Abstract

Tall and erect chickpea cultivar HC 5 (Haryana Chana 5) was primarily bred for inter-cropping with autumn planted sugarcane. Cultivar HC 5 is distinctly different in morphology from traditional bushy or semi-spreading chickpea cultivars and it is found suitable for machine harvesting. However, a general recommended planting density (30 cm × 10 cm) is being followed for cv. HC 5 as well. In this study, we hypothesized that high-density planting can improve crop productivity and also improve the plant architecture for mechanical harvesting. To test this hypothesis, four plant spacing treatments (30 cm × 10 cm, 30 cm × 7.5 cm, 22.5 cm × 10 cm, and 22.5 cm × 7.5 cm) were evaluated in two chickpea cultivars (HC 5 and JAKI 9218) for crop growth, grain yield and the desirable plant traits for mechanical harvesting. The highest grain yield of cv. HC 5 was observed with 22.5 cm × 10 cm spacing that increased the grain yield by 9% (p < 0.05) over plant spacing of 30 cm × 10 cm (conventional); this indicates that high-density planting could increase the productivity of the cv. HC 5. Where grain yield of cv. JAKI 9218 was reduced (p < 0.05) with the increase in planting density over 30 cm × 10 cm. Increased grain yield of cv. HC 5 with 22.5 cm × 10 cm spacing over 30 cm × 10 cm was mainly attributed to increase in plant density (33%); however, all the plant attributes (primary branch, secondary branch, pod plant−1) were reduced as compared to plant spacing of 30 cm × 10 cm. The decrease in intra-row spacing of cv. HC 5 resulted in a strong adverse effect on plant growth and yield parameters as compared to inter-row spacing and thus not recommended. High-density planting increased the plant height (erectness) and ground clearance of cv. HC 5 (height of first pod) (~ 30 cm), an essential prerequisite for mechanical harvesting, but not in cv. JAKI 9218. Hence, cv. HC 5 requires a dense planting for higher yield and appropriate plant structure for mechanical harvesting. Therefore, it is recommended to work out the optimum planting geometry/plant population to realize the potential yield of cultivars bred for mechanical harvesting.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Chickpea is the most important pulse crop in India covers an area of 10.2 mha with a production of 11.2 mt and contributing about 44.5% (2017–2018) to the national pulses basket (DES 2018; http://agricoop.gov.in/sites/default/files/pulses_oct.pdf). Mechanization in chickpea farming is important for reducing production cost and to ensure timely operation (Haddad et al. 1988). Chickpea is harvested manually in the Middle East, North Africa, South and West Asian countries (Chaturvedi et al. 2014). Where, mechanical harvesting of pulse crops is extensively being practiced in countries like USA, Canada, and Australia (Siddique and Sykes 1997). Although India is the leading producer of chickpea in the world, the crop is mostly harvested manually. In India, labour cost is continuously increasing and manual harvesting has become an expensive and time taking field operation.

In chickpea, erectness and first pod height from ground (ground clearance) are two important traits that primarily decide a cultivar choice for mechanical harvesting (Chaturvedi et al. 2014). Mostly, Indian chickpea cultivars are semi-spreading and have low ground clearance, and thus, not suitable for mechanical harvesting. The harvest loss during machine harvest is higher for semi-erect genotype (~ 20%) and low in tall and erect genotypes (2.6–5.0%) (Haddad et al. 1988). To date, mechanical harvesting of rice and wheat is being widely adopted in India. Likewise, there is a large demand from farmers’ for chickpea cultivars that can be directly harvested by combine harvesters (Daheriya 2014). To date, very few Indian chickpea cultivars are suitable for mechanical harvesting (Chaturvedi et al. 2014). Therefore, a great effort is now being directed towards the development of chickpea cultivars that are suitable for mechanical harvesting (Patil 2013; Daheriya 2014).

Haryana Chana 5 (HC 5) is a tall, erect, low biomass cultivar having a moderate tolerance to lodging, and therefore, suitable for mechanical harvesting (Basha et al. 2018). Despite having the contrasting plant architecture, similar agronomic management is being followed as in case of bushy and semi-spreading cultivars. Therefore, agronomic practices need to be standardized for the cultivar suitable for mechanical harvesting. It is expected that high-density planting of tall and erect and low biomass cv. HC 5 may further increase the crop productivity. However, the response of the cv. HC 5 to high-density planting has not been evaluated. Meantime, the changes in plant architecture with high-density planting may further alter the some of the plant traits like plant height and ground clearance (first pod height) which are prerequisite traits for mechanical harvesting that also needs to be studied.

Given that, a field experiment conducted for two consecutive years to optimize the planting geometry for the cv. HC 5 having plant architecture suitable for mechanical harvesting. A spreading type of cv. JAKI 9218 was also taken for comparative assessment of cultivars response to variable planting geometry/plant populations. In this study, four combinations of inter-row spacing (30 cm and 22.5 cm) and intra-row spacing (10 cm and 7.5 cm) were evaluated. We hypothesized that (1) high-density planting increases productivity of cv. HC 5, (2) high-density planting increases plant height (erectness) and ground clearance in cv. HC 5 (distance between ground and lower pod), and (3) changes in inter-row and intra-row (plant to plant) spacing has variable impact on crop growth and productivity.

Materials and Methods

Site Characteristics

The field experiment was conducted in two consecutive years (2015–2016 and 2016–2017) at the new research centre of ICAR-Indian Institute of Pulses Research, Kanpur, India (26°46′N, 80°35′E, 126 m above mean sea level). The experimental site falls in the Indo-Gangetic Plains with alluvial soil [Inceptisols (Typic Ustochrept)]. Climate of the region is tropical sub-humid. The monthly mean annual maximum and minimum temperatures of Kanpur are 33 and 20 °C, respectively and average annual rainfall of the region is 722 mm. The monthly weather variables during the crop seasons are presented in Fig. 1. The experimental field was well-drained having sandy-loam soil texture with pH 8.31–8.42, electrical conductivity 0.26–0.29 dS m−1 (non-saline), low in available nitrogen (N) (215–227 kg ha−1), medium in available phosphorus (P) (15–17 kg ha−1), available potassium (K) (167–177 kg ha−1) and available sulphur (S) (10.9–12.3 kg ha−1). The soil was also low in DTPA-extractable zinc (0.38–0.46 ppm) and iron (2.74–3.35 ppm).

Treatment Detail, Experimental Design and Crop Management

The field experiment was set up in factorial randomized block design with three replications. Treatments consist of two chickpea cultivars (JAKI 9218 and HC 5) and four levels of plant geometry treatments 30 cm × 10 cm (3,33,333 plants ha−1), 30 cm × 7.5 cm (4,44,444 plants ha−1), 22.5 cm × 10 cm (4,44,444 plants ha−1) and 22.5 cm × 7.5 cm (5,92,593 plants ha−1). The dimension of main-plot and sub-plot were 400 m2 and 100 m2, respectively. General characteristics of the selected cultivars (JAKI 9218 and HC 5) are given in Table 1. Chickpea crop was sown on 12th November in 2015 and 15th November in 2016, respectively. Before sowing, seeds were treated with phosphate solubilizing bacteria (Bacillus polymaxa) and Rhizobium at 20 g kg−1 seed) and Trichoderma at 5 g kg−1 seed. Irrespective of the cultivar, recommended fertilizer dose of N (20 kg N ha−1), P (50 kg P2O5 ha−1), K (40 kg K2O ha−1), S (20 kg S ha−1) and Zn (5 kg Zn ha−1) was supplied to the crop as basal dose through urea di-ammonium phosphate, muriate of potash, elemental sulphur, and zinc sulphate, respectively. Gap filling and thinning operations were carried out wherever necessary to maintain the optimum plant population of chickpea in each plot as per crop geometry treatment. Two irrigations (5 ha-cm each) were given to crop at pre-flowering and pod developmental stages. Weeds were controlled by pre-emergence application of pendimethalin at 1.0 kg a.i. ha−1 and one hand weeding at 40 days after sowing to keep the crop weed-free. Crop duration was the same for both the cultivars and both the cultivars were harvested in the last week of March in both the years.

Observations on Crop Parameters

At the physiological maturity stage, twenty chickpea plants were randomly sampled from each plot to take observations on plant height, number of primary branches, number of secondary branches and pod length. The observations like pods plant−1 and grains pod−1 were also recorded from these selected plants. For each chickpea plant, the height of first pod (the lowest pod) was measured. After completion of all the observations, the aboveground plant parts were oven dried at 60 °C for 48 h for estimation plant aboveground dry weight. For estimation of grain and stover yield a net plot area of 52.6 m2 was harvested separately. The harvested produce was sun-dried before recording its biomass and then threshed manually (plot-wise). Grain and stover yields were also recorded from each net plot after threshing. Stover yield was obtained by subtracting grain yield from total biomass yield (biological yield). From each plot, three samples of 100 grains were taken and recorded the weight of 100-grain weight. Harvest index (HI) was calculated using the following formula:

In the second year of experiment, a separate strip of cv. HC 5 was grown with a plant spacing of 22.5 cm × 10 cm and harvested through combine harvester to observe the efficiency of machine harvesting and to record seed loss during harvesting.

Harvesting and Threshing Efficiency

Shattering loss of chickpea grains during harvesting was measured for cv. HC 5 in 100 m2 area and expressed the shattering loss in kg ha−1. For machine harvesting (Fig. 2), the threshing efficiency is the amount net threshed grain (kg) received at main outlet to the amount of total grain input (kg) and expressed as percentage (Smith et al. 1994):

Likewise, for manual threshing, the threshing efficiency was calculated by the ratio of total amount of threshed grains to total grain input (kg) and expressed as percentage. For grain damage assessment, three samples of hundred grains were randomly taken from the separated grain sample and manually checked for signs of fissure. The percentage damaged/broken grain was then calculated as follows:

For machine harvesting, all whole, broken and un-threshed grains from sieve and chaff outlets were collected and weight recorded. Scattered and blown grains were recovered by sweeping and gathering grains around the thresher. The percentage grain loss was calculated using Eq. (4) following the procedure outlined by Smith et al. (1994).

Cleaning efficiency is the ratio of whole grains to whole material at thresher main outlet per unit time expressed as percentage by weight and was determined using Eq. (5).

Statistical Analysis

Data were analyzed using online statistical program OPSTAT (Sheoran et al. 1998). The data were subjected to F-test following the procedure given by Gomez and Gomez (1984). Least significant difference (LSD) at α = 0.05 were used for comparison of cultivar, planting geometry and their interactions effect. Besides this, data were also analyzed Duncan multiple range test (DMRT) to compare the means of planting geometry treatments for each cultivar. Pearson correlation (r) was calculated using MS Excel 2007.

Results

Crop Growth

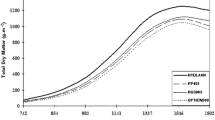

Results showed that planting geometry treatments had significant (p < 0.05) effect on crop growth as well as plant architecture in both the cultivars. Results indicated that planting density largely influenced plant height, numbers of primary branch plant−1 and secondary branch plant−1, plant aboveground biomass, and pod length (Table 2). Increasing planting density in cv. JAKI 9218 by reducing the plant spacing from 30 cm × 10 cm to 22.5 cm × 7.5 cm did not affect plant height and aboveground biomass per unit area (p > 0.05), but reduced primary branch plant−1 (20%, p < 0.05), secondary branch plant−1 (67%, p < 0.05), and pod length (8%, p < 0.05). In contrast, high density planting of cv. HC 5 (22.5 cm × 7.5 cm) increased plant height (10%, p < 0.05), aboveground biomass per unit area (23%, p < 0.05), and reduced primary branch plant−1 (27%, p < 0.05), secondary branch plant−1 (18%, p < 0.05), and pod length (2%, p > 0.05) over the plant spacing treatment 30 cm × 10 cm. Notably, high density planting had a higher negative impact on individual plant productivity in cv. JAKI 9218 over cv. HC 5.

Upon pooled analysis the effect of cultivar and planting geometry treatment was found significant (p < 0.05) on most of the plant growth and yield attributing parameters, which indicated that the treatment effect was consistent over the experimental years. The interaction of cultivar and planting geometry was found significant (p < 0.05) for aboveground biomass, primary branch plant−1, and secondary branch plant−1 (Table 3).

Yield Attributes, Grain Yield and Harvest Index (HI)

Yield attributes parameters like pod plant−1, and 100-grain weight also influenced by planting geometry treatments (Fig. 3). Reducing planting geometry from 30 cm × 10 cm to 22.5 cm × 10 cm decreased the pod plant−1 by 19% (p < 0.05) and 17% (p < 0.05) in cv. JAKI 9218 and cv. HC 5, respectively. Corresponding values of pod plant−1 for plant geometry treatment 22.5 cm × 7.5 cm were 30% (p < 0.05) and 27% (p < 0.05), respectively. In general, the 100-seed weight of cv. HC 5 was low as compared to the cv. JAKI 9218. High density planting (22.5 cm × 7.5 cm) of cv. JAKI 9218 reduced 100-seed weight by 22%, where it was only 13% for cv. HC 5. High density planting reduced (p < 0.05) the grain yield cv. JAKI 9218 and the lowest grain yield was recorded in the treatment 22.5 cm × 7.5 cm in both the years. High density planting at 22.5 cm × 7.5 cm reduced the grain yield of cv. JAKI 9218 by 25% (p < 0.05) and 35% (p < 0.05) during 2015–2016 and 2016–2017, respectively. Treatment order for grain yield of cv. HC 5 was 22.5 cm × 10 cm > 30 cm × 10 cm > 30 cm × 7.5 cm ≥ 22.5 cm × 7.5 cm (p < 0.05). High density planting of cv. HC 5 (22.5 cm × 10 cm) increased the grain yield by 9% (p < 0.05) over normal planting of 30 cm × 10 cm (Fig. 4).

Crop Architecture and Mechanical Harvesting

The height of first pod from ground (ground clearance) was measured for different plant geometry treatments in both the cultivars. The results showed that this trait can also be manipulated through increasing plant population, particularly in cv. HC 5 (Fig. 5). It was observed that the ground clearance of cv. HC 5 was ~ 25 cm in 30 cm × 10 cm, where ground clearance was further increased by 8.7 cm with increase in planting density. The effect of plant population or plant spacing on first pod height of cv. JAKI 9218 was marginal and non significant (p > 0.05). Data showed that cv. HC 5 could be efficiently harvested through combine harvester. The shattering loss of chickpea was marginal in combine harvesting and was even lower than the manual harvesting (Table 4). Threshing efficacy was comparable in combine and manual harvesting. However, grain damage was higher in combine harvesting (4.2%) over manual harvesting (1.2%). Meantime, the cleaning efficiency of combine harvesting was also found slightly low as compared to manual harvesting.

Correlations

Crop growth parameters (primary branches and secondary branches) and yield attributes (test weight, pods plant−1, pod length) had higher and significant (p < 0.05) correlations with grain yield in semi-erect type cv. JAKI 9218 (Fig. 6a). However, in erect type cv. HC 5, plant growth and yield attributes did not show significant correlations (p > 0.05) with grain yield with variable planting geometry treatments (Fig. 6b).

Correlation coefficient (r) between grain yield and different growth and yield attributing parameters in cultivar JAKI 9218 (a) and HC 5 (b). PH plant height, PB primary branch plant−1, SB secondary branch plant−1, PL pod length, AGDM aboveground dry matter, PPP pod plant−1, HGW 100-grain weight, SY straw yield. Doted lines represent the critical r value at p = 0.05

Discussion

Optimizing plant population remains crucial for higher productivity of field crops (Munirathnam et al. 2015). Optimum and required plant spacing of any crop/cultivar primarily depends on the plant architecture (branching pattern), leaf area and light interception traits of crop/cultivars, inter-plant competition for available resources (light, moisture, and nutrients) (Hazra and Chandra 2014). The present study suggests that optimum plant spacing differs in chickpea cultivars of different growth habit (erect and semi-spreading cultivars) and planting geometry strongly determined the yield level of a cultivar. High density planting of tall and erect chickpea cv. HC 5 increased productivity; where, for semi-spreading cv. JAKI 9218 optimum plant spacing was 30 cm × 10 cm and with increase in plant population grain yield of cv. JAKI 9218 was strongly reduced. This implies that cv. HC 5 have low elasticity in growth and thus the recommended plant spacing of chickpea (30 cm × 10 cm) failed to give the optimum productivity. Further, cv. HC 5 is tall and erect cultivar having less number of primary and secondary branches, and thus more number of plants could be accommodated per unit area as compared to semi-spreading cv. JAKI 9218, which have more numbers of primary and secondary branches. Meantime, aboveground biomass of cv. HC 5 was less than the cv. JAKI 9218 and thus high density planting of cv. HC 5 had an advantage on crop productivity. On the same line, Munirathnam et al. (2015) reported that grain yield of chickpea cv. NBeG47 (suitable for mechanical harvesting) could be increased by increasing the planting density from 33 plants m−2 to 55 plants m−2. According to Muehlbauer and Singh (1987), erect chickpea lines have fewer primary and secondary branches and hence fewer reproductive nodes than bushy lines, increasing the number of plants per unit area has been proposed when sowing these lines to increase their yield.

Results further demonstrate that increase in planting density reduced the growth and yield attributing parameters of individual plant in both the cultivars, being higher in cv. JAKI 9218. Notably, increase in plant population drastically reduced the pod plant−1 and 100-seed weight in cv. JAKI 9218 and thus grain yield was reduced. Where, the high density planting of cv. HC 5 increased total number of plants per unit area that compensated the reduction in plant productivity of individual plant, and that in turn resulted in higher crop productivity as compared to planting geometry of 30 cm × 10 cm. However, under variable plant spacing treatments, the correlations between grain yield and plant growth and attributes parameters were mostly non-significant in cv. HC 5. This implies that with the increase in plant population the changes in individual plant growth and yield attributes were marginal in cv. HC 5 and plant competition for resources (water, nutrient and light) was minimal.

Fundamentally, the increased biomass per unit area drastically reduced the light transmission from upper canopy to lower portion of the plant. Therefore, in spreading type high biomass cultivars, the increased biomass often resulted in reduced light transmission that directly impacting the flowering (flowers mostly appear in top of the plant). The architecture of virtual chickpea plants modified the solar light penetration inside the crop canopy, which influenced the growth and development of plants in response to different cultivars (Cici et al. 2008). On the same line, the results of this study also confirmed the fact that increases in plant population drastically reduced the number of pod plant−1 in spreading type cv. JAKI 9218. In contrast to cv. JAKI, the erect and low biomass accumulating cv. HC 5 might have higher light transmission under high density planting and yielded higher over cv. JAKI. Apart from this, the high density planting of cv. HC 5 also had suppressive effect on weeds (data not presented).

The results further demonstrate that decrease in inter-row and intra-row (plant to plant spacing within a row) spacing had a differential impact on yield attributes and yield of cv. HC 5. In fact, decrease in inter-row spacing from 30 to 22.5 cm had marginal effect on growth and yield attributes of individual plant. Where, the decrease in intra-row spacing had strongly reduced the individual plant productivity of cv. HC 5 and thus did not increase the productivity per unit area. Therefore, reduction in intra-row spacing is not recommended for cv. HC 5.

The ground clearance is an important trait of a cultivar for mechanical harvesting. The height of first podding node is much lower in case JAKI 9218, beside semi-spreading habit, which could not be recommended suitable for mechanical harvesting (IIPR 2014–2015). In fact a higher ground clearance increased the mechanical harvester efficiency and reduced the loss through shattering and non-harvested remnants in field. In general, increase in planting density of cv. HC 5 resulted in taller plants due to competition for light sources. Thus, high density planting increased the plant height and also increased ground clearance for machine harvesting. It again confirms that chickpea cv. HC 5 is suitable for mechanical harvesting, as sufficient ground clearance is available for combine harvesting. Similarly Munirathnam et al. (2015) also demonstrated the effect of crop geometry on first podding node, which led to mechanical harvesting of chickpea. The data on harvesting and threshing efficiencies also supported the fact. Shattering loss was slightly higher in combine harvesting over manual harvesting. However, there is need to improve/calibrate the machine for higher cleaning efficiency and to reduce the grain damage loss. The sieve loss and separation loss were noticeably low. Very recently, NBeG 47—a desi chickpea line with semi-erect growth habit was found promising and suitable for mechanical harvesting and has been released for large scale cultivation in Andhra Pradesh, India (ICRISAT 2017). From this study, it is suggested to work on the optimum planting geometry for the chickpea cultivars developed for mechanical harvesting. High density planting could improve the productivity of these cultivars because of the distinct morphological characters (erect, less branching, and low biomass).

Conclusion

Thus, it is concluded that high density planting of cv. HC 5 could increase the productivity as well as improve plant architecture for machine harvesting but not for semi spreading cultivar JAKI 9218. Study further suggests that plant population of cv. HC 5 should be increased by decreasing the inter-row spacing (from 30 to 22.5 cm) than by reducing the intra–row spacing (plant to plant spacing). Reduction of intra-row spacing increased the plant competition for resources that subsequently decreased the productivity of individual plant. High density planting of cv. HC 5 resulted in erect plants and increased ground clearance (> 30 cm), as essential prerequisite for mechanical harvesting. Hence, chickpea cv. HC 5 requires a dense planting for higher yield and appropriate plant structure for mechanical harvesting. To this end, it is highly recommended to work out the yield potential of the cultivars bred for mechanical harvesting with optimum planting geometry.

References

Basha, S. J., Lakshmi, V. J., Reddy, A. T., Kamakshi, N., & Ahammed, S. K. (2018). Estimate of growth and yield parameters of chickpea (Cicer arietinum L.) cultivars amenable to mechanical harvesting. Journal of Pharmacognosy and Phytochemistry, 7(5), 2089–2091.

Chaturvedi, S. K., Mishra, N., & Gaur, P. M. (2014). An overview of chickpea breeding programs in India: Legume perspectives. The Journal of the International Legume Society (Spain), 3, 50–52.

Cici, S. Z. H., Adkins, S., & Hanan, J. (2008). A canopy architectural model to study the competitive ability of chickpea with sowthistle. Annals of Botany, 101(9), 1311–1318.

Daheriya, M. (2014). Evaluation of chickpea genotypes suitable for mechanical harvesting. M.Sc. thesis submitted to the Jawaharlal Nehru Krishi Vishwa Vidyalaya, Jabalpur, India.

DES, (2018). Directorate of Economics & Statistics, Department of Agriculture, Farmers Welfare and Cooperation, Ministry of Agriculture and Farmers Welfare, Government of India. https://eands.dacnet.nic.in/APY_96_To_06.htm. Accessed Aug 2018.

Gomez, K. A., & Gomez, A. A. (1984). Statistical procedures for agricultural research (2nd ed.). Singapore: Wiley.

Haddad, N. I., Salkini, A. B., Jagatheeswaran, P., & Snobar, B. A. (1988). Method of harvesting pulse crops. In R. J. Summerfield (Ed.), World crops: Cool season food legumes (pp. 341–350). Dordrecht: Kluwer Academic Publishers. https://doi.org/10.1007/978-94-009-2764-3.

Hazra, K. K., & Chandra, S. (2014). Mild to prolonged stress increased rice tillering and source-to-sink nutrient translocation under SRI management. Paddy and Water Environment, 12(1), 245–250.

ICRISAT, (2017). First machine harvestable chickpea variety-Boon for farmers in Andhra Pradesh, India. Retrieved November 12, 2017, http://www.icrisat.org/first–machine–harvestable–chickpea–variety–boon–for–farmers–in–andhra–pradesh–india.

IIPR, (2014–2015). Annual Report, ICAR–Indian Institute of Pulses Research, Kanpur, Pradesh, pp. 24–32.

Muehlbauer, F. J., & Singh, K. B. (1987). Genetics of chickpea. In M. C. Saxena & K. B. Singh (Eds.), The Chickpea (pp. 99–125). Wallingford, UK: CAB. International.

Munirathnam, P., Jayalakshmi, V., Kumar, K. A., & Padmalatha, Y. (2015). Suitability of chickpea ‘NBeG47’ for mechanical harvesting under rainfed condition. Journal of Food Legumes, 28(2), 64–66.

Patil, S. B. (2013). Agronomic investigations on tall chickpea genotypes suitable for mechanical harvesting. Ph.D. thesis submitted to the University of Agricultural Sciences, Dharwad, India.

Sheoran, O. P., Tonk, D. S., Kaushik, L. S., Hasija, R. C., & Pannu, R. S. (1998). Statistical software package for agricultural research workers. In D. S. Hooda & R. C. Hasija (Eds.), Recent advances in information theory, statistics and computer applications (pp. 139–143). Hisar: CCS HAU.

Siddique, K. H. M., & Sykes, J. (1997). Pulse production in Australia past, present and future. Australian Journal of Experimental Agriculture, 37(1), 103–111.

Smith, D. W., Sims, B. G., & O’Neill, D. H. (1994). Testing and evaluation of agricultural machinery and equipment: Principles and practices. Rome: Food and Agriculture Organisation.

Acknowledgements

The authors acknowledge the financial support received from Department of Agricultural Cooperation & Farmers Welfare, Ministry of Agriculture and Farmers Welfare, Government of India under the National Food Security Mission project ‘Developing chickpea cultivars suited to mechanical harvesting and tolerant to herbicides’.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Singh, U., Gaur, P.M., Chaturvedi, S.K. et al. Changing Plant Architecture and Density can Increase Chickpea Productivity and Facilitate for Mechanical Harvesting. Int. J. Plant Prod. 13, 193–202 (2019). https://doi.org/10.1007/s42106-019-00047-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42106-019-00047-7