Abstract

Due to the urbanization and the need to develop the transportation services, it is inevitable to deal with ground characterized by undesirable geotechnical properties. The problematic soils are divided into swelling soils, collapsible and dispersive soils. The arid to semiarid climate of the Middle East has provided the conditions for the expansion of them. The presence of problematic soils in Iraqi Kurdistan has given rise to many damage to the construction projects of this region. The under-construction road of Gali Ali Bag designed in the vicinity of the Erbil-Haji Omeran highway in Iraqi Kurdistan was faced with pavement settlement and collapse of side slopes due to the passing through the collapsible soils. The presence of collapsible soils in the vicinity of the aforesaid international highway grew concerns about the occurrence of such settlements during its construction. Therefore, how to treat or reduce the collapsibility, especially by the use of practical methods on the site, was addressed as one of the major challenges. In this study, the behavior of treated host soil by four cementitious materials including cement, quicklime, gypsum and NaCl was determined by applying indirect and direct methods. The results show that the addition of 6% quicklime will have the greatest effect on the reduction in collapsibility. After implementing this plan on the site, the collapsibility index decreased by an average of 2.92%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The increase in population in many developing countries requires the development of transportation networks. The significant presence of the problematic soils in the Middle East, especially in the Northeast–Southeast of Iraq, has made serious problems regarding the stability of the development structures. The collapsible soils are a type of problematic soils which have a lot of volume reduction following the increase in the moisture content under constant stress, and their bearing capacity is greatly reduced as well. The collapsible soils have an open and considerably porous structure and have a metastable state in dry conditions due to weak cementation. Significant characteristics of the collapsible soils include fine grains, low density and consolidation and high void ratio. The side slopes constructed in the collapsible soils will also be raveling after the settlement. The collapsible soils will collapse following the increase in the saturation degree and upon reaching a moisture more than 50%. Therefore, they do not necessarily collapse in full saturation [1]. The collapsible soils are mostly composed of Debris flows and are naturally stiff and firm. Investigations on problematic soils have focused mainly on swelling soils, and the identification and treatment of collapsible soils has been a major challenge since the early 1990s, among which Abbeche et al. [1, 2], Basma and Tuncer [3], Houston et al. [4], Reznik [5], Rezaei et al. [6], Gaaver [7], Kalantari [8], Fattah et al. [9], Ali [10], Ayeldeen et al. [11] and Rollins and Kim [12] can be mentioned. Abbeche et al. [1, 2] had some tests on collapsible soils. They stated that it is possible to minimize the collapse potential to an acceptable level after chemical treatment with salts. They demonstrate that NaCl reduced the collapse potential and subsequently the damage associated with it to structures. Their results show that the increase in salt concentration beyond certain value (1.5 mol/L) has no significant benefit. Basma and Tuncer [3] conducted 138 one-dimensional consolidation tests on eight different soil types in order to investigate the effect of soil type, compaction moisture content, initial dry density and applied pressure at wetting on collapse potential. Houston et al. [4] introduced engineering properties of collapsible soils. Reznik [5] proposed an empirical equation between mechanical characteristics of collapsible soils and their physical properties. Rezaei et al. [6] conducted some tests to evaluate the collapsibility rate of soils in Isfahan. Gaaver [7] had some laboratory tests on collapsible soils in Egypt. He proposed some equations between collapse potential and water content for undisturbed and compacted samples. Kalantari [8] reviewed all methods to identify collapsible soils. Fattah et al. [9] conducted some tests on gypseous soil grouted by acrylate liquid. The results showed that this method can reduce collapsibility of the gypseous soil by more than 60–70%. Ali [10] investigated the behavior and performance of compacted sand replacement over treated collapsible soil by prewetting and compaction. He stated that the partial replacement by compacted sand/crushed stone layers decreases collapsibility potential risk. Ayeldeen et al. [11] used biopolymer to enhance the mechanical properties of collapsible soil. They stated that the collapsible potential has been reduced from 9 to 1% after mixing the soil with 2% biopolymer concentration in the wet state. Rollins and Kim [12] investigated dynamic compaction of collapsible soils according to the US case studies. They stated this method is an economical method for mitigating the hazard posed by collapsible soils particularly when they are deeper than 3–4 m.

The occurrence of several collapses associated with the problematic soils and the imposition of sizable rehabilitation costs in Iraqi Kurdistan projects necessitate comprehensive study on the rehabilitation of such grounds [13, 14]. This paper aims to study the reduction in collapse in Gali Ali Bag road located in Iraqi Kurdistan by adding four types of materials including quicklime, cement, gypsum and salt.

Distribution of problematic soils in Iraq

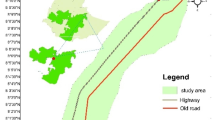

In general, problematic soils have extensively been formed in the Middle East due to the arid to semiarid weather conditions. These soils are observed in many areas in Iraq. The Iraqi Kurdistan is one of the areas where collapsible soils have created serious challenges in development projects. The collapsible soils have mostly been concentrated in Erbil Governorate, so that differential settlement of buildings and a lot of fractures in side slopes can be observed therein (Fig. 1). In terms of sedimentary–structural zonation, these soils are mainly observed in two zones of HFZ and Zagros suture zone. The major lithology of these areas consists of limestone, shale, marlstone and gypsum. Due to the young nature of the Zagros Mountains and the severe tectonics attributable to it, the crushed rock mass of this region is high, and it is mostly classified as fair to very weak from the geomechanical point of view [15].

Study area

The study area is within Iraqi Kurdistan, Erbil Governorate, 95 km northeast of Erbil city. The project is part of the diversion to the main international border road Erbil-Haji Omeran. The weather in this area varied: hot and dry in summers, and cold, dry and partly cloudy in winter. During the year, the temperature usually ranges from − 1 to 45 °C. According to statistics, the amount of rainfall in the region is low and usually ranges from 200 to 400 mm per year. The presence of two dangerous curves in the road led to the design of a new 550-m-long road to correct the path. The construction of this project will eliminate the arduous defile of Gali Ali Bag, so that road accidents will significantly be reduced. Figure 2 depicts the location of the project, topography map, road lines and the failures occurred in the study area.

Geological setting and geotechnical properties

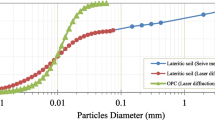

The study area is a part of the High Folded Zone, where Mesozoic rock units are folded into a series of NW–SE trending anticlines and synclines. The main lithology of the study area consists of a massive limestone and marly limestone with shale interbedds. The bedding is mainly horizontal or with a maximum dip of 20° and a strike of mainly NE–SW. In view of the intensive tectonics and high weathering, the thalweg of the valleys consists of recent alluvium and debris flows caused by the flooding of the Balak River. In order to identify the geotechnical properties of the study area, and to prepare distributed and undistributed samples, five boreholes and three test pits were drilled/excavated along the route in accordance with Fig. 3. The length of the boreholes was 20, 15, 10, 15 and 20 m, respectively, and the depth of the test pits was 2 m.

After conducting various tests, the geotechnical properties of the study area were determined according to Table 1. The soil profiles as shown in Fig. 4 in BH1 consist of a brown dense mixture of silty sand and silt. The BH2 consists of silty gravel, sand, clayey silt and silt. At BH3, a layer of high-plasticity clay and silt located at middle of the borehole, while a low-plasticity silt exists at the top of borehole. The BH4 and BH5 consist of silty sand and silt from the top to the end of the boreholes.

The results presented in Table 1 show that the soil existing in this area is fine-grained mainly consisting of silt. In addition, due to high precipitations in this region, the groundwater level is high and the samples are mainly saturated. The parameters of cohesion and the internal friction angle were determined using the direct shear test for a number of samples. The results indicate that clayey minerals are inactive in terms of activity.

Determination of collapsibility

Investigations have shown that the best method for identifying the collapsible soils is to perform laboratory tests. These tests are mainly based on two parameters: dry unit weight and liquid limit. Holtz and Hilf [16] proposed a graph based on dry unit weight and liquid limits (LL) to evaluate collapsibility of soils (Fig. 5a). The chart indicates that soils which plot above the line are susceptible to collapse upon wetting, and as their dry unit weight increases, the severity of collapsibility decreases. This method is also confirmed by Basma and Kallas [17]. Moghadam et al. [18] proposed a chart showing relations between dry unit weight and percentage finer than 0.075 mm (sieve #200) to evaluate the collapse potential of various types of soils (Fig. 5b).

Having evaluated the characteristics of the samples applying the above two methods, it was observed that the soil in which BH2 borehole had been drilled has a potential of collapsibility. Three samples were extracted from the BH2 borehole to refine the results and determine their collapsibility index and class according to ASTM D5333 [19] standard in the laboratory. In this method, after preparing the sample similar to the consolidation test [20], the vertical load up to 200 kPa is applied to the sample stepwise; then, the sample is immersed into the distilled water for 24 h. The test then continues until the maximum loading, and the strains are recorded in each step during the test. Thereafter, the collapsibility index and its class are determined by Eq. (1) and Table 2. The test results and the collapsibility index are shown in Fig. 6.

where \(\frac{{d_{\text{f}} - d_{0} }}{{h_{0} }}\) and \(\frac{{d_{i} - d_{0} }}{{h_{0} }}\) = strain at the appropriate stress level after and before wetting.

df = dial reading at the appropriate stress level after wetting (mm), d0 = dial reading at seating stress (mm), di = dial reading at the appropriate stress level before wetting (mm) and h0 = initial specimen height (mm).

After conducting the test, the collapsibility index of the three samples was achieved as 4.86, 4.24 and 3.52%, respectively. According to Table 2, the collapsibility index will be in the moderate class. After conducting direct and indirect tests on different samples, it was found that fine-grained soil of the BH2 borehole is susceptible to collapse, and therefore it needs to be improved.

Selection of improvement method

Several treatment methods were proposed for minimizing the collapse of soils such as soil replacement, prewetting, compaction control and chemical stabilization or grouting. The choice of such methods depends on the ground conditions, type of structure to be constructed, practicality and economics of the method [21]. Depending on the depth, volume and load bearing capacity that is expected for the soil, some methods such as replacement, mechanical treatment and chemical improvement can be used for the collapsible soils [2]. The first alternative can be economical in the small-scale road construction projects or in the foundation of buildings, if the amount of soil to be removed is not too high. Mechanical improvement methods also provide better performance for deep layers. Although the compaction by rollers in the basement of the roads also contributes to the reduction in collapsibility, these methods also have access restrictions. Because it is not possible to make use of the mechanical improvement methods in steep side slopes. According to Gaaver [7], if the collapsible soil is compacted up to 95% of the dry unit weight, its collapsibility is reduced to 15–23% of the soil main value. In the meantime, the use of geosynthetic products will be considered as an applicable option, but its use requires specific conditions. Chemical treatment is the most logical way among the above-mentioned methods. Because it can be implemented at any surface, and the additives, which are mainly used in ground improvement, are found abundantly and at low cost. Besides, improvement with this method will also increase the mechanical strength more than others [13, 14, 22]. As seen in the graphs of Fig. 5, the liquid limit and the unit weight of the soil are considered as two parameters in increasing or decreasing the collapsibility. Provided that the soil unit weight or the soil water content increases, the soil collapsibility will be reduced. The increase in the water content will result in a rise in the liquid limit and, as a result, the collapse of the honeycomb structure of the collapsible soil. According to Basma and Tuncer [3], in addition to the two above issues, the increase in the difference between sand and clay will also affect the reduction in collapsibility. In general, the increase in the liquid limit has a higher flexibility than other methods. Soaking at the same time as compaction will increase the liquid limit, but in addition to this, the chemical materials may also be effective in increasing the mechanical strength.

Materials and methods of testing

2400 g of soil was taken from BH2 borehole. This amount of soil was divided into 12 equal parts each with a weight of 200 g. In order to investigate the reduction in collapsibility, four materials including cement, quicklime, gypsum and salt were considered. The easy access, low cost and acceptable environmental impacts are effective indices for selecting these materials. Then, each part of the separated soils was combined with these materials with three different doses of 3, 6 and 9%; then, the Atterberg limits and their pH values were calculated. Figure 7 depicts the additives and tests.

The liquid limit, plastic limit and plasticity index of soils are also used extensively, either individually or together, with other soil properties to correlate with engineering behavior such as compressibility, permeability, compactibility, shrink–swell and shear strength. Atterberg limits are sometimes used to evaluate the weathering characteristics of clay–shale materials. When subjected to repeated wetting and drying cycles, the liquid limits of these materials tend to increase. The amount of increase is considered to be a measure of a shale’s susceptibility to weathering. After the tests, the values of the liquid limit (LL), plastic limit (PL), plastic index (PI) and pH in different doses were obtained according to Table 3 and Fig. 8.

Discussions

Figure 8a shows that the use of 3–6% of quicklime with the soil sample increases the liquid limit significantly and 6% is the optimum ratio of quicklime. However, the addition of less than 3% of quicklime decreases the liquid limit gradually compared to the controlled sample, whereas the addition of more than 6% of quicklime is no more beneficial in increasing the liquid limit. This amount of quicklime (3–6%) will increase the liquid limit up to 22.5%. In collapsible soils, the grains are honeycomb bound by clay or carbonate calcium. Due to the increase in moisture, these connections become loose and the soil loses its load bearing capacity due to the increased load. The soil will be denser by the collapse of the honeycomb structure. As the liquid limit goes up, it means that the amount of water needed to change the state of the semisolid to the liquid will increase. In fact, by increasing the liquid limit, the amount of water required to collapse the collapsible soil structure will increase. Figure 8b shows that natural salt in all doses will have a decreasing effect on the PI. However, gypsum and cement have a decreasing–increasing effect on the PI. The effect of the quicklime on the PI is decreasing up to 3%; it is increasing between 3–6%, and decreasing from 6–9%. Investigations show that as PI increases, the soil workability will increase. With this in mind, the 6% quicklime will have the highest workability. Figure 8c shows that the salt and quicklime increase the PL, and gypsum and cement cause a decreasing–increasing trend in PL. Gypsum and salt, as shown in Fig. 8d, have almost no effect on the pH of the collapsible soil. However, quicklime and cement increase the pH up to 3%, and after that, they will have no effect.

In order to investigate the effect of quicklime on collapsible soil samples, XRD test was performed. According to Fig. 9, it is clearly observed that due to adding 6% quicklime, the amount of kaolinite is decreased.

After laboratory tests and confirmation of the effect of 6% quicklime on reducing the collapsibility, this amount will be implemented along with the subgrade layer at the site as shown in Fig. 10.

After the implementation, three samples were taken from the same BH2 borehole and again their collapsibility index was determined in the laboratory. The results, according to Fig. 11, showed that the collapsibility index has decreased by an average of 2.92%.

The results of Table 4 show that the collapsibility class will tend to mild from moderate by adding 6% of quicklime. The effect of quicklime on the reduction in collapsibility can be attributed to its function as a binding agent between the grains which fill in the honeycomb cavities.

Conclusions

After performing laboratory tests and sampling following the implementation on the site, the results can be summarized as follows:

Adding 6% of quicklime has the greatest effect on reducing the collapsibility index.

6% of quicklime increases the soil liquid limit up to 22.2%, decreases the PI down to 15%, increases the PL up to 37% and increases the pH up to 59%.

The increase in the liquid limit leads to an increase in the water content required for deforming from the semisolid to the liquid state, resulting in a reduction in the collapsibility.

Adding 6% of quicklime will reduce the collapsibility index by an average of 2.92%.

Adding quicklime strengthens the bond between the grains and plays the role of the filler for honeycomb cavities in the collapsible soil.

Adding quicklime to the soil, in addition to improving the soil strength properties in both short and long terms, caused reduction in swelling and permeability.

References

Abbeche K, Bahloul O, Ayadat T, Bahloul A (2010) Treatment of collapsible soils by salts using the double consolidation method, Experimental and applied modeling of unsaturated soils. In: Proceedings of sessions of Geoshanghai, Shanghai, China, pp 69–78

Abbeche1 K, Bahloul O, Bahloul A (2016) Study of the influence of the saline solution NaCl on the potential collapse of soil. In: E3S Web of conferences, vol 9. EDP Sciences, p 07001

Basma A, Tuncer ER (1992) Evaluation and control collapsible soils. J Geotech Eng 118(10):1491–1504. https://doi.org/10.1061/(ASCE)0733-9410(1992)118:10(1491)

Houston S, Houston W, Zapata CE, Lawrence C (2001) Geotechnical engineering practice for collapsible soils. In: Toll DG (ed) Unsaturated soil concepts and their application in geotechnical practice. Springer, Dordrecht. https://doi.org/10.1007/978-94-015-9775-3_6

Reznik YM (2007) Influence of physical properties on deformation characteristics of collapsible soils. Eng Geol 92(1–2):27–37. https://doi.org/10.1016/j.enggeo.2007.03.001

Rezaei M, Ajalloeian R, Ghafoori M (2012) Geotechnical properties of problematic soils: emphasis on collapsible cases. Int J Geosci 3:105–110. https://doi.org/10.4236/ijg.2012.31012

Gaaver KE (2012) Geotechnical properties of Egyptian collapsible soils. Alex Eng J 51(3):205–210. https://doi.org/10.1016/j.aej.2012.05.002

Kalantari B (2013) Foundations on collapsible soils: a review. Proc Inst Civ Eng-Forensic Eng 166(2):57–63. https://doi.org/10.1680/feng.12.00016

Fattah MY, Al-Ani M, Al-Lamy M (2014) Studying collapse potential of gypseous soil treated by grouting. Soils Found 54(3):396–404. https://doi.org/10.1016/j.sandf.2014.04.008

Ali NA (2015) Performance of partially replaced collapsible soil—field study. Alex Eng J 54(3):527–532. https://doi.org/10.1016/j.aej.2015.05.002

Ayeldeen M, Negm A, El-Sawwaf M, Kitazume M (2017) Enhancing mechanical behaviors of collapsible soil using two biopolymers. J Rock Mech Geotech Eng 9(2):329–339. https://doi.org/10.1016/j.jrmge.2016.11.007

Rollins KM, Kim J (2010) Dynamic compaction of collapsible soils based on U.S. case histories. J Geotech Geo-environ Eng 136(9):1178–1186. https://doi.org/10.1061/_ASCE_GT.1943-5606.0000331

Daraei A, Herki BMA, Sherwani A, Zare S (2018) Rehabilitation of portal subsidence of Heybat Sultan twin tunnels: selection of shotcrete or geogrid alternatives. Int J Geosynth Ground Eng 4:15. https://doi.org/10.1007/s40891-018-0132-z

Daraei A, Herki BMA, Sherwani A, Zare S (2018) Slope stability in swelling soils using cement grout: a case study. Int J Geosynth Ground Eng 4:10. https://doi.org/10.1007/s40891-018-0127-9

Beiniawski ZT (1989) Engineering rock mass classifications. Wiley, Hoboken

Holtz WG, Hilf JW (1961) Settlement of soil foundation due to saturation. In: Proceedings of the 5th international SMFE, Paris, France, vol 1

Basma AA, Kallas A (2004) Modeling soil collapse by artificial neural networks. Geotech Geol Eng 22(3):427–438. https://doi.org/10.1023/B:GEGE.0000025044.72718.db

Moghadam MJ, Moghadam HA, Rahmannejad R (2006) Urban tunneling in collapsible soil (case study: the Kerman Metro). In: Proceedings of the National Conference on Retrofitting of Iran, Tabriz, Iran

ASTM (2003) Standard test method for measurement of collapse potential of soils. ASTM standard D5333-03, Annual Book of ASTM Standard, Philadelphia

ASTM (2004) Standard test method for measurement of collapse potential of soils. ASTM standard D2435-04, Annual Book of ASTM Standard, West Conshohocken, Philadelphia

Al-Rawas A (2000) State-of-the-art-review of collapsible soils. Sultan Qaboos Univ J Sci [SQUJS] 5:115–135

Daraei R, Herki BMAH, Sherwani A (2017) Study on the rapid drawdown and its effect on portal subsidence of Heybat Sultan twin tunnels in Kurdistan-Iraq. Civ Eng J 3(7):496–507

Acknowledgements

The authors wish to thank Scientific Research Centre (SRC) of Soran University for their assistance during the research and testing procedure.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Daraei, A., Sherwani, A.F.H., Faraj, R.H. et al. Stabilization of problematic soil by utilizing cementitious materials. Innov. Infrastruct. Solut. 4, 33 (2019). https://doi.org/10.1007/s41062-019-0220-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-019-0220-5