Abstract

The present study aims at evaluating the potential of synthesized biosorbents using NaOH-activated dead leaves of Ficus racemosa (NTFR) and Prunus dulcis (NTPD) for the treatment of real industrial effluents containing dyes. Kinetic and isotherm studies have been performed to establish the important design-related information for the treatment of industrial effluent using synthesized biosorbents. The extent of dye removal obtained as 99.19% for the studies involving pure dye solution of Acid Blue 25 dye with 50 mg L−1 as initial concentration using NTFR biosorbent was found to decrease marginally to 96.72% in the case of real effluent with similar dye loading and under similar operating conditions. Biosorption capacity for the case of pure Acid Blue 25 dye solution obtained as 83.33 mg g−1 also marginally decreased to 80.65 mg g−1 for the industrial effluent. Similarly, for the case of Acid Green 25 dye, extent of dye removal obtained as 92.09% was found to decrease to 84.51% in the case of mixed industrial effluent. In this case, reduction in chemical oxygen demand (COD) was also measured and compared with that of pure Acid Green 25 dye solution. COD reduction was obtained as 53.97% at the optimized dose of 18 g/L of NTPD for mixed industrial effluent which was lower than 92.05% obtained at the optimized biosorbent dose for pure Acid Green 25 dye solution. Langmuir and pseudo-second-order model fitted well to the obtained data in the present study. The obtained results confirmed potential of synthesized biosorbents for removal of dyes from industrial effluent and also established the influence of other compounds present in the industrial effluent on removal rate of individual dyes.

Article Highlights

-

Novel biosorbents applied for treatment of real dye-containing industrial effluent.

-

Comparison of removal rates for real effluent and simulated solutions.

-

Kinetic and adsorption isotherm fitting to the obtained experimental data.

-

COD reduction analysis confirmed the interaction of other compounds on dye removal.

-

Lower dye removal observed for real effluent as against simulated effluents.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Water pollution is one of the serious problems, increasing day by day and causing severe damage to the entire ecosystem (Natarajan et al. 2018). Dyes are contributing significantly to water pollution often due to the color associated with the effluent. Recent survey indicated that during the manufacturing of dye and subsequent processing operations, 12% of the dyes are lost and 20% of these dyes find their way into the industrial wastewater streams (Demirbas 2009). Different industries as dyestuffs, paper and plastic industries are using dyes widely and generating large volume of the colored wastewater (Rangabhashiyam et al. 2013). Textile industries also contribute significantly to water pollution as dyes have been used intensively by these industries to color textile products, which in turn generate dye-bearing wastewater due to improper dye fixation (Adegoke and Bello 2015). Dye effluents also contain other chemicals such as acids, bases, salts, surfactants, etc. which are being used in the processing to obtain desired quality in the fabrics. These chemicals along with the dyes increase the COD and also can affect the removal kinetics of dyes (Ponnusami and Srivastava 2009). Dye effluent when discharged into the water bodies without proper treatment reduces the transfer of sunlight and hence oxygen penetration to interior of the water bodies, adversely affects the photosynthetic activity of aquatic system (Li et al. 2017; Ngulube et al. 2017). Additionally, exposure of dyes to humans may cause irreparable damage to different parts of human body as kidney, liver, reproductive system, etc. (Wang et al. 2018). Thus, dye effluent represents a dangerous threat to ecosystem and hence it is of utmost importance to remove dyes from effluents to overcome the associated subsequent ecological and industrial problems (El-naggar et al. 2018).

Various physical and chemical technologies such as membrane separation, coagulation, adsorption, and oxidation have been developed and applied by the researchers to treat dye-containing wastewater. Most of these techniques have their own advantages but suffer from different limitations as sludge and byproduct formation, high cost, longer treatment times etc. (Salleh et al. 2011; Zhou et al. 2015). Adsorption is found to be an efficient technique as the method is cost effective, simple in design, produces good-quality effluent after treatment and does not lead to formation of environmentally harmful products (Crini 2006; Kim et al. 2018). Various adsorbents in their native and activated forms have been tried by the researchers for treatment of wastewater containing dyes. Various reports are available in the literature on dye removal using adsorption where synthetic (simulated) dye solutions have been prepared by the researchers and different adsorbents have been developed and tried for the treatment of dye containing wastewater. Very few reports are available in the literature where dye removal was reported from real industrial effluent, obtained from the dye or textile processing industry. For example, Ponnusami and Srivastava (Ponnusami and Srivastava 2009) applied the teak leaf powder for methylene blue removal from simulated and industrial effluent. Dye removal from effluent was reported as 57.41% and reduction in COD was reported as 45.95%. Ahmad and Hameed (Ahmad and Hameed 2009) developed activated carbon from bamboo waste based on activation using phosphoric acid and synthesized activated adsorbent was then applied for color removal from real effluent obtained from textile mill. Dye removal was reported as 91.84% and reduction in COD was reported as 75.21% under the optimized conditions of pH as 3, and adsorbent dose of 3 g L−1 in a contact time of 10 h. Considering the limited data on treatment of real industrial effluents, the current work has focused on treatment of real wastewater obtained from textile processing industry based on two activated adsorbents developed in the laboratory from sustainable resources. In our earlier work (Jain and Gogate 2017a), biosorbent was synthesized from dead (fallen) leaves of Ficus racemosa based on NaOH activation (NTFR) and then applied for Acid Blue 25 dye removal from synthetic wastewater. In the present study, the synthesized biosorbent (NTFR) has been applied for treatment of real industrial effluent mainly containing Acid Blue 25 dye. In another work (Jain and Gogate 2018), biosorbent synthesized from dead (fallen) leaves of Prunus dulcis based on NaOH activation (NTPD) was applied for Acid Green 25 dye removal again from synthetic wastewater. In the present study, the same biosorbent (NTPD) has been applied for Acid Green 25 dye removal from real industrial mixed effluent. The objective of the present study is to check the potential of synthesized biosorbents, NTFR and NTPD for dye removal from real industrial effluent and also to check the influence of other compounds present in the industrial effluent on removal efficiency of individual dye. As none of the earlier studies have reported the use of NTFR and NTPD biosorbents for the treatment of real industrial effluent, the novelty of the current work is clearly established. Kinetic and isotherm studies have also been performed and obtained results of dye removal from industrial effluent have been compared with the results obtained for dye removal from synthetic wastewater.

Materials and Methodology

Materials and Instrumentation

Dead leaves of F. racemosa (FR) and P. dulcis (PD) were collected from Nashik city. Industrial dye effluents used in the present study were obtained from Lotus Enterprises, Mumbai. One dye effluent contained single dye as Acid Blue 25 (targeted pollutant) along with other compounds. Another dye effluent was a mixture of two dyes, Acid Green 25 dye (targeted pollutant) and Acid Red 52 dye along with other compounds. Batch experiments were conducted in orbital shaker (Bio-Technics, India). UV–visible spectrophotometer (UV 1800, Shimadzu, Japan) was used for analysis of the concentration of dyes. Chemical oxygen demand (COD) analysis was also performed using COD digester (Bio Technics, India).

Biosorbent Synthesis

FR and PD leaves were washed with distilled water, dried in air and crushed. The obtained powder (10 g) of leaves was screened, impregnated with 1% NaOH solution (50 mL) and activated in oven for 4 h at 323 K. The obtained thick brown paste was then filtered and washed frequently with hot water so that lignin in the leaves gets removed. When complete lignin removal occurred as observed by no color after mixing the powder in water, the obtained lignin-free powder was then thermally activated in oven. The synthesized NaOH-treated FR (NTFR) and PD (NTPD) biosorbents were then kept in dessicators for subsequent use in the adsorption studies. The detailed characterization studies for the synthesized biosorbents and method for determination of point of zero charge (pHPZC) have been already explained in our earlier papers (Jain and Gogate 2017a, 2018).

Analysis of Dyes

Spectrums of Acid Blue 25 and Acid Green 25 dyes were initially obtained. Maximum wavelength of UV absorption, λmax of Acid Blue 25 and Acid Green 25 dyes was established using the obtained spectrums at 602 and 642 nm, respectively. Initially calibration curves were prepared based on the analysis of dye solutions of known concentrations. The quantification of dyes in the residual solutions after adsorption was then performed using established calibration curves.

Experimental Methodology

The experiments were conducted with 50 mL of solution of dye/effluent in 100 mL of conical flasks equipped with stoppers. Biosorbent in required quantity was added into the solution and stirred in orbital shaker at the speed of 150 rpm at pH of 2 and at the desired temperature. Kinetic studies have been performed for removal of Acid Blue 25 dye from industrial effluent and from pure dye solution using NTFR biosorbent. Isotherm studies have been performed over the temperature range from 293 to 323 K for Acid Blue 25 removal from industrial effluent using NTFR biosorbent. In the case of mixed industrial effluent, effect of biosorbent dose and contact time was studied for the adsorptive removal of Acid Green 25 from mixed industrial effluent and also from pure dye solution using NTPD biosorbent at pH of 2. The obtained results have been compared in terms of extent of dye removal and reduction in COD.

Biosorption capacity, qt (mg g−1) at any time t (min) was calculated using following equation:

where Ci and Ct (mg L−1) are the initial concentration and concentration of dye remaining in residual solution at time t, respectively, V is volume of dye solution (mL) and M is biosorbent mass (g).

Dye removal (%) was calculated using the equation given below:

Isotherm Study

The obtained experimental isotherm data for Acid Blue 25 removal from industrial effluent using NTFR have been analyzed using following different isotherms:

Freundlich Isotherm

Freundlich model (Freundlich 1906) is expressed as below:

The model in the linearized form is as below:

where KF is constant of Freundlich model (mg g−1) \(\left( {{\text{L}}\;{\text{mg}}^{ - 1} } \right)^{{1/n_{\text{F}} }}\), Ce is equilibrium dye concentration (mg L−1) and nF is dimensionless factor.

Langmuir Isotherm

Langmuir model (Langmuir 1918) is expressed as below:

The model in the linearized form is as below:

where qm is maximum uptake capacity (mg g−1) and KL is the model constant of Langmuir isotherm (L mg−1).

Temkin Isotherm

Temkin model (Temkin and Pyzhev 1940) is expressed as below:

where B1 (mg g−1) and KT (L mg−1) are constants of Temkin model.

Kinetic Study

The experimental kinetic data of Acid Green 25 removal from mixed industrial effluent using NTPD have been analyzed using following kinetic models:

Pseudo-First-Order Model

Pseudo-first-order model (Lagergren 1898) is described using the following equation:

The model in the linearized form is as below:

where qe is biosorption capacity at equilibrium (mg g−1) and kf is pseudo-first-order rate constant (min−1).

Pseudo-second-order model

Pseudo-second-order model (Ho and Mckay 1999) is described using the following equation:

The model in the linearized form is as below:

where ks is pseudo-second-order rate constant (g mg−1 min−1).

Fractional Power Law Model

Fractional power law model (Inyinbor et al. 2016) is described using the following equation:

The model in the linearized form is as below:

where k (mg g−1 min−b) and b are model constants.

Error Analysis

Error analysis was performed using the root mean square error (RMSE) (Dastkhoon et al. 2017). The best kinetic and isotherm model fitted to the obtained data were determined based on RMSE and correlation coefficient (R2) values. RMSE values have been determined using the equation as given below:

where N is number of observations for a particular set of operating conditions, qexp is the biosorption capacity obtained experimentally and qcal is the biosorption capacity value obtained from the model equation.

Thermodynamic Analysis

Thermodynamic parameters such as free energy change, ∆G0 (kJ kmol−1), entropy change, ∆S0 (kJ mol−1 K−1) and enthalpy change, ∆H0 (kJ kmol−1) have been estimated to predict feasibility, spontaneity, and type of adsorption. Thermodynamic parameters were evaluated using the equation as below:

where KC is biosorption equilibrium constant obtained from isotherm constants and R is gas constant (kJ kmol−1 K−1).

Results and Discussion

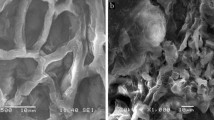

Characterization of Biosorbents

Applied NaOH treatment to dead leaves of FR and PD removed the lignin content from interior of the pores and resulted in an increase in surface areas as established using the BET analysis. Surface area of the adsorbents increased from 21.18 to 136.26 m2 g−1 for the FR (Jain and Gogate 2017b) and from 67.21 to 426.35 m2 g−1 for the case of PD due to applied NaOH treatment. pHpzc of NTFR and NTPD was estimated as 7.48 and 6.27, respectively (Jain and Gogate 2017a, 2018). The targeted pollutants in the present work are Acid Blue 25 and Acid Green 25 dye, which are anionic dyes and hence all the experiments were carried out at acidic pH of 2 as cationic charge will be formed on NTFR and NTPD biosorbents in acidic medium, which will favor removal of anionic dyes based on electrostatic attractions (Sonai et al. 2016).

Treatment of Acid Blue 25 Dye Containing Industrial Effluent

Kinetic Studies

Kinetic studies for the treatment of Acid Blue 25 dye containing industrial effluent were carried out for the solution with initial loading as around 50 and 100 mg L−1 of Acid Blue 25 dye for better comparison with the results obtained using pure dye solution (simulated effluent) of 50 and 100 mg L−1 as the initial concentration of Acid Blue 25 dye. The obtained results are depicted in Fig. 1a, b for the two cases of initial concentrations as 50 and 100 mg L−1, respectively. To check the influence of other compounds present in Acid Blue 25 dye containing real industrial effluent on dye removal and biosorption capacity of NTFR biosorbent, operating parameters as biosorbent dose, pH, contact time and temperature were kept constant at the optimum values as established during the study for removal of synthetically prepared Acid Blue 25 dye (pure) using NTFR biosorbent [15]. As observed from Fig. 1a, b dye removal from real industrial effluent using NTFR biosorbent was found to be faster in the initial periods of adsorption and then decreased gradually, a trend similar to that observed for pure solutions. In the initial treatment time, more vacant sites are available, where molecules of dye can get adsorbed easily but later the adsorption rate slowed down based on the occupancy of most of the sites (Jain and Gogate 2017c). Similar trend of faster removal in early time and then gradual reduction in adsorption extent with time was also reported for the adsorptive removal of reactive red 120 using Chara contraria (Celekli et al. 2012).

The extent of dye removal obtained in the present work was different in the two cases of simulated and real industrial effluents with 99.19% obtained for pure dye solution and 96.72% for the industrial effluent with same initial dye concentration (50 mg L−1) and same contact time of 300 min. Similarly dye removal obtained as 98.8% for the 100 mg L−1 of pure dye solution was found to decrease to 93.84% in the case of industrial effluent of same concentration and same contact time of 300 min. The obtained results indicated decrease in rate of dye removal in the case of industrial effluent in comparison with the pure dye solution attributed to the fact that the industrial effluent also contains salts and other compounds in addition to dye, which can compete with the dye for adsorption on the biosorbent, resulting in decrease in the extent of dye removal. Similar trend of decrease in dye removal due to presence of salts in dye solution has also been reported for the system of anionic dyes removal using peanut hull based biosorbent (Gong et al. 2005) and carbon nanotubes (Maleki et al. 2017). Biosorption capacity (qt) in the case of industrial effluent was observed to increase from 12.09 mg g−1 at 50 mg L−1 to 23.46 mg g−1 at 100 mg L−1 of Acid Blue 25 concentration, similar to that observed for pure dyes. Increase in Acid Blue 25 concentration leads to enhanced driving force resulting in higher values of qt. Similar trend was also reported for methylene blue removal (Baheri et al. 2016) in the literature.

Isotherm Studies Showing Effect of Temperature

Isotherm studies at different temperatures were also conducted for Acid Blue 25 containing industrial effluent. The obtained reults for the Effect of temperature on the removal of Acid Blue 25 is depicted in Fig. 2. As observed from Fig. 2, equilibrium curves obtained for industrial effluent were also found to be initially steeper and became flatter in the later stages. It can also be seen from the Fig. 2 that the biosorption capacity, qm values are higher at increased temperature and maximum value was obtained at temperature of 323 K. Quantitatively speaking, qm value increased from 74.63 to 80.65 mg g−1, when temperature of dye solution was increased from 293 to 323 K. Higher biosorption capacity values at enhanced temperature may be attributed to increased mobility of dye molecules from solution to the biosorbent surface at increased temperatures (Abdi et al. 2017). Similar trend of higher biosorption capacity values at increased temperature has also been reported for the adsorptive removal of methylene blue using saw palmetto spent (Papegowda and Syed 2017).

The biosorption capacity for the case of pure Acid Blue 25 dye solution obtained as 76.92 mg g−1 was found to marginally decrease to 74.63 mg g−1 for industrial effluent at 293 K. Similarly the biosorption capacity for the case of pure Acid Blue 25 dye solution obtained as 83.33 mg g−1 decreased marginally to 80.65 mg g−1 for industrial effluent at 323 K. The obtained results indicated decrease in biosorption capacity in the case of industrial effluent due to the presence of salts and other organic compounds in industrial effluent (Wang et al. 2015). Similar trend of decrease in adsorption capacity due to the presence of salts has also been observed for the adsorptive removal of direct 80 dye using propylene imine-based adsorbent (Hayati et al. 2011). The obtained results in the present study indicated that decrease in biosorption capacity of industrial effluent was not significant in comparison with pure dye solution, confirming that established results in present study can be applied to industrial effluents containing salts (appropriate care can be taken to slightly increase the biosorbent dose so as to get the desired removal efficacies).

Isotherm Model Fitting

Isotherm model parameters and correlation coefficient (R2) values for the fitting have been obtained from the isotherm plots of Freundlich, Langmuir and Temkin model as shown in Fig. 3a–c, respectively. The isotherm parameters obtained using model fitting, R2 and RMSE, error values have been depicted in Table 1. It can be predicted from Fig. 3a–c (representative case at 303 K) that perfect linear fitting with almost all points on a line is obtained for Langmuir model in comparison with Temkin and Freundlich models. It can also be observed from Table 1 that R2 values of Langmuir model (average value of 0.9959) are very close to unity in comparison with R2 values of Freundlich (average value of 0.9763) and Temkin model (average value of 0.9752). Additionally, as seen from Table 1, least values of RMSE are obtained for Langmuir isotherm in comparison with Temkin and Freundlich isotherms for all the studied temperatures. All these observations confirmed that isotherm data were in best agreement with the Langmuir isotherm. Similar trend of better fitting for Langmuir isotherm has also been reported for removal of methylene blue using dead leaves of Typha angustifolia (Boumaza et al. 2018). The trend of isotherm fitting reported in the present work is not generalized as other fittings have also been reported in the literature such as for adsorption of Congo red on zinc peroxide, where Freundlich fitting was reported to best (Chawla et al. 2017). It is hence recommended to check the fitting of the experimental data of specific system to various isotherm models as per the methodology described in the present work.

Adsorption Thermodynamics

Thermodynamic parameters in the present study have also been determined from the plot of ln Kc versus 1/T and obtained values are depicted in Table 2. ∆G0 values for all studied temperatures were obtained as negative, which confirmed feasible and spontaneous nature of the adsorption system (El Atouani et al. 2018). Positive value of ∆H0 was obtained which confirmed endothermic nature. Value of ∆H0 was obtained as 12.61 kJ mol−1, which is less than 40 kJ mol−1 confirming physical nature of adsorption (Bhatnagar et al. 2009). Positive value of ∆S0 confirmed increased randomness during adsorption of Acid Blue 25 from industrial effluent using NTFR (Dash et al. 2018).

Treatment of Mixed Effluent Containing Acid Green 25 Dye

Mixed dye effluent was obtained from the industry to check the influence of presence of mixtures of dyes along with salts and other compounds present in the effluent on the removal of individual dye (Acid Green 25). The obtained mixed effluent was mainly containing Acid Green 25 dye (targeted pollutant) and Acid Red 52 dye along with salts and other compounds. Mixed effluent was found to contain 409.895 mg L−1 of Acid Green 25 dye. The initial COD of the mixed effluent was measured and found as 1530.14 mg L−1. In this approach, studies were performed directly on the mixed industrial effluent without dilution. Studies related to the effect of biosorbent dose and also the kinetic studies were performed on the mixed effluent using NTPD biosorbent and obtained results have been compared with results for the pure Acid Green 25 solution of similar dye concentration as present in the industrial effluent.

Biosorbent Dose Study

The effect of biosorbent dose on the extent of dye removal was studied for the mixed effluent by varying the biosorbent (NTPD) dose over the range of 2 to 24 g L−1. Samples were withdrawn from the orbital shaker and analyzed to measure Acid Green 25 dye concentration and COD values to establish the extent of dye removal (%) and reduction in COD (%) for the industrial effluent. The obtained results are depicted in Fig. 4 and Fig. 5, respectively. Extent of dye removal was observed to increase with biosorbent dose for both the type of dye solutions, which is attributed to the fact that when biosorbent dose is increased, amount of biosorbent increases for the same of dye concentration and hence probability of dye adsorption increases, leading to enhanced dye removal. Similar trend of enhanced dye removal at higher biosorbent dose was also reported for adsorption of crystal violet on hybrid nanocomposites (Attallah et al. 2016). In the case of mixed industrial effluent studied in the current work, Acid Green 25 dye removal was found to increase from 21.89 to 84.51% with an increase in the NTPD dose from 2 to 18 g L−1. Dye removal (%) was slightly increased from 84.51 to 84.74% when biosorbent dose was subsequently increased from 18 to 24 g L−1. Similarly, the extent of COD reduction of mixed effluent was found to increase from 14.81 to 53.97% when NTPD dose was increased from 2 to 18 g L−1 and remained almost constant thereafter for an increase in biosorbent loading up to 24 g L−1. Higher value of the residual COD as 704.35 mg L−1 (COD reduction of only 53.97%) even after significant dye removal using optimum loading of biosorbent can be attributed to other dye (Acid Red 52) and organic compounds which are present in the mixed effluent, which are not completely adsorbed on the biosorbent. Considering the obtained results, biosorbent dose of 18 g L−1 was finalized as the optimum for kinetic study of mixed effluent.

The obtained results for the study of effect of biosorbent (NTPD) dose on Acid Green 25 dye removal and reduction in COD under conditions of varying NTPD dose over the range of 2 to 24 g L−1 for the case of synthetically prepared Acid Green 25 dye solution of similar concentration as present in the mixed industrial effluent indicated that dye removal increased from 29.98 to 92.09% when NTPD dose was increased from 2 to 16 g L−1. Dye removal slightly increased from 92.09 to 92.42% with a further increase in the biosorbent dose from 16 to 24 g L−1. Similarly COD of the synthetically prepared Acid Green 25 dye solution reduced from initial COD of 712.45 to 56.67 mg L−1 after the treatment using the biosorbent dose of 16 g L−1. The lower values of COD in pure Acid Green 25 dye solution as compared to the case of real effluent also confirmed the presence of organic compounds and dyes in the real industrial effluent. For the case of pure Acid Green 25 dye solution, biosorbent dose of 16 g L−1 was finalized as the optimum and used for further kinetic study.

Kinetic Study

Kinetic study was performed for the treatment of mixed effluent and pure Acid Green 25 dye solution using NTPD biosorbent. The obtained results for dye removal at different treatment times have been depicted in Fig. 6 for both types of dye solutions. It can be seen from the figure that Acid Green 25 dye removal was very rapid in the initial period of adsorption for both the types of dye solutions. In the case of mixed industrial effluent, dye removal significantly increased from 29.02 to 84.51% when the contact time was increased from 15 to 390 min. Subsequently, dye removal increased slightly from 84.51 to 84.68% with an increase in contact time from 390 to 450 min establishing that equilibrium was achieved at 390 min of treatment time. In the case of pure dye solution as seen from Fig. 6, dye removal was found to be higher as compared to the mixed effluent as no other compounds were present in pure dye solution except Acid Green 25 dye, which can compete for dye adsorption. Dye removal was observed to significantly increase from 38.57 to 92.09% when contact time was increased from 15 to 330 min and subsequently dye removal slightly increased from 92.09 to 92.52% when contact time was increased from 330 to 450 min, a trend similar to the industrial effluent. It is important to note that the equilibrium time required for pure solution is lower as compared to the mixed industrial effluent confirming the competition from other compounds. It was also established that maximum Acid Green 25 dye removal was obtained as 92.09% at 16 g L−1 of biosorbent dose and contact time of 330 min for pure dye solution whereas maximum Acid Green 25 dye removal obtained was 84.51% at 18 g L−1 of biosorbent dose and contact time of 390 min for mixed industrial effluent. All the obtained results indeed confirmed efficient removal of dye in the case of synthetically prepared effluent.

Obtained results for COD reduction (%) for both the solutions have been depicted in Fig. 7. In the case of mixed industrial effluent, COD reduction (%) was found to increase from 16.41 to 53.97% when contact time was increased from 15 to 390 min. After 390 min, COD value remained constant up to 450 min for the case of industrial effluent. COD reduction obtained was only 53.97% establishing that Acid Red dye and other compounds present in the mixed effluent were not adsorbed significantly on NTPD biosorbent. In the case of pure dye solution, COD reduction (%) was found to increase significantly from 36.36 to 92.05% when contact time was increased from 15 to 330 min and remained constant thereafter up to 450 min of treatment time, attributed to equilibrium.

The initial COD value of mixed effluent was 1530.14 mg L−1, which reduced to 704.352 mg L−1 at the end of the kinetic study in the case of mixed effluent. Higher COD value at the end of kinetic study is attributed to the fact that Acid Red 52 dye and other compounds present in the mixed effluent were not adsorbed on the NTPD biosorbent and contributed to the residual COD. In the case of pure Acid Green 25 dye solution, COD value was initially 712.45 mg L−1, which significantly reduced to 56.67 mg L−1 at the end of the kinetic study. The obtained results confirmed potential of synthesized NTPD biosorbent to effectively remove Acid Green 25 dye from real industrial effluent though the overall COD reduction is lower.

Kinetic Model Fitting

The kinetic model parameters obtained using model fitting, along with the R2 and RMSE, error values are depicted in Table 3. The degree of the kinetic model fitting to the experimental kinetic data is depicted in Fig. 8 in terms of comparison of biosorption capacity values obtained experimentally (qexp) and calculated using model equation (qcal). It can be observed from the figure that qexp and qcal are almost close to each other for pseudo-second-order model and quite different for the fractional power and pseudo-first-order models. It can also be verified from Table 3 that qexp and qcal values are closer to each other for pseudo-second-order model whereas qexp and qcal are significantly deviating from each other for the predictions using pseudo-first-order and fractional power model equations. Also, R2 values obtained for pseudo-second-order model (average value of 0.9990) are closer to unity than pseudo-first-order (average value of 0.9429) and fractional power models (average value of 0.9658). Additionally, it can be observed from Table 3 that least values of the error function, RMSE are obtained for pseudo-second-order model in comparison with pseudo-first-order and fractional power models . All these obtained findings established better fitting of pseudo-second-order model to the kinetic data of adsorptive removal of Acid Green 25 from mixed effluent and pure dye solution using NTPD. Similar trend of fitting of kinetic data to pseudo-second-order equation has also been reported earlier for crystal violet removal using modified fig leaves (Alizadeh et al. 2017). The trend of kinetic fitting reported in the present work is not generalized as cases of other best fittings have also been reported in the literature. For example for adsorption of malachite green dye, it was reported that first order model fitted best to the obtained experimental data (Gündüz and Bayrak 2017). It can be thus said that it is necessary to check the fitting of the experimental data of specific system to various kinetic models as per the methodology described in the present work and hence the importance of the current work is clearly established.

Conclusions

The present study established the potential of synthesized NTFR and NTPD biosorbents for the dye removal from real industrial effluents. The extent of dye removal and biosorption capacity was observed to be marginally lower in the case of real effluent as compared to the pure Acid Blue 25 dye solution, attributed to the salts and other organic compounds present in the industrial effluent. In the case of mixed industrial effluent containing Acid Green 25 dye also, similar trends for extent of dye removal were observed though the extent of decrease in dye removal was comparatively higher. In addition COD analysis revealed that COD reduction (%) as 53.97% at the optimized dose of 18 g L−1 of NTPD for the real effluent was much lower than 92.05% obtained at the optimized biosorbent dose of 16 g L−1 for pure Acid Green 25 dye solution. Based on the COD analysis, NTPD biosorbent was established to be less efficient in removing other dye (Acid red 52) and compounds present in the mixed effluent. The overall study established potential of synthesized biosorbents in removing specific dyes from industrial effluents and also the influence of other compounds on removal efficiency of individual dyes.

References

Abdi J, Vossoughi M, Mahmoodi NM, Alemzadeh I (2017) Synthesis of metal-organic framework hybrid nanocomposites based on GO and CNT with high adsorption capacity for dye removal. Chem Eng J 326:1145–1158

Adegoke KA, Bello OS (2015) Dye sequestration using agricultural wastes as adsorbents. Water Resour Ind 12:8–24

Ahmad AA, Hameed BH (2009) Reduction of COD and color of dyeing effluent from a cotton textile mill by adsorption onto bamboo-based activated carbon. J Hazard Mater 172:1538–1543

Alizadeh N, Shariati S, Besharati N (2017) Adsorption of crystal violet and methylene blue on azolla and fig leaves modified with magnetite iron oxide nanoparticles. Int J Environ Res 11:197–206

Attallah OA, Al-ghobashy MA, Nebsen M, Salem MY (2016) Removal of cationic and anionic dyes from aqueous solution with magnetite/pectin and magnetite/silica/pectin hybrid nanocomposites: kinetic, isotherm and mechanism analysis. RSC Adv 6:11461–11480

Baheri B, Ghahremani R, Peydayesh M et al (2016) Dye removal using 4A-zeolite/polyvinyl alcohol mixed matrix membrane adsorbents: preparation, characterization, adsorption, kinetics, and thermodynamics. Res Chem Intermed 42:5309–5328

Bhatnagar A, Kumar E, Minocha AK et al (2009) Removal of anionic dyes from water using Citrus limonum (Lemon) peel: equilibrium studies and kinetic modeling. Sep Sci Technol 44:316–334

Boumaza S, Yenounne A, Hachi W et al (2018) Application of Typha angustifolia (L.) dead leaves waste as biomaterial for the removal of cationic dye from aqueous solution. Int J Environ Res 12:561–573

Celekli A, Ilgün G, Bozkurt H (2012) Sorption equilibrium, kinetic, thermodynamic, and desorption studies of Reactive Red 120 on Chara contraria. Chem Eng J 191:228–235

Chawla S, Uppal H, Yadav M et al (2017) Zinc peroxide nanomaterial as an adsorbent for removal of Congo red dye from waste water. Ecotoxicol Environ Saf 135:68–74

Crini G (2006) Non-conventional low-cost adsorbents for dye removal: a review. Bioresour Technol 97:1061–1085

Dash S, Chaudhuri H, Gupta R, Nair UG (2018) Adsorption study of modified coal fly ash with sulfonic acid as a potential adsorbent for the removal of toxic reactive dyes from aqueous solution: kinetics and thermodynamics. J Environ Chem Eng 6:5897–5905

Dastkhoon M, Ghaedi M, Asfaram A et al (2017) Simultaneous removal of dyes onto nanowires adsorbent use of ultrasound assisted adsorption to clean waste water: chemometrics for modeling and optimization, multicomponent adsorption and kinetic study. Chem Eng Res Des 124:222–237

Demirbas A (2009) Agricultural based activated carbons for the removal of dyes from aqueous solutions: a review. J Hazard Mater 167:1–9

El Atouani S, Belattmania Z, Reani A et al (2018) Brown seaweed Sargassum muticum as low-cost biosorbent of methylene blue. Int J Environ Res. https://doi.org/10.1007/s41742-018-0161-4

El-naggar ME, Radwan EK, El-wakeel ST et al (2018) Synthesis, characterization and adsorption properties of microcrystalline cellulose based nanogel for dyes and heavy metals removal. Int J Biol Macromol 113:248–258

Freundlich HMF (1906) Over the adsorption in solution. J Phys Chem 57:385–470

Gong R, Ding Y, Li M et al (2005) Utilization of powdered peanut hull as biosorbent for removal of anionic dyes from aqueous solution. Dye Pigment 64:187–192

Gündüz F, Bayrak B (2017) Biosorption of malachite green from an aqueous solution using pomegranate peel: equilibrium modelling, kinetic and thermodynamic studies. J Mol Liq 243:790–798

Hayati B, Mahmoodi NM, Arami M, Mazaheri F (2011) Dye removal from colored textile wastewater by poly (propylene imine) dendrimer: operational parameters and isotherm studies. Clean Soil Air Water 39:673–679

Ho YS, Mckay G (1999) Pseudo-second order model for sorption processes. Process Biochem 34:451–465

Inyinbor AA, Adekola FA, Olatunji GA (2016) Kinetics, isotherms and thermodynamic modeling of liquid phase adsorption of Rhodamine B dye onto Raphia hookerie fruit epicarp. Water Resour Ind 15:14–27

Jain SN, Gogate PR (2017a) NaOH-treated dead leaves of Ficus racemosa as an efficient biosorbent for Acid Blue 25 removal. Int J Environ Sci Technol 14:531–542

Jain SN, Gogate PR (2017b) Adsorptive removal of acid violet 17 dye from wastewater using biosorbent obtained from NaOH and H2SO4 activation of fallen leaves of Ficus racemosa. J Mol Liq 243:132–143

Jain SN, Gogate PR (2017c) Acid Blue 113 removal from aqueous solution using novel biosorbent based on NaOH treated and surfactant modified fallen leaves of Prunus Dulcis. J Environ Chem Eng 5:3384–3394

Jain SN, Gogate PR (2018) Efficient removal of Acid Green 25 dye from wastewater using activated Prunus Dulcis as biosorbent: batch and column studies. J Environ Manage 210:226–238

Kim T, Song HJ, Dar MA et al (2018) Fast adsorption kinetics of highly dispersed ultrafine nickel/carbon nanoparticles for organic dye removal. Appl Surf Sci 439:364–370

Lagergren S (1898) About the theory of so called adsorption of soluble substances. Ksver Veterskapsakad Handl 24:1–6

Langmuir I (1918) The adsorption of gases on plane surfaces of glass, mica and platinum. J Am Chem Soc 40:1361–1403

Li C, Xia H, Zhang L et al (2017) Kinetics, thermodynamics, and isotherm study on the removal of methylene blue dye by adsorption via copper modified activated carbon. Res Chem Intermed 44:2231–2250

Maleki A, Hamesadeghi U, Daraei H et al (2017) Amine functionalized multi-walled carbon nanotubes: single and binary systems for high capacity dye removal. Chem Eng J 313:826–835

Natarajan S, Bajaj HC, Tayade RJ (2018) Recent advances based on the synergetic effect of adsorption for removal of dyes from waste water using photocatalytic process. J Environ Sci 65:201–222

Ngulube T, Gumbo JR, Masindi V, Maity A (2017) An update on synthetic dyes adsorption onto clay based minerals: a state-of-art review. J Environ Manage 191:35–57

Papegowda PK, Syed AA (2017) Isotherm, kinetic and thermodynamic studies on the removal of methylene blue dye from aqueous solution using saw palmetto spent. Int J Environ Res 11:91–98

Ponnusami V, Srivastava SN (2009) Studies on application of teak leaf powders for the removal of color from synthetic and industrial effluents. J Hazard Mater 169:1159–1162

Rangabhashiyam S, Anu N, Selvaraju N (2013) Sequestration of dye from textile industry wastewater using agricultural waste products as adsorbents. J Environ Chem Eng 1:629–641

Salleh MAM, Mahmoud DK, Karim WAWA, Idris A (2011) Cationic and anionic dye adsorption by agricultural solid wastes: a comprehensive review. Desalination 280:1–13

Sonai GG, De Souza SMAGU, de Oliveira D, de Souza AAU (2016) The application of textile sludge adsorbents for the removal of Reactive Red 2 dye. J Environ Manage 168:149–156

Temkin MJ, Pyzhev V (1940) Recent modifications to Langmuir isotherms. Acta Physicochim USSR 12:217–225

Wang J, Zhu H, Hurren C et al (2015) Degradation of organic dyes by P25-reduced graphene oxide: influence of inorganic salts and surfactants. J Environ Chem Eng 3:1437–1443

Wang X, Jiang C, Hou B et al (2018) Carbon composite lignin-based adsorbents for the adsorption of dyes. Chemosphere 206:587–596

Zhou Y, Zhang L, Cheng Z (2015) Removal of organic pollutants from aqueous solution using agricultural wastes: a review. J Mol Liq 212:739–762

Acknowledgements

The authors thank University Grant Commission-Networking Resource Centre at Institute of Chemical Technology, Mumbai, India and Lotus Enterprises, Mumbai.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Jain, S.N., Gogate, P.R. Treatment of Dye Containing Real Industrial Effluents using NaOH-Activated Ficus racemosa and Prunus dulcis based Novel Adsorbents. Int J Environ Res 13, 337–347 (2019). https://doi.org/10.1007/s41742-019-00179-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41742-019-00179-8