Abstract

Sulfides have been widely acknowledged as one of the most promising solid electrolytes (SEs) for all-solid-state batteries (ASSBs) due to their superior ionic conductivity and favourable mechanical properties. However, the extremely poor air stability of sulfide SEs leads to destroyed structure/performance and release of toxic H2S gas, which greatly limits mass-production/practical application of sulfide SEs and ASSBs. This review is designed to serve as an all-inclusive handbook for studying this critical issue. First, the research history and milestone breakthroughs of this field are reviewed, and this is followed by an in-depth elaboration of the theoretical paradigms that have been developed thus far, including the random network theory of glasses, hard and soft acids and bases (HSAB) theory, thermodynamic analysis and kinetics of interfacial reactions. Moreover, the characterization of air stability is reviewed from the perspectives of H2S generation, morphology evolution, mass change, component/structure variations and electrochemical performance. Furthermore, effective strategies for improving the air stabilities of sulfide SEs are highlighted, including H2S absorbents, elemental substitution, design of new materials, surface engineering and sulfide-polymer composite electrolytes. Finally, future research directions are proposed for benign development of air stability for sulfide SEs and ASSBs.

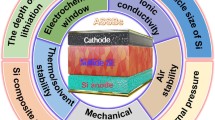

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Widespread application of lithium-ion batteries (LIBs) in electronic devices and electric vehicles confirms their great importance in modern society [1]. However, commercialized LIBs encounter the upper limit of energy density and severe safety issues due to leakage, low thermal stability and flammability of organic liquid electrolytes (OLEs) [2, 3]. Replacing OLEs with nonflammable solid electrolytes (SEs) would ultimately solve the safety problem and may potentially enable use of lithium metal anodes for higher energy density and make all-solid-state batteries (ASSBs) the most desirable energy-storage devices and technologies [4,5,6,7,8,9,10,11,12]. However, different types of SEs suffer from various challenges. For example, among these are the large grain boundary impedance and fragile ceramic nature for oxide SEs [13, 14], low room-temperature ionic conductivity and low Li+ transfer number for polymer SEs [15, 16], limited ionic conductivity and expensive manufacturing process for thin film LiPON [17], etc.

Among all kinds of SEs, sulfide SEs have been widely acknowledged as one of the most promising candidates [7,8,9,10,11,12,13,14,15] due to their remarkable ductilities and high ionic conductivities, which are on par with those of OLEs [18, 19]. However, their poor stabilities, including narrow electrochemical windows [20,21,22,23,24], chemical/electrochemical incompatibility with oxide cathodes [25,26,27] and lithium metal anodes [28,29,30,31,32,33,34,35], and poor air stability [36], greatly limit practical application of sulfide-based ASSBs [37]. Among these problems, air stability is a common issue for all or most solid-state batteries [38, 39]. Oxide-based SEs can react slowly with humid air by Li+/H+ exchange and result in the formation of ionic resistive LiOH and Li2CO3, which can increase the interfacial resistance [40,40,41,42,44]. When a halide SE such as Li3InCl6 is exposed to humid air, it first becomes a crystalline hydrate and then decomposes into In2O3, HCl and LiCl [45, 46]. Although polymer SEs such as PEO are chemically stable toward water and air, they are oxidized easily during cycling in a pure O2 environment [6, 47]. In particular, the extremely poor air stability leads to evolutions of toxic H2S gas [48], formation of completely damaged structures [49] and decayed performance [50] and also makes synthesis, storage, transportation and posttreatment of sulfide SEs very complex; they often require an inert atmosphere or dry room, which significantly increases production costs. For these reasons, numerous efforts have been made to unravel the origins of poor air stability [36, 51] and to develop air-stable sulfide SEs exhibiting other satisfactory properties [52].

In this comprehensive review, the research history of sulfide SEs and milestone breakthroughs for air stability are summarized. Then, theoretical explanations, including random network theory tailored for glass materials, hard and soft acids and bases (HSAB) theory based on the affinities of chemical species, thermodynamic analyses based on the energy changes for hydrolysis reactions, and kinetics of interfacial reactions based on the reactivity of crystalline planes, are summarized to provide scientific interpretations of the air instability problem. To better understand structure-performance relationships, characterizations of air stability, including the amount of H2S generated, morphological evolution, mass changes, component/structure variations and electrochemical performance, are reviewed. Furthermore, effective strategies for developing air-stable sulfide SEs, including use of H2S absorbents, elemental substitution, design of new materials, surface coatings and sulfide-polymer composite electrolytes, are highlighted. Finally, future research directions and perspectives for the air stability problem of sulfide SEs are proposed. The major contents of this comprehensive review are summarized with the schematic illustration in Fig. 1. This review is designed to provide fundamental understanding and facilitate benign development of air-stable sulfide SEs for mass production and wide practical application of sulfide ASSBs.

2 Research History for the Air Stability of Sulfide SEs and ASSBs

The earliest work on this topic involved the random network theory of glass proposed by Zachariasen in 1932 for glassy sulfide SEs, which was regarded as theoretical guidance for modifying glassy electrolytes. Research on the air stability of sulfide SEs attracted little attention until Martin et al. [53] proposed improving the air stability of sulfide SEs by decreasing the proportion of nonbridging sulfurs in 2008. In 2011, Tatsumisago et al. [36] investigated the structural changes undergone by glass and glass-ceramic Li2S-P2S5 sulfides in the atmosphere for the first time. In 2013, Hayashi et al. [48] successfully suppressed H2S gas generation by adding metal oxides into glassy electrolytes and used oxygen substitution to partially replace Li2S with Li2O. Subsequently, a series of studies based on an oxygen substitution strategy (e.g., xLi2O·(75 − x)Li2S·25P2S5 [54], 75Li2S·(25 − x)P2S5·xP2O5 [55] and Li6PS5−xOxBr [56]) were reported. Although these were effective in improving air stability, the loss in ionic conductivity resulting from this strategy was often criticized. In 2019, Xiao et al. [57] performed cosubstitution of Zn and O and obtained a glass-ceramic electrolyte with significantly enhanced air stability and ionic conductivity. Moreover, they calculated the energy change for hydrolysis involving the reactions of cosubstituted sulfide SEs or pristine sulfide with H2O for the first time, which further demonstrated the effectiveness of this strategy. Subsequently, the codoping strategy was also successfully applied to various sulfide SEs (e.g., Li3+3xP1−xZnxS4−xOx, Li6−2xZnxPS5−xOxBr [58] and Li6.988P2.994Nb0.2S10.934O0.6 [59]), which led to comprehensively enhanced properties. In 2014, Liang et al. [51] proposed an innovative use of HSAB theory, which was proposed by Pearson in 1963 [60], as theoretical guidance for designing air-stable sulfide SEs. Moreover, they prepared As-substituted Li4SnS4 (LSS) with the highest known ionic conductivity and air stability among air-stable and recoverable sulfide SEs. Based on HSAB theory, a series of novel air-stable materials were developed. In 2019, Hayashi et al. [61] successfully synthesized Li3SbS4 with higher air stability but reduced ionic conductivity, which was one order of magnitude less than that of LSS. Huang et al. [62] creatively synthesized air-stable Li4Cu8Ge3S12 with an open-framework structure and reversible water adsorption/desorption capability. However, the parent phases of these new materials (i.e., LSS, Li3SbS4, and Li4Cu8Ge3S12) generally exhibited superior air stability but lower ionic conductivity than the well-known thiophosphates. Fortunately, various materials (e.g., Li3.833Sn0.833As0.166S4 [51], 0.4LiI-0.6Li4SnS4 [52], Li3.8Sn0.8Sb0.2S4 [63], Li3.85Sn0.85Sb0.15S4 [64]) from the Li4SnS4 family were developed, and solution-coating was realized, which greatly advanced practical application. In aiming to develop air-stable sulfide SEs suitable for dry-room conditions, Sun et al. performed soft-acid substitution to obtain Sn-substituted Li6PS5I [65] and Sb-substituted Li10GeP2S12 (LGPS) [50] with significantly enhanced air stability and ionic conductivity in 2020. Furthermore, other strategies, such as sulfide-polymer composite electrolytes [49, 66, 67] and surface engineering [68], were proposed to improve the air stabilities of sulfide SEs. In 2020, Mo et al. [69] systematically investigated the moisture stabilities of lithium ternary sulfides (Li-M-S) with different central cations M with thermodynamic analyses, which provided guidance for designing air-stable sulfide SEs. All of this significant progress on the air stabilities of sulfide SEs is summarized in Fig. 2 for a clear demonstration.

Research history and milestone breakthroughs for air stabilities of sulfide SEs and ASSBs. Reprinted with permission from Ref. [36]. Copyright © 2010, Elsevier. Reprinted with permission from Ref. [94]. Copyright © 2012, American Chemical Society. Reprinted with permission from Ref. [119]. Copyright © 2017, Wiley-VCH. Reprinted with permission from Ref. [57]. Copyright © 2018, Elsevier. Reprinted with permission from Ref. [66]. Copyright © 2019, American Chemical Society. Reprinted with permission from Ref. [62]. Copyright © 2019, Wiley-VCH. Reprinted with permission from Ref. [61]. Copyright © 2019, Elsevier. Reprinted with permission from Ref. [69]. Copyright © 2020, Wiley-VCH. Reprinted with permission from Ref. [50]. Copyright © 2020, American Chemical Society. Reprinted with permission from Ref. [65]. Copyright © 2020, Wiley-VCH

3 Theoretical Explanations

As the understanding of the air stabilities of sulfide SEs is deepening, various theoretical explanations have been proposed from different perspectives, including the random network theory of glass, HSAB theory, thermodynamic analysis and kinetics of interfacial reactions.

3.1 Random Network Theory of Glass

In 1932, Zachariasen proposed the random network theory of glass (RNTG) to explain glass construction from ionic polyhedra (e.g., tetrahedra and octahedra) arrangements exhibiting short-range order and long-range disorder (Fig. 3a). Since early-stage SE research started from glass and glass-ceramic sulfide SEs [70], the RNTG turned out to provide theoretical guidance. In 2008, Martin et al. [53] pointed out that nonbridging sulfur anions were unstable sites vulnerable to be attacked by water molecules. Therefore, nonbridging sulfur units were bridged by introducing trivalent ions such as Ga3+ and La3+ to eliminate some nonbridging sulfurs and improve the air stabilities of glasses. However, convincing experimental data, such as the amount of H2S gas generated, XRD patterns and other direct evidence, were lacking. In 2011, Muramatsu et al. [36] found that the air stabilities of L2S-P2S5 sulfide SEs were related to their local structures. The 75Li2S·25P2S5 glass and glass-ceramic sulfides containing PS43− groups showed the highest air stabilities compared with those of 67Li2S·33P2S5 glass and Li2S crystals that contain P2S74− and Li–S–Li groups, respectively. They concluded that the bridging sulfurs in P2S74− and Li–S–Li were first attacked by water molecules and transformed into –SH groups, which subsequently reacted with water molecules and were finally transformed into H2S gas. In this case, bridging sulfurs seemed to be less stable than nonbridging sulfurs based on experimental results. Fukushima et al. [71] found that 60Li2S·25P2S5·10Li3N glass-ceramic sulfides exhibited high ionic conductivity and high stability against moisture, which was attributed to formation of crosslinks in the glass network due to nitrogen addition. In addition to comparisons of air stabilities for various materials in glass systems, air stability differences among glasses, glass-ceramic and crystalline sulfide SEs must be studied further [72].

Theoretical explanations. a Schematic illustration of the network structure of glass materials. Reprinted with permission from Ref. [150]. Copyright © 2005, Elsevier. Schematic illustration of HSAB theory for b “soft-soft” and c “hard-hard” reactions. Reprinted with permission from Ref. [74]. Copyright © 1968, American Chemical Society. d Energy for hydrolysis reactions of sulfides with different central cations. Reprinted with permission from Ref. [69]. Copyright © 2020, Wiley-VCH. e. Exposed crystalline planes (predicted) of β-Li3PS4. f Linear relationship between \(\left( {\Delta E_{\text{p}} } \right)\) and \(\left( {E_{{{\text{VS}},\;\mathop {{\text{seg}}}\limits^{\cdot\cdot} }} } \right)\). Reprinted with permission from Ref. [76]. Copyright © 2020, Elsevier. g Schematic illustration of anion polymerizations induced by atmospheric deterioration and electrochemical deterioration. Reprinted with permission from Ref. [78]. Copyright © 2021, American Chemical Society

3.2 Hard and Soft Acids and Bases Theory

In 1963, Pearson [60] proposed the hard and soft acids and bases (HSAB) theory on the basis of Lewis acid-base theory. According to the binding abilities of atoms, ions and molecules to electrons (from strong to weak), chemical species can be classified into three categories: hard, boundary and soft. Pearson [73] then defined absolute hardness to calculate and quantify the hardness of various chemical species. Subsequently, Klopman [74] further elaborated the HSAB theory with molecular orbital theory. As shown in Fig. 3b, soft bases and acids exhibit higher energy for the highest occupied molecular orbitals (HOMOs) and lower energy for the lowest unoccupied molecular orbitals (LUMOs), respectively. The energy difference between them is small and favors electron migration, which results in a low-energy hybrid orbital and a strong covalent bond. In contrast, hard bases and acids have lower HOMO energy and higher LUMO energy (Fig. 3c), respectively. The energy difference is large and unfavourable for electron migration. Therefore, they are more inclined toward ionization, thus inducing Coulomb interactions and forming strong ionic bonds. A combination of hard and soft chemical species generally induces a weak ionic bond and leads to an unstable product. In conclusion, the HSAB theory can be summarized in one sentence: soft acids/bases have high affinities for soft bases/acids, and hard acids/bases have high affinities for hard bases/acids, which is confirmed by the high stability of their products. In 2014, Sahu et al. [51] first proposed that the HSAB theory might serve as a guideline for designing air-stable sulfide SEs. With this guidance, Sn4+ [65], As5+ [51, 75], Sb5+ [50], and other soft acids [62], which are inclined to bind tightly with the soft base S2− and impede attack by H2O, have been used to improve the air stabilities of sulfide SEs.

3.3 Thermodynamic Analysis

Thermodynamic analyses based on changes in Gibbs energy for hydrolysis reactions between sulfide SEs and H2O facilitate evaluation of the air stabilities of various sulfide SEs and screening of potential air-stable candidates. Liu et al. [57] first calculated the energy change to demonstrate the improved air stability of ZnO-doped β-Li3PS4. Recently, Zhu et al. [69] performed thermodynamic analysis to systematically investigate the moisture stability of lithium ternary sulfides Li-M-S with different central cations M. As shown in Fig. 3d, the overall stability trend with respect to the central cations M is consistent with the empirical HSAB theory and previous experiments. More specifically, sulfide SEs with central cations Sn4+, Sb5+ and As5+ showed significantly better moisture stability than those containing B3+, Al3+, Si4+ and P5+.

3.4 Kinetics of Interfacial Reactions

Chemical reactions between sulfide SEs and air or moisture first occur at their interfaces, so it is necessary to study the kinetics of these interfacial reactions. Kim et al. [76] defined the p-band centre of the S-ion \(\left( {\Delta E_{\text{p}} } \right)\) and segregation energy of the S vacancy \(\left( {E_{{{\text{VS}},\;\mathop {{\text{seg}}}\limits^{\cdot\cdot} }} } \right)\) as electronic and structural descriptors with which to evaluate the atmospheric instability of β-Li3PS4 based on density functional theory. Among the four exposed surfaces (Fig. 3e), i.e., (111), (101), (001) and (100), the (110) and (111) surfaces were subsequently identified to be highly unstable due to their positive \({\Delta E_{\text{p}} }\) and negative \({E_{{{\text{VS}},\;\mathop {{\text{seg}}}\limits^{\cdot\cdot} }} }\), which were observed to present a linear relationship, as shown in Fig. 3f. Thus, formation and growth of surfaces with high surface reactivities should be suppressed during syntheses of sulfide SEs by controlling the exposed crystalline planes. However, most of the currently synthesized sulfide SEs are polycrystalline powders with randomly exposed crystalline planes that deviate from equilibrium crystal shapes following the Gibbs-Wulff theorem. Despite the successful growth of single crystals of LGPS [77], further development of a method for controlling exposed crystalline planes with high chemical stabilities and thus improving the air stabilities of sulfide SEs is required.

Subsequently, Kim et al. [78] revealed that H2O adsorption-dissociation reactions of surface Li ions constituted the initial stage for deteriorative hydrolysis reactions of sulfide SEs, as indicated by AIMD simulation results for the Li7P3S11 (100) surface. Then, they found and verified a correlation between atmospheric and electrochemical deterioration based on XPS results for air-exposed and delithiated Li7P3S11 samples. More specifically, as shown in Fig. 3g, Li-ion loss from the particle surface during delithiation caused by electrochemical charging and formation of lithium hydrates during air exposure promoted polymerizations of anions from PS43− or P2S74− to large PaSb(5a−2b) anionic clusters, which corresponded to transformations from P–S bonds to P–Sn–P bonds. Unfortunately, the polymerized anionic structures lowered the energy barriers for H2S generation and facilitated hydrolysis reactions instead of stimulating passivation.

Recently, Xu et al. [79] investigated the influence of crystallinity on air stability experimentally. They prepared two representative samples with the same Li9P3S9O3 compositions and LGPS-type structures via mechanochemical and melt quenching methods (denoted as M-Li9P3S9O3 and Q-Li9P3S9O3, respectively). Q-Li9P3S9O3 exhibited higher crystallinity, even at the particle surface, than M-Li9P3S9O3, which was confirmed by both XRD patterns and TEM images. In this case, these two samples were first exposed to air as powders and then subjected to temperature-programmed desorption-mass spectrometry (TPD-MS) to quantify the amounts of moisture and H2S gas adsorbed by the powder or to measure the ionic conductivity retained in the pellet state. Q-Li9P3S9O3 exhibited a much higher ionic conduction retention rate (> 70%) than M-Li9P3S9O3 (19%). In addition, the exposed Q-Li9P3S9O3 released H2O with a relatively lower evolution rate (1.8 ppm s−1 at 358 K, 1 ppm = 1 μmol mol−1) and generated minor amounts of H2O and H2S gas, whereas M-Li9P3S9O3 emitted H2O at a faster rate (45 ppm s−1) and generated large amounts of H2O and H2S gas. Given that the chemical compositions and LGPS-type structures were the same and there was only a small difference in BET specific surface areas for Q-Li9P3S9O3 (0.98 m2 g−1) and M-Li9P3S9O3 (0.64 m2 g−1), Xu et al. speculated that the highly crystalline particle surfaces of Q-Li9P3S9O3 provided a limited number of defect sites for H2O molecules to adsorb on, thus slowing propagation of the hydrolysis reaction from the surface to bulk regions and consequently generating minor amounts of H2S gas.

In summary, research involving the random network theory of glass and kinetics of sulfide-air interfacial reactions is limited to glassy materials and specific crystalline planes, respectively. Nevertheless, recent studies starting from the perspective of interfacial reaction kinetics still generate some interesting discoveries and deepen our fundamental understanding of the mechanisms for hydrolysis reactions. The HSAB theory based on binding of electrons to chemical species contained in sulfide SEs and thermodynamic analyses of the energy changes for chemical reactions are more widely used.

4 Characterization of Air Stability

Air stability reflects the chemical stabilities of SE materials in an air environment. Air-stable SEs will not react with any air components, such as nitrogen, oxygen, carbon dioxide and moisture, and maintain their physicochemical properties. Therefore, characterizations of the air stabilities of sulfide SEs can be based on macroscopic chemical reaction phenomena (i.e., amount of H2S gas generated [36, 80], morphology [59, 66] and mass [65] changes with exposure time), microscopic chemical components and structures, and electrochemical properties and performance before and after exposure to air, which are summarized in Fig. 4. The amount of H2S gas generated is calculated from the concentration detected by a H2S sensor after exposing sulfide SE samples to a controlled atmosphere. Morphological changes can be captured with optical photos or scanning electron microscopy (SEM) images. Furthermore, mass changes with exposure time can be recorded with thermogravimetric analysis (TGA) apparatus [65]. Characterization of the chemical components and structures of sulfide samples before and after exposure to air is beneficial for identifying the air stabilities of various sulfide SEs and understanding the mechanisms of structural degradation and chemical reactions. In addition to the common characterization methods universally adopted for materials research (e.g., X-ray diffraction (XRD), Raman and X-ray photoelectron spectroscopy (XPS)), advanced characterization methods, such as solid-state magic-angle-spinning nuclear magnetic resonance (MAS-NMR) and synchrotron radiation source (e.g., X-ray absorption near-edge spectra (XANES) and extended X-ray absorption fine structure (EXAFS)), have been applied to determining air stabilities for sulfide SEs. Finally, analyses of the electrochemical properties of sulfide SEs and electrochemical performance of sulfide ASSBs with air-exposed sulfide SEs contribute to the establishment of structure-performance relationships.

4.1 Macroscopic Chemical Reaction Phenomena

Sulfide SEs show hygroscopic properties and generation of toxic H2S gas when exposed to humid air, leading to evolutions in morphology and mass changes.

4.1.1 Amount of H2S Gas Generated

The amount of H2S gas generated has generally been regarded as a critical index for evaluating air stability and the possibility of practical applications of sulfide SEs. As shown in Fig. 5a, the conventional method for measuring the amount of H2S gas generated is to place a sulfide sample into a closed desiccator/container with a certain volume, expose the sulfide sample to a precontrolled atmosphere with temperature and relative humidity (RH) within certain ranges and record H2S gas concentrations in real time with a gas sensor [81, 82]. The total amount of H2S gas generated (V) can be calculated with Eq. (1) [80]:

where V denotes the total amount of H2S generated (cm3 g−1) normalized by the weight m of the sulfide electrolyte sample (g), C denotes the value recorded for the H2S concentration (ppm), and L is the volume of the desiccator (cm3).

Measurement of H2S gas amounts. a Conventional detecting system. Reprinted with permission from Ref. [66]. Copyright © 2019, American Chemical Society. b, c Improved detecting systems. Reprinted with permission from Ref. [83]. Copyright © 2021, American Chemical Society. d Our designed detecting system. Reprinted with permission from Ref. [84]. Copyright © 2021, Wiley-VCH

However, accurate measurement of the H2S gas amount generated still encounters three major challenges, including position-related and time-delayed detection of the H2S gas concentrations and fluctuations of RH as the hydrolysis reaction occurs. Due to point detection by the gas sensor and the heterogeneous distribution of H2S gas in the whole space of the desiccator, the detected concentration is position-related. Specifically, the large density and slow diffusion rate of H2S gas hinder uniform diffusion and instant detection, which leads to accumulation of H2S gas around the sulfide sample as the hydrolysis reaction occurs at the interface between the sulfide SE and air/moisture. In other words, the closer the gas sensor is to the sulfide sample, the higher the concentration of H2S gas detected. Therefore, a small electric fan was additionally placed in the desiccator to circulate the atmosphere (Fig. 5b and c) and create an approximately uniform distribution of H2S gas [83], which made the detected value of H2S concentration more representative. However, the possibility of time-delayed detection still exists because instantly generated H2S gas circulates with air flow until it is detected by the gas sensor. Moreover, the fluctuations of RH during the continuous hydrolysis reaction probably influence the rate for generation of H2S gas. Subsequently, Kimura et al. [61] overcame this problem by exposing sulfide samples to flowing air with a constant RH and flow rate. Inspired by this idea, a pump suction-type gas sensor was used instead of a point detection sensor based on gas diffusion, and the whole setup was connected to a pipeline to achieve unidirectionally flowing gas, instant detection of H2S gas and a constant RH for the exposed atmosphere [84], as shown in Fig. 5d. Therefore, this design overcame the aforementioned challenges for accurate measurements of H2S gas. The total amount of H2S generated was calculated with Eq. (2).

where \(A\) denotes the total/accumulated amount of H2S generated normalized by the weight \(\left( M \right)\) of S atoms in the sulfide electrolyte sample, \(C_{{{N}}}\) denotes the \(N\)th recorded value for the H2S concentration, \(v\) is the air-flow velocity and \(\Delta t\) is the time interval of recording.

In this review, reported data obtained from air stability tests of various sulfide SEs are summarized in Table 1. The improved air stabilities of modified sulfide SEs can be confirmed by the lower amounts of H2S gas generated and minor structural degradations. Two obvious conclusions can be drawn from the data in Table 1. The larger the exposed surface area between the sulfide sample and the atmosphere is, the intenser the hydrolysis reaction is, and the larger the amount of H2S gas generated. The higher the RH used for exposure of the sulfide sample is, the more H2S gas generated. However, it is difficult to quantitively identify air stability differences among various sulfide SEs based on data collected from numerous reports due to the differences in detecting systems, exposure conditions (e.g., volume of the airtight container, temperature, relative humidity and exposure time, specific surface area, morphology and crystallinity of sulfide samples) and evaluation methods. Therefore, it is necessary to establish a unified standard for measuring the amount of H2S gas generated to achieve comparable data from different labs.

4.1.2 Changes in Morphology and Mass

In addition to generation of H2S gas, morphology and mass changes also occur during hydrolysis reactions. Morphological changes in sulfide SE powders, pellets and membranes before and after exposure to humid air were investigated. Recently, Lu et al. [84] used optical imaging to record the morphological changes of Li9.54Si1.74P1.44S11.7Cl0.3 (LSPSC), Li3PS4 (LPS), LSS and Li3.875Sn0.875As0.125S4 (LSAS) powders upon exposure to a humid atmosphere (100% RH). While LSPSC and LPS suffered from large volume changes and obvious colour changes, LSS and LSAS only absorbed H2O molecules and turned into transparent solutions without hydrolysis reactions, as shown in Fig. 6a. Tufail et al. [85] performed ex situ SEM characterizations for particles of the glass-ceramic Li7P3S11 and the Li6.95Zr0.05P2.9S10.8O0.1I0.4 electrolyte. The morphology of Li7P3S11 became porous when it was exposed to humid air, while the Li6.95Zr0.05P2.9S10.8O0.1I0.4 electrolyte with enhanced air stability retained its morphology and showed no discernible variation. Tufail et al. further investigated ex situ SEM images of the cross-sections and surfaces of Li7P3S11 and Li7Sb0.05P2.95S10.5I0.5 pellets. While the morphologies of the Li7Sb0.05P2.95S10.5I0.5 pellets were similar before and after exposure to moist air with a 40%–47% humidity for 20 min, the morphology of pristine Li7P3S11 showed more cracks (Fig. 6b). Optical images captured by Li et al. [86] indicated that undoped Li7P3S11 reacted with H2O immediately, while Li7Sn0.1P2.8S10.5O0.2 remained stable for 60 min. Although Na3SbS4 is stable in dry air, the surface morphology of the Na3SbS4 pellet became rough and uneven with pulverization due to hydration in humid air, in contrast to the smooth and flat surfaces of the bare sample [87]. Tan et al. [66] recorded the morphology changes of the pristine Li7P3S11 film and the SEBS-Li7P3S11 composite SE film after flooding in water. The pristine Li7P3S11 film was completely hydrolyzed and disappeared once it came into contact with water, while the SEBS-Li7P3S11 film retained its original shape despite being immersed in water. Xu et al. [88] designed a protective layer consisting of fluorinated polysiloxane (F-POS)-coated Li1.4Al0.4Ti1.6(PO4)3 (LATP) nanoparticles on the surface of a Li6PS5Cl membrane. Even during continuous dripping of water, the Li6PS5Cl membrane with the superhydrophobic layer repelled the water droplets and maintained its original morphology, whereas the bare Li6PS5Cl membrane presented a colour change and a violent reaction, as shown in Fig. 6c.

Morphological evolution of sulfide SEs. a LSPS, LPS, LSS and LSAS particles. Reprinted with permission from Ref. [84]. Copyright © 2021, Wiley-VCH. b Li7P3S11 and Li7Sb0.05P2.95S10.5I0.5 pellets. Reprinted with permission from Ref. [85]. Copyright © 2021, Elsevier. c Spray-coated and bare Li6PS5Cl membranes. Reprinted with permission from Ref. [88]. Copyright © 2021, Wiley-VCH

Zhao et al. [65] investigated the reactivities of Li6PS5I (LPSI) and Sn-substituted LPSI-20Sn with O2 by exposing these two SEs to a pure oxygen atmosphere and monitored the mass changes with exposure times in a TGA apparatus. The mass of LPSI increased by 1.12% after exposure to pure oxygen for 10 h, while that of LPSI-20Sn increased by 0.35% after exposure to the same atmosphere for 20 h.

4.2 Microscopic Components and Structures

The structural changes and stabilities of Li2S-based sulfide SEs exposed to air were first studied by Muramatsu et al. [36]. They found that the air stabilities of L2S-P2S5 glass and glass-ceramic SEs were related to their local structures, which changed with changing molar proportions of Li2S. A series of SEs with different molar proportions of Li2S (i.e., 67%, 70%, 75%, 80% and 100%) were pressed into pellets and then exposed to humid air in the desiccator to determine their air stabilities from the amount of H2S generated. As shown in Fig. 7a, the amount of H2S generated first decreased, reached a minimum at a Li2S molar proportion of 75% and then increased. Raman spectra (Fig. 7b and c) of 67L2S-33P2S5 glass and Li2S crystals before and after exposure for 4 min, 90 min and one day showed evolution of local structures or chemical groups according to exposure time. The P2S74− peak at 407 cm−1 gradually weakened and disappeared with longer exposure, and this was accompanied by the emergence of new peaks at 2 560 and 3 300 cm−1, which corresponded to S–H and O–H groups, respectively. Similarly, Li–S groups were indicated by a peak 376 cm−1, and this gradually weakened and disappeared as new peaks emerged at 2 560, 3 300 and 3 600 cm−1; these corresponded to S–H, O–H and Li–O–H groups, respectively. Based on the aforementioned changes in local structures, they speculated that both the P2S74− group in 67Li2S-33P2S5 glass and the Li–S group in crystalline Li2S underwent two-step hydrolysis reactions (Fig. 7f and g) and ended up generating H2S gas after breaking of bridging sulfur bonds. In contrast, Raman spectra for the 75Li2S-25P2S5 glass and glass-ceramic electrolytes before and after exposure to air for one day showed no additional peaks except for those corresponding to the PS43− group (Fig. 7d and e). Furthermore, the ionic conductivity of the 75Li2S-25P2S5 glass-ceramic pellet decreased slightly from 1.9 × 10−4 S cm−1 to 1.5 × 10−4 S cm−1 after exposure to air for 7 h (Fig. 7h). Therefore, 75Li2S-25P2S5 glass and glass-ceramic electrolytes with local structures based on PS43− groups exhibited the highest air stabilities among Li2S-P2S5 sulfide SEs, which was corroborated by the amounts of H2S generated, local structures and ionic conductivities. In addition, X-ray diffraction (XRD) is generally used to identify changes in the overall crystalline structures of various sulfide SEs after exposure to air and generation of hydrolysis reaction products. Moreover, the local structures and chemical components of sulfide SEs before and after exposure to air have been characterized by MAS-NMR, XANES, EXAFS and XPS, which will be described in subsequent sections.

Evolution of the microscopic components and structures. Humid-air exposure of pelletized Li2S-P2S5 glasses with different Li2S contents. a Amount of H2S gas generated. Raman spectra for b 67%Li2S-33%P2S5 glass and c Li2S crystal before and after exposure to humid air for 4 min, 90 min and 1 day. Raman spectra of 75%Li2S-25%P2S5 glass and glass-ceramic d before and e after exposure to humid air. Structural changes of f P2S74− in 67%Li2S-33%P2S5 glass and g crystalline Li2S in humid air. h Ionic conductivity of pelletized 75%Li2S-25%P2S5 glass-ceramic as a function of exposure time. Reprinted with permission from Ref. [36]. Copyright © 2010, Elsevier

4.3 Electrochemical Properties and Performance

The air instabilities of sulfide SEs lead to structural damage and side product formation, which greatly degrades the electrochemical properties of sulfide SEs/ASSBs. At the material level, the ionic conductivities of sulfide SEs after exposure to humid air exhibit different degrees of diminution according to their different air stabilities. After exposure to humid air, the ionic conductivities of air-instable sulfide SEs (e.g., Li3PS4, Li6PS5Cl and LGPS) decrease dramatically due to hydrolysis reactions and undesired products. For air-sensitive sulfide SEs (e.g., due to oxygen or soft-acid substitution) that exhibit stability toward water, the ionic conductivity also decreased due to slow but irreversible hydrolysis reactions. In contrast, the ionic conductivities of air-stable sulfide SEs (e.g., LSS, Li3SbS4) were only reduced slightly due to absorption of water, and they can be recovered by removing the water. It is worth noting that some moisture-exposed materials, such as Li4Cu8Ge3S12 [62] and Li2Sn2S5[89], even exhibited elevated ionic conductivity, which may have originated from proton conduction or acceleration induced by coupling of Li+ and water molecules, which will be discussed in subsequent sections. However, the electronic conductivities and electrochemical stabilities of air-exposed SEs have not been studied deeply.

The electrochemical performance of a full cell is expected to worsen due to reduced ionic conductivity and undesired products. Cho et al. [90] incorporated zeolite into Li6PS5Cl as a scavenger for H2O and toxic H2S gas and to mitigate the hydrolysis reaction of Li6PS5Cl. As shown in Fig. 8a, an ASSB with zeolite-incorporated Li6PS5Cl (Z-Li6PS5Cl) showed a much lower overpotential than pristine Li6PS5Cl (P-Li6PS5Cl). While the ASSB with P-Li6PS5Cl exhibited a low discharge capacity and a rapid loss of capacity, the ASSB with Z-Li6PS5Cl showed a much higher discharge capacity and superior cyclability (Fig. 8b). Park et al. [52] assembled ASSBs from a Li3PS4/LiCoO2 mixture and a 0.4LiI-0.6Li4SnS4-coated LiCoO2 cathode before and after exposure to dry air for 24 h, respectively. While the Li3PS4/LiCoO2 mixture cathode exhibited a significantly increased overpotential and decreased capacity after exposure to dry air (Fig. 8c), the capacity of the 0.4LiI-0.6Li4SnS4-coated LiCoO2 cathode was slightly reduced after exposure to dry air, which indicated potential compatibility with practical applications. Liang et al. [50] reported that the reversible capacity (Fig. 8d) of an ASSB constructed with air-exposed Li10Ge(P1−xSbx)2S12 at 0.1 C was only slightly reduced compared with that containing fresh Li10Ge(P1−xSbx)2S12, which originated from the enhanced air stability caused by Sb substitution. Interestingly, Ye et al. [91] found that an ASSB with Li9.54Si1.74(P1−xSbx)1.44S11.7Cl0.3 (x = 9.7%) showed a slightly improved specific capacity of 182.4 mAh g−1 after one hour of air exposure and better long-term cycling stability than even pristine Li9.54Si1.74P1.44S11.7Cl0.3 (Fig. 8e and f). The mechanisms behind these phenomena are still unknown. Lu et al. [84] reported that ASSBs with air-exposed and heat-treated Li3.875Sn0.875As0.125S4 (LSAS) exhibited superior performance for the heat-treated sample, as indicated by a high discharge capacity and long-term cycling stability, whereas that with the air-exposed sample showed merely negligible discharge capacity (Fig. 8g and h). The enhanced performance may be attributed to reversible water adsorption/desorption by LSAS and favorable interfacial products generated from trace amounts of water. Xu et al. [88] designed a superhydrophobic layer for the Li6PS5Cl membrane without sacrificing the electrochemical properties even after water exposure. While the ASSB with the bare Li6PS5Cl membrane exhibited no capacity (Fig. 8i), the ASSB with the Li6PS5Cl membrane delivered a discharge capacity comparable to that seen with an unexposed membrane (Fig. 8j). Li et al. [67] prepared an air-stable membrane comprising a Li7PS6-embedded composite electrolyte in an ambient environment. The ASSB with this air-exposed membrane exhibited a high rate capacity (Fig. 8k) because the poly(vinylidenefluoride-co-hexafluoropropylene) (PVDF-HFP) polymer matrix protected the Li7PS6 sulfide SE from air. Therefore, it is crucial to investigate the interfacial stabilities of sulfide SEs with electrodes, including identification of reaction products and degradation and stabilization mechanisms for ASSBs with pristine and air-exposed sulfide SEs. Tian et al. [87] found that a Na3SbS4⋅8H2O hydrate coating layer was beneficial for interfacial stability with Na metal, which was formed in situ on the surface of the Na3SbS4 SE after exposure to humid air (68% RH) for 10 min. Due to formation of passivating products (i.e., NaH and Na2O) and the reduced fraction of the electronically conducting phase (i.e., Na3Sb) at the interface, decomposition of Na3SbS4 SEs and impedance growth upon cycling were limited. This reactivity-guided interface design ingeniously takes advantage of the instabilities of sulfide SEs toward humid air and constructs an effective passivation or protection layer, which will inspire further studies on the relationships between the air stabilities of sulfide SEs and the electrochemical performance of sulfide ASSBs.

Electrochemical performance of ASSBs with air-exposed sulfide SEs. a Charge-discharge profiles of NMC811/SE/Li-In ASSBs with P-Li6PS5Cl and Z-Li6PS5Cl before (the solid line) and after exposure (the dotted line). b Cycling performance of ASSBs with air-exposed P-Li6PS5Cl and Z-Li6PS5Cl. Reprinted with permission from Ref. [90]. Copyright © 2020, The Electrochemical Society. c Voltage profiles for LiCoO2/LPS/Li-In cells in which the LiCoO2 composite electrodes are the LPS/LiCoO2 mixed electrodes or 0.4LiI-0.6Li4SnS4-coated LiCoO2 electrodes before and after exposure of LPS powders and the 0.4LiI-0.6Li4SnS4-coated LiCoO2 powders to dry air for 24 h. Reprinted with permission from Ref. [52]. Copyright © 2015, Wiley-VCH. d Charge-discharge curves of In/Li10Ge(P0.925Sb0.075)2S12/LiCoO2 cells with Li10Ge(P0.925Sb0.075)2S12 before and after air exposure. Reprinted with permission from Ref. [50]. Copyright © 2020, American Chemical Society. Charge and discharge profiles at 0.5 C and 55 °C for ASSBs using the NMC811 cathode, the graphite-protected Li metal anode and Li9.54Si1.74(P1−xSbx)1.44S11.7Cl0.3 as the solid electrolyte before and after air exposure at e x = 9.7% and f x = 0. Reprinted with permission from Ref. [91]. Copyright © 2021, Elsevier. Charge and discharge profiles of g LCO@LNO/LSAS/LTO ASSB fabricated in humid air (70% RH, 28.9 °C) and h LCO@LNO/SE/LTO ASSB with air-exposed LSAS after heat treatment at 280 °C. Reprinted with permission from Ref. [84]. Copyright © 2021, Wiley-VCH. Charge-discharge profiles of LCO@LNO/SE/LTO ASSBs using i a bare Li6PS5Cl membrane after exposure to water and j an LATP@F-POS/Li6PS5Cl/LATP@F-POS membrane. 1 mL in−2 = 0.155 mL cm−2. Reprinted with permission from Ref. [88]. Copyright © 2021, Wiley-VCH. k Comparison of rate performance for cells with SCE and PVDF-HFP/LiTFSI polymer electrolytes. Reprinted with permission from Ref. [67]. Copyright © 2020, American Chemical Society

In summary, various characterization methods have been developed to investigate the air stabilities of sulfide SEs from different perspectives, including macroscopic chemical reaction phenomena, microscopic components/structures and electrochemical properties. Among these characterization methods, it is advisable that basic and universal methods, including measurements of H2S generation upon exposure, XRD of crystal structures, Raman spectra of local structures and measurements of ionic conductivity before and after exposure, should be performed to construct a unified system for evaluation of data from different labs. Advanced characterization methods, such as XAS, NMR and in situ TEM, can be alternative approaches providing further proof and deepening our understanding.

5 Strategies to Improve Air Stability

After decades of research, five promising strategies (Fig. 9) have been proposed to improve the air stabilities of sulfide SEs: (1) using additives to absorb H2S gas [48, 92], (2) partial substitution of S2− by oxygen anions [54, 56, 57] or the hard base P5+ by soft acids [50, 65, 93], (3) designing new materials with soft acids as the central cations [61, 94], (4) surface coating or passivation [68] and (5) construction of sulfide-polymer composite electrolytes [49, 66]. All of these strategies were shown to be effective in reducing the amount of H2S gas generated (Table 1). Among them, substitution with oxygen or soft acids and designing new materials are currently considered optimal solutions for improving the inherent air stabilities of sulfide SEs. The strategy of constructing composite SEs is promising for integrating the advantages of sulfide and polymer SEs [95], thus potentially satisfying all prerequisite properties of SEs and accelerating commercialization of ASSBs. However, as H2S absorbents, metal-oxide additives decrease the ionic conductivities of sulfide SEs and consume only H2S via chemical reactions instead of improving the inherent air stability. It is noteworthy that strategies tailored toward improving air stability generally induce changes in other critical properties (e.g., ionic conductivity and compatibility with Li metal) of sulfide SEs, as summarized in Table. 2.

5.1 H2S Absorbents

Given that ZnO reacts with H2S gas to function as an absorbent, Hayashi et al. [48] speculated that the chemical reaction between metal oxide MxOy and H2S gas follows Eq. (3).

As the change in Gibbs free energy should be large and negative to absorb H2S gas effectively, three metal oxides (Fe2O3, ZnO and Bi2O3) were screened due to their large Gibbs free energy (∆G) (−43.9, −78.0 and −232.0 kJ mol−1, respectively). Fe2O3, ZnO and Bi2O3 nanoparticles were physically mixed with Li3PS4 glass powders by ball milling at 230 r min−1 for 2 h. As shown in Fig. 10a and b, both the ZnO and LPS glasses remained after ball milling, and 31P MAS-NMR spectra taken before and after ZnO addition did not differ, suggesting that there was no chemical interaction between ZnO and LPS glass. Fe2O3, ZnO and Bi2O3 in composite electrolytes absorb H2S gas effectively. Among them, Bi2O3 showed the optimal absorption effect because it has the most negative ∆G, and almost no H2S gas was detected by the gas sensor (Fig. 10c). Furthermore, formation of ZnS (Fig. 10d) after air exposure of composite electrolytes with ZnO and LPS glass indicated that the reaction between ZnO and H2S followed Eq. (3). Unfortunately, the ionic conductivity decreased monotonically with increasing mole percentage of ZnO, as shown in Fig. 10e. Therefore, it is necessary to find the optimal mole percentage of ZnO to strike a balance between air stability and ionic conductivity.

Air stability enhanced by H2S absorbents. a XRD pattern for the composite consisting of 90 mol% Li3PS4 glass and 10 mol% ZnO (mol% means the molar fraction). b 31P MAS-NMR spectra of the composite and Li3PS4 glass. c Amount of H2S generated as a function of exposure time to air. d XRD patterns of the 90Li3PS4·10ZnO composite and Li3PS4 glass after exposure to air for one day. e Ionic conductivity at 25 °C for (100 − x)Li3PS4·xZnO (mol%) composite electrolytes as a function of ZnO content. Reprinted with permission from Ref. [48]. Copyright © 2013, Royal Society of Chemistry. f XRD patterns for the 70(0.75Li2S·0.25P2S5)·30MxOy (MxOy: Li2O, MgO, CaO and CuO) composites, the 75Li2S·25P2S5 glass, and the 70(0.75Li2S·0.25P2S5)·30FeS composite. g Exposure time dependence of H2S gas amount generated from the 70(0.75Li2S·0.25P2S5)·30MxOy (MxOy: Li2O, MgO, CaO and CuO) composites, the 75Li2S·25P2S5 glass, and the 70(0.75Li2S·0.25P2S5)·30FeS composite. Reprinted with permission from Ref. [92]. Copyright © 2013, Springer Nature. h Schematic illustration of the composite electrode prepared with the zeolite-incorporated Li6PS5Cl SE. i Quantities of H2S gas produced by P-Li6PS5Cl and Z-Li6PS5Cl when exposed to humid air. Reprinted with permission from Ref. [98]. Copyright © 2021, Royal Society of Chemistry

Subsequently, Hayashi et al. [92] added FeS and basic metal oxides (e.g., Li2O, MgO, CaO and CuO) into 75Li2S·25P2S5 glass to catalyze the decomposition of H2S and react with acidic H2S gas. It was obvious from the XRD patterns that the additives and 75Li2S·25P2S5 glass existed independently without any chemical interactions (Fig. 10f). As shown in Fig. 10g, these additives suppressed H2S gas generation, and the inhibition effects decreased in the order FeS > CuO > CaO > Li2O > MgO. However, the ionic conductivities of these composite electrolytes decreased due to addition of nonionic conductors. Fortunately, FeS showed optimal inhibition of H2S gas generation and induced minimal loss of ionic conductivity.

Apart from some specific metal oxides that react with H2S or even H2O, porous materials, such as zeolites, absorb H2O molecules and target harmful gases [96, 97] due to their three-dimensional porous structures. Lee et al. [98] first incorporated calcined ZSM-5 zeolite into Li6PS5Cl (Z-Li6PS5Cl) powder to scavenge H2S gas and H2O molecules surrounded by Li6PS5Cl particles (Fig. 10h), thus mitigating hydrolysis reactions and associated irreversible degradation of structure and performance. While the concentration of H2S for pristine Li6PS5Cl underwent a dramatic increase and reached ~ 120 ppm after exposure to humid air (50% RH) for 1 h, that of Z-Li6PS5Cl first rose slowly and then dropped from ~ 50 ppm to 40 ppm, as shown in Fig. 10i. This indicated that H2O molecules and H2S gas were effectively adsorbed into the pores of zeolites, which resulted in a low H2S generation rate and a subsequent decrease in the H2S concentration. However, introduction of lithium-ion-insulated zeolites will inevitably lower the ionic conductivity.

In conclusion, introduction of ion-insulated H2S absorbents by physical mixing with sulfide SEs inevitably impedes ion conduction. Using additives to absorb H2S or catalyze its decomposition suppresses H2S gas generation but does not enhance air stability, since separation of S atoms from sulfide SEs is always accompanied by structural degradation/collapse. Given that sulfide SEs exhibit inherent hydroscopic properties and a tendency to hydrolyze, only modification methods tailored to overcome these two challenges will improve the air stabilities of sulfide SEs.

5.2 Element Substitution

Element substitution processes can be classified into three types. The first is oxygen substitution, which potentially combines the high chemical stabilities of oxide SEs and the high ionic conductivities of sulfide SEs by forming oxysulfides. Soft acid substitution based on HSAB theory, which generates robust M–S bonds to resist attack by O2 and H2O, is the second type. Other element substitutions with complicated mechanisms belong to the last type.

5.2.1 Oxygen Substitution

Ohtomo et al. [54] synthesized xLi2O·(75 − x)Li2S·25P2S5 by replacing Li2S with Li2O with certain proportions x. As shown in Fig. 11a, the structure of 75Li2S·25P2S5 glass was retained from x = 4% to x = 17% without Li2O diffraction peaks, which did not indicate physical mixing of oxide additives. When x = 4%, the amount of H2S gas generated began to decrease significantly (Fig. 11b). When x \(\geqslant\) 7%, the generated H2S gas concentration reached the lower limit of the gas sensor. Ohtomo et al. speculated that introduction of Li2O reduced the residual amount of Li2S in 75Li2S·25P2S5 glass, thus suppressing H2S gas generation and improving air stability. Unfortunately, the ionic conductivity of 75Li2S·25P2S5 glass decreased monotonically with increases in the proportion x for Li2O (Fig. 11c). Therefore, x = 7% was regarded as the optimal proportion allowing xLi2O·(75 − x)Li2S·25P2S5 to exhibit both decent air stability and ionic conductivity. Recently, Ren et al. [99] obtained a (70 − x)Li2S·30P2S5·xLi2O glass ceramic by replacing Li2S with different amounts of Li2O. While the highest ionic conductivity of 1.2 × 10−3 S cm−1 was achieved with x = 1%, the best moisture stability and a compromised ionic conductivity of 9.9 × 10−4 S cm−1 were displayed for x = 5%.

Air stability enhanced by oxygen substitution. a XRD patterns for xLi2O·(75 − x)Li2S·25P2S5 (x = 4, 7, 11, and 17) samples prepared by two-step mechanical milling. b Amounts of H2S gas generated from xLi2O·(75 − x)Li2S·25P2S5 (x = 0, 4, 7, 11, and 17) glass powders. c Ionic conductivities of pelletized xLi2O·(75 − x)Li2S·25P2S5 (x = 0, 4, 7, 11, and 17) glass powders. Reprinted with permission from Ref. [151]. Copyright © 2013, Springer Nature. d 31P MAS NMR spectra of 75Li2S·(25−x)P2S5·xP2O5 (x = 0 and 10) glasses. e Amounts of H2S gas generated from pelletized 75Li2S·(25−x)P2S5·xP2O5 (x = 0 and 10) glasses after exposure to air. f Composition dependence of conductivity at 25 °C and activation energy (Ea) for conduction by pelletized 75Li2S·(25−x)P2S5·xP2O5 glasses. Reprinted with permission from Ref. [55]. Copyright © 2013, Elsevier. g XRD patterns for Li3+3xP1−xZnxS4−xOx (x = 0, 0.02, 0.06) and 0.98Li3PS4·0.02ZnO. h Amount of H2S generated from Li3.06P0.98Zn0.02S3.98O0.02 after exposure to humid air for different durations. i Arrhenius plots for Li3+3xP1−xZnxS4−xOx (x = 0, 0.01, 0.02, 0.03, 0.04, 0.05, 0.06). Reprinted with permission from Ref. [57]. Copyright © 2018, Elsevier

By following the same strategy for oxygen substitution, Hayashi et al. [55] synthesized 75Li2S·(25 − x)P2S5·xP2O5 by replacing P2S5 with P2O5 with a certain proportion x. 31P NMR spectra (Fig. 11d) indicated that the coordination environment of P was changed, and a series of oxysulfide units (e.g., PS3O, PS2O2, PSO3, PO4) were formed by oxygen doping with P2O5; this was significantly different from simple generation of POS3 by oxygen doping with Li2O. Although the total amount of H2S generated (Fig. 11e) for 75Li2S·(25 − x)P2S5·xP2O5 with x = 10 was almost identical to that of pristine 75Li2S·25P2S5 glass, emergence of the maximum concentration of H2S was delayed. Therefore, oxygen doping with P2O5 significantly suppressed the generation rate rather than the total amount of H2S generated. Unfortunately, the ionic conductivity of 75Li2S·(25 − x)P2S5·xP2O5 glass (Fig. 11f) also decreased monotonously with increasing P2O5 content in the range 0 \(\leqslant\) x \(\leqslant\) 10, for which nonbridging oxygens in the newly formed oxysulfide units served as strong traps for lithium-ion conduction. However, Xu et al. [100] reported that the ionic conductivity of 75Li2S·(25 − x)P2S5·xP2O5 with low-concentration doping (x = 1) reached a maximum value of 8 × 10−4 S cm−1. By considering the experimental results reported by Hayashi et al., they concluded that nonbridging sulfur atoms were replaced directly by bridging oxygen atoms that served as weak traps for lithium ions when the substitution proportion x = 1, which led to the increased ionic conductivity. However, a larger proportion for substitution of sulfur atoms by oxygen atoms resulted in formation of a series of oxysulfide units with nonbridging oxygen atoms serving as strong traps for lithium-ion conduction, which led to reduced ionic conductivity.

Furthermore, Zhang et al. [56] found that O-doped Li6PS5−xOxBr (0 \(\leqslant\) x \(\leqslant\) 1) exhibited comprehensively but not significantly enhanced properties, including good air stability, excellent dendrite suppression capability and superior electrochemical/chemical stability against Li metal and high-voltage oxide cathodes. In contrast to other O-incorporated sulfides, the O atoms were more inclined to substitute S atoms at free S2− sites instead of at PS43− tetrahedral sites, which was confirmed by the unchanged relative intensities and symmetries of Raman peaks with the increased O content. Although impurity phases appeared after exposing the samples to humid (35% RH) air for 10 min, the amounts reached a minimum at x = 0.3. However, due to the strong electrostatic attraction between O2− and Li+ and increases in the levels of impurities, the ionic conductivity decreased with increasing O content. Due to the enhanced shear modulus and oxide-containing interfacial layer (e.g., Li3OBr), O-doped Li6PS5−xOxBr achieved a high critical current density (CCD) close to 0.9 mA cm−2. Since CCD is defined as the lowest current density at which battery shorting occurs due to Li dendrite penetration [101, 102], the high CCD value reveals excellent dendrite suppression capability. Peng et al. [103] synthesized O-substituted Li5.5PS4.5−xOxCl1.5 (x = 0, 0.075, 0.175, 0.25) SEs by partially replacing the raw material P2S5 with P2O5. The air stability of Li5.5PS4.5−xOxCl1.5 determined from the total amount of H2S produced increased monotonically with increasing O content, whereas the ionic conductivity dropped monotonically with increasing O content. Ultimately, Li5.5PS4.425O0.075Cl1.5 with compromised properties was selected. Recently, Xu et al. [104] synthesized Li6.25PS4O1.25Cl0.75 exhibiting high stability toward moist air and an enhanced ionic conductivity of 2.8 mS cm−1 caused by partial oxygen substitution at both S and Cl sites. After exposure to humid air (53% RH), the argyrodite structure of Li5.5PS4.425O0.075Cl1.5 was well maintained, whereas the XRD patterns for Li6PS5Cl showed numerous unknown peaks. Air-exposed Li6.25PS4O1.25Cl0.75 after 180 °C postannealing still maintained an argyrodite structure with minor Li2S impurities, in stark contrast with the collapsed structure of Li6PS5Cl. In addition, the H2S sensing response curve for Li6.25PS4O1.25Cl0.75 was much weaker than that for undoped Li6PS5Cl. Xu et al. [79] performed oxygen substitution on Li9P3S12 and obtained Li9P3S9O3 with an LGPS-type structure by a melt quenching method. Li9P3S9O3 showed ionic conductivity retention as high as 70%, which was much higher than that for undoped Li9P3S12 (10%), after exposure to dry air for 6 h, which confirmed the effectiveness of oxygen substitution for improving air stability. However, the highest ionic conductivity of > 1 × 10−3 S cm−1 was obtained for a low oxygen content. The opposite trends seen for variations of ionic conductivity and air stability with O substitution amount inevitably hinder the development of O-substituted sulfide SEs with optimal comprehensive properties.

In addition to single oxygen substitution for sulfur to enhance air stability, dual substitution of either Li+, P5+ or S2− sites has been performed recently to improve properties, including air stability, ionic conductivity and interfacial stability, toward Li metal. Liu et al. [57] selected ZnO as the dopant based on theoretical calculations and synthesized a Li3+3xP1−xZnxS4−xOx (0 \(\leqslant\) x \(\leqslant\) 0.06) glass-ceramic electrolyte by partially substituting P5+ and S2 with Zn2+ and O2−, respectively. Only diffraction peaks of β-Li3PS4 were observed in the XRD pattern (Fig. 11g) when x = 0.02, which confirmed successful dual doping of ZnO into the crystalline lattice instead of physical mixing. It was noted that the crystal structure of β-Li3PS4 was changed when x = 0.06, consistent with theoretical calculations showing that dissolution of ZnO into crystalline β-Li3PS4 was energetically unfavourable. Subsequently, the energy changes (∆Es) for hydrolyses of the Li3+3xP1−xZnxS4−xOx electrolytes with x = 0 and x = 0.02 were calculated. ∆E was found to increase from −912.15 to −882.3 J mol−1 after doping, indicating the improved air stability of the ZnO-doped electrolyte. The improved air stability was also supported by the low amount of H2S gas generation (0.017 5 cm3 g−1) after exposing Li3.06P0.98Zn0.02S3.98O0.02 to humid air for three hours (Fig. 11h). The ionic conductivity reached a highest value of 1.12 mS cm−1 when x = 0.02 (Fig. 11i). Theoretical calculations showed a synergistic effect in which the O atom tended to locate next to a Zn atom and enlarge the migration channel for Li+ when x = 0.021 (thus increasing the ionic conductivity), while doping with Zn alone hindered migration of Li+. No apparent changes were observed in a symmetric cell during galvanostatic charge-discharge testing at a current density of 0.5 mA cm−2, which indicated good interfacial stability for Li3.06P0.98Zn0.02S3.98O0.02 and Li metal. Chen et al. [58] also adopted the ZnO codoping strategy and realized comprehensively enhanced properties for Li6−2xZnxPS5−xOxBr (0 ≤ x ≤ 1.5). However, Li sites rather than P sites were substituted by Zn atoms in Li6PS5Br. Due to substitution of Zn atoms by Li, which increased the Li content, the high ionic conductivity was maintained despite the negative impacts of oxygen substitution of sulfur and impurity formation. After exposure to air with a humidity of ~ 10% for 10 min, an impurity phase comprising LiBr·H2O quickly appeared for Li6PS5Br, but no impurity phase was observed for Li6−2xZnxPS5−xOxBr (x = 0.15); this demonstrated the enhanced air stability of ZnO-codoped Li6PS5Br. Furthermore, when x = 0.15, the polarization voltages of symmetric cells were lower and more stable than that for cells with x = 0. This enhancement in interfacial stability and suppression of Li dendrites was attributable to formation of Li-Zn alloy and Li3OBr at the Li/Li6−2xZnxPS5−xOxBr interface, as well as to reduced electronic conductivity resulting from ZnO doping.

Ahmad et al. [59] developed a Nb and O codoping strategy to improve the chemical/electrochemical stability of glass-ceramic Li7P3S11. The ionic conductivity reached a maximum at x = 0.2, which was attributed to precipitation of a highly conductive crystalline phase with PS43− and P2S74− units. However, this was compromised when the dopant level was further increased (x ≥ 0.4) due to formation of a low-conductivity phase Li4P2S6. With increasing content of the LiNbO3 dopant, the amount and rate of H2S generation from glass-ceramic sulfide SEs decreased monotonically. In particular, a sharp decrease appeared when x = 0.2, at which point bridging sulfurs with poor air stability in the P2S74− units were substituted by oxygen to give P2OS64− units that were difficult to hydrolyze. Moreover, the symmetric cell with a Nb- and O-codoped Li7P3S11 SE displayed a lower overpotential and flat and stable stripping/plating behaviour compared with pristine Li7P3S11. Recently, Li et al. [86] designed a Sn and O cosubstitution strategy and obtained Li7Sn0.5xP3−xS11−2.5xOx (x = 0.2) with enhanced stability against moisture and Li metal. After exposure to humid air (40%–45% RH) for 250 s, the amount of H2S generated by Li7Sn0.1P2.8S10.5O0.2 was 6.7 times lower than that of pristine Li7P3S11. Moreover, the symmetric cell with Li7Sn0.1P2.8S10.5O0.2 exhibited a flatter and more stable Li plating/stripping curve and a higher CCD of 0.4 mA cm−2 than pristine Li7P3S11. Although Sb and O cosubstitution was first performed on β-Li3PS4 by Xie et al. [105] and resulted in a high ionic conductivity of 1.08 mS cm−1 and excellent stability against lithium even at a current density of 1 mA cm−2, an investigation of air stability was not performed. Fortunately, Zhao et al. [106] demonstrated the effectiveness of congener substitution of Sb and O for P and S in improving the air stability of Li7P3S11. Due to formation of the oxysulfide units POS33− and P2OS64−, Li7P3−xSbxS11−2.5xO2.5x (x = 0.1) showed an enhanced ionic conductivity of 1.61 mS cm−1 and air stability. The amount of H2S it generated after exposure to humid air was nearly 2.8 times lower than that of pristine Li3P3S11. Recently, Tufail et al. [85] even performed triple substitution of Li3P3S11 by ZrO2 and LiI dopants and obtained a Li6.95Zr0.05P2.9S10.8O0.1I0.4 (LZPSOI) SE with a high ionic conductivity of 3.01 mS cm−1. While the Zr dopant was regarded as the cause, introduction of a small amount of oxygen promoted the motion of Li+ and stability against moist air, based on previous reports. In addition, the introduction of larger and more polarizable I− anions enhanced the ionic conductivity, lithium-metal compatibility [107] and utilization of Li2S-based active materials. After exposure to humid air (41%–43% RH) for 50 min, the amount of H2S generated by LZPSOI was five times lower than that of pristine Li7P3S11. The enhanced air stability was attributed to formation of oxysulfide units (i.e., POS33− and P2OS64−). However, it is inevitable that numerous attempts will be required to achieve improvements in comprehensive properties with multisubstitution due to the variability of atom sites and contents upon substitution.

Therefore, oxygen substitution effectively improved the air stability of sulfide SEs due to changes in the coordination environment (i.e., oxygen atoms partially replaced sulfur atoms and were bound tightly with the hard acid P5+). However, to obtain both satisfactory ionic conductivity and high air stability, more effort is required to optimize oxygen substitution at a relatively low content level and within a narrow range to form favourable oxysulfide units, since a large oxygen substitution level dramatically reduces ionic conductivity. Fortunately, the codoping strategy with introduction of another cation results in enhanced properties of sulfide SEs and promotes practical application.

5.2.2 Soft Acid Substitution

Based on HSAB theory, Liang et al. [50] proposed that reducing the P content would improve the air stability of Li10GeP2S12 (LGPS), since the hard acid P5+ tends to react with the hard base O and form P to O bonds instead of maintaining only P–S bonds. Inspired by the presence of Na3SbS4·xH2O in the natural environment rather than decomposed products of Na3SbS4, they predicted that Sb-substituted LGPS would exhibit both improved air stability and ionic conductivity, because the large Sb5+ ion would broaden Li+ diffusion pathways. No broadening or additional diffraction peaks (Fig. 12a) appeared for Li10Ge(P0.925Sb0.075)2S12 after exposure to a dry-room environment with a relative humidity of 1%–3% for 24 h. In contrast, broadening and split diffraction peaks (Fig. 12b) as well as impurity phases emerged for undoped LGPS under the same conditions. Furthermore, the amount of H2S generated (Fig. 12c) decreased continuously with increasing Sb content (i.e., decreasing P content). The ionic conductivity (Fig. 12d) of undoped LGPS decreased by 54% from 10.9 to 5 mS cm−1 after exposure to dry air, while that of Sb-doped Li10Ge(P1−xSbx)2S12 only decreased by 5%–18%. Ye et al. [91] subsequently performed Sb substitution and obtained Li9.54Si1.74(P1−xSbx)1.44S11.7Cl0.3 (x = 0.097) and an increase in ionic conductivity from 5.4 to 8.8 mS cm−1. Although enhanced air stability was demonstrated by XRD patterns in which no obvious changes were observed, the ionic conductivity still dropped from 8.8 to 5.8 mS cm−1 because the exposure conditions (15% RH and 35 °C) were harsher than those of Sb-substituted LGPS. Tufail et al. [82] obtained a Li7Sb0.05P2.95S10.5I0.5 SE by dual substitution of Sb and I into Li7P3S11. The ionic conductivity of Li7Sb0.05P2.95S10.5I0.5 was increased from 1.40 to 2.55 mS cm−1 after doping. The amount of H2S generated (Fig. 12e) by Li7P3S11 was 1.32 cm3 g−1 (92 ppm) after exposure to humid air (40%–47% RH) for 35 min, while that of Li7Sb0.05P2.95S10.5I0.5 was only 0.37 cm3 g−1 (26 ppm). The intensities of the diffraction peaks for Li7Sb0.05P2.95S10.5I0.5 (Fig. 12f) remained unchanged after exposure, in contrast to the peak broadening and diminished intensity seen for Li7P3S11; this indicated improved air stability for Li7Sb0.05P2.95S10.5I0.5.

Air stability enhanced by Sb and Sn substitution. XRD patterns for a Li10Ge(P1−xSbx)2S12 (x = 7.5%) and b Li10GeP2S12 samples before and after air exposure. c Amounts of H2S gas generated from commercial Li10GeP2S12 and synthesized Li10Ge(P0.925Sb0.075)2S12 powders. d Room-temperature ionic conductivities of the Li10Ge(P1−xSbx)2S12 (0 ≤ x ≤ 15%) sample before and after air exposure. Reprinted with permission from Ref. [50]. Copyright © 2020, American Chemical Society. e Amounts of H2S gas produced from both Li7Sb0.05P2.95S10.5I0.5 and Li7P3S11 solid-state electrolyte samples when exposed to moist air. f XRD patterns for Li7Sb0.05P2.95S10.5I0.5 and Li7P3S11 before and after exposure to humid air. Reprinted with permission from Ref. [82]. Copyright © 2020, Elsevier. XRD patterns of g LPSI-20Sn and h LPSI electrolytes before and after exposure to air with 10% humidity, as well as after a postheating process. i XANES of the P K-edge in LPSI-20Sn after exposure to 10% humidity. j Arrhenius plots for the LPSI-20Sn electrolyte before and after exposure to air with 10% humidity, as well as after the postheating process. k Li plating/stripping polarization of the Li//LPSI-20Sn//Li symmetric cell tested under a high current density of 1.26 mA cm−2 and cut-off capacity of 1 mAh cm−2. Reprinted with permission from Ref. [65]. Copyright © 2020, Wiley-VCH. l Synchrotron-based XRD patterns for gc-Li3.2P0.8Sn0.2S4 SSEs before and after exposure to air with 5% humidity. Arrhenius plots for m gc-Li3.2P0.8Sn0.2S4 and n gc-Li3PS4 SSEs before and after exposure to air with 5% humidity. Reprinted with permission from Ref. [93]. Copyright © 2021, Wiley-VCH

Based on HSAB theory, Zhao et al. [65] used another soft acid, Sn4+, to partially replace the hard acid P5+ in Li6PS5I (LPSI) and synthesized Sn-doped LPSI (LPSI-20Sn) with superior air stability demonstrated by various characterization methods. The XRD spectra (Fig. 12g) and P K-edge X-ray absorption spectra (Fig. 12i) showed little difference for LPSI-20Sn before and after exposure to an atmosphere with 10% humidity for 12 h. However, LiI and other impurity phases formed after exposure of LPSI to humid air (Fig. 12h). Furthermore, the ionic conductivity (Fig. 12j) of LPSI-20Sn dropped slightly from 3.5 × 10−4 to 2.2 × 10−4 S cm−1 after exposure to humid air and recovered to 3.1 × 10−4 S cm−1 after a postheating process (180 °C in the vacuum oven). To reveal the mechanism of enhanced air stability for LPSI-20Sn SE, density functional theory (DFT) calculations of the oxygen replacement reaction energy (ΔE) were conducted. The higher ΔE of LPSI-20Sn indicated that the bonding energy for (P/Sn)–S in (P/Sn)S4 tetrahedra was much higher than that of P–S in PS4 tetrahedra after replacing S with O. Therefore, the crystalline structure of Sn-doped LPSI-20Sn was more stable against ambient air. In addition, a Li//LPSI-20Sn//Li symmetric cell demonstrated very stable Li plating and stripping behaviours (Fig. 12k) for ≈200 h (125 cycles) at RT, even with a high current density of 1.26 mA cm−2 and a cut-off capacity of 1 mAh cm−2. The LiI formed at the Li anode interface served as a vital component and created a uniform electron/ion distribution pathway and suppressed Li dendrite formation, thus resulting in good Li metal compatibility. Zhao et al. [93] also synthesized a Sn-substituted glass-ceramic Li3PS4 (gc-Li3.2P0.8Sn0.2S4) with high ionic conductivity, improved air stability and good Li-metal compatibility. gc-Li3.2P0.8Sn0.2S4 exhibited a 6.2-fold increase in ionic conductivity compared with pristine glass-ceramic Li3PS4 due to an enlarged lattice and higher Li+ ion concentration. Benefiting from the strength of the Sn–S bond, gc-Li3.2P0.8Sn0.2S4 showed excellent overnight air stability in humid air (5% RH), as corroborated by the unchanged crystal structure (Fig. 12l), negligible reduction in ionic conductivity (Fig. 12m) and unchanged P, S K-edge and Sn L3-edge XANES data. In contrast, a significant reduction in ionic conductivity resulted for gc-Li3PS4 exposed to humid air (Fig. 12n). Moreover, a symmetric cell with gc-Li3.2P0.8Sn0.2S4 demonstrated stable Li plating/stripping behaviour for over 600 h at a current density of 0.1 mA cm−2, and the lifetime was 4 times longer than that of pristine glass-ceramic Li3PS4. This is attributable to regulation of Li deposition at the Li/sulfide SSE interface by Li-Sn alloys. Rajagopal et al. [108] prepared a Sn-doped Li7P2S8I0.75Br0.25 solid electrolyte with an improved ionic conductivity of 7.78 mS cm−2 and high air stability. After exposure to humid air (5%–10% RH), the ionic conductivity retention for Sn-doped Li7P2S8I0.75Br0.25 was as high as 71%, and no structural changes or decomposition were observed.

Cu+ is a soft acid with an ionic radius (74 pm) similar [109] to that of Li+ (73 pm) and is rarely used for substitution of the hard-acid P5+ with a smaller ionic radius (31 pm). Recently, Taklu et al. [110] successfully obtained argyrodite Li6+3xP1−xCuxS5−xClx (x = 0.1, LPSC-1) via dual substitution of P5+ and S2− by Cu+ and Cl−, respectively. The highest ionic conductivity of 4.34 mS cm−2 was obtained at x = 0.1 and was attributed to synergetic effects of multiple factors, including an increased charge carrier density from extra Li+, enhanced anion disorder from added Cl−, and a smaller electronegativity difference between the Cu+ dopant and S2−. The relatively low amount of H2S generated (Fig. 13a) suggested the improved air stability of LPSC-1. The strong Cu–S bond resulting from incorporation of the soft acid Cu+ stabilized the localized structure of PS43−, which was demonstrated by the side product Cu3PS4 (Fig. 13b). Apart from the enhanced ionic conductivity, the lowest electronic conductivity and improved interfacial compatibility of LPSC-1 brought about by Li metal jointly contributed to superior suppression of dendrite formation with critical current densities as high as 3 mA cm−2 and stable Li plating and stripping processes for more than 200 h at the same current density. In contrast, pristine Li6PS5Cl (LPSC-P) with the highest electronic conductivity showed a low critical current density of 0.75 mA cm−2 (Fig. 13c), unflattened plating/striping profiles and fast short circuit at 3 mA cm−2, which indicated the lowest dendrite suppression capability and severe Li incompatibility, respectively. Ce3+, a rare earth element, was regarded as a soft acid and was first verified to enhance air stability through strong bonding to the soft acid S2− by Zhou et al. [111]. They prepared a Li7P2.9Ce0.2S10.9Cl0.3 glass-ceramic with an enhanced ionic conductivity of 3.2 mS cm−1 and improved air stability via dual substitution of Ce3+ and Cl− for P5+ and S2−, respectively. After exposure to humid air (40% RH), Li7P2.9Ce0.2S10.9Cl0.3 exhibited a lower amount H2S generation (Fig. 13d) compared with those of pristine and Ce-substituted Li7P3S11. XPS results showed that the introduction of Ce3+ facilitated the formation of Ce–S bonds without impacting the bridging sulfurs in Li7P3S11. The greater strengths of Ce–S or P = S bonds in Li7P2.9Ce0.2S10.9Cl0.3 compared with those of the other two air-exposed samples (Fig. 13e and f) indicated high chemical resistance of the Ce–S bond toward moist air. Yu et al. [75, 112] synthesized Na3P0.62As0.38S4 by substitution with the soft-acid As, and it exhibited an increase in ionic conductivity from 0.46 to 1.46 mS cm−1 and high moisture stability. The XRD pattern for Na3P0.62As0.38S4 was well maintained even after exposure to humid air (15% RH) for 100 h.

Air stability enhanced by substitution with Cu, Ce and In. a H2S amount generated under a controlled humidity of 55%–60%. b XRD patterns for LPSC-1 before and after exposure to ambient air (66% RH) for 1 h followed by sintering for 1 h at 550 °C. c Critical current density with increasing step size current density of LPSC-1. Reprinted with permission from Ref. [110]. Copyright © 2021, Elsevier. d Concentration of H2S within 60 min when exposed to humid air (40% RH). High-resolution S 2p spectrum and peak-deconvolution results for e Li7P3S11 and f Li7P2.9Ce0.2S10.9Cl0.3. Reprinted with permission from Ref. [111]. Copyright © 2021, American Chemical Society. g Quantities of H2S gas produced from Li6.5In0.25P0.75S5I and Li6PS5I electrolytes when exposed to moist air. h XRD patterns and i Raman spectra for Li6.5In0.25P0.75S5I and Li6PS5I electrolytes before and after exposure to moist air. Reprinted with permission from Ref. [113]. Copyright © 2021, Wiley-VCH

According to the thermodynamic analytical results of Mo et al., [69] In3+ is a good candidate dopant for enhancing the air stabilities of sulfide SEs. Jiang et al. [113] enhanced the air stability and ionic conductivity of Li6PS5I (LPSI) through incorporation of In3+. As shown in Fig. 13g, the amount of H2S generated by In-doped LPSI decreased dramatically from almost 1.2 to 0.18 cm3 g−1 after exposure to dry-room air (10% RH) for 60 min. While some unknown peaks appeared in the XRD pattern for LPSI, that of In-doped LPSI remained unchanged (Fig. 13h) after air exposure. In addition, Raman spectroscopy also confirmed the unchanged structure of air-exposed In-doped LPSI, whereas the enlarged Raman spectra of pristine LPSI showed two additional peaks (Fig. 13i).

5.2.3 Substitution with Other Elements

In addition to substitutions with oxygen and soft acids to enhance the air stabilities of sulfide SEs, substitutions with other elements were also investigated and showed positive effects, despite the complicated controlling mechanisms. Fukushima et al. [71] synthesized (75–1.5x)Li2S·25P2S5·xLi3N glass-ceramics by partial substitution of Li2S with Li3N. The 60i2S·25P2S5·10Li3N glass-ceramic achieved the highest ionic conductivity of 1.4 mS cm−2 (Fig. 14a) and enhanced moisture stability with less H2S generation (Fig. 14b), which was attributed to formation of crosslinked P and N in the glass network (Fig. 14c). In addition to the S2− bonded in PS43−, nonbonded S2− was considered another site in the argyrodite structure that was vulnerable to oxygen and moisture. Subramanian et al. [114] substituted nonbonded S2− with Br− and reported Li5.6PS4.6ClBr0.4 SEs with both enhanced air stability and improved ionic conductivity. After exposure to low-humidity air (10% RH), Li5.6PS4.6ClBr0.4 exhibited a lower rate for generation of H2S (Fig. 14d) and a higher ionic conductivity retention of 61.5% (Fig. 14e) than Li6PS5Cl. However, it was difficult to identify the minor structural changes for both pristine and Br-substituted Li6PS5Cl from XRD patterns and Raman spectra (Fig. 14f), which may be ascribed to the low humidity. Min et al. [115] synthesized Li6+2xAlxP1−xS5Cl (x = 0, 0.025, 0.05, 0.075) by partial substitution of Al2S3 for P2S5. As shown in Fig. 14g, H2S generation was suppressed as the Al3+ content was increased from x = 0 to x = 0.075, which verified the enhanced air stability resulting from Al2S3 substitution. Moreover, the XRD pattern (Fig. 14h) for undoped Li6PS5Cl presented stronger peaks for the side-product Li3PO4 compared with its Al2S3-substituted counterparts, again revealing the positive effects of Al3+. Although the ionic conductivity decreased monotonically as the amount of Al2S3 incorporation was increased (Fig. 14i), the decrease was relatively small compared to that of sulfide SEs substituted with oxygen alone.

Air stability enhanced by substation with other elements. a Room-temperature ionic conductivities of (75 − 1.5x)Li2S·25P2S5·xLi3N glasses and glass-ceramics. The Li2S crystal was precipitated from composition with 25 \(\leqslant\) x \(\leqslant\) 40. b Amounts of H2S gas generated from 60Li2S·25P2S5·10Li3N and 75Li2S·25P2S5 glass-ceramic powders. c N 1 s XPS spectrum of the 60Li2S·25P2S5·10Li3N glass-ceramic. Reprinted with permission from Ref. [71]. Copyright © 2017, Elsevier. d H2S amount, e bar diagram of the ionic conductivity values before and after air stability testing and f Raman spectra after air stability testing of Li6PS5Cl and Li5.6PS4.6Cl1.0Br0.4 solid electrolytes. Reprinted with permission from Ref. [114]. Copyright © 2021, Elsevier. g Amount of H2S generated by Li6+2xAlxP1−xS5Cl (x = 0, 0.025, 0.05, 0.075) in air. h XRD patterns for Li6+2xAlxP1−xS5Cl (where x = 0, 0.075) after reacting with moisture for 300 s. i Ionic conductivity of Li6+2xAlxP1−xS5Cl (x = 0, 0.025, 0.05, 0.075). Reprinted with permission from Ref. [115]. Copyright © 2021, The Electrochemical Society