Abstract

Pre-harvest infection of groundnut (Arachis hypogea) during drought stress by strains of Aspergillus flavus and Aspergillus parasiticus is a major health and food safety concern worldwide. The fungi release aflatoxins, which are carcinogenic and hepatotoxic at levels of parts per billion. In this study, a formulated biocontrol agent, Trichoderma harzianum strain kd (Tkd), was used to control Aspergillus flavus infection of groundnut in the field. Groundnut seeds treated with Tkd developed more root biomass than the control (untreated with Tkd). Growth of Trichoderma mycelium from sterilized roots of groundnuts grown on Trichoderma selective media indicates root colonization of the intercellular spaces in groundnut roots by Tkd. Even the control plants showed evidence of root colonization by Trichoderma but at much lower levels. This shows that groundnuts are particularly a compatible host of Trichoderma acting as an endophyte. Under scanning electron microscopy, T. harzianum showed the ability to parasitize A. flavus by coiling around A. flavus hyphae, penetrating and degrading the mycelium of A. flavus. The levels of aflatoxin B1 contamination from Aspergillus infection were determined using a MaxiSignal® ELISA test kit. The aflatoxin levels of A. flavus-inoculated control plants were significantly (p < 0.001) higher than that of the Tkd-treated plants, by 57 and 65%, in two trials. Yields from plants treated with Tkd were 35 and 49% higher than that from the control (untreated with Tkd) plants in these field trials. It can be concluded that application of Tkd to groundnut seeds may reduce infection of the groundnut seeds by Aspergillus flavus, and hence, it may reduce the contamination of the seed by aflatoxin, especially under drought stress condition. Concurrently, Tkd treatment may result in yields being enhanced by more than 35%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Groundnut (Arachis hypogaea L.) is an oilseed widely grown in the tropical and subtropical regions of the world. Groundnut typically contains 25–32% protein and 48–56% oil content [15] and is an excellent source of multiple nutrients including vitamin E and magnesium. Therefore, it is important for food security globally [14]. There is also an association between consumption and a reduced incidence of cardiovascular and coronary heart disease [19, 28]. Consumption of groundnuts has also been found to lower total cholesterol and triacylglycerol [17]. However, groundnuts are often contaminated with aflatoxins at levels beyond 20 parts per billion (ppb), which is the limit set by the World Health Organization (WHO) for human consumption [23, 24, 32]. Aflatoxins in food may contribute to cancer and other health problems [2]. Aflatoxin B1 is the most toxic and potent carcinogen [16]. Exposure to aflatoxin B1 leads to liver cancer and strongly associated with stunting and immune suppression in children [20, 21]. Aflatoxin contamination should be controlled during cultivation, storage, transport and processing [5, 9].

Aflatoxins have been found in crops such as groundnut, maize and cotton used for human and animal foods [12, 22, 25, 26, 33]. Aspergillus flavus is the most common species associated with aflatoxin contamination of agricultural crops [7, 8]. Aflatoxins are toxic secondary metabolites produced by some species of the Aspergillus fungus [4]. Infection by A. flavus increases during drought stress, extreme temperatures and hot dry weather affecting groundnut crops close to harvest [3]. Such conditions play an important role in invasion of the plant by the fungus and result in high level of aflatoxin contamination in groundnut [13]. Biological control is a recognized method of controlling several plant diseases. Lyn et al. [18] and Torres et al. [31] reported the use of biocontrol agents to reduce Aspergillus contamination of crops pre-harvest. A biocontrol agent, Aflasafe™, is being used to provide protection of crops from Aspergillus sp., both pre- and post-harvest in Africa [3]. In other laboratory study, Burkholderia spp., Bacillus subtilis, Pseudomonas spp., Lactobacillis spp and Ralstonia spp. all inhibited fungal growth and reduced production of aflatoxins by Aspergillus [24]. Therefore, the use of biocontrol agents to interrupt pre-harvest infection and aflatoxin contamination may provide a sustainable solution.

The aim of this study was to control or reduce pre-harvest infection by A. flavus of groundnut and to reduce aflatoxin levels, using biological control.

Materials and methods

Source of seeds

Certified groundnut seed of the variety (Akwa) was purchased from Vaalharts Groundnuts marketing (VGM), P.O.Box 420, Hartswater, Republic of South Africa.

Source of biocontrol agent

Trichoderma harzianum strain kd (Tkd) was provided by Plant Health Products (Pty) Ltd., Nottingham Road, Republic of South Africa. It is a formulated biocontrol product with a final concentration of 109 conidia g−1. This product has been found to be effective against a range of soil-borne fungal pathogens.

Seed treatment

Seed treatment was done in a plastic bag. The bag was filled with 1 kg seeds, and formulated Tkd was applied at a rate of 4 g kg−1 seeds. Seeds were moistened to allow treatment adherence.

Source of Aspergillus flavus Inoculum

A fungal aflatoxigenic strain which was previously isolated from groundnut seeds and identified as A. Flavus by Chiuraise et al. [6] was provided by the Department of Plant Pathology, University of KwaZulu-Natal, South Africa. Mycelium of 1 cm square plugs was subcultured on newly prepared potato dextrose agar (PDA) and incubated at 28 °C for 7 days. Inoculum was prepared by weighing 150 g of barley seeds and placed into 1-liter (1L) Erlenmeyer flasks. Three hundred milliliters of distilled water was added to cover the seeds and left for 4 h on a laboratory bench. Excess water was drained off, and the flask was covered with a non-absorbent cotton plug and aluminum foil. The flask and the content were then autoclaved at 121 °C for 15 min. The barley seed was then inoculated with five 1 cm2 mycelia plugs from the edge of young A. flavus cultures growing on PDA plates and incubated at 28 °C. After 7 d, the barley seeds were completely colonized by A. flavus. The contents of the flask were poured out and air-dried for 4 d. The colonized barley seeds were maintained at room temperature in sterile plastic bags and used to inoculate field plots. The A. flavus inoculum was applied 5 weeks before harvest at a rate of 200 kg/ha.

Study sites

Two study sites were used for the field experiments. One was at Ukulinga Farm (University of KwaZulu-Natal is experimental farm), located at 29°40′S-30°24′E of Pietermaritzburg, South Africa. The annual mean rainfall is 500 mm. At this farm, field trail was carried out from January to May 2014. The trial was repeated from December 2014 to April 2015. The second experimental site was in Baynesfield Estate, located at 29°45′ 54.43°92″ S of Pietermaritzburg, South Africa, with a mean annual rainfall of 800 mm. At this farm, a trail was carried out from December 2014 to April 2015.

Antifungal bioassay test

The formulated biocontrol agent was inoculated onto Trichoderma selective media (TSM) and incubated for 7 days at 28 °C. A 1 cm2 of mycelium plug was cut out and placed face down on PDA Petri dish (9 cm) on one end of a Petri dish, and 1 cm2 plug of A. flavus was placed face down on the other end of the PDA plate. Mycelium plugs (4 × 4 mm2) were cut from the point where the mycelia of Tkd and A. flavus interacted and examined under a scanning electron microscope (SEM). The plugs were put in vials and then covered with a 3% buffered glutaraldehyde solution for a 2-h sample fixation. The samples were dehydrated in a graduated ethanol series (10, 30, 50, 70, 90 and 100%) with 10 mints in each, with three changes in the 100% ethanol, which lasted 10 mints each. The specimens were then transferred into critical point drying (CPD) baskets and placed into the CPD chamber for 2 h. After drying, the specimens were placed onto scanning electron microscope (SEM) stubs and transferred into an ion coater chamber for gold ion coating. After coating, the samples were examined at 4000× magnification using an EVO LS15 ZEISS SEM (Carl Zeiss, Oberkochen, Germany).

Root colonization assessment

Ten weeks after planting, treated and untreated plants were carefully uprooted. Excess soil was shaken off, before washing the root mass under tap water. The roots were then photographed to visually compare the untreated and treated root biomass. At harvest, roots from treated and untreated plants were assessed for root colonization by Trichoderma harzianum. The roots were gently washed under tap water to remove all soil adhering to the roots. Pieces of roots taken from treated and untreated plants were surface-sterilized in 1:9 Jik/water ratio (3% sodium hypochlorite) solution for 3 min and then in 70% alcohol for 1 min. The roots were rinsed three times in sterile distilled water and air-dried on paper towels in sterile Petri dishes. They were then plated onto Trichoderma selective media (TSM) and incubated for 7 days at 28 °C. After 7 days, the growing mycelium was viewed under a light microscope to confirm the presence of Trichoderma spp.

Determination of aflatoxin B1

Harvested groundnut seeds were tested for aflatoxin B1 levels by direct competitive enzyme-linked immunosorbent assay (ELISA) using a MaxiSignal® kit (BIOO Scientific Corp., Austin, USA), as per the manufacturer’s instructions. Absorbance values were determined at 430 nm using a FLUOstar OPTIMA spectrophotometer ELISA plate reader (BMG, Labtech Ortenberg, Germany).

Experimental design

The experiment was arranged in a randomized complete blocks design with four treatments: A. flavus only (pathogen-inoculated control), T. harzianum (Tkd) plus A. flavus, T. harzianum (Tkd) alone and an un-inoculated control (no pathogen and no biocontrol agent). The treatments were replicated four times. The seeds were directly planted into the soil from January to May 2014. However, germination was poor, resulting in a high CV% for yield (Table 1). Therefore, in the field trials conducted from December 2014 to April 2015 at both sites, the method of planting was modified. Treated and untreated seeds were planted into Speedling® trays containing composted pine bark and placed in greenhouse tunnels operating at 26–28 °C and an RH of 75–85%. Once the seedlings reached 15–20 cm, they were then transplanted to both sites. The replicates were also increased from four to six. Each plot was 3.5 m long and 2 m wide, consisting of five rows with a 0.5-m inter-row spacing and eleven plants per row and 0.3 m between plants within a row.

Fertilization

Limestone ammonium nitrate (LAN) fertilizer was used for source of nitrogen (Sasol Nitro, P.O. Box 5486, Johannesburg 2000, South Africa) and applied at planting at a rate of 80 kg ha−1. Superphosphate was used as a source of phosphorous (Omnia Fertilizer, P.O. Box 69888, Bryanston), applied at a rate of 40kg ha−1. No potassium fertilizer was applied because existing levels of k were satisfactory.

Data analysis

Data were subjected to two-way analysis of variance (ANOVA) and analyzed using GenStat 14th Edition of statistical analysis software. Significant differences between treatments were determined using Fischer’s least significant differences (LSD) test at a 5% significance level.

Results

Plant biomass, crop yield and concentration of aflatoxin B1 in groundnut

In the field tail running from January 2014 to May 2014 at Ukulinga, the pathogen-inoculated control plants showed 18% higher plant dry biomass than the un-inoculated control plants. However, there was no significant difference (p < 0.05) between the two controls. Though there were no significant differences (p < 0.05) between all the treatments (Table 1), the plants treated with Tkd developed 28–39% more biomass than both the pathogen-inoculated control and the un-inoculated control plants. Yield of groundnut from plants treated with Tkd was 127% higher than from the pathogen-inoculated control and 55% higher than from the un-inoculated control (Table 1). The concentration of aflatoxin B1 was significantly (p < 0.001) lower in plants treated with Tkd than that in the pathogen-inoculated and un-inoculated control. The un-inoculated control also developed aflatoxin contamination, but it was significantly (p < 0.001) lower than the pathogen-inoculated control (Table 1). In the field trail of December 2014 to April 2015 conducted at Ukulinga, no significant increases (p < 0.005) was observed in yield between the pathogen-inoculated control plants and the un-inoculated control and between Trichoderma-treated and untreated plants. However, yield from plants treated with Tkd was 35% higher than the yield from pathogen-inoculated and un-inoculated control plants. The aflatoxin content of A. flavus-inoculated plants was significantly (p < 0.001) higher than that of the Tkd-treated plants by 57% (Table 2). At Baynesfield Farm, Tkd-treated plants produced significant (p < 0.05) increases in yield, 49% higher than the untreated control plants (Table 2). The aflatoxin content of A. flavus-inoculated plants was significantly (p < 0.001) higher than that of the Tkd-treated plants, by 65% (Table 2). The A. flavus-inoculated plants developed significantly (p < 0.001) higher aflatoxin content than the un-inoculated control (Table 2).

Assessment of root colonization by Trichoderma harzianum strain kd

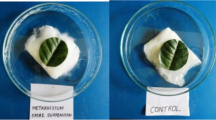

Colonization of roots by Trichoderma spp was evident in both treated and untreated plant roots when sterilized plant roots were plated on TSM. However, colonization of roots by Trichoderma was more substantial in the treated plant roots than in the untreated controls (Fig. 1). The presence of Trichoderma spp was confirmed microscopically.

Mycoparasitism test

Under SEM, Tkd parasitized A. flavus by coiling around its hyphae (Fig. 2) and degrading and lysing the hyphae.

Discussion

In this study, a formulated biocontrol agent, Trichoderma harzianum strain kd (Tkd), was used to control Aspergillus flavus infection of groundnut in the field. Growth of Trichoderma mycelium from sterilized roots of groundnuts grown on Trichoderma selective media (TSM) indicates root colonization of the intercellular spaces in groundnut roots by Tkd. Even the control plants showed evidence of root colonization by Trichoderma but at much lower levels. This shows that groundnuts are particularly a compatible host of Trichoderma acting as an endophyte. The colonization of roots by Trichoderma spp in mature plants roots reflects the potential for long-term protection by the biocontrol agent. The colonization of roots enhances uptake of minerals and the release of phytohormones mechanisms involved in plant growth promotion by Trichoderma spp. [10, 29]. Some Trichoderma strains have also the potential to promote plant growth by interacting directly with roots [11]. In this study, under scanning electron microscopy, T. harzianum showed that the ability to parasitize A. flavus by coiling around A. flavus hyphae, penetrating and degrading the mycelium of A. flavus. Chiuraise et al. [6] also found Tkd was mycoparasitic on A. flavus. Aflatoxin contamination was recorded with all the treatments. The un-inoculated plants and those treated with Tkd developed less aflatoxin contamination than the pathogen-inoculated control.

The detection of aflatoxin in the un-inoculated control seeds could be as a result of the presence of Aspergillus flavus strains that are commonly found in the soil. Starr and Selim [30] stated that strains of Aspergillus are frequently found from farmland and top soils and may serve as the primary source of inoculum for colonization of crops. Therefore, groundnut crops are at risk of aflatoxin contamination. The present study showed the use of Tkd for reducing Aspergillus infection pre-harvest in growing groundnuts, subsequently reducing aflatoxin contamination that typically develops under drought conditions. In another study, Trichoderma spp applied for seed treatment helped to suppress A. flavus infection in the pod zone and was able to reduce infection in groundnut seeds [1]. In this study, 35–49 % yield increases were observed in plants treated with Tkd in both fields in 2014 and 2015. In another study, groundnut yield was boosted when T. harzianum was applied as a seed treatment in Argentina [27]. It can be concluded that application of Tkd to groundnut seeds may reduce infection of the groundnut seeds by Aspergillus flavus, and hence, it may reduce the contamination of the seed by aflatoxin, especially under drought stress condition. Concurrently, Tkd treatment may result in yields being enhanced by more than 35%. Therefore, application of Tkd as a seed treatment not only controlled the soil-borne pathogens but also boosted the yield as a bonus.

References

Anjaiah, V., Thakur, R., & Koedam, N. (2006). Evaluation of bacteria and Trichoderma for biocontrol of pre-harvest seed infection by Aspergillus flavus in groundnut. Biocontrol Science and Technology, 16, 431–436.

Awuah, R., Fialor, S., Binns, A., Kagochi, J., & Jolly, C. (2009). Factors influencing market participants decision to sort groundnuts along the marketing chain in Ghana. Peanut Science, 36, 68–76.

Bhatnagar-Mathur, P., Sunkara, S., Bhatnagar-Panwar, M., Waliyar, F., & Sharma, K. K. (2015). Biotechnological advances for combating Aspergillus flavus and aflatoxin contamination in crops. Plant Science, 234, 119–132.

Calvo, A. M., & Cary, J. W. (2015). Association of fungal secondary metabolism and sclerotial biology. Frontiers in Microbiology 6.

Chiewchan, N., Mujumdar, A. S., & Devahastin, S. (2015). Application of drying technology to control aflatoxins in foods and feeds: A review. Drying Technology, 33, 1700–1707.

Chiuraise, N., Yobo, K. S., & Laing, M. D. (2015). Seed treatment with Trichoderma harzianum strain kd formulation reduced aflatoxin contamination in groundnuts. Journal of Plant Diseases and Protection, 122, 74–80.

Cotty, P. J. (1997). Aflatoxin-producing potential of communities of Aspergillus section flavi from cotton producing areas in the United States. Mycological Research, 101, 698–704.

Cotty, P. J., Bayman, P., Egel, D., & Elias, K. (1994). Agriculture, aflatoxins and Aspergillus. The genus Aspergillus. (pp. 1–27). US: Springer.

Grace, D., Mahuku, G., Hoffmann, V., Atherstone, C., Upadhyaya, H. D., & Bandyopadhyay, R. (2015). International agricultural research to reduce food risks: Case studies on aflatoxins. Food Security, 7, 569–582.

Harman, G. E., Howell, C. R., Viterbo, A., Chet, I., & Lorito, M. (2004). Trichoderma species—opportunistic, avirulent plant symbionts. Nature Reviews Microbiology, 2, 43–56.

Hermosa, R., Viterbo, A., Chet, I., & Monte, E. (2012). Plant-beneficial effects of Trichoderma and of its genes. Microbiology, 158, 17–25.

Kamika, I., Mngqawa, P., Rheeder, J. P., Teffo, S. L., & Katerere, D. R. (2014). Mycological and aflatoxin contamination of peanuts sold at markets in Kinshasa, Democratic Republic of Congo, and Pretoria, South Africa. Food Additives and Contaminants: Part B, 7, 120–126.

Katam, R., Gottschalk, V., Survajahala, P., Brewster, G., Paxton, P., Sakata, K., Lee, C., Williams, C., Guo, B., & Latinwo, L. M. (2014). Advances in proteomics research for peanut genetics and breeding. Genetics, Genomics and Breeding of Peanuts, 161.

King, J. C., Blumberg, J., Ingwersen, L., Jenab, M., & Tucker, K. L. (2008). Tree nuts and peanuts as components of a healthy diet. The Journal of Nutrition, 138, 1736S–1740S.

Li, X., Zhang, T., Wang, X., Hua, K., Zhao, L., & Han, Z. (2013). The composition of root exudates from two different resistant peanut cultivars and their effects on the growth of soil-borne pathogen. International Journal of Biological Sciences, 9, 164–173.

Liu, Y., Yan, T., Li, Y., Cao, W., Pang, X., Wu, D., et al. (2015). A simple label-free photoelectrochemical immunosensor for highly sensitive detection of aflatoxin b 1 based on cds–fe 3 o 4 magnetic nanocomposites. RSC Advances, 5, 19581–19586.

Lokko, P., Lartey, A., Armar-Klemesu, M., & Mattes, R. D. (2007). Regular peanut consumption improves plasma lipid levels in healthy ghanaians. International Journal of Food Sciences and Nutrition, 58, 190–200.

Lyn, M., Abbas, H. K., & Zablotowicz, R. (2015). Water dispersible formulation for delivery of biocontrol fungi to reduce aflatoxin. Google Patents.

Mattes, R. D., Kris-Etherton, P. M., & Foster, G. D. (2008). Impact of peanuts and tree nuts on body weight and healthy weight loss in adults. The Journal of Nutrition, 138, 1741S–1745S.

Mossanda, K. S. (2015). Hepatocellular carcinoma: Putative interactive mechanism between aflatoxins and hepatitis viral infections implicating oxidative stress during the onset and progression of cancer. Hypothesis, 1, 18.

Obade, M., Andang’O, P., Obonyo, C., & Lusweti, F. (2015). Aflatoxin exposure in pregnant women in kisumu county, kenya. Current Research in Nutrition and Food Science Journal, 3.

Ortega-Beltran, A., Guerrero-Herrera, M. D., Ortega-Corona, A., Vidal-Martinez, V. A., & Cotty, P. J. (2014). Susceptibility to aflatoxin contamination among maize landraces from Mexico. Journal of Food Protection, 77, 1554–1562.

Otsuki, T., Wilson, J. S., & Sewadeh, M. (2001). What price precaution? European harmonisation of aflatoxin regulations and African groundnut exports. European Review of Agricultural Economics, 28, 263–284.

Palumbo, J., Baker, J., & Mahoney, N. (2006). Isolation of bacterial antagonists of Aspergillus flavus from almonds. Microbial Ecology, 52, 45–52. doi:10.1007/s00248-006-9096-y.

Perrone, G., Haidukowski, M., Stea, G., Epifani, F., Bandyopadhyay, R., Leslie, J. F., et al. (2014). Population structure and aflatoxin production by Aspergillus sect. flavi from maize in Nigeria and Ghana. Food Microbiology, 41, 52–59.

Probst, C., Bandyopadhyay, R., & Cotty, P. (2014). Diversity of aflatoxin-producing fungi and their impact on food safety in sub-Saharan Africa. International Journal of Food Microbiology, 174, 113–122.

Rojo, F. G., Reynoso, M. M., Ferez, M., Chulze, S. N., & Torres, A. M. (2007). Biological control by Trichoderma species of Fusarium solani causing peanut brown root rot under field conditions. Crop Protection, 26, 549–555.

Sabaté, J., & Ang, Y. (2009). Nuts and health outcomes: New epidemiologic evidence. The American Journal of Clinical Nutrition, 89, 1643S–1648S.

Shoresh, M., Harman, G. E., & Mastouri, F. (2010). Induced systemic resistance and plant responses to fungal biocontrol agents. Annual Review of Phytopathology, 48, 21–43.

Starr, J. M., & Selim, M. I. (2008). Supercritical fluid extraction of aflatoxin B1 from soil. Journal of Chromatography A, 1209, 37–43.

Torres, A., Barros, G., Palacios, S., Chulze, S., & Battilani, P. (2014). Review on pre-and post-harvest management of peanuts to minimize aflatoxin contamination. Food Research International, 62, 11–19.

Williams, J. H., Phillips, T. D., Jolly, P. E., Stiles, J. K., Jolly, C. M., & Aggarwal, D. (2004). Human aflatoxicosis in developing countries: A review of toxicology, exposure, potential health consequences, and interventions. The American Journal of Clinical Nutrition, 80, 1106–1122.

Yunus, A. W., Sulyok, M., & Böhm, J. (2015). Mycotoxin cocktail in the samples of oilseed cake from early maturing cotton varieties associated with cattle feeding problems. Toxins, 7, 2188–2197.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kifle, M.H., Yobo, K.S. & Laing, M.D. Biocontrol of Aspergillus flavus in groundnut using Trichoderma harzianum stain kd. J Plant Dis Prot 124, 51–56 (2017). https://doi.org/10.1007/s41348-016-0066-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41348-016-0066-4