Abstract

Ag and ZnO nanoparticles (NPs) were synthesized by a green synthesis from a Pinus latteri tree extraction. Characterizations of the as-prepared Ag and ZnO NPs were determined by DSC/TGA analyses, XRD patterns, and FE-SEM images. The average particles of the as-prepared materials, including Ag NPs and ZnO NPs, are approximately 25 nm and 45 nm, respectively. The XRD patterns confirmed the presence of the Ag metal and ZnO wurtzite crystalline phases. In addition, an agar-well diffusion method was used to evaluate the Escherichia coli (E. coli) antibacterial activity of as-prepared materials. Results show that Ag NPs and ZnO NPs have a high inhibitory ability against E. coli bacteria. Specially, E. coli antibacterial activity of Ag NPs is higher than ZnO NPs under the same conditions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nanomaterials, i.e., Ag and ZnO NPs, are widely studied and applied in industry, medicine, pharmaceutical, environmental treatment, renewable energy, and antibacterial applications [1,2,3,4,5,6,7]. Recently, Ag NPs are most used the antibacterial fields because of their strong antimicrobial effect and low cytotoxicity [8,9,10]. Furthermore, Ag NPs can against gram-negative and -positive bacteria through protein dysfunction and destruction of cell membranes and DNA of bacteria [4, 11, 12]. Also, ZnO NPs can kill both gram-positive and gram-negative bacteria, such as Escherichia coli, Pseudomonas aeruginosa, Staphylococcus aureus, Bacillus subtilis, and Vibrio cholerae [5, 13]. Many studies reported that reducing the particle size enhanced antibacterial activity of Ag and ZnO NPs [14,15,16,17,18]. In addition, the antibacterial ability of ZnO NPs is explained by the release of ions Zn2+ [19, 20] or contributing ROS radicals to the destruction of bacterial cell membranes [21, 22]. Ag NPs and ZnO NPs generally expressed many advantages in the antibacterial, prevention, and growth inhibition of bacteria, which can be applied in coating technology, medical devices, etc. Furthermore, Ag and ZnO are inexpensive materials that are easy to synthesize and scale up synthesis for practical applications [5, 23, 24].

There have many synthesis methods of Ag NPs and ZnO NPs, such as sol-gel [25, 26], wet chemical route [16, 27], electrochemical reduction [28, 29], chemical vapor deposition [30, 31], microemulsion [32, 33], high-energy irradiation [34], etc. Recently, the green chemistry synthesis method from a plant extraction was used to replace harmful substances and reduce byproducts’ exhaustion to the environment, which is the current development trend [15, 35]. Synthesizing nanomaterials from natural origin is considering an environmentally and economically sustainable pathway [36, 37]. For instance, ZnO NPs were synthesized by a green method from pineapple peel extract with diameters of 73–123 nm [38]. Mohammadi Arvanag et al. used Silybum marianum L. seed to synthesize ZnO, which can ultimately kill E. coli bacteria [39]. Kaviya synthesized hexagonal ZnO NPs from pomegranate peel (Punica granatum) for E. coli and Staphylococcus aureus antibacterial [40]. Similarly, Ag NPs were synthesized by a green method from Garcinia mangostana L. extraction, expressing a higher antibacterial activity on both gram-negative and -positive bacteria [41]. The leaf extract, i.e., Capsicum annum L., Camellia sinensis, and Datura metel, was used as reducing and stabilizing agents for synthesizing Ag NPs that achieved effective antibacterial performance [42,43,44].

Recent literate reviews indicated that metal and metal oxide NPs have many achievements in the antimicrobial field. However, the toxicity and the optimization dosage of NPs in the antimicrobial is still a problem, which can decrease the minimum toxicity of metal and oxide metal NPs for biomedical applications shortly [45,46,47]. Based on this problem, a green chemistry synthesis of Ag and ZnO NPs was conducted toward a highly antimicrobial performance. Besides, a rosin was extracted from the Pinus latteri tree which obtains more than 95% acid compounds. The synthesized Ag NPs and ZnO NPs were evaluated for their antibacterial activity against E. coli at the same conditions.

Materials and methods

Materials

Rosin, having the general formula C19H29COOH, was purchased from Loc Thien company, Vietnam. Zinc chloride (ZnCl2), silver nitrate (AgNO3), and sodium hydroxide (NaOH) were supplied by Xilong Scientific Co., Ltd, China. Nutrient Broth and Agar powder were provided by Titan Co., Ltd. The Escherichia coli gram-negative bacteria (VTCC–B–482) was used by the Institute of Microbiology and Biotechnology, Vietnam National University, Hanoi.

Synthesis of Ag NPs and ZnO NPs

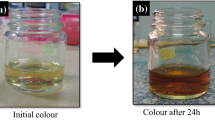

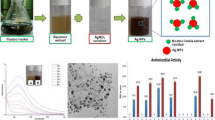

The synthesis process of the ZnO NPs and Ag NPs samples is shown in Fig. 1 in two steps with a following procedure: firstly, 4 g of rosin was placed into a beaker and 24 mL of 0.5N NaOH solution was slowly added to form sodium resinate (C19H29COONa) at 90 °C for 90 min. The amount of NaOH was added slowly to avoid excessive alkalinity causing dissociation of soap. After that, to synthesize ZnO NPs, 8.16 g of 10% ZnCl2 solution was added to the C19H29COONa mixture and magnetically stirred for 60 min. The obtained precipitate was washed several times with hot distilled water, then dried at 100 °C for 12 h to get zinc resinate ((C19H29COO)2Zn). Then, the mixture was heated at 600 °C with a heating rate of 5 °C/min, remaining at 600 °C for 2 h.

To synthesize Ag NPs, 20.40 g of 10% AgNO3 solution was added to the above mixture (C19H29COONa) and magnetically stirred for 60 min. The obtained precipitate was washed several times with hot distilled water (60 °C), then dried at 100 °C for 12 h. Next, the mixture was annealed at 600 °C for 2 h with a heating rate of 5 °C/min.

Characterization of materials

The structure of prepared materials was characterized by X-ray diffraction (XRD) pattern in the range of 20–80° with a scan rate of 0.02°/s, using a Philips with Cu Kα radiation (λ = 1.5418 Å). The surface morphology and size of materials were determined by field emission scanning electron microscope (FE-SEM) on Hitachi S-4800 equipment. The thermal properties and the weight change of C19H29COO)2Zn and silver resinate (C19H29COOAg) were determined using thermogravimetry differential thermal analysis (TG/DTA) on Labsys Evo (TG-DSC 1600 °C) device.

Escherichia coli cell preparation

Escherichia coli culture medium consisting of 2.6 g of Nutrient Borth and 2 g of Agar was added to a beaker and dissolved with 200 mL of distilled water; then, the mixture was sterilized at 120 °C for 15 min. Next, petri dishes were sterilized at 120 °C for 15 min to remove all bacteria. Then, 20 mL of culture medium (40–45 °C) was poured into a petri dish in a microbiological incubator which was sterilized under UV light for 30 min, and continuously incubated at 37 °C for 24 h.

Escherichia coli antibacterial test

ZnO NPs and Ag NPs were prepared at various contents: 1, 5, and 10 mg/mL. Adding 1 mL of the E. coli cells with different concentrations was adjusted 5.108, 5.107, 5.106, 5.105, and 5.104 CFU/mL and let the bacteria contact the material at intervals of 0, 1, 3, and 6 h, respectively. Then, 10 mL of the above mixture was taken on the agar plate prepared above and incubate at 37 °C for 24 h. After incubation, the number of E. coli colonies grown on the petri dish was counted with a colony counter, and the results were recorded and repeated three times.

Results and discussion

The TG-DTA curve results of (C19H29COO)2Zn (Fig. 2a) show that the weight loss of (C19H29COO)2Zn occurred in three steps. The first weight loss was about 5.7% at the temperature range of 30–280 °C. There have two peaks at 152 °C and 181 °C of exothermic effect, related to the physical dehydration and desorption of chemically absorbed water on the (C19H29COO)2Zn, respectively. The second weight loss occurs between 280 and 480 °C, corresponding to a weight loss of about 64%, with a little exothermic DTA peak at 346.27 °C related to organic combustion. The third step takes place between 480 and 580 °C. There is a robust exothermic peak at 523 °C and a weight loss of approximately 16%. This process corresponds to the oxidation of Zn to ZnO and continues organic combustion

The TG-DTA results of C19H29COOAg (Fig. 2b shows that with a 2% weight loss, the exothermic effect has two typical peaks at 143 °C and 168 °C, indicating a physical water loss on the material’s surface). A typical peak for the exothermic effect in a temperature range of 200 to 340 °C and a weight loss of 32% indicate that this process has a significant decomposition of organic matter. Moreover, the weight loss decreases by around 18% between the 340 and 550 °C range, and the process is substantially exothermic, demonstrating that the burning of the organic materials continues. The TG-DTA results of both (C19H29COO)2Zn and C19H29COOAg show physical dehydration at the temperature range of a 30–250 °C, the decomposition of the organic matter at the temperature range of a 300–580°C, and the oxidation to form metal oxides also occurs at this temperature. Therefore, to completely decompose organic matter and the product developed is an entirely crystalline phase, choosing the calcination rate of (C19H29COO)2Zn and C19H29COOAg at 5 °C/min with a maximum calcination temperature of 600 °C.

XRD patterns of Ag NPs and ZnO NPs (Fig. 3) show diffraction peaks at 2θ = 31.85°; 34.52°; 36.37°; 47.66°; 56.65°; 62.99°; 66.50°; 68.01°; 69.22°; 72.69°; and 77.09°, corresponding to (100); (002); (101); (102); (110); (103); (200); (112); (201); (004); and (202) planes of hexagonal wurtzite structure of ZnO (JCPDS card no. 36-1451). Also, the XRD pattern of the Ag NPs displays diffraction peaks at positions 2θ = 38.11°; 44.28°; 64.45°; and 77.35°, corresponding to (111), (200), (220), and (311) planes of Ag metal (JCPDS card no. 04-0783).

Furthermore, the FE-SEM images and distributions of ZnO and Ag NPs were expressed in Fig. 4. It can be found that the Ag NPs have a uniformly spherical structure and a particle size of about 25 nm (Fig. 4 a–b). The ZnO materials have a tetragonal shape and a larger particle size with an average length of about 45 nm (Fig. 4 c–d).

To determine the E. coli antibacterial activity of Ag NPs and ZnO NPs, an experimental work was conducted on the efficiency of inhibiting E. coli bacteria by Ag and ZnO NPs with the same amount of material (10 mg/mL). The initial bacterial concentration was from 5.104 to 5.108 CFU/mL; the exposure time between bacteria and materials was 1 h, 3 h, and 6 h as in Fig. 5. For the initial bacterial concentration was 5.108 CFU/mL and the exposure time was 1 h, the bacterial inhibition percentage was only 48.25% for ZnO NPs and 99.98% for Ag NPs. When the exposure time increased to 3 h and 6 h, the inhibition percentage of E. coli increased, reaching 59.37% and 74.65% for ZnO NPs and 99.99 and 100% for Ag NPs, respectively. When the initial bacterial concentration decreased by 10, 100, 1000, and 10000 times, representing the E. coli concentration of 5.107, 5.106, 5.105, and 5.104 CFU/mL, respectively, the antibacterial performance of ZnO NPs increased significantly and achieved 96.76%, 98.43%, 99.39%, and 99.99% in 1-h exposure. Moreover, Ag NPs only need 1-h exposure to completely inhibit E. coli bacteria at concentrations of 5.105 and 5.104 CFU/mL while ZnO NPs completely inhibited E. coli with a concentration of 5.104 in 6 h of exposure.

To evaluate the effect of material contents on E. coli antibacterial ability, an investigation of E. coli antibacterial activity with the initial concentration of 5.104 CFU/mL over Ag and ZnO NPs with the range varying from 1, 5, and 10 mg/L for 1 h, 3 h, and 6 h exposure periods were investigated (Fig. 6). At 1 mg/mL of the material content, the inhibitory percentage against E. coli of ZnO NPs was 94.25, 98.96, and 99.97% for the exposure time of 1 h, 3 h, and 6 h, respectively. Meanwhile, Ag NPs with a content of 1 mg/L could completely inhibit an E. coli concentration of 5.104 in 1 h. Continuing to perform the antibacterial experiment, when increasing the material content to 5 mg/L and 10 mg/L, the bacterial inhibition rate increased. Specifically, the inhibitory rate of E. coli bacteria in the exposure time of 1, 3, and 6 h reached 98.12, 99.86, and 100% when using 5 mg/L ZnO nanomaterials and 99.99, 99.99, and 100% when using 10 mg/L ZnO NPs. Thus, Ag NPs can be killed completely bacteria even at low concentrations and exposure times (1 mg/L and 1 h exposed), while ZnO NPs can be inhibited entirely at 6 h exposed and 5 mg/L.

The difference in the E. coli antibacterial activity over Ag NPs and ZnO NPs was also illustrated based on the digital photographs of E. coli bacterial culture plates in the control sample and after existing of Ag NPs and ZnO NPs (Fig. 7). As we can see in Fig. 7, the decrease of the amount of E. coli bacteria in the plates when the existence of Ag and ZnO NPs when their weight content of these materials as well as the increase of the exposure time. This expressed a high antibacterial activity, and the quantitative performance was also indicated in Fig. 5 and Fig. 6. Besides, a comparison of the antibacterial ability of Ag NPs and ZnO NPs is also presented in Table 1. Therein, the E. coli antibacterial of the Ag NPs and ZnO NPs, synthesized by the green chemistry method from rosin agent in this study, expressed a highly efficient performance (nearly 100%) even at a very short exposure time (3 h for Ag NPs and 6 h for ZnO NPs).

Conclusion

In summary, we successfully fabricated Ag and ZnO NPs by a green synthesis from inexpensive precursors and a non-toxic rosin compound. The particle size of the synthesized Ag NPs are smaller than the ZnO NPs with the average size of Ag NPs being 10–40 nm while the ZnO is 30–90 nm. The E. coli antibacterial activity of Ag NPs is higher than that of ZnO NPs because Ag NPs are smaller particle size than ZnO, leading to Ag NPs easily penetrate the cell membrane and kill bacteria. In 6 h of exposure, the synthesized Ag NPs completely inhibited E. coli bacteria at the concentration of 5.108, while ZnO NPs inhibited E. coli bacteria at the concentration of 5.104 CFU/mL.

Data Availability

The raw/processed data required to reproduce the above findings cannot be shared at this time as the data also forms part of an ongoing study.

References

Kaur, A., et al.: Synergetic effect of vancomycin loaded silver nanoparticles for enhanced antibacterial activity. Colloids Surf. B: Biointerfaces. 176, 62–69 (2019)

Silva, G., et al.: Antibacterial effect of silver nanoparticles on Klebsiella spp. Aust. Health Rev. 1(2), 8–15 (2020)

Keshavarz, M., et al.: Self-assembled N-doped Q-dot carbon nanostructures as a SERS-active biosensor with selective therapeutic functionality. Sensors Actuators B Chem. 323, 128703 (2020)

Yuwen, L., et al.: MoS2@ polydopamine-Ag nanosheets with enhanced antibacterial activity for effective treatment of Staphylococcus aureus biofilms and wound infection. Nanoscale. 10(35), 16711–16720 (2018)

Raha, S., Ahmaruzzaman, M.: ZnO nanostructured materials and their potential applications: progress, challenges and perspectives. Nanoscale. Adv. 4(8), 1868–1925 (2022)

Dias, H.B., et al.: Synthesis, characterization and application of Ag doped ZnO nanoparticles in a composite resin. Mater. Sci. Eng. C Mater. Biol. Appl. 96, 391–401 (2019)

Varudkar, H.A., et al.: Structural, morphological, and gas sensing properties of Co-doped ZnO nanoparticles. J. Aust. Ceram. Soc. 58(3), 793–802 (2022)

Tang, S., Zheng, J.: Antibacterial activity of silver nanoparticles: structural effects. Adv. Healthc. Mater. 7(13), 1701503 (2018)

Surwade, P., et al.: Augmented antibacterial activity of ampicillin with silver nanoparticles against methicillin-resistant Staphylococcus aureus (MRSA). J. Antibiot. 72(1), 50–53 (2019)

Elbehiry, A., et al.: Antibacterial effects and resistance induction of silver and gold nanoparticles against Staphylococcus aureus-induced mastitis and the potential toxicity in rats. Microbiol. Open. 8(4), e00698 (2019)

Vasil’kov, A.Y., et al.: Plasmon resonance of silver nanoparticles as a method of increasing their antibacterial action. Antibiotics. 7(3), 80 (2018)

Ahmad, S.A., et al.: Bactericidal activity of silver nanoparticles: a mechanistic review. Materi. Sci. Energy Technol. 3, 756–769 (2020)

Mehnath, S., et al.: Biosynthesized/green-synthesized nanomaterials as potential vehicles for delivery of antibiotics/drugs. In: Comprehensive Analytical Chemistry, pp. 363–432. Elsevier (2021)

Premanathan, M., et al.: Selective toxicity of ZnO nanoparticles toward Gram-positive bacteria and cancer cells by apoptosis through lipid peroxidation. Nanomedicine. 7(2), 184–192 (2011)

Abebe, B., et al.: PVA assisted ZnO based mesoporous ternary metal oxides nanomaterials: synthesis, optimization, and evaluation of antibacterial activity. Mater. Res. Exp. 7(4), 045011 (2020)

Raza, M.A., et al.: Size-and shape-dependent antibacterial studies of silver nanoparticles synthesized by wet chemical routes. Nanomaterials. 6(4), 74 (2016)

Lu, Z., et al.: Size-dependent antibacterial activities of silver nanoparticles against oral anaerobic pathogenic bacteria. J. Mater. Sci. Mater. Med. 24, 1465–1471 (2013)

Nair, S., et al.: Role of size scale of ZnO nanoparticles and microparticles on toxicity toward bacteria and osteoblast cancer cells. J. Mater. Sci. Mater. Med. 20(1), 235–241 (2009)

Espitia, P.J.P., et al.: Zinc oxide nanoparticles: synthesis, antimicrobial activity and food packaging applications. Food Bioprocess Technol. 5, 1447–1464 (2012)

Kasemets, K., et al.: Toxicity of nanoparticles of ZnO, CuO and TiO2 to yeast Saccharomyces cerevisiae. Toxicol. In Vitro. 23(6), 1116–1122 (2009)

Jalal, R., et al.: ZnO nanofluids: green synthesis, characterization, and antibacterial activity. Mater. Chem. Phys. 121(1-2), 198–201 (2010)

Lin, H., et al.: Effect of minor Sc on the microstructure and mechanical properties of AZ91 Magnesium Alloy. Progr. Nat.Sci.: Mater. Int. 28(1), 66–73 (2018)

da Silva, D.J., et al.: Questioning ZnO, Ag, and Ag/ZnO nanoparticles as antimicrobial agents for textiles: do they guarantee total protection against bacteria and SARS-CoV-2? J. Photochem. Photobiol. B. 234, 112538 (2022)

Taheri, M., Montazer, M., Rezaie, A.B.: A cleaner affordable method for production of bactericidal textile substrates by in situ deposition of ZnO/Ag nanoparticles. Fibers Polym. 22(10), 2792–2802 (2021)

Reyes-López, S.Y.: ZrO2–ZnO nanoparticles as antibacterial agents. Instituto de Ciencias Biomédicas (2019)

Anaya-Esparza, L.M., et al.: Synthesis and characterization of TiO2-ZnO-MgO mixed oxide and their antibacterial activity. Materials. 12(5), 698 (2019)

Bönnemann, H., Richards, R.M.: Nanoscopic metal particles− synthetic methods and potential applications. Eur. J. Inorg. Chem. 2001(10), 2455–2480 (2001)

Zhao, W., et al.: Electrodeposition of platinum nanoparticles on polypyrrole-functionalized graphene. J. Mater. Sci. 48, 2566–2573 (2013)

Raoof, J.B., Ojani, R., Hosseini, S.R.: Electrocatalytic oxidation of methanol onto platinum particles decorated nanostructured poly (1, 5-diaminonaphthalene) film. J. Solid State Electrochem. 16, 2699–2708 (2012)

Saminathan, K., et al.: Preparation and evaluation of electrodeposited platinum nanoparticles on in situ carbon nanotubes grown carbon paper for proton exchange membrane fuel cells. Int. J. Hydrog. Energy. 34(9), 3838–3844 (2009)

Shafiei, M., et al.: Improvement of platinum adhesion to carbon surfaces using PVD coatings. Surf. Coat. Technol. 205(2), 306–311 (2010)

Feng, A., et al.: Facile synthesis of silver nanoparticles with high antibacterial activity. Materials. 11(12), 2498 (2018)

Krutyakov, Y.A., et al.: Aggregative stability and polydispersity of silver nanoparticles prepared using two-phase aqueous organic systems. Nanotechnol. Russia. 3, 303–310 (2008)

Chen, P., et al.: Synthesis of silver nanoparticles by γ-ray irradiation in acetic water solution containing chitosan. Radiat. Phys. Chem. 76(7), 1165–1168 (2007)

Kharissova, O.V., et al.: Greener synthesis of chemical compounds and materials. R. Soc. Open Sci. 6(11), 191378 (2019)

Soni, R.A., Rizwan, M.A., Singh, S.: Opportunities and potential of green chemistry in nanotechnology. Nanotechnol. Environ. Eng. 7(3), 661–673 (2022)

Duan, H., Wang, D., Li, Y.: Green chemistry for nanoparticle synthesis. Chem. Soc. Rev. 44(16), 5778–5792 (2015)

Hassan Basri, H., et al.: Effect of synthesis temperature on the size of ZnO nanoparticles derived from pineapple peel extract and antibacterial activity of ZnO–starch nanocomposite films. Nanomaterials. 10(6), 1061 (2020)

Arvanag, F.M., et al.: A comprehensive study on antidiabetic and antibacterial activities of ZnO nanoparticles biosynthesized using Silybum marianum L seed extract. Mater. Sci. Eng. C. 97, 397–405 (2019)

Kaviya, S., Kabila, S., Jayasree, K.: Hexagonal bottom-neck ZnO nano pencils: a study of structural, optical and antibacterial activity. Mater. Lett. 204, 57–60 (2017)

Nishanthi, R., Malathi, S., Palani, P.: Green synthesis and characterization of bioinspired silver, gold and platinum nanoparticles and evaluation of their synergistic antibacterial activity after combining with different classes of antibiotics. Mater. Sci. Eng. C. 96, 693–707 (2019)

Li, S., et al.: Green synthesis of silver nanoparticles using Capsicum annuum L. extract. Green Chem. 9(8), 852–858 (2007)

Vilchis-Nestor, A.R., et al.: Solventless synthesis and optical properties of Au and Ag nanoparticles using Camellia sinensis extract. Mater. Lett. 62(17-18), 3103–3105 (2008)

Kesharwani, J., et al.: Phytofabrication of silver nanoparticles by leaf extract of Datura metel: hypothetical mecha-nism involved in synthesis. J Bionanosci. 2009(3), 39–44 (2009)

Panda, P., et al.: Synthesis and antimicrobial abilities of metal oxide nanoparticles. In: Bio-manufactured Nanomaterials: Perspectives and Promotion, pp. 41–58. Springer International Publishing, Cham (2021)

Azam, A., et al.: Antimicrobial activity of metal oxide nanoparticles against Gram-positive and Gram-negative bacteria: a comparative study. Int. J. Nanomedicine. 7, 6003–6009 (2012)

Gold, K., et al.: Antimicrobial activity of metal and metal-oxide based nanoparticles. Adv. Ther. 1(3), (2018)

Li, W.R., et al.: Antibacterial activity and mechanism of silver nanoparticles on Escherichia coli. Appl. Microbiol. Biotechnol. 85(4), 1115–1122 (2010)

Maiti, S., et al.: Antimicrobial activities of silver nanoparticles synthesized from Lycopersicon esculentum extract. Journal of Analytical. Sci. Technol. 5(1), (2014)

Kim, S.H., Lee, H.S., Ryu, D.S., Choi, S.J., Lee, D.S.: Antibacterial activity of silver-nanoparticles against staphylococcus aureus and escherichia coli. Korean J. Microbiol. Biotechno. 39(1), 77–85 (2011)

Raffi, M., Hussain, F., Bhatti, T.M., Akhter, J.I., Hameed, A., Hasan, M.M.: Antibacterial characterization of silver nanoparticles against E. Coli ATCC-15224. J. Mater. Sci. Technol. 24(2), 192–196 (2008)

Silvestre, A.J.D., Gandini, A.: Rosin: major sources, properties and applications. In: Monomers, Polymers and Composites from Renewable Resources, pp. 67–88. Elsevier (2008)

Xie, Y., et al.: Antibacterial activity and mechanism of action of zinc oxide nanoparticles against Campylobacter jejuni. Appl. Environ. Microbiol. 77(7), 2325–2331 (2011)

Saliani, M., Jalal, R., Kafshdare Goharshadi, E.: Effects of pH and temperature on antibacterial activity of zinc oxide nanofluid against Escherichia coli O157: H7 and Staphylococcus aureus. Jundishapur. J. Microbiol. 8(2), e17115 (2015)

Doan Thi, T.U., et al.: Green synthesis of ZnO nanoparticles using orange fruit peel extract for antibacterial activities. RSC Adv. 10(40), 23899–23907 (2020)

Acknowledgements

The authors gratefully acknowledge the Ministry of Education and Training and the Ho Chi Minh City University of Technology and Education for supporting instruments and apparatus for experiments. This work belongs to the project grant No: B2021-SPK-01- HH, funded by the Ministry of Education and Training and hosted by the Ho Chi Minh City University of Technology and Education, Vietnam.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vo, N.T.T., Do, M.Q. & Van Pham, V. Green chemistry synthesis and Escherichia coli antibacterial activity of silver and zinc oxide nanoparticles. J Aust Ceram Soc 59, 1205–1212 (2023). https://doi.org/10.1007/s41779-023-00926-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-023-00926-3