Abstract

Manipulating the structure of electroactive materials with hierarchical frameworks can boost the electrochemical properties. The soaring fidelity of mixed nanostructured materials in electrochemistry verifies their candidature as appropriate electrodes for sustainable energy storage and conversion devices. Herein, we present facile and economical techniques to develop three-dimensional (3D) hierarchical nanoframes-like sulfurized nickel aluminum (sulfurized NiAl) as a positive electrode material and ternary bismuth cerium sulfide (Bi-Ce-S) as the negative electrode material for constructing an aqueous asymmetric supercapacitor system. These hierarchical architectures with well-developed pores and hollow spaces can capitalize the surface-to-volume ratio and maximize the contact area between the active material and electrolyte, therefore immensely reduce the ion penetration distances and promote the electron transport rates. Tuning the conductivity of electrode materials affords rich contact sites and integrates the features of all components, thus resulting in better electrochemical enhancements. As expected, sulfurized NiAl nanosheet arrays with unique porous architectures exhibit a good electrochemical performance with commendable specific capacitance of 1230.6 F g–1 at 1 A g–1 current density and stable rate capability (69.8% up to 20 A g–1). In addition, the obtained Bi-Ce-S hybrid provides a high specific capacitance (411.7 F g–1 at 1 A g–1) with 92.2% capacitance retention even after 4000 cycles. An asymmetric supercapacitor (ASC) device is established with the designed composites, which realizes a high energy density of 38.5 Wh kg–1 at a power density of 750 W kg–1 and reveals an enhanced cycle stability (80.6% retention after 8000 GCD times).

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The depletion of traditional energy resources and ever-increasing environmental pollution have recently impelled intensive research efforts to explore sustainable energy storage and conversion technologies [1, 2]. As a novel division of cost-effective and environmentally friendly energy harvesting systems, electrochemical supercapacitors with a good charge–discharge efficiency have received an enormous research interest during the recent years. They have been considered as one of the most competitive energy storage candidates for the next-generation electronic systems and transportation industries [3,4,5,6]. Nevertheless, the large-scale investigation of supercapacitors is hindered by their relatively limited energy density. The effectiveness of supercapacitors strongly depends on the structure and composition of electrode materials. Therefore, modifying the physicochemical and surface properties of materials is a key to attain supercapacitor devices that are capable of realizing high power and energy outcomes.

Generally, the development of nano/micro-structured earth abundant compounds is in demand for a wide-range of applications such as energy harvesting [7, 8] and electromagnetic interference shielding [9,10,11,12,13]. In this regard, controlling the structural characteristics of these compounds via relatively simple means can greatly reduce the overall cost and renovate their performances, thereby enlarging their large-scale usage [14,15,16,17]. Accordingly, considerable pursuits have been enshrined to rationally construct active transition metals and eliminate their several inevitable difficulties as well as achieve satisfactory activities [18,19,20,21,22,23]. In particular, optimizing the capacitance and operating voltage range are key issues to raise up the energy density. Given above consideration, fabricating an ASC cell has been considered as a feasible mean to broaden the potential window [3,4,5,6, 24].

Ni-based layered double hydroxides (LDHs) with various morphologies and sizes possess promising pseudocapacitive characteristics as positive electrode materials due to their large availability and favorable faradaic redox capability. These materials contain positively charged layers with exchangeable anions distributed into the interlayer gallery to provide a charge balance [25,26,27]. Most important, the interlayer negative ions and host layers can flexibly exchange without a significant structural change. Hence, LDHs bring versatile pseudocapacitive materials. Besides, the self-assembly of primary particles and building units endows the resultant LDHs with unique porous characteristics and copious diffusion channels [26]. However, the slow charge transfer kinetics and low-rate capability largely limit the practical employment of LDHs [27]. Therefore, ameliorating the intrinsic conductivity of LDHs is a top-priority strategy to overcome these limitations and improve their electrochemical performances. Typically, transition-metal sulfides are extensively investigated as electrode materials for supercapacitors due to their improved electrochemical activity and conductivity [4, 5]. The lower electronegativity of sulfur can speed up the rate of electron transfer and bring favorable electronic configuration [28]. Furthermore, the hierarchical structures can facilitate the reaction kinetics and maintain the structure integrity during cyclic test due to the mutual protection and support. Concomitantly, smart porous features can expose a large domain of active sites, provide rich contact centers and short ion diffusion channels. These characteristics achieve the complementary merits of all active components and produce a synergy promotion in electrochemical performance [24].

On the other hand, the research on highly active negative electrode materials is still limited. As we know, carbon-based materials are commonly used to prepare negative electrodes. However, the specific capacitances of such electrodes are still far from fulfilling the energy requirements of commercial applications [29]. Remarkably, the utilization of transition metals and their hybrids as negative electrode materials can further boost the charge storage ability owing to their reversible redox reactions [30, 31]. Bimetallic heterostructures combining two different elements with high tunability of cations and intrinsic electrochemical properties have become the major aim of many researchers [32, 33]. Generally speaking, bimetallic materials represent a more appropriate approach to realize high capacitive activity. Among these potential electrode materials, Bi-based materials have several advantages (i.e., large capacitance, low cost and easy manufacture) beyond those of carbon-based negative electrodes [34, 35].

To collectively enlighten these issues, the present work proposes the construction and employment of sulfurized NiAl and heterostructured Bi-Ce-S as electrode materials for supercapacitor applications. The hierarchical architectures of these materials with open windows and channels can offer rich contact sites and maximize the utilization efficiency of integrated active components, thus boost the electrochemical activity. Radially oriented nanosheet or thorn arrays expose more electrochemically active species for faradaic redox reactions and decrease the diffusion bridges. The open pores modify the interfacial contact between active material and electrolyte as well as mitigate the volumetric change during electrochemical processes. Moreover, the S atoms can further improve the intrinsic electrochemical performance. Benefiting from the smart structural features, the sulfurized NiAl nanomaterial as a positive electrode and ternary Bi-Ce-S hybrid as a negative electrode reveal large enhancements among the integrated transition metal ions and reinforce the charge storage capacity. In addition, the assembled ASC device exhibits a high energy and power outcomes.

2 Experimental section

2.1 Preparation of materials

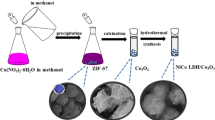

2.1.1 Fabrication of sulfurized NiAl nanoframes-based positive electrode

In this procedure, 20 mmol Ni(NO)3.6H2O and 10 mmol Al(NO)3.9H2O were dissolved into 150 mL deionized water containing 5 g glycine and 5 g Na2SO4. The system was allowed to stir for a certain time. After that, 30 mL NaOH (5 M) was slowly poured into the above reaction under stirring. The obtained reaction solution was tightly covered, fixed into an oil-bath system, and maintained at 85 °C for 24 h. After being cooled down to room temperature, the resulting yield denoted as NiAl LDHs was collected, washed repeatedly with ethanol absolute and deionized water, and then dried at 60 °C overnight. Subsequently, sulfurized NiAl nanocomposite was constructed via a simple anion-exchange reaction. As-obtained NiAl LDHs precursor (0.2 g) was dispersed into 20 mL deionized water containing 0.15 g thioacetamide. After stirring for 10 min, the mixture was treated hydrothermally at 140 °C for 8 h. Finally, the precipitate was taken out, washed, and dried at 60 °C.

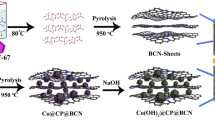

2.1.2 Fabrication of Bi-Ce-S negative electrode

Briefly, 24 mmol bismuth (III) nitrate pentahydrate (Bi(NO3)3.5H2O), 8 mmol cerium(III) nitrate hexahydrate (Ce(NO3)3.6 H2O), and 50 mmol thioacetamide were immersed into 60 mL isopropanol/glycerol (v:v = 3:1) under strong magnetic stirring. Afterward, the resultant mixture was loaded into a Teflon-lined stainless-steel autoclave and maintained at 180 °C for 8 h. The collected precipitate was rinsed with ethanol absolute and water and dried overnight in air.

2.2 Materials characterization

The phase components and composition of as-prepared samples were explored by X-ray powder diffraction (XRD) patterns using a Bruker D8 Advance diffractometer with the Cu Ka radiation. The microstructure and morphologies of samples were monitored using a field-emission scanning electron microscopy (FE-SEM, JEOL-6380LV) and transmission electron microscope (TEM- JEOL JEM-2100). X-ray photoelectron spectroscopy (XPS) analysis was employed to examine the surface states and element valence using a Thermo-Scientific K-alpha machine. The Brunauer–Emmett–Teller (BET) specific surface area of samples was measured by the N2 adsorption–desorption technique using ASAP2460 instrument. The pore characteristic was calculated by a Barrett-Joyner-Halenda (BJH) method.

2.3 Electrochemical testing

2.3.1 Three-electrode system

The as-received Ni foam pieces were sequentially dipped into diluted HCl, acetone, and deionized water, each for 15 min. Thereafter, treated substrates were dried at 60 °C for 8 h in a vacuum oven. The formation of the working electrodes was carried out via a conventional slurry coating protocol. In this regard, a homogeneous ink of active material, acetylene black, and polyvinylidene fluoride (at a weight ratio of 8:1:1) in N-methyl pyrrolidone (NMP) solvent was carefully deposited on a clean Ni foam substrate (1 cm*1 cm) and then compressed at 10 MPa. The mass loading of active material was controlled within 2.1 ± 0.3 mg cm–2. Electrochemical measurements such as cyclic voltammetry (CV), galvanostatic charge/discharge (GCD), and electrochemical impedance spectroscopy (EIS) were implemented in a 3 M KOH aqueous solution at room temperature by using a CHI660E potentiostat/galvanostat instrument (Shanghai, China). The three-electrode setup was assembled with a Pt plate counter electrode and Ag/AgCl reference electrode. The specific capacitance (C, F g−1) of electrodes was calculated from the GCD results according to Eq. (1) as follows [26, 35]:

where I/m, Δt, and ΔV, respectively demonstrate the charge–discharge current density (A g–1), discharge time (s), working potential window (V).

2.3.2 Construction of ASC full device

The two-electrode full cell was operated with sulfurized NiAl as a positive electrode and Bi-Ce-S as a negative electrode. The as-prepared electrodes were soaked into a 3 M KOH electrolyte and assembled together with a porous filter paper as the separator. Before assembly, the mass ratio between the positive to negative electrode materials was determined based on the charge balance theory (Eqs. (2) and (3)) [32, 33]. Optimizing the mass ratio is a critical issue to realize suitable electrochemical kinetics and better energy storage performance.

where ΔV, C, and m are the working potential window, specific capacitance, and mass of electrode material, respectively.

The capacitance of the ASC device (Ccell, F g−.1) could be measured using Eq. (4)

Note that (m+ + m–) indicates the masses of the positive and negative electrode materials. The energy density (E, Wh kg–1) and power density (P, W kg–1) of the device were calculated by using Eqs. (4) and (5) as follows [34, 35].

3 Results and discussion

3.1 Morphological and physico-chemical characteristics

The formation of 3D sulfurized NiAl nanoframes is schematically depicted in Fig. 1. First, NiAl LDH nanosheet arrays were obtained using a simple oil-bath treatment in presence of glycine as the structure-directing agent and Na2SO4 as the stabilizer. Afterward, the NiAl LDHs precursor underwent an anion exchange reaction in presence of thioacetamide as the sulfur source (Fig. 1). At initial stage, the hydrolysis of metal salts in a pure water system generates Ni2+ and Al3+ ions, directing the growth of NiAl LDHs nuclei. Alongside, glycine molecules are easily adsorbed onto the surface of formed nuclei, decomposed gradually, and spontaneously produce loosely attached aggregates/tiny flakes. Therefore, nanosheets begin to form, implying that the annexation of flaked or aggregated LDH nucleus facilitates the crystallization of nanosheets. This role is mainly attributed to the high ability of glycine to control specific metal cation complexation and eclectic absorption properties [36]. Moreover, the formed nanosheets are highly activated and prone to link together to minimize their surface energy. Thus, the nanosheets are integrated into micro-sized flower-like superstructures due to surface free energy or minimal magnetic anisotropic energy. Such superstructures further crystallize and tend towards perfection due to the Ostwald ripening mechanism [4].

In general, the dimensionality and crystal structure, as well as the shape of obtained products, are closely related to the corresponding growth time [24]. Our adopted oil-bath protocol can be employed as a physical model to elaborate the decomposition of reactants and subsequent complexation processes. The growth conditions of NiAl LDHs are quite suitable for their nucleation and growth rates. While keeping other conditions unchanged (i.e., temperature, concentration of metal salts and quantities of glycine and Na2SO4 ions), the NiAl composite exhibits nanoparticle, nanoflake/nanosheet, and ultrathin nanosheet-like morphologies at 6, 12, and 24 h, respectively (Fig. S1). This finding indicates that changing the growth time can induce the morphology evolution [29].

We hypothesize that the use of glycine ions and Na2SO4 micelles with alkali sodium (Na+) cations is beneficial to boost the kinetic reaction and tailor the compact morphology of LDHs nanostructure [37]. These salts may guide the growth of LDHs preferentially along a specific plane and thereby the orientated building units can assemble into an ordered fashion, forming a flower-like morphology. The salt template of Na2SO4 micelles can be removed by water rinsing, resulting in hollow architectures [38]. Accordingly, the Na2SO4 soluble template facilitates the formation of 3D nanostructured hybrid and serves as a pore-extending agent to optimize the pore architecture and size. Furthermore, the introduced NaOH modulates the release rate of metallic ions and improve the growth rate throughout the selective absorption of OH− [39]. The influential role of NaOH can be profoundly manifested through tuning the release rate of Ni2+ and Al3+ ions and guiding the preferential growth, enabling the construction of smart hierarchical architectures. During sulfurization, thioacetamide gradually decomposes to generate H2S, which in turn reacts with LDHs framework and simultaneously generates sulfurized-NiAl. Thus, the S2− anions replace the ligands of precursor throughout thermodynamically favorable process.

The FE-SEM micrographs of as-prepared NiAl LDHs precursor and sulfurized NiAl product are illustrated in Figs. 2 and S2. As illustrated in Figs. 2a–b and S2a–b, the sub-microflower-like architectures of NiAl LDHs precursor consist of abundant thin nanosheet arrays, which are closely packed with each other, producing 3D porous network. The two-dimensional (2D) nanosheets are arranged vertically to the hollow interiors, forming horn-like edges. The hierarchical architectures are full of pores that exist between the interconnected nanosheets, allowing better ion accessibility into the inner regions and short diffusion distances. After sulfurization treatment, the hierarchical flower-like structures with the original morphology are well-maintained (Figs. 2c–d and S2c–d). Moreover, the surface of interlaced nanosheets becomes slightly rough, which may ascribe to the recrystallization and reorganization processes during sulfurization treatment. The intersheet loopholes free of face-to-face stacking can increase the infiltration rate of electrolyte into inner skins and core regions, prevent the aggregation of sulfurized NiAl nanosheets during redox reactions, and minimize the length of ion diffusion paths as well as expose wide range of active surfaces for pronounced faradaic reactions.

The microscopic structure of sulfurized NiAl nanomaterial is further characterized by TEM (Fig. 2e–f). The sample reveals 2D interlaced nanosheets with slit-like tunnels, implying the construction of several paths for electrolyte penetration (Fig. 2e). The interconnected nanosheets display a folding silk-like structure with a transparent feature, manifesting their ultrathin nature (Fig. 2f). Moreover, the characteristics of curling and crumpling of nanosheets can be obviously noticed owing to their much larger lateral size than thickness. The dark strips are mainly related to the wrinkles of nanosheets or folded edges, confirming that the ultrathin nanosheets are interlaced together. These observations agree well with the above SEM results. The ultrathin character of nanosheets is ideal for rapid intercalation caused by short diffusion distances and tiny crystallites inside the thin nanosheets, thus providing a high-rate capability. The S-TEM image and corresponding elemental mapping profiles (Fig. 2g) reveal the even distribution of Ni, S, and Al elements throughout the sulfurized NiAl nanoframes.

XRD patterns of the obtained samples are displayed in Fig. 3a. The discernible diffraction peaks of NiAl LDHs precursor are associated with the rhombohedral takovite crystal structure (JCPDS No. 1500087). The peaks centered at 11.8°, 23.6°, 35.2°, 39.7°, 47.2°, 53.4°, 56.6°, 61.3°, 62.6°, 66.5°, 72.6°, and 75.4° can be indexed to (003), (006), (012), (015), (018), (1010), (0111), (110), (113), (116), (202), and (205), respectively, ensuring the formation of nanostructured NiAl LDHs with a high crystallinity. The XRD characteristic peaks of sulfurized sample are well matched with the diffraction peaks of orthorhombic Ni9S8 crystal structure (JCPDS No. 78–1886). The representative peaks at around 9.5°, 12.3°, 15.6°, 18.5°, 25.7°, 34.4°, 35.4°, 38.6°, 61.3°, 62.7°, and 72.7° are assigned to (001), (110), (111), (021), (130), (203), (312), (133), (026), (335), and (445) planes, respectively. This result discloses that the sulfurized derivative has the same crystal structure as Ni9S8 [40]. The bulk composition of sulfurized NiAl is further characterized by XPS analysis as summarized in Table S1. The Ni 2p photoelectron spectrum of sulfurized NiAl is depicted in Fig. 3b. As can be seen, the fitted Ni 2p core-level reveals two major energy bands namely, Ni 2p3/2 and Ni 2p1/2, proposing the coexistence of Ni2+ and Ni3+states [41, 42]. The lower energy band can be divided into a couple of characteristic peaks located at 857.4 and 859.5 eV, which are assigned to Ni2+ and Ni3+ states, respectively. Similarly, the high energy band displays two components at 875.7 and 877.3 eV, respectively ascribe to Ni2+ and Ni3+. The shake-up satellite peaks (named as Sat.), which are related to the spin coupling of unpaired electrons can be found at 863.6 and 882 eV, validating the occurrence of Ni2+. During alkali electrochemical reactions, Ni2+ can be further oxidized to the higher valence Ni3+ sites and then reduced back to Ni2+, releasing charges into the outer circuit. The Ni2+/Ni3+ reversible transitions control the charge storage process and thereby improve the pseudocapacitive property of active electrode material. In the high-resolution Al 2p pattern (Fig. 3c), the main peak at 73.5 eV demonstrates the occurrence of Al3+ species in the form of Al − O [43]. Figure 3d displays the XPS spectrum of S 2p region with two main peaks and two satellite peaks. The characteristic peaks at round 161.8 and 163 eV are attributed to the doublet S 2p3/2 and S 2p1/2 binding energies, respectively (Fig. 3d) [44, 45]. The S 2p3/2 band represents the sulfur ions (S2–) on the surface with a low coordination, while the S 2p1/2 band presents the metal-sulfur bonding (i.e., Ni-S and Al-S) [44, 45]. Moreover, the satellite peaks at 164.9 and 167.9 eV are due to oxidized sulfur to sulfate.

Specific surface area and pore structure of an electrode material can impact its electrochemical performance. Fig. S3a–b illustrates the N2 adsorption–desorption curves and pore size distribution of NiAl LDHs precursor and sulfurized NiAl. The samples reveal type IV characteristic isotherms with H3-type hysteresis loops, suggesting the establishment of porous nanoframes. The pores are slits and caused by the orientation of sheet architectures. The specific surface area of NiAl LDHs precursor and sulfurized NiAl are calculated as 42.4 and 54.1 m2 g−1, respectively. Therefore, the specific surface area of NiAl LDHs increases because of sulfurization reaction. Besides, both samples are awarded with mesopores (less than 5 nm). Such mesoporous structures are resulted from the interstitial spaces among the adjacent nanosheet building units. Moreover, the notable uptake step at P/P0 approaching 1.0 indicates the coexistence of large mesopores or narrow macropores due to interparticle distance between the contiguous microflowers [46,47,48]. The meso/macroporous architectures promote the adsorption of electrolyte ions, hasten the penetration of ions not only at the surface but also inside the inner core, and offer more electrochemically active sites, hence strengthen the electrochemical performance.

Thioacetamide as a general sulfur source is utilized to prepare semiconducting Bi-Ce-S hybrid via a simple solvothermal method (Fig. 4a). The thiol groups can quickly supply S2– species inside the solution during the growth and crystallization processes [30]. Simultaneously, the outward Bi3+/Ce3+ ions with enough energy can diffuse into the solution, combine with the released S2–, and spontaneously nucleate to form the primary particles/units. As the Ostwald ripening process and mass diffusion proceed, numerous nanoslices/thorns are formed accompanied with their self-organization into 3D nest-like architectures [4, 42]. These nanoslices/thorns possess a relative roughness and may provide a large surface area. More interestingly, all thorns grow vertically, and many interspaces are generated between them, thereby the rate of ion/electron transport can be sufficiently boosted.

Figure 4b and c shows the cross-sectional view SEM images of Bi-Ce-S sample. The hybrid exhibits 3D nest-like structures with a large cavity and constructed by an intercalated shell of many nanoblades/thorns. It can be seen that the nanoblades/thorns grow radially, exposing copious edge sites. Concurrently, multiple tiny gaps are formed between the staggered nanoblade/thorn building units, which are advantageous to speed up the penetration of ions and electrons. This increases the contact area at interfaces and therefore the space volume can be investigated more effectively. Based on the above observations, we temporarily speculate that the heterostructured Bi-Ce-S hybrid can enhance the energy storage capacity.

The XRD pattern of Bi-Ce-S is depicted in Fig. 4d. The spectrum displays sharp and narrow diffraction responses, validating the good crystallinity of sample. Almost all the observed diffraction peaks coincide well with those of orthorhombic Bi2S3 phase (JCPDS No. 75–1306). The lattice for (211) at 25.2°, (220) at 29.2°, (310) at 32.7°, (321) at 39° and (420) at 47° of Ce2S3 (JCPDS No. 50–0851) overlaps with the peaks of Bi2S3 [49, 50]. The chemical binding information of Bi-Ce-S hybrid are studied by XPS analysis (Fig. 4e-g and Table S2). The fitted Bi 4f XPS spectrum (Fig. 4e) exhibits two strong peaks at binding energies of 157.9 and 163.2 eV ascribe to Bi 4f7/2 and Bi 4f5/2, respectively. This observation matches with Bi3+ states of Bi2S3 [30, 31]. In addition, the week peaks around 160.6 and 161.9 eV signify the S 2p3/2 and S 2p1/2 species, respectively and ensure the formation of S2− within the hybrid [51]. Moreover, the deconvoluted Ce 3d core-level in the respective binding energy range of 880–920 eV (Fig. 4f) reveals two sets of peaks related to Ce 3d5/2 and Ce 3d3/2 spin–orbit splitting. The peaks located at ~ 881.7, 885.7, 900.4, and 904 eV are attributed to Ce4+, suggesting that the main valence of Ce in the composite is +4, irrespective of the valences of starting cerium precursor [52]. On the other hand, the remaining two peaks positioned at ~ 884.2 and 902.9 eV are attributed to Ce3+ states, ascertaining the presence of a handful of Ce3+ ions in the composite [53]. Figure 4g divulges the narrow XPS spectrum of S 2p with two peaks at 161.7 and 163.2 eV, which fit the S 2p3/2 and S 2p1/2 characteristics, respectively of Bi/Ce-S bonding.

3.2 Supercapacitive and charge storage performances

The capacitive performances of as-prepared materials are tentatively evaluated by CV technique with a three-electrode cell as shown in Fig. 5. The comparative CV profiles of samples at a scan rate of 10 mV s–1 are illustrated in Fig. 5a. Clearly, both electrodes feature a couple of redox peaks within the potential range of 0.0–0.5 V vs. Ag/AgCl, signifying the contribution of a faradaic pseudocapacitance. Markedly, the well-defined redox signatures are caused by the reversible redox reactions of Ni2+/Ni3+ chemical states in an alkaline media as expressed by Eq. (7) [32, 44].

a Comparison of the CV curves of NiAl LDHs and sulfurized NiAl at a scan rate of 10 mV s−1. b GCD loops of NiAl LDHs and sulfurized NiAl at a current density of 1 A g−1. c CV responses of sulfurized NiAl at different scanning rates. d GCD curves of sulfurized NiAl at different current densities. e Relationship between specific capacitance and current density for the electrodes. f Cyclic performance of sulfurized NiAl at 20 A g.–1

In general, the complementary area of CV curve for each electrode directly correlates with the electrochemical behavior of active material and achieved capacitance. Accordingly, the capacitance of NiAl LDHs is a relatively low as indicated by the realized redox characteristics. On the other hand, it is evident that the bounded area of sulfurized NiAl is enlarged, endorsing its enhanced specific capacitance.

Figure 5b presents the GCD curves of electrodes at 1 A g–1. Result demonstrates that sulfurization ostensibly tunes the surface chemistry of active electrode material and provides more electroactive centers, therefore boosts the pseudocapacitive effect. The GCD curves elucidate that the substitutional S boosts the specific capacitance of LDHs. According to our previous report [54], S heteroatoms play a role in optimizing the LDHs structure and improving the reaction kinetics. These atoms may serve as the buffering region for reserving spots to induce the electron conduction rate. The voltage plateaus in both charge and discharge processes ensure the pseudocapacitive nature, coinciding with the CV outcomes. The discharge time of sulfurized NiAl is much longer than that of NiAl LDHs, manifesting a higher specific capacitance. The reason for such phenomenon can be assigned to the collaborative effect and change in the contribution of ions to specific capacitance.

To perform further analysis on the electrochemical behaviors of sulfurized NiAl, CV signals at diverse sweep rates are acquired. As shown in Fig. 5c, the CV profile of electrode still preserves its original shape even at higher scan rates, implying better reversibility and good rate capability. The peak current response progressively enhances upon increasing the sweep rate, suggesting a proper reaction kinetics during electrochemical process. Because of internal diffusion resistance and polarization effect, the oxidation and reduction peak position shifts towards a more positive and negative value separately as the sweep rate increases. The plots of oxidation and reduction peak current response against the square root of scan rate (Fig. S4) declare a linear correlation. This denotes that the alkaline electrochemical reaction is a diffusion-controlled redox process. The linear fitting of corresponding oxidation peak current signal represents a mirror-image identical to the linear dependency of the reduction peak current signal, which further suggests the remarkable reversibility of electrode.

To quantify the specific capacitance and rate ability of electrodes, a series of GCD tests is executed at different current densities (1–20 A g–1). The GCD curves of sulfurized NiAl and NiAl LDHs electrodes are recorded as presented in Figs. 5d and S5. All the obtained GCD curves with approximately symmetric forms are completely distanced from the optimal triangle pattern, evidencing that the charge storage process is accomplished through a pseudocapacitive contribution controlled by the faradaic reactions. Each discharge curve has two exclusive voltage regions: a gradual potential decay (0.5– ~ 0.2 V vs. Ag/AgCl) due to the pseudocapacitive characteristics of electrode active material, while the steep voltage drop (0.2–0.0 V vs. Ag/AgCl) demonstrates the internal resistance. The specific capacitance value of both electrodes is assessed at different current densities on the basis of discharging time using Eq. (1). The relationship between specific capacitance and current density is depicted in Fig. 5e. Apparently, the sulfurized NiAl delivers a large specific capacitance compared to NiAl LDHs precursor. Consequently, the capacitance of sulfurized NiAl at a lower current density of 1 A g–1 (1230.6 F g–1) significantly outperforms that of NiAl LDHs (896 F g–1), revealing that the substitutional S species are conductive to capacitance enhancement. At a 20-fold increase of current density, the sulfurized NiAl can still reach 859 F g–1 with the good capacitance retention of 69.8%, manifesting its notable rate capability. On the one hand, the capacitance of NiAl LDHs reduces to 523 F g–1 with about 58.3% capacitance retention at 20 A g–1. The specific capacitance of electrodes diminishes at higher current densities. This is possibly ascribed to the ultrafast intercalation of a great deal of OH– ions at electrolyte–electrode interface under a higher current density. The introduction of S affects the electronic configuration of LDHs framework in sulfurized NiAl. This can boost the capacitive behavior and rate capability. Remarkably, the sulfurized NiAl delivers a good pseudocapacitive performance compared with other reported materials in literature (Table S3).

To further assess the electrochemical performance of sulfurized NiAl as a pseudocapacitive electrode material, cyclic stability is a crucial aspect. As displayed in Fig. 5f, the cyclic performance of electrode is calculated by duplicated charge–discharge processes at a higher current density of 20 A g−1 for 4000 times. The respective electrode reaches 81.4% retention after 4000 cycles, which is probably assigned to the tunable porosity of interlaced nanosheets. The unique porous features of electrode provide a continuous access of electrolyte solution into the inner frames during fast charge–discharge processes, maximizing the pseudocapacitance contribution of all components.

Furthermore, the electrochemical behaviors of NiAl LDHs and sulfurized NiAl are also compared by EIS tests. The corresponding Nyquist spectra and equivalent circuit configuration are given in Fig. S6. The proposed circuit model (inset-Fig. S6) comprises the equivalent series resistance (Rs), charge transfer resistance (Rct), double-layer capacitance (CPE: constant phase element), and Warburg impedance (Zw). Generally, the intersection spot of spectral line with the real axis demonstrates the Rs of electrochemical system. The semicircle stands for the Rct at interfaces, while the straight line in the low frequency section indicates the Zw of ion diffusion along electrode design [55]. The Rs of NiAl LDHs and sulfurized NiAl are quite similar (~ 0.95 Ω), manifesting that the formed nanoframes with enough pores and spaces afford well-defined trajectories for the ion/electron movement. The analyzed curves illustrate a semicircle in the high-frequency region with a straight line in the low-frequency region. The sulfurized NiAl reaches a smaller Rct value (2.1 Ω) than NiAl LDHs (2.95 Ω), which is beneficial for promoting the charge transfer ability. Such finding strongly correlates with the regulated structural characteristics of sulfurized NiAl. The interconnected nanosheet-like 3D porous nanoframes with short diffusion paths and enlarged contact area enable the formation of percolated conductive frameworks. The accelerated mass and electron transport rates along electrode material can tune the kinetics of redox processes, thus providing a high pseudocapacitive performance and reinforced cycling stability.

The above outcomes certainly prove that the sulfurized NiAl nanoframes can supply more surface and core active sites to boost the pseudocapacitive performance via accelerating the ion penetration rate and charge transport kinetics. The hierarchical structural and electronic advantages support the recruitment of sulfurized NiAl as a positive electrode material to design ASC device as schematically illustrated in Fig. 6.

The 3D nanoframes with large amounts of rich holes/voids can greatly modulate the electrochemical characteristics and pseudocapacitive behavior. The regulated porous architectures can speed up the transport rate of electrons/ions with low diffusion resistance and provide copious active sites per unit volume, which are advantageous to boost the redox processes [56]. The construction of hierarchical mesopores enhances the accessibility of active centers and modulates the adsorption energy of OH― molecules through establishing a large-range of channels (ion storage pools). The arrayed networks with plentiful site exposure and hetero-charge transferability can effectively reinforce the diffusion kinetics and improve the active materials usage during electrochemical reactions, thus capitalizing the capacitance and cycling stability. The inserted S heteroatoms not only form synaptic conduction network and modify the conductivity but also increase the active sites. These favorable merits of sulfurized NiAl verify its potential application in supercapacitors.

The electrochemical performances of Bi-S and Bi-Ce-S samples-based negative electrodes are explored by using a standard three-electrode system in a 3 M KOH aqueous electrolyte. The CV curves at 5 mV s−1 are shown in Fig. 7a. As shown, the Bi-Ce-S composite displays stronger redox peaks and larger area of the CV plot, ensuring its enhanced charge storage capability. Besides, the GCD results of the above negative electrodes at 1 A g−1 (Fig. 7b) reveal similar outcomes and the Bi-Ce-S electrode presents a longer discharge time than single Bi-S. This may attribute to the combined advantages induced by the synergistic interactions between Bi and Ce species. The CV curves of Bi-Ce-S electrode at different scan rates (2–100 mV s–1) in the voltage window of –1.0–0.0 V vs. Ag/AgCl are presented in Fig. 7c. Significant redox peaks can be clearly observed in both anodic and cathodic scans due to the typical pseudocapacitive behavior of integrated Bi and Ce components. Such finding implies that the active components participate not only in the electron transfer process but also in redox reaction. The peak potential deviation is largely caused by the electrochemical polarization and fast diffusion of ions into the composite. The shape of the CV profiles is well preserved, demonstrating the exceptional electrochemical reversible property. The GCD loops of Bi-S and Bi-Ce-S electrodes are recorded at different current densities from 1 to 10 A g−1 in the potential range from −1.0 to 0.0 V (Figs. 7d and S7). The obtained GCD curves are not linear and feature intrinsic discharge platforms caused by the faradaic redox reactions. It is well known that Bi-based negative electrodes always suffer from a noticeable IR drop [30, 57, 58]. Each discharge segment has two distinct regions, featuring a steep voltage drop and an obvious voltage plateau. The sudden steep decay of voltage within the first few seconds of discharge is mainly related to the internal resistance (IR drop) while, the relatively large voltage plateau correlates with the involvement of faradaic processes. The small kink in the discharge part is probably assigned to the oxidation platform of untransformed species during the reduction process [59, 60]. The slight change in voltage drop upon increasing the current density validates the enhanced kinetics of faradaic redox processes.

Electrochemical properties of Bi-S and Bi-Ce-S negative electrodes. a Comparative CV curves of electrodes at 5 mV s–1 and b GCD results of electrodes at 1 A g−1. c CV responses of Bi-Ce-S composite at different sweep rates. d GCD cures of Bi-Ce-S electrode at different current densities. e Rate performance and capacitance value of electrodes at various current densities. f Cyclic stability test of Bi-Ce-S electrode at 10 A g.−1

The specific capacitances of Bi-S and Bi-Ce-S are acquired from the GCD analyses and the dependence of capacitance on current density is illustrated in Fig. 7e. When the current density increases from 1 to 10 A g−1, the capacitance of Bi-Ce-S electrode decreases from 411.7 to 248.6 F g−1. Under similar conditions, the capacitance of Bi-S is lower than that of Bi-Ce-S. While, the specific capacitance of Bi-S electrode reduces from 312 to 167 F g−1 as the current density raises from 1 to 10 A g−1. The acquired capacitance tends to decrease at higher current densities because of insufficient time for ions to reach the active sites. On the other hand, there is enough time for ions to migrate at lower current density, enabling more charges to be transferred and thereby a higher capacitance is realized. Open 3D nest-like Bi-Ce-S enhances the ultimate contact between electrolyte and electrode material.

Figure 7f depicts the cycle performance of Bi-Ce-S electrode at a higher current density of 10 A g−1 for 4000 cycles. The capacitance value retains about 92.2% after 4000 GCD cycles, suggesting a good long-time cyclic stability. The Nyquist profile of Bi-Ce-S is displayed in Fig. S8. The sample shows a small Rs value of 1.13 Ω in the high frequency region and a straight line with a minor deflection at the low frequency area. Notably, there is a small semicircle existing in the high frequency part with the Rct value of 1.38 Ω. These observations prove the improved charge transfer kinetics and good conductivity as well as low electrolyte penetration resistance into the Bi-Ce-S material.

It is well known that sulfides-based electrode materials usually show favorable pseudocapacitive characteristics. The low electronegativity of S atoms can promote the electron transfer, bring favorable charge regulation, and hence modify the overall electrochemical behavior. The sulfurized NiAl compound reveals improved capacitive features; however, the limited potential range may hinder its further practical employment in energy storage systems. In general, constructing an ASC device is supposed to be a pragmatic pathway to enlarge the working potential. Accordingly, an ASC device is assembled in a 3 M KOH electrolyte by using the sulfurized NiAl as a positive electrode and Bi-Ce-S as the negative electrode. The schematic assembly of sulfurized NiAl//Bi-Ce-S ASC system is depicted in Fig. 8a. In order to attain the best energy storage behavior, the active masses of electrode materials are carefully balanced and the optimized mass ratio between negative and positive is adjusted as 1:0.67 (Eqs. (2) and (3)). The CV curves at 10 mV s–1 and GCD results at 1 A g–1 of sulfurized NiAl and Bi-Ce-S under the three-electrode setup are illustrated in Fig. S9 and S10. Thus, it is reasonable to deduce that the working potential range of as-fabricated sulfurized NiAl//Bi-Ce-S ASC device can be extended up to 1.5 V in a 3 M aqueous KOH solution.

The representative CV profiles of sulfurized NiAl//Bi-Ce-S cell at various scanning speeds from 10 to 100 mV s–1 within the operating potential of 0.0–1.5 V (Fig. 8b) reveal obvious capacitive features with a prominent discrepancy from the common rectangle-shaped CV loop of classical carbon-based symmetric devices. The apparent redox peaks corroborate the viable ions insertion/extraction processes and enhanced redox kinetics. There is no observable change in the shapes of CV profiles with the increase of scan rate, manifesting the good rate performance and exceptional reversibility. The current response reveals a gradual increase upon increasing the scan rate, suggesting better capacitive property and desirable Coulombic efficiency. Figure 8c presents the GCD results of the device at 1–10 A g–1. The analyzed GCD curves with non-linear and approximate symmetric forms disclose the strengthened energy storage characteristics. These findings are in accordance with those illustrated by CV results. The specific capacitance outcomes of sulfurized NiAl//Bi-Ce-S ASC device are adopted from GCD results according to Eq. (4) and the respective results are given in Fig. 8d. As shown, the device achieves a good specific capacitance outcome of 123.3 F g–1 at 1 A g−1 and maintains about 73.5 F g–1 at 10 A g–1. Hence, the rate performance can reach about 59.6% at 10 A g–1.

According to Eqs. (5) and (6), the energy density and power density as two key cursors to further probe the charge storage ability of sulfurized NiAl//Bi-Ce-S ASC device are computed and presented in Ragone plot (Fig. 8e). Encouragingly, the fabricated device delivers commendable energy densities of 38.5–23 Wh kg–1 at power densities of 750–7500 W kg–1, superior to other previously presented ASC systems (Table S4). Figure 8f illustrates the cycle life diagram of device over 8000 sequential cycles at 10 A g–1. The capacitance retention rate is still up to 80.6% after 8000 cycles, which is a guide for the reinforced cycle character. Moreover, the full device has a high Coulombic efficiency of ~ 96.9%, demonstrating the high reversible performance and good energy storage ability. The distinctive combination and collaborative effect of pseudocapacitive sulfurized NiAl and heterostructured Bi-Ce-S with plentiful active sites effectively promote the energy storage properties and cycle service life. The intrinsic porous frameworks of representative electrode materials may alleviate the stress caused by continuous ion insertion/desertion. Beyond that, the hierarchically open configurations favor more effective electrochemical activity due to the fast diffusion of ions and expanded exposure of active sites. Skillfully, complexing electrodes with multiple redox sites and hierarchical structures prominently endorses the full utilization of active materials during electrochemical reactions. The collaborative effect of all constituents and ease accessibility of active sites benefits the charge transmission and enhances the rate performance.

4 Conclusions

An aqueous ASC device is constructed by using sulfurized NiAl nanoframes as the positive material and ternary Bi-Ce-S hybrid as the negative material. Because of its porous architecture, sulfurized NiAl nanoframes display an enhanced pseudocapacitive behavior, reaching a specific capacitance of 1230.6 F g–1 at 1 A g–1 and notable rate performance (69.8% from 1 to 20 A g–1) with a good cyclic stability (81.4% after 4000 cycles). The enhanced capacitive performance of sulfurized NiAl nanomaterial is largely attributed to the unique structural advantages: superficial flower-like arrayed nanoframes can sufficiently expose large contact areas, enabling a good accessibility of ions on both surface and core regions, thereby providing robust redox reactions. The 2D ultrathin nanosheet as the building units offer copious active sites and facilitate the radial charge transport rate. The incorporated S atoms boost the electrochemical activity and offer extra electrochemical sites as a result of the collaborative interactions. The S heteroatoms improve the transport of electrons and further strengthen the electrochemical kinetics. Impressively, ternary Bi-Ce-S composite achieves a high capacitance of 411.7 F g–1 at 1 A g–1 and an improved capacitance retention of 92.2% after successive 4000 cycles. Combining Bi and Ce sites facilitates the transfer of electrons, promotes the redox processes, and provides a large capacitance. With these considerations, the as-devised sulfurized NiAl//Bi-Ce-S ASC device realizes a large energy density of 38.5 Wh kg–1 at a power density of 750 W kg–1. The device maintains about 80.6% of initial capacitance even after 8000 cycles. These encouraging results may contribute to the exploration of high performance aqueous supercapacitors.

References

Titirici MM, White RJ, Brun N, Budarin VL, Su DS, Del Monte F, Clark JH, MacLachlan MJ (2015) Sustainable carbon materials Chem Soc Rev 44:250–290

Lukatskaya MR, Dunn B, Gogotsi Y (2016) Multidimensional materials and device architectures for future hybrid energy storage. Nat Commun 7:1–13

Wu N, Bai X, Pan D, Dong B, Wei R, Naik N, Patil RR, Guo Z (2021) Recent advances of asymmetric supercapacitors. Adv Mater Interfaces 8:2001710

Khalafallah D, Zou Q, Zhi M, Hong Z (2020) Tailoring hierarchical yolk-shelled nickel cobalt sulfide hollow cages with carbon tuning for asymmetric supercapacitors and efficient urea electrocatalysis. Electrochim Acta 350:136399

Khalafallah D, Ouyang C, Ehsan MA, Zhi M, Hong Z (2020) Complexing of NixMny sulfides microspheres via a facile solvothermal approach as advanced electrode materials with excellent charge storage performances. Hydrogen Energy 45:6885–6896

Patil SS, Bhat TS, Teli AM, Beknalkar SA, Dhavale SB, Faras MM, Karanjkar MM, Patil PS (2020) Hybrid solid state supercapacitors (HSSC’s) for high energy & power density: an overview. Eng Sci 12:38–51

Rehman S, Ahmed R, Ma K, Xu S, Tao T, Aslam MA, Amir M, Wang J (2021) Composite of strip-shaped ZIF-67 with polypyrrole: a conductive polymer-MOF electrode system for stable and high specific capacitance. Eng Sci 13:71–78

Wang Y, Liu Y, Wang C, Liu H, Zhang J, Lin J, Fan J, Ding T, Ryu JE, Guo Z (2020) Significantly enhanced ultrathin NiCo-based MOF nanosheet electrodes hybrided with Ti3C2Tx MXene for high performance asymmetric supercapacitors. Eng Sci 9:50–59

Luo F, Liu D, Cao T, Cheng H, Kuang J, Deng Y, Xie W (2021) Study on broadband microwave absorbing performance of gradient porous structure. Adv Compos Hybrid Mater 4:591–601

Wang W, Deng X, Liu D, Luo F, Cheng H, Cao T, Li Y, Deng Y, Xie W (2021) Broadband radar-absorbing performance of square-hole structure. Adv Compos Hybrid Mater. https://doi.org/10.1007/s42114-021-00376-0

Wu H, Zhong Y, Tang Y, Huang Y, Liu G, Sun W, Xie P, Pan D, Liu C, Guo Z (2022) Precise regulation of weakly negative permittivity in CaCu3Ti4O12 metacomposites by synergistic effects of carbon nanotubes and grapheme. Adv Compos Hybrid Mater. https://doi.org/10.1007/s42114-021-00378-y

Xie P, Liu Y, Feng M, Niu M, Liu C, Wu N, Sui K, Patil RR, Pan D, Guo Z, Fan R (2021) Hierarchically porous Co/C nanocomposites for ultralight high-performance microwave absorption. Adv Compos Hybrid Mater 4:173–185

Qi G, Liu Y, Chen L, Xie P, Pan D, Shi Z, Quan B, Zhong Y, Liu C, Fan R, Guo Z (2021) Lightweight Fe3C@Fe/C nanocomposites derived from wasted cornstalks with high-efficiency microwave absorption and ultrathin thickness. Adv Compos Hybrid Mater 4:1226–1238

Wu N, Zhao B, Liu J, Li Y, Chen Y, Chen L, Wang M, Guo Z (2021) MOF-derived porous hollow Ni/C composites with optimized impedance matching as lightweight microwave absorption materials. Adv Compos Hybrid Mater 4:707–715

Ramalingam S, Subramania A (2021) Effective removal of nitrates from the drinking water by chemical and electrochemical methods. Eng Sci 15:80–88

Borate H, Bhorde A, Waghmare A, Nair S, Pandharkar S, Punde A, Shinde P, Vairale P, Jadkar V, Waykar R, Rondiya S, Hase Y, Aher R, Patil N, Prasad M, Jadkar S (2021) Single-step electrochemical deposition of CZTS thin films with enhanced photoactivity. ES Mater Manuf 11:30–39

Khalafallah D, Zhi M, Hong Z (2021) Rational engineering of hierarchical mesoporous CuxFeySe battery-type electrodes for asymmetric hybrid supercapacitors. Ceram. Int. 47:29081–29090

Khalafallah D, Li XY, Zhi MJ (2020) Hong ZL (2020) 3D hierarchical NiCo layered double hydroxide nanosheet arrays decorated with noble metal nanoparticles for enhanced urea electrocatalysis. ChemElectroChem 7:163–174

Khalafallah D, Ouyang C, Zhi M, Hong Z (2019) Heterostructured nickel-cobalt selenide immobilized onto porous carbon frameworks as an advanced anode material for urea electrocatalysis. ChemElectroChem 6:5191–5202

Deokate RJ (2021) Chemically deposited NiCo O thin films for electrochemical study. ES Mater Manuf 11:16–19

Gite AB, Palve BM, Gaikwad VB, Shinde SD, Jain GH, Pathan HM (2021) Physicochemical properties and thermoelectric studies of electrochemically deposited lead telluride films. ES Mater Manuf 11:40–49

Khalafallah D, Zhi M, Hong Z (2019) Recent trends in synthesis and investigation of nickel phosphide compound/hybrid-based electrocatalysts towards hydrogen generation from water electrocatalysis. Top Curr Chem 377:29

Khalafallah D, Zhi M, Hong Z (2021) Development trends on nickel-based electrocatalysts for direct hydrazine fuel cells. ChemCatChem 13:81–110

Khalafallah D, Quan X, Ouyang C, Zhia M, Hong Z (2021) Heteroatoms doped porous carbon derived from waste potato peel for supercapacitors. Renew Energy 170:60–71

Li X, Du D, Zhang Y, Xing W, Xue Q, Yan Z (2017) Layered double hydroxides toward high-performance supercapacitors. J Mater Chem A 5:15460–15485

Li L, Li R, Gai S, He F, Yang P (2014) Facile fabrication and electrochemical performance of flower-like Fe3O4@C@layered double hydroxide (LDH) composite. J Mater Chem A 2:8758–8765

Liang H, Lin J, Jia H, Chen S, Qi J, Cao J, Lin T, Fei W, Feng J (2018) Hierarchical NiCo-LDH/NiCoP@NiMn-LDH hybrid electrodes on carbon cloth for excellent supercapacitors. J Mater Chem A 6:15040–15046

Zong W, Lai F, He G, Feng J, Wang W, Lian R, Miao YE, Wang GC, Parkin IP, Liu T (2018) Sulfur-deficient bismuth sulfide/nitrogen-doped carbon nanofibers as advanced free-standing electrode for asymmetric supercapacitors. Small 14:1801562

Khalafallah D, Miao J, Zhi M, Hong Z (2021) Confining self-standing CoSe2 nanostructures and Fe3C wrapped N-doped carbon frameworks with enhanced energy storage performances. Appl Surf Sci 564:150449

Khalafallah D, Zhi M, Hong Z (2022) Bi-Fe chalcogenides anchored carbon matrix and structured core-shell Bi-Fe-P@Ni-P nanoarchitectures with appealing performances for supercapacitors. J Colloid Interface Sci 606:1352–1363

Khalafallah D, Li X, Zhi M, Hong Z (2021) Nanostructuring nickel–zinc–boron/graphitic carbon nitride as the positive electrode and BiVO4-immobilized nitrogen-doped defective carbon as the negative electrode for asymmetric capacitors. ACS Appl Nano Mater 4:14258–14273

Yan M, Yao Y, Wen J, Long L, Kong M, Zhang G, Liao X, Yin G, Huang Z (2016) Construction of a hierarchical NiCo2S4@PPy core−shell heterostructure nanotube array on Ni foam for a high-performance asymmetric supercapacitor. ACS Appl Mater Interfaces 8:24525–24535

Fu F, Wang H, Yang D, Qiu X, Li Z, Qin Y (2022) Lamellar hierarchical lignin-derived porous carbon activating the capacitive property of polyaniline for high-performance supercapacitors. J Colloid Interface Sci 617:694–703

Shinde NM, Xia QX, Yun JM, Mane RS, Kim KH (2018) Polycrystalline and mesoporous 3-D Bi2O3 nanostructured negatrodes for high-energy and power-asymmetric supercapacitors: superfast room-temperature direct wet chemical growth. ACS Appl Mater Interfaces 10:11037–11047

Kim SJ, Sharma V, Kshetri T, Kim NH, Lee JH (2022) Freestanding binder-free electrodes with nanodisk-needle-like MnCuCo-LTH and Mn1Fe2S2 porous microthorns for high-performance quasi-solid-state supercapacitors. ACS Appl Mater Interfaces 14:12523−12537

Xie D, Su Q, Dong Z, Zhang J, Du G (2013) L-cysteine-assisted preparation of porous NiO hollow microspheres with enhanced performance for lithium storage. CrystEngComm 15:8314–8319

Wang Y, Zhu Q, Zhang H (2005) Fabrication of β-Ni(OH)2 and NiO hollow spheres by a facile template-free process. Chem Commun 5231–5233

Ding R, Chen Q, Luo Q, Zhou L, Wang Y, Zhang Y, Fan G (2020) Salt template-assisted in situ construction of Ru nanoclusters and porous carbon: excellent catalysts toward hydrogen evolution, ammonia-borane hydrolysis, and 4-nitrophenol reduction. Green Chem 22:835–842

Tong G, Yuan J, Wu W, Hu Q, Qian H, Li L, Shen J (2012) Flower-like Co superstructures: morphology and phase evolution mechanism and novel microwave electromagnetic characteristics. CrystEngComm 14:2071–2079

Li B, Liu M, Zhong W, Xu J, Zhang X, Zhang X, Zhang X, Chen Y (2021) Partially contacted NixSy@N, S-codoped carbon yolk-shelled structures for efficient microwave absorption. Carbon 182:276–286

Khalafallah D, Zhi M, Hong Z (2019) Shape-dependent electrocatalytic activity of carbon reinforced Ni2P hybrids toward urea electrocatalysis. Energy Technol 7:1900548

Khalafallah D, Ouyang C, Zhi M, Hong Z (2020) Synthesis of porous Ag2S−NiCo2S4 hollow architecture as effective electrode material with high capacitive performances. Nanotechnology 31:475401

Wu S, Hui KS, Hui KN, Kim KH (2017) Electrostatic-induced assembly of graphene-encapsulated carbon@nickel−aluminum layered double hydroxide core−shell spheres hybrid structure for high-energy and high-power-density asymmetric supercapacitor. ACS Appl Mater Interfaces 9:1395–1406

Zou J, Xie D, Zhao F, Wu H, Niu Y, Li Z, Zou Q, Deng F, Zhang Q, Zeng X (2021) Microwave rapid synthesis of nickel cobalt sulfides/CNTs composites as superior cycling ability electrode materials for supercapacitors. J Mater Sci 56:1561–1576

Li C, Balamurugan J, Nguyen DC, Kim NH, Lee JH (2020) Hierarchical manganese-nickel sulfide nanosheet arrays as an advanced electrode for all-solid-state asymmetric supercapacitors. ACS Appl Mater Interfaces 12:21505–21514

Xu R, Xu D, Zeng Z, Liu D (2022) CoFe2O4/porous carbon nanosheet composites for broadband microwave absorption. Chem Eng J 427:130796

Qin Y, Xue C, Yu H, Wen Y, Zhang L, Li Y (2021) The construction of bio-inspired hierarchically porous graphene aerogel for efficiently organic pollutants absorption. J Hazard Mater 419:126441

Cheng C, Shi J, Wen L, Dong C-L, Huang Y-C, Zhang Y, Zong S, Diao Z, Shen S, Guo L (2021) Disordered nitrogen-defect-rich porous carbon nitride photocatalyst for highly efficient H2 evolution under visible-light irradiation. Carbon 181:193–203

Chen G, Zhu Z, Liu H, Wu Y, Zhu C (2013) Preparation of SiO2 coated Ce2S3 red pigment with improved thermal stability. J Rare Earth 31:891–896

Rahman MM, Ahmed J, Asiri AM (2017) A glassy carbon electrode modified with γ-Ce2S3-decorated CNT nanocomposites for uric acid sensor development: a real sample analysis. RSC Adv 7:14649–14659

Bera S, Ghosh S, Basu RN (2018) Fabrication of Bi2S3/ZnO heterostructures: an excellent photocatalyst for visible-light-driven hydrogen generation and photoelectrochemical properties. New J Chem 42:541–554

Wang L, Meng F, Li K, Lu F (2013) Characterization and optical properties of pole-like nano-CeO2 synthesized by a facile hydro-thermal method. Appl Surf Sci 286:269–272

Gong J, Meng F, Yang X, Fan Z, Li H (2016) Controlled hydrothermal synthesis of triangular CeO2 nanosheets and their formation mechanism and optical properties. J Alloys Compd 689(2016):606–616

Khalafallah D, Wu Z, Zhi M, Hong Z (2020) Rational designing of porous structured nickel manganese sulfides hexagonal sheets-in-cage structures as an advanced electrode material for high-performance electrochemical capacitors. Chem Eur J 26:2251–2262

Khalafallah D, Miao J, Zhi M, Hong Z (2021) Structuring graphene quantum dots anchored CuO for high-performance hybrid supercapacitors. J Taiwan Inst Chem Eng 122:168–175

Malak-Polaczyk A, Vix-Guterl C, Frackowiak E (2010) Carbon/layered double hydroxide (LDH) composites for supercapacitor application. Energy Fuel 24:3346–3351

Ma CJ, Chen Y, Zhu C, Chen Q, Song W-L, Jiao S, Chen H, Fang D (2019) Bismuth ferrite: an abnormal perovskite with electrochemical extraction of ions from A site. J Mater Chem A 7:12176–12190

Khalafallah D, Huang W, Wunn M, Zhi M, Hong Z (2022) Promoting the energy storage capability via selenium-enriched nickel bismuth selenide/graphite composites as the positive and negative electrodes. J Energy Storage 45:103716

Shinde NM, Xia QX, Yun JM, Singh S, Mane RS, Kim K-H (2017) A binder-free wet chemical synthesis approach to decorate nanoflowers of bismuth oxide on Ni-foam for fabricating laboratory scale potential pencil-type asymmetric supercapacitor device. Dalton Trans 46:6601–6611

Wang SX, Jin CC, Qian WJ (2014) Bi2O3 with activated carbon composite as a supercapacitor electrode. J Alloys Compd 15:12–17

Acknowledgements

We fully appreciate the financial supports from the National Key Research and Development Program (Grant No. 2016YFB0901600), Zhejiang Provincial Natural Science Foundation of China (Grant No. LY19E020014), and the National Natural Science Foundation of China (NSFC, Grant No. 21303162 & Grant No. 11604295). The authors also acknowledge the financial support of the Academy of Scientific Research and Technology, Egypt (Grant No. 6568).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ahmed, F.B.M., Khalafallah, D., Zhi, M. et al. Porous nanoframes of sulfurized NiAl layered double hydroxides and ternary bismuth cerium sulfide for supercapacitor electrodes. Adv Compos Hybrid Mater 5, 2500–2514 (2022). https://doi.org/10.1007/s42114-022-00496-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-022-00496-1