FEP generally produces negative charges, while Kapton generally produces positive charges. When FEP and Kapton triboelectrodes rub against each other, due to friction electrification and electrostatic induction, equal amounts of different charges are induced on the sensing electrodes, thereby driving free charges to flow in the external circuit [21]. With the external force, the distance between the two friction layers will change. When the two electrodes collide, due to the electric repulsion, free charges with equal density but opposite polarity are formed on the surface of the two electrodes, and current flows in the external circuit. The TENG sensor structure implemented in this mode utilizes short-range cyclic motions (such as periodic vibration and shock) to efficiently switch between the close-contact state and the fully separated state, and generate a signal output. TENG in this working mode is not only suitable for solid–solid, but even for solid–liquid and liquid–liquid triboelectrodes. The devices that have been developed include arched structures, spring structures, etc. Sensors using this structure have the advantages of high instantaneous power and simple structure design. The vertical contact separation model is established on the basis of the planar charge separation method, and there are also two types of sliding layers: dielectric to conductive and dielectric to dielectric. Two metal electrodes are attached to the back of the dielectric layer, and TENG utilizes the relative motion of the triboelectrodes in parallel directions to generate triboelectric charge. When the two layers are separated, the lower surface of the upper layer and the upper surface of the lower layer carry opposite charges in non-overlapping regions, and the two electrodes generate opposite charges respectively. Compared with the vertical contact separation type, the free charges generated by the relative friction of two triboelectrodes are more abundant, and in the sensor fabrication process, the frequency of separation-contact can be increased by making a grating structure for the sliding layer, so as to achieve a more efficient charge transfer process, thereby increasing the power output. At present, TENG with this structure include disc rotation type, planar motion type, cylindrical rotation type, etc. Traditional linear separation model TENG and vertical separation model TENG need to connect power and wires to the moving parts of the device, and this structure limits the use of TENG. Although single-electrode TENG and independent-layer TENG overcome this shortcoming, the single-electrode type has only one electrode connected to the fault and the other electrode as a reference terminal, which can be placed in any open space, even the ground. Its working mode adopts the most basic vertical contact-separation model of TENG. TENG harvests energy from freely moving objects, such as handwriting and walking, etc., without additional energy. Therefore, TENG is widely used, and single-electrode TENG are especially suitable for self-powered sensors to detect any charged materials. The single-electrode mode of TENG is limited by the electrostatic shielding effect of the main voltage, and the maximum transmission efficiency can only reach 50%. To overcome this shortcoming, fixed-electrode TENG are designed. The independent layer mode is developed on the basis of a single electrode, which uses a pair of symmetrical electrodes without reference to the ground. When the object moves freely, asymmetric triboelectric charges are generated at the two electrodes and output to the load. The independent layer mode takes into account the advantages of the single-electrode mode and can collect mechanical energy from any mechanical energy without the problem of electrostatic shielding. An important way to fabricate this structure is a self-powered dynamic vibration sensor for amplitude measurement.

Four basic work modes of TENG. Reproduced with permission from Ref. [22]. Copyright 2020 Elsevier

TENG has the superiority of high environmental friendliness, low cost, rich structure, light weight, and rich material selection. It can obtain a variety of energies from the external environment and convert them into electrical energy and is widely used as a micro-nano power source. The mechanical energy of human movement, such as pulse vibration and heartbeat, is often overlooked in energy conversion. Recently, researchers reported a TENG module consisting of an elastomeric polymer coating and a conductive liquid. Constructing a stretchable TENG by exploiting the unique stiffness of liquid crystals and the outstanding flexibility of plastic coatings. For example, the hole structure is designed to capture the energy of human motion, or the shape of adaptive bracelet TENG is worn on the wrist to collect vibration energy, which has the advantages of simple structure and high strength. In addition, as portable energy sources, TENG have been used in many self-powered systems, such as hygiene inspection, water disinfection, electrochemical degradation and synthesis, etc. One of the ultra-lightweight rotary motors of TENG is used to convert the previous low-frequency rotary motion into ultra-high-speed rotary motion. With the advantages of a simple manufacturing process, light weight, and high output power, TENG can be used as an effective and durable portable self-powered device to power home blood glucose meters [23]. An autonomous ammonia-electrocatalytic hybrid system powered by two TENG is also offered. Nitrogen is first fixed in NO utilizing TENG-induced air emissions. At the same time, the NOx produced is used for ammonia electrolysis in a chemical cell using TiO2 as a catalyst. At the gas flow rate of 3.5 m3/min, the ammonia production observed in the TENG system reached 2.4 μg/h. Compared with traditional ammonia synthesis, the synthesis system has the benefits of convenient production, large-scale, low cost, and environmental protection. Finally, they had obvious advantages in obtaining energy in low-frequency water wave motion. By combining many TENG power sources connected together, it could harvest a large amount of energy from water waves, and a power supply system composed of 18 TENG networks could easily light up hundreds of LEDs under water waves. It had the obvious advantages of simple and renewable pathways. Table 1 presents the latest research and potential applications of TENG, including novel macroscopic superlubricated TENG with tribovoltaic effect, suitable for real-time monitoring of equipment friction state and mechanical energy harvesting, electrophoresis technology for removing micro/nanoparticles in water, and realizing nighttime alarm and electroluminescent devices for information exchange. However, these TENG are currently only in the scientific research stage, and their process optimization is feasible for future applications.

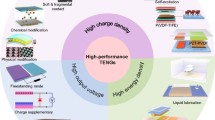

This paper mainly introduces the TENG with the following four parts, namely its applications in self-powered sensing, biomedicine, IoT, and blue energy (Fig. 2).

Applications of TENG-based self-powered sensors, biomedicine, IoT, and blue energy. Reproduced with permission from Ref. [30]. Copyright 2020 Wiley–VCH

Nowadays, how to develop a smart sensor system with sustainable power supply, convenient deployment and flexible use has become a serious problem. TENG based on Maxwell’s equations can directly convert mechanical energy into electrical energy, which is used as self-driven sensors [29]. TENG-based sensors have the advantages of simple structure and high energy density, which provide an effective method to building intelligent sensor systems. At the same time, machine learning, as a technology with simple manufacturing structure, short development cycle, and strong data processing and prediction capabilities, has a significant effect on processing a large number of electrical signals generated by TENG.

This paper summarizes the latest research progress of TENG-based sensor systems for signal processing and intelligent recognition by using machine learning technology. In addition, the technical characteristics and research status of this research direction are introduced. We believe that the combination of machine learning technology and TENG sensors will promote the rapid development of smart sensor networks in the future. TENG also has important implications for biomedicine [31,32,33]. Physical monitoring at all times is crucial to human health and life, so that people use sensitive and stable electronic devices to continuously monitor changes in their bodies. Traditional sensors have complex structures, high operating costs, and require an external power supply, which limit their practical applications to a large extent. As a new type of electrical energy, TENG can power sensing components to analyze the relationship between mechanical energy input (amplitude and frequency) and electrical output signal (including output voltage and current) to work. By combining mechanical inputs with other measurements, different autonomous systems have been developed to detect different physical variables, such as pressure detection, motion detection, and sound sensors. In addition, since the signal amplitude generated by TENG is positively correlated with triboelectric charge density, TENG-based self-powered sensors can be applied to the nervous system and cardiac pacemakers in biomedicine to realize data monitoring of body signals such as the heart rate. Then there is the connection between the IoT and TENG. The traditional power supply method is to burn coal and oil to drive the heat engine to generate electricity and collect the electricity to the place where it is needed. The emergence of the IoT and the popularity of mobile communications have made object sensors widely distributed and can move at any time. While the power required for each sensor is small, typically in the microwatt to milliwatt range, the sheer volume makes the energy requirements of small devices important as well. One possible solution is to have any device self-powered by harvesting its own energy. Because the power consumption required by each device is not large, ranging from only a few microwatts to a few watts. Converting ambient energy such as mechanical energy into useful electrical energy, and then efficiently harvesting and utilizing any available energy in the environment is the perfect solution to this problem. Distributed energy in the environment is often easily overlooked, but it is needed in the new era of IoT and artificial intelligence. Blue energy is an excellent renewable energy that exists widely in the world, but traditional generators are difficult to effectively convert ocean energy into electricity due to their limitations. In recent years, TENG is mainly based on the coupling of triboelectrification and electrostatic induction, and converts the vibration energy of water waves into electrical energy, so as to supply power for electrical equipment on water. This paper reviews the research progress of TENG-based water wave energy-harvesting devices. The power generation mechanism of TENG is introduced; then, as the performance of TENG is continuously improved, the application direction and architecture become more and more extensive, and the development challenges and prospects of this technology are outlined. This paper reviews the development of TENG from the basic principles and working mechanism of TENG. In addition, we introduce the theoretical origins, material selection, and application projects of TENG. Subsequently, this paper reviews the development of TENG in detail, including representative materials and innovative structural designs.

2 Self-powered sensors based on TENG

For most IoT sensors, if they are not self-sustaining, then the entire IoT functionality will be greatly compromised. As the “tentacles” to perceive the world, the sensor has a large amount of “idle” mechanical energy around its environment, including vibration, pressure, sound wave, linear displacement, rotation, thermal energy, etc. Therefore, using the energy in these environments as the energy source of the sensor will be the optimal solution to the self-sustaining and maintenance-free problem of wireless sensor networks. The self-powered sensor integrates the sensor and the TENG into a single system. The TENG structure converts the energy around the sensor into electrical energy to provide energy supply for the sensor to work, so that it can maintain normal operation without external power supply. This TENG-based self-powered system has important scientific research value and broad commercial prospects. The characteristics of these distributed sensors include low power, can be applied to different equipment types, low cost and compact design, and various unique functions. Owing to these features, TENG’s self-powered sensors can be used to monitor various physical conditions, such as sound, vibration and vibration, etc. It can also be used to monitor changes in environmental physical and chemical information, such as data such as NH3, NO2, lactic acid, humidity, and carbon monoxide. In addition, TENG can also play an important role in data detection systems, powering functional systems such as point distribution statistics systems, multicast wireless sensor systems, train health wireless monitoring systems, vehicle detection systems, point detection systems, and many clean energy smart systems.

2.1 Sensors powered by TENG and applications in signal analysis and data detection

The application of sensor technology has been realized in many fields, especially flexible electronics, IoT, smart wearable devices, and mobile communication electronics. However, the maintenance and construction costs of sensing networks are very high, and how to effectively power the huge sensor capacity to save costs has become a major challenge. Traditional batteries have disadvantages such as short life, low capacity, and polluting the environment, which limit the wide application of sensors, and the constant replacement of batteries also wastes a lot of resources and pollutes the environment, making it difficult for mobile sensors to operate, especially in harsh environments. Therefore, replacing traditional batteries to power sensors has become an important technology for energy supply. Various regenerable energy such as solar energy, biomass energy, water energy, light energy, sound, mechanical motion, heat energy, etc. exist in the environment. In order to effectively harvest green energy, a lot of research has been done on energy harvesting technologies. The energy-harvesting system converts renewable energy into electrical energy according to various energy conversion methods, such as photoelectric effect, electromagnetic induction, triboelectric effect, piezoelectric effect, electric pulse effect, and their combinations. In recent years, NG based on piezoelectric effect and triboelectrification has attracted much attention due to its advantages of durability and low cost in power supply of distributed electronic devices. In addition, the development of artificial intelligence and human–machine interface (HMI) [9] has greatly facilitated the development of self-powered sensors, which provide new energy solutions for IoT systems and self-powered sensing systems. The working mechanism of TENG is the coupling effect of triboelectricfication and electrostatic induction [34], which were designed for the first TENG with flexible PET films in 2012. PET and polyimide have different electron-accepting abilities, and when the two materials are rubbed, negative and positive charges are generated at the contact interface. A dipole layer is formed between the positively charged Kapton triboelectrode and the negatively charged PET triboelectrode. In order to balance the potential difference resulting from the change in the distribution of the electric dipole moment in the dielectric friction material due to triboelectrification the free charge flows on the external load between the two electrodes to produce a current. This kind of TENG has broad application prospect in self-powered sensing system and flexible electronic device power supply. Compared with traditional generators, TENG has the preponderance of strong flexibility, simple manufacturing method, wide application range, low cost, and high reliability. In general, TENG are prepared using nanomaterials with different electron affinities to obtain higher output performance, and nanomaterials with high triboelectric density are usually selected as the friction material of TENG. In the selection of materials for manufacturing TENG, polytetrafluoroethylene (PTFE) with strong electronegativity is generally used, which is negatively charged after friction, and metal and nylon are generally used as triboelectric materials, which are positively charged after friction. Self-powered sensors can effectively collect external energy and convert it into electrical energy according to their own advantages, and have many applications in various fields. Table 2 introduces some different TENG-powered sensors with excellent point output performance and different applications, including TENG-powered sensors for water level monitoring fabricated from dielectric films and metal triboelectric electrodes, with high sensitivity PTFE/nylon/polyester wearable health monitoring TENG-powered sensors, super mechanical durability HMI, etc.

Acceleration is an important physical parameter in the field of transportation. Accurate and continuous acceleration measurements are critical to the development and maintenance of intelligent transportation systems. A TENG for accelerometer sensor was developed with a measurement range of 1 ~ 11 m/s and a sensitivity of 20.4 V/(m/s)2 [36]. The structure of the device consisted of a metal triboelectrode and an outer shell of indium tin oxide (ITO) and PET (Fig. 3a-i). When the acceleration direction was upward, the detected object was pressed to the ITO/PET layer, so that the two friction layers contacted each other, and the electrons flowed to the external circuit to form a path. In addition, as the direction of acceleration changes, the output direction of the electrical signal generated by TENG was opposite, and its electrical energy could light up 100 LEDs (Fig. 3a-ii). Besides, this TENG could be installed in wearable smart clothing to measure people’s falls (Fig. 3a-iii). The researchers fabricated a TENG-based self-powered acoustic sensor that could transform energy from the environment for acoustic detection. As shown in Fig. 3b-i, electrospun polyvinylidene fluoride (PVDF) nanofibers acted as a vibrating membrane to detect acoustic signals, received acoustic energy, and converted it into electrical signals. Under the sound source vibration of 115 dB and 170 Hz of frequency, the short-circuit current (ISC) of TENG was 175 μA, the open-circuit voltage (VOC) was 400 V, and the maximum output power density was 7 W m−2. Based on this self-powered TENG, self-powered sensors for identifying the source of sound and the moving speed of objects had great application value (Fig. 3b-ii). A TENG-based ultrasensitive endocardial pressure sensor was developed for real-time monitoring of endocardial pressure and diagnosis of the heart. The self-powered endocardial pressure data detection sensor was small and flexible enough to be implanted in the heart (Fig. 3c-i). The sensor detected the output of electrical signals as the heart expands and contracts, a strategy that could bring the development of self-powered medical sensors that could be implanted in the cardiovascular system to monitor disease (Fig. 3c-ii). In addition, TENG could also be used to detect changes in chemical signals in the surrounding environment, NO2 detection sensor (Fig. 3d). When the NO2 concentration in the environment changes, the TENG-powered chemical data detection sensor produced a change in electrical signal, which was due to the change in the voltage of the device due to the change in resistance. In this work, a TENG self-powered sensor for detecting ambient humidity was designed based on vapor-entrained ionic fluorosulfonic acid monomers. It can be seen from Fig. 3e-i that different humidity environments would cause different degrees of deformation of the equipment. Therefore, the humidity of the environment could be determined through the different electrical signals obtained by TENG.

TENG-based self-powered sensors. a A self-powered high-sensitivity accelerometer. b Multifunctional sensing for efficient acoustic energy harvesting and self-powered. c Self-powered ultra-high-sensitive endocardial pressure sensor. d Self-powered room temperature NO2 sensor. e TENG-based self-powered humidity sensor. f TENG-based self-powered lactate detection sensor. Reproduced with permission from Ref. [37]. Copyright 2020 Elsevier

In addition to detecting the data of ambient humidity, this TENG collects the mechanical energy of wind and rain and converts it into electricity (Fig. 3e-ii). The anaerobic exercise of the human body would produce lactic acid, and a large amount of lactic acid accumulation in the human body would cause lactic acidosis. Figure 3f-i shows a self-activated liquefied liquid and a sensing system with metal nanoparticles grown on carbon fibers as an active substrate, which hosted nanoparticles of different sizes and densities (Fig. 3f-ii). The device could directly detect the lactic acid concentration in human sweat, which had great value for wearable fabrics and future multifunctional applications.

2.2 TENG-based self-powered sensors for harvesting mechanical energy

The distributed energy in the environment can be effectively converted into electrical energy by the self-powered TENG sensor system to supply power for electrical devices, which can help to solve the energy shortage problem. Figure 4a-i is a TENG-based self-powered integrated wireless sensor system. The system consisted of power module, sensor part, and circuit. On the top was a multifunctional spring-assisted TENG for power supply, and a device integrating power management and Bluetooth transmitter was placed on the bottom. The TENG-based device had an output VOC of 3.1–3.6 V and a max output ISC of 100 mA. The results showed that the sensor could detect the operating frequency of the car and be used to monitor the vibration of the car engine (Fig. 4a-ii). The automatic control system helped people to free themselves from some complex, repetitive, and tedious work environments, which could reduce labor supervision costs and improve work efficiency. For example, self-driving cars could ease traffic congestion and allow drivers to enjoy the journey, which was critical for maintaining good traffic order and reducing traffic accidents. Continuous real-time monitoring of the steering angle and direction of an autonomous vehicle was a major challenge, but a TENG-based dual-mode automatic pulse angle self-powered sensor that could automatically convert motion variables into two electrical signals of different motion directions (AC or DC) (Fig. 4b). A large-area sandwich film TENG (LSF-TENG) was prepared by co-extrusion blown film forming method, and the triboelectrode surface materials were pure polypropylene (PP) and carbon nanotubes (CNT). The engineered LSF-TENG enabled more efficient harvesting of mechanical energy than previous self-powered biomimetic devices. This work developed an effective, sustainable, low-cost, environmentally friendly, and long-lived LSF-TENG (Fig. 4c). An autonomous wireless sensor system for railway health monitoring is shown in Fig. 4d-i. The triboelectric vibration accelerator (TEVA) had been able to collect the extremely low vibration energy generated by train operation, and the analysis device based on the simulation platform for railway vibration data detection is shown in Fig. 4d-ii. The electricity generated by TENG triboelectricity is used to charge lithium batteries, and any system using lithium batteries could enable wireless communication. The device converts mechanical energy in the environment into electrical energy without additional stress and had good operability and reliability and broad application prospects. A TENG based on electrospun cellulose acetate nanofibers and surface-modified PDMS encapsulation reached an output VOC of 400 V, an ISC of 3 mA/m, and a maximum power of 0.9 W/m (Fig. 4e). These output performances were all attributed to the TENG converting vibrational energy into electrical energy for self-powered sensors. The hybrid NG composed of water-TENG (W-TENG), disk-TENG (D-TENG), and EMG components (Fig. 4f), the output voltages of D-TENG, W-TENG, and EMG were 500 V, 11 V, and 0.4 V, respectively, which was used in energy-efficient smart systems. The wireless self-powered sensing system based on hybrid NG could effectively and accurately monitor the data of humidity and temperature in the environment.

a Multicast wireless sensor system, reproduced with permission from Ref. [38]. Copyright 2019 Elsevier. b Conceptual application of dual-type signal (DS-TENG), reproduced with permission from Ref. [39]. Copyright 2021 Wiley–VCH. c Automated guided vehicle system, reproduced with permission from Ref. [40]. Copyright 2022 Elsevier. d Railway health monitoring wireless transmission system sensor system, reproduced with permission from Ref. [41]. Copyright 2017 Elsevier. e Fault detection system, reproduced with permission from Ref. [42]. Copyright 2022 Elsevier. f Multi-clean energy smart sensor system. reproduced with permission from Ref. [43]. Copyright 2017 Wiley–VCH

2.3 Fabric-based smart wearable TENG sensors

As we all know, food, clothing, housing, and transportation are the basic necessities of human life. The textiles and fibers used to make clothing are considered a second skin for humans and have been widely used by humans for a long time for their intended properties. First, textiles and fabrics can withstand various complex mechanical deformations, such as twisting, stretching, bending, tearing, etc., and exhibit excellent structural retention and mechanical properties during wearing and washing. Secondly, due to the required air permeability of the fabric, a large amount of air is trapped inside the clothes, so that the clothes have good air permeability and warmth retention. Third, splicing of multiple colors and different designs can easily endow fibers with different types of fabrics, which are elastic, soft, wear-resistant and comfortable, and suitable as HMI materials. Entering the information age, the world is no longer limited to safety, warmth, and beauty, but more intelligent, convenient, and comfortable. We need to combine functions, intelligence, and information to meet the needs of the times and improve the environment in which we live. In contrast, fabrics with various designs and excellent properties are attractive materials for electronic integration technologies in HMI. Electronic devices with functions such as data monitoring can be seamlessly integrated into clothing through built-in technology without imposing additional burdens on normal human activities. The combination of electronic components and conventional textiles has resulted in revolutionary products, which are smart textiles or e-textiles. Electronic textiles that can collect, process, store, transmit and detect data are crucial to the technology that enables wearable electronics. In addition, TENG can be used as a valid device to generate energy, monitor and respond to environmental stimuli, and even exchange information with users, these features have led to a lot of research achievements in the field of smart fabrics. The combination of emerging energy harvesting technologies with traditional textile structures has led to the development of new smart textiles. While endowing fabrics with intelligent features for data detection and even data calculation, TENG can be easily designed or integrated into textile structures such as fibers, threads, and fabrics to provide mechanical energy harvesting and sensing capabilities. Furthermore, textiles are very promising, especially in the industrial field, because they are strong, breathable, and comfortable and their excellent mechanical properties are technologically sound for low-cost research and mass production. Since the mechanical energy of human body motion is an inexhaustible and cheap energy source, and clothing is an indispensable necessity in people’s life, TENG devices based on clothing can become a good choice for harvesting the mechanical energy of human body motion. With the help of fabric-based nanoparticles, human motion can be viewed not only as a source of biomechanical energy but also as a transmitter of various signals. The collected electrical energy can not only power various small electronic devices, but also serve as a signal for humans to interact with the external environment. Since the electrical energy generated by the fabric-based TENG is generated by human motion, a complete smart sensing system can be constructed. In the absence of additional forces and intentional external operating conditions, the system can operate normally and continuously without interruption. A wearable fabric TENG (F-TENG) for health data signal monitoring, this F-TENG is washable (Fig. 5a). The fabric made of molecules contained a large number of F atoms on the surface and inside, which had poor electrical conductivity, high durability, good washability, and strong self-cleaning ability. These self-cleaning, washable, and self-healing electrodes offer an effective method to collect harmful substances and transport bio-attractive wearable electronics. The output ISC and VOC were 26.04 µA and 465.63 V, respectively (Fig. 5c). F-TENG had a strong power output and excellent charging ability, and the time required to charge a 47-µF capacitor to 1.5 V was reduced from 486 to 74 s, which fully shortened the time required for charging and could effectively drive electronic clocks (Fig. 5d). A schematic diagram of a TENG self-powered robot inspired by slug was shown in Fig. 5e, which consisted of a simple printed circuit board (PCB), two magnetic sheets, a FEP film, and a polyurethane (PU) film in the form of a sandwich. The upper magnetic sheet was attached to the controller PCB, the controller PCB was attached to the FEP film as the top layer, and the lower magnetic sheet was attached to the PU film as the bottom layer (Fig. 5e). The TENG-Robot generated strong triboelectric output performance while crawling and rotating in difficult terrains such as holes, tunnels, curves and slopes (Fig. 5f). TENG-Robot had good environmental adaptability and triboelectric performance when moving on various terrains.

a Schematic of the device. b, c Fabric TENG's ISC and VOC for wireless drowning sensors. d Charging and discharging curves of a 47-µF capacitor. Reproduced with permission from Ref. [44]. Copyright 2021 Elsevier. e Schematic illustration of the slug-inspired TENG robot. f Voltage output of TENG-Robot on different terrains. Reproduced with permission from Ref. [45]. Copyright 2022 Elsevier

The research on self-powered sensors based on TENG is very extensive, mainly in signal sensing, data transmission, conversion of mechanical energy to electrical energy, and functional textiles. TENG self-powered sensors should be a complete system in the future, such as in collaborative vehicle infrastructure systems (CVIS) [46]. Human-vehicle–road-environment was a complex system, and each part was interrelated and independent of each other. Research in CVIS was still in its infancy, and most of it remained in laboratory experiments, and there was still a long way to go. As the world entered the era of collaborative vehicle infrastructure, it was time to develop a pervasive technology to achieve zero-casualty, zero-latency, zero-maintenance, zero-emission, and reliable TENG self-powered sensing systems. With the help of research on intelligent creatures, CVIS would have the ability of self-perception, automatic analysis, self-adaptation, information exchange, and continuous energy supply (Fig. 6).

Application of self-powered sensor based on TENG in the future. Reproduced with permission from Ref. [46]. Copyright 2022 Elsevier

Although the manufacture and application of nanofibers in fabrics has received extensive attention, its development history is relatively short, and some fundamental issues, such as material selection systems, general preparation methods, basic working mechanisms, potential performance improvement methods, extensive evaluation criteria, and a wide range of applications, have yet to be elucidated in a comprehensive and systematic overview. For textile-based natural industries, the basics of textiles and methods of incorporating energy harvesting units into traditional textile structures have not been comprehensively summarized. In addition, the standardization of textile raw materials and the shortcomings of some raw materials are not clear. These pressing issues have seriously hindered the commercialization and industrialization of the textile industry. Although the technology is still advancing and more and more prototypes are coming out, there is still a big gap between the best textile electronic products and practical applications, which will also become an urgent problem for researchers to solve in the future.

3 Emerging applications of TENG in biomedicine

Over the past 30 years, biomedical sensors have played an important role in healthcare applications, but limited power supply and user-wearing constraints have limited them from having long-term and active effects in our daily life as medical sensors. TENG have shown high potential and adaptability in powering biomedical sensors and wearable devices, preparing for the development of new technology platforms that can be fully integrated into the 5th-generation mobile networks (5G)/IoT environment. This novel capability of biomedical sensors powered by TENG aims to provide continuous power for human health and wellness. This article reviews the remarkable progress of TENG for biomedical sensing over the past decade, focusing on in vivo implantable solutions and powering biosensing. First, TENG powers biomedical sensors applicable to lung and heart-related clinical conditions, as well as biosensors in related organs [47, 48]. We outline an area of growing interest in TENG for biomedical sensing as powering devices for health monitoring [49, 50]. Then, TENG as power devices for biomedical sensors in multiple areas is summarized, and the future prospects of TENG biosensors are summarized. Key focus areas for the full translation of biomedical sensors powerd by TENG into practical and effective devices as well as wireless and medical consumer products are highlighted.

3.1 TENG for pulse and cardiac data monitoring

As the important role of human biological parameters, heart rate can reflect parameters of a person’s physical health, including sleep status, heart condition, and blood vessel-related diseases (such as anemia). Heart rate variability (HRV) is a beating of the heart judged by the pressure; a good HRV parameter reflects a healthy heart condition [51]. Ischemic heart disease and stroke are a massive cause of mortality in humans, both caused by cardiovascular disease. More importantly, In terms of deaths from disease, experts predict that the two leading reasons of death in the next 20 years will be severe heart disease and stroke. So people’s heart rate is an important parameter that reflects the health status of the body, and it is generally continuously monitored when it needs to be checked. Monitoring heart data to understand the health of the body can be achieved by using wrist-worn devices. Additionally, not everyone may have access to regular healthcare and monitoring of their heart health, because there are many people in the world who cannot walk to the hospital due to physical reasons. In the absence of widespread and consistent testing, technologies such as wearable heart rate sensors have important medical advantages. Most applied heart rate monitoring devices use two technologies: photoplethysmography (PPG), which uses light to measure blood flow in arteries, and electrocardiography (ECG), which uses electrical signals to measure heart rate. However, both PPG and ECG have limitations, which make them suboptimal as standard test methods for heart rate monitoring. While PPG is convenient during use because this device is affected by light, and parameters such as skin color, light intensity, and distance between the device and the artery will greatly affect the accuracy of the measurement results. In addition, electrocardiography is currently the most accurate method for measuring heart health, because it needs many electrodes to work when measuring the data of the heart. But due to the many electrodes required for measurement, it has certain limitations and is very inconvenient to use. Because a PPG or ECG needs a power supply at all times to work properly, this means that the use of these measuring devices can be limited. The TENG is developing rapidly as a self-powered device that can be used for a long time with overcoming all the limitations of wearable heart rate monitors. By converting the human body’s mechanical energy into electrical energy, the TENG can achieve an output VOC exceeding 1 kV when powering heart rate monitoring devices with high-pressure sensitivity and signal-to-noise ratio, which can be seen in self-powered devices. Additionally, they are small and lightweight and can be made from materials such as silk, synthetic polymers, cotton, and silicone rubber. In addition, due to the small size of TENG, it is suitable for permanent installation on biomedical sensors only, and the application of TENG to convert the mechanical energy of human body movement into electrical energy to power other electronic devices is developing rapidly. In fact, lots of closed-loop pulse-based TENG have been manufactured, each with its excellent design. The first TENG-based wearable heart rate monitoring device is worked on a thin film, and the TENG is used directly on the skin. In 2014, a TENG-based thin-film sensor was developed [52] for health monitoring (Fig. 7). M-TES utilizes changes in air pressure to produce triboelectric energy, laying a latex film on an FEP layer and two copper electrode layers separated by acrylic. Changes in pressure in the intermediate air conduction channel caused expansion and contraction of the membrane, resulting in a potential difference. At 0.04 V kPa (small size, high sensitivity) average sensitivity and stability, M-TES could accurately measure heart rate of 72 beats per min even after 10,000 cycles (Fig. 7a). Scholars also developed an eardrum biomimetic membrane sensor (BMS) [53], which could be used for monitoring human health (Fig. 7b). The BMS was an elliptical multilayer structure with indium tin oxide (ITO) triboelectrodes and nylon triboelectrodes supported by thin PET film, which were all connected by a tent-shaped layer of PTFE. As a single-electrode TENG, the BMS generated electrical energy by pressing the PTFE membrane during vasoconstriction and dilation, with a pressure sensitivity of 51 mV Pa. By testing continuously after 40,000 cycles, BMS could continuously monitor heart rate parameters through TENG self-powered with carotid frequency, chest respiration data and pulse (Fig. 7c). The self-powered ultrasensitive pressure sensor (SUPS) was fabricated by the vertical contact separation model (Fig. 7d). The device was consisted by a nanostructured Kapton film as a triboelectric layer, an ultra-thin Cu layer as an electrode, and a nanostructured Kapton layer as an electrode, with nanostructured Cu made by Kapton as another triboelectric layer and electrode. This TENG-based sensor had a high signal-to-noise ratio of 45 dB and a long-term performance of 10 million cycles, making it suitable for local arterial measurements. Accurate measurements were obtained even when the vein was compressed at two sites 4.5 cm apart (Fig. 7d). Like SUPS, TES operated in a vertical contact-separation mode; a skin-inspired TENG-based sensor was developed. Similar to human skin, TES had hardness gradients and interlocking micronized polymers with a layer of rigid polyvinylidene fluoride copolymer (trifluoroethylene) (PVDF-TrFE) and soft poly(vinylidene fluoride) methyl silicon oxane (PDMS) layer (Fig. 7e). This small bridge structure also allowed for variations in spacing and position, eliminating the need for large spans. In addition, it was absorbed to form impulsive liquids that do not contain moisture. The TES was very sensitive, with pressure sensitivity of 0.55 V kPa, allowing effective measurements under weak radiation (Fig. 7f).

TENG-based thin film sensor for cardiac monitoring. a M-TES as heartbeat monitor to output voltage signal. b Schematic diagram of the BMS. c Electrical signals of three sites monitored by BMS. d Schematic diagram of the SUPS structure and detected pulses. e Schematic diagram of wrist-type humidity TES monitoring device. f Ultraflexible TESs at the wrist to detect radial pulse waves. Reproduced with permission from Ref. [54]. Copyright 2022 RSC

As a heart rate sensor, the wearable thin-film TENG self-powered heart rate sensor is a widely available, reliable, and inexpensive heart rate monitoring device. However, the wearable heart rate monitoring device based on TENG can realize the function of persistent monitoring. Due to the different materials and manufacturing methods, the current research direction of fabric-based TENG is how to wear it as clothes to ensure comfort and good mechanical properties.

3.2 Flexible TENG driven by human respiratory airflow for health signal monitoring

Respiration is the most basic activity of the human body and one of the important indicators of health. Respiration monitoring acts an important role in medical human health indicators. Therefore, it is necessary to develop a portable, continuous, and real-time respiratory monitoring device. The airflow in a TENG-powered sensor is detected to realize real-time self-powered respiration monitoring by converting the mechanical energy of vibration during breathing into electrical energy. The TENG device operates by conversing the airflow vibrating with flexible nanostructured polytetrafluoroethylene (n-PTFE) films. When exposed to airflows with different breathing characteristics, the TENG generates different electrical signals in real time. It could also be shown that the total air volume during exhalation was equal to the total air exchange of the breath. This TENG device was used to develop a wireless smart respiratory monitoring system that uses signals to automatically trigger wireless alarms or mobile phone ringtones to alert and report changes in breathing patterns. It aims to provide an effective method for real-time self-powered respiratory monitoring devices, contributing to medical emergency, early warning, and treatment of diseases. This advanced technology is used to monitor pulse rate, heart rate, vascular parameters and respiratory airflow, among which respiratory airflow monitoring is the important symbols widely used in human health. Long-term respiratory monitoring equipment mostly adopts the principle of capacitive sensing, which has the characteristics of large volume, complex structure, and high price. Furthermore, like other medical systems, these respiratory monitoring devices are powered by traditional batteries or other external power sources, which limit their portability and longevity. The miniaturization and high durable availability of the new generation of respiratory monitoring systems are highly desired. As a device for generating mechanical energy and power generation, TENG has been developed unprecedentedly due to its advantages of easy processing, portability, wide application range, and low cost. Surface charges are induced when two charged films with different potentials come into contact with each other. The two friction electrodes’ continuous contact and separation drives free charges’ flowing in external circuit, generating an electrical signal output. Therefore, if the flexible triboelectric material is periodically contacted/disconnected with another triboelectric material, simple harmonics are generated due to the vibration of the airflow, resulting in converting mechanical energy from respiratory airflow into electrical energy. A TENG-based Ce-doped ZnO-PANI nanocomposite film for respiratory monitoring could convert wind energy into electrical signals to detect multiple respiration parameters including NH3 concentration monitoring (Fig. 8a) [55]. The designed TENG had excellent ability to monitor respiratory flow (2–6 L/min), detect human respiratory rate, and detect different breathing patterns. Compared with the power of breathing TENG under the same constraints, the TENG’s output was higher. The result depends on the reaction of a small amount of NH3 molecules in the gas flow with the composite film. Figure 8b shows the stability of the good output technique of the TENG driven by the optimized system, as the output voltage of the TENG barely changed after 30 min of continuous testing. Slow breathing showed a low respiratory rate of about 0.3 Hz and a low Vpeak-peak output of about 0.46 V, which usually occurs during rest or relaxation states such as sleep. The rapid respiration monitor showed a high respiration rate up to 0.77 Hz and a positive output VOC (approximately 0.71 V). Due to the obvious increase in human breathing rate, the voltage generated by deep breathing (about 0.94 V) is significantly higher than that of slow and fast breathing (Fig. 8c). The results showed that the breathing TENG could not only be used to monitor various breathing processes, but also could realize continuous monitoring of breathing in time. A metal mesh electrode (MME)-based TENG was proposed, which exhibits low operating cost, high productivity, and durability (Fig. 8d). The MME was developed using a controllable, simple, and low-cost method that uses an integrated approach to develop specific contact points to act as positive electrodes [56]. Due to the comprehensive effect of the microstructure and nanostructure of MME, the electrical output of TENG could be greatly improved, and Fig. 8e shows the effect of elapsed time on the output power of the sensor. The participants wore the mask continuously for 4 h, and the output voltage did not change significantly after the 4-h test.

a Schematic diagram of human breathing-driven mask. b Stable output of TENG in 30 min of continuous testing. c Electrical signal output of three breathing modes. Reproduced with permission from Ref. [55]. Copyright 2019 Elsevier. d Optical photos based on TENG as a breathing sensor inside the breathing valve of a mask. e Output performance of the TENG with different wearing times from 0 to 4 h. Reproduced with permission from Ref. [56]. Copyright 2021 Elsevier

In conclusion, the mechanical vibration of human respiration is converted into an electrical signal, and a TENG durable real-time respiration monitoring device driven by airflow vibration is successfully developed. An n-PTFE-fabricated TENG exhibits sensitive electrical signals in instructing different air flow rates; thus, when the n-PTFE-made TENG is attached to a standard mask, it enables real-time monitoring of different respiratory systems. The total amount of airflow delivered during respiration has been shown to be closely related to the volume of air delivered to the device, which is the basis for TENG-based respiration monitoring. The real-time electrical signals detected by such TENG devices can be directly integrated with wireless transmitters and signal processors to realize smart health monitoring systems.

3.3 Textile-based TENG sensors in biomedicine

People are most exposed to wearable TENG heart rate sensors, which have become a rapidly growing field due to excellent comfort for long-term wear. A highly stretchable energy-harvesting textile (SEHT) [57] was developed for monitoring heart rate (Fig. 9a). SEHT was a single-electrode mode TENG composed of multiple twisted stainless steel conductive wires as electrodes and a silicone coating as a triboelectric layer. To power the wire-based TENG, they were designed to rub against the human skin, which acted as another electrode. SEHT was implanted on either side of a flexible, serpentine wire that, when worn, bends when in contact with the skin, generating electricity. A wristband was attached to the wrist to monitor the beating of the pulse, and the TENG was used as a power supply for the heart rate monitoring (Fig. 9b). TENG in single-layer clothing that could be made from other materials, multi-layer fabrics in clothing could also assemble TENG modules. For example, the woven-constructed self-powered pressure sensor (WCSPS) was a multilayer TENG, in which PTFE strips were interwoven on PET and ITO layers under the protection of a PDMS layer. WCSPS had a high sensitivity with the cross-linked PTFE material, besides, it did not decelerate after 40,000 cycles, and it could measure frequently and reliably at different locations such as the finger, ear, and shoulder. Many fabrics were made with machines, so it was necessary that fabric-based TENG could also be made with sewing machines. In fact, PVDF fibers fabricated TENG with different patterns using a sewing machine. Combined with supporting PET threads, the PVDF interlayer is sewn between two layers of fabric. When the PVDF wire was in contact with the nylon fabric of the aluminum electrode, the generated electric wave signal could be used to detect the pulse generated by the pressure change in real time, such as carotid pulses [58]. Additionally, PVDF-based embroidery can be customized on garments using a sewing machine, adding to its beauty.

TENG-based fabrics sensors. a Schematic diagram of SEHT. b Measurement of pulse signal with SEHT.Reproduced with permission from Ref. [59]. Copyright 2017 Wiley–VCH. c Photo of self-powered chitosan humidity sensor. d Voltage output for self-powered humidity sensor. Reproduced with permission from Ref. [60]. Copyright 2018 Elsevier. e Schematic diagram of TATSA clothing. f Pulse was measured at (e-i) neck, (e-ii) wrist, (e-iii) fingertip, and (e-iv) ankle using TATSA. Reproduced with permission from Ref. [61]. Copyright 2020 AAAS

The chitosan-based TENG (C-TENG) for biomechanical energy harvesting was developed, in which chitosan-glycerol thin films developed a moisture sensor for high-performance flexible fabrics. Compared with the conventional TENG, the electrical performance of the composite C-TENG was more stable in different humidity environment (Fig. 9c). With the relative humidity (RH) changed from 20 to 80%, the electrical conductivity of C-TENG did not change compared with the electrical properties of traditional TENG. It could be seen that the humidity-dependent open circuit VOC of chitosan decreased from 30 to 8 V as the relative humidity changed from 20 to 80%. The chitosan-based humidity sensor shows a higher slope than ordinary sensors, which shows its flexibility (Fig. 9d). Another way to create unique designs with fabrics was to add yarns, and in 2020, a TENG-based sensor fabric was developed by weaving yarns into a core–shell. Weft yarns were wrapped with stainless steel cores wrapped with nylon or PTFE filaments, while warp yarns were wrapped with pure nylon or PTFE filaments. Contacted between the yarns generates electricity when deformed. The pressure sensitivity was 1.33 V kPa ± 0.32 V kPa, the pressure range was 1.95–3.13 kPa and 3.20–4.61 kPa, the electrical output performance was stable after 4200 cycles, and the sensor could continuously measure the carotid artery heart rate. When spinning yarns into garments, not only the material used but also the shape of the garment must be considered (Fig. 9e). Triboelectric all-textile sensor array, which weaves conductive and nylon threaded into a complete vegetal pattern, which resulted in a large effective area against triboelectric loading, a pressure sensitivity of 7.84 mV Pa, and a stability of over 100,000 cycles. The heart rate data could be tested by attaching the sewn cloth to different parts of the body (Fig. 9f). In fabric-based TENG design and fabrication, the use of machines was limited to creating specific fabric patterns. A sensor fabric fabricated using a simple electroplating technique was reported; a layer of polyvinylidene fluoride/nanowire nanofibers, a nanofiber membrane, and ethyl cellulose layer formed the sensor. The nanofiber structure made the sensor to exhibit a pressure sensitivity of 1.67 V kPa at 0–3 kPa and 0.20 V kPa pressure and remained stable after 7200 cycles. So sensors placed on the neck and clothing could measure the actual heart rate. The aforementioned heart rate monitoring sensors tested arterial parameters directly. The ultra-soft, single-layer smart fabric was a sensor that monitors physiological signals in a non-invasive way during sleep. As with SEHT, the wires consisted of twisted wires snaked by winding polyester wires around stainless steel rods and inserting hollow silicon fibers. The ultra-smooth smart level had a maximum pressure sensitivity of 10.79 mV Pa, and the pulse shape was precisely obtained by measuring the pulse. By directly inserting the small-sized TENG fabric, it could be made as a heart rate monitoring device. The clothing-based TENG was a reliable, comfortable, and stylish way to monitor heart rate over time. However, many studies had not focused on validating heart rate measurements with approved heart rate measurement methods, such as using electronic devices. To further corroborate these results, the textile-based wearable TENG could be used as a heart rate monitoring device for commercial and professional use. TENG-based data monitoring of the heart, pulse, respiration, etc. is currently a relatively extensive research direction of TENG in biomedicine. The precise treatment of cancer and implantable TENG are the key to data collection, data detection, and treatment feedback, which are necessary research topics in biomedicine. TENG-based portable devices have three applications in cancer treatment: TENG for early cancer detection and effective treatment; it serves for cancer monitoring; third, it can use TENG-based portable devices to increase sample size and different data. By modifying mitochondrial targeting peptides (MLS) and PEG on ZnO-nanorods/gold nanoparticles (AuNPs) nanoassemblies and coating C6 cell membranes (MP-Au/ZnO@CCM), a novel device for effective tumor therapy had been constructed (Fig. 10). The device performed well in many aspects, enabling targeted electrical stimulation catalytic therapy of tumors via ultrasound induction. First, when targeting mitochondria (by the MLS moiety), the ZnO nanogenerator generated piezoelectric potential and ultrasonic motors, which can disrupt mitochondrial function via electrical stimulation. The development of ultrasound-stimulated NG would provide the strategy for electronic tumor therapy and opened avenues for improving the therapeutic effect of nanozymes.

Synthesis and schematic diagram of MP-Au/ZnO@CCM Trojan nanogenerator. Reproduced with permission from Ref. [62]. Copyright 2021 Elsevier

4 Self-powered IoT devices based on TENG

The IoT is a new technology that has the potential to be a candidate for integrating global IoT networks, and IoT will play an important role in future technologies. From an industrial perspective, the importance of IoT can be seen when devices connected to a global network of machines can interact with each other, providing support systems for customers, smart applications for businesses, and suppliers as needed and an inventory system for business analysis. The IoT industry is rapidly adopting the technology as a solution to the innovative and competitive pressures on power delivery technology. At present, the interaction between IoT technology and the Internet has been unprecedentedly developed in industrial production and life, and it represents the largest number of wireless devices that can be connected to the Internet. IoT devices have four building blocks: processors, gateways, actuators/sensors, and applications. The processor acts as the brain of the IoT system and works based on the data captured by the sensors. IoT technology is responsible for sending the processed data to the appropriate site, such as low-power wide-area network (LPWAN), which are common technologies for transmission and communication of IoT. Data is collected by sensors from its surroundings, actuators/sensors process data to the surroundings, and the collected data must be used by appropriate applications. Important IoT application areas include healthcare systems, traffic management, environmental data monitoring, and intelligent buildings. As IoT develops wireless sensor nodes (WSNs), they can be used to monitor roads and traffic in the environment. In wireless sensor network equipment, its power supply is divided into two types: regenerable energy and non-regenerable energy, among which regenerable energy includes light energy, thermal energy, and mechanical energy. Non-regenerable energy includes fossil fuels and storage batteries, and regenerable energy collection has the advantages of light weight, small size, long service life, and light environmental pollution. In energy, mechanical energy is divided into continuous mechanical energy, vibration mechanical energy and intermittent mechanical energy. Depending on the vibration frequency and amplitude of the object, mechanical energy can be extracted from the vibration source and converted into electrical energy. Permanent mechanical energy sources are water waves, wind currents, solar energy, etc., which are used to generate electricity on both macro and micro scales, such as power plants. Decentralized power sources are cyclic in nature, and their energy can only be used for a section of the cycle. This includes the human body’s mechanical energy, such as jump and run, or vehicles through energy-harvesting devices. Many environmental constraints make battery replacement in wireless sensor networks a daunting task. In addition, chemical batteries are very expensive and lead to environmental pollution, thus encouraging researchers to look for alternative energy sources. To generate electricity from sustainable ambient energy sources, many sources can be used, such as radiation, mechanical motion, heat, and light, which are often renewable and clean. Wireless sensors are at the forefront of sensor network technology. In order to overcome the limitations of wireless sensor networks, it is necessary to study an effective acquisition system suitable for wireless sensor network environments. The ideal energy source can provide stable energy, which is a difficult task to accomplish, but can be improved by energy conversion and storage technology. Over the past few years, the IoT has been widely adopted around the world, and by 2020, more than 50 billion digital devices will be connected to the Internet. Harvesting energy from renewable sources is a promising research area that allows powered devices to convert energy into electricity by absorbing ambient energy. This technology overcomes the problems of battery replacement and maintenance, providing a reliable and long-lasting solution. IoT requires various sensors for health, safety, health monitoring, infrastructure monitoring, and environmental protection. Battery problems such as high cost, limited service life, high replacement frequency, and environmental pollution make traditional batteries unable to play a more effective role in power supply. General IoT devices require additional power supply devices to operate normally, to achieve data detection or other functions. NGs have been developed by Zhonglin Wang’s team since 2006 and these convert mechanical energy into electrical current and the earliest NGs were based on the triboelectric effect [63]. Zhonglin Wang’s team proposed the basic theory of NGs and discussed the similarities and differences between triboelectrically charged TENG and classical electromagnetic generators from Maxwell’s equations [64]. The main applications of TENG are self-powered sensors, blue energy sources, and micro-nano power-powered devices, which have been widely studied due to their low-cost and simple structure. The rapid expansion of the IoTs in many areas of life, such as smart homes, has driven the development of HMI. A TENG function was based on the control disc wire, which was coupled by a copper electrode, PTFE, and photovoltaic cell (Fig. 11a). In addition to being used for signal output and signal detection, this device could also use Bluetooth communication to control programs. This TENG control unit showed reliability, efficiency, and flexibility as the sole function of smart home control and privacy control. A combination of energy harvesters is required to harvest energy and solar energy to power the internal electronics.

Self-powered TENG control system. a Schematic diagram of the structure of the TENG control panel. b The open-circuit voltage of the hand-knocked down TENG disk. c Short-circuit current for hand knocking down the TENG disk. Reproduced with permission from Ref. [65]. Copyright 2020 Elsevier. d Demonstration of TENG as a sustainable power source for driving (c); i) a calculator, ii) a portable music player and iii) a smart wristband for continuous monitoring of life (scale bars: 2 cm). Reproduced with permission from Ref. [66]. Copyright 2020 Elsevier

TENG could generate electricity through mechanical shocks, such as tapping with a hand, and in addition, solar cells could harvest energy from the environment. The combined power generation from the TENG and solar panels could be stored in high-capacity or thermal batteries for electricity use. All three electrodes were connected to the load to increase the voltage output performance. Figure 11b and c are the VOC (measured with a 100 Mohm probe) and ISC at high voltage with a frequency of 3 Hz, respectively, with an average open circuit VOC of 570 V and an average ISC of 30 μA. A low-cost, high-efficiency, hand-driven TENG (HD-TENG) was developed, assisted by a rotary circuit, to collect energy from a low-frequency biomechanical device. It is worth mentioning that the HD-TENG function can easily reach more than 10,000 rpm for a period of time through a simple hand-pull method. The HD-TENG report shows a smart wristband for life monitoring and an audio player (Fig. 11d). Combining high output power, light weight, good portability, easy transportation, efficient use, and environmental protection, HD-TENG represents an ideal way to provide green power for bioelectronics and wearable devices in the IoT era.

With the discovery of new materials, engineering techniques, and sensing methods, it is possible not only to expand the sensing capabilities of TENG in IoTs, but also to enhance the power, accuracy, and signal strength of TENG. The development progress of TENG-based environmental monitoring systems is still hindered by many practical problems, including high temperature, exposure to ambient temperature and environmental pollution, and other variables that cannot be controlled in real time. In addition, the combination of TENG in IoTs and artificial intelligence is also an issue that needs attention, and these will become the development direction of TENG in IoTs.

5 Emerging applications of TENG in harvesting blue energy

Energy is the main source of the global economy, and energy shortage is one of the most urgent problems that countries need to solve. Today, energy is powered by fossil fuels such as coal and oil, which supplied for about 80% of the energy. However, due to the continuous increase in energy demand and the continuous rise in energy cost, the energy problem will soon become a big problem that the world needs to solve, and the current situation that ocean energy is in short supply to the environment is the most potential candidate. The ocean is estimated that the total energy of the global ocean exceeds 75 TW (1 TW = 1012 W). Ocean energy can be divided into five types, namely: seawater energy, water energy, water wave energy, salinity energy, and temperature gradient energy. Water wave energy is an important form of ocean energy, which is inexhaustible and renewable without being affected by seasonal changes. The wave energy near the world’s coastlines is estimated to be around 2–3 TW, making full use of ocean waves is a great help in solving the energy crisis. At present, TENG in blue energy can generally be divided into oscillating water column, flow converter, point absorption, flow system, and low flow system. Ocean wave energy is underutilized as wave energy converters (WECs) typically use expensive, bulky and inefficient EMGs for high-volume commercial needs. Therefore, some new approaches are needed for cost-effective wave energy harvesting. TENG was first used to collect blue energy In 2014, that was wave energy. TENG had advantages such as light weight (10 g), high power density, low production cost, and high efficiency. Researchers had developed different types of TENG with different properties and functions, which significantly enhanced the energy harvesting efficiency of human activities, water cycle, and water flow. The surface power density of TENG modules could reach 3200 W/m2, and the energy conversion rate could reach 70%, which met the needs of many low-cost and high-efficiency applications. Traditional generators are very heavy and must float on wave energy during the process of harvesting wave energy, while TENG is light and can easily float on the sea. The efficiency of traditional WEC is not high, while the efficiency of TENG can reach 70%. Due to the advantages of TENG in small-scale energy harvesting, TENG has been applied in wave energy.

5.1 TENG devices for harvesting low-frequency water wave energy

A distributed wave-based TENG (SSF-TENG) was fabricated to harvest water wave energy. The application of dense rabbit fur improved the wear resistance of the product, and the design and development of the component structure continuously improved the continuous performance of TENG materials (Fig. 12a). Using high-performance lubricated bearings, the device could achieve an ultra-long rotation time of more than 5 min with a single trigger, and the total energy conversion rate was 23.6%. In water wave stimulation, the SSF-TENG could generate an average current of 0.74 mW and 6.2 mW of maximum power. In addition, through the efficient method of hydroelectric power generation, the SSF-TENG power supply device had successfully met the requirements of the marine environment, laying a foundation for ocean TENG. Under the condition of water wave amplitude of 10 cm and frequency of 1.1 Hz, the capacitance was charged to 5.0 V within 109 s (Fig. 12b). When the sensor was turned off, the temperature and humidity data received by the receiver were displayed by computer. Self-powered TENG sensor powers temperature/humidity monitoring system such that data was transmitted every 10 s. Figure 12c shows the optical image of Q235 carbon steel to demonstrate the inhibition of specific corrosion in simulated seawater by the steel protection system constructed with SSF-TENG. The photos of the steel with and without SSF-TENG protection at different times clearly showed that the carbon steel without SSF-TENG protection was severely corroded after immersion in NaCl solution for 3 h. The spherical shell structure was a promising TENG-based energy harvesting technology, and the circular shell was not only easy to assemble, but also had the characteristics of light weight and flexible structure, which could absorb water wave energy from all directions. Wang et al. developed a TENG with a spherical structure, called a free triboelectric layer nanogenerator [67]. With this design, under the 1.43-Hz water wave, RF-TENG could light up some LEDs with good electrical characteristics (Fig. 12d). In particular, with a reasonable configuration, the electrical output characteristics of the RF-TENG were almost constant, enabling the maximum output under any water wave. In order to improve production technology of TENG, a comparative experiment was carried out between nylon/Kapton film and PTFE/Al film, and data showed that the electrical output performance of nylon/Kapton was better than that of PTFE/Al. Then, through theoretical verification and practical test results, the balls’ size was adjusted to obtain higher energy conversion efficiency (Fig. 12e–f).

a Schematic diagram of the segmented swing structure fur TENG. b The charging and discharging process of the 470 µF capacitor. c Optical photos of carbon steel micro-areas, (i–ii) with SSF-TENG protection and (iii–iv) without SSF-TENG protection. Reproduced with permission from Ref. [68]. Copyright 2021 VCH. d Photo of TENG in water wave system driving 70 green LEDs. e Schematic diagram of the TENG and QSC of the nylon/Kapton triboelectrode. f Schematic diagram and QSC)of PTFE/Al TENG. Reproduced with permission from Ref. [67]. Copyright 2015 VCH