Abstract

Sunlight is the most abundant and inexhaustible energy source on earth. However, its low energy density, dispersibility and intermittent nature make its direct utilization with industrial relevance challenging, suggesting that converting sunlight into chemical energy and storing it is a valuable measure to achieve global sustainable development. Carbon–neutral, clean and secondary pollution-free solar-driven water splitting to produce hydrogen is one of the most attractive avenues among all the current options and is expected to realize the transformation from dependence on fossil fuels to zero-pollution hydrogen. Artificial photosynthetic systems (APSs) based on photoelectrochemical (PEC) devices appear to be an ideal avenue to efficiently achieve solar-to-hydrogen conversion. In this review, we comprehensively highlight the recent developments in photocathodes, including architectures, semiconductor photoabsorbers and performance optimization strategies. In particular, frontier research cases of organic semiconductors, dye sensitization and surface grafted molecular catalysts applied to APSs based on frontier (molecular) orbital theory and semiconductor energy band theory are discussed. Moreover, research advances in typical photoelectrodes with the metal–insulator–semiconductor (MIS) architecture based on quantum tunnelling are also introduced. Finally, we discuss the benchmarks and protocols for designing integrated tandem photoelectrodes and PEC systems that conform to the solar spectrum to achieve high-efficiency and cost-effective solar-to-hydrogen conversion at an industrial scale in the near future.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

As the cleanest energy source, hydrogen will make a predictable contribution to inhibiting the growth of environmental carbon. Hydrogen, as a key industrial raw material, has been widely used in power generation, transportation, and synthetic fuels, upgrading oil/biomass, ammonia/fertilizer, metal production and chemical processes [1], because it has a superior gravimetric heating value of up to 141.9 MJ kg−1, which is higher than that of methane (55.5 MJ kg−1), gasoline (47.5 MJ kg−1), diesel (44.8 MJ kg−1) and methanol (20 MJ kg−1), and a competitive advantage of zero emissions after combustion [2]. Conventional routes to industrial hydrogen production are based on coal-based water–gas shift (WGS) and fossil fuel reformation (generally, methane-dominated natural gas) processes, which commonly emit a large amount of CO2 [2]. Among all hydrogen production options, the excess production capacities of power plants in the nighttime and solar energy in the daytime exhibit cost-effectiveness and superiority. A mature industrial system has been established for electrocatalytic hydrogen production from water splitting [3, 4], while solar-to-hydrogen conversion is still in the laboratory exploration and preliminary application stages due to the longstanding scientific challenges [5,6,7]. The solar energy received on the total surface (the land and the ocean) of the earth is 173 000 TW [8], which is 9 830 times the global primary energy consumption (17.6 TW) in 2020 [9]. The production capacity of installed photovoltaic (PV) power that can directly utilize solar energy was only 707.5 GW in 2020 [9]. Therefore, solar energy, as a renewable energy, urgently needs to be reasonably developed and utilized. Given the dispersion, intermittent nature and low power density of solar irradiation, the US Department of Energy has set an energy conversion target of 5% for valuable solar H2 production [10]. To date, there are three typical conversion routes for solar water splitting: photocatalysis, PV-driven electrocatalysis (PV-EC) and integrated artificial photosynthetic systems (APSs) based on photoelectrochemical (PEC) devices [11, 12]. We focus on the last route, in which the integration of the light-harvesting and water splitting modules enables direct solar-to-hydrogen conversion, leading to fewer energy conversions and lower energy loss. [10]. Although considerable progress has been made in APS water splitting in recent years, there are still key issues, such as the solar-to-hydrogen conversion efficiency and stability, that need to be optimized to meet the cost-effective industrial requirements.

In this review, based on the latest research results on solar-driven hydrogen production, we review the recent advancements in APSs and discuss the difficulties and solutions encountered in photocathode materials. Moreover, the applications of organic semiconductors in PEC systems are highlighted from the perspective of frontier (molecular) orbital theory and semiconductor energy band theory, and their application potential is prospected. In particular, the application frontier of quantum (electron) tunnelling with statistical significance in photoelectrodes is introduced. Finally, the benchmarks and protocols for the design of high-efficiency tandem photoelectrodes and PEC systems are discussed.

2 Fundamentals of Water Splitting

The water splitting reaction consists of hydrogen evolution reaction (HER) and oxygen evolution reaction (OER). An energy input of ΔG = 273.15 kJ mol−1 is required in thermodynamics for water splitting, which corresponds to a minimum Nernstian potential of + 1.23 V. The reaction equation has several manifestations depending on the conditions.

The water splitting reaction is

In an alkaline electrolyte,

In an acidic electrolyte,

Generally, a potential larger than 1.23 V is required for electrochemical water splitting due to the voltage drop and overpotential. Among these, the voltage drop of the electrochemical cell originates from the resistance of the electrolyte, ohmic contact and ionic membrane. The catalytic activity of the electrocatalyst, the kinetic parameter activation energy and the restriction of diffusion on the electrode surface are the primary causes of overpotential in the anode and the cathode. The voltage drop can be reduced by optimizing the structural design of the electrochemical cell, but an overpotential decrease requires an electrocatalyst with superior performance. Figure 1a shows the mechanism of the HER in an acidic electrolyte, which includes three typical steps: the Volmer, Tafel and Heyrovsky steps. Specifically, in the Volmer step, H* is adsorbed on the surface of the catalyst by coupling a proton and an electron. Then, bonding of two adsorbed H* into H2 is the Tafel step, whereas combination of the adsorbed H*, a free proton in the electrolyte and an electron into H2 is the Heyrovsky step.

Mechanism of the HER and the activity trend of electrocatalysts. a Mechanism of the HER on the surface of an electrode in an acidic electrolyte. b Volcano plot of the exchange current density for electrolytic hydrogen evolution vs. strength of the intermediate metal-hydrogen bond formed between absorbed H and the electrode surface. Reprinted with permission from Ref. [14]. Copyright © 1972 Published by Elsevier B.V. c Experimentally measured exchange current density for hydrogen evolution over different metal surfaces plotted as a function of the calculated hydrogen chemisorption energy per atom, ΔEH. Reprinted with permission from Ref. [15]. Copyright © 2005 ECS-The Electrochemical Society, Inc. d Periodic table depicting the HER activity over different metals based on the electronic structure and physical properties. Based on data from Ref. [14, 15]

The Tafel slope, reflecting the overpotential and current density, is widely accepted for use in experimental assessment of the electrocatalytic performance of a material for a specific reaction. A low Tafel slope means that the catalyst only needs a small increase in overpotential to achieve a large increase in the current density [13]. However, a bond strength between the catalyst and adsorbed H* that is neither strong nor weak is the essential factor of efficient HER. Volcano diagrams were reported by Trasatti [14] and Nørskov [15] from the perspectives of the strength of the metal-hydrogen bond and hydrogen chemisorption energy, respectively (Fig. 1b and c). The active metals in Fig. 1b and c were divided into five categories based on the HER activity, combined with the electronic structure and physical properties (Fig. 1d). The chemisorption energies in the green and yellow regions are not moderate, and the ferromagnetic and d10s1 groups are not superior to noble metals in the HER (Fig. 1b and c). There is no doubt that platinum exhibits the best HER activity and the lowest overpotential among all noble metals.

3 Band Bending of Semiconductors

Thermodynamically, an input voltage of at least − 1.23 V from the grid is required even if platinum with unprecedented performance is used as the electrocatalyst for water splitting. Although solar-to-electricity conversion is considered to be the most scientific method, the energy dissipation and entropy increment depend on the number of conversions from low-density energy (e.g., solar energy) to high-density energy (e.g., electricity and chemical energy).

Therefore, the solar-driven HER is a perfect way to efficiently utilize solar energy. Specifically, hydrogen production by photocatalysis (PC) is a promising approach, but industrializing it is currently difficult because it commonly requires a high-value sacrificial agent to consume photogenerated holes [16]. Solar thermochemical or photothermal synergistic water decomposition to produce hydrogen is another feasible method, but it requires external facilities to maintain a high temperature (300–1 500 °C), which makes it uncompetitive [17,18,19]. Among all the options for solar-driven HER, the PEC system is superior due to the easy product separation, high efficiency, good durability and continuous operability [20,21,22,23,24]. The light-harvesting module in the PEC system is a semiconductor, which can be classified into the positive-type (the p-type, holes are the majority carriers), which is beneficial for the HER, and the negative-type (the n-type, electrons are the majority carriers), which is beneficial for the OER [25,26,27].

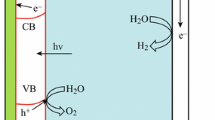

As shown in Fig. 2a and d, the band diagram is composed of the forbidden band/band gap, whose electron probability is quantum mechanically forbidden, the valence band (VB) and the conduction band (CB). The Fermi level (EF) should be located at the midpoint of the band gap in intrinsic semiconductors since the number of electrons is equal to the number of holes. However, the EF of p-type semiconductors is close to the VB [28]. When a p-type semiconductor is immersed in an electrolyte and its EF is more positive than the Fermi level (EF(redox)) of the electrolyte, the charge carriers will be transferred from the electrolyte to the semiconductor until an equilibrium is established between EF and EF(redox), while the opposite is true for an n-type semiconductor (Fig. 2b and 2e). After equilibrium, a depletion layer (the space-charge layer) is formed because the majority carriers of the semiconductor are depleted at the interface. Furthermore, the electrons and holes transfer in opposite directions due to the electric field derived from the band bending; specifically, the majority carriers transfer to the bulk, and the minority carriers move to the depletion layer (Fig. 2b and e).

Band diagram of p-type and n-type semiconductors immersed in an electrolyte with redox potential EF(redox) a, d before equilibrium; b, e at equilibrium; c, f with illumination of light or when biased. The open-circuit voltage is symbolized by VOC, and the quasi-Fermi level is symbolized by EF, p (holes) and EF, n (electrons)

Obviously, the minority carriers determine whether a reduction or an oxidation reaction occurs at the semiconductor–electrolyte interface. That is, a cation-dominated Helmholtz layer is formed on the surface of a p-type semiconductor, while the opposite is true for an n-type semiconductor. However, the semiconductor is in a nonequilibrium state when illuminated or biased, and the quasi-Fermi level is employed to present the statistical gradient distribution of electrons (EF, n) and holes (EF, p) (Fig. 2c and f). The difference between EF, p and the redox potential of the HER in p-type semiconductors and the difference between EF, n and the potential of the OER in n-type semiconductors under illumination is termed “photovoltage” or “open-circuit voltage (VOC)” (Fig. 2c, f). In addition to irradiation, the applied bias is another nonnegligible factor contributing to the shift of the quasi-Fermi level. Both VOC and the applied bias are commonly accepted to be the driving force for water splitting. However, a bias-free light-driven PEC device that can generate a sufficiently large VOC under irradiation is desired to reduce or even eliminate the bias requirement.

4 Configuration of PEC Devices

The wavelengths of solar radiation are generally divided into ultraviolet (UV), visible (Vis) and infrared (IR) regions according to the sensitivity of human vision (Fig. 3a). The absorption band edge of semiconductors depends on Eg, and VOC depends on the position of the quasi-Fermi level, which is also related to Eg. Therefore, the most efficient utilization of solar radiation involves achieving full-band absorption by coupling semiconductors with different band gaps under the premise that VOC can drive water splitting.

Solar spectrum and APSs for solar-to-hydrogen conversion. a Solar spectrum and irradiance power collected in Fuzhou (26°05'N, 119°20'W) by a light intensity meter (ILT950). b–d Photosynthetic systems with different configurations: b electrode and tandem photoelectrode configuration; c tandem photocathode and photoanode configuration; d integrated tandem photosynthetic system configuration

According to the functions of semiconductor photoelectrodes (Fig. 3b, c and d), the configurations of PEC devices are classified into three categories. Figure 3b shows a typical H-type configuration, where the photoelectrode and electrode are separated by an ion exchange membrane (IEM), such as an anion exchange membrane (AEM), a cation exchange membrane (CEM) and a bipolar membrane (BM), which is formed by stacking an AEM and a CEM [29]. A photoelectrode can be either a photocathode for the HER or a photoanode for the OER. Notably, a photoelectrode can be a multicomponent composite or a single-component semiconductor without HER or OER cocatalysts. The photogenerated carriers transfer in opposite directions under the synergy of band bending and applied bias to achieve spatial separation. Specifically, the minority carriers in the semiconductor migrate to the photoelectrode surface for the HER or OER, while the majority carriers migrate to the counter electrode along the external circuit for the other half-reaction. The ions in the electrolyte migrate from one side to another side through an IEM, forming a closed electrochemical circuit. In addition, if the VOC is insufficient to drive the entire reaction, then it needs to be compensated by applying a bias (Fig. 3b and c).

Connecting the photocathode and photoanode in series is an effective strategy to further increase VOC (Fig. 3c). However, the unfavourable voltage drop caused by the IEM and the electrolyte is still inevitable. In further optimization, constructing tandem photoelectrodes in which a photocathode and a photoanode are coupled without an IEM is a superior approach (Fig. 3c and d). With the inner electric field (IEF) caused by VOC, the electrons flow from the anode to the cathode inside the tandem photoelectrode, while the protons in the electrolyte rapidly migrate and supplement the cathode surface for the HER (Fig. 3c). In this configuration of PEC devices, integrating light-harvesting modules such as PVs into the tandem photoelectrode is an advanced choice to achieve bias-free light-driven water splitting. This strategy not only improves the efficiency of solar utilization but also simplifies the device structure. Therefore, many researchers are making efforts for preliminary attempts in this field [2, 30,31,32,33].

5 Evaluation Criteria for Energy Conversion of PEC Devices

For a biased PEC system, the applied biased photon-to-current efficiency (ABPE) is generally employed to evaluate the contribution of the incident light,

where Eredox is the redox potential of 1.23 V for water splitting, j is the photocurrent (A), Ecell voltage is the cell voltage (V) of the PEC device, and Plight is the intensity (AM 1.5G, 100 mW cm−2) of incident light collected by the light meter.

The solar-to-hydrogen conversion efficiency (ηSTH) is commonly used as an indicator to evaluate the performance of PEC devices. The formula is as follows:

where ΔG is the Gibbs free energy (273.15 kJ mol−1) of water splitting, \({\it Y}_{{\mathrm{H}}_{2}}\) is the yield of hydrogen (mol s−1), Plight is the intensity (AM 1.5G, 100 mW cm−2) of the incident light, and S is the irradiated area (cm2).

The use of the photon quantum efficiency (QE) to evaluate the photon-to-chemical conversion efficiency in PEC devices is also accepted.

where \({Y}_{{\text{H}}_{2}}\) is the yield of hydrogen (mol s−1), ne represents the number of electrons (ne = 2) required to generate a hydrogen molecule, NA is the Avogadro constant (6.02 × 1023 mol−1), Pi (mW cm−2) is the light intensity of the incident light with wavelength λi (nm) measured by a light meter, is and ie (nm) represent the start and end wavelengths of the incident light spectrum integration, respectively, S is the illuminated area (cm2), h is the Planck constant (6.626 × 10−34 J s), and c is the speed of light (3 × 108 m s−1). Note that if incident light with a centre wavelength of λ is generated by a bandpass filter, then ie, is and λi in the formula are all equal to λ.

The incident photon-to-current efficiency (IPCE) evaluates the water splitting performance of an electrode from the perspective of photoelectric conversion. It is commonly obtained at a fixed wavelength of incident light. The formula is as follows:

where i is the photocurrent (A), e (1.602 × 10−19 C) is the charge of an electron, h is the Planck constant (6.626 × 10−34 J s), c is the speed of light (3 × 108 m s−1), λ (nm) is the wavelength of the incident light, Pλ (mW cm−2) is the light intensity of the incident light measured by a light meter, and S is the irradiated area (cm2).

The Faraday efficiency (FE) is the most commonly used evaluation criterion for electrode stability. The photocorrosion of the photoelectrode will make the FE far from 100% because not all electrons are used for water splitting. The formula for the FE is as follows:

where \({Y}_{{\text{H}}_{2}}\) is the experimental hydrogen throughput (mol s−1), j is the photocurrent (A), ne is the number of transferred electrons required to generate a hydrogen molecule (ne = 2), and F is the Faraday constant (96 485.3 C mol−1).

6 Electrode Materials for the HER in PEC Devices

This section will discuss the perspectives of light-harvesting materials in photoelectrodes, HER catalysts on the surface of photoelectrodes, and innovative materials with potential applications.

6.1 Silicon-Based Materials

Silicon (Si) is abundant in the Earth’s crust [34]. As a p-type semiconductor, it is not only widely used in integrated circuits in the electronics industry but also shines in the PV field of solar energy conversion. For PEC water splitting, Si has become a supermaterial due to its structural inclusiveness, a CB position of − 0.5 V (vs. the reversible hydrogen electrode (RHE)), which is more negative than the potential for hydrogen production (Si is therefore suitable for water reduction), narrow Eg of 1.12 eV, wide spectrum absorption, high carrier migration rates and suitable band diagrams. In theory, the photocurrent density of Si as high as ca. 44 mA cm−2 under 100 mW cm−2 irradiation surpasses that of most current photoelectrodes [35, 36]. Compared with polycrystalline silicon, monocrystalline silicon exhibits a faster photogenerated carrier transport speed and a lower recombination probability [37].

6.1.1 Surface Treatment of Silicon

However, planar Si has an inherently high reflectivity of up to 30%. In practical applications, surface treatment and antireflection coating (ARC) are widely used strategies to suppress the reflection of incident light [38, 39]. Constructing nanowires (NWs) on the surface is a universal treatment method. Liu et al. reported a vertically aligned NW array Si-based photoelectrode, which is a favourable configuration for the HER (Fig. 4a–d) [38, 40,41,42,43,44]. This configuration not only enhances the light absorption through multiple scattering of incident light but also decouples the light absorption and photogenerated carrier raial transmission and collection [40]. Moreover, the low photogenerated carrier fluxes caused by the high specific surface area of NWs make the photoelectrode more compatible with the loaded HER electrocatalyst compared to the planar photoelectrode [45, 46]. Liu et al. employed a top-down microfabrication technique including e-beam lithography and a subsequent deep reactive ion etching (DRIE) process, which are well established in the semiconductor industry (Fig. 4a and b) [40]. A systematic study of the structural parameters of the NWs showed that arrays with a diameter of 200 nm, a length of 1 mm and an interwire spacing of 175 nm exhibit superior HER performance [40]. Huskens et al. prepared tapered Si microwire arrays by combining DRIE with a Si slow etchant (Fig. 4c) [38]. Next, a multilayer composite photocathode with a tight bonding interface was fabricated by spin-coating, sputtering and electrodeposition (Fig. 4d) [38]. This PEC device features a photocurrent density of ca. 10 mA cm−2 at 0 V vs. RHE and outstanding durability over 200 h [38]. Moreover, an external quantum yield of 80% for the HER is achieved by matching the absorption band edge of the composite material [38]. Therefore, the ordered Si NWs not only ameliorate light harvesting but also serve as the foundation for the preparation of tandem photoelectrodes.

Surface treatment strategy of planar silicon. Top-view images of Si NW photocathodes with lengths of a 2 µm and b 5 µm. Reprinted with permission from Ref. [40]. Copyright © 2018 The Royal Society of Chemistry. Scanning electron microscopy (SEM) images of c silicon microwires obtained by wet etching and d the completed Si microwire photocathode, ITO/Au (pink), Cu2O (red), Ga2O3 (orange), and TiO2 (blue). Reprinted with permission from Ref. [38]. Copyright © 2019 American Chemical Society. e Top-view and f cross-sectional images of bare n+p-Si micropyramid arrays. Reprinted with permission from Ref. [47]. Copyright © 2018 Published by Elsevier B.V. and Science Press. g Cross-sectional SEM image of SiNW arrays. h Schematic of the synthesis procedures for fabricating SiNWs/MoS2 by the CVD method. Reprinted with permission from Ref. [53]. Copyright © 2018 The Royal Society of Chemistry. i SEM image of the MoS2|TiO2|SiNW structure, and j schematic diagram of the photoelectrode architecture. k SEM image of the MoS2|TiO2|ZnONW|Si structure, and l schematic diagram of the photoelectrode. Reprinted with permission from Ref. [54]. Copyright © 2019 American Chemical Society

Zhang et al. prepared a silicon micropyramid structure by employing a chemical etching method to treat p-type Si (Fig. 4e and f) [47]. The micropyramid configuration is a commonly used surface treatment strategy because the enhanced roughness will make the other components of the photoelectrode and the light absorber Si closer composites [38, 48,49,50,51]. Similarly, it exhibits a broadband light-harvesting capability due to the omnidirectional surface structure [47, 52]. Combining Si, which is inert to the HER, and materials with high catalytic activity is an effective strategy to reduce the overpotential. Hu et al. used metal-assisted chemical etching (MACE) technology to prepare high-density vertically aligned Si NWs (Fig. 4g) [53]. Then, a one-step chemical vapour deposition (CVD) method was used to directionally grow a few layers of cocatalyst MoS2 on the surface of Si NWs to improve the HER performance (Fig. 4h) [53]. Jaramillo et al. employed a pseudo-Bosch etching process and a wet chemical deposition technique to prepare Si NWs and ZnO NWs on a Si substrate, respectively (Fig. 4i, j, k and l) [54]. The core highlight is the decoupling of the light absorber surface area and the electrocatalytic active surface area (ECSA) through the structured ZnO interface layer (Fig. 4k and l). By comparison, the effect of the absorber surface area on the photovoltage and the essential contribution of the ECSA to the HER performance were verified. The results showed that the photocathode with the ZnO NW configuration has both the electrocatalytic activity of the structured catalyst and the photoactivity of planar silicon [54].

6.1.2 Interface Protection and Passivation

Due to the active chemical properties of Si, chemical reactions or corrosion occur when it is directly placed in an electrolyte. Therefore, surface passivation is widely used to keep Si stable but without compromising its outstanding light absorption [55,56,57,58,59,60]. Liu et al. used electrochemical etching, drop casting and heat treatment processes to prepare inverted pyramid textured p-Si photoelectrodes, and then, Co2P as both a protective layer and an HER electrocatalyst was deposited onto the p-Si (Fig. 5a) [61]. The authors stated that the macroscopically continuous but locally unevenly distributed Co2P layer makes the light absorber (vertices) and catalytically active (top edges) sites separate spatially (Fig. 5a). With this strategy, the PEC device exhibited a photocurrent as high as ca. 35.2 mA cm−2 under bias-free simulated light irradiation (AM 1.5G) and catalysed hydrogen production at a current density higher than 30 mA cm−2 for at least 150 h without significant attenuation [61]. Because of its instability in alkaline electrolytes, Si has been studied under acidic conditions, as reported in most literature. In view of this, Huskens et al. electrodeposited metallic Ni after precisely removing the SiNx on the top of NWs and then obtained a defect-free protective layer of NiSi after a rapid thermal annealing (RTA) process (Fig. 5b) [62]. The NiMo catalyst for the HER was electrodeposited on top of the prepared NiSi, and it was also directly deposited on the metallic Ni without the RTA process for comparison (Fig. 5b). The results showed that only the photoelectrode with NiMo deposited on NiSi has enhanced corrosion resistance in the 1 M KOH solution (1 M = 1 mol L−1) and exhibits superior HER performance. In this way, the electrocatalyst on the surface can also be regarded as a protective layer for the light absorber. In addition, Wang et al. and Kim et al. presented a novel PEC architecture based on 3D pyramid-like graphene/p-Si Schottky junctions, which greatly enhances the light-harvesting efficiency and exhibits promising PEC performance for hydrogen generation. A graphene interlayer is applied between p-Si and MoP nanorods to enable fully engineered interfaces without forming a metallic secondary compound, which absorbs parasitic light and provides an inefficient electron path for hydrogen evolution. Growth on graphene-passivated silicon photocathodes has been successfully demonstrated to remarkably improve the PEC-HER performance in balance [63,64,65]. However, inert materials that are generally resistant to acid–base corrosion and light corrosion and that have outstanding self-stability are the first choice for the protective layer in PEC systems. To date, TiO2 has been one of the most widely used materials for photoelectrode protection. Wang et al. reported that TiO2 can be used as a protective layer to decouple the trade-off between Si-based photoelectrode efficiency and stability (Fig. 5c and d) [66]. The key factor stated by the authors was the graded oxygen defects of the crystalline TiO2 protective layer. For this factor, a comparative experiment designed by the author showed that a photoelectrode with a well-crystallized and defect-free TiO2 protective layer cannot exhibit PEC properties (Fig. 5c). In contrast, the use of black TiO2 with oxygen defects as a protective layer led to a limiting current density of ca. − 35.3 mA cm−2 and stable operation at 10 mA cm−2 in 1.0 M KOH for at least 100 h (Fig. 5c). The author stated that there are conducting paths generated by defects, as well as suitable band alignment, in black TiO2 that can be used as photogenerated carrier transport channels (Fig. 5d). Moreover, the authors also proposed that the protons adsorbed on the electrocatalyst Pd would spill over onto the surface of black TiO2 for the HER. Therefore, TiO2 as a protective layer can be considered to possibly have a nonnegligible contribution to the catalytic HER.

Interface protection and passivation strategies of Si-based photoelectrodes. a Schematic illustration of the influence of catalyst loading on inverted pyramid textured p-Si. Reprinted with permission from Ref. [61]. Copyright © 2019 American Chemical Society. b Fabrication scheme for alkaline-stable photocathodes. Reprinted with permission from Ref. [62]. Copyright © 2018 American Chemical Society. c Surface protection strategies for nanoporous black Si photocathodes. d Schematic of the Pd nanoparticle/black TiO2/black Si photocathode. Reprinted with permission from Ref. [66]. Copyright © 2018 The Author(s). e J − V curves and durability for pn+-Si/Pt, pn+-Si/Ta2O5/Pt and pn+-Si/TiO2/Pt electrodes; band diagrams of pn+-Si/TiO2 and pn+-Si/Ta2O5. Reprinted with permission from Ref. [69]. Copyright © 2019 American Chemical Society. f Integrated photocathode with the MoS2/Al2O3/n+p-Si configuration. Reprinted with permission from ACS [72]. Copyright © 2017 American Chemical Society. g TEM image of a photocathode with the MoS2/SiO2/Si configuration. Reprinted with permission from Ref. [74]. Copyright © 2017 The Royal Society of Chemistry

In addition, Ti3+ species induced by UV photons in TiO2 as traps for photogenerated carriers were previously reported to possibly deteriorate the performance of the protective layer [67, 68]. Gong et al. prepared a series of protective layers on Si substrates by atomic layer deposition (ALD) and employed photoelectrochemistry and spectroscopy to conduct an in-depth study (Fig. 5e) [69]. As expected, pn+-Si/TiO2/Pt is similar to pn+-Si/Pt without a protective layer, and its photocurrent density drastically drops within a few hours (Fig. 5e). However, the photoelectrode pn+-Si/Ta2O5/Pt shows outstanding stability for up to 200 h, which is protected by another nearly transparent Ta2O5 layer with superior chemical stability and a band gap of 4.2 eV (Fig. 5e). In addition, Ta2O5 has been demonstrated to not only exhibit superior stability over a wider pH range as a protective layer [70] but also efficiently transport electrons from light absorbers, such as Si PVs, as an electron-selective heterogeneous contact layer [71]. Shen et al. reported an Al2O3 protective layer with a thickness of ca. 2 nm and a MoS2 catalyst layer with a thickness of ca. 67 nm fabricated on Si substrates by ALD and magnetron sputtering methods, respectively (Fig. 5f) [72]. The MoS2/Al2O3/n+p-Si photocathode exhibited a current density of 35.6 mA cm−2 and remarkable durability over 120 h. Among the layers, Al2O3 not only protects Si from corrosion but also suppresses the interface recombination of photogenerated carriers as a passivation layer [72]. However, the instability in acid–base electrolytes limits its application [73]. Kim et al. also deposited MoS2 on a Si substrate by the ALD method and then heat-treated it at 500–700 °C to further make it crystalline (Fig. 5g) [74]. Interestingly, the heat treatment process produced a protective layer of SiO2 with good light transmittance and an inconspicuous interface with the Si substrate (Fig. 5g). The MoS2/SiO2/Si photocathode exhibited a photocurrent density of ca. 31 mA cm−2 and durability without obvious degradation within 24 h under simulated light irradiation of 100 mW cm−2 in 0.5 M H2SO4 electrolyte [72].

6.1.3 Construction of Junctions

The most commonly used strategy to improve the conductivity of pure Si (the intrinsic semiconductor) is doping with impurity atoms (the extrinsic semiconductor) [75,76,77]. The valence electron configuration of the host Si atom is 3s23p2, while the impurity atoms are generally nonmetallic B (2s22p1) and P (3s23p3). A hole-rich p-type semiconductor will be generated when the electron acceptor B with fewer valence electrons than the host atom replaces the lattice site of Si. Conversely, electron donor P doping creates an electron-rich n-type semiconductor [78]. The p–n junction is a commonly used junction structure in the electronics industry, and it also has advantages when applied to photoelectrodes [79,80,81,82] because the internal electric field in the space-charge region (SCR, also termed the depletion region, where the diffusion of majority carriers and drift of minority carriers have reached an equilibrium) of the p–n junction contributes to the separation of photogenerated carriers. The direction of the electric field is from the n region, where holes are the minority carriers, to the p region, where electrons are the minority carriers. Liu et al. fabricated a sandwich p–i–n (p-type-intrinsic-n-type) amorphous silicon (a-Si) photoelectrode with ferrihydrite (Fh) as the hole storage interlayer and Ni as the hydrogen evolution catalyst (Fig. 6a) [83]. The authors stated that the a-Si/Fh/Ni photoelectrode achieved a record bias-free photocurrent density of ca. 15.6 mA cm−2 and a half-cell energy conversion efficiency of ca. 4.08% [83]. The “ + ” (n+ and p+) represents heavy doping of impurities and “ − ” (n− and p−) represents light doping in the semiconductor [84]. The generally accepted purpose of heavy doping is to reduce the barrier at the interface to achieve ohmic contact [85, 86, 87]. He et al. reported a MoS2/p+nn+-Si photoelectrode for the HER with a photocurrent density of ca. 36.3 mA cm−2, a half-cell solar-to-hydrogen (STH) efficiency of 5.57% and an open-circuit potential (OCP) of 0.5 V vs. RHE under AM 1.5G illumination (Fig. 6b) [88]. Tilley et al. demonstrated a pn+Si/TiO2/Pt photocathode containing a buried junction, where TiO2 is used as a protective layer and Pt is used as a catalyst for the HER (Fig. 6c) [89]. In this model PEC system, dual working electrode (DWE) technology was employed to systematically study the independent properties of the light absorber and electrocatalyst under operation conditions (Fig. 6c) [89]. The focus of this method was the semiconductor–electrolyte interface and the mechanism of light absorber performance degradation due to photocorrosion and other reasons. The DWE methodology can also be applied to other newly developed and more complex PEC systems based on various types of junctions [90, 91].

Construction of junctions commonly used in Si-based photocathodes. a An a-Si/ferrihydrite(Fh)/Ni photocathode. Reprinted with permission from Ref. [83]. Copyright © 2021 Wiley–VCH GmbH. b Schematic illustration of the MoS2-integrated Si photocathode. Reprinted with permission from Ref. [88]. Copyright © 2019 Optical Society of America under the terms of the OSA Open Access Publishing Agreement. c DWE configuration used during PEC measurements with a pn+Si/TiO2/Pt photocathode. Reprinted with permission from Ref [89]. Copyright © 2018 The Royal Society of Chemistry. d Schematic device structure of the a-Si:H/a-SiGe:H tandem photocathode with the protective layer. Reprinted with permission from Ref. [94]. Copyright © 2016 The Royal Society of Chemistry. e Schematic of the components of the BBJ cell. Reprinted with permission from Ref. [95]. Copyright © 2020 The Author(s). f Schematic of the n+-GaN NW/n+-p Si photocathode. Reprinted with permission from Ref. [96]. Copyright © 2018 American Chemical Society

The multijunction structure assembled by stacking a single junction structure can enhance the output potential of the light absorber [92, 93]. Zhang et al. fabricated a tandem photocathode on textured aluminium-doped zinc oxide (AZO) with an HTO/a-SiGe:H p–i–n/Si:H p–i–n structure, in which H-doped TiO2 (HTO) was used as the protective layer (Fig. 6d) [94]. The authors designed and optimized the photoelectrode from the aspects of the band diagram, electron transport barrier, interface ohmic loss and factors related to electron tunnelling probability, such as carrier density and depletion layer width. This work successfully found a breakthrough for the conventional trade-off between the activity and stability of Si-based PEC devices [94]. He et al. demonstrated both back-buried junction (BBJ) and spatial decoupling of absorber–electrocatalyst strategies on silicon to achieve bias-free water splitting (Fig. 6e) [95]. In the structure of the photoelectrode, SiNx was used as an antireflection coating, and SiO2 was used as a passivation layer (Fig. 6e). Benefiting from the tandem absorber structure design and the precise preparation of the interdigitated carrier separation path, the PEC device exhibited an absorption of 95% for the solar spectrum, a VOC of ca. 1.8 V, an STH efficiency of ca. 15.6% and a photocurrent density of ca. 40.5 mA cm−2 [95]. In particular, this PEC system shows promise for industrial applications because multiple devices can be integrated (p+nn+-p+nn+-p+nn+) through an easy tin soldering connection to expand production. Mi et al. constructed a photocathode with a p+pn+–Si/GaN/n+–GaN NW/Pt structure and an approximately aligned CB minimum (CBM) in the band diagram (Fig. 6e) [96]. Among the components, the authors stated that the GaN NW array not only protects Si from corrosion but also reduces the transfer resistance of charge carriers [95]. Furthermore, the PEC device at that time exhibited the highest ABPE of approximately 10.5% among all current Si-based photocathodes and outstanding stability up to 120 h at a photocurrent density of approximately 35 mA cm−2.

6.2 Cuprous and Copper Oxide

Among all the current p-type oxide photocathode semiconductors, Cu-based semiconductors are promising materials because they exhibit superior performance in PEC water splitting [96]. Furthermore, cuprous (Cu2O) and copper oxide (CuO) are more advantageous due to their low production cost and technical threshold compared with Si-based materials. The CB positions of Cu2O and CuO are at −0.7 and −0.1 V (vs. RHE), respectively. Compared with hydrogen production, they have a more negative voltage and are suitable for water reduction. In addition, the high photoactivity and abundance make them competitive [97,98,99]. Among them, Cu2O exhibits Eg of ca. 2.1 eV, a theoretical photocurrent density of ca. 14.7 mA cm−2 and an STH conversion efficiency of ca. 18.7% under simulated light irradiation of AM 1.5G [100, 101]. Generally, the use of surface conformal protective coatings, including stable oxides [80, 102], films [103,104,105] and polymers [106,107,108], is a favourable approach to suppress the poor stability of Cu2O [95]. For CuO, many researchers believe that its Eg is between 1.4 and 1.7 eV, so it can absorb a large proportion of the solar spectrum [109, 110]. A joint experimental and theoretical study by Pierson et al. accurately proved that CuO has direct Eg of 1.46 eV [111]. The research on the application of CuO to solar-driven water splitting is not comprehensive [112,113,114,115]. Li et al. prepared a Cu2O photoelectrode with a conformal protective layer of CuO through straightforward one-step fast annealing of copper foil in a H2–O2 flame (ca. 1 300 K) (Fig. 7a) [116]. Researchers performing similar works using CuO to protect Cu2O believe that this configuration has an appropriate band alignment that is conducive to the transport of photogenerated carriers [117,118,119,120,121,122]. The proportion of each layer in the composite Cu/Cu2O/CuO photocathode with a sandwich structure depends on the annealing time (Fig. 7a and b). The intimate junction is composed of the (110) plane of Cu2O and the (111) plane of CuO [116]. The authors stated that in the annealing time range of 0–10 s, the photocurrent exhibits an upward trend with the thickness of CuO (Fig. 7b). However, a thicker CuO negatively affects the light absorption of Cu2O when annealed for 15 s, resulting in a decrease in the photocurrent (Fig. 7b). The main challenge faced by CuO as a protective layer here is the inherent photocorrosion in an aqueous solution [113, 123]. Specifically, CuO will be reduced to Cu under the joint effects of photogenerated electrons and protons [124]. The reason is that the electrochemical reduction potentials from CuO to Cu2O and from Cu2O to Cu are both located in the band gap of CuO. The widely accepted effective strategy to suppress photocorrosion is to avoid direct contact between the light absorber and protons in the electrolyte.

Architecture, band diagram and performance of Cu-based photocathodes. a Preparation of a Cu2O/CuO composite photocathode. b Current decay curves of composite Cu2O/CuO photocathodes. Reprinted with permission from Ref. [117]. Copyright © 2015 The Royal Society of Chemistry. c The structure of a photocathode is related to the function of each layer. d Current density–potential curves of CuO/TiO2 CuO/CdS/TiO2 photocathodes. Reprinted with permission from Ref. [124]. Copyright © 2017 American Chemical Society. e Equilibrium band edge diagrams of Cu2O/AZO and Cu2O/Ga2O3 heterojunctions. f J–E response for Cu2O-based photocathodes. g Illustration of the all-oxide tandem solar water splitting device. h Stability test of the photocathode at 0.5 V vs. RHE with chopped illumination. Reprinted with permission from Ref. [130]. Copyright © 2018 Macmillan Publishers Limited, part of Springer Nature. i Schematic diagram of the CuSCN-incorporated Cu2O photocathode. j J–E responses of Cu2O photocathodes with or without the CuSCN-D layer. Reprinted with permission from Ref. [137]. Copyright © 2020 The Author(s). k Schematic illumination of the TiO2 and polyurethane acrylate (PUA)-protected Cu2O photocathode. l Schematic illumination of the multilayered Cu2O photocathode and J–E characteristics. Reprinted with permission from Ref. [142]. Copyright © 2019 The Royal Society of Chemistry

Tielly et al. confirmed that the FE of the HER for the bare CuO thin-film photocathode at 0.4 V vs. RHE is ca. 0.01% in a 1 M phosphate buffer (pH = 7) under chopped irradiation of simulated AM 1.5G (100 mW cm−2) [125]. That is, the photocurrent of the unprotected CuO photocathode is mainly from the photocorrosion and degradation of the photoelectrode rather than the HER. Tielly et al. also demonstrated an optimized high-efficiency CuO photocathode with a classical TiO2 protective overlayer featuring an n-type CdS buffer layer that can form a buried p–n junction with the photoabsorber (Fig. 7c) [125]. The CuO/CdS/TiO2/Pt photocathode with a favourable band alignment exhibited a superior performance (Fig. 7d) and a nearly 100% hydrogen evolution FE [125]. This configuration achieves effective suppression of photocorrosion, which is attributed to the powerful extraction of minority carriers in p-type CuO by the integrated junction of n-type CdS.

Since a seminal benchmark strategy of using the ALD method to prepare a protective overlayer for preventing Cu2O photocorrosion was reported in 2011 [98], Grätzel and others subsequently carried out systematic research on optimization of the Cu2O photocathode performance. Specifically, the stability of the Cu2O photocathode was further improved by utilizing a thinner TiO2 protective overlayer and the hydrogen evolution electrocatalyst RuOx [126]. After that, they developed a coaxial Cu2O NW array photocathode based on the surface p–n junction with a remarkable photocurrent density of 10 mA cm−2 at the RHE potential [127]. Benefiting from the development of Cu2O PV devices, Ga2O3 was introduced as a superior surface multifunctional layer [128,129,130]. Among all the current Cu2O-based photocathodes, many studies have focused on the configurations of Cu2O/AZO/TiO2 [131,132,133,134,135,135,136,137] and Cu2O/Ga2O3/TiO2 [89, 138, 139,140,141,142]. Generally, a planar photoelectrode has difficulty reconciling the depth of light absorption and diffusion length of minority carriers [127]. In view of this, Luo et al. demonstrated an efficient photocathode featuring coupling of coaxial NWs and a buried junction (Fig. 7e–h) [125]. Specifically, the authors stated that the radial heterojunction is beneficial to both enhancement of light absorption and transport of photogenerated carriers. Compared with AZO, the CB edge of Ga2O3 is close to that of Cu2O in band alignment (Fig. 7e), which is beneficial for reducing the interface recombination and improving the photovoltage output (ca. 1 V vs. RHE) (Fig. 7f). A bias-free water splitting tandem system was constructed by using a Cu2O photocathode (Cu/Cu2O/Ga2O3/TiO2/NiMo) coupled with a state-of-the-art molybdenum-doped BiVO4 photoanode and achieved a record STH conversion efficiency as high as ca. 3%, rivalling the current all-oxide device (Fig. 7g). The authors stated that the stable operation of the tandem system for more than one week in alkaline electrolytes should be attributed to the superior durability of the photocathode (Fig. 7h).

Gold has been widely employed as the back contact of Cu2O photocathodes due to its appropriate work function and VB edge [125, 126]. Compared with the base material nickel oxide, which is specialized for hole transport, the precious metal Au will result in a considerable amount of recombination since it is not a hole-selective contact [138]. On these grounds, Hagfeldt et al. developed an effective hole transport layer (HTL) of CuSCN for a Cu2O photocathode (Fig. 7i) [138]. Compared with the conventional photocathode, the ameliorated photocathode with defective CuSCN (CuSCN-D) is uncompetitive in the onset potential of ca. 1 V vs. RHE and the current density of ca. 6.6 mA cm−2 at 0 V vs. RHE, but it exhibits a superior fill factor (Fig. 7j). An in-depth study of the band diagram revealed that the band-tail states, which reduce the hole injection barrier rather than shift the Fermi level via heavy doping, allow holes to be transported smoothly [138]. Meanwhile, the difference in the CB edges between Cu2O and CuSCN-D as high as 2 eV results in a very large barrier for electron injection into CuSCN-D and inhibits recombination of photogenerated carriers [137]. Therefore, the construction of barrier-free energy level channels in the reciprocal space (k-space) for majority and minority carrier reverse transmission in the photoelectrode is the key factor for further improvement of the PEC performance.

Among all the current technologies for preparing inorganic oxide protective layers, the light absorber Cu2O cannot be effectively protected for a long period of time. There are two main reasons: (i) the “penetration effect” formed by the island growth of the protective layer makes the absorber partially unprotected; (ii) the electrolyte and protons can reach the surface of the absorber via the micropores and grain boundaries through the “capillary effect”. For this reason, Shao et al. reported a compact macromolecular polymer (solid polyurethane acrylate, PUA) as a hydrophobic layer, which was employed to prevent Cu2O inactivation (Fig. 7k) [142]. Compared with classical TiO2, PUA shows extreme hydrophobicity with a contact angle up to 100° (Fig. 7k). The multilayered Cu2O photocathode with the configuration of Pt/n-TiO2/PUA/p-Cu2O/Ag exhibited an enhanced photocurrent density of ca. 5.5 mA cm−2 at 0 V vs. RHE and an IPCE peak of 68.3% at 415 nm (Fig. 7i) [142]. In addition, the retained 98% durability after 6 h highlights the promising application of this strategy in the further development of PEC systems for solar water splitting.

6.3 Sulphides and Selenides

The tunability of the band gap is the key to accurately designing a solar water splitting system with superior energy conversion efficiency. Benefiting from the development of the close cousins of kesterite Cu2ZnSnS4 (CZTS) and chalcopyrite CuIn1−xGa1−xSe2 (CIGS) with flexible crystal structures, the continuously tuneable band gap has been widely used in PEC systems [143,144,145,146,147]. In addition to the low toxicity and earth abundance that make CZTS competitive, the band gap is ca. 1.5 eV, with a CB position of − 0.8 V (vs. RHE), which is more negative than the hydrogen production voltage, rendering an ideal open-circuit photovoltage and a higher photocurrent for solar water splitting [148]. Since Domen and coworkers first demonstrated a CZTS-based photocathode in 2010 [149], its superior solar water splitting efficiency has attracted the attention of many scientists and led to follow-up studies. Sivula et al. reported that the incorporation of an AZO coating enhances the stability of the photocathode [150]. Subsequently, Domen et al. employed a feasible electroplating annealing method to prepare a photocathode by depositing CZTS onto Mo mesh, revealing that the photocathode with irregular hollow column CZTS exhibits the highest photocurrent density [149]. Ikeda et al. reported a photocathode with the configuration of Pt/In2S3/CdS/Cu2ZnSnS4, revealing that the deposition of In2S3 significantly enhances the stability [151]. Jooho Moon et al. developed a hybrid ink method via a molecular chemistry-controlled technique to prepare CZTS thin films with a conformal dual coating of TiO2/CdS and a Pt electrocatalyst, achieving a remarkable photocurrent density as high as 13 mA cm−2 at − 0.2 V vs. RHE under simulated sunlight illumination (AM 1.5G) [151]. However, the significantly degenerated durability within 1 h needs to be further optimized. Minegishi and coworkers attempted to partially substitute Zn in CZTS with Cd and obtained a photocathode with the Pt/Tio/CdS/Cu2Cd0.4Zn0.6SnS4 configuration, delivering a superior photocurrent density as high as 17 mA cm−2 at 0 V vs. RHE under simulated sunlight irradiation of AM 1.5G [152]. However, the introduction of environmentally unfriendly toxic Cd is not conducive to its practical application. In addition, Mitzi and coworkers fabricated a Pt/TiO2/CdS/Cu2BaSnS4−xSex (x ≈ 3) stacked film photocathode derived from CZTS, achieving a photocurrent density of ca. 12.1 mA cm−2 at 0 V vs. RHE under simulated sunlight of AM 1.5G [153].

At present, surface protection and passivation are key strategies to improve the performance of CZTS-based photocathodes. Jiang et al. developed a surface photocorrosion-resistant passivation film of HfO2 with a thickness of 6 nm to enhance the PEC stability of CdS/Cu2ZnSnS4, revealing a photocurrent stability of over 10 h and a retained half-cell STH conversion efficiency of 2.7% [154]. After that, the authors constructed a bias-free tandem PEC system for solar water splitting based on a Pt/HfO2/CdS/Cu2ZnSnS4 photocathode and a conventional BiVO4 photoanode (Fig. 8a), achieving a full-cell STH conversion efficiency of approximately 1% and a long-term durability of over 10 h [154]. More specifically, an operating point with a photocurrent of approximately 0.64 mA and a cell voltage of approximately 0.57 V was obtained for the tandem system at the crossing point of two independent linear sweep voltammetry (LSV) curves (Fig. 8b) [154]. Following this research, Jiang et al. recently demonstrated a reformative bias-free integrated tandem PEC device with the configuration of a Pt-HfO2/CdS/HfO2/CZTS photocathode and a BiVO4 photoanode for solar water splitting (Fig. 8c), revealing an STH conversion efficiency of approximately 3.7% and a superior durability of at least 20 h under simulated sunlight AM 1.5G irradiation [155]. Similarly, an operating point with a current density of approximately 2.6 mA cm−2 and a cell voltage of approximately 0.58 V was obtained at the crossing point of two individual LSV curves (Fig. 8d). Moreover, the CZTS-based photocathode exhibited a long-term durability of over 24 h and a remarkable ABPE of approximately 7.3%. This exemplary PEC device highlights the promising application potential of the CZTS light absorber [148, 156,157,158].

Architecture and performance of group III and IV semiconductor-based photocathodes. a Diagram of the Pt/HfO2(H6)/BiVO4 tandem device for bias-free solar water splitting. b J − E curves of the H6 photocathode and the BiVO4 photoanode. Reprinted with permission from Ref. [154]. Copyright © 2018 American Chemical Society. c Cu2ZnSnS4(CZTS)–BiVO4 tandem device under AM 1.5G solar simulated illumination. d J–E curves of series photoelectrodes. Reprinted with permission from Ref. [155]. Copyright © 2021 The Royal Society of Chemistry. e SEM image of the CuInxGa1−xSe2 photocathode. f Stability of the CuInxGa1−xSe2 photocathode with the overlayer and Pt catalyst coatings. Reprinted with permission from Ref. [168]. Copyright © 2015 WILEY–VCH Verlag GmbH & Co. KGaA, Weinheim. g Schematic illustration of the Cu(In,Ga)Se2/CdS/TiO2/Pt photocathode. Reprinted with permission from Ref. [169]. Copyright © 2017 American Chemical Society. h Proposed model and band diagram describing the working principles of the Cu(In,Ga)Se2/CdS/rGO/Pt photocathode. Reprinted with permission from Ref. [170]. Copyright © 2018 WILEY–VCH Verlag GmbH & Co. KGaA, Weinheim. i Optical image of CuGaSe2 (first) and Cu(InxGa1−x)S2 (the second to the fourth). j LSV measurement of a CuInGaS2 photocathode. Reprinted with permission from ACS. [165]. Copyright © 2019 American Chemical Society. k Band diagram of the p+-InGaN/TJ/n+p-Si photocathode. l Schematic of the InGaN NW with Pt and Al2O3, the scanning transmission electron microscopy-high-angle annular dark-field (STEM-HAADF) image of the top p+-InGaN segment, and the bright-field STEM image of the TJ region. Reprinted with permission from Ref. [180]. Copyright © 2020 American Chemical Society

Benefiting from the in-depth study of CIGS-based solar cells, a record power conversion efficiency of over 21.5% was revealed [159]. Moreover, Mannstadt et al. reported another remarkable CIGS-based solar cell whose short-circuit photocurrent density reaches 80% of the theoretical limit [160]. The superior light absorption performance and tuneable band edge make CIGS promising for application in PEC systems for solar water splitting [161,162,163]. Gaillard et al. demonstrated a bare CIGS-based PEC device without an electrocatalyst, which exhibited a photocurrent density that rivalled that of the solar cell counterpart and an FE of approximately 86% [164]. Theoretically, the CIGS-based PEC device with a band gap of 1.13 eV should exhibit a maximum STH conversion efficiency of 17.5% and an outstanding photocurrent density of 42.6 mA cm−2 [165]. However, in previous reports, the CIGS-based standalone device with a coplanar architecture exhibited an STH conversion efficiency of approximately 3.7%–10% [166, 167]. Therefore, optimization of the photoelectrode configuration and interface protection are necessary to further improve the performance. Luo et al. demonstrated a remarkable PV-PEC tandem water splitting device with an organic–inorganic metal halide perovskite solar cell and a Pt/TiO2/ZnO/CdS/CIGS photocathode (Fig. 8e), achieving an STH conversion efficiency of approximately 6% [168]. Moreover, the multilayer photocathode exhibited stability for up to 1 h, but with significant degradation (Fig. 8f). Afterwards, Shin et al. reported a similar photocathode without ZnO (Fig. 8g), highlighting the positive effects of the n-type buffer layer (CdS) between CIGS and protective layer TiO2 in enhancing the solar water splitting performance [169]. The shedding caused by poor electrocatalyst adhesion is an important factor for device performance degradation [169]. In view of this, Nam et al. introduced a reduced graphene oxide (rGO) layer to the photocathode as an electrocatalyst binder, revealing the multiple beneficial roles of rGO (Fig. 8h) [170]. More specifically, rGO not only contributes to electron transfer to the Pt electrocatalyst due to its superior in-plane conductivity but also anchors Pt to prevent agglomeration and shedding via defect sites and functional groups. Furthermore, rGO protects CdS and CIGS from photocorrosion in an aqueous electrolyte as a protective layer and then enhances the stability of the photocathode. Moreover, Choy et al. employed an environmentally friendly and cost-effective nonvacuum electrostatic spray-assisted vapour deposition method to prepare a CIGS photocathode. With cobalt sulphide (Co–S) as an electrocatalyst, a photocurrent density of approximately 19 mA cm−2 at − 0.34 V vs. RHE was achieved on this photocathode [171]. Yoon et al. confirmed that the photocurrent density depending on the Pt load can reach 37 mA cm−2 at − 0.7 V vs. RHE and attributed the outstanding performance to the effective separation of photogenerated carriers caused by the surface p–n junction [146]. Domen et al. developed a solid solution of (ZnSe)0.85(CIGS)0.15 prepared by a coevaporation method as a photocathode, delivering a photocurrent density of approximately 7.1 mA cm−2 and an STH conversion efficiency of 0.91% after coupling with a BiVO4 photoanode [172]. After that, Nishikiori et al. highlighted the multiple functions of the Pt/TiO2 layer in the Pt/TiO2/CdS/ZnSe:CIGS photocathode, including prevention of photocorrosion, surface wettability for hydrogen production and dependence of the surface potential on the Pt content [173]. Recently, a study on the optimal particle size of ZnSe:CIGS that composes the photocathode was reported by Nishikiori and coworkers, revealing a particle size-dependent solar water splitting performance that can be attributed to the synergistic effect of the specific surface area, carrier density and bulk resistance [174].

Chalcopyrite CuInGaS2, whose crystal structure and optical properties are similar to those of CIGS, is also a superior light absorber with a flexible structure. Experiments and theoretical calculations have confirmed that CuInGaS2 can achieve a tuneable band gap from 1.54 eV (CuInS2) to 2.46 eV (CuGaS2) [67, 68]. Gaillard and coworkers developed a feasible close-space sulphurization method to fabricate Cu(In,Ga)S2 from CIGS precursors on FTO substrates at low temperature [165]. They obtained a series of Cu(In,Ga)S2 with a variable band gap from approximately 2 to 2.5 eV by tuning the content of In and Ga in CIGS precursors (Fig. 8i). Among all the obtained samples, bare CuInGaS2 with a band gap of 2.05 eV and a thickness of 800 nm exhibited a superior performance, achieving a saturation photocurrent density of approximately –5.2 mA cm−2, corresponding to 38% of the theoretical limit [165]. Analogous to CIGS, if protective layers to prevent photocorrosion and heterojunctions that facilitate carrier separation and minority carrier transfer are constructed on CuInGaS2, then its performance may be further optimized [175]. In addition, the optical band gap is approximately linearly dependent on the Ga or In content.

The InGaN absorber is another promising candidate material for photoelectrodes because of its composition-dependent tuneable band gap (0.6–3.4 eV) [176]. In particular, InGaN nanorods theoretically exhibit a superior STH conversion efficiency of approximately 27%, a shorter minority carrier diffusion distance and appropriate band edge levels for solar water splitting [177,178,179]. Mi et al. developed a double-junction photocathode with the configuration of Al2O3/Pt/p+p++n++n+–InGaN/n+pp+–Si (Fig. 8k), where n++/p++ InGaN is the tunnel junction (TJ) (Fig. 8k and l) [180]. More specifically, p-type InGaN containing the TJ was monolithically integrated onto the bottom p–n junction of Si with a conformal surface passivation layer of Al2O3 and an electrocatalyst of Pt [180]. The authors stated that the top p+–InGaN segment, TJ and surface modification promote electron extraction and reduce the recombination of photogenerated carriers [180]. Moreover, the double-junction photocathode exhibited a bias-free photocurrent of approximately 8.4 mA cm−2, an STH conversion efficiency of approximately 10.3% and a long-term durability of at least 100 h under simulated sunlight AM 1.5G irradiation in the 0.5 M H2SO4 electrolyte.

The p-type semiconductor CuIn(S1−xSex)2 derivative series of chalcopyrite Cu(In,Ga)(S,Se)2 (CIGSSe) also exhibit a superior tuneable band gap and excellent light absorption properties [181,182,183,184,185]. Generally, the flat band potential derived from Mott–Schottky analysis and the VB spectrum obtained from X-ray or UV photoelectron spectroscopy (XPS or UPS) are used to determine the thermodynamic band edge of a semiconductor. Recently, Bocarsly and coworkers found that the flat band potentials derived from the two techniques of photocurrent onset under chopped-light irradiation and Mott–Schottky analysis are in good agreement for the CuIn(S1−xSex)2 semiconductor series (Fig. 9a) [186]. Calculating the band structure based on first principles is a commonly used method for material property prediction. However, compared to experimental facts, theoretical calculations generally offer a smaller band gap, and the positions of the Fermi level and the vacuum level are not accurate. The photocurrent onset technique has universal significance for quick, cost-effective and accurate determination of the band edge. In Fig. 9a, the variation in the CB edge is small, and the VB edge depends on the ratio of anions, delivering edges that all possess appropriate energetics for the thermodynamic requirement of water splitting [186]. However, the CuIn(S1−xSex)2 series exhibit superior HER performance when x = 0.4, indicating kinetic limitations. In view of this, according to the Gärtner model [187], the authors proposed a probability of the diffusion theoretical model (PD = \({\text{e}}^{-b/{L}_{\text{n}}}\)) related to the minority carrier diffusion length (Ln) and initial distance b (under illumination, R1 is the SCR, R2 is the diffusion region, and R3 is the dark region) (Fig. 9b) [187]. Generally, the R1 width decreases as the majority carrier concentration increases, and the decrement is ΔR1 in Fig. 9b, resulting in a decrease in PD. The reason is attributed to photogenerated carrier recombination. Therefore, the performance of the photocathode for solar water splitting can be directly influenced by the majority carrier concentration.

Architecture, band diagram and performance of sulfide- and selenide-based photocathodes. a Schematic diagram of the electronic band positions of CuIn(S1−xSex)2. b Schematic of the three regions emerging in a semiconductor. Reprinted with permission from ACS. [186]. Copyright © 2018 American Chemical Society. c Schematic illustration of charge separation and transfer for the NiS/CuInS2/NiO composite photocathode. d SPV spectra of photocathodes in (c). Reprinted with permission from Ref. [189]. Copyright © 2019 American Chemical Society. e I − E curves for Pt/CuGaSe2 and Pt/CdS/CuGaSe2 photoelectrodes. f Calculated band alignment for CuGaSe2 and CdS/CuGaSe2 photoelectrodes. Reprinted with permission from ACS. [151]. Copyright © 2013 American Chemical Society. g Approximate energy diagram of Sb2Se3, CdS and TiO2. Reprinted with permission from ACS. [217]. Copyright © 2019 American Chemical Society. h Scheme of the NiFeOx/H,Mo:BiVO4/FTO–Pt/TiO2/CdS/Sb2Se3/Au/FTO tandem cell. i JE response for the photoanode and the photocathode. Reprinted with permission from Ref. [218]. Copyright © 2020 The Author(s)

In addition, the surface photovoltage (SPV) spectra represent the separation of photogenerated carriers in space [188]. Zhou et al. employed SPV technology to clarify the mechanisms of the NiO hole transfer layer and NiS catalyst in a photocathode with the NiS/CuInS2/NiO configuration (Fig. 9c) [189]. In their study, the positive (negative) signal of SPV spectra represents the photoinduced holes (electrons) in the bulk reaching the irradiation surface of the photocathode [189]. Back illumination showed an enhanced positive signal after introducing the NiO layer, indicating that CuInS2/NiO achieved effective charge separation (Fig. 9d). Similarly, front illumination exhibited a typical feature of p-type semiconductors in that the minority carriers (electrons) transferred to the NiS catalyst, while NiS/CuInS2/NiO showed a superior SPV compared to the other configurations (Fig. 9d). Note that this SPV technology criterion is only applicable to the study of a single solid photoelectrode and not to the two- or three-electrode configuration in a liquid electrolyte. In addition to NiO, FeOOH can also transport holes generated by the light absorber. Moreover, surface modification of CuInS2 is also an effective method to improve the solar water splitting performance. Among all the reports, CdS and In2S3 are most commonly used as surface modification layers for chalcopyrite [190,191,192,193]. Ikeda et al. reported the band diagram of CdS/CuInS2 (cliff–type CB offset) and In2S3/CuInS2 (notch–type CB offset) heterojunctions, revealing that interface recombination is suppressed at the notch–type junction of In2S3/CuInS2, which is favourable for solar water splitting [191]. CdS [193,194,195,196], In2S3 [197, 198], CuS2 [199, 200], MoS2 [201], SnS [202, 203], WS2 [204], ReS2 [205, 206], CoSe2 [207] and CdSe2 [208, 209] are widely used in photocathodes as modification layers, electrocatalysts or light absorbers. In particular, MoS2 has attracted much attention as an excellent and cost-effective hydrogen evolution electrocatalyst that is most likely to replace state-of-the-art precious Pt [204].

Domen et al. demonstrated a photocathode with the typical Pt/CdS/CuGaSe2 configuration [151, 210], achieving enhanced photocurrent density and onset potential after introducing the CdS surface modification layer and outstanding durability over 10 days (Fig. 9e) [151]. They proposed two reasons for the improved performance of Pt/CdS/CuGaSe2. One is that the increased thickness of the SCR promotes the separation of photogenerated carriers, and the other is that the constructed p–n junction allows the minority carriers (electrons) in CuGaSe2 to selectively diffuse into CdS (Fig. 9f) [151]. The nontoxic and cost-effective light absorber antimony selenide (Sb2Se3) exhibits a theoretical photocurrent density of approximately 40 mA cm−2 and a band gap of 1.2 eV [211].

Since Tang et al. successfully fabricated thin-film solar cells based on Sb2Se3 light absorbers [212,213,214], Sb2Se3 as a PEC photocathode for solar water splitting has achieved notable developments. Recently, Zhu et al. employed an antiphotocorrosive CdS/TiO2 bilayer to enhance the performance of the Sb2Se3 photocathode, achieving a photocurrent density of approximately 8.6 mA cm−2 at 0 V vs. RHE and durability over 10 h under simulated sunlight AM 1.5G irradiation [215]. In addition, use of earth-abundant MoSx as an electrocatalyst to replace precious Pt was reported by Tielly and Moon et al., resulting in a remarkable photocurrent density up to approximately 16 mA cm−2 at 0 V vs. RHE [216]. Moon et al. developed a facile spin-coating method to prepare self-oriented Sb2Se3 nanoneedle photocathodes [217]. Afterwards, they employed ultrafast terahertz (THz) spectroscopy, time-resolved photoluminescence (TRPL) and intensity-modulated photocurrent–photovoltage spectroscopy (IMPS/IMVS) to observe the photogenerated charge carrier dynamics in a photocathode with the RuOx/TiO2/Sb2Se3/Au/FTO configuration, revealing the dual functions of RuOx in reducing surface recombination and accelerating charge transfer [211]. Then, they reported a photocathode with the Pt/TiO2/CdS/Sb2Se3/Au/FTO configuration, achieving an outstanding photocurrent density of approximately 13.5 mA cm−2 at 0 V vs. RHE under simulated sunlight AM 1.5G irradiation in a pH 1 electrolyte (Fig. 9g) [217]. After optimization, they obtained a high-quality compact thin film with favourable crystallographic orientation by suppressing the growth kinetics via a close-space sublimation strategy, resulting in a benchmark photocurrent density of approximately 30 mA cm−2 at 0 V vs. RHE [218]. They constructed a tandem PEC device for bias-free solar water splitting with an optimized Pt/TiO2/CdS/Sb2Se3/Au/FTO photocathode and a classic BiVO4 photoanode, which exhibited an STH conversion efficiency of 1.5% with durability over 10 h (Fig. 9h) [218]. In addition, the voltage contribution of the photocathode to the bias-free PEC system was approximately 0.52 V (Fig. 9i). At present, the study of surface modification and heterostructures to enhance the performance of Sb2Se3 photocathodes has made remarkable progress [219, 220].

6.4 Nitrides, Phosphides and Arsenides

Gallium indium phosphide (GaInP2) is a promising p-type semiconductor for application as a top light absorber of tandem PEC devices for solar water splitting [221,222,223]. The CB position is at − 0.6 V (vs. RHE). Benefiting from the high lattice matching, GaInP2 with a band gap of approximately − 1.8 eV and gallium arsenide (GaAs) are suitable for constructing tandem photoelectrodes. A photocathode with the p–n–GaAs/p–GaInP2 configuration has been demonstrated to exhibit a superior STH efficiency up to 12.4% [224]. However, the photocurrent density significantly decreased within 1 h due to the instability caused by photocorrosion. In view of this, Yoon et al. achieved an outstanding stability of over 120 h via a developed corrosion-resistant surface and a structure-tailored reactive interface (Fig. 9a and b) [225]. Specifically, (NH4)2S-treated nanostructured (NS) GaInP2 photocathodes were fabricated by inductively coupled plasma reactive ion etching (ICP-RIE) and thermal annealing technologies (Fig. 10a), achieving ca. 91% FE and a photocurrent density of ca. –12.5 mA cm−2 (Fig. 10b). Moreover, Jaramillo and coworkers employed MoS2 as an electrocatalyst and a surface protection layer to construct a photocathode with the MoS2/Mo/GaInP2/GaAs/Au configuration, resulting in a long-term stability of over 10 h without significant degradation (Fig. 10c) [226]. In addition, wurtzite p-type gallium phosphide (GaP) with a direct band gap of 2.1 eV exhibits reasonable stability in aqueous solution [227, 228]. The application of GaP to photocathodes has made considerable progress [229, 230]. Bakkers and coworkers reported a GaP NW photocathode for decoupling of light absorption (axial) and photogenerated carrier transfer (radial) (Fig. 10d), achieving a photocurrent density of approximately 9.5 mA cm−2 at 0 V vs. RHE (Fig. 10e) [231]. Furthermore, the p-type InP nanopillar photocathode with the Ru electrocatalyst reaches a photo-to-energy conversion efficiency of approximately 14% at a cell voltage of 0.5 V [232]. CoP and GaN are widely used in the electrocatalyst and protective layer of Si-based photocathodes [61, 96, 233, 234]. Jin et al. developed cost-effective ternary pyrite-type cobalt phosphosulphide (CoSP) as an electrocatalyst of a Si-based photocathode for solar water splitting, achieving a remarkable photocurrent density up to ca. 35 mA cm−2 at 0 V vs. RHE, rivalling the state-of-the-art precious Pt [235]. Furthermore, they highlighted that both the work function and light absorption of the overlayer in the integrated photocathode are crucial factors for achieving superior solar-driven water splitting [235].

Architecture and performance of nitride-, phosphide- and arsenide-based photocathodes. a Schematic illustration of the fabrication procedures for GaInP2 photocathodes. b Long-term measurements under various material configurations. Reprinted with permission from Ref. [225]. Copyright © 2019 The Author(s). c Schematic of the synthesized p-GaInP2/MoS2 photocathode. Reprinted with permission from ACS. [226]. Copyright © 2016 American Chemical Society. d SEM image of a GaP NW array defined by nanoimprint lithography. The scale bar, 400 nm. e LSV curve of the GaP photocathode loaded with the platinum electrocatalyst. Reprinted with permission from Ref. [231]. Copyright © 2015 Macmillan Publishers Limited

6.5 Fe-Based Compounds

The p-type MFexOy (M = La, Bi, Cu, Mn, Zn, Ca) series are promising photocathode candidates because of their superior photoelectric conversion properties and outstanding stability in aqueous electrolytes [236, 237, 238, 239]. The band gap of LaFeO3 is approximately 2.1–2.6 eV, and the CB position is at − 0.6 V (vs. RHE), which allows absorption and utilization of most of the visible wavelengths of sunlight [236, 240, 241, 242]. However, the lower photocurrent density limits its large-scale application as a photocathode in PEC systems. In view of this, Tahir et al. recently demonstrated a strategy of concentrating the photon flux via a Fresnel lens and a back reflector to enhance the photocurrent density of the LaFeO3 photocathode, revealing that the photocurrent density depends approximately linearly on the photon flux and is enhanced nine times under a flux of 18 sun (1 sun = 1 367 W m−2) (Fig. 11a) [243]. Moreover, they employed Ag particles with the optimal dimension of 50–80 nm, screened by finite difference time domain (FDTD) simulations, to construct a photocathode, in which surface plasmon resonances (SPRs) enhanced LaFeO3 light harvesting to promote PEC hydrogen evolution (Fig. 11b) [244]. In addition, the LaFeO3 photocathode optimized by lithium doping and an Au buffer layer also showed promise for applications [240, 245, 246]. Recently, Yang and coworkers constructed a type-II heterojunction film photocathode with the Bi2O3/BiFeO3 configuration on an indium tin oxide (ITO) substrate, resulting in a superior PEC response under AM 1.5G sunlight irradiation [247]. In addition to the TiO2 protective layer and Au buffer layer used by Shen et al. [248, 249], use of the plasma effect of Au has also been attempted by Cheng et al. to enhance the performance of BiFeO3-based photocathodes [250].

Architecture and fabrication of Fe-based photocathodes. a Schematic of the experimental setup. A 350 W high-stability mercury (Hg) lamp with an AM 1.5G filter is used as the light source for the experiments, and a Fresnel lens is used to control the flux concentration of incident light. Reprinted with permission from Ref. [243]. Copyright © 2020 American Chemical Society. b Ag nanoparticles were modelled by using FDTD simulations, and the results show an optimal dimension of 50 − 80 nm for SPR enhancement. Reprinted with permission from Ref. [244]. Copyright © 2018 American Chemical Society. c Schematic of CuFe2O4 on FTO annealed by a furnace and a flame. Reprinted with permission from Ref. [254]. Copyright © 2019 American Chemical Society

CuFe2O4 with a band gap of 1.54–1.95 eV exhibits a theoretical maximum photocurrent density of approximately 27 mA cm−2 and an STH conversion efficiency of approximately 33% [251,252,253]. Zheng and coworkers developed a superior rapid high-temperature flame annealing method (> 980 °C), which only takes 16 min to prepare crystalline and porous CuFe2O4 photocathodes (Fig. 11a) [254]. Compared with furnace-annealed dense CuFe2O4, the photocurrent density of the flame-annealed CuFe2O4 photocathode is increased by approximately 2.9 times, reaching 3.5 mA cm−2 at 0.4 V vs. RHE. In addition, the hybrid microwave annealing strategy, heterojunctions and three-dimensional ordered periodic macroporous structures have also been applied to improve the performance of CuFe2O4-based photocathodes [255,256,257,258]. MnFe2O4 and ZnFe2O3 are widely used in integrated composite photocathodes with superior solar water splitting performance [259, 260]. CaFeO3 with a narrow band gap of 1.9 eV and a band edge across the redox potential of H2O was first applied to photocathodes by Ida and coworkers in 2010 [261]. Afterwards, their optimized RuOx/TiO2/CaFeO3 photocathode with TiO2 as a protective layer and RuOx as an electrocatalyst achieved a beneficial shift in the onset potential, delivering bias-free hydrogen evolution under 470 nm excitation [262].

6.6 Organic Polymers and Small Molecule Semiconductors

The light absorption and excitation mechanisms of organic small molecules and polymers, which are different from those of conventional inorganic absorbers, make them exhibit promise for application in the field of organic optoelectronics, such as in organic light-emitting diodes (OLEDs), organic solar cells, organic field-effect transistors (OFETs) and organic photocathodes [263,264,265,266,267,268]. Organic molecules or monomers exhibit the property of being an electron donor (D) or an acceptor (A) due to the difference in group electronegativity and energy levels [269]. Similar to band theory, the highest occupied molecular orbital (HOMO) in frontier (molecular) orbital theory of the excited state is widely accepted to be the electron-donating region, while the lowest unoccupied molecular orbital (LUMO) is the electron-accepting region [270, 271]. For polymers, precise control of the degree of polymerization (DP) is an effective way to directly tune the HOMO–LUMO gap and change the optical properties because generally, the HOMO–LUMO gap decreases with increase in DP [270, 271]. Eventually, if the material is polymerized into an ordered polymer such as a covalent organic framework (COF), then the periodicity will split the discrete energy levels into continuous energy bands, as in inorganic crystals [269]. Similarly, the degree of orderly self-assembly from small molecules to supramolecules will also affect the band gap [272].

Recently, Feng et al. demonstrated a practical strategy to modulate the band edge and optical gap by tailoring aromatic units of conjugated acetylenic polymers from benzene- to thiophene-based, resulting in the poly(2,5-diethynylthieno[3,2-b] thiophene) (pDET) photocathode exhibiting a benchmark HER performance with a photocurrent of 370 μA cm−2 and an IPCE of 12.6% under simulated sunlight illumination (Fig. 12a) [263]. Specifically, the evaluated HOMO and LUMO levels from the monomer to decamer of DET gradually approached the VB and CB edges of pDET, respectively (Fig. 12a) [263]. In addition, on the basis of conventional heterojunctions, including type-I, type-II and type-III heterojunctions, they developed a strategy for preparing a gradient homojunction by controlling the copolymerization of 1,4-diethynylbenzene (DEB) and 1,3,5-triethynylbenzene (TEB) (Fig. 12b) [273]. The highlight is that the gradient distribution of the TEB monomer in poly(DEB) leads to continuous band bending, producing a gradient homojunction. The organic gradient homojunction has far-reaching significance for the development of ideal solar spectrum absorbers with artificially tuned band structures Afterwards, they constructed a Z-scheme organic–inorganic hybrid photocathode by grafting pDET to cuprous oxide, achieving a carrier separation efficiency of approximately 16% and a photocurrent density of 370 μA cm−2 at 0.3 V vs. RHE under AM 1.5G irradiation in a 0.1 M Na2SO4 aqueous solution.