Abstract

Chitosan-based films incorporated with lemongrass (Cymbopogon citratus) essential oil (LEO) were developed and their properties as an active food packaging were investigated. The thickness and percentage elongation at break (EAB) of the films increased significantly (p < 0.05) with the higher concentrations of LEO. At 9% LEO (wt/wt chitosan), the film experienced a 101% improvement in percentage EAB compared to control chitosan films. On the other hand, the moisture content, solubility and tensile strength decreased significantly (p < 0.05). The water vapor permeability (WVP) was reduced by 15% with the incorporation of 9% wt/wt LEO. Creases were observed on the otherwise smooth surface microstructure of the films with the incorporation of LEO, which explained the decrease in the tensile strength. Confocal laser scanning microscopy (CLSM) results showed a corresponding increase in the number of oil droplets when the concentration of LEO increased. Incorporation of 9% LEO was found to be the most effective (p < 0.05) in controlling the growth of Bacillus cereus, Escherichia coli, Listeria monocytogenes and Salmonella typhi, showing the potential of the films as a material for antimicrobial food packaging.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Current packaging materials are usually petroleum oil derivatives based which many of those are not readily recyclable and environmentally sustainable. This leads to the rise of environmentally sustainable active packaging. Active packaging is created by adding an active substance into the packaging material, so that it interacts with the product and the surrounding environment to extend the shelf life and to maintain and improve the organoleptic properties of its contents [6, 55]. Numerous researchers have reported the feasibility of antimicrobial active packaging systems [13, 22]. However, the technology is still not applied on a large scale thus far [35].

Microbial spoilage is one of the factors that lead to quality deterioration, rendering a product undesirable or unacceptable for consumption and thus reducing its shelf life [14, 22]. Direct addition of antimicrobial agents is commonly applied but it can modify the taste and quality of the food. In addition, consumers nowadays gravitate towards products, especially food, with natural instead of artificial additives [21]. Therefore, new active packaging systems that possess natural antimicrobial agent which is separated from the food are good alternatives to current packaging systems. This is made possible by incorporating active components in packaging materials.

Chitosan is a type of biopolymer that has received much attention as a sustainable packaging material due to its high biodegradability, biocompatibility and antimicrobial properties [6, 17]. Chitosan is the deacetylated form of chitin, which is a cellulose-like biopolymer commonly found in the shells of crustaceans, insects, fungi and yeast [17]. Chitosan is considered safe to be used as a food preservative, since the US FDA has classified it as Generally Recognised as Safe (GRAS) [18, 24]. In the application of active packaging, chitosan is either used alone or blended with other natural polymers or essential oils (EOs). It also exhibits good mechanical properties, excellent film forming ability and selective permeability to gasses, which make it an ideal material to be used as food packaging. However, its high water vapour permeability limits its uses though Atarés et al. [10] reported that the poor moisture barrier property of the hydrophilic chitosan was improved by the addition of hydrophobic EO.

Cymbopogon citratus (DC.) Stapf, or more commonly known as lemongrass, is a tall, coarse grass with a strong lemony taste. Lemongrass is commonly cultivated in the tropics and sub-tropics and is a perennial herb. Besides being widely used in culinary to enhance the flavours of cooking, its essential oil also exhibits antimicrobial activity. The essential oils of Cymbopogon species mainly consist of monoterpenes. Several bioactive compounds are reported in the essential oils, which include citral, which is a mixture of geranial and neral; geraniol, citronellol, citronellal, linalool, elemol, 1,8-cineole, limonene, β-caryophyllene, methyl heptenone, geranyl acetate and geranyl formate. Among these bioactive compounds, geranial, geraniol and neral were found to be effective antimicrobial compounds [4, 21]. In fact, the antibacterial activity of LEO against a broad range of bacteria, yeast and fungi was vastly reported in previous literatures [1, 4, 19, 30, 36]. Previous researchers have incorporated LEO into edible alginate coatings for fresh-cut fruit such as pineapple, melon and apple [13, 47, 50]. Hence, the incorporation of LEO in chitosan film is expected to improve the films’ antimicrobial properties. In a previous study, 0.5 and 1.0% (v/v) LEO enriched chitosan coatings were found to be effective against fungi that causes anthracnose in bell peppers [4]. However, there might be possibilities of transferring the LEO to the contents if the material is used as a coating, thus imparting the characteristics scent of LEO onto the food product [33]. The application of chitosan/LEO film packaging might be an alternative to minimize the transfer of LEO due to the embedded LEO droplets inside the chitosan matrix in contrast to coating, which often requires dipping the food into the film forming emulsion. In this case, the volatile antimicrobial efficiency of the films is important to ensure a relatively rapid and thorough diffusion of the bioactive compounds in vapor phase, into the food product.

The aim of this study was to develop antimicrobial chitosan-based edible films incorporated with LEO. The antimicrobial efficiency of the chitosan/LEO composite films was evaluated by the Kirby–Bauer disk-diffusion method using B. cereus, E. coli, L. monocytogene and S. typhi as the test organisms. In practical application, not the entire surface of a food product is in contact with the film packaging. Therefore, the volatility of an EO is important to make sure the active compounds infiltrate the entire food evenly. The volatility antimicrobial properties of LEO were demonstrated in a recent study, where LEO fumigation was found to be effective against anthracnose of papaya fruit without affecting its quality [5]. Thus, in this study, the volatile antimicrobial efficiency of LEO after incorporated into chitosan was tested against S. typhi to determine the efficiency of a chitosan/LEO composite film as an antimicrobial active packaging.

Materials and Methods

Chemicals

The powdered medium-molecular weight chitosan (450 kDa, 85% degree of deacetylation, DDA), Tween 20, and glycerol (99.5% purity) were purchased from Sigma-Aldrich Co. (St. Louis, Missouri, USA). LEO was procured from Spectrum Chemical Manufacturing Corp. (New Brunswick, New Jersey, USA). Glacial acetic acid was obtained from Fisher Scientific (Hampton, New Hampshire, USA). For the microbiological tests, nutrient agar and Mueller–Hinton agar (MHA) were both purchased from Merck KGaA (Darmstadt, Germany).

Preparation of Test Microorganisms for Antibacterial Activity

The test microorganisms used in this study was obtained from the culture collections of the Institute of Bioscience, Universiti Putra Malaysia. The bacteria used in this study include two Gram-positive bacteria (B. cereus and L. monocytogenes) and two Gram-negative bacteria (E. coli and S. typhi). The test organisms were streaked on nutrient agar plates and were incubated overnight at 37 ± 1 °C. The cultures were kept at 4 °C and were subcultured every 10 days. For each test microorganism, a few colonies from the nutrient agar plate were inoculated into 0.85% sterile saline solution and the inoculum was adjusted to absorbance of 0.08 to 0.10 under light wavelength of 600 nm with a visible spectrophotometer (ThermoFisher Scientific, Waltham, Massachusetts, USA), which made a microbial suspension with bacteria amount of about 108 cfu/mL [52].

Preparation of LEO Incorporated Chitosan Films

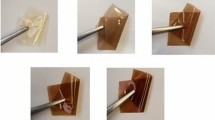

Figure 1 shows the method of preparation of LEO incorporated chitosan films. The chitosan/LEO films were produced according to the method by Zivanovic et al. [62]. To begin, 1.5 g chitosan (1.5% wt/v) was dissolved in 100 mL of distilled water (50 ± 2 °C) containing 1.5 mL acetic acid (1.5% v/v). The solution was then stirred overnight at a room temperature (25 ± 2 °C) followed by a filtering process to remove any impurities. Then, Tween 20 (0.5 mL) and glycerol (0.5 mL) were added as an emulsifying agent and a plasticizer, respectively. Consequently, LEO was added into the chitosan solution, followed by homogenization (13,500 rpm, room temperature (25 ± 2 °C)) (WiseTisHG-15D, Witeg Labortechnik GmbH, Wertheim, Germany) for three min. The concentrations of LEO were defined at 1, 3, 5, 7 and 9% wt/wt chitosan. Then, 20 mL of the emulsion was spread evenly onto a 150 mm-diameter petri dish. The films were dried at a room temperature for 48 h. Dried films were peeled off manually. All the films were conditioned in a dry cabinet at 50 ± 5% relative humidity (RH) and at a temperature of 25 ± 2 °C until analysis.

Thickness

The thickness of each film was measured manually using a digital micrometer (Mitutoyo, Kawasaki, Kanagawa, Japan) which has a sensitivity of 0.001 mm. Measurements were taken at ten different points, evenly spaced, on the film. The thickness values were expressed in terms of the mean of the measurement, mean ± SD.

Moisture Content

The moisture content of the film samples was determined according to ASTM D 644-99 method with slight modifications [7]. The film sample was cut into a strip measuring 1 × 3 cm2. The strip was weighed and dried in an electric oven (Memmert, Schwabach, Germany) at 110 °C for 24 h until a constant weight was obtained. Each film sample was weighed again and the moisture content of the film was expressed in percentage moisture content and was determined according to the equation, Moisture content = (\(w_{0} - w_{1}\))/ \(w_{1}\), where w1 represents the weight of the sample after the drying process (g) and w0 represents the initial weight of the sample (g). The moisture content was measured in triplicates.

Water Solubility

The solubility of the film in water was determined with reference to method by Fundo et al. [25]. It was measured as the content of dry matter solubilized after 24 h of immersion in water. Three pieces of film samples, each measuring 1 × 3 cm2 were prepared and weighed, followed by 24 h of oven drying at 110 °C until a constant weight was obtained. The samples were then immersed in 10 mL of distilled water with constant agitation. After 24 h, undissolved film was dried at 110 °C for 24 h and the weight was recorded. The percentage of solubility was calculated based on the equation, Solubility = (\(w_{0} - w_{1}\))/ \(w_{0}\), where w1 represents the weight of the undissolved film after the drying process (g) and w0 represents the weight before immersion (g).

Colour Analysis

The colour of each film sample was measured using a chromameter (Minolta CR 300 Series, Minolta Camera Co. Ltd, Osaka, Japan). The International Commission on Illumination (CIE) L∗, a∗, b∗ scales were used in this test. The L* coordinate represents the lightness of the colour, where L* = 0 represents black and L* = 100 indicates white. The a* coordinate characterizes its position between magenta and green. A negative a* value indicates green, while a positive value indicates magenta. Finally, the b* coordinate characterizes its colour between yellow and blue, where negative and positive b* values indicate blue and yellow, respectively [31]. A standard white plate (L* = 93.50, a* = 0.25, b* = 0.10) was used for the calibration of the chromameter. Three readings were taken for each sample and the results were expressed as individual L*, a*, b* parameters.

Opacity

The opacity of the film samples was determined with reference to Nur Fatin Nazurah and Nur Hanani [40]. Two strips of film samples measuring 1 × 4 cm2 were placed in opposite sides of a blank cuvette and the absorbance was measured at a light wavelength of 600 nm with a spectrophotometer (Shimadzu UV–VIS 1601, Japan). An empty cuvette was used for the blank. Readings were taken in triplicates and the film opacity was determined using the equation, Opacity = \({\text{Abs}}_{600}\)/x, where Abs600 represents the light absorbance at 600 nm, whereas x represents the film thickness (mm).

Water Vapour Permeability (WVP)

The WVP of each film sample was determined using the standard method ASTM E96-90 with slight modifications [9]. Each film sample was placed onto a test cup filled with 6 mL of distilled water and was secured with a rubber band. The test cup was weighed and placed into a desiccator with a relative humidity (RH) maintained at 50 ± 5% with silica gel and a temperature of 23 ± 2 °C. The test cup was weighed every hour for 8 h and the values were rounded to the nearest 0.0001 g. The test was conducted in triplicates for each sample and WVP was determined according to the equation WVP= (\(\Delta m \cdot x)/\left( {A \cdot \Delta p} \right)\), where \(\Delta m\) represents the slope of weight loss vs time plot (g s−1), x represents the thickness of the samples (m), A is the test area (m2) and ∆p is the partial pressure difference of water vapour across the film (Pa).

Mechanical Properties

Tensile strength (TS) and the percentage elongation at break (EAB) of the films were determined according to the ASTM Standard Method D 882 using the Instron Model 3365 Tensile Tester (Instron, Norwood, Massachusetts, USA) [8]. Film samples of 1.5 × 9 cm2 were fixed between the grips of the machine with an initial separation of 50 mm. The initial strain rate was fixed at 50 mm/min. A 5 kN load cell was used. All tests were conducted in triplicates.

Scanning Electron Microscopy (SEM)

The surface microstructure of each film sample was observed using the LEO 1455 VP SEM (Zeiss, Germany). Specimens of all the composite films were prepared by mounting a film piece measuring 0.5 × 0.5 cm2 onto a bronze stub by double-sided tape. Each specimen was coated with gold using SCD 005 Sputter Centre (BalTec, Pfäffikon, Switzerland) and was viewed under the SEM under the magnification of 1000 × .

Confocal Laser Scanning Microscopy (CLSM)

The appearance of the LEO droplets in all the composite films was observed using CLSM with reference to the method proposed by Auty et al. [11]. The polysaccharide phase and LEO distribution within chitosan films was investigated. For each composite film, sample measuring 1 × 1 cm2 was cut and placed onto a microscope glass slide. Upon the placement of cover slip, a few drops of a 3:1 mixture of 0.01% wt/wt Nile Red in polyethylene glycol and 0.1% wt/wt aqueous Fast Green FCF was used to stain the samples. The samples were washed with distilled water to remove excess staining prior to analysis. The samples were then placed under the MRC 1024 ES confocal scanning laser microscope (BioRad, Hercules, California, USA). Two separate channels were used to obtain fluorescence images, which were a Krypton/Argon laser (405 nm excitation) and a Helium/Neon laser (573 nm excitation). The micrographs were acquired using a 20 × objective lens.

Quantitative Assay of Antibacterial Activity by Disk-Diffusion Method

The antibacterial activity of the films when they were in direct contact with the media was evaluated using the Kirby–Bauer disk-diffusion method. This step was performed based on the method proposed by Shemesh et al. [52] with slight modifications. Film disks of 5 mm diameter from all the chitosan films (0, 1, 3, 5, 7 and 9% LEO) were prepared and sterilized using ultraviolet (UV) rays. Under aseptic conditions, the disks were placed onto a MHA surface swabbed with the standardized bacteria inoculum. Chitosan film without LEO was used as a control. The plates were incubated at 37 ± 1 °C for 18 h and the diameter of the clear zone which formed around the film disks was measured. The disk-diffusion test was performed in triplicates for each concentration of LEO. The chitosan/LEO composite film which exhibited the significantly (p < 0.05) largest inhibition zone was selected to be tested using the disk-volatility method.

Qualitative Assay of Antibacterial Activity by Volatility Method

The disk-volatility test was performed with reference to the method by Passarinho et al. [45]. MHA plates were swabbed with the standardized bacteria inoculum. Under aseptic conditions, chitosan film of 10 cm diameter was attached onto the cover of the petri dish. The petri dish was sealed and incubated at 37 ± 1 °C for 18 h. Bacterial growth was observed after the incubation period. The antibacterial activity of the film depended on the volatility of LEO. This volatility test was performed in triplicates.

Statistical Analysis

All the data recorded were statistically analysed using one-way analysis of variance (ANOVA) by the mean of Minitab Statistical Software Version 17 (Pennsylvania, USA). The significant differences of the readings were determined by the Turkey’s multiple range test with the level of significance set at p < 0.05.

Results and Discussion

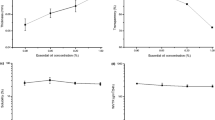

Thickness

The thickness of all film samples was measured to determine the effect of LEO on the film matrices of chitosan films. Table 1 summarizes the thickness of chitosan films incorporated with different LEO concentrations. All the films were produced by 20 mL of the film forming emulsions. However, the thickness of films varied between 40.30 and 52.10 μm. It was found that adding 1% of LEO into chitosan did not cause a significant (p ≥ 0.05) difference to the film thickness, as compared to the control chitosan film. However, the thickness increased significantly (p < 0.05) from 41.80 to 47.90 μm once the LEO concentration increased to 3%.

The results in present study appear consistent with Jouki et al. [34] that reported a similar behaviour of the films’ thickness with the addition of thyme EO, which is due to the formation of a looser film matrix when a considerable amount of EO is added. This suggested that polymer chains of chitosan could not form a compact film network in the presence of LEO Ahmad et al. [2]. The increase in thickness in composite chitosan films with a higher LEO concentration was also supported by the findings from moisture content analysis, which showed decreasing moisture content with increasing LEO concentration. A previous literature showed that the thickness of film depended on the content that remained in the film after all the moisture has evaporated [3]. Thus, a lower moisture of the film content suggests that more solid mass would remain in the film after the films dried and hence, increasing the thickness of the film.

Moisture Content

Table 1 shows a summary of the moisture content of all chitosan films. In this study, it was observed that the incorporation of LEO, even at 1%, caused a significant decrease (p < 0.05) in moisture content of the film, from 15.74% in the chitosan control film to 11.91%. Adding more LEO did cause a slight (p ≥ 0.05) reduction in the moisture content, to 2.56% in chitosan film with 9% LEO. As chitosan has high hydrophilic nature, the control chitosan film exhibited the highest moisture content, as expected. This can be explained by the higher molecular entanglement and viscosity in pure chitosan solutions, leading to higher retention of water molecules during drying of the films [25]. The addition of LEO, which is hydrophobic, reduced the ability of the film to adsorb and retain water molecules. Similar finding was observed by Ghasemlou et al. [27], in which the incorporation of 3% Zataria multiflora Boiss and Mentha pulegium EOs caused a reduction in the moisture content of corn starch films from 21.95% in the control films to 14.04 and 13.21%, respectively.

Water Solubility

Water solubility of the material is one of the most important criteria when selecting an appropriate material to be used as food packaging, especially for raw meats, seafood, fresh fruits and vegetables, as these foods generally contain high water content. Chitosan on its own is highly water soluble due to its hydrophilic nature, which limits its use as a film packaging material [60].

In present study, the addition of 1% LEO into chitosan significantly (p < 0.05) decreased its water solubility from 21.77% in the chitosan control film to 7.39%. However, further increment of LEO concentration in the composite films did not cause any significant effect (p ≥ 0.05) on the film water solubility, although 9% LEO did reduce the film’s water solubility to 5.22%. The reduction in water solubility was due to the hydrophobic nature of LEO. This was due to the decrease in the number of OH bonds and the presence of aliphatic groups in the film when oil was added. Thus, the formation of hydrophobic portions of the film led to a less soluble material. This caused the repulsion of water molecules, so that they were less able to penetrate and dissolve the films. The observation in present study was supported by the findings of Nur Fatin Nazurah and Nur Hanani [40], where the solubility of κ-carrageenan films decreased significantly (p < 0.05) with the addition of plant oils.

Colour Analysis

The colour property of film for food packaging is an important criterion when selecting a suitable material. A lighter film packaging is generally preferred over a darker one, because it will not alter the original colour of the contents. Besides, the film should be clear and not heavily tinted, so that it will not affect the aesthetic of the food product during display.

The parameters of L*, a* and b* for each of the film samples are summarized in Table 2. The L* parameter which represents the lightness of the chitosan film samples, only exhibited a significant (p < 0.05) decrease when 9% of LEO was incorporated. For a* parameter, chitosan composite films with 5, 7 and 9% LEO concentration were significantly (p < 0.05) lower compared to the neat chitosan film, which indicated that the increase in LEO concentration caused the composite films to have a slightly greenish tint. In addition, a significant increase (p < 0.05) in the b* parameter was observed with the increasing LEO concentration in the films. The b* value of the samples increased from − 2.39 in the control sample, to 1.43 in the chitosan composite film with 9% LEO. The changes in the colour of the film were contributed by the colour of LEO, which is bright yellow in nature. This finding is consistent with Ghasemlou et al. [27] and Shojaee-Aliabadi et al. [54], where the incorporation of plant EOs into polysaccharide-based films significantly increased the intensity of yellow colour in the films. In addition, Ojagh et al. [41] have reported similar results during the investigation of chitosan-based films containing cinnamon EO.

Opacity

The opacity of film material determines its transparency which is a crucial property in determining the suitability of a film as packaging. Generally, a film with high transparency is preferred over opaque films. This is to ensure that the appearance and condition of the food is clearly visible throughout storage.

However, opaque films are preferable when exposure to light is the cause of food spoilage. This is because sunlight, fluorescent or incandescent light will cause photodegradation in some food products. Photodegradation usually happens when chemical reactions of food constituents are triggered by the absorption of light. Specific components of food, such as proteins, fats, pigments and vitamins are usually susceptible to photodegradation. Vitamin loss is the main damage caused by photodegradation. Besides, photodegradation also leads to development of off-flavours and this might be accompanied by colour changes in the food.

In present study, higher light absorbance indicates higher opacity of the film. The results of opacity are summarized in Table 2. The opacity of the chitosan control film was the lowest, at 1.16. Generally, the transparency of the films decreased with the addition of LEO. This is due to the light scattering effect of the LEO droplets in the chitosan matrix [26]. The incorporation of LEO at 1–5% concentration caused an insignificant effect (p ≥ 0.05) to the opacity of the films. However, further increment of LEO from 7 to 9% caused a significant increase (p < 0.05) on the film’s opacity from 2.31 to 4.84. In present study, incorporation of LEO increased the film’s opacity, indicating the composite films became less transparent with the incorporation of LEO. This is in good agreement with findings from Shojaee-Aliabadi et al. [54], where the incorporation of 3% Satureja hortensis oil into κ-carrageenan films increased their opacity. Similar results were reported by Maryam Adilah and Nur Hanani [37], in which 3% Morinda citrifolia oil significantly (p < 0.05) increased the opacity of fish gelatin films. Nevertheless, even at the highest concentration of LEO, all the chitosan/LEO composite films were not heavily tinted and their opacity was still comparable to opacity value of 4.26 obtained for low-density polyethylene (LDPE) film [28].

Water Vapour Permeability (WVP)

One major function of food packaging is to avoid or decrease the transfer of moisture between the food and its surrounding atmosphere or between two components of food products with different moisture content. This is a major step in prolonging the shelf life of food products. Hence, WVP of a food packaging material should be as low as possible.

In present study, a decrease in WVP was observed with the increasing of LEO concentration, from 2.54 × 10−8 g s−1 m−1 Pa−1 in the control chitosan film to 2.15 × 10−8 g s−1 m−1 Pa−1 in 9% chitosan/LEO films. The decrease in WVP caused by LEO was also proven in earlier studies, where the incorporation of lipids and waxes in chitosan films was found to increase the hydrophobicity of the material [38, 48]. The addition of LEO might have caused a higher degree of cross-linking of the chitosan network, leading to a lower water vapour transmission, as reported by Oudgenoeg et al. [44].

Incorporation of hydrophobic compound composition such as EOs in edible film usually results in a reduction of WVP [51, 58]. The lower WVP of the chitosan/LEO films may be caused by the hydrogen and covalent interactions between the polysaccharide network and the polyphenolic compounds in LEO. These interactions probably limited the availability of hydrogen groups for the formation of hydrophilic bonds with water, and consequently leading to a decrease in the film’s water affinity [53]. Nevertheless, chitosan on its own is highly hydrophilic and this might be one of the factors which led to an insignificant change in the WVP among all films.

Mechanical Properties

The results of TS and percentage EAB are summarized in Table 1. It was found that TS decreased with the increase in LEO concentration and the addition of 5, 7 and 9% of LEO into chitosan films significantly (p < 0.05) reduced their TS as compared with the control film.

The control film exhibited the highest TS due to the formation of a dense network of chitosan. The results for present study corresponded with Morillon et al. [38] and also with Rhim [48], where TS of chitosan films was compromised by the addition of oils. The TS of a film depends on the intra- and intermolecular forces of the chitosan polymer chains and how they interact within the network in the film [3]. The addition of LEO disrupted the network, subsequently leading to a different cross-linking of the polymer, which resulted in the lowering of the TS of the films.

The brittleness of chitosan is the innate property which contributed to the lowest EAB of the control film when compared to other chitosan/LEO composite films. This finding was supported by Elsabee and Abdou [20], where an increasing chitosan coating on starch films tremendously decreased the percentage EAB. This is because the chitosan used in this study has an 85% DDA, which is considered highly deacetylated. It was shown that chitosan with higher degree of deacetylation often showed a greater crystallinity compared to those with lower DDA, which makes it strong but also brittle [59].

The percentage EAB of the chitosan films has shown a steady increase with the increasing concentration of LEO, from 32.53% in the control chitosan film to 65.34% in the chitosan film incorporated with 9% LEO. The addition of 5, 7 and 9% LEO into the chitosan film caused a significant increase (p < 0.05) in percentage EAB, as compared to the control film. The higher plasticity of the chitosan/LEO films could be attributed to the complex structures formed between the LEO and the chitosan chains which reduced the cohesion of the chitosan network forces subsequently allowing them to be stretched further without breaking [32]. This observation was supported by Zivanovic et al. [62] who also reported a decrease in TS and an increase in EAB for chitosan films combined with EOs.

Scanning Electron Microscopy (SEM)

SEM was conducted to observe the surface of all film samples and to observe the effect of LEO incorporation on the microstructure of the films. SEM micrographs of the surface of chitosan control film and chitosan/LEO composite films under 1000 × magnification are shown in Fig. 2.

It was observed that chitosan, on its own, produced film with a surface which was visually smooth, homogeneous and nonporous. A smooth and nonporous surface usually indicates a dense network and this gave rise to strong mechanical properties of pure chitosan films. With the addition of LEO, creases and irregular shaped folds were observed on the surface of the films and the creases were more prominent with the increase in LEO concentration. The creases might have caused the weakened TS as the LEO concentration increased, supporting the current finding. The formation of creases and folds were probably related to phase separation among chitosan and LEO [20] and also because of aggregation of the oil droplets at the surface of the films. The increase in LEO content would also contribute to faster cross-linking of the chitosan, which might alter the structure of the biopolymer network formed [16].

From the SEM micrographs, it was proven that the surface characteristics of the film play an important role to allow water uptake. The rough and uneven surface of chitosan/LEO composite films disallowed more water molecules to be adsorbed. This could be explained by the disruption in the cross linkages among the chitosan polymer chains upon the incorporation of LEO, lowering the ability of the chitosan molecules to bind with water molecules [15]. This phenomenon explains the decrease in moisture content of the films with the increase in LEO concentration.

Confocal Laser Scanning Microscopy (CLSM)

Confocal laser scanning microscopy was successfully used to observe the distribution of oil and polysaccharide in chitosan-based composite films incorporated with LEO. The LEO droplets were stained red by Nile Red which was dissolved in polyethylene glycol, whereas chitosan was stained green by the aqueous Fast Green FCF stain.

Figure 3 shows a corresponding increase in the number of LEO droplets when the LEO concentration increased from 1 to 9%. For chitosan/LEO 9% composite films, LEO droplets, which were red in colour, were homogenously distributed within the chitosan phase, which was green in colour. Some of the LEO droplets were evidently larger than the others. This indicates that agglomeration of LEO droplets might have occurred after the homogenization process, or during the film drying process. The agglomeration might be due to the non-polar components in LEO. It has been reported that EOs with higher concentration of polar compounds might reduce the interfacial tension which leads to a better droplet disruption during homogenization [61]. In this case, the low polarity compounds in LEO tend to agglomerate and form micelles in the aqueous phase. To further reduce the LEO droplet size and to ensure a homogenous distribution, Tween 80 could be used in place of Tween 20, because it was found to be effective in reducing droplet size and emulsion appearance [56].

Quantitative Assay of Antibacterial Activity by Disk-Diffusion Method

Table 3 shows the mean values of the inhibition zones for all films. No inhibition was observed for the control chitosan film and chitosan/LEO composite film with 1% LEO. This observation was not in agreement with previous studies which shown that chitosan exhibits innate antimicrobial properties [6, 17, 18, 24, 57]. The absence of antimicrobial activity of the pure chitosan films can be attributed to the inability of the disk to dissolve and diffuse through the adjacent agar media in agar diffusion test method. This is because the antimicrobial activity of chitosan depends mainly on the protonation of amino groups in dilute acid solutions, to bind to the negatively charged bacterial cell wall, consequently disrupting the cell wall [18, 46]. In addition, chitosan was also reported to inhibit microbial growth by selectively binding to essential metal ions and nutrients required by bacteria [49]. Due to these reasons, the pure chitosan films were unable to provide a clear inhibition zone on the agar without dissolving [20].

Higher inhibition zones were observed as the LEO concentration increased. Previously, researchers have reported that a possible mechanism that gives rise to the antimicrobial effect of LEO is by disrupting the cell wall and membrane, which results in the release of their cellular contents [1]. For all four test microorganisms, 9% LEO was significantly effective (p < 0.05) in resulting a larger inhibition zone when compared to lower LEO concentrations. This indicates that the incorporation of 9% LEO into chitosan was the most effective dosage to improve the antimicrobial properties of chitosan.

Among all four test microorganisms, the chitosan/LEO composite, regardless of the concentration of LEO, resulted in significantly (p < 0.05) largest inhibition zones in S. typhi, indicating that S. typhi was more susceptible towards the antimicrobial activity of the chitosan/LEO composite films. This finding was supported by Rodríguez-Núñez et al. [49], where Salmonella sp. was found to be very susceptible towards chitosan composite films. This can be attributed to geraniol in LEO as reported by a previous study, where geraniol was an effective bactericide against some Gram-negative bacteria such as E. coli and Salmonella enterica [23]. On the other hand, Naik et al. [39] have found that Gram-negative bacteria were less susceptible towards LEO and were not inhibited even at higher concentration. To confirm this phenomenon, the antibacterial activity of chitosan/LEO films could be further tested using the Broth Dilution Method [39].

Qualitative Assay of Antibacterial Activity by Volatility Method

The successful application of antimicrobial activity of active film packaging relies on the knowledge of how the antimicrobial compound is released from the film. A volatile antimicrobial compound will be an advantage to the antimicrobial properties of the films as the volatile compound will be able to penetrate and saturate the food [43].

In this study, a qualitative method was used to demonstrate the antimicrobial properties of LEO in its vapour phase. Chitosan/LEO composite films with 7 and 9% LEO were selected for the volatility test, because they exhibited the highest antimicrobial activity in the disk-diffusion test. S. typhi was selected as the test microorganism, because it was found to be most susceptible towards the antimicrobial treatment.

Figure 4 shows the comparison of S. typhi growth between the control plate which was not treated with any film samples and the plates in which chitosan/LEO films of 7 and 9% were placed on the petri dish covers, respectively. It was observed that chitosan film with 7% LEO produced an inhibition zone of 8 cm, whereas chitosan film with 9% LEO completely inhibited the growth of S. typhi. This shows that LEO is volatile and exhibits antimicrobial properties, even in its vapour form. The antimicrobial effect is contributed by the volatile antimicrobial compounds such as nerol, citral, and geraniol, as reported by Ahmad and Viljoen [1]. The finding is in good agreement with previous literatures, where plant EOs such as garlic, rosemary and oregano showed volatile antimicrobial properties [12, 29, 42].

Conclusions

The present study indicated that chitosan incorporated with LEO can be used to formulate edible active packaging films with antimicrobial properties. The tensile strength (TS) of the chitosan/LEO composite films was significantly (p < 0.05) lowered by incorporation of higher LEO concentrations, whereas the percentage EAB of the films improved significantly (p < 0.05). The incorporation of LEO has caused the formation of creases and irregular shaped folds on the surface microstructure of the films which prevented water molecules from being adsorbed, consequently leading to the lowering of the moisture content in the chitosan/LEO composite films.

The incorporation of 9% LEO was found to be effective (p < 0.05) in controlling the growth of all four test microorganisms (B. cereus, E. coli, L. monocytogene and S. typhi) using the disk-diffusion test, with S. typhi being the most susceptible bacteria. The antimicrobial activity of LEO in volatile phase was also demonstrated in this study, in which chitosan film with 9% LEO completely inhibited the growth of S. typhi. Based on this study, chitosan/LEO composite film with 9% LEO was found to have potential for applications in antimicrobial food packaging as it exhibited the strongest antimicrobial activity and also desirable mechanical, physical and optical properties. To further comprehend the feasibility of the chitosan/LEO films to improve the shelf life of food products susceptible to oxidation or microbial spoilage, the application on food product has to be investigated, together with specific tests on antioxidant activity and microbial count throughout the storage period.

References

Ahmad A, Viljoen A (2015) The in vitro antimicrobial activity of Cymbopogon essential oil (lemon grass) and its interaction with silver ions. Phytomedicine 22(6):657–665

Ahmad M, Benjakul S, Prodpran T, Agustini TW (2012) Physico-mechanical and antimicrobial properties of gelatin film from the skin of unicorn leatherjacket incorporated with essential oils. Food Hydrocoll 28(1):189–199

Ahmad M, Hani NM, Nirmal NP, Fazial FF, Mohtar NF, Romli SR (2015) Optical and thermo-mechanical properties of composite films based on fish gelatin/rice flour fabricated by casting technique. Prog Org Coat 84:115–127

Ali A, Noh NM, Mustafa MA (2015) Antimicrobial activity of chitosan enriched with lemongrass oil against anthracnose of bell pepper. Food Packag Shelf Life 3(March):56–61

Ali A, Wee Pheng T, Mustafa MA (2015) Application of lemongrass oil in vapour phase for the effective control of anthracnose of “Sekaki” papaya. J Appl Microbiol 118(6):1456–1464

Al-Naamani L, Dobretsov S, Dutta J (2016) Chitosan-zinc oxide nanoparticle composite coating for active food packaging applications. Innov Food Sci Emerg Technol 38:231–237

ASTM (1999) Standard test method for moisture content of paper and paperboard by oven drying. Standard designation: D644-99. In: Annual book of American standards testing methods. ASTM, Philadelphia, pp 911–917

ASTM (1985) Standard test methods for tensile properties of thin plastic sheeting. Standard designation: D882. In: Annual book of American standards testing methods. ASTM, Philadelphia, pp 182–188

ASTM (1990) Standard test methods for water vapour transmission of materials. Standard designation: E96-90. In: Annual book of American standards testing methods. ASTM, Philadelphia, pp 834–841

Atarés L, Bonilla J, Chiralt A (2010) Characterization of sodium caseinate-based edible films incorporated with cinnamon or ginger essential oils. J Food Eng 100:678–687

Auty MA, Twomey EM, Guinee PT, Mulvihill DM (2001) Development and application of confocal scanning laser microscopy methods for studying the distribution of fat and protein in selected dairy products. J Dairy Res 68:417–427

Ayala-Zavala JF, Gonzalez-Aguilar GA (2010) Optimizing the use of garlic oil as an antimicrobial agent on fresh-cut tomato through a controlled release system. J Food Sci 75:398–405

Azarakhsh N, Osman A, Mohd H (2014) Lemongrass essential oil incorporated into alginate-based edible coating for shelf-life extension and quality retention of fresh-cut pineapple. Postharvest Biol Technol 88:1–7

Benavides S, Villalobos-Carvajal R, Reyes JE (2012) Physical, mechanical and antibacterial properties of alginate film: effect of the crosslinking degree and oregano essential oil concentration. J Food Eng 110(2):232–239

Bhuvaneshwari S, Sruthi D, Sivasubramanian V, Niranjana K, Sugunabai J (2011) Development and characterization of chitosan film. Int J Eng Res Appl 1(2):292–299

Chen H, Hu X, Chen E, Wu S, McClements DJ, Liu S, Li B, Li Y (2016) Preparation, characterization, and properties of chitosan films with cinnamaldehyde nanoemulsions. Food Hydrocoll 61:662–671

Cobos M, González B, Fernández MJ, Fernández D (2018) Study on the effect of graphene and glycerol plasticizer on the properties of chitosan- graphene nanocomposites via in situ green chemical reduction of graphene oxide. Int J Biol Macromol 114:599–613

Cota-Arriola O, Onofre Cortez-Rocha M, Burgos-Hernández A, Marina Ezquerra-Brauer J, Plascencia-Jatomea M (2013) Controlled release matrices and micro/nanoparticles of chitosan with antimicrobial potential: development of new strategies for microbial control in agriculture. J Sci Food Agric 93(7):1525–1536

Cui H, Wu J, Li C, Lin L (2016) Promoting anti-listeria activity of lemongrass oil on pork loin by cold nitrogen plasma assist. J Food Saf 37(2):1–10

Elsabee MZ, Abdou ES (2013) Chitosan based edible films and coatings: a review. Mater Sci Eng C 33:1819–1941

Ergönül B (2013) Consumer awareness and perception to food safety: a consumer analysis. Food Control 32:461–471

Fancello F, Petretto GL, Zara S, Sanna ML, Addis R, Maldini M, Foddai M, Rourke JP, Chessa M, Pintore G (2016) Chemical characterization, antioxidant capacity and antimicrobial activity against food related microorganisms of Citrus limon var. pompia leaf essential oil. LWT Food Sci Technol 69:579–585

Friedman M, Henika PR, Mandrell RE (2002) Bactericidal activities of plant essential oils and some of their isolated constituents against Campylobacter jejuni, Escherichia coli, Listeria monocytogenes, and Salmonella enterica. J Food Prot 65(10):1545–1560

Friedman M, Juneja VK (2010) Review of antimicrobial and antioxidative activities of chitosans in food. J Food Prot 73:1737–1761

Fundo JF, Quintas MAC, Silva CLM (2011) Influence of film forming solutions on properties of chitosan/glycerol films. In: ICEF11—11th int congress on eng and food: food process eng in a changing world (proceedings), vol 2, pp 963–964

Galus S, Kadzińska J (2015) Whey protein edible films modified with almond and walnut oils. Food Hydrocoll 52:78–86

Ghasemlou M, Aliheidari N, Fahmi R, Shojaee-Aliabadi S, Keshavarz M, Cran MJ, Khaksar R (2013) Physical, mechanical and barrier properties of corn starch films incorporated with plant essential oils. Carbohydr Polym 98(1):1110–1126

Guerrero P, Nur Hanani ZA, Kerry JP, De La Caba K (2011) Characterization of soy protein-based films prepared with acids and oils by compression. J Food Eng 107(1):41–49

Han JH, Parel D, Kim JE, Min SC (2014) Retardation of Listeria monocytogenes growth in mozzarella cheese using antimicrobial sachets containing rosemary oil and thyme oil. J Food Sci 79:2272–2278

Hyun JE, Bae YM, Song H, Yoon JH, Lee SY (2015) Antibacterial effect of various essential oils against pathogens and spoilage microorganisms in fresh produce. J Food Saf 35(2):206–219

International Commission on Illumination (2004) CIE 15: technical report: colorimetry. CIE Extension Services, Vienna

Jiménez A, Fabra MJ, Talens P, Chiralt A (2013) Phase transitions in starch based films containing fatty acids. Effect on water sorption and mechanical behavior. Food Hydrocoll 30:408–418

Jirukkakul N (2013) A study of Mu yor sausage wraps using chitosan films incorporating garlic oil, lemon grass oil and galangal oil. Int Food Res J 20(3):1199–1204

Jouki M, Mortazavi SA, Yazdi FT, Koocheki A (2014) Characterization of antioxidant—antibacterial quince seed mucilage films containing thyme essential oil. Carbohydr Polym 99:537–546

Krepker M, Shemesh R, Poleg YD, Kashi Y, Vaxman A, Segal E (2017) Active food packaging films with synergistic antimicrobial activity. Food Control 76:117–126

Liakos IL, Francesca D, Garzoni A, Bonferoni C, Scarpelini A, Brunetti V, Carzino R, Bianchini P, Pompa PP, Athanassiou A (2016) All natural cellulose acetate—Lemongrass essential oil antimicrobial nanocapsules. Int J Pharm 510(2):508–515

Maryam Adilah ZA, Nur Hanani ZA (2016) Active packaging of fish gelatin films with Morinda citrifolia oil. Food Biosci 16:66–71

Morillon V, Debeaufort F, Blond G, Capelle M, Voilley A (2002) Factors affecting the moisture permeability of lipid-based edible films: a review. Crit Rev Food Sci Nutr 42(1):67–89

Naik MI, Fomda BA, Jaykumar E, Bhat JA (2010) Antibacterial activity of lemongrass (Cymbopogon citratus) oil against some selected pathogenic bacterias. Asian Pac J Trop Med 3(7):535–538

Nur Fatin Nazurah R, Nur Hanani ZA (2017) Physicochemical characterization of kappa-carrageenan (Euchema cottoni) based films incorporated with various plant oils. Carbohydr Polym 157:1479–1487

Ojagh SM, Rezaei M, Razavi SH, Hosseini SMH (2010) Effect of chitosan coatings enriched with cinnamon oil on the quality of refrigerated rainbow trout. Food Chem 120(1):193–198

Oral N, Vatansever L, Sezer C, Ayudin B, Güver A, Gülmez M, Kürküoglu M (2009) Effect of absorbent pads containing oregano essential oil on the shelf life extension of overwrap packed chicken drumsticks stored at four degree Celsius. Poult Sci 88:1459–1465

Otoni CG, Espitia PJP, Avena-Bustillos RJ, McHugh TH (2016) Trends in antimicrobial food packaging systems: emitting sachets and absorbent pads. Food Res Int 83:60–73

Oudgenoeg G, Hilhorst R, Piersma SR, Boeriu CG, Gruppe H, Hessing M (2001) Peroxidase-mediated cross-linking of a tyrosine-containing peptide with ferulic acid. J Agric Food Chem 49:2503–2510

Passarinho ATP, Dias NF, Camilloto GP, Crruz RS, Otoni CG, Moraes ARF, Soares NFF (2014) Sliced bread preservation through oregano essential oil-containing sachet. J Food Process Eng 37:53–62

Ramezani Z, Zarei M, Raminnejad N (2015) Comparing the effectiveness of chitosan and nanochitosan coatings on the quality of refrigerated silver carp fillets. Food Control 51:43–48

Raybaudi-Massilia RM, Mosqueda-Melgar J, Martín-Belloso O (2008) Edible alginate-based coating as carrier of antimicrobials to improve shelf-life and safety of fresh-cut melon. Int J Food Microbiol 121(3):313–327

Rhim JW (2004) Increase in water vapour barrier property of biopolymer based edible films and coatings by compositing with lipid materials. Food Sci Biotechnol 13:528–535

Rodríguez-Núñez JR, López-Cervantes J, Sánchez-Machado DI, Ramírez-Wong B, Torres-Chavez P, Cortez-Rocha MO (2012) Antimicrobial activity of chitosan-based films against Salmonella typhimurium and Staphylococcus aureus. Int J Food Sci Technol 47(10):2127–2133

Rojas-Graü MA, Raybaudi-Massilia RM, Soliva-Fortuny RC, Avena-Bustillos RJ, McHugh TH, Martín-Belloso O (2007) Apple puree-alginate edible coating as carrier of antimicrobial agents to prolong shelf-life of fresh-cut apples. Postharvest Biol Technol 45(2):254–264

Sánchez-González L, Cháfer M, Chiralt A, González-Martínez C (2010) Physical properties of edible chitosan films containing bergamot essential oil and their inhibitory action on Penicillium italicum. Carbohydr Polym 82:277–283

Shemesh R, Krepker M, Goldman D, Danin-Polega Y, Kashia Y, Nitzanc N, Vaxmanb A, Segal E (2014) Antibacterial and antifungal LDPE films for active packaging. Polym Adv Technol 26:110–116

Shen LX, Wu JM, Chen Y, Zhao G (2010) Antimicrobial and physical properties of sweet potato starch films incorporated with potassium sorbate or chitosan. Food Hydrocoll 24:285–290

Shojaee-Aliabadi S, Hosseini H, Mohammadifar MA, Mohammadi A, Ghasemlou M, Ojagh SM, Hosseini SM, Khaksar R (2013) Characterization of antioxidant-antimicrobial κ-carrageenan films containing Satureja hortensis essential oil. Int J Biol Macromol 52(1):116–124

Sirelkhatim A, Mahmud S, Seeni A, Kaus NHM, Ling CA, Bakhori SKM, Hasan H, Mohamad D (2015) Review on zinc oxide nanoparticles: antibacterial activity and toxicity mechanism. Nano-micro Lett 7(3):219–242

Sugumar S, Mukherjee A, Chandrasekaran N (2015) Eucalyptus oil nanoemulsion-impregnated chitosan film: antibacterial effects against a clinical pathogen, Staphylococcus aureus, in vitro. Int J Nanomed 10(1):67–75

Tsai GJ, Su WH, Chen H, Pan CL (2002) Antimicrobial activity of shrimp chitin and chitosan from different treatments and applications of fish preservation. Fish Sci 68(1):170–177

Wang Z, Zhou J, Wang X, Zhang N, Sun X, Ma Z (2014) The effects of ultrasonic/microwave assisted treatment on the water vapor barrier properties of soybean protein isolate-based oleic acid/stearic acid blend edible films. Food Hydrocoll 35:51–58

Yuan Y, Chesnutt BM, Haggard WO, Bumgardner JD (2011) Deacetylation of chitosan: material characterization and in vitro evaluation via albumin adsorption and pre-osteoblastic cell cultures. Mater 4(8):1399–1416

Zemljič LF, Tkavc T, Vesel A, Šauperl O (2012) Chitosan coatings onto polyethylene terephthalate for the development of potential active packaging material. Appl Surf Sci 265:697–703

Ziani K, Fang Y, Julian D (2012) Fabrication and stability of colloidal delivery systems for flavor oils: effect of composition and storage conditions. Food Res Int 46(1):209–216

Zivanovic S, Chi S, Draughon E (2005) Antimicrobial activity of chitosan films enriched with essential oils. J Food Sci 70:45–51

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Han Lyn, F., Nur Hanani, Z.A. Effect of Lemongrass (Cymbopogon citratus) Essential Oil on the Properties of Chitosan Films for Active Packaging. J Package Technol Res 4, 33–44 (2020). https://doi.org/10.1007/s41783-019-00081-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41783-019-00081-w