Abstract

Field test data on the simultaneous variations of leachate level, temperature and gas pressure in waste can be used in verifying the theoretical solution of coupled model of gas pressure and temperature in municipal solid waste (MSW) landfills. The correlation between the variations of these properties caused by leachate pumping is a major concern in the management of landfills. Therefore, temperature and gas pressure monitoring and leachate pumping tests were conducted in a newly filled MSW layer of a landfill located at Wuxi, southeastern China. The multifunctional extraction well and monitoring wells were designed to monitor the simultaneous variations of leachate level, temperature and gas pressure. The spatial and temporal distributions of these parameters and their correlation were investigated and analyzed. The results show that the highest waste temperature occurs near the leachate level. The gas pressures measured in the waste above the leachate level increase with depth. During the leachate pumping test, the temperature and gas pressure increase in the leachate level decreasing zone. When the leachate level has stably recovered, the temperature decreases slightly and gas pressure in this zone decreases to nearly zero. In addition, the MSW permeability of the newly filled MSW layer is calculated.

Graphical Abstract

The variation in the water content caused by the change in the leachate level affected the temperature and gas pressure in the waste. The temperature and gas pressure increased in the leachate level decreasing zone. The gas pressure was collectively affected by the water content and temperature in the waste.

Article Highlights

-

Simultaneous variations of leachate level, temperature and gas pressure were investigated.

-

The multifunctional extraction well and monitoring wells were used to monitor the field data.

-

The highest temperature observed in the waste occurred near the leachate level.

-

The temperature and gas pressure increased in the leachate level decreasing zone.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Landfill gas, heat and leachate are byproducts of MSW biodegradation and can lead to various environmental and safety issues. High leachate level can cause slope failure of landfill (Koerner and Soong 2000; Blight 2008; Giri and Reddy 2014; Batali et al. 2017). The perforated high-density polyethylene (HDPE) pipe in waste mass easily deforms due to high temperatures (Krushelnitzky and Brachman 2013). The incessant gas production from the waste causes an increase in the gas pressure in landfills, which in turn lead to the release of landfill gas into the atmosphere (Reinhart et al. 1992; Powell et al. 2015). On the other hand, the higher gas pressure is favorable for landfill gas collection (Feng et al. 2015). Therefore, the distributions of the gas pressure, temperature and leachate level in a MSW landfill have become important research areas being pursued by numerous researchers. The leachate levels in landfills with high leachate levels have been monitored using monitoring wells by earlier researchers to investigate the distribution of leachate level in various landfills (Rees 1980; Jang 2000; Jang and Kim 2003; Yuen et al. 2001; Lee et al. 2006). Different kinds of temperature measuring instruments have been used to monitor waste temperatures at different depths in landfills to investigate the distribution of temperature in various landfills (Rees 1980; Spokas and Bogner 1996; Townsend et al. 1996; El-Fadel 1999; Lefebvre et al. 2000; Lee et al. 2002; Yesiller and Hanson 2003; Yoshida and Rowe 2003; Powell 2005; Hanson et al. 2006; Koerner and Koerner 2006; Hanson et al. 2010; Bouazza et al. 2011; Kadambala et al. 2011, 2016; Bonany et al. 2013; Ko et al. 2013; Faitli et al. 2015; Vaverkova and Adamcova 2015; Liu et al. 2016; Yesiller et al. 2016; Jafari et al. 2017). In addition, Yesiller et al. (2015) summarized that MSW temperatures at different locations, climatic conditions, rainfall and waste age vary between a minimum of − 6 °C to a maximum of 60–90 °C. The HDPE pipe in landfill waste easily deforms due to high temperatures above 55 °C (Krushelnitzky and Brachman 2013). The temperature that is beneficial for waste biodegradation and gas production is between 34 and 45 °C (Rees 1980; Hartz et al. 1982; Mata-Alvarez and Martinez-Viturtia 1986). Therefore, the waste temperature outside this suitable range may be not beneficial for gas production. Gas pressures have been monitored using pressure transducers and monitoring wells to investigate the distribution of gas pressure in various landfills (Lu and Kunz 1981; Kjeldsen and Fischer 1995; Spokas and Bogner 1996; Martin et al. 1997; Lee et al. 2002; Gebert and Groengroeft 2006; Jung et al. 2011; Larson et al. 2012; Stevens 2012; Collins et al. 2013; Ko et al. 2013; Liu et al. 2017).

The leachate level, temperature and gas pressure have been, respectively, measured in MSW landfills, and their respective properties have also been analyzed. However, information on the investigations into the simultaneous variations of leachate level, temperature and gas pressure in the newly filled MSW layer is limited. The monitoring methods of leachate level, temperature and gas pressure have been mentioned, respectively, in Townsend et al. (2015) and the above published papers. Therefore, multifunctional extraction well and monitoring wells were designed based on the existing measured methods to monitor the leachate level in the well and gas pressure at the well-head in this study. In addition, a piezometer and a temperature sensor were combined into a whole sensor and installed at the bottom of well to monitor the pore water pressure and temperature at the designated depth. Thus, the simultaneous monitoring of leachate level, temperature and gas pressure was achieved using a multifunctional well in the newly filled MSW layer of a landfill.

Pumping tests are widely performed in aquifers with soil using pumping well and monitoring wells to determine the hydraulic characteristics, which are based on the variation of the water level (Niemann and Rovey 2000; Chapuis et al. 2005; Shen et al. 2015; Wu et al. 2017; Marco et al. 2018). Leachate pumping is an effective solution for decreasing the high leachate level in a landfill (Oweis et al. 1990; Zhan et al. 2015). In addition, the leachate pumping test is commonly performed in landfills, which is beneficial in increasing the efficiency of landfill gas collection (Townsend et al. 2015; Zhan et al. 2015). Permeability is an important factor for analyzing the seepage in landfills. Therefore, researchers have conducted field pumping tests to calculate the waste permeability based on the variation of the leachate level (Oweis et al. 1990; Jones et al. 1992; Shank 1993; Jang 2000; Olivier et al. 2009; Zhan et al. 2014). Basic equations developed by fitting the data to the theoretical results have been used to evaluate the radius and spacing of pumping wells for application in engineering design (Rowe and Nadarajah 1996). In another study, the leachate levels were measured during the leachate pumping test, and based on the numerical model of Richard’s equation, the flow behavior of the leachate was analyzed considering the decrease in the waste permeability with depth (Slimani et al. 2017).

The water and leachate levels are always the focus of attention during the water and leachate pumping tests. Because the hydraulic characteristics of waste and soil can be investigated according to the variation of liquid level. The difference between waste and soil is that waste produces leachate, gas and heat due to its biodegradation. In recent study, it is found that the appearance of leachate level decreasing zone affects the efficiency of landfill gas collection (Townsend et al. 2015; Zhan et al. 2015). However, the simultaneous variations of temperature and gas pressure in the leachate level decreasing zone have not been reported. This is a zone where water content varies greatly; furthermore, waste temperature and gas production are affected by the water content (Tchobanoglous et al. 1977; Rees 1980; Hartz et al. 1982; Kasali 1986; Mata-Alvarez and Martinez-Viturtia 1986). Therefore, the simultaneous variations of temperature and gas pressure in the leachate level decreasing zone with the variation of leachate level were investigated in this study. Besides, in order to study the stabilities of gas pressure and temperature in this zone, the leachate level was controlled to a specified depth for a period of time.

The objectives of this study were to: (1) obtain the basic data on the simultaneous variation of leachate level, temperature and gas pressure in the newly filled MSW layer during a 1.4-year monitoring test, which is beneficial to understand these properties in the new waste layer; (2) investigate the correlations between leachate level, temperature and gas pressure during a 28-day leachate pumping test; (3) calculate the MSW permeability of the newly filled MSW layer, which is beneficial to analyze the seepage in landfill.

Materials and Methods

MSW Landfill Profile

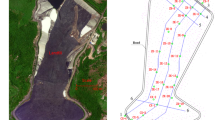

Wuxi landfill, where the field testing was conducted, is located in the city of Wuxi, China (as shown in Fig. 1). The test area was located at a new waste filling zone with dimensions of 24 m (length) × 12 m (width) × 10 m (depth), which was completed on December 19, 2015. A 30-m-thick old waste layer lay below the 10-m-thick new waste layer. The installations of the monitoring instruments were started on January 18, 2016 and completed on January 30, 2016. Eleven waste samples were collected from drilling holes in the test area. The MSW components were analyzed by sorting and weighing, which was mainly based on the components provided by Qian et al. (2011). The average results of the waste components are listed in Table 1.

Installation for the Monitoring and Leachate Pumping Tests

One extraction well (#0 well) and nine monitoring wells (#1 to #9 wells) were used in this study. The extraction well and monitoring wells had a HDPE pipe with perforations at the bottom 7.7 m and 0.5 m section of the well, respectively, as shown in Fig. 2a. Temperature sensor (model: KXR-200; design range: − 10 to 100 °C; accuracy: ± 0.1 °C; manufactured by Youshan Dianqi Instrument Factory) and piezometer (model: KXR-200; design range: − 200 to 200 kPa; accuracy: ± 0.01 kPa; manufactured by Youshan Dianqi Instrument Factory) were combined into a sensor. Ten KXR-200 combined sensors and one temperature sensor (model: ST-3; manufactured by Youshan Dianqi Instrument Factory; design range: − 10 to 100 °C; accuracy: ± 0.1 °C) were used in this study.

The processes for the construction of the wells were conducted as follows: In the first step, a backhoe was used to excavate the marked positions for the wells on the test area to the designated depths. In the second step, the backhoe was used to lift the HDPE pipe; the PE bucket and the combined sensor were fixed at the bottom and the bottom side wall of the HDPE pipe, respectively. The PE bucket was filled with water and fine gravel. In the third step, the assembled HDPE pipe was placed at the bottom of the excavated pit using the backhoe; the pit was filled with the excavated waste to the original surface. The MSW landfill surface around both the extraction and monitoring wells was covered and sealed by compacted clay with a thickness of 0.5 m and radius of 1.0 m. In the fourth step, a polyamide cap (PA-1 cap) was installed on the top of the HDPE pipe; the piezometer cable and temperature sensor cable were separately passed through two holes with a diameter of 10 mm on the PA-1 cap. An air valve was also installed at a hole with a diameter of 20 mm on the PA-1 cap for monitoring of gas pressure using a micromanometer (model: AS510; manufactured by Smart Sensor Co., Ltd.; measurement range: 0 to 1000 Pa; accuracy: 1 Pa) at the well-head. Another polyamide cap (PA-2 cap) was installed on PA-1 cap for monitoring the leachate level in the HDPE pipe, as shown in Fig. 2b, c. The depths and distributions of #0 to #9 wells are illustrated in Fig. 3. In the fifth step, A ST-3 temperature sensor was placed on the surface of test area. Finally, the test area was covered by a 1-mm-thick HDPE geomembrane on January 30, 2016 to prevent the infiltration of rainfall and snow and the emission of landfill gas. The gaps and cracks in the geomembrane cover were repaired artificially by a hot glue and geomembrane. Thus, the leachate level, pore water pressure, gas pressure and temperature could be measured simultaneously using the multifunctional wells during the monitoring and pumping tests.

Preparation for the Leachate Pumping Test

A tubular submersible pump (QJY-TSP) (model: QJY; manufactured by Shimge Pump Group Industry Co., Ltd.; diameter: 98 mm; height: 905 mm; discharge head: 40 m; pump capacity: 4 m3 h−1) was used in the leachate pumping test. PA-1 and PA-2 caps of the #0 well were opened, and the QJY-TSP was placed in #0 well. Three leachate level controlling wires with different lengths and the power cable of the QJY-TSP were passed through the top side wall of the HDPE pipe into #0 well and connected with an automatic pump controller (model: CCYJ; made by Jilin Tianhe Water Supply Equipment Co., Ltd.) for controlling the leachate level in #0 well. The discharging pipe (polyvinyl chloride (PVC) steel-wired hose with an outer diameter of 45 mm and inner diameter of 38 mm) of the QJY-TSP was passed through a 45-mm-diameter hole on PA-2 cap and connected with a watermeter (model: LXS, manufactured by Ningbo Haichuan Water Meter Co. Ltd.) on the outside of #0 well for monitoring the pumping volume, as shown in Fig. 2a. Thereafter, the PA-1 and PA-2 caps were closed and sealed with a rubber ring and glass cement.

The pumping test was conducted on July 11, 2016, after the leachate level was relatively stable. At this moment, the initial mean elevation of leachate level was + 4.54 m (relative to the bottom elevation of pumping well). The extracted leachate was released in the leachate collecting pipe to prevent the extracted leachate from having an adverse effect on the environment and the test. The accumulated pumping volume and leachate level were monitored during the leachate pumping test. In addition, waste temperature and gas pressure were monitored simultaneously, which was to study the influence of leachate pumping on waste temperature and gas pressure in the leachate level decreasing zone. The leachate pumping procedure consisted of five stages. The equipment and instruments were tested and adjusted during the 6.2-day trial and adjusting stages. An average pumping flowrate of 0.3 m3 h−1, which was within the range of pumping flowrate of 0–0.9 m3 h−1 reported by Al-Thani et al. (2004); Zhan et al. (2014) and Slimani et al. (2017), was selected during 10.8-day pumping stage. The elevation of leachate level in #0 well was controlled at an elevation of approximately + 3.0 m by the automatic pump controller during 5-day stable stage. Finally, the recovery was monitored during 6.3-day recovering stage after pumping operation was stopped.

Results and Discussion for the Monitoring Test

Leachate Level during the Monitoring Test

The leachate levels observed from #0, #1, #2, #4, #6 and #9 wells (with bottom elevations of + 0.0 m, + 3.5 m, + 3.5 m, + 2.0 m and + 4.1 m, respectively), whose bottom elevations were below the leachate level, and the local precipitation are shown in Fig. 4. The local precipitation data were obtained from China Meteorological Administration Public Meteorological Service Center (CMAPMSC) (2016) during the monitoring test. The waste in the test area was exposed for approximately 40 days before the test area was covered by the geomembrane on January 30, 2016. Subsequently, rainfall barely affected the leachate level in the test area because of the geomembrane cover. A high leachate level was observed in the test area during this field investigation as was also reported during a monitoring of the leachate levels in Kimpo landfill by Jang (2000) and Jang and Kim (2003). The highest leachate level reached a height of 16 m in Kimpo landfill, which was mainly attributed to the high-water content in the waste and ineffective leachate drainage system (Dho et al. 2002). In the newly filled MSW layer of Wuxi landfill, the leachate level decreased by approximately 0.8 m from January 30, 2016 to April 1, 2016 (time B). Because the test area was a new filling area, and the temporary elevation of the surface of the newly filled MSW layer and leachate level were relatively high (as shown in Fig. 1), the leachate in the newly filled MSW layer migrated to the adjacent old MSW layer with a lower elevation and lower leachate head until a new equilibrium was reached. The leachate level decreased and increased between July 11, 2016 (time C) and August 8, 2016 (time D) due to the leachate pumping test. The leachate level exhibited a sharp increase and then a decrease between December 20, 2016 (time E) and January 3, 2017 (time F) because of the liquid injection test (mentioned in Zhang 2017). The leachate level rapidly increased from January 16, 2017 (time G) to July 4, 2017 (time H), because the test area had a lower elevation relative to another adjacent newer filling MSW layer (as shown in Fig. 1). Subsequently, the leachate from the newer MSW layer migrated to the test area with a lower leachate head until the test area was buried by another newer filling MSW layer at time H.

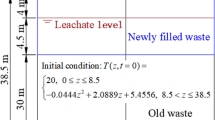

Temperature During the Monitoring Test

The ambient temperature and temperature at the landfill surface under the geomembrane cover are shown in Fig. 5. The ranges of the landfill surface temperature and ambient mean temperature were 4.0–46.9 °C and − 7.0 to 35.0 °C, respectively. The landfill surface temperature varied with the seasonal fluctuation in the ambient temperature, because only a 1-mm-thick geomembrane was used for covering the landfill surface. The same phenomenon was also observed by Yesiller and Hanson (2003) and Koerner and Koerner (2006). And it was higher than the ambient mean temperature on average by 7.0 °C in this test, because the geomembrane impeded heat transfer to the environment which resulted in an increase in temperature. Temperature variations with time in the newly filled MSW layer are shown in Fig. 6. In the 1.4 years of monitoring, the range of the measured temperatures in the waste was 9.1–42.0 °C. The initial waste temperatures were relatively low. Because the temperature sensors and the backfilled waste were buried during a cold winter period. The waste temperatures rapidly increased within 12 days from time A at a rate of approximately 0.14–0.70 °C day−1. Lefebvre et al. (2000) also found that the temperature of fresh waste in the Montech landfill increases rapidly within 20 days mainly because of the aerobic reactions occurring in the waste. The waste temperatures gradually increased to the peak value within the subsequent approximately 228 days (from January 30, 2016 to September 13, 2016). This is because of the occurring anaerobic reactions (Lefebvre et al. 2000); furthermore, the shallow waste temperature is also affected by air temperature (Gholamifard et al. 2008). The increasing rates of the temperature were approximately 0.02–0.06 °C day−1. From September 14, 2016 to January 16, 2017, the temperatures at the bottoms of #7 and #8 wells (with bottom elevations of + 6.8 m and + 6.1 m, respectively) decreased slowly, because the temperatures in the shallow waste were affected by the decreasing ambient temperature. However, the waste temperatures were slightly affected by the ambient temperature when the depth was more than 2.05 m (bottom depth of #8 well). There were obvious temperature variations between time E and time F due to the liquid injection test (mentioned in Zhang 2017). After January 17, 2017, the waste temperatures slightly decreased because of the increase in the leachate level. In particular, the waste temperature decreased abruptly on April 11, 2017. Due to the existence of breaks in the geomembrane in the test area, which was caused by the strong tension in the geomembrane that covered the adjacent MSW layer, a large amount of rainwater permeated the MSW layer. The gap in the geomembrane caused by its stretching was also observed in landfill capping by Gallagher et al. (2016). However, the geomembrane cover in the test area was repaired on April 12, 2017 ; thereafter the sudden change in the waste temperature was not recorded. The bottom elevations of #0 and #1 wells were similar to those of #2 and #4 wells, but the differences in the temperatures between the bottoms of #0 and #2 wells (with bottom elevations of + 0.0 m and + 0.2 m, respectively) were 0.1–10.3 °C and between the bottoms of #1 and #4 wells (with bottom elevations of + 3.50 m and + 3.49 m, respectively) were 0.1–12.1 °C. The authors attribute this to the different initial temperatures and heterogeneous composition of the waste. Because the proportion of degradable organic matter at different sites of the same depth was different. Higher portion of degradable organic matter produces more heat in waste (Hao et al. 2017), which results in higher waste temperatures.

Temperature variations with elevation in the newly filled MSW layer are shown in Fig. 7. The highest waste temperature was recorded at an elevation of approximately + 4 m, which was near the leachate level and mid-point elevation of the newly filled MSW layer. The leachate level can be regarded as the dividing line between saturated waste layer and unsaturated waste layer. The specific heat capacity of saturated MSW is higher than that of unsaturated MSW (Yoshida and Rowe 2003). When the waste produces the same heat, the increasing rate of waste temperature in the saturated layer is slower than that in the unsaturated layer. Therefore, the leachate level can also be regarded as the place where the highest temperature occurs. Hanson et al. (2010) also found that the maximum waste temperature is observed within the middle third fraction of the depth of the waste mass. As shown in Fig. 6, the temperature at the bottom of #9 well was higher than that at the bottoms of the other wells. Because the bottom of #9 well (with bottom elevation of + 4.1 m) was close to the leachate level where the moisture content was suitable for the biodegradation of the organic fraction of the waste, the biodegradation reaction was more intense at the bottom of #9 well, leading to a higher temperature. A summary of the landfill locations, peak temperature and waste age at the peak temperature for the MSW is provided in Table 2. At different landfills, the peak temperature, waste age at peak temperature and peak temperature location are different. The main reasons are as follows: The organic matter content in the waste of different landfills is different (Qian et al. 2011). The high organic matter content in the waste produces more heat through biodegradation reaction (Hao et al. 2017), which causes the higher peak temperature. However, the rate of consumption of organic matter is different in the complex condition, which causes a difference in waste age at peak temperature. And then the heat production of waste and its heat production rate are also different in the different environments (Hanson et al. 2008, 2013), which also cause the different peak temperature and waste age at peak temperature. In addition, the placement process, climatic conditions, waste components and water content determine peak temperature and peak temperature location (Yesiller and Hanson 2003). In a word, the peak temperature is collectively determined by all these properties. Even if a few parameters are similar, the peak temperature may be different. In the Wuxi landfill, the MSW in the test area was placed in the winter and the water content, unit weight and void ratio for the MSW were 34.9%, 7 kN m−3 and 4.0, respectively. The maximum waste temperature in newly filled MSW layer was 42 °C under the above conditions.

Gas Pressure During the Monitoring Test

Gas pressure variations with time in the newly filled MSW layer are shown in Fig. 8. The gas pressure in #0 well varied between 4 and 30 Pa. The gas pressures in #3, #5, #7 and #8 wells (with bottom elevations of + 5.5 m, + 4.7 m, + 6.1 m and + 4.1 m, respectively), whose bottoms were above the leachate level, varied between 0 and 30 Pa. The bottoms of #1, #2, #4, #6 and #9 wells (with bottom elevations of + 0.2 m, + 3.5 m, + 3.5 m, + 2.0 m and + 4.1 m, respectively) were below the leachate level, and the screen sections of these wells were submerged in the leachate which made the measurement of gas pressure very difficult. The perforated pipe of the gas collection well was submerged by leachate, which decreased the efficiency of landfill gas collection as this observation was reported by Townsend et al. (2015) and Zhan et al. (2015). The difficulty involved in the flow of landfill gas through the leachate barrier into the well has been illustrated. In addition, the gas permeability of highly saturated waste is relatively low (Shi et al. 2018); therefore, the migration of landfill gas below the leachate level comes with much difficulty. Then the gas pressures measured at the well-heads of these wells only varied between 0 and 3 Pa, except time C to time D (the stage of the leachate pumping test). Local fluctuations in the gas pressures occurred in #0, #3, #5, #7 and #8 wells because of the minor fluctuations in the atmospheric pressure. However, owing to the accelerated waste biodegradation (Findikakis et al. 1988; Liu et al. 2011), there was a steady increase in the overall trend of the gas pressures before the peak values were reached on May 4, 2016 (approximately day 95 for the commencement of gas pressure monitoring). Thereafter, it slowly decreased in the case of a minimal variation in water content due to the decelerated waste biodegradation (Findikakis et al. 1988; Liu et al. 2011). In the laboratory tests conducted by Ahmadifar et al. (2016) and Mahar et al. (2016), the rate of gas production decreased after the MSW was placed in the anaerobic bioreactor for 109 days and 65 days, respectively. In this study, the screen sections of #3 and #5 wells got submerged with the increase in the leachate level after time G, which presented a difficulty in monitoring gas pressures in #3 and #5 wells (with bottom elevations of + 5.5 m and + 4.7 m, respectively); thereafter the gas pressures later decreased to nearly zero.

Gas pressure variations with time in the newly filled MSW layer. (Note: gas pressure is relative to the atmospheric pressure; the bottom elevations of #0, #1, #2, #3, #4, #5, #6, #7, #8 and #9 wells are + 0.0 m, + 3.5 m, + 0.2 m, + 5.5 m, + 3.5 m, + 4.7 m, + 2.0 m, + 6.8 m, + 6.1 m and + 4.1 m, respectively)

Gas pressure variations with elevation in the newly filled MSW layer are shown in Fig. 9; the gas pressure below the leachate level varied between 0 and 3 Pa. The gas pressure increased with the decrease in the elevation above the leachate level, and its maximum value occurred near the leachate level. Because porosity decreases with depth in landfills (Chen et al. 2009; Feng et al. 2017), pore volume decreases with depth. When gas production is equal in the waste and waste temperature increases with depth above the leachate level, gas pressure also increases with depth. Hashemi et al. (2002) also found that the gas pressure increases with depth by calculating the mathematical model, and the range of the gas pressure is between 0.011 and 0.075 kPa at a depth of 4 m. A summary of the maximum gas pressures for MSW landfills at different depths is provided in Table 3. In the landfills shown in Table 3, the maximum gas pressures differs at different depths. The maximum measured gas pressures in landfills are as low as 0.01 kPa and as high as 3.81 kPa. Although the maximum value of gas pressure in this study is relatively low, the value is within this range. Cellulose and hemicellulose are the main sources of gas production (Mehta et al. 2002; Liu et al. 2011). The content of cellulose and hemicellulose in waste may be relatively low in the test area of this study. Furthermore, it is also found that the methane generation potential of waste in Chinese landfills is generally lower than that in European and American landfills (Amini et al. 2012). In addition, the gas pressure increases with depth under the conditions where the bottom of the landfill is an impermeable boundary (Townsend et al. 2005); then the gas pressure measured in shallower waste layer is relatively low. The water content, waste temperature, void ratio and other parameters in the test area also jointly determine the relatively small value of gas pressure measured in this study.

Results and Discussion for the Leachate Pumping Test

Leachate Level during the Leachate Pumping Test

The leachate pumping test was conducted after the gas pressure; temperature and leachate levels were relatively stable. The accumulated pumping volume and the leachate level during the pumping test are shown in Fig. 10. Elevations of leachate Levels and pumping volume at different times and stages during the leachate pumping test are shown in Table 4. The leachate pumping test can be divided into five stages. Stage I–II was trial stage, which was to inspect the technical parameters of the equipment and the procedures of the leachate pumping test. Stage II–III was adjusting stage, which was to adjust the equipment parameters and pumping process, such as the inlet of the QJY-TSP was wrapped with a nylon wire netting to prevent clogging. Stage III–IV was pumping stage, which was carried out to decrease the leachate level. In this stage, the oscillations in the leachate level during this stage occurred in #0, #1, #2 and #6 wells, because the leachate pumping was alternately conducted and stopped to maintain a lower pumping rate. Because the QJY-TSP QJY-TSP operating at a high pumping rate was readily to be damaged by the fine particles existed in leachate. However, the oscillations in the leachate level did not occur in #4 and #9 wells, because the two wells were relatively far from #0 well (distances between #0 well and #4 and #9 wells were 9.4 m and 11.3 m, respectively). The screen section of #9 well was less and less submerged in the leachate. Stage IV–V was stable stage, which was to stabilize the leachate level, and study the stabilities of gas pressure and temperature. In this stage, the elevation of leachate level in #0 well was controlled between + 2.95 m and + 3.09 m by an automatic pump controller. The amplitudes of the leachate levels in #1, #2, #4, #6 and #9 wells (with bottom elevations of + 0.2 m, + 3.5 m, + 3.5 m, + 2.0 m and + 4.1 m, respectively) were controlled within 30 mm. The screen section of #9 well was rarely submerged in the leachate. Stage V–VI was recovering stage, which was to study the effect of leachate level on temperature and gas pressure after leachate pumping was stopped. In this stage, the screen section of #9 well was gradually submerged in the leachate again. The elevations of leachate levels at time VI did not get to the initial elevations of the leachate levels, as shown in Fig. 10. The range of differences was 0.0–0.41 m. The differences between the initial leachate level and the recovered leachate level are also presented in the leachate pumping tests reported by Zhan et al. (2014) and Slimani et al. (2017), with the maximum differences of 1.3 and 1.4 m, respectively. It is possible that there was not enough time for the leachate level to recover.

Accumulated pumping volume and leachate levels with time during the leachate pumping test. (Note: Q—accumulated pumping volume; 0, 1, 2, 4, 6 and 9—Leachate levels in #0, #1, #2, #4, #6 and #9 wells, respectively; the bottom elevations of #0, #1, #2, #4, #6 and #9 wells are + 0.0 m, + 0.2 m, + 3.5 m, + 3.5 m, + 2.0 m and + 4.1 m, respectively)

The extraction well (#0 well) used in the leachate pumping test was a partially penetrating well. In order to calculate the horizontal permeability for MSW, the waste in the horizontal direction of the new MSW layer was assumed to be homogeneous, and the pumping well was divided into two sections using Dupuit–Babushkin method mentioned in Ministry of Water Resources of the People’s Republic of China (MWR) (2005). The height of the dividing point is l, which is relative to the bottom height of pumping well. l can be expressed as

where Ha represents average height of aquifer with waste, which is relative to the bottom height of pumping well; S0 represents drawdown in pumping well. The upper section of pumping well can be treated as a fully penetrating well, and according to the standard (Ministry of Water Resources of the People’s Republic of China (MWR) 2005), the pumping flowrate from the upper section of pumping well can be expressed as follows:

where Q1 represents pumping flowrate from the upper section of pumping well; K represents horizontal permeability for MSW; i and j represent the well number; Hi and Hj represent the heights of leachate level in #i and #j wells, which are relative to the bottom height of pumping well, respectively; ri and rj represent the distances from #i and #j wells to the. pumping well, respectively.

The lower section of pumping well can be treated as a partially penetrating well. When l/2 < 0.3 M (where M represents the thickness of confined aquifer), according to the standard (Ministry of Water Resources of the People’s Republic of China (MWR) 2005), the pumping flowrate from the lower section of pumping well can be expressed as

where Q2 represents pumping flowrate from the lower section of pumping well; r0 represents the radius of pumping well.

Equation (2) plus Eq. (3), total pumping flowrate from pumping well can be expressed as follows:

where Q represents total pumping flowrate from pumping well. Hence, horizontal permeability for MSW can be expressed as follows:

According to Eq. (5) and the leachate levels in #0, #1, #2, #4, #6 and #9 wells, the horizontal permeability for MSW can be calculated. Its range was 4.64 × 10−6–5.15 × 10−5 m s−1 in the newly filled MSW layer of Wuxi landfill based on the Dupuit-Babushkin method. A summary of horizontal permeabilities for MSW and soil from field pumping tests is presented in Table 5. It is found that the MSW permeability measured by Oweis et al. (1990); Jones et al. (1992) and Jang (2000) in the New Jersey, Iowa and Kimpo landfills, respectively, fall within the range of this test results. But the test results fall within the MSW permeability measured by Slimani et al. (2017) in a landfill located in France. The MSW permeability measured by Shank (1993); Olivier et al. (2009) and Zhan et al. (2014) for the Florida, northern France and Suzhou landfills, respectively, correspond with the present test results in the order of magnitude. It is also found that the MSW permeability is equivalent to that of fine sand, silty sand and silt in the order of magnitude. However, there are differences with the results of this test, which are related to the anisotropy of the MSW in the landfill. Because component, porosity, waste age, density, depth and other parameters collectively determine the MSW permeability (Carman 1939; Olivier and Gourc 2007; Reddy et al. 2009; Feng et al. 2017).

Figure 11 exhibits the radial distribution of the drawdown when the leachate pumping was stopped. Slimani et al. (2017) conducted a pumping test in July 2010, in which the pumping well (diameter: 1 m; depth: 14 m) was a fully penetrating well; two flowrates (0.5 m3 h−1 and 0.9 m3 h−1) were chosen, and 53 m3 of leachate was pumped during 70 h after which the leachate pumping was stopped. A partially penetrating well was used in this test, and the pumped volume and pumped time were 120 m3 and 529 h, respectively. This test consisted of five stages, and the associated procedure is different from that employed by Slimani et al. (2017); in particular, this test includes a leachate level controlling stage. When the leachate pumping was stopped, the drawdowns in the pumping well obtained from this test and the test of Slimani et al. (2017) were 1.4 m and 3.8 m, respectively, because the above parameters and MSW permeability (2 × 10−6–3 × 10−4 m s−1 in Slimani et al. 2017) in the two landfills are different. However, depression cones are nicely exhibited, even when the leachate flows in the heterogeneous MSW.

Temperature during the Leachate Pumping Test

Temperature variations with time in the newly filled MSW layer during the leachate pumping test are shown in Fig. 12. Compared with the initial leachate level, the leachate level had decreased by approximately 0.4–1.5 m in stage IV–V. The temperatures at the bottoms of #0, #1, #2, #4, #6 and #9 wells (with bottom elevations of + 0.0 m, + 0.2 m, + 3.5 m, + 3.5 m, + 2.0 m and + 4.1 m, respectively) increased and the maximum increments in the temperatures were 3.2 °C, 3.5 °C, 4.1 °C, 0.2 °C, 1.3 °C and 0.5 °C, respectively. The water content in the leachate level decreasing zone was suitable for waste biodegradation, which resulted in an increase in temperature during the leachate pumping test. In addition, the higher temperature was transferred to the bottoms of these wells due to the heat convection caused by the leachate pumping. The temperatures at the bottoms of #0, #1, #2, #6 and #9 wells slightly decreased after the leachate pumping was stopped and the leachate levels slowly recovered. But the temperatures when the leachate level had stably recovered were still higher than the initial temperatures at the beginning of the leachate pumping test, the range of differences was 0.5-2.5 °C. Because the elevated temperature was slowly transferred to surrounding waste, and the heat was continuously generated by MSW biodegradation.

Gas Pressure During the Leachate Pumping Test

Gas pressure variations with time in the newly filled MSW layer during the leachate pumping test are shown in Fig. 13. The maximum increments in the gas pressures of #3, #5, #7 and #8 wells (with bottom elevations of + 5.5 m, + 4.7 m, + 6.1 m and + 4.1 m, respectively), whose bottoms were above the leachate level, were lesser than that in the gas pressures of #1 and #9 wells (with bottom elevations of + 3.5 m and + 4.1 m, respectively), whose bottoms were below and close to the leachate level. In all the monitoring wells, the change in the gas pressure was particularly evident in #9 well, because the screen section of #9 well was rarely submerged in the leachate during the leachate pumping. The simultaneous variations of leachate level and gas pressure in #9 well and bottom temperature of #9 well during the leachate pumping test are shown in Fig. 14. During the stage I–IV, the gas pressure increased almost synchronously with the decrease in the leachate level. It slowly increased, because the screen section of #9 well was less and less submerged in the leachate. However, the increase in temperature was delayed for approximately 3 days, after which, the temperature increased by 0.6 °C due to the suitable water content for waste biodegradation in the leachate level decreasing zone. Furthermore, the range of the waste temperature in this zone was beneficial to the increase in the gas pressure. Because the suitable water content to maximize the gas production is between 50 and 75% (Tchobanoglous et al. 1977; Kasali 1986), the water content in this zone is less than 75%, which is within the range of suitable water content. In addition, the suitable temperature for the gas production from waste biodegradation is between 34 and 45 °C (Rees 1980; Hartz et al. 1982; Mata-Alvarez and Martinez-Viturtia 1986), and the range of temperature in this zone is 41.2–41.8 °C, which is within the range of suitable temperatures. During the stage IV–V, compared with the initial leachate level, the leachate level decreased by approximately 44 cm. When the leachate level remained at the stable elevation, gas pressure and temperature attained a new equilibrium at the bottom of #9 well, and only minor variations in the ranges of 33–39 Pa and 41.6–41.7 °C, respectively, were noted. A stable temperature was also one of the conditions for maintaining the stability of the gas pressure. During the stage V–VI, when the leachate pumping was stopped, the leachate level started increasing after approximately 1 day, because the #9 well was relatively far from the #0 well (distance between #0 well and #9 well was 11.3 m), resulting in a gas pressure that was still in the range of 36–42 Pa. About a day after the leachate pumping was stopped, the screen section of #9 well was slowly submerged, and the gas pressure slowly decreased. When the screen section of #9 well was entirely submerged, the gas pressure decreased to 3 Pa. However, the temperature practically did not decrease, because the processes of heat conduction and convection were slow at the bottom of #9 well and the waste biodegradation still continued. Thus, the gas pressure was affected collectively by the water content and temperature in the waste.

Conclusions

The monitoring and leachate pumping tests were conducted in a newly filled MSW layer of a landfill. Simultaneous variations of leachate level, temperature and gas pressure in the waste landfill were investigated. The MSW characteristics of a landfill in southeastern China are defined by the field test data for determining engineering performance. The monitoring method in this study is effective, and it provides reliable results for practical engineering conditions. Summaries of leachate level, temperature and gas pressure in newly filled MSW layer are shown in Table 6, and the following main conclusions can be drawn from the two tests.

The conclusions from the monitoring test are as follows: (1) The laying of HDPE geomembrane on the landfill surface effectively impeded the permeation of rainfall and snow into landfill. (2) The fluctuating landfill surface temperature was higher than the ambient mean temperature with an average value of 7.0 °C. The highest temperature observed in the waste occurred near the leachate level. The waste temperatures were slightly affected by the ambient temperature when the depth was more than 2.05 m. The waste temperatures rapidly increased in the first 12 days; subsequently the waste temperature increased slowly before the temperature reached the peak value. (3) The gas pressure above the leachate level increased with depth in the newly filled MSW layer.

The conclusions from the leachate pumping test are as follows: (1) The range of MSW permeability was 4.64 × 10−6–5.15 × 10−5 m s−1 in the Wuxi landfill. The elevations of the leachate levels did not reach the initial elevations after the leachate levels had stably recovered, and the differences were 0.08–0.41 m. (2) The maximum increments of the waste temperatures were 0.5–4.1 °C during the leachate pumping test. When the leachate level had stably recovered the waste temperatures slightly decreased, but the temperatures were still higher than the initial temperatures and the differences were 0.5–2.5 °C. (3) The gas pressure in the leachate level decreasing zone increased to 33–42 Pa during the leachate pumping test, and it was higher than that at other areas above the leachate level at this period. When the leachate level had stably recovered, it decreased to nearly zero. The variation in the water content caused by the change in the leachate level affected the temperature and gas pressure in the waste. The gas pressure was collectively affected by the water content and temperature in the waste.

Overall, the field tests are significant to the design and operation of MSW landfill. The correlation between the variations in leachate level, temperature and gas pressure in the newly filled MSW layer is analyzed, which establishes the behavior of one of the MSW characteristics. The following suggestions for landfill operation are offered: (1) A complete monitoring system should be established; (2) newly filled MSW layer should be covered with an HDPE geomembrane in time; (3) high temperature near the leachate level should be noticed; (4) the leachate level in pumping well should be maintained at a relatively constant depth, which is beneficial to increase the gas production and stabilizes the gas pressure and the temperature in the leachate level decreasing zone.

References

Ahmadifar M, Sartaj M, Abdallah M (2016) Investigating the performance of aerobic, semi-aerobic, and anaerobic bioreactor landfills for MSW management in developing countries. J Mater Cycles Waste Manag 18(4):703–714

Al-Thani AA, Beaven RP, White JK (2004) Modelling flow to leachate wells in landfills. Waste Manag 24(3):271–276

Amini HR, Reinhart DR, Mackie KR (2012) Determination of first-order landfill gas modeling parameters and uncertainties. Waste Manag 32(2012):305–316

Batali L, Carastoian A, Popa H, Pantel G (2017) Instability phenomena in municipal waste landfill. Numerical modeling in saturated and unsaturated conditions. Energ Proc 112(2017):481–488

Bentley HW, Smith SJ, Tang J, Walter GR (2003) A method for estimating the rate of landfill gas generation by measurement and analysis of barometric pressure waves. In: Proceedings of the 18th International Conference on Solid Waste Technology and Management, Philadelphia, USA

Blight G (2008) Slope failures in municipal solid waste dumps and landfills: a review. Waste Manag Res 26(5):448–463

Bonany JE, Van Geel PJ, Burak GH, Burkan IO (2013) Heat budget for a waste lift placed under freezing conditions at a landfill operated in a northern climate. Waste Manag 33(5):1215–1228

Bouazza A, Nahlawi H, Aylward M (2011) In situ temperature monitoring in an organic-waste landfill cell. J Geotech Geoenviron Eng 137(12):1286–1289

Carman PC (1939) Permeability of saturated sands, soils and clays. J Agric Sci 29(02):262–273

Chapuis RP, Chenaf D, Acevedo N, Marcotte D, Chouteau M (2005) Unusual drawdown curves for a pumping test in an unconfined aquifer at Lachenaie, Quebec: field data and numerical modeling. Can Geotech J 42(4):1133–1144

Chen YM, Zhan TL, Wei HY, Ke H (2009) Aging and compressibility of municipal solid wastes. Waste Manag 29(1):86–95

China Meteorological Administration Public Meteorological Service Center (CMAPMSC) (2016, 2017). http://www.weather.com.cn/. Accessed 18 Jan 2016–18 Jun 2017

Collins F, Orpen D, Mcnamara E, Fay C, Diamond D (2013) Landfill gas monitoring network: development of wireless sensor network platforms. In: Proceedings of the 2nd International Conference on Sensor Networks, Limerick, Ireland

Dho NY, Koo JK, Lee SR (2002) Prediction of leachate level in Kimpo metropolitan landfill site by total water balance. Environ Monit Assess 73(3):207–219

El-Fadel M (1999) Leachate recirculation effects on settlement and biodegradation rates in MSW landfills. Environ Tech Lett 20(2):121–133

Faitli J, Erdelyi A, Kontra J, Magyar T, Varfalvi J, Muranyi A (2015) Pilot scale decomposition heat extraction and utilization system built into the “Gyal Municipal Solid Waste Landfill”. In: Proceedings of 15th International Waste Management and Landfill Symposium, Cagliari, Italy

Feng SJ, Zheng QT, Xie HJ (2015) A model for gas pressure in layered landfills with horizontal gas collection systems. Comput Geotech 68(6):117–127

Feng SJ, Gao KW, Chen YX, Li Y, Zhang LM, Chen HX (2017) Geotechnical properties of municipal solid waste at Laogang landfill, China. Waste Manag 63(2017):354–365

Findikakis AN, Papelis C, Halvadakis CP, Leckie JO (1988) Modelling gas production in managed sanitary landfills. Waste Manag Res 6(2):115–123

Gallagher EM, Tonks DM, Shevelan J, Belton AR, Blackmore ER (2016) Investigations of geomembrane integrity within a 25-year old landfill capping. Geotext Geomembr 44(5):770–780

Gebert J, Groengroeft A (2006) Passive landfill gas emission—influence of atmospheric pressure and implications for the operation of methane-oxidising biofilters. Waste Manag 26(3):245–251

Gholamifard S, Eymard R, Duquennoi C (2008) Modeling anaerobic bioreactor landfills in methanogenic phase: long term and short term behaviors. Water Res 42(20):5061–5071

Giri RK, Reddy KR (2014) Slope stability of bioreactor landfills during leachate injection: effects of heterogeneous and anisotropic municipal solid waste conditions. Waste Manag Res 32(3):186–197

Hanson J, Yesiller N, Howard KA, Liu WL, Cooper SP (2006) Effects of placement conditions on decomposition of municipal solid wastes in cold regions. In: Proceedings of the 13th International Conference on Cold Regions Engineering, Orono, Maine, USA

Hanson JL, Liu WL, Yesiller N (2008) Analytical and numerical methodology for modeling temperatures in landfills. Geotechnics of waste management and remediation, ASCE GSP 177, Reston, USA

Hanson JL, Yesiller N, Oettle NK (2010) Spatial and temporal temperature distributions in municipal solid waste landfills. J Environ Eng 136(8):804–814

Hanson JL, Yesiller N, Onnen MT, Liu LW, Oettle NK (2013) Development of numerical model for predicting heat generation and temperatures in MSW landfills. Waste Manag 33:1993–2000

Hao Z, Sun M, Ducoste JJ, Benson CH, Luettich S, Castaldi MJ, Barlaz MA (2017) Heat generation and accumulation in municipal solid waste landfills. Environ Sci Technol 51(21):12434–12442

Hartz KE, Klink RE, Ham RK (1982) Temperature effects: methane generation from landfill samples. J Environ Eng Div 108(4):629–638

Hashemi M, Kavak HI, Tsotsis TT, Sahimi M (2002) Computer simulation of gas generation and transport in landfills-I: quasi-steady-state condition. Chem Eng Sci 57(13):2475–2501

Jafari NH, Stark TD, Thalhamer T (2017) Progression of elevated temperatures in municipal solid waste landfills. J Geotech Geoenviron Eng 143(8):05017004

Jang YS (2000) Analysis of flow behavior in a landfill with cover soil of low hydraulic conductivity. Environ Geol 39(3–4):292–298

Jang YS, Kim YI (2003) Behavior of a municipal landfill from field measurement data during a waste-disposal period. Environ Geol 44(5):592–598

Jones LD, Lemar T, Tsai CT (1992) Results of two pumping tests in Wisconsin age weathered till in Iowa. Ground Water 30(4):529–538

Jung Y, Imhoff P, Finsterle S (2011) Estimation of landfill gas generation rate and gas permeability field of refuse using inverse modeling. Transp Porous Med 90(1):41–58

Kadambala R, Townsend TG, Jain P, Singh K (2011) Temporal and spatial pore water pressure distribution surrounding a vertical landfill leachate recirculation well. Int J Environ Res Publ Health 8(5):1692–1706

Kadambala R, Powell J, Singh K, Townsend TG (2016) Evaluation of a buried vertical well leachate recirculation system for municipal solid waste landfills. Waste Manag Res 34(12):1300–1306

Kasali GB (1986) Optimisation and control of methanogenesis in refuse fractions. Ph. D. Thesis, University of Strathclyde, Glasgow, UK

Kjeldsen P, Fischer EV (1995) Landfill gas migration-field investigations at Skellingsted landfill, Denmark. Waste Manag Res 13(5):467–484

Ko JH, Powell J, Jain P, Kim HD, Townsend T, Reinhart D (2013) Case study of controlled air addition into landfilled municipal solid waste: design, operation, and control. J Hazard Toxic Radioact Waste 17(4):351–359

Koerner GR, Koerner RM (2006) Long-term temperature monitoring of geomembranes at dry and wet landfills. Geotext Geomembr 24(1):72–77

Koerner RM, Soong TY (2000) Leachate in landfills: the stability issues. Geotext Geomembr 18(5):293–309

Krushelnitzky RP, Brachman RWI (2013) Buried high-density polyethylene pipe deflections at elevated temperatures. Geotext Geomembr 40(5):69–77

Larson J, Kumar S, Gale SA, Jain P, Townsend T (2012) A field study to estimate the vertical gas diffusivity and permeability of compacted MSW using a barometric pumping analytical model. Waste Manag Res 30(3):276–284

Lee J, Lee C, Lee K (2002) Evaluation of air injection and extraction tests in a landfill site in Korea: implications for landfill management. Environ Geol 42(8):945–954

Lee JY, Cheon JY, Kwon HP, Yoon HS, Lee SS, Kim JH, Kim CG (2006) Attenuation of landfill leachate at two uncontrolled landfills. Environ Geol 51(4):581–593

Lefebvre X, Lanini S, Houi D (2000) The role of aerobic activity on refuse temperature rise, I, Landfill experimental study. Waste Manag Res 18(5):444–452

Liu XD, Shi JY, Qian XD, Hu YD, Peng GX (2011) One-dimensional model for municipal solid waste (MSW) settlement considering coupled mechanical-hydraulic-gaseous effect and concise calculation. Waste Manag 31(12):2473–2483

Liu L, Xue Q, Zeng G, Ma J, Liang B (2016) Field-scale monitoring test of aeration for enhancing biodegradation in an old landfill in China. Environ Prog Sustain Energy 35(2):380–385

Liu L, Ma J, Xue Q, Zeng G, Zhao Y (2017) The viability of design and operation of the air injection well for improvement in situ repair capacity in landfill. Environ Prog Sustain Energy 36(2):412–419

Lu AH, Kunz CO (1981) Gas-flow model to determine methane production at sanitary landfills. Environ Sci Technol 15(4):436–440

Mahar RB, Sahito AR, Yue D, Khan K (2016) Modeling and simulation of landfill gas production from pretreated MSW landfill simulator. Front Environ Sci Eng 10(1):159–167

Marco D, Andrea Z, Fausto C (2018) Oscillatory pumping test to estimate aquifer hydraulic parameters in a Bayesian geostatistical framework. Math Geosci 50(2):169–186

Martin S, Maranon E, Sastre H (1997) Landfill gas extraction technology: study, simulation and manually controlled extraction. Bioresour Technol 62(1–2):47–54

Mata-Alvarez J, Martinez-Viturtia A (1986) Laboratory simulation of municipal solid waste fermentation with leachate recycle. J Chem Technol Biotechnol 36(12):547–556

Mehta R, Barlaz MA, Yazdani R, Augenstein D, Bryars M, Sinderson L (2002) Refuse decomposition in the presence and absence of leachate recirculation. J Environ Eng 128(3):228–236

Ministry of Water Resources of the People’s Republic of China (MWR) (2005) Borehole pumping test procedures for water resources and hydropower engineering SL 320-2005. China Water Power Press, Beijing

Niemann WL, Rovey CW (2000) Comparison of hydraulic conductivity values obtained from aquifer pumping tests and conservative tracer tests. Ground Water Monit Remediat 20(3):122–128

Olivier F, Gourc JP (2007) Hydro-mechanical behavior of municipal solid waste subject to leachate recirculation in a large-scale compression reactor cell. Waste Manag 27(1):44–58

Olivier F, Oxarango L, Mugnier V, Tinet AJ, Marcoux MA (2009) Estimating the drawdown of leachate in a saturated landfill: 3D modeling based on field pumping tests. In: Proceedings of the 12th International Waste Management and Landfill Symposium, S. Margherita di Pula, CISA, Cagliari, Italy

Oweis IS, Smith DA, Ellwood RB, Greene DS (1990) Hydraulic characteristics of municipal refuse. J Geotech Eng 116(4):539–553

Powell J (2005) Trace gas quality, temperature control and extent of influence from air addition at a bioreactor landfill. Master Thesis, University of Florida, Gainesville, Florida, USA

Powell JT, Townsend TG, Zimmerman JB (2015) Estimates of solid waste disposal rates and reduction targets for landfill gas emissions. Nat Clim Change 6(2):162–165

Qian XD, Shi JY, Liu XD (2011) Design and construction of modern sanitary landfill, 2nd edn. China Architecture and Building Press, Beijing

Reddy KR, Hettiarachchi H, Parakalla NS, Gangathulasi J, Bogner JE (2009) Geotechnical properties of fresh municipal solid waste at Orchard Hills Landfill, USA. Waste Manag 29(2):952–959

Rees JF (1980) Optimisation of methane production and refuse decomposition in landfills by temperature control. J Chem Tech Biotechnol 30(1):458–465

Reinhart D, Cooper D, Walker B (1992) Flux chamber design and operation for the measurement of municipal solid waste landfill gas emission rates. Air Repair 42(8):1067–1070

Rowe RK, Nadarajah P (1996) Estimating leachate drawdown due to pumping wells in landfills. Can Geotech J 33(1):1–10

Shank KL (1993) Determination of the hydraulic conductivity of the Alachua county southwest landfill. Master Thesis, University of Florida, Gainesville, USA

Shen SL, Wu YX, Xu YS, Hino T, Wu HN (2015) Evaluation of hydraulic parameters from pumping tests in multi-aquifers with vertical leakage in Tianjin. Comput Geotech 68(7):196–207

Shi JY, Wu X, Ai YB, Zhang Z (2018) Laboratory test investigations on soil water characteristic curve and air permeability of municipal solid waste. Waste Manag Res 36(5):463–470

Slimani R, Oxarango L, Sbartai B, Tinet AJ, Olivier F, Dias D (2017) Leachate flow around a well in MSW landfill: analysis of field tests using Richards model. Waste Manag 63(2017):122–130

Spokas KA, Bogner JE (1996) Field system for continuous measurement of landfill gas pressures and temperatures. Waste Manag Res 14(3):233–242

Stevens WD (2012) An empirical analysis of gas well design and pumping tests for retrofitting landfill gas collection. Master Thesis, University of Saskatchewan, Saskatoon, Canada

Tchobanoglous G, Theisen H, Eliassen R (1977) Solid wastes: engineering principles and management issues. Mcgraw-Hill, Toronto

Townsend TG, Miller WL, Lee HJ, Earle JFK (1996) Acceleration of landfill stabilization using leachate recycle. J Environ Eng 122(4):263–268

Townsend TG, Wise WR, Jain P (2005) One-Dimensional gas flow model for horizontal gas collection systems at municipal solid waste landfills. J Environ Eng 131(12):1716–1723

Townsend TG, Powell J, Jain P, Xu Q, Tolaymat T, Reinhart D (2015) Sustainable practices for landfill design and operation. Waste Management Principles and Practice. Springer, New York

Vaverkova M, Adamcova D (2015) Long-term temperature monitoring of municipal solid waste landfill. Pol J Environ Stud 24(3):1373–1378

Wu YX, Shen JS, Chen WC, Hino T (2017) Semi-analytical solution to pumping test data with barrier, wellbore storage, and partial penetration effects. Eng Geol 226(2017):44–51

Yesiller N, Hanson JL (2003) Analysis of temperatures at a municipal solid waste landfill. In: Proceedings of the 9th International Waste Management and Landfill Symposium, Christensen et al (eds), CISA, Sardinia, Italy

Yesiller N, Hanson JL, Yee EH (2015) Waste heat generation: a comprehensive review. Waste Manag 42(2015):166–179

Yesiller N, Hanson JL, Kopp KB (2016) The design and installation of a prototype heat extraction system at a municipal solid waste landfill. Geo-Chicago: Sustainability, Energy and the Geoenvironment, Chicago, USA

Yoshida H, Rowe RK (2003) Consideration of landfill liner temperature. In: Proceedings of the 9th International Waste Management and Landfill Symposium, S. Margherita di Pula, CISA, Cagliari, Italy

Yuen STS, Wang QJ, Styles JR, Mcmahon TA (2001) Water balance comparison between a dry and a wet landfill—a full-scale experiment. J Hydrol 251(1–2):29–48

Zhan LT, Hui XU, Lan JW, Zhao L, Chen YM (2014) Field and laboratory study on hydraulic characteristics of MSWs. J Zhejiang Univ (Eng Sci E) 48(3):478–486 (in Chinese)

Zhan LT, Xu XB, Chen YM, Ma XF, Lan JW (2015) Dependence of gas collection efficiency on leachate level at wet municipal solid waste landfills and its improvement methods in China. J Geotech Geoenviron Eng 141(4):040150021

Zhang T (2017) Temperature monitoring during water injection test using vertical well in a newly filled MSW layer of a landfill. Research Report, Hohai University, Nanjing, China, (in Chinese)

Acknowledgements

The authors express their appreciation to Leslie Okine for checking and revising the language of this paper, and appreciate the financial support provided by the National Natural Science Foundation of China (No. 41530637, No. 41372268 and No. 41877222).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Zhang, T., Shi, J., Qian, X. et al. Temperature and Gas Pressure Monitoring and Leachate Pumping Tests in a Newly Filled MSW Layer of a Landfill. Int J Environ Res 13, 1–19 (2019). https://doi.org/10.1007/s41742-018-0157-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41742-018-0157-0