Abstract

In this research, the north and northwest parts of Damghan in the northeast of Iran were selected as the study areas, and different sedimentary rocks including, sandstone, limestone, travertine, and conglomerate, were collected. Laboratory investigations including petrography study, X-ray diffraction, dry density, porosity, point load strength (PLS), Brazilian tensile strength (BTS), block punch strength (BPS), uniaxial compressive strength (UCS), and ultrasonic P-wave velocity (VP) were determined. The main aim of this study is to establish predictive models to estimate the PLS, BTS, BPS, and UCS of the studied rocks based on P-wave velocity. Four experimental models were developed using multivariate regression analysis (MRA), artificial neural network (ANN), and adaptive neuro-fuzzy inference system (ANFIS). Statistical parameters including, R, RMSE, VAF, MAPE, and PI, were calculated and compared to assess the performance of MRA, ANN, and ANFIS models. Correlation coefficient values were obtained from 0.73 to 0.85, 0.96 to 0.99, and 0.99 for the MRA, ANN, and ANFIS models, respectively. A good RMSE value equal to 0.11 was obtained for ANFIS when using VP for predicting block punch strength. Calculating residual error and correlation between experimental and predicted values indicated that the ANFIS models have the best coefficients. Also, the results of this research demonstrated that the ANN approach is more efficient than MRA in predicting the mechanical properties of the studied rocks.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Determining the geotechnical properties of rocks is considered to be the most important component in different projects such as tunnels, dams, mining, rock mass classification (Khajevand and Fereidooni 2018; Diamantis et al. 2021; Hassan et al. 2021), rock slopes stability (Johari et al. 2013, 2015), oil and gas reservoirs (Wang et al. 2020), and damage to historical buildings (Hemeda and Pitilakis 2010). Ultrasonic measurement is one of the non-destructive geophysical methods commonly used in engineering projects that are standardized by the American Society for Testing and Materials (ASTM) and the International Society for Rock Mechanics (ISRM). In rock engineering, ultrasonic testing has become very popular due to its low cost, simplicity, portable nature, and high precision (Chawre 2018). This method can be applied in the laboratory and field (Ajalloeian et al. 2020). Until now, ultrasonic wave velocity has been widely used as a reliable geotechnical test by various researchers for predicting the mechanical and physical properties of different rocks (Tuğrul and Zarif 1999; Kahraman 2001; Yasar and Erdogan 2004; Kilic and Teymen 2008; Diamantis 2019; Kianpour et al. 2019; Wang and Han 2020; Arman and Paramban 2021). Evaluating the strength of rocks by performing direct tests is the most expensive and requires high-quality core specimens and considerable time. Therefore, indirect laboratory tests such as ultrasonic wave velocity are often used for predicting the mechanical properties of rocks (Khajevand and Fereidooni 2019).

In engineering geology and rock mechanics, various simple and multivariate regression models have been developed for correlation between P-wave velocity and some physical and mechanical properties (e.g., Cobanoğlu and Çelik 2008; Diamantis et al. 2011, 2012; Yagiz 2011; Fener 2011; Tandon and Gupta 2015; Kurtulus et al. 2016; Shirole et al. 2020; Yang et al. 2020; Benavente et al. 2020; Khajevand and Fereidooni 2022). Several researchers attempted to determine the uniaxial compressive strength (UCS) of different rocks by wave velocity (Khandelwal and Singh 2009; Altindag 2012; Azimian and Ajalloeian 2015; Ferentinou and Fakir 2017; Heidari et al. 2018; Aboutaleb et al. 2017; Armaghani et al. 2018; Aldeeky and Al Hattamleh 2018; Mohammed et al. 2019; Aliyu et al. 2019; Salehin et al. 2020; Vasanelli et al. 2020; Teymen and Mengüç 2020). Some researchers have utilized soft computing approaches, including artificial neural network (ANN) (Sarkar et al. 2010; Ceryan et al. 2013; Momeni et al. 2015; Mozumder and Laskar 2015; Armaghani et al. 2016; Sharma et al. 2017; Paul et al. 2018; Mahdiabadi and Khanlari 2019; Moussas and Diamantis 2021) and adaptive neuro-fuzzy inference system (ANFIS) (e.g., Singh et al. 2013; Basarir and Dincer 2019; Jing et al. 2021) for estimating geotechnical characteristics of different rocks based on ultrasonic wave velocity.

In this regard, Singh et al. (2017) attempted to predict the compressive and shear strength of rocks from point load index, tensile strength, unit weight, and ultrasonic velocity using statistical analysis and neural networks. This study showed ANN can predict the same strength parameters with better reliability than regression analysis. Shen et al. (2017), using P-wave modulus, estimated the mechanical properties of the rock mass. Jamshidi et al. (2018) evaluated the effect of porosity and density on the correlation between UCS and P-wave velocity. Ghafoori et al. (2018) established correlations between the physical, mechanical, and dynamic properties of limestone through statistical analysis. A strong correlation between UCS, E, and wave velocity was found. Asheghi et al. (2019) predicted UCS of different quarry rocks by a generalized feed-forward neural network (GFFN) and some engineering properties, including density, porosity, P-wave velocity, point load index, and water absorption. Saedi et al. (2019) used multiple regression and fuzzy inference system to estimate UCS and E of migmatites samples. Some index tests including porosity, cylindrical punch index, block punch index, Brazilian tensile strength, point load index, and P-wave velocity were determined and employed to develop predictive models. Ersoy et al. (2019) studied the effect of sample dimension on ultrasonic wave velocity. The results of this study indicated that wave velocity is more controlled by material homogeneity rather than sample length or diameter. Abdelhedi et al. (2020) used a non-destructive ultrasonic technique for studying the mechanical strength of carbonate rock aggregates. Heidari et al. (2020) investigated the dynamic characteristics of pyroclastic rocks by ultrasonic tests during loading in triaxial tests. Ding et al. (2020) investigated the P-wave velocity of anisotropic slate with various foliation orientations and indicated VP increases with increasing foliation angle. Amirkiyaei et al. (2020) determined the VP of some carbonate building stones including, limestone, travertine, and marble, during freeze–thaw (F–T) cycles and the performance of the obtained experimental equations was evaluated using statistical indices. Ajalloeian et al. (2020) studied the effects of petrographic properties on ultrasonic wave velocity including, P-wave and S-wave velocity and dynamic elastic constants of granitic rocks. The results showed that the grain size of minerals and the ratio of quartz to feldspar are reliable parameters for estimating the VP and VS.

In this research, geotechnical tests such as dry density, porosity, and ultrasonic P-wave velocity were used to determine the mechanical properties including, point load strength, Brazilian tensile strength, block punch strength, and uniaxial compressive strength of some sedimentary rocks. Studied samples, including sandstone, limestone, travertine, and conglomerate, were collected from north and northwest parts of Damghan in northeast Iran. Considering the advantages of the ultrasonic wave velocity test mentioned in the literature, the main aim of this research is to determine the strength of sedimentary rocks most simply and cheaply possible in the laboratory based on ultrasonic P-wave velocity. During field investigations, the lithological units were described, and the studied samples were classified according to mineralogical studies and laboratory investigations. Finally, the results of this research were analyzed using multiple regression analysis, artificial neural network, and adaptive neuro-fuzzy inference system to propose some predictive models for estimating the strength of rocks.

From a practical point of view, the present research is generally significant because construction materials and building stones in this region are dominantly composed of sedimentary rocks. These rocks are extracted from quarries and mines and have been used in various engineering projects, such as pavement, foundations, kerb, railway ballast, the rip-rap of dams, and facade stone. The novelty of this research is in the comprehensiveness of geotechnical tests and strength parameters so that all parameters have been reviewed and compared with each other by statistical methods and soft computing approaches, which is not seen in previous research.

2 Material and Methods

2.1 Field Investigations

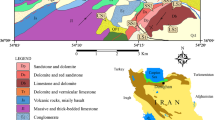

Northern and northwestern parts of Damghan in northeast Iran were selected as study areas. From a geological point of view, the area is located in the Alborz-Azarbayejan structural zone, and a complete succession of Paleozoic to Neogene rocks exists. Suitable sampling locations were selected from the 1:100,000 geological map prepared by the Geological Society of Iran (GSI 1977). Four different sedimentary rocks, including limestone, sandstone, travertine, and conglomerate, were selected for the study. Sampling has been carried out from the quarries, trenches, and road cuttings. Firstly, the specimens were inspected macroscopically, and only the homogeneous, isotropic, un-weathered, and free of visible joints, cracks, fissures, or other discontinuities were considered.

2.2 Mineralogical and Petrographic Analysis

In this research, thin sections were prepared for studying mineralogical and petrographic properties by optical microscopic observations using a modern polarizing microscope based on ISRM (2007). The mineral content of the rock samples was quantified based on the point-counting method. Based on the results of the mineralogical investigations, the studied samples were commonly composed of quartz and calcite. The investigated rock types and the average modal abundance of their minerals are presented in Table 1. X-ray diffraction analysis was conducted according to ISRM (2007) and compositions of the samples were determined in the 2θ ranges from 4° to 70°. Results show that calcite and quartz are the two most important minerals in all samples. Microscopic images of the samples in polarized light are shown in Fig. 1a–d. Also, the diffractograms of XRD analysis for the studied samples are shown in Fig. 2a–d.

2.3 Sample Preparation

Rock blocks were cored in the laboratory using 54 mm diameter (NX core) diamond coring bits. The cut end faces of cores were smoothed and made perpendicular to the core axes with a polishing and lapping machine. Point load strength, Brazilian tensile strength, block punch strength, and uniaxial compressive strength were performed as mechanical tests on high-quality prepared cylindrical core specimens. Before destructive tests, physical properties and ultrasonic P-wave velocity (UPV) tests were carried out as non-destructive tests. To avoid any influence on mechanical properties, the length-to-diameter ratio of the tested specimens was prepared carefully following the suggested method of ISRM (2007). All tests were conducted at room temperature and under the same conditions.

2.4 physical Properties

Physical Properties including dry density (γdry) and effective porosity (ne) were determined using prepared NX core specimens following the standard procedures recommended in ISRM (2007). The dry density of the studied rocks was obtained from the ratio of sample weight to bulk volume. The values of effective porosity for each specimen were obtained from the ratio of pore volume to the sample volume. The dry mass of the studied samples was determined after drying in an oven at a temperature of 110 °C for a period of 24 h. The average values of physical properties are presented in Table 2. According to the results, the TS6-1 and LS1-1 samples have minimum and maximum values of dry density equal to 2.11 and 2.63, respectively. Also, the samples of TS3-2 and SS3-2 have minimum and maximum values of effective porosity, equal to 2.24 and 10.95, respectively.

2.5 Point Load Strength

Point load test is widely used to evaluate the strength of rocks, as it is easy to prepare and test the specimens. In the present research, the axial point load test was performed to measure the point load index (IS(50)) of the studied samples. Obtained NX core samples with a length-to-diameter ratio equal to 1 were prepared, and all tests were performed using automatic point load apparatus. The formula of IS is (ISRM 1985; ASTM 2008):

where P is the applied force and De is the distance between the platens at failure. The point load index for a core diameter equal to 50 mm (Is(50)) was calculated from the following formula:

where F is the size correction factor, F = (De/50)0.45; Is is the uncorrelated point load strength, MPa; and De is the equivalent core diameter in mm.

The point load test was performed based on ISRM (2007) and values of the point load strength are presented in Table 2. According to the results, the CS2-2 and LS3-2 samples had the minimum and maximum values of the point load index, equal to 4.87 and 12.06 MPa, respectively. According to the histogram, the average and standard deviation (Std. Dev.) of IS(50) are equal to 7.91 MPa and 1.98, respectively (Fig. 3). Based on Broch and Franklin (1972) classification of the strength of intact rocks, the studied samples were considered as high to extremely high strength rocks. The failure mode of the study samples is presented in Fig. 4 and shows tested specimens fail in typical tensile splitting failure modes under point load tests. As regards axial point load tests were performed, in most samples, a unique failure mode was observed and rock specimens were split into two pieces. Also, a few specimens fail to split into three blocks.

2.6 Brazilian Tensile Strength

The Brazilian tensile strength test (also known as indirect tensile strength) was performed on NX-prepared disk-shaped core specimens with lengths-to-diameter ratios from 0.5 to 0.75, according to ISRM (2007). The Brazilian tensile strength was calculated by the following formula:

where P is the maximum load recorded during the test and D is the diameter and t is the thickness of the specimen.

The obtained values of BTS for the studied rock samples are presented in Table 2. According to the results, the CS2-2 and LS3-2 samples had the minimum and maximum BTS values, equal to 2.18 and 9.70 MPa, respectively. The histogram of BTS which is presented in Fig. 5, indicated the average and standard deviation of BTS are equal to 5.91 MPa and 2.02, respectively. Two types of failure modes under the BTS test were observed, which are presented in Fig. 6. In sandstone and travertine samples, central and central multiple failure modes were found. While in limestone and conglomerate specimens, central and layer activation failure patterns were observed.

2.7 Block Punch Strength

To carry out the block punch strength test, the thin disk-shaped NX core specimens are cut into discs of various raw thicknesses ranging between 5 and 15 mm using a diamond saw perpendicular to the core axis. This test was performed based on the ISRM (2007) suggested method using the block punch apparatus that was made in this research. The corrected block punch index (BPIC) can be calculated as follows:

where D and t are the diameter and thickness of the disc specimen in mm and P is the failure load in kN.

Results of the block punch test are presented in Table 2 and indicated the CS2-2 and LS1-3 samples had the minimum and maximum values of BPS, equal to 2.18 and 10.54 MPa, respectively. Based on the histogram of BPS, the average and standard deviation are equal to 6.37 MPa and 1.65, respectively (Fig. 7). According to Ulusay et al. (2001), rock classification, TS3, and CS2 are weak, and other tested samples were classified as moderate rocks.

The failure modes of the study rocks under the block punch test are presented in Fig. 8 and show that after failure, the specimens are broken into three parts. Two marginal parts of the specimens were fixed in the punch apparatus and the middle part was punched out. As can be seen, regular failure occurred and fractured planes were parallel together. In a few travertine samples, cross joints developed during the block punch test, and unexampled fracture planes as irregular failure was observed. For this reason, the test was rejected as invalid results and the block punch test was repeated.

2.8 Uniaxial Compressive Strength

The uniaxial compressive test was conducted with a length-to-diameter ratio of 2 to 2.5 based on ASTM (1995) and ISRM (2007) suggested methods. By using the following equation, the UCS of the rock samples can be computed:

where P is the failure load and A cross-sectional area of the cylindrical specimen.

The 50 kg/Sec stress rate was applied to the UCS test and the automatic machine having 200 tons of capacity was used. The UCS test was repeated at least five times for each rock type, and the average value was calculated as the UCS that is presented in Table 2. According to the results, the CS2-2 and LS1-1 samples had the minimum and maximum values of UCS, equal to 14.07 and 53.49 MPa, respectively. The mean values and standard deviation of UCS are equal to 29.07 MPa and 11.61, respectively. Normal distribution curves of the UCS test are also shown in the histogram in Fig. 9. Higher standard deviation values of UCS indicated that studied samples had various ranges of strength. Based on ISRM (1981) rock classification, the tested samples were classified as low to moderate strong rocks.

Various failure patterns of the studied rocks were observed under the UCS test that are presented in Fig. 10. Results of the UCS test show that most of the sandstone specimens failed in a Y-shaped. The failure mode of limestone samples is axial splitting. In the case of travertine samples, most specimens failed along layering. Most conglomerate specimens have axial splitting, whereas in many samples, shearing along a single plane was observed.

2.9 Ultrasonic P-wave Velocity

The ultrasonic P-wave velocity (VP) of the studied rocks was determined using a Portable Ultrasonic Non-destructive Digital Indicating Tester (PUNDIT) in the laboratory, based on ASTM (1996) and ISRM (2007). The PUNDIT has a pulse generator, transducers, and an electronic counter for time interval measurements. An accuracy of 0.1 mm to the length of the measuring base was used. Before the measurements, the cut ends of the samples were polished to provide a flat and smooth surface. A thin layer of petroleum jelly (Vaseline) was fulfilled to the surface of the transducers (receiver and transmitter) to provide complete contact and to remove the air gap between the transducers and the specimen surface. In the tests, the ultrasonic pulse time was measured with an accuracy of 0.1 ms and at ultrasonic frequencies of 500 kHz. The UPV was obtained by dividing the length of the NX-sized core and the travel pulse time. P-wave velocity apparatus and prepared core specimens are presented in Fig. 11a and b, respectively.

Results of the P-wave velocity test show that the CS2-2 and TS1-1 samples had the minimum and maximum values of wave velocities, equal to 2826 and 6053 m/s respectively, as presented in Table 3. The histogram of VP (Fig. 12) indicated that the average and standard deviation are equal to 4303.38 m/s and 907.65, respectively. Based on IAEG (1979) rock classification, the P-wave velocity values of the studied rocks ranged from low to very high. Also, according to Bell (2000), the studied samples were classified as weathered to fresh rocks based on P-wave velocity values.

Travel pulse time and P-wave modulus for studied samples are also calculated and presented in Table 3. Pulse times are in the range of 19.9–42.9 μs. P-wave modulus was calculated by the following formula, which is in the range of 20.92 to 69.87 GPa.

where M is P-wave modulus in GPa, and ρ is density in g/cm3.

Obtained echo signal of P-wave velocity, pulse time, and P-wave modulus is presented in Fig. 13a–c. these figures show the first echo arrives at approximately 19.9 μs and corresponds to the TS1-1 with the highest wave velocity equal to 6053 m/s. A lesser echo wave appears in 42.9 μs which corresponds to CS2-2. The correlation between P-wave velocity values, pulse time, and P-wave modulus was performed by simple regression analysis and is presented in Fig. 14. According to Fig. 14a, the relation between VP and time is a reverse power relation, with R2 = 0.99. Therefore, when pulse time travel increased, the VP decreased. Whereas the relation between VP and P-wave modulus is, a direct linear relation with R2 = 0.98 that shows these parameters increased together (Fig. 14b).

3 Results

In the present research, mechanical properties including point load strength, Brazilian tensile strength, block punch strength, and uniaxial compressive strength of some sedimentary rocks have been predicted by dry density, porosity, and ultrasonic P-wave velocity by using multivariate regression analysis and soft computing methods including artificial neural network and adaptive neuro-fuzzy inference system. The results of this research are described and discussed in the next sections.

3.1 Multivariate Regression Analysis

In recent years, simple and multivariate regression analysis (MRA) are widely used as a statistical technique in various fields of geotechnical engineering and engineering geology to develop mathematical expression between significant geotechnical parameters of soils and rocks (Sharma and Singh 2018). Regression analysis is a statistical tool for estimating the relationship between variables and predicting unknown from known parameters (Yagiz 2011). Multivariate regression is a classic linear statistical forecasting technique for understanding the relationship between a dependent variable and two or more independent variables. The multivariate regression technique formulates a model to obtain an estimation of the values of the dependent variable by fitting a linear equation to observed variables. Generally in the form of the regression model is expressed as follows:

where y is the value of the variable that is to be determined, α0 is the y-intercept by the regression line, x1, x2, …, xn are the values of dependent variables, β represents the error, α1, α2, …, αn are the regression coefficient, defined as the amount of the response variable changes due to change in the corresponding dependent variable by 1 unit (Khandelwal et al. 2017; Sharma et al. 2017).

In this research, multivariate regression analyses were modeled by IBM SPSS Statistics (v. 24). In this method, γdry, ne, and VP are considered as independent variables or predictors, and mechanical properties including PLS, BTS, BPS, and UCS are considered as the dependent variables or outputs and were modeled in models 1 to 4, respectively. Table 4 presents the summary of coefficients of multivariate regression results including the Beta coefficient, standard error of Beta, significant level (Sig.), lower and upper confidence interval, tolerance, and VIF of established models. Table 5 presents the summary of the multivariate correlation coefficient including R, R square, adjusted R, standard error, and Durbin-Watson of established models. The coefficient of determination (R2) is equated in Eq. 8, as follows:

where y and y′ are the experimental and predicted values, respectively. \(\overline{y}\) is the average of the set y and n is the number of data. The coefficient of determination measures the proportion of variance in the dependent variable that is predictable from the independent variables. It is the square of the correlation coefficient (R) and ranges from 0 to 1.

By obtaining coefficients from multivariate regression analysis, four experimental models were developed as follows:

3.2 Artificial Neural Network

An artificial neural network (ANN) is an intelligent soft computing method that has been used to predict various complex parameters in recent years. It consists of numerous simple processing elements (neurons) capable of performing complex data processing and knowledge representation (Sarkar et al. 2010). The neural network is normally trained by processing a large number of input and output patterns to achieve matching and prediction. The structure and data processing technique of ANN is inspired by the human brain. The configuration of ANN is composed of a highly layered structure that constitutes many simple processing elements capable of performing highly complex computations for data processing and knowledge representation (Singh et al. 2017).

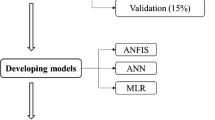

In this research, due to no time-dependent parameter used in the ANN, the feed-forward (FF) neural network by MATLAB Version 9.9.0 (R2020b) (MATLAB 2020) was used to establish predictive models. For ANN modeling, similar to multiple regression analysis, γdry, n, and VP are constant inputs in all models, and mechanical properties including PLS, BTS, BPS, and UCS are considered outputs that are predicted in models 1 to 4, respectively. Architectures of ANN that were used in this study are presented in Fig. 15 which is composed of an input layer, hidden layer, and output layer. All data were then divided into three data sets such as training, validation, and testing, which are 70% for the training, 15% for the testing, and 15% for the validation, respectively. The Levenberg–Marquardt algorithm was applied for prediction and 10 hidden neurons were utilized in models.

Figure 16a–c shows the results of ANN modeling. Figure 16a shows the training state of the ANN model 1. In model 1 after epoch number 9 the errors are happening 6 times and the test is stopped at epoch number 15. In model 2 for predicting BTS, the test is stopped at epoch number 13 and the errors happen 6 times. In model 3, which predicted BPS, after epoch number 4 the errors are happening 6 times and the test stopped at epoch number 10. Finally, in models of UCS, after epoch number 3 the test is stopped at epoch number 9. Therefore, results indicated in all model errors happen 6 times. Figure 16b shows the validation curves in ANN models for predicting the output PLS. In model 1 the best validation performance is 0.039 which happened at epoch number 9. In models 2, 3, and 4; the best validation performances are equal to 0.68, 0.043, and 40.44 which happened in epoch number 7, 4, and 3 which predicted BTS, BPS, and UCS, respectively. The values of mean squared error (MSE) that can be seen in the Y-axis of the graph of Fig. 16b, are different in ANN models, as in model 3 for predicting BPS was less than other models. Figure 16c is a cross-correlation between the predicted (output) and measured (target) data that shows a regression graph for the ANN model 1. The correlation coefficient (R) for models 1, 2, 3, and 4 are equal to R = 0.975, 0.983, 0.986, and 0.955, respectively, which shows the accuracy of the model for predicting PLS, BTS, BPS, and UCS.

3.3 Adaptive Neuro-Fuzzy Inference System

Adaptive neuro-fuzzy inference system (ANFIS) is an admixture of two soft computing methods, including ANN and fuzzy logic (FL). Jang (1993) developed ANFIS based on the Takagi–Sugeno fuzzy inference system (FIS). Fuzzy logic, which was proposed by Zadeh (1965), can change the qualitative aspects of human knowledge and insights into the process of precise quantitative analysis. Unlike ANN, it has a higher capability in the learning process to adapt to its environment. Adaptive network is one example of a feed-forward neural network with multiple layers. This type of FIS was first introduced by Takagi and Sugeno (1985).

In the ANFIS modeling, the same data sets that were used in MRA and ANN were also employed. Therefore, γdry, n and VP are constant inputs, and PLS, BTS, BPS, and UCS as outputs predicted in models 1 to 4, respectively. The ANFIS models are developed by MATLAB (R2020b) (MATLAB 2020). The structure of the ANFIS models is shown in Fig. 17. The training of the ANFIS models was carried out using 50 epochs. In the training process, the dataset was randomly used. In this study, a hybrid learning algorithm that was proposed by Jang (1993), was applied for predicting UCS, and grid partition was applied to make the propositions of the fuzzy rules. Also, a linear type of Gaussian membership function (gaussmf) was used to predict the dependent mechanical properties. Finally, using the trained model, the training and testing datasets were simulated and assessed. The plot showing the relationship between the models’ inputs with the 27 rules used in predicting the UCS is shown in Fig. 18.

4 Discussion

The predicted values of PLS, BTS, BPS, and UCS that were obtained by models of multiple regression, artificial neural network, and adaptive neuro-fuzzy inference system are presented in Table 6. Based on the comparison between predicted and experimental data that are presented in Table 2, results show obtained values of ANN and ANFIS models with very low errors approximately similar to experimental values. Whereas, obtained values from MRA models have differences from experimental data. Also, some statistical parameters including mean, standard deviation (Std. D.), median, mode, and variance are calculated for the output of MRA, ANN, and ANFIS models that are presented in Table 7. Based on the results, standard deviation, and variance values were obtained from 1.14 to 8.63, 1.59 to 10.84, 1.65 to 11.49, and 1.30 to 74.52, 2.52 to 117.60, and 2.72 to 132.00 for MRA, ANN, and ANFIS models, respectively.

For assessing the performance of models, statistical parameters including correlation coefficient (R), root mean square error (RMSE), variance account for (VAF), mean absolute percentage error (MAPE), and performance index (PI) were calculated by the following equations:

where y and y′ are the experimental and calculated values, respectively; and N is the total number of data. The model will be excellent if R = 1, RMSE = 0, VAF = 100, MAPE = 0, and the PI has the biggest value. When an RMSE value approaches zero, the predicted values from the regression equation are closer to the experimental values.

Statistical parameters for models of multiple regression, artificial neural network, and adaptive neuro-fuzzy inference system were calculated and presented in Tables 8, 9, and 10, respectively. Also, comparative diagrams of R, RMSE, VAF, MAPE, and PI for the results of MRA, ANN, and ANFIS models are presented in Fig. 19a–e. Results show R values were obtained between 0.73 and 0.85, 0.96 and 0.99, and equal to 0.99 for MRA, ANN, and ANFIS models, respectively. RMSE values were obtained between “8.04 and 0.11”, the best value dependent on model 3 of ANFIS. Based on the diagrams, the ANFIS model obtained the best results in R, RMSE, VAF, MAPE, and PI values. Also, it was seen, ANN and ANFIS models have better results than MRA with highly different.

For comparing the results of MRA, ANN, and ANFIS for predicting mechanical properties of studied rocks, experimental and predicted values of PLS, BTS, BPS, and UCS; also a 45° line (y = x) has been plotted in diagrams that are shown in Fig. 20a–d, as models 1 to 4, respectively. In this method, the adoption rate of MRA, ANN, and ANFIS trend lines with a 45° line (y = x) shows the validity of experimental equations. Based on these diagrams, the trend lines of ANN and ANFIS data completely fit the 45° line. Whereas, trend lines of MRA in models of PLS and UCS (Fig. 20a and d) slightly intercept the 45° line. Also, the trend lines of BTS and BPS models (Fig. 20b and c) are partly parallel to 45° lines. Therefore, the results of the correlation between experimental and predicted values indicated that ANN and ANFIS models presented more accurate results than MRA.

Another method for assessing and comparing the results of MRA, ANN, and ANFIS models, is calculating the residual error of calculated data. Residual error was calculated by subtraction of the experimental values from the calculated values for all models. For comparing the obtained value of residual error, graphs of residual error are presented in Fig. 21a–d, for PLS, BTS, BPS, and UCS models, respectively. Based on diagrams of Fig. 21, obviously can be seen trend lines of residual error for ANFIS and ANN more fit with a horizontal line (X-axis) than MRA trend lines. Also, some statistical parameters including mean, standard deviation, median, mode, and variance are calculated for obtaining values of residual error that are presented in Table 11. Based on the results, standard deviation, and variance values were obtained from 1.03 to 7.99, 0.28 to 3.45, 0.11 to 1.08, and 1.06 to 63.94, 0.08 to 11.88, and 0.01 to 1.17 for MRA, ANN, and ANFIS models, respectively. Results show standard deviation and variance were decreased from MRA to ANN and ANFIS models. Therefore, from a statistical point of view, ANFIS models presented very good results for predicting the mechanical properties of the studied rocks. Also, it noted that ANN shows better results than MRA models.

5 Conclusion

In this research, the north and northwest parts of Damghan, northeast of Iran are selected as the study area. Some sedimentary rock samples with different lithologies including sandstone, limestone, travertine, and conglomerate were collected from these areas. For determining geotechnical properties laboratory testing including dry density, effective porosity, point load strength, Brazilian tensile strength, block punch strength, uniaxial compressive strength, and ultrasonic P-wave velocity were performed based on recommended standard methods by the ISRM and ASTM. Results of petrography and mineralogy studies by thin sections and XRD analysis show that studied samples are dominantly composed of quartz and calcite. Results of the mechanical testing show, the studied samples were classified as weak to extremely strong rocks. Ultrasonic P-wave velocity values ranged from low to very high and were classified as weathered to fresh rocks based on the VP. The reverse power relation with R2 = 0.99 and direct linear relation with R2 = 0.98 were found between VP, pulse time travel, and P-wave modulus, respectively. To establish predictive models, γdry, ne and VP are considered as inputs, and mechanical properties including PLS, BTS, BPS, and UCS are considered as outputs. Four predictive models were established using multivariate regression analysis, artificial neural network, and adaptive neuro-fuzzy inference system. Results of MRA show the average values of the variance inflation factor and tolerance obtained, 1.18 and 0.86, respectively. The ANN models were constructed using a feed-forward neural network and trained using the Levenberg–Marquardt algorithm. The rules of ANFIS models were obtained by fuzzy if–then rules in a Takagi–Sugeno type inference system, and the Gaussian membership function is also used. Statistical parameters including R, RMSE, VAF, MAPE, and PI were calculated and compared to assess the performance of MRA, ANN, and ANFIS models. Results show R values were obtained from 0.73 to 0.85, 0.96 to 0.99, and equal to 0.99 for MRA, ANN, and ANFIS models, respectively. RMSE values were obtained between “8.04 and 0.11”. Based on the results of comparative diagrams, ANFIS models obtained the best results in R, RMSE, VAF, MAPE, and PI values. Also, it was found, ANN models have better results than MRA. The correlations between experimental and predicted values of PLS, BTS, BPS, and UCS that were obtained by MRA, ANN, and ANFIS models and compared with a 45° line (y = x) indicated that the trend lines of ANN and ANFIS models completely fit the 45° line. Whereas, trend lines of MRA slightly intercept or are partly parallel to the 45° line. Calculating residual error shows trend lines of ANFIS and ANN are fitter to the horizontal line (X-axis) than MRA trend lines. Results indicated standard deviation and variance of residual error were decreased from MRA to ANN and ANFIS models. Therefore, statistical analysis and soft computing methods presented acceptable results, but it was noted that ANN and ANFIS are more reliable methods for establishing predictive models for predicting the mechanical properties of the studied rocks. Considering that the mechanical behavior of rocks depends on the type of rock, this research has limitations. Therefore, the results of the current research are valid and feasible for sandstone, limestone, travertine, and conglomerate. In this regard, it is recommended that similar modeling for other rock types be applied.

References

Asheghi R, Shahri AA, Zak MK (2019) Prediction of uniaxial compressive strength of different quarried rocks using metaheuristic algorithm. Arab J Sci Eng 44:8645–8659

Abdelhedi M, Jabbar R, Mnif T, Abbes C (2020) Ultrasonic velocity as a tool for geotechnical parameters prediction within carbonate rocks aggregates. Arab J Geosci. https://doi.org/10.1007/s12517-020-5070-0

Aboutaleb S, Bagherpour R, Behnia M, Aghababaei M (2017) Combination of the physical and ultrasonic tests in estimating the uniaxial compressive strength and young’s modulus of intact limestone rocks. Geotech Geol Eng 35:3015–3023

Ajalloeian R, Jamshidi A, Khorasani R (2020) Assessments of ultrasonic pulse velocity and dynamic elastic constants of granitic rocks using petrographic characteristics. Geotech Geol Eng 38:2835–2844

Aldeeky H, Al Hattamleh O (2018) Prediction of engineering properties of basalt rock in Jordan using ultrasonic pulse velocity test. Geotech Geol Eng 36:3511–3525

Aliyu MM, Shang J, Murphy W, Lawrence JA, Collier R, Kong F, Zhao Z (2019) Assessing the uniaxial compressive strength of extremely hard cryptocrystalline flint. Int J Rock Mech Min Sci 113:310–321

Altindag R (2012) Correlation between P-wave velocity and some mechanical properties for sedimentary rocks. J Southern Afr Inst Min Metall 112(3):229–237

Amirkiyaei V, Ghasemi E, Faramarzi L (2020) Determination of P-wave velocity of carbonate building stones during freeze–thaw cycles. Geotech Geol Eng 38:5999–6009

ISRM (2007) The Blue Book: the complete ISRM suggested methods for rock characterization, testing and monitoring. In: Ulusay R, Hudson JA (eds) Compilation arranged by the ISRM Turkish National Group, Ankara, Turkey. Kazan Offset Press, Ankara, pp 1974–2006

Armaghani DJ, Amin MFM, Yagiz S, Faradonbeh RS, Abdullah RS (2016) Prediction of the uniaxial compressive strength of sandstone using various modeling techniques. Int J Rock Mech Min Sci 85:174–186

Armaghani DJ, Safari V, Fahimifar A, Amin MFM, Monjezi M, Mohammadi MA (2018) Uniaxial compressive strength prediction through a new technique based on gene expression programming. Neural Comput Applic 30:3523–3532

Arman H, Paramban S (2021) Dimensional effects on dynamic properties and the relationships between ultrasonic pulse velocity and physical properties of rock under various environmental conditions. Geotech Geol Eng 39:3947–3957

ASTM (1995) D2938: Standard test method for unconfined compressive strength of intact rock core specimens. ASTM International West Conshohocken

ASTM (1996) D2845-D2895: Standard test method for laboratory determination of pulse velocities and ultrasonic elastic constants of rock. ASTM International West Conshohocken

ASTM (2008) D5731-08: Standard test method for determination of the point load strength index of rock and application to rock strength classifications. ASTM International West Conshohocken

Azimian A, Ajalloeian R (2015) Empirical correlation of physical and mechanical properties of marly rocks with P wave velocity. Arab J Geosci 8:2069–2079

Basarir H, Dincer T (2019) Prediction of rock mass P wave velocity using blast hole drilling information. Int J Min Rec Environ 33(1):61–74

Bell FG (2000) Engineering properties of soils and rocks, 4th edn. Blackwell Science, Oxford

Benavente D, Galiana-Merino JJ, Pla C, Martinez-Martinez J, Crespo-Jimenez D (2020) Automatic detection and characterisation of the first P and S-wave pulse in rocks using ultrasonic transmission method. Eng Geol. https://doi.org/10.1016/j.enggeo.2020.105474

Broch E, Franklin JA (1972) The point load strength test. Int J Rock Mech Min Sci 9:669–697

Ceryan N, Okkan U, Kesimal A (2013) Prediction of unconfined compressive strength of carbonate rocks using artificial neural networks. Environ Earth Sci 68:807–819

Chawre B (2018) Correlations between ultrasonic pulse wave velocities and rock properties of quartz-mica schist. J Rock Mech Geotech Eng 10:594–602

Cobanoğlu I, Çelik S (2008) Estimation of uniaxial compressive strength from point load strength, Schmidt hardness and P-wave velocity. Bull Eng Geol Environ 67:491–498

Diamantis K (2019) Estimation of tensile strength of ultramafic rocks using indirect approaches. Geomech Eng 17(3):261–270

Diamantis K, Bellas S, Migiros G, Gartzos E (2011) Correlating wave velocities with physical, mechanical properties and petrographic characteristics of peridotites from the Central Greece. Geotech Geol Eng 29(6):1049–1062

Diamantis A, Karamousalis T, Gartzos E, Migiros G (2012) Pulse transmission techniques for the characterization of serpentinites from central Greece. Q J Eng Geol Hydro 45(3):369–678

Diamantis K, Fereidooni D, Khajevand R, Migiros G (2021) Effect of textural characteristics on engineering properties of some sedimentary rocks. J Cent South Univ 28:926–938

Ding C, Hu D, Zhou H, Lu J, Lv T (2020) Investigations of P-Wave velocity, mechanical behavior and thermal properties of anisotropic slate. Int J Rock Mech Min Sci. https://doi.org/10.1016/j.ijrmms.2019.104176

Ersoy H, Karahan M, Babacan AE, Sünnetci MO (2019) A new approach to the effect of sample dimensions and measurement techniques on ultrasonic wave velocity. Eng Geol 251:63–70

Fener M (2011) The effect of rock sample dimension on the P-wave velocity. J Nondestruct Eval 30:99–105

Ferentinou M, Fakir M (2017) An ANN approach for the prediction of uniaxial compressive strength, of some sedimentary and igneous rocks in Eastern KwaZulu-Natal. Procedia Eng 191:1117–1125

Ghafoori M, Rastegarnia A, Lashkaripour GR (2018) Estimation of static parameters based on dynamical and physical properties in limestone rocks. J Afr Earth Sci 137:22–31

GSI (Geological Society of Iran) (1977) Geological quadrangle map of Iran, No. 6862, Scale 1:100000, Printed by Offset Press Inc. Tehran

Hassan A, Sanuade OA, Olaseeni OG (2021) Prediction of physico-mechanical properties of intact rocks using artificial neural network. Acta Geophys 69:1769–1788

Heidari M, Mohseni H, Jalali SH (2018) Prediction of uniaxial compressive strength of some sedimentary rocks by fuzzy and regression models. Geotech Geol Eng 36:401–412

Heidari M, Ajalloeian R, Ghazifard A, Isfahanian MH (2020) Evaluation of P and S wave velocities and their return energy of rock specimen at various lateral and axial stresses. Geotech Geol Eng 38:3253–3270

Hemeda S, Pitilakis K (2010) Serapeum temple and the ancient annex daughter library in Alexandria, Egypt: geotechnical–geophysical investigations and stability analysis under static and seismic conditions. Eng Geol 113:33–43

IAEG (1979) Classification of rocks and soils for engineering geological mapping, part 1: rock and soil materials. Rep Comm Eng Geol Mapp Bull Int Assoc Eng Geol 19:364–371

ISRM (1981) Suggested methods for determining hardness and abrasiveness of rocks, Part 3. Commission on standardization of laboratory and field tests 101–112

ISRM (1985) Suggested method for determining point load strength: ISRM Comm. on testing methods. Int J Rock Mech Min Sci Geomech Abstr. 22(4):112

Jamshidi A, Zamanian H, Sahamieh RZ (2018) The effect of density and porosity on the correlation between uniaxial compressive strength and P-wave velocity. Rock Mech Rock Eng 51:1279–1286

Jang JSR (1993) ANFIS: adaptive network-based fuzzy inference systems. IEEE Trans Sys Man Cybern 23(3):665–685

Jing H, Nikafshan Rad H, Hasanipanah M, Armaghani DJ, Noman Qasem S (2021) Design and implementation of a new tuned hybrid intelligent model to predict the uniaxial compressive strength of the rock using SFS-ANFIS. Eng Comput 37:2717–2734

Johari A, Fazeli A, Javadi AA (2013) An investigation into application of jointly distributed random variables method in reliability assessment of rock slope stability. Comput Geotech 47:42–47

Johari A, Momeni M, Javadi AA (2015) An analytical solution for reliability assessment of pseudo-static stability of rock slopes using jointly distributed random variables method. Iran J Sci Technol Trans Civil Eng 39(C2):351–363

Kahraman S (2001) Evaluation of simple methods for assessing the uniaxial compressive strength of rock. Int J Rock Mech Min Sci 38:981–994

Khajevand R, Fereidooni D (2018) Assessing the empirical correlations between engineering properties and P wave velocity of some sedimentary rock samples from Damghan, northern Iran. Arab J Geosci. https://doi.org/10.1007/s12517-018-3810-1

Khajevand R, Fereidooni D (2019) Utilization of the point load and block punch strengths to predict the mechanical properties of several rock samples using regression analysis methods. Innov Infrastruct Solut. https://doi.org/10.1007/s41062-019-0201-8

Khajevand R, Fereidooni D (2022) The effects of water acidity and engineering properties on rock durability. Earth Sci Res J 6(1):67–79

Khandelwal M, Singh TN (2009) Correlating static properties of coal measures rocks with p-wave velocity. Int J Coal Geol 79:55–60

Khandelwal M, Armaghani DJ, Faradonbeh RS, Yellishetty M, Majid MZA, Monjezi M (2017) Classification and regression tree technique in estimating peak particle velocity caused by blasting. Eng Comput 33(1):45–53

Kianpour M, Fatemi Aghda SM, Talkhablou M (2019) Classification of limestone rock masses using laboratory and field P-wave velocity by ArcGIS fuzzy overlay (AFO) (case study: five dam sites in Zagros Mountains, western Iran). Geotech Geol Eng 38:631–650

Kilic A, Teymen A (2008) Determination of mechanical properties of rocks using simple methods. Bull Eng Geol Environ 67:237–244

Kurtulus C, Sertcelik F, Sertcelik I (2016) Correlating physico-mechanical properties of intact rocks with P-wave velocity. Acta Geod Geophys 51:571–582

Mahdiabadi N, Khanlari G (2019) Prediction of uniaxial compressive strength and modulus of elasticity in calcareous mudstones using neural networks, fuzzy systems, and regression analysis. Period Polytech Civil Eng 63(1):104–114

MATLAB and Statistical Toolbox Released 2020b the mathworks (2020), Inc., Natick, Massachusetts, United States

Mohammed DA, Alshkane YM, Abdalqadir ZK (2019) Evaluation of empirical equations to estimate the mechanical properties of sedimentary rocks using ultrasonic pulse velocity (UPV). Eur J Sci Eng 4(4):135–147

Momeni E, Armaghani DJ, Hajihassani M, Amin MFM (2015) Prediction of uniaxial compressive strength of rock samples using hybrid particle swarm optimization-based artificial neural networks. Measurement 60:50–63

Moussas VC, Diamantis K (2021) Predicting uniaxial compressive strength of serpentinites through physical, dynamic and mechanical properties using neural networks. J Rock Mech Geotech Eng 13:167–175

Mozumder RA, Laskar AI (2015) Prediction of unconfined compressive strength of geopolymer stabilized clayey soil using Artificial Neural Network. Comput Geotech 69:291–300

Paul S, Ali M, Chartterjee R (2018) Prediction of compressional wave velocity using regression and neural network modeling and estimation of stress orientation in Bokaro Coalfield, India. Pure Appl Geophys 175:375–388

Saedi B, Mohammadi SD, Shahbazi H (2019) Application of fuzzy inference system to predict uniaxial compressive strength and elastic modulus of migmatites. Environ Earth Sci. https://doi.org/10.1007/s12665-019-8219-y

Salehin S, Hadavandi E, Chelgani SC (2020) Exploring relationships between mechanical properties of marl core samples by a coupling of mutual information and predictive ensemble model. Model Earth Sys Environ 6:575–583

Sarkar K, Tiwary A, Singh TN (2010) Estimation of strength parameters of rock using artificial neural networks. Bull Eng Geol Environ 69:599–606

Sharma LK, Singh TN (2018) Regression-based models for the prediction of unconfined compressive strength of artificially structured soil. Eng Comput 34:175–186

Sharma LK, Vishal V, Singh TN (2017) Developing novel models using neural networks and fuzzy systems for the prediction of strength of rocks from key geomechanical properties. Measurement 102:158–169

Shen X, Chen M, Lu W, Li L (2017) Using P wave modulus to estimate the mechanical parameters of rock mass. Bull Eng Geol Environ 76:1461–1470

Shirole D, Hedayat A, Ghazanfari E, Walton G (2020) Evaluation of an ultrasonic method for damage characterization of brittle rocks. Rock Mech Rock Eng 53:2077–2094

Singh R, Vishal V, Singh TN, Ranjith PG (2013) A comparative study of generalized regression neural network approach and adaptive neuro-fuzzy inference systems for prediction of unconfined compressive strength of rocks. Neural Comput Applic 23:499–506

Singh PK, Tripathy A, Kainthola A, Mahanta B, Singh V, Singh TN (2017) Indirect estimation of compressive and shear strength from simple index tests. Eng Comput 33:1–11

Takagi T, Sugeno M (1985) Fuzzy identification of systems and its applications to modeling and control. IEEE Trans Syst Man Cybern 15(1):116–132

Tandon RS, Gupta V (2015) Estimation of strength characteristics of different Himalayan rocks from Schmidt hammer rebound, point load index, and compressional wave velocity. Bull Eng Geol Environ 74:521–533

Teymen A, Mengüç EC (2020) Comparative evaluation of different statistical tools for the prediction of uniaxial compressive strength of rocks. Int J Min Sci Tech 30:785–797

Tuğrul A, Zarif IH (1999) Correlation of mineralogical and textural, characteristics with engineering properties of selected granitic rocks from Turkey. Eng Geol 51(4):303–317

Ulusay R, Gokceoglu C, Sulukcu S (2001) Draft ISRM suggested method for determining block punch strength index (BPI). Int J Rock Mech Min Sci 38(8):1113–1119

Vasanelli E, Micelli F, Colangiuli D, Calia A, Aiello MA (2020) A non-destructive testing method for masonry by using UPV and cross validation procedure. Mat Struct 53:134–149

Wang Y, Han JQ (2020) Geomechanical and ultrasonic characteristics of black shale during triaxial deformation revealed using real-time ultrasonic detection dependence upon bedding orientation and confining pressure. Geotech Geol Eng 38:6773–6794

Wang T, Zhang H, Gamage RP, Zhao W, Ge J, Li Y (2020) The evaluation criteria for rock brittleness based on double-body analysis under uniaxial compression. Geomech Geophys Geo-Energ Geo-Resour 6:49. https://doi.org/10.1007/s40948-020-00165-x

Yagiz S (2011) P-wave velocity test for assessment of geotechnical properties of some rock materials. Bull Mater Sci 34(4):947–953

Yang F, Hu D, Zhou H, Lu J (2020) Physico-mechanical behaviors of granite under coupled static and dynamic cyclic loadings. Rock Mech Rock Eng 53:2157–2173

Yasar E, Erdogan Y (2004) Correlating sound velocity with the density, compressive strength and Young’s modulus of carbonate rocks. Int J Rock Mech Min Sci 41:871–875

Zadeh LA (1965) Fuzzy sets. Info Control 8:338–353

Acknowledgements

The author like to express his thanks to Mr. P. Khajevand for the English editing.

Funding

No external funding was used.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author does not have any conflict of interest.

Ethical Approval

This article does not contain any studies with human participants.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Khajevand, R. Estimating Geotechnical Properties of Sedimentary Rocks Based on Physical Parameters and Ultrasonic P-Wave Velocity Using Statistical Methods and Soft Computing Approaches. Iran J Sci Technol Trans Civ Eng 47, 3785–3809 (2023). https://doi.org/10.1007/s40996-023-01148-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40996-023-01148-0