Abstract

A prototype thick-GEM-based cooling storage ring external-target experiment (CEE) time projection chamber (TPC) is constructed and tested with the pulsed ultraviolet laser beams. The results indicate that the prototype TPC has a good performance in three-dimensional track resolution. In X direction the position resolution is about 0.2 mm, and in Y direction the position resolution is about 0.5 mm. The results also determine that the energy resolution is about 5.4%, which achieve the requirements of the CEE experiment and can be used to study the nuclear state equation and the quantum chromo dynamics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

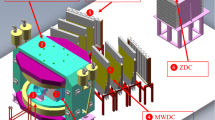

Experiments of heavy-ion collisions using high-energy beams from the Heavy Ion Research Facility at Lanzhou-Cooling Storage Ring (HIRFL-CSR) [1] provide a significant opportunity to study the nuclear equation of state at high baryon densities [2, 3] and the Quantum Chromo Dynamics (QCD) phase diagram, especially the possible existence of critical point [4] and quarkoyanic matter [5, 6]. The HIRFL-CEE spectrometer [7,8,9,10,11,12,13,14,15,16] is conceptually designed to measure the various products of 100 to 800 MeV/u heavy-ion beams hitting on a heavy-ion target. In the CEE spectrometer, at the center of the homogeneous magnetic field provided by a large acceptance superconducting dipole, a time projection chamber (TPC) [17] is designed to be installed. The task of the TPC is to provide track reconstruction, particle identification and momentum measurement of the light charged particles. The sensitive volume of the TPC is about 90 cm (length) × 100 cm (width) × 80 cm (height).

Before the construction of the full-scale CEE-TPC, a small prototype TPC should be constructed and tested to determine whether the TPC’s performance meets the experiment’s requirements. The 3D track resolution and energy loss resolution of charged particles are essential in the TPC performance. Furthermore, a laser beams calibration system is required for the large volume type of TPC [18]. This article provides the description of the prototype CEE-TPC and test results of laser beams.

2 Detector design

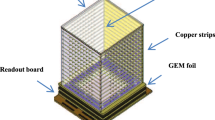

The prototype CEE-TPC is also a cubic shape TPC, whose sensitive volume is 20 cm (length) × 20 cm (width) × 22 cm (height). A photo of prototype TPC’s field cage is shown in left image of Fig. 1, and the photo of the laser test’s setup is shown in the right image of Fig. 1. The top panels are one layer thick Gas Electron Multiplier (GEM) foil and the readout plane, while the bottom panel is the cathode. The electron drifting field cage lies between the top panels and the bottom panel. The walls of the field cage are made of two kinds of layers, gold-plated metal and insulative plastic. The metal and plastic is arranged at regular intervals that the width of the gold-plated metal is 6 mm and the width of insulative plastic is 4 mm. In order to produce step voltage between the metal strips and fill the cage with an electric field with perfectly uniform intensity, there is a divider resistor of 20 MΩ soldered between adjacent metal strips. The thickness of the GEM foil [19,20,21,22] is 0.6 mm. The diameter of holes in the GEM foil is 0.6 mm, and the distance between the holes is 1.1 mm.

Figure 2 shows the working principle of TPC. The readout panel is divided into several pads and each pad is connected to one channel of preamplifier. The arrow shows the incident direction of the laser beam, and there are three dimensions, X, Y, and Z. The X–Z plane is parallel to the readout plane, and the Y coordinate is perpendicular to X–Z plane. There are two types of pads in this prototype. The size of the rectangle pad is 8 mm (width) × 10 mm (length). The triangle pad can provide precise position resolution in the X direction using the charge-weighting technique.

3 Experimental results

3.1 The energy loss and its resolution

The gas mixture of this TPC is composed of 90% argon, 7% methane, and 3% CF4. A pulsed laser beam with 266 nm in wavelength, which imitates straight charged particle tracks, is used to test the prototype CEE-TPC at three gas pressure conditions (101, 75, and 50 kPa). First, the dependence of the energy loss of the laser beam in the gas on the high voltage applied on the GEM foil is studied. Figure 3 shows that the energy loss of the laser beam increases exponentially with the increase of the high voltage applied on the GEM foil. This figure helps to choose an appropriate voltage during the experiment. It is more difficult to apply high voltage on GEM foil, if the gas pressure is lower, the detector could generate sparks more easily. However, changing the voltage among the drift cage or the voltage between the GEM foil and anode panel has a slight effect on the gain of the GEM foil, because changing the voltage slightly changes the electric field near the holes of the GEM foil.

We used a Laser Pyroelectric Energy Sensor to measure the energy of the laser beam per pulse with a wavelength of 266 nm. Figure 4 shows that there is a linear correlation between the energy of the laser beam and energy loss measured on one readout pad. Also the smaller of the gas pressure, the less the energy loss of laser beam. Since the instability of the energy of laser beam is about 1.5%, we can calculate that in most cases, the average energy resolution of prototype CEE-TPC is about 5.4%.

Figure 5 shows the energy loss measured along the laser beam tracks. The differences of energy loss indicate that the gain of the whole piece of GEM foil is not uniform. There is a maximum variation of 5%, which affects the position resolution when using the charge-weighting technique. Further work should be done to calibrate the gain of the GEM.

3.2 The drifting velocity of electrons

It is important to know the drifting velocity of electrons at different gas pressures. We changed the electric-filed strength at three kinds of gas pressures and used E/P (electric-field strength per atmosphere pressure) as abscissa. A linear correlation between drifting velocity and E/P can be observed from Fig. 6.

3.3 The track resolution

Figures 7 and 8 show the different laser beam tracks measured by the prototype CEE-TPC at one atmosphere. The position resolution in the X direction for each pad is about 0.5 mm, and the errors come from energy error. After a full scan of the gain of the GEM foil, the resolution is determined to be about 0.2 mm. The position resolution in the Y direction for each pad is about 0.5 mm, and the errors come from the errors of drifting time of the electrons.

4 Conclusion

We have constructed a prototype CEE-TPC with Thick-GEM-based readout that has the ability to reconstruct three-dimensional position. The performance of the TPC detector is studied in details by the test of pulsed ultraviolet laser beams. The correlation between energy loss and GEM’s voltage is exponential relation. The correlation between drifting velocity and electric-field strength is linear relation. The energy loss has a linear relation with total heat quantity. The position resolution in X and Y directions is about 0.2 mm and 0.5 mm, respectively. The average energy resolution of prototype CEE-TPC is about 5.4%. The track resolution and the energy loss resolution of the TPC achieves the requirement of the CEE experiment.

References

J.W. Xia, W.L. Zhan, B.W. Wei et al., The heavy ion cooler-storage-ring project (HIRFL-CSR) at Lanzhou. Nucl. Instrum. Meth. A 488, 11–25 (2002). https://doi.org/10.1016/S0168-9002(02)00475-8

C.J. Horowitz, E.F. Brown, Y. Kim et al., A way forward in the study of the symm-etry energy: experiment, theory, and observation. J. Phys. G Nucl. Partic. 41, 97 (2014). https://doi.org/10.1088/0954-3899/41/9/093001

B.A. Li, L.W. Chen, C.M. Ko, Recent progress and new challenges in isospin phys-ics with heavy-ion reactions. Phys. Rep. 464, 113–281 (2008). https://doi.org/10.1016/j.physrep.2008.04.005

M.A. Stephanov, Sign of kurtosis near the QCD critical point. Phys. Rev. Lett. 107, 052301 (2011). https://doi.org/10.1103/PhysRevLett.107.052301

L. McLerran, Quarkyonic matter and the revised phase diagram of QCD. Nucl. Phys. A 830, 709c–712c (2009). https://doi.org/10.1016/j.nuclphysa.2009.10.063

A. Andronic, D. Blaschke, P. Braun-Munzinger et al., Hadron production in ultra-relativistic nuclear collisions: quarkyonic matter and a triple point in the phase diagr-am of QCD. Nucl. Phys. A 837, 65–86 (2010). https://doi.org/10.1016/j.nuclphysa.2010.02.005

L.M. Lü, H. Yi, Z.G. Xiao et al., Conceptual design of the HIRFL-CSR external-target experiment. Sci. China Phys. Mech. 60, 012021 (2017). https://doi.org/10.1007/s11433-016-0342-x

Z. Xiao, L.W. Chen, F. Fu et al., Nuclear matter at a HIRFL-CSR energy regime. J. Phys. G Nucl. Partic. 36, 064040 (2009). https://doi.org/10.1088/0954-3899/36/6/064040

C.G. Lu, L.M. Duan, H.S. Xu et al., Test and simulation of a MICROMG-S detector. Chin. Phys. C 2011, 35 (1033). https://doi.org/10.1088/1674-1137/35/1/010

C.S. Ji, M. Shao, H. Zhang et al., Prospects for searching the η → e + e − rare decay at the CSR. Chin. Phys. C 37, 046201 (2013). https://doi.org/10.1088/1674-1137/37/4/46201

Z.G. Xiao, G.C. Yong, L.W. Chen et al., Probing nuclear symmetry energy at high densities using pion, kaon, eta and photon productions in heavy-ion collisions. Eur. Phys. J. A 50(2), 1–10 (2014). https://doi.org/10.1140/epja/i2014-14037-6

P.F. Wang, Z.K. Li, H.X. Li et al., Build-up of the silicon micro-strip detector array in ETF of HIRFL-CSR. Nucl. Phys. Rev. 31, 63–68 (2014). https://doi.org/10.11804/NuclPhysRev.31.01.063

X.W. Zhao, H. Su, Y. Qian et al., Development of a multi-channel front-end electronics module based on ASIC for silicon strip array detectors. Nucl. Phys. Rev. 31, 499–504 (2014). https://doi.org/10.11804/NuclPhysRev.31.04.499

L.F. Kang, L. Zhao, M. Li et al., Prototype readout electronics system of external experiment in HIRFL-CSR. At. Energy Sci. Technol. 49, 154–161 (2015). https://doi.org/10.7538/yzk.2015.49.01.0154. (in Chinese)

L. Zhao, L.F. Kang, J.W. Zhou et al., A 16-channel high-resolution time and char-ge measurement module for the external target experiment in the CSR of HIRFL. Nucl. Sci. Tech. 25, 010401 (2014). https://doi.org/10.13538/j.1001-8042/nst.25.010401

L. Kang, L. Zhao, J. Zhou et al., A 128-channel high precision time measurement module. Metrol. Meas. Syst. 20(2), 275–286 (2013). https://doi.org/10.2478/mms-2013-0024

L. He, S. Zhang, F. Lu et al., Simulation of momentum resolution of the CEE-TPC in HIRFL. Nucl. Tech. 39, 070401 (2016). https://doi.org/10.11889/j.0253-3219.2016.hjs.39.070401. (in Chinese)

J. Abele, J. Berkovitz, J. Boehm et al., The laser system for the STAR time projection chamber. Nucl. Instrum. Methods 499, 692–702 (2003). https://doi.org/10.1016/S0168-9002(02)01966-6

H.B. Liu, Q. Liu, S. Chen et al., A study of thinner-THGEM, with some applications. J. Instrum. 7(06), C06001 (2012). https://doi.org/10.1088/1748-0221/7/06/C06001

Q. Liu, H.B. Liu, S. Chen et al., A successful application of thinner-THGEMs. J. Instrum. 8, C11008 (2013). https://doi.org/10.1088/1748-0221/8/11/C11008

B.L. Wang, Q. Liu, H.B. Liu et al., Ion transportation study for thick gas electron multipliers. Chin. Phys. Lett. 31, 122901 (2014). https://doi.org/10.1088/0256-307X/31/12/122901

X.K. Zhou, Q. Liu, S. Chen et al., Study of thick gaseous electron multipliers gain stability and some influencing factors. Chin. Phys. Lett. 31, 032901 (2014). https://doi.org/10.1088/0256-307X/31/3/032901

Acknowledgments

The authors would like to thank Prof. Qian Liu from University of Chinese Academy of Sciences for his support on thick GEM production and Hai-Yun Wang from Institute of High Energy Physics, Chinese Academy of Sciences for providing equipment to measure the laser beam energy per pulse.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Key Research and Development Program of China (Nos. 2016YFA0400502 and 2015CB856904), the National Natural Science Foundation of China (Nos. U1332129, 11475243, 11421505, 11775288 and 11405005), and the “100-talent plan” of Shanghai Institute of Applied Physics from the Chinese Academy of Sciences (Nos. Y290061011 and Y526011011).

Rights and permissions

About this article

Cite this article

Huang, W., Lu, F., Li, H. et al. Laser test of the prototype of CEE time projection chamber. NUCL SCI TECH 29, 41 (2018). https://doi.org/10.1007/s41365-018-0382-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41365-018-0382-4