Abstract

The growing demand for advanced electrochemical energy storage systems (EESSs) with high energy densities for electric vehicles and portable electronics is driving the electrode revolution, in which the development of high-mass-loading electrodes (HMLEs) is a promising route to improve the energy density of batteries packed in limited spaces through the optimal enlargement of active material loading ratios and reduction of inactive component ratios in overall cell devices. However, HMLEs face significant challenges including inferior charge kinetics, poor electrode structural stability, and complex and expensive production processes. Based on this, this review will provide a comprehensive summary of HMLEs, beginning with a basic presentation of factors influencing HMLE electrochemical properties, the understanding of which can guide optimal HMLE designs. Rational strategies to improve the electrochemical performance of HMLEs accompanied by corresponding advantages and bottlenecks are subsequently discussed in terms of various factors ranging from inactive component modification to active material design to structural engineering at the electrode scale. This review will also present the recent progress and approaches of HMLEs applied in various EESSs, including advanced secondary batteries (lithium-/sodium-/potassium-/aluminum-/calcium-ion batteries, lithium metal anodes, lithium-sulfur batteries, lithium-air batteries, zinc batteries, magnesium batteries) and supercapacitors. Finally, this review will examine the challenges and prospects of HMLE commercialization with a focus on thermal safety, performance evaluation, advanced characterization, and production cost assessment to guide future development.

Graphic Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Clean and sustainable energy storage techniques have attracted tremendous attention due to the pressing energy crisis involving the deletion of fossil fuels. And considering the unstable and intermittent nature of renewable energy production from water, wind, solar, and geothermal sources, advanced electrochemical energy storage systems (EESSs) are critical power supplies in emerging electric vehicle, smart grid and portable electronic device applications [1]. And among various EESSs, rechargeable batteries (RBs) and supercapacitors (SCs) are particularly promising and have been widely applied in different applications due to distinct charge/discharge mechanisms. In terms of RBs, energy is stored through redox reactions under evaluated electrochemical potentials and involves the reversible insertion/extraction of metal ions to/from active host materials to provide relatively high energy density but low power density due to slow charge kinetics [2], allowing RBs to be particularly suitable for electronic devices in long-term operations. Alternatively, SCs possess high charge/discharge rates and power densities due to relatively fast electrochemical processes based on rapid ion absorption/desorption or fast surface redox reactions [3]. However, SC energy densities are far lower than RBs due to limited active surfaces for ion accumulation, meaning SCs are more suitable for application in rapid power supply and immediate stop-and-go recovery systems. Accordingly, great efforts have been devoted in the past decades to the development of corresponding EESSs with high energy density and uncompromised power density; however, enormous challenges remain. In general, advanced strategies proposed to obtain high energy EESSs include: (1) the development of emerging battery systems based on newly discovered electrochemical mechanisms such as multi-electron reaction systems [4]; (2) the broadening of battery electrochemical potential windows through rational strategies such as electrolyte engineering [5]; (3) the design of anode/cathode active materials (AMs) to achieve high specific capacity; and (4) the engineering of electrode structures to achieve ideal battery configurations with high mass loadings [6].

Overall, RBs and SCs are comprised of similar components, including positive/negative electrodes, a separator, an electrolyte, a current collector and a cell case. Among these, electrode materials have decisive impacts on the electrochemical performance of EESSs and recent reviews have provided comprehensive overviews of corresponding novel AMs [7,8,9,10]. In brief, the AM design principle can be summarized into the fine-tuning of electrical/ionic conductivity, intrinsic electronic states, morphological/dimensional adaptability, structural stability, high capacity, and low-cost properties in which problem-oriented methods such as morphology regulation, electronic structure tuning, pore structure control, heteroatoms doping, and composite AM design have attracted significant interest and have been employed to fabricate ideal AMs. Of these, the design of nanostructured AMs is the most appealing to improve EESS electrochemical performance due to advantages including: (1) shortened ionic diffusion distances; (2) enlarged electrode/electrolyte contact areas; (3) suppressed volume variations during ion insertion/extraction; (4) increased AM utilization efficiency; and (5) homogenized AM coatings or distributions on composite slurries [11]. Despite this, the great progress of AM design is mainly focused on the intrinsic performance evaluation of AMs in which corresponding electrode configurations are mostly based on ultrathin slurry film coatings (low mass loading) on current collectors [6, 12]. And because gravimetric performance as a common performance parameter is based on the amount of energy stored per unit weight, the inclusion of overall device component mass (including electrodes, polymer binders, conductive additives, current collectors, separators, electrolytes, and packing units) will lead to significantly lower gravimetric performances in these ultrathin electrodes as compared with values obtained based only on AM mass [13]. However, performance parameters based on overall device mass are of practical significance in electric vehicle, portable and miniaturized electronics applications that require power sources that can deliver maximum energy in very limited spaces and therefore, to realize the commercial application of AMs and achieve high energy density EESSs [14], ideal battery configurations should involve the rational design of high-mass-loading electrodes (HMLEs) with low mass ratios of passive components [6, 12, 15, 16]. However, research into the differences between laboratory and commercial devices remains insufficient and effective strategies for HMLEs are still in early stages.

Based on the different electrode configurations of HMLEs and conventional ultrathin film electrodes (Fig. 1a, b), HMLEs possess clear advantages, including (1) lowered production costs due to the reduction of inactive components and (2) significantly enhanced overall energy densities in the limited spaces of devices due to full occupation by AMs [17]. Despite this, the current progress of advanced HMLEs to achieve equivalent electrochemical performances to conventional ultrathin electrodes remains lacking. One reason involves unfavorable cohesion with AMs and weak attachment between AMs and current collectors that can give rise to weakened electrode mechanical strength (Fig. 1c) and cause the easy fracture and delamination of AMs from current collectors during charge/discharge [18]. In addition, AMs can experience severe volume variation (Fig. 1d) due to the significant accumulation of internal micro-strains during metal ion insertion/extraction [19]. These adverse dynamic microstructural variations can also affect stable solid electrolyte interphase (SEI) formation, which can result in the poor cycling life of corresponding HMLEs (Fig. 1e) [20]. Another prominent issue of advanced HMLEs involves poor electron/ion transport efficiency due to ultrathick electrode designs in which HMLEs based on conventional slurry coating processes are densely packed and possess high tortuosity, which will lead to low electrolyte diffusion efficiency (Fig. 1f) and limited electron transfer depth (Fig. 1g) [12, 17]. These factors will also considerably increase battery polarization and capacity degradation during cycling that are further exasperated under high current density or fast scan rates. In other words, the rate performance (Fig. 1h) and power density of HMLEs are relatively poor compared with conventional thin electrodes. The poorly developed pore structure of dense slurry coatings on HMLEs can further result in weak affinity and limited electrode/electrolyte contact area to increase charge transfer resistance and low electron/ion transport efficiency can lead to uncontrollable dendrite formation during metal plating/stripping [21], which can penetrate separators to result in short circuiting and potential safety hazards [22]. Based on all of this, the exploration of novel electrode material chemistry and advanced electrode configurations to address these issues is urgently needed as the development of HMLEs remains in early stages.

a Low mass loading electrode configuration and its disadvantages. b High mass loading electrode configuration and its advantages. c–h Key issues of HMLEs. c Electrode deformation after long-term cycling. Reprinted with permission from Ref. [18]. Copyright © 2017, Wiley–VCH. d Schematic of silicon expansion after cycling. Reprinted with permission from Ref. [24]. Copyright © 2014, American Chemical Society. e Poor cycling performances of HMLEs derived from conventional coating processes showing only 44% capacity retention after 100 cycles. Reprinted with permission from Ref. [25]. Copyright © 2020, Elsevier. f Poor electrolyte diffusion. Reprinted with permission from Ref. [17]. Copyright © 2017, Wiley–VCH. g Limited charge transfer depth in conventional 2D current collector-based electrodes. h Poor rate capability. Reprinted with permission from Ref. [26]. Copyright © 2019, Elsevier

And although pioneering reviews in recent years have discussed HMLE designs in EESSs such as thick electrodes for lithium batteries through low-tortuosity structural design [6] and vertically aligned nanostructure design [16], hierarchical 3D electrodes design [12], pseudocapacitor electrode design under high mass loading [23], these generally focus on the summarization of special or single strategies or limited EESS application (for SCs or lithium batteries only). To address this, this review will provide a current and comprehensive overview of emerging HMLEs with special attention on recent developments in advanced HMLEs towards EESS applications. This review will first provide a basic understanding of HMLE electrochemical properties and based on these understandings, this review will subsequently provide an overview of pioneering strategies in the design of advanced HMLEs to meet the requirements of high-performance EESSs, including inactive component optimization, electroactive material modulation and integrated electrode construction. This review will further discuss the advantages and disadvantages associated with the further development of these strategies and comprehensively analyze the recent progress of HMLEs in emerging battery systems containing advanced secondary battery systems and supercapacitors. Finally, this review will propose challenges and prospects to guide future development towards reliable HMLEs for commercial application.

2 Basic Electrochemical Behaviors of HMLEs

The development of HMLEs towards practical application requires the in-depth understanding of the fundamental electrochemical behaviors of HMLEs. Based on this, this section will analyze the diverse performance metrics and fundamental parameters reflecting electrochemical behavior as a result of mass loading or electrode thickness change as summarized in Fig. 2.

The basic electrochemical behaviors of HMLEs. a The theoretical capacitance of porous carbons with different pore sizes. Reprinted with permission from Ref. [36]. Copyright © 2014, The Royal Society of Chemistry. b Relationship between porosity and tortuosity. Reprinted with permission from Ref. [37]. Copyright © 2014, Wiley–VCH. c Li ion diffusion pathways from crystal lattices to bulk electrolytes. Reprinted with permission from Ref. [38]. Copyright © 2018, American Chemical Society. d Internal resistances of porous electrodes for lithium-ion batteries (LIBs) and the relationship between power density and energy density with changing electrode thickness. Reprinted with permission from Ref. [39]. Copyright © 2015, American Chemical Society. e The design of a working electrode for the operando measurement of potential drops and f the galvanostatic discharge profiles of cells based on LFP (up) and NMC 622 (down) electrodes. Reprinted with permission from Ref. [40]. Copyright © 2020, Elsevier

Pore structures are physical parameters that can determine the electrochemical performance of HMLEs [15, 16]. At the molecular level, hierarchical pore structures (Fig. 2a) can benefit electrolyte diffusion to improve energy storage capacity and rate capability in HMLEs as demonstrated by using a transmission line model proposed by Black et al. [27] and experimental data obtained by Ervin et al. [28]. However, the correlation between ultra-micropores (pore sizes smaller than ions) and capacity enhancements remains controversial as first reported by Chmiola et al. [29] and has since attracted many follow-up studies. Correspondingly, ion de-solvation and correlated superionic state theories based on molecular simulations have been proposed, involving the storage of ions in pores resulting from de-shelled ionic solvation shells [30], and the entering of pores with sizes comparable to or smaller than ion sizes [31]. Subsequently, great efforts have been devoted to the further understanding of influences based on pore width, shape, and spatial distribution on electrochemical performance in which advanced characterization methods such as Raman spectroscopy combined with nuclear magnetic resonance [32], in situ small-angel X-ray scattering [33], in situ X-ray diffraction [34], and density functional theory (DFT) calculations [35] have been carried out. Due to complex interactions between pore sizes, pore volumes, and pore distributions within electrolyte systems (such as ionic liquid, inorganic and aqueous electrolytes), however, reasonable and suitable pore structures obtained through molecular simulations remain difficult. Moreover, these factors become more complex and difficult to study in HMLEs because molecular simulations need to take into consideration electrode mass loading or thickness. Porosity and tortuosity (Fig. 2b) are correlating factors that can influence the internal electrochemical properties of HMLEs, especially electron and ion transfer properties within porous electrodes in which based on the definition of effective diffusion coefficients [6]:

in which D0 is the diffusion coefficient of the electrolyte, Deff is the electrode diffusion coefficient, ɛ is the electrode porosity and τ is the tortuosity. Porosity enlargement and tortuosity reduction can promote ion diffusivity, indicating that the structural engineering of low-tortuosity electrodes can enhance the performance of HMLEs.

The fundamental understanding of internal resistance and electron/ion transport in HMLEs is also important. Based on this, Chen et al. [38] used a lithium Ni–Mn–Co oxide (NMC) cathode 100–300 μm in thickness as a model system to study the rate-limiting Li-ion diffusion pathways within the thick electrode during charge/discharge and reported that Li-ion diffusion from electrodes to electrolytes can be sorted into five categories (Fig. 2c), including solid-phase diffusion into AM crystal structures, solid-phase diffusion into primary particles, liquid-phase diffusion from one primary particle to another particle, liquid-phase diffusion into porous electrodes and liquid-phase diffusion in bulk electrolytes. Galvanostatic intermittent titration technique (GITT) and electrochemical impedance spectroscopy (EIS) measurements were used to quantify Li+ diffusivity (DLi). These researchers also reported the critical thickness of thick electrodes to be ~ 200 μm, above which the reduction of specific capacity and rate capability would occur. Through the analysis of DLi versus potential variations of electrodes with increasing thickness, these researchers also confirmed that the rate-limiting mechanism governing diffusion kinetics involved the liquid-phase diffusion region of porous electrodes rather than the solid-state diffusion of Li+, demonstrating that the structural engineering of electrodes with varying morphology and porous structures can enhance ion transport efficiency. Li et al. [41] also used COMSOL multiphasic software to numerically model the limiting factors of thick electrode performance and obtained a similar critical thickness for optimal volumetric energy density. These researchers further studied the effects of AM particle size, electrolyte molarity and several electrode fabrication methods on thick electrode performance and highlighted cell polarization and material underutilization as key factors offsetting thick electrode performance in which increased electrolyte molarity and nanoscale AM particle size can contribute to enhanced ion diffusion and reduced internal resistance in HMLEs. Takeuchi et al. [39] further combined EIS using a symmetric cell and the transmission line model theory to systematically investigate ionic resistance in pores (Rion) and charge-transfer resistance for Li intercalation (Rct) and found that changes in Rion and Rct negatively correlated with increasing electrode thickness (Fig. 2d). These researchers also reported that the power density of thick electrodes strongly correlated with internal resistance as influenced by Rion and Rct. To further operando probe ion and electron transport in porous HMLEs, Wang et al. [40] characterized Rion and Rct of HMLEs based on phase-transformation-type LiFePO4 (LFP) and solid-solution-type LiNi0.6Mn0.2Co0.2O2 (NMC622) with a high mass loading of 20 mg cm−2 by measuring the dynamic variations of the potential drop as caused by ion/electron transport (Fig. 2e, f). They highlighted the facts that HMLE capacity loss at high rates was related to the ion/electron potential drop in thick electrodes and that different AMs possess different sensitivities to the potential drop due to different lithiation mechanisms. These researchers also reported that HMLE capacities based on phase transformation materials were more sensitive to the ion/electron transport potential drop as compared with solid solution materials and that the further understanding of the effects of electrode design on battery performance can be obtained by using this method.

Currently, most studies into HMLEs only roughly investigate the influence of mass loading or thickness on battery performance using single or limited controlling experiments that often ignore correlating but vital factors. However, Wood et al. [37] comprehensively quantified and determined the origins of tortuosity anisotropy in different porous electrodes through experimental (synchrotron radiation X-ray tomographic microscopy, electron microscopy) and theoretical (diffusion simulation, differential effective medium approximation) methods. Iyuke et al. [42] carried out modeling analysis to report that many electrochemical merits of HMLEs were co-influenced and required optimization, such as effective electrode thickness utilization (or AM utilization efficiency), optimal applied charge current density and effective electrode and electrolyte conductivity. For example, electrode effective thicknesses can increase with high electrolyte conductivity but decrease with high applied charge current, which suggests the existence of a maximum or optimal charge current, above which effective thickness or AM utilization is reduced.

Based on all of this, enhanced HMLE electrochemical performance can be achieved through the development of hierarchically porous structures, decreased electrode tortuosity, reasonable AM morphology, increased electrolyte molarity, nanosized AM particle sizes, etc. In addition, various performance influencing factors and technical parameters need to be carefully optimized in HMLEs for practical application.

3 Advanced Strategies for High-Performance HMLEs

Various advanced strategies have been developed to tackle the key challenges of HMLEs and improve electrochemical performance. Based on this, this section will summarize representative strategies in which an overview is provided in Fig. 3.

Overview of advanced strategies summarized in this review. (1) Conductive additive regulation. Reprinted with permission from Ref. [43]. Copyright © 2019, Wiley–VCH. (2) Binder modification. Reprinted with permission from Ref. [44]. Copyright © 2016, American Chemical Society. (3) Current collector regulation. Reprinted with permission from Ref. [45]. Copyright © 2018, Wiley–VCH. (4) Heteroatoms doping in porous carbon. Reprinted with permission from Ref. [46]. Copyright © 2015, American Chemical Society. (5) Core–shell structure design. Reprinted with permission from Ref. [47]. Copyright © 2019, Wiley–VCH. (6) Hierarchical pore structure design. Reprinted with permission from Ref. [48]. Copyright © 2017, The Royal Society of Chemistry. (7) Dimensional morphological structure control. Reprinted with permission from Ref. [49]. Copyright © 2017, Elsevier. (8) 3D printing. Reprinted with permission from Ref. [50]. Copyright © 2020, Wiley–VCH. (9) Vertical-aligned structure design. Reprinted with permission from Ref. [51]. Copyright © 2020, American Chemical Society. (10) Template-free phase separation. Reprinted with permission from Ref. [52]. Copyright © 2019, The Royal Society of Chemistry. (11) Charge density distribution of heterostructured material design. Reprinted with permission from Ref. [53]. Copyright © 2017, American Chemical Society. (12) Interlayer spacing regulation. Reprinted with permission from Ref. [54]. Copyright © 2020, The Royal Society of Chemistry. (13) Wood-based 3D integrated SC. Reprinted with permission from Ref. [55]. Copyright © 2017, The Royal Society of Chemistry. (14) Composite network design. Reprinted with permission from Ref. [56]. Copyright © 2019, Wiley–VCH

3.1 Inactive Component Regulation

Slurry coating is a major electrode process in both laboratory and industrial settings. Due to the random self-packing of electrode components through uncontrollable processing however, the homogenous distribution of slurry components is difficult to achieve which will result in poor electrical contact and weak internal adhesion and interconnection of components. This phenomenon is exasperated in the case of HMLEs and can lead to insufficient electron transfer and ion transport. Battery capacity and cycling stability also experience significant reduction under high charge/discharge rates, meaning that the establishment of stable and electron/ion conductive networks through the control of ratios, distribution states, material types and manufacturing conditions for individual electrode components is essential in high performance HMLEs.

3.1.1 Conductive Additive Regulation

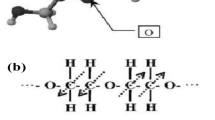

AMs such as silicon, sulfur and several metal oxides commonly possess low electrical conductivities making them not conducive to high rate capability electrodes. For example, current LIB cathode materials such as LiCoO2 (10−3 S cm−1), LiMn2O4 (10–5 S cm−1), LiFePO4 (10–9 S cm−1) and LiNiO2 (10−2 S cm−1) generally experience low electronic conductivity [57]. Here, the addition of conductive additives (CAs) with a certain compensation ratio of AMs can enhance the overall electronic conductivity of electrodes in which CA/AM electrical contact states differ based on the dimensional/morphological properties of CAs and AMs and can be classified into four types (Fig. 4a), including: (1) widely studied composite slurries based on powdered AMs coupled with powdered carbon black to show “point-to-point” electrical contact; (2) “point-to-line” electrical contact between powdered AMs and 1D carbon nanofibers or nanotubes (CFs or CNTs); (3) “point-to-plane” electrical contact for powdered AMs coupled with 2D CAs (e.g., graphene and MXene); and (4) “plane-to-plane” electrical contact derived from 2D AMs connected to 2D CAs. And because many advanced electrode designs possess multiple electrical contact states due to the constitution of various dimensional/morphological AMs and CAs, corresponding identification is often difficult.

Among CAs, carbon black (CB) with “point-to-point/line/plane” electrical contact is the most commonly studied due to advantages including cost effectiveness, easy fabrication and resource abundance. However, the irregular morphological properties and non-uniform distributions of CB make corresponding electrode conductivity and battery performance generally insufficient. Here, the simplest method to improve CB-based electrode performance is to control CB versus AM ratios in composites. In addition, the rational change of electrode manufacturing processes can ensure the uniform distribution of CB in composites to enhance the electrical conductivity of electrodes. The introduction of capillary suspensions into slurry preparation can further allow for a stable composite graphite/CB/binder electrode with a mass loading of 16.5 mg cm−2 and a thickness of 250 μm and CA/AM homogenous interconnections can easily be controlled through mechanical energy adjustments [58]. Overall, the influence of CAs on HMLE behavior is of great significance in the enhancement of performance. Based on this, Karkar et al. [59] employed three morphologically representative CAs including powdery CB, carbon nanofibers (CFs) and carbon nanoplatelets (CPs) to incorporate with high-loading LIB anode materials and found that “point-to-plane” electrical contact between AMs and CPs not only ensured electrical conductivity improvements in corresponding electrodes, but also contributed to electrode mechanical strength that is vital for long-term cycling, which these researchers attributed to the efficient cohesion and robust electron conductive structure of the CP framework.

a Different CA/AM electrical contact states: (1) “point-to-point” state. Reprinted with permission from Ref. [47]. Copyright © 2019, Wiley–VCH. (2) “Point-to-line” state. Reprinted with permission from Ref. [60]. Copyright © 2018, Wiley–VCH. (3) “Point-to-plane” state. Reprinted with permission from Ref. [61]. Copyright © 2018, American Chemical Society. (4) “Plane-to-plane” state, reproduced with permission Ref. [62], Copyright © 2018, Wiley–VCH. b Schematic illustration of the 3D the intertwined network of the Si@ CNT anode, and c corresponding TEM images of Si@CNT anode. Reprinted with permission from Ref. [63]. Copyright © 2013, American Chemical Society. d Comparison of conventional and future battery electrodes using advanced binder systems for LIBs. Reprinted with permission from Ref. [64]. Copyright © 2017, American Chemical Society. e Schematic of a polysaccharide-based polymer binder in a Si electrode with strong interactions. Reprinted with permission from Ref. [65]. Copyright © 2020, Wiley–VCH. f Differences between planar current collectors and 3D porous current collectors. Reprinted with permission from Ref. [66]. Copyright © 2018, Wiley–VCH. g A 3D nickel nanoarray-based current collector enabling thick MnO2 coating. Reprinted with permission from Ref. [45]. Copyright © 2015, Wiley–VCH. h Nonplanar HMLE structure with interwoven carbon fibers as the current collector. Reprinted with permission from Ref. [67]. Copyright © 2015, American Chemical Society

Compared with powdered CAs, 1D fiber-like (containing CFs and CNTs) and 2D sheet-like carbon materials (such as graphene and MXene) possess high-aspect ratios that can more efficiently increase overall electronic conductivity in electrodes at specific volume fractions [57]. This is because CNTs possess enriched sp2 hybridized C=C bonds and unique 1D cylindrical tubules of graphite sheets that can enhance electron transfer. High electrical conductivities are reflected by a low resistivity of 10–6 Ω cm−1 and maximum current densities for individual single-walled CNTs (SWCNTs) of 109–1010 A cm−2 as well as high conductivities of 106 S m−1 and over 105 S m−1 for SWCNTs and multi-walled CNTs (MWCNTs) respectively [10, 68]. Because of this, the serious inter-particle resistance of HMLEs can be improved by prolonging CNT-based conducting networks (Fig. 4b, c) to provide robust potentials in the fabrication of high conductivity HMLEs [69]. Planar structured graphene also exhibits high electrical conductivity (106 S m−1) with high electron mobility in excess of 15000 cm2 (V s)−1 at room temperature and is therefore also a promising conductive agent for high performance HMLEs. Compared with acetylene black, graphene possesses a unique heavily crumpled structure with a large surface area that is beneficial for the absorption of nanostructured AMs and the accommodation of volume change, all of which can further contribute to excellent cycling stability [70]. Despite this, Yang et al. [71] reported that the rate performance of thick electrodes constructed using LFP/graphene decreased with increasing the graphene content and attributed this to the prolonged ion diffusion pathways as a result of large graphene layer stacking. Because of this, the graphene content should be precisely controlled to balance the electronic conductivity and ionic diffusion efficiency of HMLEs. MXene can also be applied as a CA to obtain highly conductive electrodes such as an MXene bonded AC electrode with an electrical conductivity of 166 S cm−1 and an MXene bonded hard carbon electrode [61]. Continuous MXene scaffolds can also efficiently improve electrode stability due to the greatly enhanced ability to accommodate volume change [72]. Overall, CNTs, graphene, and MXene can allow for the effective construction of HMLEs with highly conductive network structures that can display compact and structurally stable properties due to superior structural features and strong interactions. Because of this, electrode conductivity can be improved through the addition of only small amounts of CNTs, graphene and MXene. Despite this, easy stacking and aggregation as well as complex fabrication processes, high production costs and low yields all limit further application in which scalable yet cost-effective manufacturing methods need to be developed for future application.

3.1.2 Binder Modification

Ideal electrodes that are structurally robust should possess optimized components that are rationally shaped, sized, dispersed, interconnected and wired to current collectors. In addition, these electrodes should be compatible with electrolytes to allow for low resistances. Here, polymer binders can be applied to enhance cohesion between slurry components and adhesion between electrode slurries and current collectors [64]. Advanced binder systems should also provide adequate mechanical adhesion, good compatibility and AM/CA surface modification to allow for stable SEI layers and accommodate volume variation to increase HMLE cycling performance (Fig. 4d). In addition, the even control of binder dispersion is vital for electron and ion transport through the formation of continuous internal pathways. And because binder distribution and migration during drying are major factors influencing electrode performance, pioneered research has been conducted to investigate the correlation between binder migration and electrode drying kinetics using characterization methods such as X-ray photoelectronic spectroscopy (XPS), energy-dispersive spectrometry (EDS), and Raman spectroscopy [73,74,75]. For example, the EDS mapping of a 400-μm-thick electrode under quick drying showed the existence of uneven binder fluctuation on the electrode surface and the AM/current collector interface as well as a concentration gradient across the thick electrode, which suggested the heterogeneous diffusion of the binder [74], indicating low drying rates are more conducive to ideal HMLEs. Binders also impart blocking effects on pore structures and corresponding distribution and migration can affect the porosity and tortuosity of electrodes. For example, Gasteiger et al. [76] systematically studied five types of polymer binders and their influence on thick electrode performances and found that different binders led to different tortuosity in correspond graphite anodes in which the rate performance of the electrodes decreased with increased tortuosity, suggesting that the reasonable control of binder types and distributions to optimize electrode porosity/tortuosity is essential in advanced HMLEs.

As a conventional polymer binder, PVDF has been widely used to fabricate HMLEs due to desirable binding capabilities and good electrochemical stability. However, PVDF cannot maintain electrode integrity during substantial AM volume expansion due to weak van der Waals forces between binders and AMs, leading to rapid capacity fading during cycling [77]. Alternatively, binders with abundant carboxylic groups possessing large molecular polarity such as carboxymethyl cellulose (CMC), poly(acrylic acid) (PAA), and alginate can mitigate this by enabling the uniform coverage and formation of stable SEI layers due to strong interfacial interactions between binders and AMs [78]. Regardless, optimal binders should be able to be scaled up to be compatible with electrode processing such as blade coating. For example, CMC binders with high viscosity can lead to inhomogeneous mixing and coating and the formation of cracks during electrode drying in thick dry films, which demonstrates unsuitability in HMLE construction [79]. To address this problem, Schappacher et al. [79] proposed a composite binder design that provided a targeted solution to fulfill the different requirements of HMLEs through the control of diverse binder advantages and synergistic effects, in which the designed composite binder was composed of CMC, PAA and polyethylene oxide (PEO) as well as a high solid content (65%) to enable crack-free thick electrodes. Here, the binder system was rationally designed based on careful considerations of crack-free and porous HMLE design requirements in which high viscosity CMC was partially replaced with low-viscosity PAA to ensure homogenous blade coating and moderate electrode porosity. PAA can also buffer mechanical stress to improve cycling performance whereas PEO is a commonly applied polymeric component in polymer electrolytes with high ionic conductivity [80, 81]. Carbon microfibers were also added to regulate the mechanical properties and pore size of the electrode during blade coating to contribute to the maintenance of crack-free strength.

Because conventional PVDF is an expensive fluorinated polymer and N-methyl pyrrolidone (NMP) is a toxic solvent, corresponding electrode formation is suboptimal. And although natural polysaccharide binders such as xanthan gum, guar gum, sodium alginate and catechol-conjugated polymers are promising choices due to the ease of production, these binders cannot accommodate substantial stress due to linear chain structures [65]. However, the cross-linking of natural binders using small molecules as crosslinkers to precisely modulate bond strength can enable the delocalizing of concentrated stress on single chains and improve binder resilience. For example, Park et al. [65] engineered a novel polysaccharide binder to incorporate high-loading silicon nanoparticles over 2 mg cm−2 in which ion-conductive boronic crosslinkers spontaneously reacted with guar gum and polystyrene backbones to result in a high mechanical strength supramolecular network with well-balanced secondary interactions and covalent bonding (Fig. 4e). The regulation of intrinsic structural parameters in binders is another promising approach to enhance performance because multi-grafted block copolymer binders can be well defined through the altering of side chain lengths and tuning of grafting density degrees in which copolymer binders with optimized side chain lengths and adequate grafting densities can enhance the interconnections of electrode components to contribute to desirable electrode performances [82]. For example, Cao et al. [83] designed a structurally optimized copolymer binder that was able to interconnect with high-loading silicon over 2.5 mg cm−2. Based on this, the deeper exploration of structure–performance relationships between polymer binders and electrochemical performance involving the control of binder morphology and structure is necessary for HMLEs.

Conducting polymers are promising multifunctional binder systems that can minimize inactive component occupation in electrode formulation because of their ability to act as both binders and CAs. Conducting polymers can also be modified to improve electronic conductivity, mechanical adhesion and electrolyte uptake through the introduction of various functional groups and the design of multidimensional nanostructures [64]. For example, formic acid was introduced to the in situ secondary doping of PEDOT:PSS to further improve electrical conductivity up to 4.2 S cm−1 and produce high-performance high-silicon-content electrodes (80%) [44]. Despite this, conducting polymer binders suffer from complex preparation methods and high costs.

3.1.3 Current Collector Design

Conventional current collectors generally involve 2D planar shaped materials such as copper foil, aluminum foil and carbon foil. However, these 2D current collectors are unsatisfactory for HMLEs due to several reasons, including: (1) high planar current collector densities that can lead to low effective material mass ratios in which AM occupation in electrodes is only 22.94% and 36.27% for 2D Cu and Al current collectors, respectively, but more than 50% for current collector colonization [84]; (2) poor resistance to electrochemical corrosion during repeated cycling; (3) weak cohesion between current collectors and AMs as well as repeated volume change (ion intercalation/extraction) during cycling, which will lead to the cracking, dropout and exfoliation of AMs in HMLEs [18, 85]; and (4) limited charge transfer to AMs in HMLEs leading to the underutilization of active sites [86]. Alternatively, porous 3D current collectors (Fig. 4f) can not only offer robust 3D scaffolds to reinforce AM loading, but also act as 3D conducting networks for effective charge delivery throughout thick electrodes [66]. In addition, 3D current collectors with high surface area, excellent conductance and outstanding physical–chemical stability can significantly increase AM mass loading to further promote utilization efficiency in which 3D porous Al or Cu current collectors are typical substitutes for conventional 2D ones [12]. Shear testing has also indicated that electrodes based on 3D porous current collectors can exhibit better mechanical responses than conventional planar current collectors due to improvements in AM/current collector interconnections. In addition, the smooth electron transfer and rapid ion transport of 3D porous electrodes can allow for thick electrodes with good rate capability. Different cell sizes of 3D current collectors can also influence electrode performance. For example, Joo et al. [87] prepared 3D nickel foams 450, 800, and 1200 μm in cell size to establish 300–600 μm thick HMLEs in a range of 30–60 mg cm−2 and reported that although the electrode using the 1200 μm cell sized nickel foam demonstrated the highest areal capacity, corresponding rate performance was the lowest due to low charge transport in the thick electrode. These researchers further suggested based on the combined consideration of high capacity and moderate rate capability, suitable nickel foam cell sizes should be in the range of 450–800 μm. 3D nanostructured current collectors (3D-NCC) with various dimensional units such as nanowires, nanotubes, nanorods, nanosheets and nanoflakes are also ideal alternatives to reduce interfacial resistance between electroactive materials and current collectors due to enlarged interfacial contact spots as a result of the high surface area of 3D-NCCs [88]. Because of this, the electrochemical performance of thick-film-coated electrodes can be improved due to efficient charge transport and enhanced active site utilization. For example, Liu et al. [44] prepared a 3D nickel current collector with vertical nanoarrays using Anodic Aluminum Oxide (AAO) template methods (Fig. 4g) and reported that due to the significantly reduced interfacial resistance of the AM/current collector as a result of enlarged interfacial contact, the 3D nickel current collector allowed for a high-loading electrode with a nearly 3-μm-thick MnO2 coating that possessed excellent rate capability.

Despite the large mass ratios of metal current collectors in electrode components, performances still fail to meet practical HMLE requirements. Here, the development of ultralight current collectors with high mechanical strength is promising. For example, Fang et al. [84] obtained an ultralight, highly conductive and porous carbon nanofiber-based 3D carbon current collector (3D-CCC) through the one-pot carbonization of commercial biomass cotton and reported that this 3D-CCC can allow for AM loadings of over 50% to enable 300 μm thick electrodes, resulting in significantly enhanced areal capacities and rate performances as compared with electrodes obtained from conventional 2D current collectors. This is because the porous carbon structure can facilitate ionic diffusion and effectively alleviate electrode volume expansion to contribute to long-term cycling performance. In addition, the 3D nanofiber interwoven structure is a suitable scaffold to build nonplanar electrode structures with robust electronic/ionic contact. Nonplanar electrodes can also overcome limited electron transport as compared with traditional planar current collectors to provide efficient ion transfer in thick electrodes (Fig. 4h). For example, Zheng et al. [67] used commercial carbon cloth as a current scaffold and electron transport medium coupling with LiCoO2 (LCO) to obtain an 800-μm-thick composite electrode that possessed an ultrahigh mass loading of 213 mg cm−2. Based on this, ultralight porous carbon current collectors with improved conductivity, multiscale pore structures, high elasticity, compressibility, and stretch-ability are promising research topics.

3.2 Regulation of AM Properties

3.2.1 Improving the Electrical Conductivity of AMs

Heteroatoms Doping The timely transport of electrons and ions as mass loadings increase is vital to ensure the rapid delivery of charge in high capacity or high rate HMLEs [12]. Because of this, the electrical conductivity of porous electrode materials is a decisive factor in high performance HMLEs. For example, although porous carbon (PC) is a widely used material in EESSs due to high specific surface areas (SSAs), stable physical–chemical properties and low production costs, PCs with ultrahigh SSAs generally exhibit undesirable electrical conductivity, which is detrimental to HMLEs [43]. To compensate for the poor performance of PCs, heteroatoms doping is considered to be an effective route to regulate corresponding electronic states and facilitate electron transfer [89], in which single atom doping (N, S, P, B, O) and multi-atom doping (N/S, N/P, N/B, N/P/S, etc.) are common methods to tailor the electronic conductivity of PCs (Fig. 5a) [90,91,92]. Here, theoretical calculations based on density functional theory (DFT) are key indicators that can be used to understand the effects of foreign element incorporation on carbon material electronic property. For example, comparisons of H2SO4 adsorption energy for carbon materials with single doping (N-, B-, P-), co-doping (N/B, N/P) and ternary doping (N/B/P) indicated that multi-atom doping can contribute to higher adsorption energy and superior electrochemical performances (Fig. 5b) [93]. In general, the introduction of heteroatoms with different electronegativities from carbon can induce the charge density redistribution of carbon materials and lead to low band gap energy and rapid electron transfer on graphene basal planes [94,95,96,97,98]. Heteroatoms possessing relatively large atomic sizes can further distort carbon structures and enlarge interlayer spacing to break balanced spin density and expose more electroactive defects [89].

a Schematics of possible N, P, S, B, and O configurations in carbon matrixes. N, P, O configurations are reprinted with permission from Ref. [46]. Copyright © 2017, American Chemical Society. B and O functionalization are reprinted with permission from Ref. [102]. Copyright © 2020, Elsevier. b H2SO4 adsorption energy on single and multi-heteroatom-doped graphene, reprinted with permission from Ref. [93]. Copyright © 2018, Elsevier. c Charge density distributions of α-Fe2O3/carbon composites with and without P-doping. Reprinted with permission from Ref. [99]. Copyright © 2019, Elsevier. d Water contact angles of vertical graphene before and after O-plasma treatment. Reprinted with permission from Ref. [100]. Copyright © 2018, Elsevier. e Core–shell structured AMs. Reprinted with permission from Ref. [47]. Copyright © 2019, Wiley–VCH. f Fabrication process of hollow core–shell interlinked carbon spheres and g corresponding SEM image. Reprinted with permission from Ref. [103]. Copyright © 2015, American Chemical Society

Interactions between metal-based active centers and carbon supports can also improve the electrical conductance of electrodes. For example, charge density distributions clearly indicate enhanced charge transfer efficiency between α-Fe2O3 and P-doped carbon but isolated interconnections in un-doped carbon, confirming the regulation of electronic configuration through P-doping (Fig. 5c) [99]. In fact, heteroatom-doping can affect many properties in carbon materials other than electrical conductivity, including wettability (Fig. 5d), interlayer spacing (especially for hard carbons) and porosity [100]. And therefore, the rational design of heteroatom-doping configurations is useful in the regulation of carbon surface states to improve interfacial electronic/ionic contact between electrodes and electrolytes and contribute to advanced HMLEs. However, heteroatom doping levels must be controlled at reasonable levels as well because excessive doping can negatively influence the electronic structure of carbon. In the case of carbon nitride (C3N4, a typical N-doped carbon with ultrahigh N contents up to 57% atomic N but poor electrical conductivity of nearly 10–5 S cm−1), for example, Pender et al. [101] found that highly defective C3N4 (a high N content) endowed much higher Li+ storage than highly graphitized C3N4 (a low N content) in which the defects contributed to increased Li+ adsorption sites and reversible faradaic Li+ reactions with N atoms. Based on this, suitable doping and rational tuning are both key methods to improve the performance of heteroatom-doped carbon electrodes.

Core–Shell Design The design of core–shell structures with AM cores and CA shells can effectively ensure stable electronic contact between electroactive materials and conductive agents. Based on this, many core–shell designs (Fig. 5e) including carbon coatings, conducting polymer coatings, hollow core–shell morphology and core–shell AM clusters have been proposed [47]. And among these, carbon coatings are a more promising approach because carbon layers can not only lower electron migration distance, but also protect core AMs from serious volume expansion. And although varying carbon morphology including 1D carbon nanofibers, 2D carbon nanosheets and 3D graphene networks has been employed to design nanostructured core–shell AMs, carbon coatings inevitably introduce additional challenges including high SSA and low tap density for core–shell AMs that can lead to side reactions and low volumetric performances, respectively [104]. Here, the design of rational structures involves the complete encapsulation of secondary AM particles with carbon frameworks to form micronized particles with highly interconnected structures (Fig. 5f, g) such as a pomegranate-inspired Si/C nanostructure and hollow core–shell interlinked carbon spheres that cannot only prevent severe side reactions and large SEI formation on individual nanoparticles, but also improve electrode packing density [103, 105].

In terms of fabrication, one widely used strategy involves the pretreatment of AM precursors with additional carbon precursors through co-annealing under high temperature to in situ form ultrathin carbon coating layers that can homogenously and flexibly match with the morphology and microstructure of the AM. Another promising strategy involves the simple, cost-effective and direct carbonization of metal–organic molecules to in situ form core–shell AMs. Here, intrinsically coordinated compounds can possess strong chelating effects between metal centers and surrounding organic frameworks to enable the uniform and stable embedding of metal nanoparticles in carbon frameworks. Typical organic compounds also possess strong chelating effects with metal ions to allow for the fabrication of core–shell AMs. Moreover, 3D hydrogel foam derived from organic components is another promising precursor to obtain the homogeneous dispersion of active nanoparticles in 3D conductive matrixes [106], in which the interconnected hierarchically porous structure and continuous conductive pathways are conducive to electronic/ionic transport and allow for HMLEs with high areal capacities and excellent rate capabilities. Typical organic molecules such as polyvinyl pyrrolidone (PVP), dopamine, citric acid and chitosan can further be used as complexing agents to anchor metal ions for further processing into ultrathin carbon nanosheets incorporated with ultrafine metal nanoparticles. Synthesis processes such as chemical vapor deposition (CVD), atomic layer deposition (ALD), 3D printing and other advanced techniques can also be used to obtain core–shell nanostructures. However, complex procedures, unique equipment requirements and high costs impede easy application. In addition, precursor costs need to be reduced to meet commercial demands.

3.2.2 Improving the Ionic Diffusion Efficiency of Porous Electrodes

Nanostructured AM Design Nanostructured AMs are promising in advanced HMLEs due to unique properties derived from confined dimensional features and combined bulk and surface properties that can reduce ionic diffusion pathways as a result of the synergetic effects of nanoscaled morphology and porous structure [11, 115, 116]. Here, hierarchical porous AM structures involve two or more porous structures that include micropores with pore widths smaller than 2 nm, mesopores with pore widths ranging from 2 to 50 nm and macropores with pore widths higher than 50 nm in which micropores can generally act as active sites for ion adsorption whereas mesopores/macropores can act as electrolyte buffer regions to lower mass transport distance, resulting in high rate capability HMLEs [48]. Corresponding fabrication methods of hierarchical porous AMs involve hard and soft template methods (such as the silica template, the salt template, the metal oxide template, the ice template, the organic polymer template and the surfactant template), double-template methods, molecular unit self-assembly methods and template-free methods [12, 48, 117]. Alternatively, 3D hierarchical electrodes (Fig. 6a) with continuous conductive networks and open porous structures can significantly enhance electron and ion transport efficiency and are therefore also ideal structures for advanced HMLEs [12, 118]. However, 3D hierarchical electrodes possess low packing densities due to the presence of many dead macropores and void spacing that can lead to low volumetric battery performance. To address this, a balance between material density, porosity and electrode thickness through dedicated strategies is necessary. In terms of cost-effective starting materials for hierarchical porous electrodes, biomass precursors and corresponding derivates are good choices due to their sustainability, abundance and environmental friendliness. In particular, some biomass-derived AMs can inherent the natural pore/morphology properties of biomass precursors without the need for templates, thus allowing for facile and large-scale production processes. Natural biomass materials can also possess unique 3D microstructures such as interconnected channels over multiple length scales (Fig. 6b, c) to provide natural 3D hierarchical conductive scaffolds and templates to fabricate HMLEs [107, 108, 119].

a Illustration of different 3D nanostructured electrodes. Reprinted with permission from Ref. [88]. Copyright © 2020, Wiley–VCH. b, c Biomass derived 3D hierarchical porous structures, including (b) crab shells. Reprinted with permission from Ref. [107]. Copyright © 2013, American Chemical Society. c Wood. Reprinted with permission from Ref. [108]. Copyright © 2019, Elsevier. d Illustration of a folded graphene electrode with abundant ionic transport channels. Reprinted with permission from Ref. [109]. Copyright © 2018, American Chemical Society. e The formation process of CaV4O9 micro-flowers. Reprinted with permission from Ref. [110]. Copyright © 2018, Elsevier. f The 3D printing of a 3D graphene microlattice. Reprinted with permission from Ref. [111, 112]. Copyright © 2016, The Royal Society of Chemistry. g The ice-template-assisted fabrication of a vertical-channeled thick electrode. Reprinted with permission from Ref. [113]. Copyright © 2019, Wiley–VCH. h Wood-template for a thick LCO cathode. Reprinted with permission from Ref. [17]. Copyright © 2019, Wiley–VCH. i Illustration of the construction of vertical aligned VOPO4 electrodes and the corresponding SEM image. Reprinted with permission from Ref. [114]. Copyright © 2015, Wiley–VCH

The tuning of nano-dimensional morphology is also a viable strategy to engineer the mass diffusion properties of AMs. For example, graphene quantum dots (GQDs) are 0D graphene derivatives with ultrafine lamellar sizes (< 10 nm) and a π-conjugated core structure as well as enriched edge sites for charge storage that can couple with conductive materials such as graphene, CNTs, activated carbon, and conducting polymers to effectively fabricate interconnected porous HMLEs and provide abundant active sites and sufficient ion transport pathways [120]. Alternatively, 1D CNTs and 2D graphene both suffer from serious restacking due to strong interlayer interactions that can lead to undesirable electrochemical performances in corresponding HMLEs. In addition, the electrochemical performance of 2D graphene nanosheets without ion migration channels under high mass loading is generally hindered. However, Wang et al. [109] reported that folded graphene structures (Fig. 6d) did not possess these issues because folded graphene electrodes possess abundant multi-channels and built-in voids between folded graphene layers that allowed for abundant and short ion diffusion pathways. The control of the pore structure of graphene nanosheets can also effectively enable mass transfer between graphene layers in which Su et al. [121] reported that nano-copper-assisted annealing followed by the removal of nano-copper led to the uniform distribution of small hierarchical in-plane pores within graphene layers as well as sufficient ionic diffusion regions. Multi-dimensional AM structures constructed by using 2D/1D/0D microstructures are also promising due to the combination of multiple advantages. For example, Mai et al. [110] were able to construct HMLEs based on 3D compact CaV4O9 micro-flowers assembled by using 2D nanosheets (Fig. 6e) that ensured rapid electron/ion transport as induced by ultrathin nanosheets and pore-enriched 3D networks with interconnected channels for electrode–electrolyte contact. Despite this, future research should focus on the understanding of structure-performance relationships in these complex nanostructured AMs.

Lower Tortuosity Design Because low-tortuosity structures can contribute to enhanced ion transport efficiency in thick electrodes, effective strategies have been proposed to engineer low-tortuosity electrode structures. For example, extrusion-based 3D printing (Fig. 6f) is an emerging and reliable technology that can accurately and efficiently construct complex 3D structures for advanced electrodes [122]. Extrusion-based 3D printing is also highly versatile and flexible in the rational design of HMLEs due to the ability to fine-tune electrode thicknesses, ordered internal pore structures, geometric shapes and functional composition [123]. One key issue for 3D printing is the preparation of suitable printing inks that possess favorable shear-thinning and good viscoelastic properties however, which prevents the direct printing of highly robust 3D structures without collapse. Because of this, the final electrochemical performance of corresponding HMLEs is related to many factors such as the printing speed, the printing shape, the ink precursor intrinsic rheological property and the electrode porosity in which the search for optimal ink materials and matched printing parameters is vital in 3D-printed HMLEs [122]. Here, flexible carbon materials featuring nanostructures and changeable shapes that can allow for facile 3D printing include materials such as graphene oxide (GO), CNTs and carbon black whereas most reported AMs for energy-related applications involve inorganic materials that require additional additives to incorporate, which hinder resulting electrochemical performance and require the development of additive-free and highly stable AMs for 3D printing. In addition, more attention needs to be paid to the manufacturing size and time of 3D printing methods to meet the demands of large-scale and inexpensive HMLE production.

Alternatively, vertically aligned nanostructures (VANs) can allow for the precise regulation of nanosized and ordered porous AM structures to obtain low-tortuosity electrodes [16]. Based on this, extensive research has been conducted in the past decades in the search for rational fabrication methods to obtain VAN-based AMs, which include magnetically assisted [124], template-assisted and directly oriented growth methods. And because enhanced ion diffusion properties can contribute to the thickness-independent performance of HMLEs, the structurally templated formation of oriented pores/channels is an appealing method to synthesis VAN electrodes. Ice-template-assisted freeze drying is another widely used method to design vertical-channeled nanostructures through the assembly of small molecules (Fig. 6g) [125]. Alternatively, natural wood with its inherent microstructure composed of numerous ordered and vertically aligned microchannels is also a fascinating bio-template to engineer VAN electrodes in which continuous networks with numerous vertical channels and wide pores as inherited from wood (Fig. 6h) can enable rapid ion diffusion [17]. Despite this, most template-guided methods generally generate large pores in electrodes to result in numerous “death pores” without charge storage contribution to result in low volumetric performance. To address this, pore structures need to be rationally adjusted and inactive porosity needs to be reduced through the use of controllable templates such as easily removable salt templates that are uniform and small in size. Based on this, the use of controllable templates combined with advanced printing techniques can become promising in the fine regulation of porosity in low-tortuosity HMLEs.

As for template-free approaches, these can be used to directly form VAN electrodes for the scalable production of low-touristy HMLEs. For example, Yu et al. [114] reported that the rational control of solvent evaporation rates in conventional slurry drying procedures can induce dense film electrodes with VAN nanosheets and that the key to the successful synthesis of orientation ordered composites is the rapid evaporation of mixed solvents in which nanosheets can experience rotating clockwise processes as induced by opposite forces (downward gravitational force and upward force) until vertically aligned (Fig. 6i). Park et al. [126] also used physical vapor deposition to fabricate vertically aligned monolithic electrodes involving 40-μm-thick WS2/C arrays on Al foil. Another promising template-free method involves phase inversion that can be applied to prepare hierarchical porous membranes for water cleaning treatment processes but is less useful for energy storage applications. However, Yu et al. [127] recently pioneered this strategy to fabricate carbon electrodes with hierarchically and near vertically aligned pore structures in which the resulting hierarchical macroporous structure allowed a corresponding carbon electrode to become an ideal sulfur host with rapid ion/electrolyte transport and high sulfur loading capability.

3.2.3 Reduction in Ionic Solid-Phase Diffusion Resistance

One key obstacle for metal ion batteries involves low ionic solid-phase migration efficiency into crystal structures during ion insertion/extraction, which will lead to poor rate capability and low energy storage capacity. Here, heterostructured materials obtained through the coupling of nanocrystals with different band gaps to generate built-in electric field (BIEF) effects near heterointerfaces due to charge redistribution can boost interfacial charge transport and surface reaction kinetics [130]. Based on this, various heterostructured materials have been explored, such as Bi2S3-Bi2O3 nanosheets [131], SnS/SnO2 [128], Bi2MoO6 nanosheets [130], Ni2+-doped Co3O4 nanocrystals with generated Co vacancies [132] and ternary CuGeO3 nanosheets with modulated oxygen vacancies [53], most of which suggest that BIEF effects can improve ion diffusion and electron conduction (Fig. 7a) to result in desired specific capacity, rate performance and cycling stability. Alternatively, oxygen vacancy (Vo) engineering through the removal of oxygen in perfect crystal structures is considered to be an effective method to generate BIEF effects [133], in which DFT calculations suggest that abundant Vo sites can significantly reduce Li+ diffusion activation energy to lead to rapid Li+ migration [133]. Ion-doping is another promising approach to enhance bulk phase electronic conductivity and ion mobility in which Zhang et al. [129] partially substituted V with Ce3+ in a Na3V2(PO4)3/C complex (Fig. 7b) and reported that the resulting Ce3+-doped sample possessed a Na ion diffusion coefficient of 4.903 × 10−11 cm2 s−1 that was higher than that of the pristine NVP/C electrode with 1.719 × 10−11 cm2 s−1, which indicated enhanced Na ion migration efficiency. Moreover, interlayer spacing modulation is an ideal strategy to design open structured AMs for efficient ionic diffusion (Fig. 7c, d), whereas the insertion of guest ions or small molecules is a common method to expand the interlayer spacing of layered compounds [134]. For example, Liu et al. [54] used molybdenum pentachloride (MoCl5)-graphite intercalation compounds (GICs) with high binding energy as HMLEs and reported that intercalated MoCl5 was tightly grafted between adjacent graphite layers to result in a high electrical conductivity of 2.8 × 105 S cm−1 (Fig. 7e) as well as rapid ion diffusion due to the open structures as a result of the rationally expanded interlayer distances. These researchers also reported that the tuning of interlayer spacing can enhance active site utilization on inner graphene layers.

a Schematic of the induced BIEF effects of SnS/SnO2 heterostructures showing facilitated Na+ migration and enhanced rate performance. Reprinted with permission from Ref. [128]. Copyright © 2016, Wiley–VCH. b Ce3+ partial substitution for V in NVP/C complex to design heterostructured AMs. Reprinted with permission from Ref. [129]. Copyright © 2017, Elsevier. c Schematic structures of enlarged interlayer distances after MoCl5 intercalation. d Enlarged Raman G-band regions. d Tap density and electrical conductivity of the samples. c–e Reprinted with permission from Ref. [54]. Copyright © 2020, The Royal Society of Chemistry

3.3 Integrated Electrode Design

Although HMLE structural engineering is a feasible method to improve battery energy density, advanced HMLEs are not easily attained through conventional blade coating methods due to pore blocking, enlarged internal resistance and poor interfacial stability as a result of polymer binders as well as unstable electronic contact between AMs and current collectors. Alternatively, binder-free and current-collector-free HMLE configurations, referred to as integrated electrode designs, can guarantee improved energy density in overall devices through the maximization of AM packing and the reduction of inactive components, allowing integrated electrodes to possess robust mechanical strength for self-support, stable chemical properties for long time cycling, abundant multiscale pores for efficient ion diffusion and interconnected conductive frameworks for electron transport. Because of this, numerous integrated electrodes have been developed in the past decades and can be divided into two aspects, including (1) 3D conductive scaffolds as electroactive components or supports to load AMs and (2) composite network structures through the use of robust and conductive building blocks.

3.3.1 3D Conductive Scaffold Electrodes

3D conductive scaffold electrode (3D-CSE) designs can provide multifunctional platforms for the engineering of HMLEs with complex structures based on diverse AMs such as carbon foam, carbon sponge, monolithic carbon, nanofiber interweaved carbon cloth/fiber, ultralight and porous carbon aerogels and other 3D carbon frameworks. For example, carbon cloth (CC) as a flexible carbon support containing interwoven 1D microfibers has been widely used to fabricate flexible and bendable electrodes due to intrinsically excellent electrical conductivity, porous structure, good corrosion resistance and highly integrated strength [141], in which many controllable methods have been applied to load AMs onto CC surfaces, such as hydrothermal methods, chemical vapor deposition, electrodeposition and dip-coating methods (Fig. 8a). Despite this, the surface attachment of AMs on CC leads to the insufficient utilization of CC and restricted mass loading whereas the utilization of gaps and void spaces between CC fibers to accommodate increased AM loading can improve the overall mass loading of electrodes [135]. For example, the incorporation of additional components into CC voids to bridge surrounding gaps can improve CC electrode mass loading to enable well-defined 3D porous conductive networks to fulfill gaps and void spaces among fibers. The introduction of multilevel pores into carbon fiber backbones can also improve utilization efficiency because these structures can not only provide more surface area to storage active components, but also ensure electrolyte penetration within thick active layers [142]. Despite this, the internal mechanical strength of corresponding carbon fibers will inevitably be reduced under highly porous conditions and therefore, a balance between structural porosity and mechanical stability needs to be carefully optimized.

a Schematic of the synthesis of HMLEs by coating Na3V2(PO4)3/C onto carbon cloth. Reprinted with permission from Ref. [135]. Copyright © 2017, Elsevier. b CNT sponge as a conductive scaffold loaded with Co3O4 that can be densified. Reprinted with permission from Ref. [136]. Copyright © 2018, Wiley–VCH. c Preparation process of melamine resin-derived compressible carbon foam. Reprinted with permission from Ref. [137]. Copyright © 2016, Elsevier. d Synthesis of the poly(ionic liquid)-derived nanoporous carbon monolith through phase separation. Reprinted with permission from Ref. [138]. Copyright © 2019, American Chemical Society. e, f Growing CNTs into wood-derived carbon. Reprinted with permission from Ref. [139]. Copyright © 2019, Elsevier. g Filling graphene into wood carbon as sulfur hosts for Li–S batteries. Reprinted with permission from Ref. [140]. Copyright © 2017, American Chemical Society

CNT sponge is another promising conductive scaffold that possesses large inner spacing to accommodate high AM loading as well as structural integrity with high compression tolerance to enable densified thick electrodes with high packing density (Fig. 8b). Here, the use of conductive scaffolds with highly deformable features (elastic, compressible, bendable, stretchable, etc.) to construct hybrid structures can provide novel opportunities to engineer advanced HMLEs with dense but porous structures that can be extended to graphene sponge, graphene foam and carbon aerogels.

Polymers can also be directly processed into carbon monoliths as a facile, scalable and sustainable method to fabricate integrated HMLEs in which melamine foam (MF) as a typical commercial polymer foam possesses a highly elastic and interconnected network structure. Based on this, MF obtained monolithic carbon materials possess ultralow densities of 5 mg cm−3 that are comparable to CNT sponge (5–10 mg cm−3) and graphene foam (~ 5 mg cm−3), demonstrating potential as an ultralight carbon support for hybrid electrodes [143]. In addition, these MF polymers possess combined advantages including macroporous structures favorable for rapid mass diffusion and MF frameworks with nitrogen-enriched components that can induce abundant active defects to enhance energy storage capacity. Unfortunately, the presence of ultra-large and inactive pores in MF backbones can also lead to low volumetric performance. Alternatively, polymers assembled through molecular precursors can provide pore/composition tunable routes to engineer monolithic carbon electrodes because of maneuverable synthesis processes through the dedicated selection of appropriate molecules and rational reaction mechanisms. For example, He et al. [144] fabricated a monolithic carbon electrode based on chemically cross-linked molecules including lignin as the central crosslinking sites, a copolymer template (Pluronic P123) as the mesopore-forming agent and a hard template (KIT6) as the macropore-forming agent. Wong et al. [137] also conducted molecular engineering based on strong cross-linking interactions between melamine and paraformaldehyde to produce a hierarchical N-doped carbon electrode (H-NC) using P123 as a micropore forming agent and pentane as a macropore forming agent (Fig. 8c). Poly(ionic liquid) (PIL) membrane-derived nanoporous carbon materials have also attracted intensive attention recently for application [145, 146]. PIL polymers are composed of two polymerized IL molecules through electrostatic crosslinking in which Zhao et al. [138] used phase separation to obtain a N/B-doped porous carbon monolith based on PIL (Fig. 8d) that possessed an interconnected hierarchical pore structure. Despite this, these PIL-derived carbon membranes remain in early investigation stages and extended application in batteries requires further exploration.

In recent years, natural wood has further been presented as a promising platform to engineer integrated HMLEs due to a naturally hierarchical porous structure, low tortuosity, aligned channels and moderate mechanical strength [21]. In addition, the unique microstructure of wood-derived carbon materials allowed for the investigation of structure-performance relationships between mass loading and parallel/vertical aligned electrode structures to clearly demonstrate the better areal capacity of VAN electrodes as compared with parallel electrodes [147]. Nevertheless, the existence of inactive void spaces in wood carbon structures will lead to low electrode utilization efficiency and poor volumetric performance. To address this, Chen et al. [139] incorporated CNTs into CW inner walls through nickel assisted CVD to enhance SSAs and electron/ion transfer (Fig. 8e, f). Hu et al. [140] also directly filled rGO into an ultrathick wood carbon framework to obtain a stable 3D framework host and achieved high sulfur loading (Fig. 8g). Overall, wood-derived ultrathick and integrated electrodes are efficient and cost-effective candidates for commercial batteries; however, the intrinsically rigid structure and permanent composition of wood carbon result in difficult structural regulation or functionalization. In addition, the physical–chemical properties of wood are greatly influenced by factors such as climate, soil condition and tree types and require more in-depth research.

3.3.2 Integrated Composite Network-Based Electrodes

Although 3D-CSE designs can promote the development of HMLEs, most are rigid structures that are unsuitable in flexible electronics applications. Alternatively, integrated composite network-based electrodes (ICNEs) fabricated from intrinsically flexible, bendable and stretchable components possess great potential for application in flexible and wearable devices. In terms of synthesis, CNTs have been widely used to fabricate freestanding ICNEs through mechanical interlocking due to excellent conductivity and high mechanical properties as a result of large length-to-diameter ratios. In addition, 3D CNT frameworks can provide adequate mechanical strength to suppress structural distortion, sufficient inner spacing for high mass loading and highly porous and conductive channels for efficient ions diffusion [148]. 2D MXene or graphene with high aspect ratios of nanosheets has also been applied to fabricate high-mass-loading ICNEs due to favorable mechanical stability and outstanding electronic/ionic conductivity in which the large 2D structure and high mechanical strength of rGO nanosheets can allow for advanced flexible batteries that can function well after folding and bending (Fig. 9a) [149], whereas graphene can wrap irregular particles into densely compact integrated structures because its large sheet-like morphology can strongly overlap each other to function as “peels” for packaging. For example, Yang et al. [150] fabricated an ICNE with graphene-packed ACs through a capillary process (Fig. 9b) that possessed high intercontact and a dense and compact structure but with ion channels. These researchers further reported that their highly dense but porous AC/graphene electrode can minimize the thickness of conventional thick AC electrodes [151], highlighting the benefits of this thickness-matching strategy in terms of unimpeded electron/ion conductive pathways built by 3D graphene networks.

a Fabrication of flexible ternary Fe1−xS@porous carbon nanowires/rGO hybrid film electrodes and their bending/rolling/twisting/folding properties. Reprinted with permission from Ref. [149]. Copyright © 2019, Wiley–VCH. b Fabrication of packed ACs into dense graphene networks. Reprinted with permission from Ref. [150]. Copyright © 2019, Wiley–VCH. c Photograph and d SEM image of a compact and freestanding electrode as enabled by the conductive cellulose nanofiber and corresponding microstructure and e schematics illustrating ion/electron conductive pathways. Reprinted with permission from Ref. [60]. Copyright © 2018, Wiley–VCH. (f–h) Paper electrode derived from vacuum infiltration and its bending performance. Reprinted with permission from Ref. [152]. Copyright © 2015, Wiley–VCH

Despite great success in the development of HMLEs based on ICNE achieved through CNTs, graphene and MXene, high production costs and complex fabrication processes make them less competitive than conventional commercial electrodes. Alternatively, the cellulose nanofiber (CNF) as an emerging biomass-derived material that is able to fabricate freestanding and flexible electrodes due to a nanofiber-like structure and high mechanical strength has been reported to be promising in the synthesis of highly conductive 3D networks through combination with conducting agents as effective scaffolds to establish ICNEs. For example, Hu et al. [60] engineered a flexible ICNE based on LFP up to 60 mg cm−2 with abundant electron/ion transfer pathways through the spontaneous electrostatic self-assembly of negatively charged CNFs and conductive CB particles and reported that the obtained ICNE possessed many desirable characteristics including: (1) a mechanically robust CNF backbone that contributed to compact electrodes after post-densification (Fig. 9c, d); (2) the essential electrolyte affinity of the CNF and an interconnected network structure that resulted in continuous electron/ion transport pathways (Fig. 9e); and (3) the naturally abundant CNF and low-cost CB that allowed the composite electrode to be attractive for practical application.

Aside from ICNEs based on singular CNTs, graphene, MXene and CNFs, corresponding composite networks can also provide promising performances due to synergetic effects. For example, Lee et al. [153] fabricated an ICNE by coupling 1D nano-building blocks of polyacrylonittrle nanofibers with MWCNTs through electrospraying and electrospinning as well as a hetero-nanonet paper electrode using CNFs as 1D building blocks to incorporate with MWCNTs through vacuum infiltration (Fig. 9f) that was able to provide an LFP cathode material loading of over 90 mg cm−2 at an electrode thickness of 1400 μm [152]. These hybrid paper electrodes also exhibited flexibility and high mechanical robustness (Fig. 9g, h), indicating practical significance in the building of flexible, wearable, and portable electronics.

4 Recent Progress of HMLEs in Advanced Secondary Batteries and Supercapacitors

4.1 Lithium-Ion Batteries

Lithium-ion batteries (LIBs) have been successfully commercialized and are integral to our daily life for portable electronic devices and electric vehicles. However, current commercial LIBs have encountered a bottleneck in terms of limited energy density due to the fundamental capacity limits of intercalation-type cathodes and graphite anodes, and great efforts have been devoted to the exploration of high voltage cathodes [177, 178], high capacity anodes and electrolyte engineering [7, 179]. Figure 10 displays representative commercial and high voltage cathode materials and state-of-the-art anode materials as well as corresponding gravimetric capacities. Based on this, the intensive research into HMLEs based on these electrode materials is ongoing and in this section, a summary of the recent advancement in HMLEs based on these cathode and anode materials along with their advantages and bottlenecks will be provided. Table 1 lists the electrochemical performances of select HMLEs for LIBs.