Abstract

The present paper discusses terminological and technological issues related to prominent stone artifacts of the Middle Paleolithic. The Keilmesser with tranchet blow in focus can be described as asymmetrical (mostly bifacial) knives with a back, whose active edge has been shaped by a modification called tranchet blow (Fr. coup de tranchet, Ger. Schneidenschlag) in such a way that a straight, stable, small-angled cutting edge is formed. With regard to the spatial and chronological setting, this paper focuses on Western and Central European assemblages from the late Middle Paleolithic. Referring to earlier contributions, the difficulty of these artifacts lies not only in their recognition and analysis, but also in the disparate terminology underlying other studies. Therefore, this work represents an attempt to propose a uniform terminology in order to enable the comparison of these remarkable lithic artifacts within different assemblages. Furthermore, we offer a precise description of the pieces with regard to their technological differentiation from pieces with supposedly similar modifications. This study is an attempt to use technological aspects to further develop a tool concept that reflects the flexibility and conceptual fidelity in the production of Keilmesser with tranchet blow. The decisive factor for this concept is its great dynamic, since the equifinal property of the tranchet blow can be achieved flexibly via different production paths.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

One of the most important aspects in the analysis of lithic objects is to ensure that a comparison across assemblages is possible. This comparison is sometimes considerably complicated by disparate approaches to lithic objects or technological aspects. This issue was vividly illustrated by Koehler (2009, 2011a, b), who analyzed assemblages from the Paris Basin and concluded that within different scales of analysis, the similarities or differences appear. At first glance, this may seem banal, but when we see the various assemblages used for comparison purposes that have been evaluated by different analysts, it seems highly relevant to develop a common analytical language for evaluation that allows inter-site comparisons. This contribution does not presume to produce generally applicable guidelines for this purpose, but would like to enrich the discussion on stone artifacts in order to ensure the comparability of technological phenomena between sites and, at its best, on different regional scales.

To this end, it is important to create a consensus in terminology. The increasing technological analysis of lithic objects since the 1980s has created an apparatus not only to use the shape of the lithic objects as a classification criterion, but also to take into account the method of manufacture, the use and certain technologically relevant features. To describe these aspects, it makes sense to develop a common analytical language. Years ago, attempts were already being made to provide practicable terminology across language boundaries (e.g., Tixier et al. 1980; Inizan et al. 1993; Inizan et al. 1995, 1999; Kozłowski 1967; Toepfer 1968; Schwabedissen 1972). Concerning the example of Keilmesser with tranchet blow, the sometimes divergent terminology in the course of research history has recently been highlighted (Frick et al. 2017b).

In addition to the naming of lithic objects or distinguishable parts thereof, it is essential to analyze technological production patterns in the most precise way rather than building up a new typology on the basis of morphological characteristics. The inherent idea is that there are technical and technological elements a Paleolithic producer must know and take into account in order to achieve the desired result, regardless of the nomenclature we use today. The shape of surfaces and edges predetermines the shape of the desired negative or blank. This predetermination is the linchpin of any lithic reduction (see also Boëda 2013; Shimelmitz and Kuhn 2018; Frick and Herkert 2014). Similar to sculpture, not only the finished or desired piece must be seen in the matrix as a three-dimensional object (in the sense of Frick 2016b: 281–282), but also the way to achieve this must be recognized by means of technical and technological knowledge.

We have made it our task to bring together and evaluate the data collected in recent decades on the production of these enigmatic Keilmesser with tranchet blow and to describe them using a uniform terminology so that inter-site comparisons can be made. Thus, this contribution aims to discuss terminological and technological criteria that are considered necessary as a background for understanding the tranchet blow phenomenon, which will be aproached mainly related to late Middle Paleolithic Keilmessser assemblages. Furthermore, we show the differences between this and similar reduction concepts. We will discuss various aspects of its production, where only the morphology of certain parts of the matrix are relevant, instead of the matrix as a whole. Thus, it can be demonstrated that, regardless of the matrix or its three-dimensional shape and due to interchangeable working stages, the same goal can be achieved, hence demonstrating the flexibility and the conceptual fidelity in production.

Short Research History

Although lithic pieces that we would now call Keilmesser with tranchet blow were discovered as early as 1868 during one of the first Paleolithic excavations in Saône-et-Loire, France (Méray 1869), these pieces became the focus of research 100 years later (Desbrosse and Texier 1973b; Desbrosse et al. 1976). In the course of the first excavations conducted at the site of Grotte de Germolles (today called Grotte de la Verpillière I; see Fig. 1), three of the relevant stone artifacts were identified and described in the second half of the nineteenth century. In a report on the excavations carried out in 1868, Méray depicted them and described one of them with the following words (Méray 1876: 262–263):

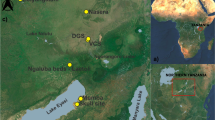

Assemblages and sites mentioned in the text (listed in order they are mentioned): (1) Forecourt at Grotte de la Verpillière I (Frick et al. 2017c; Gros and Gros 2005; Frick and Floss 2017; Desbrosse et al. 1976); (2) Upper site layer IIIb and lower site layer 4, 5b and below 8 at Buhlen (Bosinski 1969; Jöris 1993b, 1994, 2001; Fiedler 2009); (3) almost in all layers at Ciemna (Valde-Nowak et al. 2014; Sudoł 2014; Valde-Nowak et al. 2016b; Valde-Nowak et al. 2016a; Alex et al. 2017); (4) layers 5, 6, 7/8 at Wylotne (Kozłowski 2006); (5) Mesvin IV (Soriano 2000, 2001); (6) layers 3, 5, 7, A, B, C and H-D at La Cotte de Saint Brelade (Callow and Cornford 1986; Bates et al. 2013; Scott et al. 2014; Shaw et al. 2016); (7) layer B1 at Rheindahlen (Schmitz and Thissen 1998; Thissen 2006); (8) GU5/AU3 at Abri du Musée (Bourguignon 1992; Coudenneau 2005; Frick submitted); (9) Obere Klause (Uthmeier 2004); (10) Sablière Seuron at the Mont du Beuvry in Béthune (Marcy 1991; Urbanowski 2003); (11) Balver Höhle (Jöris 1992, 1993a; Schunk 2017); (12) Grotte de la Verpillière II (Frick 2016a, b; Frick and Floss 2017); (13) La Roche in Saint-Martin-sous-Montaigu (Herkert et al. 2015; Herkert 2016, in prep.; Pouliquen 1982); (14) La Clôsure in Bissy-sur-Fley (Daudey and Bonnot 1970; Desbrosse and Texier 1973a; Farizy 1995a; Schiller 2018; Gros and Gros 2005); (15) Rue Cataux in Chenôves (Guillard 1959, 1960; Gros and Gros 2005); (16) Vogelherd (Desbrosse et al. 1976); (17) Hohle Stein bei Schambach (Desbrosse et al. 1976); (18) Kulna (Desbrosse et al. 1976); (19) Okiennik (Desbrosse et al. 1976); (20) Pouch-Terrassenpfeiler (Weiss 2015; Weiss et al. 2018; Weiss 2019); and (21) Le Dessous de Bailly in Champlost (Gouédo 1999; Lhomme 2000; Vassilogamvrou 1984; Farizy 1985, 1988, 1995b). The sites are marked on a topographic map of Western and Central Europe with a sea level 80 m below today’s level. Base map: temporalmapping.org layer in Google Earth Pro (downloaded in 2015), modification and drawings by J. A. Frick

“Ils devaient servir à découper les peaux ; l’un d’entre eux , privé de son manche , a la forme d’une véritable serpe coupant dessus et dessous […]” [They were used to cut skins; one of them, deprived of his handle, has the form of a true billhook cutting on and under …].

Méray made no reference to the manufacture of the tools or the special modification of the cutting edge. Only the shape and the intended use of the pieces were at the center of his description. Until they were revised in the 1970s by R. Desbrosse and his colleagues, these bifacially processed pieces had no impact on the literature. Before these works, pieces with tranchet blow from the European Middle Paleolithic were known only from Central European contexts. Until the beginning of the 1970s, research only knew of three sites with this phenomenon: Buhlen in Germany (Bosinski 1969), Ciemna (Kowalski 1967), and Wylotne (Chmielewski 1969) in Poland. Desbrosse’s work made it possible to add the Grotte de la Verpillière in the mid 1970s (Desbrosse and Texier 1973b; Desbrosse et al. 1976). However, we must note that these typological contributions regarded the tranchet blow as a subordinate classification criterion, while their morphology was the primary focus of the reflections. This was only to change in the course of the 1990s with the aid of technological criteria (Jöris 1992, 1993b; Richter 1997), and thus, the number of assemblages with tranchet blow presence has steadily increased over the last 20 years, allowing this phenomenon to be studied increasingly in its spatial distribution and chronological time range.

This paper discusses assemblages with evidence of tranchet blow performance from Western and Central Europe, but mainly focuses on sites from the Saône-et-Loire Department (Bourgogne-Franche-Comté Region, France). For comparison purposes, however, other sites from Western and Central Europe are also included in these considerations. In chronological terms, we are referring on the late Middle Paleolithic (MIS 5d to early MIS 3).

Terminological and Technological Delimitation

Circumferential Edges and Techno-Functional Units

At the beginning of the 1970s, Kozłowski (1972) compared the terminology of Krukowski (1939–1948) and Chmielewski (1969) to parts of a Pradnik knife (knife of the Prądnik type). Krukowski distinguished four parts (working edge, apex or beak, obtuse end, and part near the apex) and Chmielewski put the focus on other aspects (Retouch, bord droit, bord arqué, and talons). Kozłowski (1972: 462) summarizes both views and describes the following parts: working edge (kind of working and shape), apex, obtuse end, back, and base. In more recent contributions, almost the same parts are described, so Jöris (1993b: 81) speaks of the following parts: working edge with Pradnik cutting edge (Arbeitskante mit Pradnik-Schneide), bow (Bogen), back (Rücken), base (Basis), distal end (Distalende), and striking platform for tranchet blow (Schlagfläche für Schneidenschlag). This terminology was only slightly modified by him in subsequent contributions (see Fig. 2c). For example, he used the term distal posterior part as equivalent for the bow (Jöris 2006). The terminology used in this paper is quite similar: active edge with tranchet blow, bow, back, base, terminal end, and truncation (see Fig. 2a). The surface called the top side (T) is generally more convex than the flatter bottom side (B), whereby the tranchet blow is usually produced on the top side.

Comparison of approaches to describe outer edges and techno-functional units of Keilmesser with tranchet blow; a combined approach in English terminology of volume and edge sections (Frick et al. 2017b, c); b techno-functional approach (taken from Soriano 2001); c German terminology for a Keilmesser with tranchet blow, as used by Jöris (2001: 33, Abb. 4.1.1); and d possible contact zone for the hand and modifications that may have been made for gripping, according to Bourguignon (1992: 79, planche no 1). Drawings and compilation by J. A. Frick

If a techno-functional approach is used, a KMTB consists of a prehensile part which includes the volume of the back and the base as the handle for the palm and thumb, a transmission part (a volume on the bow on which a finger (often the index finger) can press and the transformation part, which provides the cutting edge (active edge). This corresponds approximately to Soriano’s (2001) approach, which assigns the edges and adjacent volumes to three techno-functional units (see Fig. 2b). In addition to the position of the edges for handling, Bourguignon (1992) also recognized concave areas, which also have to be considered for force transmission with a finger and coordination (see Fig. 2d). For a direct comparison, these approaches are shown in Fig. 2.

Why Use the Term Tranchet Blow?

The reason for using the term tranchet blow is based on the fact that it is a direct (literal) translation of the terms coup de tranchet (Fr.) and Schneidenschlag (Ger.). These terms are therefore compatible with each other and are also translated by Inizan et al. (Inizan et al. 1993; Inizan et al. 1995, 1999) in this way as well. Already in the 1970s, a distinction was made between lateral and transversal tranchet blow (Zuate y Zuber 1972; Desbrosse et al. 1976). The terms tranchet blow and coup du (sic!) tranchet were already used in the 1920s in an archeological context. The earliest known use of the term coup du tranchet is found in Octobon (1922) in a late Mesolithic context (Tardenoisien). He introduced the term coup du tranchet into stone age research in making a bipartition between le tranches à coups du tranchet and le tranchet banal. For him, the edge is sometimes created before the tool specialization (Octobon 1922: 70):

“Leur tranchant est tantôt créé avant la spécialisation de l’outil, tantôt obtenu spécialement par l’enlèvement d’un éclat oblique par un « coup du tranchet » d’après une -technique rappelant celle du « coup du burin ».” [its cutting edge is sometimes formed before the specification of the tool, sometimes specially achieved by reduction of an inclined flake by means of a tranchet blow, which is a reminiscent of the burin technique].

Thus, a distinction has already been made between tranchet blow and burin blow. Shortly thereafter, Krukowski (1924) described material from his excavations at Ciemna and used the term burin (Pol. rylców) to describe special negatives on artifacts. The English variant, the tranchet blow, was used as a term the following year in a Neolithic and Chellean context (Moir 1925).

Early use and the possibility of direct translation are the decisive reasons for us to use these terms.

However, other terms were used to describe the tranchet blow, which are briefly discussed here (in detail, this can be read in Frick et al. 2017b). We refer to the terms Prądnik (scraper, implement, technique, method) and Ciemna which are closely related to the lateral tranchet blow phenomenon. In Polish literature, the term Prądnik was used, beginning with Krukowski (1939–1948), for a special type of knife, which could have been made with or without a tranchet blow (e.g., Kowalski 1967; Chmielewski 1969). Bosinski (1967) narrowed the term Prądnik to a special type of Keilmesser (Pradnikmesser). Familiar with the fact that both Keilmesser with and without tranchet blow and various shapes were given the term Prądnik, Kozłowski and Kozłowski (1977) proposed to name only the pieces with tranchet blow Prądnik knives. However, pieces without tranchet blow were called Ciemna knives. The fact is remarkable that Sobczyk (1994) proposed to name the pieces in exactly the opposite way. With reference to Kozłowski and Kozłowski (1977), Richter (1997) used the term Ciemna for a special Keilmesser shape which was provided with the addition of tranchet blow (mit Schneidenschlag). To avoid these nomenclatural differences, Jöris (2001, 2003, 2012, 1992, 1993b, 2002) uses the term Prądnik technique or method for what we call tranchet blow, but is aware of the problem that the term Prądnik was often used as synonym for bifacial backed knives (Jöris 2006). Therefore, he uses the term Keilmesser as a neutral reference to the coarse form and the supposed function, and being aware that the tranchet blow was also applied to semi-bifacial or unifacial scrapers (Jöris 2001).

The approach we have chosen distinguishes the pieces provided with tranchet blow on the basis of their intended (techno) function and thus the size of the angle of the cutting edge.

What Is Modified by a Tranchet Blow?

As the early texts mentioned above show, the tranchet blow is used to generate a straight, stable working edge. Such a working edge may have been created on different matrices. Basically, it is possible to apply a tranchet blow to a variety of lithic artifacts, and therefore, this edge modification can be carried out on simple blanks or complex bifacial pieces. The fact that a tranchet blow can be applied to a variety of pieces is taken into account by different authors through the terminology they use. We would therefore like to draw your attention shortly to the different ways in which this has been reflected in the terminology.

Jöris (2001), for example, distinguished bifacial (Keilmesser) and unifacial (Pradnik-Schaber) Pradnik implements (‘Pradnik-Geräte’) with tranchet blow (he uses the term Pradnik technique) from the Buhlen site. We assume that this distinction is based on the matrix used and the listed associative triple: core tool <> Keilmesser <> surface retouch vs. blank tool <> Pradnik-Scraper <> surface and edge retouch (Jöris 2001: 52). In this terminology, a clear distinction is made between bifacial (shape revised pieces with a clear back) and unifacial pieces. In contrast, Schmitz and Thissen (1998) use a different terminology: all (bifacial) Keilmesser with tranchet blow are called ‘Pradnik knives’ (Pradnikmesser) and for unifacial pieces the term ‘Unifacial knife with Pradnik technique’ (Unifaziales Messer mit Anwendung der Pradniktechnik) is used instead.

We would like to avoid this sometimes-confusing typology, and thus, we choose the term Keilmesser (unifacial and bifacial) when the tranchet blow ensures that the piece would fulfill an intended knife function and the morpho-technological setting of the piece is given. In a similar way, Weiss et al. (2018) made a synonymous distinction by calling unifacial tools with a Keilmesser-like morphology a Keilmesser.

The term Keilmesser is used as synonym for asymmetrically backed knife and can be worked unifacially and bifacially. If a tranchet blow is present on these pieces, this will be added (see also Frick et al. 2017c: 8), since the performance of a tranchet blow requires a specific morphology of the working edge and the adjacent surfaces, as well as the striking platform and the volume to be removed. Only then the conditions are created to perform a tranchet blow.

Irrespective of whether a piece has been worked unifacially or bifacially, certain parts must be kept in a specific morphology in order to execute a tranchet blow. This independence from the previous production step can be seen in various assemblages. Although the previous bifacial processing is more common, there are prominent assemblages with unifacial knives modified with a tranchet blow. We would like to illustrate this with examples from three different assemblages (see Fig. 3). These are pieces from Buhlen 4 (lower site), Rheindahlen B1 and Grotte de la Verpillière I (Méray excavation). In all examples, it is clearly visible that the striking platform was prepared by truncations that were produced differently. The bottom side (ventral side) is shaped only as much as necessary. On the top side, however, changes were made in order to obtain the required convexities.

Furthermore, in most cases, the cutting edge produced is so acute that its use in a scraping activity will inevitably lead to massive splintering, making the working edge unusable. Therefore, it is supposed in many contributions that Keilmesser and in particular pieces with tranchet blow were used in a cutting activity as it can be assumed for a knife (Jöris 2006; Urbanowski 2003). So far, only a few contributions describe the functionality (use-wear) of these tools. Essentially, we must refer here to the contributions of Frame (1986), Coudenneau (2005), Uomini (2006), Claud (2008), or Rots (2009). However, they all agree that the part of the cutting edge that was modified with a tranchet blow was used for cutting.

It has to be considered here that the active edge on many Keilmesser (especially if a tranchet blow has been applied) can be two-parted, while each part is suitable for different types of tasks. The part of the edge modified by the tranchet blow is mostly straight and acute-angled (Fig. 4a, b). It is therefore not suitable for scraping, as the edge will break out immediately, but for cutting purposes, as mentioned. A different part of the edge can usually also be used in a scraping movement, as this section often has a larger edge angle (Fig. 4c). Thus, a Keilmesser with tranchet blow with its two-parted cutting edge inevitably becomes a multifunctional device that can be used for numerous activities. These considerations follow Mauser’s (1965) specifications, who uses terminology from machining, and are summarized in Fig. 4.

Hypothetical use of a Keilmesser with tranchet blow with a two-parted cutting edge; a cutting-in with pulling motion, b cutting-off (whittling) with pushing motion, and c scraping with pulling motion (use of terms according to Mauser 1965). Drawings by J. A. Frick

Positioning and Directions of the Tranchet Blow

In the literature, the term tranchet blow is used for quite different modifications at the working edge. In order to define the lateral tranchet blow in an understandable way, it is useful to compare the descriptions of other authors. When reviewing contributions of colleagues, we noticed that both edge modifications that run along an edge (see Fig. 5a–e) and those that run orthogonally to it (see Fig. 5f–h) are described by the same term. Furthermore, a tranchet blow could have been executed on a variety of tools. This fact and the different use of terms sometimes make it difficult to draw direct comparisons.

Positioning and directions of tranchet blows as found in other contributions; a, b lateral tranchet blow; c lateral to transversal tranchet blow; d, e transversal tranchet blow; f–h invasive, orthogonal tranchet blow; in detail: a lateral tranchet blow as described by Bourguignon (1992; coup de tranchet latéral) and Jöris (2001; Schneidenschlag & Pradnik-Schneide); b lateral tranchet blow as described by Bordes (1961; “coup de tranchet” latéral) and Inizan et al. (1999; lateral tranchet blow); c lateral to transversal tranchet blow as described by Bordes (1961; “coup de tranchet”); d transversal tranchet blow as described by Roe (1981; tranchet finish); e transversal tranchet blow as described by Bradley and Sampson (1978; tranchet blow); f transversal (invasive, orthogonal) tranchet blow as described by Blaser et al. (2012; coup de tranchet transversal); g terminal (invasive, orthogonal) tranchet blow as described by Le Tensorer (2006; coup de tranchet distal); and h terminal (invasive, orthogonal) tranchet blow as described by Guichard and Guichard (1966; coup de tranchet secondaire). Drawings by J. A. Frick

Nevertheless, introducing a little more clarity into this terminology should be possible. We differentiate between the position and the direction of a negative. If we align an object so that the maximum length of a piece is taken as the reference axis, we can describe the position of the negative of a tranchet blow. In this case, a negative of a tranchet blow can either run along a lateral edge (Fig. 6a) or a terminal edge (Fig. 6b). In case the edge is rounded, there is also an intermediate position which can be described as lateral to transversal or vice versa (Fig. 6c). In accordance with other definitions (e.g., Desbrosse et al. 1976), we will call tranchet blow only those negatives that run along an edge and move it back in some way (Fig. 6a–c). This means that negatives that are orthogonal to an edge cannot be called tranchet blow (Fig. 6d–f), because these negatives rather belong to orthogonal edge working (i.e., edge retouching) or are part of surface working.

Differentiation between tranchet blow and orthogonal negatives; a–c negatives of tranchet blow; d–f orthogonal negatives; in detail: a lateral negative of tranchet blow; b transversal negative of tranchet blow; c transversal to lateral negative of tranchet blow; d diagonal orthogonal negative; e terminal orthogonal negative and f lateral orthogonal negative. Drawings by J. A. Frick

Delimitation to Other Reduction Concepts

After describing the position and the direction of negatives, which were defined as tranchet blow, we will try to distinguish them from other, quite similar reduction concepts. Here, the central point is to show the differences between tranchet blow and burin blow. This appears justified because early approaches indeed used the term burin for description of the tranchet blow, to which they saw technical correspondences, but at the same time they noted that differences could be found. Thus, in his early descriptions of pieces from Ciemna, Krukowski (1924, 1939–1948) used the term burin (Pol. rylców) to describe negatives he noticed. In the 1960s, the term para-burin (Pol. pararylcowe, pararylcowego) was used to describe the same and other pieces from Ciemna (Kowalski 1967). To emphasize the similarity as well as the differences, Chmielewski (1969) used the term flat burin (Fr. burin plat) for the tranchet blow on Prondniks. The term para-burin was also still used in more recent times (Conard and Fischer 2000). Knowing that it was not a real burin, the term was used to keep up the tradition of early Polish describers (pers. comm. N. J. Conard, Nov. 2018).

Of course, there are numerous similarities between tranchet and burin blow. This is especially true for the position and direction of the negatives created. However, if we consider the tranchet blow as a tool for creating an acute-angled working edge, then this aspect can be seen as a central point for distinguishing these two concepts. A tranchet blow thus leads to an acute-angled working edge (Fig. 7a), while a burin blow increases the angle of a working edge (Fig. 7b). Furthermore, the resulting blanks of tranchet blow and burin blow are also different in their morphology, although both blanks are removed along an edge. The morphological differences in the cross section of both blanks were impressively represented by Cornford (1986: 341, Fig. 29.6 & 29.7) and correspond to the cross sections in Fig. 7a and b. For clarification, these cross-sections are shown enlarged in Fig. 7e and f.

Comparison of reduction possibilities along an edge and on surfaces; a tranchet blow on a Keilmesser; b burin blow on a blank; c dorsal reduction on a blank; d ventral reduction on a blank; e magnification of a tranchet blow with the designation of surfaces; and f magnification of a burin blow with the designation of surfaces. Drawings by J. A. Frick

Furthermore, we would like to try to make a technological distinction between the reduction on an edge (edge reduction) for the tranchet and burin blow, and the reduction on a surface (surface reduction). In other words, these two reduction variations can also be regarded as technological reduction principles. The edge reduction corresponds to the crest principle and the surface reduction to the convexity principle (see also Frick 2016b: 227–231). Hence, the reduction on the Dorsal face (also named Kostenki reduction; Fig. 7c) and on the Ventral face (also named Kombewa reduction; Fig. 7d) correspond to the surface reduction and therefore must be separated from the edge reduction. Aside from the manufacturing techniques, the question of the purpose/function of the lateral edge reduction via tranchet blow arises. According to the previous research, the tranchet blow serves two purposes, to straighten a working edge and to make it more acute-angled (Jöris 2006).

There are only a few studies on use traces of blanks of tranchet blow (Coudenneau 2005; Frame 1986; Gysels and Cahen 1981), hence it is not yet possible to say whether these pieces have been used more than once for other purposes. This contrasts blanks from burin, ventral and dorsal reduction, where the pieces may have been produced as blanks for further use, or the corresponding edges and surfaces may have been modified for other purposes (e.g., hafting, cutting). Thus, it seems as if only the negative generated by a tranchet blow is anticipated. This is different with the other reduction concepts mentioned, because both the negative and the blank can be used for further tasks.

Perhaps we should pause here for a moment to think about whether the terminology used has also been applied meaningfully. We would like to refer here to the term Kostienki, which in Western and Central Europe is mostly associated with the reduction of blanks on the Dorsal surface and a truncation necessary for this (Frick 2012, 2013; Eickhoff 1988; Escutenaire 1997; Floss and Terberger 2002). If we follow the explanations of Klaric et al. (2015), then the term Kostenki cannot be regarded as a simple counterpart for Dorsal reduction, since the resharpening by means of the Kostenki technique does not happen on the surface, but at the transition from a lateral edge to a surface. The theoretical reconstruction of the knife resharpening process by the Kostienki technique (see Klaric et al. 2015: 454, Fig. 26), carried out on the basis of numerous Eastern European examples, includes several working stages. At the end of them a blank is removed, which can also be referred to as blank of tranchet blow without considering the context. The Kostenki technique thus combines a reduction and resharpening concept that includes reductions at the edge as well as on the surface. For this reason, we want to avoid using the term Kostenki as synonym for Dorsal reduction on blanks, but see it as a highly specific reduction and resharpening concept of the Upper Paleolithic.

Morphology of the Volume to Be Removed

As with most reduction variants, the surface of the volume to be removed must have a specific morphology. Since the goal seems to be the production of a negative along an edge (which becomes more acute and straighter than before), it must be ensured in advance that enough volume is available so that the edge does not break or becomes blunted by the blow. If both surfaces meet at an acute angle at a working edge, there is not enough volume available. There are three ways to form this volume. Either the necessary volume is already available by selecting a suitable matrix, or it has to be formed. There are two conceivable possibilities for forming a suitable shape: It is usually done with a fan-shaped faceting on the top side (see Jöris 2001: 56, Abb. 4.21; Urbanowski 2003: 34), but can also be achieved by blunting the later working edge to such an extent that the necessary volume is created in this way (Jöris 2001: 38). Furthermore, it is quite challenging to hit the striking platform at a specific point.

In a similar way as a notch for burins or a terminal convexity for Levallois cores is created, the volume to be reduced for the tranchet blow is generated at its potential terminal end by configuring a convexity that limits the length of the negative to be generated. In many cases, this convexity is not visible by an invasive reduction of the top side, but due to the fact that the entire top side is convex.

Similar to the top side, the striking platform for the tranchet blow does not have to be created separately. If an expedient surface already exists, it will be used unprocessed. Otherwise, a truncation is created at the terminal end that functions as a striking platform. In many cases, however, it is evident that the area formerly used as a striking platform has been intensively reduced. A refitting from the Abri du Musée (see Bourguignon 1992: 82, planche no 4) reveals the assumed reason for this. If the blank of tranchet blow is removed, the negative of the bulb of reduction appears at the basal end of the negative. Lateral to it, there is now a small overhang (Fig. 8a), which has to be removed in order to have a straight working edge. There are two ways to remove this overhang: a reduction in length of the entire piece (Fig. 8b) or minimally invasive orthogonal retouching (Fig. 8c).

Spatial and Chronological Frame

However, it is worth noting, that the use of the tranchet blow for the modification of mostly bifacially shaped pieces is not limited exclusively to the European late Middle Paleolithic, but was also used before and after it.

In the Western European Acheulian it is already used for bifaces (mostly lateral), but also for cleavers or hachereaux (mostly transversal) to produce a straight, stable, small angle cutting edge (Zuate y Zuber 1972; Tuffreau and Zuate y Zuber 1975; Bordes 1971; Wenban-Smith 1989; Lamotte 1999; Chevrier 2006). Further examples come from the Acheulian in Syria (Jagher et al. 1997; Jagher 2016) and Israel (Matskevich 2006; Zaidner and Grosman 2015), or from North Africa (Schild and Wendorf 1977; Alimen and Zuate y Zuber 1978; Douze 2014).

Although the focus of this work is on the late Middle Paleolithic, to our current knowledge, there are probably about two dozen assemblages from the early Middle Paleolithic that also provide evidence for the tranchet blow phenomenon. In this context, we would like to list two of the best known: Mesvin IV (Soriano 2000) and La Cotte de Saint Brelade (Cornford 1986). For the late Middle Paleolithic, we were able to verify more than 90 assemblages containing evidence for the presence of the tranchet blow. We will not try to present this totality, but instead we will address individual assemblages where appropriate in order to be able to shed more light on the concerns presented here. It remains to be noted that the amount of assemblages in the late Middle Paleolithic with this phenomenon can be assumed to be much greater than earlier contributions would suggest (see Richter 1997; Jöris 2003; Urbanowski 2003).

The tranchet blow phenomenon can also be observed in a more recent context. In the Belgian Gravettian it can be observed at Font-Robert points and Maisières points (Pesesse and Flas 2012). In this case, however, it is discussed whether the negatives are intentional modifications or impact traces (Touzé et al. 2016; Milks et al. 2016). In the course of the Last Glacial Maximum, various bifacial points in Japan were modified using the Omegura technique (Suto 2014), which can also be addressed as a lateral tranchet blow, as Plumet and Lebel (1997) did (unfortunately, we are not aware of any other linguistically accessible publications that could shed more light on this modification). Also, the tranchet blow phenomenon has been reported from the Mesolithic context in Belorussia (Vashanau 2017) and on Neolithic axes, this edge modification can also often be observed, e.g., in the Levante (Barkai and Yerkes 2008; Moore 1982) or in the early Neolithic (Ältere Trichtebecherkultur), in Northern Germany, Denmark and Poland, to resharpen core-axes (Hartz and Lübke 2013).

Technological Observations on Keilmesser

How Important Is the Matrix?

As demonstrated by the pieces from the Grotte de la Verpillière I (Frick et al. 2017c), the three-dimensional shape for the possibility of executing a tranchet blow is only of importance in so far as it must have a certain morphological setting. We refer to this as equifinality (Gummerman 1976), since the same result can be achieved from different forms through different production paths. A piece with tranchet blow can be made either from a raw piece, a core, a frost shard, or a blank.

Similar observations for Keilmesser without tranchet blow were made by Veil et al. (1994) for Lichtenberg and for Pouch-Terrassenpfeiler by Weiss (2015) and Weiss et al. (2018).

Here, we would like to discuss the importance of the raw piece shape briefly. It is impressive when raw materials can be selected either as slabs or nodules. If flat raw material (slab) is used as matrix, sometimes only a few working stages are necessary to transform such a piece into a Keilmesser. In many cases, the configuration of surfaces and edges can be started directly after creating angles at the edge of the slab. To demonstrate this, we would like to choose a simple Keilmesser from Obere Klause cave as an example (Fig. 9a). The situation is different if not slabs but nodules are to be or have to be used for production. In this case, far more working stages are necessary to produce the desired configuration of the surfaces. A major reason for this is that far more effort has to be invested in order to create adequate angles on convex surfaces. This is illustrated by an example from Grotte de la Verpillière I (Fig. 9b). Furthermore, the thickness and strength of the cortex also plays an important role in the way raw pieces are initialized.

Various Keilmesser made from cortical raw pieces; a simple Keilmesser (Keilmesser mit winkliger Arbeitskante (“Reduktion 1”)) from Obere Klause, Bavaria made from a flat raw material (chert slab?), redrawn from Uthmeier (2004, Tafel 8.1) and b Keilmesser with tranchet blow from Grotte de la Verpillière I, Saône-et-Loire made from bulbous raw material (flint of the argiles à silex nodule), redrawn from Desbrosse et al. (1976: 435). Compilation by J. A. Frick

A different procedure can be observed if uncortical blanks are used instead of cortical raw pieces. We would like to demonstrate this with a unifacial Keilmesser with tranchet blow from the Abri du Musée, Dordogne, France (Inv.-Nr. FMNP’91.zII.n3.N4b7.59). If the blank is already asymmetrical in cross-section, a back for holding the piece in the palm of the hand does not necessarily have to be created. Either the edge is left in its original condition or the edge is blunted, either intensively or minimally invasively. In the present case, the blank has a rather symmetrical cross-section and the holding edge (the back) has been blunted with a simple orthogonal retouch (Fig. 10a). A procedure that was apparently completely sufficient to meet the desired requirements. Thus, the minimal invasive back retouch makes it possible to hold such a piece in the bare hand. The question should, however, also be considered as to whether a piece that will certainly press into the hand at the edge has been wrapped with leather or tendons, etc. to ensure better handling. Also, different degrees of intensity can be used for the restructuring of surfaces. Neither the top side nor the bottom side have to be shaped into a specific morphology if the shape of the surfaces is already provided by the matrix. On the present artifact, only a small area on the bottom side of the second active edge was retouched (Fig. 10b). The truncation (inverse edge retouching), which serves as a striking platform for the tranchet blow, was created in the same minimally-invasive way (Fig. 10c). If the lateral edge, defined as the working edge opposite the back, is not yet in an entirely suitable shape, it can be formed with a few blows and orthogonal retouching (Fig. 10d). In order to generate the tranchet blow, a volume must be available, which is defined by a convex bulge on the top side. If this bulge is not already present on the matrix, it must be created (see above). In the case of the piece from the Abri du Musée, this convexity was achieved with a very limited number of negatives (Fig. 10e). After the tranchet blow was produced, the resulting small overhang was removed with two negatives and the working edge was regularized (Fig. 10f).

Size Independence and Maintenance Processes

Moreover, the proposed concept is independent of size. This is clearly visible when examining the maximum length of the pieces with tranchet blow. The data taken from the literature (Mont du Beuvry) and collected from our own measurements (Abri du Musée and Grotte de la Verpillière I) shows that the size range of the pieces varies considerably (Fig. 11). While the smallest pieces are merely longer than 20 mm, the largest are about 140 mm long. The values demonstrate that the application of the concept is independent from matrix size, but may nevertheless be influenced by matrix selection and thus by the size of the available raw material. Furthermore, the values represent the size of discard and do not take possible size reduction through recycling (remolding, resharpening...) into account.

Maximum length of pieces with tranchet blow from four different sites; own analysis: data for pieces from Abri du Musée and Grotte de la Verpillière I, data taken from literature for pieces from Sablière Seuron at the Mont du Beuvry near Béthune, Pas-de-Calais, France (Marcy 1991). Compilation by J. A. Frick

Recent research assumes that maintenance processes (or recycling) of stone artifacts from the Paleolithic are more the rule than the exception (Ioviţă 2014; Vaquero Rodriguez et al. 2015; Jöris 2001). This dynamic view stands in clear contrast to the assumptions of earlier researchers who wanted to see a stone artifact as a morphological type. This static assumption can be seen in various artifact-typological works from the previous century (see, e.g., Bordes 1961; Debénath and Dibble 1994; Demars and Laurent 1989; Bosinski 1967).

To repair a piece with tranchet blow whose cutting edge has become blunt, various processes are feasible (see Fig. 12). The question that arises is whether the piece should be used in the same or a similar way as a knife (i.e., reshaping). This would require the cutting edge to be renewed by a tranchet blow (e.g., for cutting; see Fig. 12b–f). Alternatively, the piece should be provided with a steeper angle at the working edge (i.e., remolding), which is suitable for other tasks (e.g., for scraping; see Fig. 12a). Due to the morphological peculiarities of a piece with tranchet blow, it is sometimes necessary to go through various of these processes before the piece has the corresponding morphology again, so that a new tranchet blow is possible (see Migal and Urbanowski 2006 for a detailed explanation). If the morphological peculiarities described above are taken into account in the analysis for the production of a piece with tranchet blow, the maintenance, if carried out, can sometimes be observed well. Sometimes, it is also possible that an artifact with orthogonal retouching at the working edge (e.g., a side scraper) was redesigned so that it became possible to create a tranchet blow. In this case, the process shown in Fig. 12a is reversed.

Maintenance processes that can be observed on Keilmesser with tranchet blow; a parallel size reduction at active edge for remolding/retreating a Keilmesser with tranchet blow into a side scraper; b parallel size reduction at active edge and bow; c inclined size reduction at active edge and bow; d reduction by repeated tranchet blow performance without any further reduction; e parallel size reduction and rotating; and f removal of terminal part and parallel size reduction on active edge and bow. Reduction process in a bases on own observation; b–e experimental studies of Migal and Urbanowski (2006) and f observation of Jöris (2001). Drawing by J. A. Frick

Permutation of Production or Interchangeability of Working Stages

As the examples discussed in the previous section already illustrated well, the production sequence of a piece with tranchet blow can vary in length and complexity. The decisive factor here is the selected matrix that is used for production. If the morphology is so close to what is technologically necessary to execute a tranchet blow even before production, simply by selecting a suitable piece, the production sequence can be kept very short. If the desired and technologically necessary shape has to be “peeled” out of the three-dimensional volume first, the production sequence will be accordingly longer.

Due to the relative independence of the working steps from one another, they can be interchanged sequentially. The only fixed rule is that the truncation must be generated before the tranchet blow is executed, but it is not necessary to generate this truncation right before the tranchet blow.

Let us assume, for example, that only four non-recurring stages (flattening, backing, truncation, and tranchet blow performance) needed to be performed: this results in a total of 24 possible combinations (4! = 24). This only holds if the truncation and the execution of the tranchet blow can also be exchanged. If we accept these two executions as one working stage, the possible combination is reduced to 6 (3! = 6). This means that there are still numerous possibilities for interchanging work stages.

Focusing on the assemblage from Grotte de la Verpillière I (see also Frick et al. 2017c: 38, Fig. 35) here, we can see that a total of 17 exchange possibilities can be found there, but the majority of the working stage succession follows two paths, which are briefly described. A total of n = 11 pieces follows the production path Flattening- > Truncation- > Edge formation- > Tranchet blow. For a further n = 9 pieces, the stages Truncation and Edge Formation are interchanged (Flattening- > Edge formation - > Truncation - > Tranchet blow). The number of pieces without backing (n = 27) clearly outweighs the number of pieces with backing (n = 16), a clear signal for matrix selection. Following the execution of the tranchet blow, there is only one stage left in many cases: the edge regularization. This sort of regularization ensures that the edge created by the tranchet blow is straight (in top and side view). This concerns the removal of the small overhang on the negative of the bulb of percussion described above or a minimally invasive correction on the lateral side of the terminal end of the negative of the tranchet blow.

The concept described above for the performance of a tranchet blow is characterized by two opposing aspects. On the one hand, it is characterized by a high degree of flexibility, which becomes apparent due to the different matrices and the interchange of working stages. On the other hand, there is a conceptual fidelity, which ensures that the piece is formed so that the technical prerequisites are present to be able to carry out a tranchet blow at all. In combination, these two aspects culminate in equifinality.

To conclude our technological considerations on the tranchet blow phenomenon, we can observe that the technological phenomenon described here represents a chronologically far-reaching moment (see above), but it occurs increasingly in the (second half of the) late Middle Paleolithic on Keilmesser (see also Jöris 2003). The tranchet blow modification serves (a) a specific purpose (straight sharp cutting edge), but requires (b) certain necessary basic prerequisites, which can be achieved through the matrices used and/or various production sequences. However, they require well-trained craftsmanship and a highly specific mechanical knowledge of the producers.

This increase in specific expressions can be observed in large parts of the Middle Paleolithic in Europe attributed to Neanderthals. In one phase, not quite at the end of the Middle Paleolithic (in our case the end of MIS 4 and the beginning of MIS 3), the diversification of lithic technologies seems to be highest (Delagnes et al. 2007; Delagnes and Rendu 2011; Delagnes and Meignen 2006; Koehler 2009, 2011b; Locht et al. 2016; Hérisson et al. 2016). The high presence of the tranchet blow phenomenon at this time is one aspect of this great diversification in the lithic technologies.

Recently, the Keilmesser-concept (for pieces without tranchet blow performance) was described using the assemblage from Pouch-Terrassenpfeiler, located near Bitterfeld, Saxony-Anhalt/Germany (Weiss et al. 2018) as case study, with slightly different results than ours. Perhaps this is due to the fact that it is not our concern to find an index fossil that is name-giving for a Middle Paleolithic unit in time and space, but we are attempting to fathom an observed phenomenon that is increasingly to be found in Central Europe. But our results demonstrate, as do those of Weiss et al. (2018), the huge variability within the concept of Keilmesser, even within a regional scale. This variability includes flexibility in the production of unifacial and bifacial Keilmesser with and without tranchet blow using different three-dimensional shapes (matrices), while retaining the individual techno-functional units (that are necessary for holding and cutting purposes).

Short Note on a Regional Cluster of Sites Containing Keilmesser with Tranchet Blow

Sometimes, continuous research shows that phenomena formerly assumed to be individual do not possess this singularity. One of these phenomena concerns one of our research areas Saône-et-Loire, France. The appearance of Keilmesser with tranchet blow in this French department is no longer a singular affair. In addition to the well-known assemblage (Grotte de la Verpillière I) and its immediate neighbor (Grotte de la Verpillière II), which together yielded the most pieces in quantitative terms, research in recent years has been able to identify further assemblages containing corresponding pieces. In this way, the distribution radius of Keilmesser with tranchet blow was regionally extended.

Based on the data base built up over the last decade (review of collections in museums and from hobby collectors, as well as the evaluation of the material from excavations under the direction of H. Floss), it is now possible to mention further assemblages in the vicinity of the Grotte de la Verpillière I, which also contain elements of the tranchet blow phenomenon. It should be noted, however, that with the exception of the pieces from the intact stratigraphy of Verpillière II, all other artifacts come from so-called decontextualized assemblages. So far, it has been possible to identify a total of five sites (listed in their geographical context on Fig. 13):

-

Grotte de la Verpillière I (Frick et al. 2017c)

-

Grotte de la Verpillière II (Frick 2016b)

-

La Roche in Saint-Martin-sous-Montaigu (Herkert 2014; Herkert et al. 2015; Herkert 2016, in prep.; Herkert et al. submitted)

-

La Clôsure in Bissy-sur-Fley (Herkert 2014; Herkert et al. 2015; Herkert 2016, in prep.; Herkert et al. submitted; Daudey and Bonnot 1970; Desbrosse and Texier 1973a; Farizy 1995a; Schiller 2018)

-

La Rue Cataux in Chenôves (Herkert 2014; Herkert et al. 2015; Herkert 2016, in prep.; Herkert et al. submitted; Gros and Gros 2005)

Topographical maps of Southern France and the position of sites with assemblages bearing Keilmesser with tranchet blow from the Côte chalonnaise; a topographical map of Southern France showing the position of the Côte chalonnaise between the Massif central and the Morvan massive on the western margin of the Bresse basin (base map: NASA, SRTM 2000, www.pachacartographie.com, modified) and b topographical map of the Côte chalonnaise in the North of the Saône-et-Loire department showing the position of the sites yielding Keilmesser with tranchet blow (map: IGN France 2016, mapping Hoyer, modified). Compilation by J. A. Frick

We observe the presence of Keilmesser with tranchet blow on a regional scale in some assemblages, although their number of yet identified pieces differs from site to site and for the moment, the cave (rock shelter) sites apparently yield the more important numbers. In addition, further studies have shown that these pieces go along with other technological and compositional similarities, like other bifacial tools and the nearly unique use of the Levallois concept for the production of blanks, wherein always a significant number of blades can be found and where common Middle Paleolithic tools are manufactured on a wide variety of blanks (Frick 2016b; Frick and Floss 2017; Frick 2017; Frick et al. 2017a; Herkert in prep.; Frick et al. submitted-b, submitted-a). For a better understanding of the significant similarities in the technological structure of the sites, the features are listed here:

-

Presence of Keilmesser with and without tranchet blow

-

Morphological diversity of bifacial objects

-

Prevalent use of Levallois reduction

-

Almost no evidence of other elaborated reduction concepts

-

Evidence of opportunistic reduction

-

Ventral reduction on blanks for configuration of Levallois cores

-

Incidental presence of blades

-

Tools on blanks and cores

-

Tools from cortical, configuration and target blanks

-

Bulb reduction on tools

-

Minor presence of Groszaki

-

Minor presence of dorsal reduction

-

Minor presence of Janus flakes

-

Almost absence of “Upper Paleolithic” tool types

-

Evidence for hafting of tool

Detailed technological, morphometric, and metric analyses of the assemblages are in preparation and will contribute to the argumentation. The similarity pattern clearly shows the connection between various bifacial objects and the reduction by means of the Levallois concept. Farizy (1995b) has already drawn attention to this connection. In her presented concept of the Charentien à influence micoquienne (Charentian with Micoquian influence, CIM), she drew attention to the common occurrence of Levallois, Bifaces, Fäustel, bifacial scrapers, and Pradniks.

Although it is not yet possible to fix the sites mentioned in the short note chronologically, we would like to try to list chronological markers that already exist at this time. It is safe to say that this chronological working hypothesis on this cluster of sites, with its technological similarities, requires a firm fixation.

So far, the most reliable dates come from Grotte de la Verpillière II (via ESR/U-Th, IRSL and AMS 14C) and all point towards the early MIS 3 (Fig. 14a, b). In addition to the radiometric dating, the analysis of the micro-vertebrates by Jeannet (2014) provided evidence for a cool but humid climate setting of GH 3 (upper find layer). Further evidence comes from the Grotte de la Verpillière I (via ESR/U-Th and AMS 14C; Fig. 14c), which also points to the early MIS 3 (Zöller and Schmidt 2016; Richard et al. 2016; Heckel et al. 2016). For the other three sites in the Côte chalonnaise, no chronometric data exists yet (see Fig. 14d). In addition to these recent attempts to establish a chronological fixation based on radiometric data, other authors also attempted to create a chronological framework (only the so far known Grotte de la Verpillière I was included in the considerations).

Summary of radiometric dating attempts at Middle Paleolithic sites from the Côte chalonnaise and its comparison of chronological frameworks (the ESR/U-Th, IRSL and AMS 14C data come from Richard et al. (2016), Zöller and Schmidt (2016) and Heckel et al. (2016). The light blue bars within the data from Grotte de la Verpillière II indicate the reliable time span assumed by Zöller and Schmidt (2016) for the deposition of the two geological units); a GH 3 of Grotte de la Verpillière II; b GH 4 of Grotte de la Verpillière II; c GH 15 of Grotte de la Verpillière I; d assumed chronological range of Rue Cataux in Chenôves, La Clâusure in Bissy-sur-Fley and La Roche in Saint-Martin-sous-Montaigu; e chronological framework by further authors for industries containing Keilmesser with and without tranchet blow (Jöris 2002, 2003, 2006; Baales and Jöris 2018; Richter 1997, 2018; Koehler 2009, 2011c). Compilation by J. A. Frick

In this way, the site Grotte de la Verpillière I was placed in KMG B2 (see Fig. 14e) by Jöris (2002, 2003, 2006), based on the presence of Keilmesser with tranchet blow and its spatial position in Western Europe. KMG B2 corresponds approximately to the second half of MIS 4 or the beginning of MIS 3.

The chronological frame proposed by Richter (1997, 2018), based on the G-layer sequence of the Sesselfelsgrotte, can be described as a very short chronology that touches mainly the early MIS 3. In our opinion, this framework is likely too short. In his chronological frame, Grotte de la Verpillière I was set into M.M.O.-A (early phase of the Mousterian with Micoquian option, non-Levallois-Schemata), as well as Bockstein III. But the assemblage of Bockstein III is probably situated in MIS 5a (Krönneck 2012) and not in the second half of MIS 4 or the beginning of MIS 3, as Richter (1997) assumed. Another example for a longer chronology of a Keilmesser-bearing assemblage is the Neumark-Nord 2/0, which was placed in MIS 5a/5c (Richter and Krbetschek 2014).

The supposed positioning in a late MIS 4 or early MIS 3 context would also fit into the chronological framework of the CIM assumed by Koehler (2009, 2011c). She assumed for the CIM (Charentien à influence micoquienne) a positioning into the second half of MIS 4 or the beginning of MIS 3 (Fig. 14e), based, among other things, on old ESR data from Champlost (Farizy 1995b). If the larger known assemblages with tranchet blow are used as a basis, a striking accumulation is observed at the end of MIS 4 and at the beginning of MIS 3. The framework conditions described here suggest that an early MIS 3 can be assumed for Grotte de la Verpillière I and II. Hypothetically, the three other Keilmesser with tranchet blow-bearing sites could be considered to be in a similar framework.

Discussion and Conclusion

Our research in Saône-et-Loire points to regional technological similarities, which could be observed at several sites in the region (Frick et al. submitted-b; Herkert et al. submitted; Frick et al. submitted-a). All of which yielded among others Keilmesser with tranchet blow as connective element.

If we focus on this technological phenomenon, the tranchet blow, we see, as demonstrated on material from Grotte de la Verpillière I and which could also be observed in other assemblages that it can be executed quite independently of the selected matrix. The closer the surfaces and edges of the three-dimensional volume used correspond to the mechanically relevant shape, the shorter the sequence of working stages can be. Not the entire shape of the used three-dimensional volume is of importance here, but the specific shape of certain parts. Furthermore, the application of the tranchet blow is also independent of the size of the pieces and the necessary steps of the production process can be interchanged depending on the necessity and capability of the knapper.

The working memory of the knapper (Coolidge and Wynn 2007) contains not only the function and execution of the individual working stages, but also the extent to which these can be interchanged due to technological necessity or the nature of the knapper, or in the words of Wynn and Coolidge (2004: 467): “Our hypothesis is that Neandertals relied on a form of expert cognition known as long-term working memory, that this ability was essentially modern in scope, and that it formed the centerpiece of Neandertal problem solving.”

Due to the existence of the highly specific technology of the tranchet blow and the other similarities of the assemblages as observed in our research on sites, which are in close proximity to each other, the question arises whether these assemblages are based on a common lithic approach shared by the Neanderthals settling there. Although this hypothesis is supported by the fact that the two Grottes de la Verpillière fit into a very narrow window of time, the other assemblages so far lack a chronological framework. In this respect, the assumption of shared knowledge for the production of artifacts must clearly remain hypothetical.

Weissmüller called this shared knowledge a concept reservoir, distinguishing between an individual and a collective one (Weißmüller 1995: 28–36). For the sake of general understanding we would like to explain this in more detail. The individual procedures of making a tranchet blow (or reducing a core) can then be seen as part of the individual concept reservoir and was formed by knowledge transmission (Assaf 2019) and own trial and error. Tostevin (2012: 151–152) formulated three hypotheses on change in flintknapping behaviors and the implicit transmission of knowledge, which can also be applied in this context: (1) independent innovation, (2) cultural transmission, and (3) the combination of both. In our case, the individual innovation (own determination of the sequence of the working stages, as well as recognition of the necessity to carry out a working stage) would only take place when the knowledge about the relevance and the execution of a tranchet blow was passed on by knowledge transmission.

The sometimes very different variations for the production of the pieces not only within one assemblage but also in other assemblages are thus an expression of individual approaches of a highly specific technology. In addition to these individual approaches to the production of the pieces, we expect a common knowledge of the production and the advantages of this technology. This common knowledge was described by Weißmüller (1995: 28–36) as a collective concept reservoir.

In addition to the common knowledge of such a highly specific technology, its learning can also be demonstrated in the same way. At the current stage of analysis, we are not yet in a position to determine learning levels as Apel (2001: 34–43) was able to do for the production of Late Neolithic flint daggers. However, serious differences can be observed in the execution of the tranchet blow. Here, we would like to refer to two pieces from the assemblage of the Grotte de la Verpillière I (see Fig. 15). In the first case, a total of six tranchet blows were performed extremely successfully in series (Frick et al. 2017c: 24, Fig. 18). In another case, an attempt was also made to produce tranchet blows, each of which further ruined the piece and rendered it unusable (Frick et al. 2017c: 33, Fig. 29).

Keilmesser with tranchet blow from Grotte de la Verpillière I; a piece with a sequence of 6 successive and successful tranchet blows, from the Méray excavation and Méray collection from Musée Denon, Inv. No. CA27.171 (see also Frick et al. 2017c: 24, Fig. 18) and b piece with a sequence of 6 successive but unsuccessful tranchet blows that ruined the cutting edge, from the Floss excavation, Inv. No. GER15.204–104.10.2 (see also Frick et al. 2017c: 33, Fig. 29)

Given the presence of this very particular Keilmesser with tranchet blow phenomenon, which does not only involve a simple sharpening of the edge, but is composed of several components as a concept, it is likely to have been brought about by an association of persons. This personal association does not have to have been present at the same time, since there is always the possibility that another component of the individual concept reservoir was created through attempts, which in turn is absorbed for a short time in the collective concept reservoir of the group.

In this context, Bolus (2016) refers to the term isocrestic style used by Sackett (1982), as choices between variants that are equivalent in use. This refers to the degree of flexibility for choosing specific cultural performances from a common pool of cultural capacities. In that way, even highly dynamic and thus transient artifacts may point to such a kind of style.

In the case of the tranchet blow, it can even be assumed that not only the exact surface shaping, the generation of specific convexities and edges indicates that an individual is familiar with the exact manufacturing, but that this skill also shows itself in very simplistic pieces, since only an expert should be able to select exactly the three-dimensional volume that can be transformed into a knife with very few working stages. This reversed view could suggest that the development direction of a technology does not always tend from simple to highly elaborated pieces, but that sometimes the most developed variant of a technology can be found at the supposedly “simple” pieces.

Since a tranchet blow responds to specific needs (straight low angled edge), applicable as final (even targeted and anticipated) step within the production of Keilmesser with tranchet blow or as possibility of resharpening for even unifacial pieces, its implementation requires the said specific technological parameters, of which a knapper has to be aware of. Technological know-how, transmitted through apprenticeship combined with practical know-how through practice, leading to individual applications of the concept.

Nevertheless, as shown before, this special modification pops up several times autonomously throughout the Paleolithic and even in the Neolithic as an innovative means to respond on specific demands on certain tools. So, once the innovation has been socially accepted, it is (for a certain time) incorporated into the common pool of cultural capacities (the collective concept reservoir) and may thus serve as indicator of a style. Such a view of artifacts might help to provide further evidence that one is more aware and sensitive to this type of relationship between humans and their archeological remains, but these relations are more promising reachable from a litho-technological position rather than from a static morpho-typological one.

Even if the concept of Keilmesser with tranchet blow seems to be regionally clustered in Saône-et-Loire, the inherent technological concept is universal. It does not reveal itself in a specific sequence of working stages, but requires the knapper to have a three-dimensional notion, according to which the individual volumes and surfaces must be designed in order to make the execution of a tranchet blow technically possible. Thus, the concept is based on strict physical-morphological preconditions, which must be created in advance, should they not be met. It is irrelevant whether these conditions are already met by the selected matrix (the selected three-dimensional shape) or whether they have to be created first. The (almost entirely) free choice of the order of the working stages and the possibility of using disparate matrices shows the great flexibility of the concept. At the same time, the underlying physical conditions make it necessary to strictly adhere to the necessary conditions of volumes, areas and angles during production, thus revealing the adherence to concept.

Weißmüller (2003: 181) has elegantly outlined this flexibility and the freedom inherent in it with the following words:

“Die Neandertaler, ausgestattet mit einem realen Blick für das Nötige, sahen nirgends die Veranlassung, etwas über den Zweck hinaus zu tun, und waren so im Besitz vollständiger Gestaltungsfreiheit.” [The Neanderthals, endowed with a realistic view for what was necessary, saw no reason anywhere to do anything beyond its purpose and were thus in possession of complete creative freedom].

The simultaneity of flexibility and concept fidelity in the production of stone artifacts can also be observed in reduction concepts for the production of blanks. Even though a limited number of reduction schemes for, e.g., Levallois cores have been observed in the course of research (Boëda 1988, 1995; Richter 1997), this shows that different methods are possible to reduce a core accordingly. Again, there are fixed (physical) parameters that have to be observed strictly, while other parameters can be chosen freely. We assume that the longer and narrower the blank to be generated, the more important it is to follow the physically relevant prerequisites. Not only is this true for the production of blades, but particularly so for the reduction along an edge. For us, the tranchet blow takes a special position here, because an exact point has to be hit by a freehand blow, which is not located directly at the edge, as in the burin reduction, but is slightly shifted into the surface laterally. Therefore, it is much more difficult to accurately hit the pertinent point. The objection may be raised that other reduction varieties are also quite complicated, which we agree with. However, we would like to point out that it takes a lot of practice to execute a tranchet blow in exactly the desired form (see also Migal and Urbanowski 2006).

The assemblages analyzed by us are on the periphery of the distribution of the unit called Keilmessergruppen. Currently, we use the term Keilmessergruppen as an umbrella term for classification, as this is for the moment the best way to describe the explored aspects of these assemblages. However, there are differences to other KMG assemblages. Similarly, attempts have been made in previous decades to delineate the phenomena observed in eastern France. Thus, Farizy (1995b) described the assemblages discussed here and further with the term Industries charentiennes à influences micoquiennes (CIM). Because these assemblages could no longer be described with the Bordesian typology alone, other analysis systems had to be used. The name she used to describe the assemblage combined the approaches of Bordes (1961; unifacial Levallois or Quina reduction) and Bosinski (1967; Micoquian bifacial objects).

Regardless of whether it has been processed unifacially or bifacially, we regard the Keilmesser with tranchet blow as a particular variation of a backed knife, which must have specific surfaces and edges either through the selected matrix or in the course of production, so that a tranchet blow can be performed at all. The variability presented and thus the concept of pieces with tranchet blow involves different technological levels of reflection. By recognizing and describing the technological basic prerequisites, which must be fulfilled, this concept is revealed to be largely independent from static morphotypes. The dynamic element in the tool concept is not only visible during maintenance processes, but also during their production, allowing the use of given morphologies of surfaces and edges of the matrices, or their generation in a variable production sequence.

References

Alex, B., Valde-Nowak, P., Regev, L., & Boaretto, E. (2017). Late middle Paleolithic of southern Poland: Radiocarbon dates from Ciemna and Obłazowa caves. Journal of Archaeological Science: Reports, 11, 370–380. https://doi.org/10.1016/j.jasrep.2016.12.012.

Alimen, M.-H., & Zuate y Zuber, J. (1978). L'évolution de l'Acheuléen au Sahara nord-occidental (Saoura - Ougarta - Tabelbala). Atlas. Meudon: Service des Publications du Centre National de la Recherche Scientifique.

Apel, J. (2001). Daggers Knowledge & Power. The Social Aspects of Flint-Dagger Technology in Scandinavia 2350-1500 cal BC (coast to coast-book, Vol. 3). Uppsala: Wikström.

Assaf, E. (2019). Core sharing. The transmission of knowledge of stone tool knapping in the lower Palaeolithic, Qesem cave (Israel). Hunter Gatherer Research, 3(3), 367–399. https://doi.org/10.3828/hgr.2017.19.

Baales, M., & Jöris, O. (2018). Wohin es die mitteleuropäischen Neandertaler zog, als es richtig kalt wurde. In M. Wemhoff & M. M. Rind (Eds.), Bewegte Zeiten. Archäologie in Deutschland. Begleitband zur Ausstellung. 21. September 2018 bis 6. Januar 2019 Gropius Bau, Berlin (pp. 58–61). Michael Imhof Verlag: Petersberg.

Barkai, R., & Yerkes, R. W. (2008). Stone axes as cultural markers: Technological, functional and symbolic changes in bifacial tools during the transition from hunter-gatherers to sedentary agriculturalists in the southern Levant. In L. Longo & N. Skakun (Eds.), “Prehistoric Technology” 40 Years Later: Functional Studies and the Russian Legacy (pp. 159-167, British archaeological reports international series, Vol. 1783). Oxford: Archaeopress.

Bates, M. R., Pope, M. I., Shaw, A., Scott, B., & Schwenninger, J.-L. (2013). Late Neanderthal occupation in North-West Europe: Rediscovery, investigation and dating of a last glacial sediment sequence at the site of La Cotte de saint Brelade, Jersey. Journal of Quaternary Science, 28(7), 647–652. https://doi.org/10.1002/jqs.2669.

Blaser, F., Bourguignon, L., Sellami, F., & Rios, J. (2012). Une série lithique à composante laminaire dans le Paléolithique moyen du Sud-Ouest de la France : le site de Cantalouette 4 (Creysse, Dordogne, France). Bulletin de la Société préhistorique française, 109(1), 5–33. https://doi.org/10.3406/bspf.2012.14141.

Boëda, É. (1988). Le concept Levallois et évaluation de son champ d’application. In M. Otte (Ed.), L'homme de Néandertal. 4: La technique. Actes du colloque international de Liège (4-7 décembe 1986) (Vol. 4, pp. 13-26, Études det Recherchese Archéologiques de l'Université de Liège, Vol. 31). Liège: Service de Préhistoire, Université de Liège.

Boëda, É. (1995). Levallois: A volumetric construction, methods, a technique. In H. L. Dibble & O. Bar-Yosef (Eds.), The Definition and Interpretation of Levallois Technology (pp. 41-68, monographs in world archaeology, Vol. 23). Madison: Prehistory press.

Boëda, É. (2013). Techno-logique & Technologie. Une Paléo-histoire des objets lithiques tranchants (Préhistoire au Présent). Paris: Institut Universitaire de France. Université Paris Ouest Naterre La Défence. @rchéo-éditions.com.

Bolus, M. (2016). Tracing group identity in early upper Paleolithic stone and organic tools – Some thoughts and many questions. In M. N. Haidle, N. J. Conard, & M. Bolus (Eds.), The Nature of Culture. Based on an Interdisciplinary Symposium ‘The Nature of Culture’, Tübingen, Germany (pp. 79-85, vertebrate Paleobiology and paleoanthropology series). Dordrecht: Springer.

Bordes, F. H. (1961). Typologie du Paléolithique ancien et moyen (Publications de l'Institut de préhistoire de l'Université de Bordeaux., Vol. 1). Bordeaux: Delmas.

Bordes, F. H. (1971). Observations sur l'Acheuléen des grottes en Dordogne. Munibe, 23(1), 5–23.

Bosinski, G. (1967). Die mittelpaläolithischen Funde im westlichen Mitteleuropa (Fundamenta, Monographien zur Urgeschichte, Vol. A4). Köln: Böhlau.

Bosinski, G. (1969). Eine Variante der Micoque-Technik am Fundplatz Buhlen, Kreis Waldeck. Jahresschrift mitteldeutscher Vorgeschichte, 53, 59–74.

Bourguignon, L. (1992). Analyse du processus opératoire des coups de tranchet latéraux dans l'industrie moustérienne de l'abri du Musée (Les Eyzies-de-Tayac, Dordogne). Paléo, 4(1), 69–89. https://doi.org/10.3406/pal.1992.1195.

Bradley, B., & Sampson, C. G. (1978). Artifacts from the cottages site. In C. G. Sampson (Ed.), Paleoecology and archeology of an Acheulian site at Caddington, England (pp. 83–137). Dallas: Department of Anthropology, Institute for the Study of Earth and Man, Southern Methodist University.

Callow, P., & Cornford, J. M. (1986). La Cotte de St. Brelade, 1961–1978: Excavations by C.B.M. McBurney. Norwich: Geo Books.

Chevrier, B. (2006). De l’Acheuléen méridional au technocomplexe trifacial: la face cachée des industries du Bergeracois. Apport de l’analyse technologique de l’industrie lithique de Barbas I C’4 sup (Creysse, Dordogne). Gallia préhistoire, 48(1), 207–252. https://doi.org/10.3406/galip.2006.2451.

Chmielewski, W. (1969). Ensembles micoquo-prondnikiens en Europe centrale. Geographica Polonica, 17, 371–386.

Claud, É. (2008). Le statut fonctionnel des bifaces au Paléolithique moyen récent dans le Sud-Ouest de la France. Étude tracéologique intégrée des outillages des sites de La Graulet, La Conne de Bergerac, Combe Brune 2, Fonseigner et Chez-Pinaud / Jonzac. Doctoral thesis, Université Bordeaux I, Bordeaux.

Conard, N. J., & Fischer, B. (2000). Are there recognizable cultural entities in the german middle Palaeolithic? In a. Ronen, & M. Weinstein-Evron (Eds.), Toward Modern Humans: The Yabrudian and the Micoquian 400-50 k-years ago. Proceedings of a Congress held at the University of Haïfa November 3-9, 1996. (pp. 7-21, British archaeological reports international series, Vol. 850). Oxford: Archaeopress.

Coolidge, F. L., & Wynn, T. (2007). The working memory account of Neandertal cognition—How phonological storage capacity may be related to recursion and the pragmatics of modern speech. Journal of Human Evolution, 52(6), 707–710. https://doi.org/10.1016/j.jhevol.2007.01.003.

Cornford, J. M. (1986). Specialized Resharpening techniques and evidence of handedness. In P. Callow & J. M. Cornford (Eds.), La Cotte de St. Brelade 1961–1978. Excavations by C.B.M. McBurney (pp. 337–351). Norwich: Geobooks.

Coudenneau, A. (2005). Analyse fonctionnelle des pièces à coup de tranchet latéral au Paléolithique Moyen. Les exemples de l’Abri du Musée (Les Eyzies-de-Tayac, Dordogne) et de la Baume de Gigny (Gigny, Jura). Master 2, Université de Provence, Aix-en-Provence.

Daudey, J., & Bonnot, J.-J. (1970). La station moustérienne de Bissy-sur-Fley. Trouvailles récentes. La Physiophile, 73, 7–8.

Debénath, A., & Dibble, H. L. (1994). Handbook of Paleolithic typology. Volume one: Lower and middle Palaeolithic of Europe. Philadelphia: University Museum University of Pennsylvania.

Delagnes, A., Jaubert, J., & Meignen, L. (2007). Les technocomplexes du Paléolithique moyen en Europe occidentale dans leur cadre diachronique et géographique. In B. Vandermeersch, & B. Maureille (Eds.), Les néandertaliens: biologie et cultures (pp. 213-229, Documents préhistoriques Vol. 23). Paris: Comité des Travaux Historiques et Scientifiques.

Delagnes, A., & Meignen, L. (2006). Diversity of lithic production systems during the middle Paleolithic in France. In E. hovers, & S. L. Kuhn (Eds.), Transitions before the transition: Evolution and stability in the Middle Paleolithic and Middle Stone Age (pp. 85-107, interdisciplinary contributions to archaeology). New York: Springer.

Delagnes, A., & Rendu, W. (2011). Shifts in Neandertal mobility, technology and subsistence strategies in western France. Journal of Archaeological Science, 38(8), 1771–1783. https://doi.org/10.1016/j.jas.2011.04.007.

Demars, P.-Y., & Laurent, P. (1989). Types d'outils lithiques du Paléolithique supérieur en Europe (Cahiers du Quaternaire, Vol. 14). Paris: CNRS Éditions.

Desbrosse, R., Kozłowski, J. K., & Zuate y Zuber, J. (1976). Prondniks de la France et d‘Europe centrale. L'Anthropologie, 80, 431–488.

Desbrosse, R., & Texier, P.-J. (1973a). La station moustérienne de Bissy-sur-Fley (S.-&-L.). La Physiophile, 79, 8–31.

Desbrosse, R., & Texier, P.-J. (1973b). Les silex de Germolles dans la collection Jeannin. La Physiophile, 79, 64–69.