Abstract

The purpose of this study is to develop a method for highway tunnel performance evaluation using combined weight theory and fuzzy multi-criteria decision-making analysis (FMCDM). This study takes the MWP highway tunnel as the research object, and analytic hierarchy process (AHP), entropy theory (ET), game theory (GT), and FMCDM theory were used to study the tunnel performance. The evaluation index system and the classification value limits are determined, the key factors affecting the tunnel performance level were analyzed, and the subjective and objective weights of each index are calculated using AHP and ET. By applying the membership function of FMCDM theory to solve the single index membership of each index at different levels, and combining GT to obtain the comprehensive weights, and the weights of lining structure and Communication Systems is the largest among all index, 0.389 and 0.214, respectively, and in line with engineering practice. The multi-index comprehensive membership evaluation value and target comprehensive membership evaluation vector of the tunnels based on FMCDM theory at different levels are obtained. According to the principle that with the larger the value, the performance is better, the tunnel performance is comprehensively evaluated. Finally, the scientific of the evaluation method is tested in combination with the MWP tunnel case, and the deterioration model of the tunnel performance is proposed based on the structure reliability theory, and the model results are compared with actual observations during tunnel inspection. The results show that the degradation model has strong operability and high accuracy and can effectively predict and ensure the safety of the tunnel structure. The performance evaluation method has objectivity, relevance, and intuitiveness. It can identify the key links of the evaluation and enable construction planners and managers to improve the robustness and safety of the tunnels.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

At present, with the increasing investment and construction of infrastructure, the importance of the civil engineering industry is becoming increasingly prominent, especially the number of new tunnels. But at the same time, there are some new problems for the tunnels, which is to ensure the new tunnels with excellent structural quality and safe operation and requires that the tunnels with built for many years can operate normally. Therefore, the evaluation with performance of highway tunnel structures has become an important solution to this problem (Lai et al. 2017; Xun 2006; Menendez et al. 2018; Bhalla et al. 2005; Wu et al. 2017).

In recent years, many scholars have conducted a lot of research on the health of highway tunnel structures and have achieved a series of results. Yuan et al. (2012), based on the idea with limit state design, analyzed the influence of internal and external loads and environmental factors on the life of tunnel structures. Aldo Minardo et al. (2018) applied distributed optical fiber strain sensing technology to tunnel structure monitoring and verified the safety and stability of tunnel lining structures through real-time monitoring of tunnel linings deformation. Wu et al. (2017) proposed a method for evaluating the safety of tunnel linings based on the fractal dimension of cracks. Through the digital detection test of the Hidake tunnel in Japan, the fractal dimension of the tunnel lining cracks was obtained using statistical methods TCI to evaluate the health of the tunnels. Arends et al. (2005) proposed a tunnel safety evaluation method based on risk assessment from the perspective of economic optimization. Maleki and Mousivand (2014) evaluated the safety of the tunnels based on the elasto-viscoplastic constitutive model by defining two safety parameters related to the short-term and long-term behavior of the tunnels. Zhou et al. (2014) proposed a new structural health evaluation method based on torsional wave velocity. This method uses the torsional wave velocity to determine the Young’s modulus of the tunnel structures, which provides a theoretical basis for future application in the health assessment of the shield tunnels. Jinxing Lai et al. (2017) used crack width monitoring technology, concrete strength monitoring technology, electromagnetic wave nondestructive monitoring technology, and other modern detection technologies to comprehensively detect lining cracks, tunnel seepage, and lining voids. Through the statistical analysis of the test results, the distribution characteristics, development rules, and damage levels of structural defects are obtained, which provides some experience for the design and health evaluation of the existing multi-arch tunnel projects. Huang et al. (2019) proposed a tunnel damage visualization evaluation method based on the cloud theory, which effectively considered the ambiguity and randomness of the evaluation system, and improved the accuracy of the structural damage evaluation results. Rao et al. (2016) established a fuzzy comprehensive evaluation model for the safety of in-service structures of highway tunnels in karst areas, based on the Huilongshan tunnel, and conducted a safety evaluation using the maximum membership method. Olsson and Sturk (1994) evaluated the risks of the construction of particularly long highway tunnels, considered many uncertainties, analyzed the target’s safety risks, investment, and environmental risks, and established the risks evaluation system. McFeat-Smith (2000, 2005) studied the risk assessment of tunnel projects under complex geological conditions in Asia and proposed the risk grading Codes, and the risk is divided into 5 levels.

In addition, due to the increasingly prominent deterioration of the tunnel structures, a lot of Codes and standards have been carried out in the assessment of the safety of the tunnel structures during the operation period. The Japan Railway Tunnel proposes two inspection methods, general inspection and individual inspection. The “soundness” index is used to judge the safety level of the tunnels, and the criteria for the soundness of lining cracking, deterioration, water leakage, and spalling are established, and the safety condition of the tunnels is divided into A (also divided into AA, A1, A2), B, C, S four levels. Diseases of Japanese highway tunnels were divided into external force, material degradation, and leakage water diseases. They, respectively, propose criteria for external force collapse, deformation, cracking, damage, stagger, material deterioration, strength reduction, rebar corrosion, and water leakage. According to the urgency priority of the measures during the inspection and the investigation, the safety levels of the tunnels are divided into three levels: inspection phase A, B, and C, and investigation phase 3A, 2A, A, and B. The German Railway Tunnel Design, Construction and Maintenance Code (DS853) stipulates the inspection period of the structural parts and electromechanical facilities of existing tunnels and newly built tunnels and divides the structural defects into three levels according to the damage of the tunnels. China’s “Technical Codes for Maintenance of Highway Tunnels” will be divided into three categories according to tunnel defects: external force, material degradation, and water leakage diseases, and are divided into four safety levels of B, A, 2A, and 3A. The criteria for determining the deformation speed of the tunnel linings, the length and width of the cracks, layering and spalling, reduced strength of the lining through the cross section, rebar corrosion, and water leakage from the roadway is based on the Chinese standard (JTG H12-2015, 2015). The US “Highway and High-speed Railway Tunnel Inspection Manual” uses a combination of qualitative and quantitative methods to divide the structural defects of the tunnels into 0–10 grades and gives the classification standards and judgment criteria for the relevant grades.

In summary, although there are many studies and Codes on the performance evaluation of highway tunnel structures, various assessment theories have differences and advantages and disadvantages. However, there are still certain shortcomings. In the assessment steps, subjective factors and objective reality are rarely considered at the same time. For example, analytic hierarchy process (AHP) is highly subjective (Vladeanu and Matthews 2019; Yuan et al. 2019; Wu et al. 2020), the sample size required by gray theory is large, and the optimal value of some indicators is difficult to determine (Li et al. 2016), while the calculation of cloud theory is more complicated (Huang et al. 2019). AHP can fully integrate the experience and opinions of experts (Lyu et al. 2020), while entropy theory can make full use of actual test data to obtain objective weights of indicators (Huang et al. 2019), and game theory can fully combine the characteristics of these two weights (Wang et al. 2021), which can not only compensate for the subjectivity of AHP but also consider the objectivity of entropy theory. In addition, although some of the above-mentioned researchers use fuzzy comprehensive evaluation method or cloud model for evaluation, few researchers combine combined weight model with fuzzy comprehensive evaluation method to evaluate tunnel performance level. The fuzzy comprehensive evaluation method based on the combined weight model can reduce the influence of subjective factors to a certain extent and effectively solve the deficiency of fuzzy theory to make the final result more accurate (Zhou et al. 2021). The main purpose of this study is to propose a reasonable evaluation method that combines the combined weight model theory with the fuzzy comprehensive evaluation method and apply it to the tunnel performance evaluation.

Based on the comprehensive weight-fuzzy theory, this study puts forward the performance evaluation framework of the highway tunnels. It fully combines the inspection data and expert opinions to achieve the objective of subjective and objective comprehensive evaluation, and the fuzzy membership function is adopted to determine the level of components, structures, and overall performance. Using the evaluation method proposed in this study, a Guizhou tunnel is tested and evaluated, and compared with the current Codes about tunnel maintenance performance, gray clustering method, etc., and the degradation model of the tunnel structures is proposed. The results show that the tunnel performance method and degradation model proposed in this study have sufficient stability and strong applicability, which can provide theoretical support and experience for the safe operation and daily maintenance of the tunnels.

2 Construction of a Tunnel Combined Weight-fuzzy Evaluation Model

2.1 Overview of Combined Weighting Methods

The analytic hierarchy process is a simple and subjective decision-making method. The entropy theory is used to objectively evaluate problems with engineering. The combination of weights can link subjective and objective factors and comprehensively weight the evaluation indicators, so that the results’ error is small and even omitted.

2.1.1 Calculation of Index Weights based on AHP

The basic idea of the analytic hierarchy process (AHP) is to decompose and refine and then comprehensively analyze, to quantify the levels of the problems (Vladeanu and Matthews 2019 ). And the detailed process of the AHP in this paper is as follows:

-

(1)

Establishing a hierarchical structure system, as shown in Fig. 1.

-

(2)

Constructing judgment matrix: In order to quantify the important performance of each element and the specific importance and quantification of the relative importance of factors, the method of matrix judgment scale is usually used to determine, that is, the 1–9 scale method, as shown in Table 1. Judgment matrix form is as follows:

$$X\; = \;\left[ {\begin{array}{*{20}c} {x_{11} } & {x_{12} } & \cdots & {x_{1n} } \\ {x_{22} } & {x_{22} } & \cdots & {x_{2n} } \\ \cdots & \cdots & \cdots & \cdots \\ {x_{m1} } & {x_{n2} } & \cdots & {x_{nn} } \\ \end{array} } \right]$$ -

(3)

Solving the judgment matrix: each column vector of the judgment matrix A is normalized and summed, so as to calculate the eigenvector (weight coefficient) and maximum eigenvalue of each index

-

(4)

Consistency testing:

The judgment matrix usually has inconsistency, but in order to use the feature vector corresponding to the feature root as the full vector of the compared factors, the degree of inconsistency should be within the allowable range. CI is the consistency index of A, recorded as lCI, and the calculation formula is as follows:

When CI is 0, the judgment matrix A is consistent; the greater the CI, the more significant the inconsistency of A.

The consistency ratio is recorded as lCR,

Among them, RI is the random consistency index of A, recorded as lRI. For specific values, please refer to Table 2.

When lCR < 0.1, the degree of inconsistency of A is within the allowable range; that is, the judgment matrix meets the consistency requirements. At this time, the feature vector of A is used as the weight vector; otherwise, the judgment matrix A needs to be readjusted until the consistency criterion is reached.

2.1.2 Entropy Weight Theory

Entropy was originally a thermodynamic concept. It was first introduced by C. E. Shannon into information theory, which is called information entropy. It has some broader and universal meaning, so it is called generalized entropy (Yuan et al. 2019). The general steps of calculating weights in the method of entropy weight are: (1). establishment of initial data matrix; (2). initial data processing; (3). determination of index entropy value; and (4). calculation of objective weights.

The calculation steps of this study are as follows:

-

(1)

Establishing the initial data matrix

The initial matrix consists of m × n elements, of which m are evaluation objects and n are evaluation indicators.

$$R\; = \;\left[ {\begin{array}{*{20}c} {r_{11} } & {r_{12} } & \cdots & {r_{1n} } \\ {r_{22} } & {r_{22} } & \cdots & {r_{2n} } \\ \cdots & \cdots & \cdots & \cdots \\ {r_{m1} } & {r_{n2} } & \cdots & {r_{mn} } \\ \end{array} } \right]$$ -

(2)

Regularization of initial data standards

In each indicator, it can be divided into a positive indicator (the larger, the better indicator) and a reverse indicator (the smaller, the better indicator). In addition, whether it is a quantitative index or a qualitative index, it can be converted into an index value within the range of 0–1 according to the calculation formulas (3) and (4).

Calculation formula of positive index,

Calculation formula of reverse index,

In the formula, tij is the data after the range transformation, rij is the original data, and max{rij}, min{rij} are the maximum and minimum values of the data in the i-th row and j-th column of the initial matrix.

Finally, the standard matrix after standard normalization is obtained,

-

(3)

Calculating the index entropy

According to the definition of information entropy, for m samples and n indicators, formula (5) can be used to calculate the information entropy value of the j-th indicator,

Among them, since the range of tij is [0, 1], in order to ensure that lnyij is meaningful, then amend \(y_{ij} \; = \;\frac{{t_{ij} }}{{\sum\nolimits_{i - 1}^{m} {t_{ij} } }}\) as \(y_{ij} \; = \;\frac{{1 + t_{ij} }}{{1 + \sum\nolimits_{i - 1}^{m} {t_{ij} } }}\), and \(k\, = \;1/1n\;m\).

-

(4)

Determining the objective weight of the indicator

In accordance with the entropy value calculated in step (3), the objective weight of the j-th indicator is calculated according to Eq. (6).

2.1.3 Determination of Comprehensive Weights based on Game Theory

To make the ranking results more reasonable and scientific, the game theory is used to comprehensively assign weights. This method determines the combined weights through the planning model (Zhou et al. 2015, 2018).

The basic idea of game theory to calculate the comprehensive weights is: (1) determining the number of methods to solve the weights; (2) solving the linear combination of weight vectors; (3) optimizing the combination coefficient; (4) solving the linear equations; and (5) determining the comprehensive weight Value.

-

(1)

By using Q methods to solve the weights of the evaluation indicators of the system layer and the factor layer, Q factor weight vectors can be obtained,

$$\eta_{k} \; = \;(\eta_{k1} ,\;\eta_{k2} ,\;\eta_{k3} ,...,\;\eta_{kn} \;)\;(k = 1,\;2,...,\;q)$$(7)

Thus, a basic set of weights can be established: ηk = {ηk1,ηk2,ηk3,…,ηkn}.

-

(2)

By performing any linear combination processing on the Q weight vectors, it can be expressed by Eq. (8),

$$\eta = \sum\limits_{1}^{q} {\alpha_{k} \eta_{k}^{T} }$$(8)

η is a weight vector value that may appear after free combination of Q weight coefficients based on the basic weight set, and its weight set {\(\eta\)|\(\eta = \sum\nolimits_{1}^{q} {\alpha_{k} \eta_{k}^{T} }\)} is expressed as a weight vector set that may become the target obtained in the evaluation.

-

(3)

By performing data optimization processing on Q linear combination coefficients αk, the purpose of optimization is to minimize the dispersion between η and ηk. In this way, the game model can be derived,

$$\min \left\| {\sum\limits_{j}^{q} {\alpha_{j} \eta_{j}^{T} - \eta_{i} } } \right\|\;\;\left( {i = 1, \, 2, \, \ldots ,q} \right)$$(9) -

(4)

Based on the differential properties of the matrix, it is not difficult to understand that the optimal first derivative condition can be transformed into a linear system of Eq. (10),

$$\left[ {\begin{array}{*{20}c} {\eta _{1} \eta _{1}^{T} } & {\eta _{1} \eta _{2}^{T} } & \cdots & {\eta _{1} \eta _{q}^{T} } \\ {\eta _{2} \eta _{1}^{T} } & {\eta _{2} \eta _{2}^{T} } & \cdots & {\eta _{q} \eta _{q}^{T} } \\ \vdots & \vdots & \cdots & \vdots \\ {\eta _{q} \eta _{1}^{T} } & {\eta _{q} \eta _{2}^{T} } & \cdots & {\eta _{q} \eta _{q}^{T} } \\ \end{array} } \right]\,\left[ {\begin{array}{*{20}c} {\alpha _{1} } \\ {\alpha _{2} } \\ \vdots \\ {\alpha _{q} } \\ \end{array} } \right] = \left[ {\begin{array}{*{20}c} {\eta _{1} \eta _{1}^{T} } \\ {\eta _{2} \eta _{2}^{T} } \\ \vdots \\ {\eta _{q} \eta _{q}^{T} } \\ \end{array} } \right]$$(10) -

(4)

(α1,α2,…,αq) are calculated and then normalized, i.e.,

$$\alpha_{k}^{ * } = {{\alpha_{k} } \mathord{\left/ {\vphantom {{\alpha_{k} } {\sum\limits_{k}^{q} {\alpha_{k} } }}} \right. \kern-\nulldelimiterspace} {\sum\limits_{k}^{q} {\alpha_{k} } }}$$(11)

The overall weight is,

2.2 Fuzzy Theory

The fuzzy evaluation method is based on fuzzy mathematics, comprehensively considering various factors that affect the final goal, and conducting a comprehensive and systematic evaluation of the evaluation object (Prakash and Barua 2017; Karasan et al. 2018). The steps of fuzzy comprehensive evaluation method are as follows.

-

(1)

Constructing membership function

The membership values of various factors at different levels are obtained through membership functions. In this study, the cubic parabolic distribution is used as the membership function (k = 3). This function is continuous and simple to calculate and is suitable for engineering.

For the positive (with the larger the value, the better the performance is) factors, the large distribution in the membership function is used. All indicators in this study are positive factors. Let x be the index factor variable, then: 100 ≥ x ≥ 80 is rated as Class I; 80 ≥ x ≥ 60 is rated as Class II; 60 > x ≥ 40 is rated as Class III; 40 > x ≥ 20 is rated as Class IV; and 20 > x ≥ 0 is rated as Class V. The membership functions UI(x), UIIx), UIII(x), UIV(x), and UV(x) corresponding to each level of I, II, III, IV, and V are established. Considering the continuation of the distribution function, we can get the membership function Eqs. (13), (14), (15), (16), (17) corresponding to the levels of I, II, III, IV, and V.

Class I membership function,

Class II membership function,

Class III membership function,

Class IV membership function,

Class V membership function,

-

(2)

Single-factor evaluation

According to the single index membership function above, the membership of the factors for each evaluation level is determined. Thus, the sub-factor uij (j = 1, 2, 3,…, m) of any index factor ui (i = 1, 2, 3…, n) in the factor set U is evaluated by a single factor, and the initial single-factor evaluation matrix A is obtained. Then, the elements in the initial matrix are standardized, and the single-factor evaluation matrix R is calculated.

Among them, the element rijp in the single-factor evaluation matrix represents the degree of membership of the j-th underlying index under the i-th first-level index in the p-th evaluation level vp.

-

(3)

Comprehensive evaluation

According to Eqs. (18), (19), the final evaluation results can be obtained according to the principle of maximum membership. Since the value is normalized in the process of fuzzy processing and reduced by 100 times, the final performance score is calculated based on Eq. (20).

3 Overview of Tunnel Technical Status and Performance Assessment

3.1 Constructing an Evaluation Index System

According to the comprehensive performance characteristics of the tunnel structures and Code (JTG H12-2015 2015), the tunnel structure is divided into civil building structures, electromechanical facilities (safety factors), and other projects. Among them, the civil engineering structure includes 9 parts of openings, doors, linings, pavements, access roads, drainage systems, suspended ceilings and various embedded parts, interior decoration, and signs; the electromechanical facilities include five components: power supply and distribution facilities, lighting facilities, ventilation facilities, firefighting facilities, monitoring, and communication facilities, thus constructing the index system of tunnel performance evaluation (as shown in Fig. 1) and the grade classification of each performance evaluation index (as shown in Table 3).

3.2 Evaluation Process

For the assessment of the performance of highway tunnels, the infrastructure to the overall structure is divided into individual facility evaluation indicators, structures (civil engineering, mechanical and electrical facilities, other facilities), and the overall assessment of the tunnels. The combined weight-fuzzy theory of tunnel performance and safety assessment is also carried out in this order.

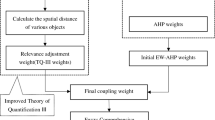

First of all, according to the test data, the factor indicators of each detailed facility are expressed as membership degrees, and the combined weight theory is used to synthesize the evaluation indicator performance, and the structural performance and safety assessment membership matrix is calculated. Then, combined with the combined weight of the structures, the overall performance of the tunnels is expressed by the membership matrix, and the performance level of the tunnels is determined according to the principle of maximum membership. Combined weight-fuzzy theory of tunnel performance process is shown in Fig. 2.

3.3 Representation of Tunnel Performance Level

The performance of the overall tunnels is divided into I-V level, and the value range Gj corresponding to the performance is [0, 100]. According to the Codes or experts opinion to determine the value range of the index corresponding to each performance level, based on studies and “Technical Specifications for Maintenance of Highway Tunnels” (Lai et al. 2017; Menendez et al. 2018; Bhalla et al. 2005; Wu et al. 2017; JTG H12-2015 2015), the overall performance classification of the tunnels can be gotten, as shown in Table 4. For the performance of the tunnel structures, 100 ≥ Gj ≥ 80 is rated as Class I; 80 ≥ Gj ≥ 60 is rated as Class II; 60 > Gj ≥ 40 is rated as Class III; 40 > Gj ≥ 20 is rated as Class IV; and Gj < 20 is rated as Class V.

3.4 Tunnel Repair Measures under Different Performance Levels

With reference to Codes and studies about the tunnel performance, the disease characteristics and maintenance measures of highway tunnel structures at different levels are summarized (Lai et al. 2017; Xun 2006; Menendez et al. 2018; Bhalla et al. 2005; Wu et al. 2017; JTG H12-2015 2015), as shown in Table 5.

4 Case Study and Results Discussion

4.1 Project Overview

A highway tunnel is located in Guizhou Province, China, with a total length of 160 m, and the entrance stake of the Tunnel is K2504 + 950, the exit stake is K2505 + 110, and the center stake of the tunnel is K2505 + 030, and it is part of China’s G210 national highway. It is the only road that passes through the main traffic between north and south China, and the road grade is level II, the calculated driving speed is 40 km/h, and the clear height of the tunnel is 4.5 m. The arc length of the tunnel is 18 m. The width of the tunnel road surface is 7.5 m. The tunnel pavement type is asphalt pavement. The tunnel lining form is spray anchor lining. The entrance and exit of the tunnel are end-wall entrances. The geomorphology of the tunnel is characterized by trough dissolution and erosion geomorphology, which is shallow, medium-cut ridged middle-low hills. The project area of the tunnel belongs to the subtropical southeast monsoon climate zone. It is mild and humid, and the four seasons are not clear. There are no severe cold in winter and no scorching heat in summer. The climate changes slightly with the elevation of the terrain. The mountainous area has lower temperature and abundant rain than the valleys and depressions. The average annual precipitation is 1448.1 mm, mostly in May–August, accounting for 55–60% of the whole year. The annual average temperature is 15.9 ℃, the hottest from June to August, the extreme maximum temperature is 34.4 ℃, and the extreme minimum temperature is − 7.9 ℃. The average frost-free period is 294 days/year, and the average frozen area is 7 days/year. The exposed strata in the tunnel site are Quaternary alluvium, landslide accumulation, collapsed slope, residual slope accumulation of gravel soil, cohesive soil, etc., and the underlying strata are limestone of the Permian Wujiaping Formation. In addition, there are a large amount of loose layer pore water, bedrock fissure water, and carbonate karst water around the tunnel. The typical cross-sectional view of the tunnel is shown in Fig. 3.

4.2 Tunnel Inspection Results

Based on the literature (Lai et al. 2017; Xun 2006; Menendez et al. 2018; Bhalla et al. 2005; Wu et al. 2017; JTG H12-2015 2015), through the organization of experts and inspection professional and technical personnel, the tunnel deterioration in Guizhou Province was evaluated in detail. The main diseases of the tunnel are: ① Cracks in the retaining wall, the presence of subsurface flow gushing, serious clogging of the drain hole, the existence of staggered gaps in the foundation, and slope protection and subsidence; ② there are many cracks in the wall of the door, the concrete is slightly peeled off, and the structure is slightly inclined; ③ there are many long and thin penetrating cracks in the lining, the surface of the lining is peeled, there is serious water leakage, the water inflow on the surface of the lining can be clearly seen, and the steel bars in the lining structure are exposed to corrosion; ④ the road surface is arched and settlement, and there is serious water accumulation; ⑤ the maintenance road is damaged, the ceiling is leaking, the interior decoration is dirty, the sign is seriously dirty, and the appearance is damaged; ⑥ the lighting fixture is seriously damaged, and the circuit is abnormal; and ⑦ imperfect monitoring equipment, firefighting facilities, etc. The on-site inspection is shown in Fig. 4, and the test results are shown in Fig. 5.

4.3 Theoretical Results Based on Current Tunnel Code

Case studies include discussion of utility data and evaluation of performance models (Angkasuwansiri 2013). The purpose of the meeting is to promote the exchange and learning of tunnels management experience, and to obtain important feedback on the proposed performance indicators, and then discuss the current performance of tunnel infrastructure data management in each community. A total of 5 public utilities participated in this study, but for security reasons, the specific files and data in these case studies were manipulated, and only part of the data can be disclosed, as shown in Figs. 4, 5, 6.

-

(1)

DuYung County Sanitation District, DuYung County

-

(2)

DuYung Tunnel Authority, DuYung

-

(3)

GUIZHOU Tunnel Resources Authority, GuiYang

-

(4)

GUIZHOU Public Utilities, GuiYang

-

(5)

GUIZHOU Infrastructure Commission, GuiYang

According to the papers (Lai et al. 2017; Xun 2006; Menendez et al. 2018; Bhalla et al. 2005; Wu et al. 2017; JTG H12-2015 2015), the evaluation index system was constructed (as shown in Fig. 1), and then, this project invited 4 experts to evaluate and score various indicators of the tunnel structures, and the performance is scored to reveal the damage, defects, and deterioration of each part of the tunnel’s hierarchy structure. The evaluation scores of various factors are shown in Fig. 6. The score of the test data is slightly higher than the expert’s score. The expert is more conservative in evaluating the performance of the tunnel. The results are shown in Table 6. According to the Code (JTG H12-2015 2015), the overall performance score of the tunnels is 54.56.

4.4 Evaluation Index System and Weights

According to the evaluation process of the tunnel technical status assessment model described above, the assessment of the performance of tunnels in Guizhou Province is carried out using three levels: single index, structural level, and overall tunnel evaluation.

For the different evaluation layers and components of the Guizhou tunnel, the combination weight theory described above is used to determine the weights of each index. Limited to the length of the study, the following takes the 5 indicators in the structure of electromechanical facilities (safety factors in Fig. 2) as an example, based on expert opinions and on-site evaluation scores, using the above weight calculation method to obtain a comprehensive weight. In addition, the various weight calculation steps of civil structure factors (shown in Fig. 2) and other works factors (shown in Fig. 2) are the same with that of safety factors in Fig. 2, and the calculation value of subjective weight, objective weight, comprehensive weight is shown in Figs. 7–8, and the weight calculation steps are as follows:

-

(1)

Subjective weight

According to Eqs. (1)–(2) and calculation steps in Section 2.1.1, the judgment matrix is,

\(A\; = \;\left[ {\begin{array}{*{20}c} 1 & {1.4} & {1.1} & {1.1} & {1.1} \\ {\frac{1}{1.4}} & 1 & {0.95} & {0.9} & {0.9} \\ {\frac{1}{1.1}} & {\frac{1}{0.95}} & 1 & {0.9} & 1 \\ {\frac{1}{1.1}} & {\frac{1}{0.9}} & {\frac{1}{0.9}} & 1 & {0.9} \\ {\frac{1}{1.1}} & {\frac{1}{0.9}} & 1 & {\frac{1}{0.9}} & 1 \\ \end{array} } \right]\),

And λmax = 5.006 is obtained, CI = 0.002, RI = 1.120, CR = 0.002 < 1, which meets the requirements. The subjective weights of safety factors in Fig. 2w1 = [0.226, 0.177, 0.194, 0.2, 0.204] are solved.

-

(2)

Objective weights

According to the above and the expert score table, and based on Eqs. (3)–(6) and calculation steps in Sect. 2.1.2, the R matrix is,

\(R\; = \;\left[ {\begin{array}{*{20}c} {0.326} & {0.268} & {0.272} & {0.267} & {0.345} \\ {0.349} & {0.357} & {0.382} & {0.533} & {0.328} \\ {0.442} & {0.536} & {0.545} & {0.267} & {0.241} \\ {0.395} & {0.304} & {0.364} & {0.433} & {0.414} \\ {0.465} & {0.429} & {0.527} & {0.467} & {0.397} \\ {0.651} & {0.446} & {0.273} & {0.367} & {0.483} \\ \end{array} } \right]\),

Ej = [− 0.169, − 0.194, − 0.179, − 0.186, − 0.205] is calculated, and objective weights of safety factors in Fig. 2w2 = [0.182, 0.208, 0.191, 0.2, 0.219] are obtained.

-

(3)

Comprehensive weights

According to Eqs. (7)–(12), α1 = 0.627, α2 = 0.373 are obtained, so that the comprehensive weights of safety factors in Fig. 2, w = [0.198, 0.196, 0.192, 0.2, 0.214] are solved. The same method can be used to determine the objective, subjective, and comprehensive weight values of each level and index of the tunnel, as shown in Table 7.

-

(4)

Weight analysis

In Figs.7 and 8, the subjective weights, comprehensive weights, and weights in the standard (JTG H12-2015, 2015) are relatively small and almost identical. The difference between the objective weights and the other three weights is relatively large. In the four weight distributions, the objective weights of indicators C11-C14 belong to the minimum value, while the weights of C15-C31 are the maximum values. The subjective weight of each indicator calculated by the analytic hierarchy process is basically the same as the standard weight (JTG H12-2015 2015), both of which are derived from the experience evaluation of experts, with a certain degree of subjectivity.

Figure 7 is the graph of the weights of the factor layer. It can be found that the subjective and weights based on Code are consistent, but the objective and comprehensive weights are different. In addition, the comprehensive weight values of various indicators are almost stable between the objective and subjective weights, which balance the subjectivity of subjective weights combined with the objective conditions of actual on-site testing.

4.5 Combined Weight-fuzzy Theory to Evaluate Tunnel Performance

According to the above combined weight-fuzzy theory evaluation method, even for each index, according to the equation in Sect. 2.2, the fuzzy membership degree of each hierarchy structure and factor evaluation index is obtained, as shown in Table 8.

According to Table 8, the performance deterioration of the overall tunnel is [0, 0.039, 0.363, 0.073, 0.527]. With reference to the principle of maximum membership, the overall performance of the tunnel is level III, and the calculated score is 52.70.

4.6 Discussion and Analysis of Evaluation Results

4.6.1 Comparative Analysis with Other Evaluation Methods

To verify the feasibility and scientific of the combined weight-fuzzy theory to assess the performance of the tunnel, the performance value of the evaluation model in this study is compared with the current code evaluation value (JTG H12-2015) and gray clustering theory value.

Gray clustering is a commonly used effective method in multi-objective decision analysis in civil engineering. Gray clustering method ranks different samples according to the proximity between evaluation objects and the idealized objective and evaluates the relative merits of the existing evaluation objects (Golinska et al. 2015). In general, the traditional gray clustering method adopts the way of subjective empowerment based on uncertain AHP. Details are shown in Table 9 and Fig. 9.

In addition, AHP-fuzzy evaluation method is widely used to evaluate the performance of engineering (Ebrahimiana et al. 2015; Lyu et al. 2019). According to the calculation steps of AHP-fuzzy method and taking the 5 indicators in the structure of safety factors in Fig. 2 as an example, the weight of 5 factors is w1 = [0.226,0.177,0.194,0.2,0.204], and the judgment matrix is C21 = [0, 0, 0.8826, 0.1174, 0], C22 = [0, 0.8316, 0.1684, 0, 0], C23 = [0, 0, 0.9714, 0.0286, 0], C24 = [0, 0, 0, 0.0982, 0.9018], C25 = [0, 0, 0, 0.0435, 0.9565]. Then, the judgement matrix of safety factors in Fig. 2 is [0, 0.1472, 0.4177, 0.0606, 0.3755] and the weight of safety factors in Fig. 2 is 0.2320, so the final evaluation matrix of safety factors in Fig. 2 is [0.0, 0.0341, 0.0969, 0.0141, 0.0871]. Similarly, the final evaluation matrix of civil structure factors (shown in Fig. 2) and other works factors (shown in Fig. 2) is [0.0, 0.0, 0.2319, 0.0554, 0.4477], [0.0, 0.0, 0.0298, 0.0032, 0.0], separately. As a result, the final evaluation matrix of tunnel is [0.0, 0.0341, 0.3586, 0.0726, 0.5348] and the final score is 0.5348*100 = 53.48, so based on Table 4, the tunnel performance is level III.

The evaluation result of the tunnel performance using combination weight-fuzzy theory is 52.70, which is almost the same as the evaluation score (54.56) (JTG H12-2015 2015), gray cluster evaluation score (53.47), and AHP-fuzzy evaluation score (53.48). The comparison of the evaluation results of the three methods shows that the result of the tunnel performance is reliable and effective. What’s more, Table 7 shows that the results of different evaluation cases calculated by the three methods are different, but the overall variation trend is same. The performance and safety assessment of tunnel is level III. This is consistent with the test results, indicating that the performance of highway tunnels can be systematically evaluated by the four methods. However, the difference in the evaluation scores of the tunnel calculated by the combined weight-fuzzy method is lower than that calculated by the traditional gray clustering method, AHP-fuzzy method, and Code JTG H12-2015. This is because the traditional gray clustering method and AHP-fuzzy method focus on subjective regulation, but ignore the objective changes in the data itself. It affects the weight distribution of each index, which in turn interferes with the performance and safety assessment of tunnels. In some special cases, if the test values of the indicator change greatly, this has a significant effect on the objective weights of the indicators. At this time, the traditional gray clustering method, AHP-fuzzy method, and Code (JTG H12-2015) still use subjective weights, ignoring the importance of objective weights. This will lead to large deviations in the final results. What’s more, the final evaluation score of combined weight-fuzzy method is the lowest, compared with the traditional gray clustering method, AHP-fuzzy method, and Code (JTG H12-2015), so this also provides timely warnings for tunnel maintenance which helps to ensure the safety of the tunnel structure. Therefore, the superiority of the combined weight-fuzzy theory is highlighted. To a certain extent, the combined weight-fuzzy method is an improvement of the traditional gray clustering method, AHP-fuzzy method, and Code (JTG H12-2015).

4.6.2 Discussion on Portability of Models

In this study, based on the MWP highway tunnel, a performance level evaluation model for the highway tunnel was established. The model established in this study is only applicable to mountain highway tunnels for the following reasons. First, this study selects the factors that affect the performance of MWP highway tunnels. These factors may not be applicable to other tunnels (such as deep sea tunnels and tunnels in extreme environments). Then, this study classifies the tunnel performance based on the inspection data of the MWP highway tunnel, so the feasibility of this model for other tunnels has certain limitations. However, the methods, ideas, and conclusions of this study can provide certain references for other tunnel projects.

4.7 Determination of Tunnel Deterioration Model

At present, the deterioration model of tunnel performance mainly focuses on the durability of concrete, and the research is not systematic. Therefore, this study builds a model of the deterioration of the tunnels,

The above model is suitable for various types of tunnel (railway tunnels, pedestrian tunnels, canal tunnels, mountain tunnels, underwater tunnels, underwater tunnels, etc.) aging. In the tunnel projects, the tunnel will be regularly inspected and the performance was assessed. If the tunnel has been tested and evaluated k times, the tunnel age sequence corresponding to the tunnel inspection and evaluation time is expressed as N = {n1, n2, n3,…, nk}. The results of K times of inspection and evaluation obtained by the comprehensive weight-fuzzy theory are expressed as G = {G1, G2, G3,…, Gk}. In Eq. (21), λ and T are undetermined parameters of the degradation model. Using the results of the existing N evaluations, the generalized least squares method is used to find a set of optimal solutions, λ* and T*, and then, the deterioration model of the tunnels is determined. To solve λ* and T*, constructing the following objective function F(λ, T),

The set of solutions when the objective function F(λ, T) obtains the minimum value is the optimal solution of λ* and T*.

Equations (24) and (25) are established at the same time, which can make the function F(λ, T) obtain the minimum value.

After decomposing the calculation, the binary linear equation can be obtained, and the unique solutions of λ* and T * can be obtained by solving them simultaneously. Substituting the unique solutions of λ* and T* into Eq. (21), the deterioration model of the tunnel technical condition can be determined.

Based on the above academic backgrounds, the Guizhou tunnel was built in 1995 and has a design life of 50 years. By 2017, only 6 times performance assessments were carried out. The age of the tunnel and the performance assessment results were [1a, 7a, 11a, 15a, 19a, 22a], [95, 85, 81, 75, 69, 57]. According to Eqs. (21)–(25), λ* and T* are 0.0023 and 0.5048, respectively. According to the detection score of 52.7, the initial performance score of the tunnel is 95, so that the degradation model of the tunnel in the natural condition is as follows:

. According to the above equation, MATLAB calculation is performed, and the final performance deterioration function of the tunnel is G(n) = 9−50.926n−0.032n2, R2 = 0.9635. And the deterioration curve of the tunnel performance with the previous 22 years is shown in Fig. 10. The tunnel management organization and technical personnel can effectively preventively maintain the tunnel according to the deterioration of the tunnel performance.

4.8 Reinforcement and Maintenance of MWP Tunnel

According to the performance, class of the MWP tunnel is level III, and the measures for maintenance of the tunnel are as follows: carrying out grouting to fill the voids and hollow sections behind the tunnel lining, and applying the method of chiseling and burying pipes for the seepage area, and then adopting shotcrete concrete (or impermeable concrete) with rebar mesh hanging, and replacing the road surface, and reducing the road elevation by 15 cm.

4.8.1 Reinforcement and Maintenance Measures for the Lining and Surrounding Rock

Grouting is used for the location of the void, and the rock drill is used to accurately drill the hole where the initial support exists and then install the grouting pipe. The grouting pipe needs to be equipped with a valve so that the second grouting can be performed in real time when the grouting is not dense. The operation process is shown in Fig. 11. In addition, the supporting parameters of reinforced mesh shotcrete was C25 shotcrete (thickness: 8 cm), and wet shotcrete technology was applied. Reinforced mesh specifications were 6 mm diameter rebar, single-layer layout, and grid 10 cm × 10 cm. Anchor rod was as follows: 22 mm diameter screw steel was used, and additional backing plate screw anchor was selected, and it’s length 3 m and spacing 200 cm × 200 cm, plum blossom arrangement was designed, and connected with steel mesh. Reinforced mesh anchoring bars were as follows: diameter was 12 mm, length was 20 cm, implanted with the existing lining length 15 cm, the exposed part is welded firmly to the rebar mesh, and the anchoring bar layout is 50 cm × 50 cm, as shown in Fig. 11.

4.8.2 Maintenance Measures for Road Pavement

Subgrade cavities and void sections are treated with grouting. As the tunnel pavement disease is more and more serious, the entire tunnel subgrade pavement was renovated and the asphalt layer was re-paved. At the same time, because the tunnel needs to be reinforced with steel–concrete combined lining, and the 25 cm curb in the original design has not been implemented in practice. To ensure the building boundary requirements, the original road marking will be reduced by 15 cm. A 100-m transition section is set at both ends of the tunnel to connect the original road to ensure driving safety and comfort, as shown in Fig. 12.

4.8.3 Maintenance Measures for Drainage Ditch

Weeds in the side drain and silt in the drainage side ditch are removed. The connection section outside the tunnel also considers the setting of the side ditch, which is gradually transitioned according to the reduced 15 cm elevation and the height of the side ditch, in order to follow the original side ditch. At the same time, due to the need to use W-shaped steel–concrete combined lining to strengthen the tunnel, the side drain cover also needs to be redesigned and manufactured, as shown in Fig. 12.

The overall layout of the MWP tunnel after reinforcement is shown in Fig. 13. It can be seen from Fig. 13 that the leaking pores of the tunnel lining structure have been blocked, and the lining cracks have been repaired, and the tunnel doorway cracks have also been repaired. The MWP tunnel is now officially in operation.

5 Conclusions

This study optimizes the tunnel performance assessment system for the random ambiguity of tunnel information, the diversity of performance indicators, and the complexity of the evaluation process. And the qualitative and quantitative evaluation indicators were combined, uncertain AHP is used to determine subjective weights, entropy theory is used to calculate objective weights, and game theory is applied to determine the comprehensive weights, and combined with the fuzzy theory to calculate the membership of each level of the index, the performance of each structural component of the tunnel is calculated layer by layer, so that the combined weight-fuzzy theory evaluation model is constructed. The conclusions of this study are as follows,

-

(1)

The evaluation model based on the combined weight-fuzzy theory can analyze the weight change of each index and combine the field test data and experts’ experience in detail, which can effectively and accurately evaluate the performance of the tunnels.

-

(2)

Based on the on-site inspection results, it is possible to effectively establish the deterioration model of the performance of the tunnel and the deterioration function of operation ages and performance, thereby avoiding the mutual influence of the subjectiveness with the code evaluation process and the evaluation indicators complexity. By comparing the performance and safety assessment of a tunnel in Guizhou, China, the evaluation results of the four assessment methods are consistent. Most importantly, the method in this study considers the problems of random ambiguity of evaluation information, rough evaluation steps, and strong subjectivity.

-

(3)

The tunnel degradation prediction model is very important for predicting the safety of the tunnels. Based on the tunnel performance evaluation level and deterioration model, this study proposes the maintenance and reinforcement measures for the MWP tunnel. First, the tunnel should be repaired by low-pressure injection method. In addition, for the severely diseased areas such as wide cracks, open, dense distribution, unfavorable combination, or staggered longitudinal rings, carbon fiber should be pasted on the surface for reinforcement. All cracks with a width ≥ 0.5 mm are first repaired by injection, and a high-strength repair glue is injected into the crack cavity with a certain pressure to reduce the viscosity. All leaking water cracks are slotted, the leaking water channels around the cracks are dredged, and the water in and around the tank is introduced into the drain pipe buried in the tank by the method of “water cut and water absorption.”

-

(4)

Drawing on the concrete structure deterioration model, based on the tunnel inspection results, the tunnel deterioration model is determined, and the application evaluation of the performance of a tunnel in Guizhou is carried out. According to the tunnel’s performance and safety condition deterioration function, the tunnel management agency and relevant technical personnel can make timely maintenance, repair, and reinforcement decisions for the tunnel.

-

(5)

In general, the analysis of this evaluation method provides new ideas for tunnel performance evaluation. This method not only takes into account the professional level of the evaluators, but also helps local, national, private, and urban planners make decisions. Expert opinion, as an indispensable tool in the decision-making of many tunnel performance indicators, can play a role, but it often carries certain subjective deviations. This research shows that fuzzy models can systematically and mathematically simulate human reasoning and allow expert knowledge to be incorporated into the evaluation process. To achieve this, the evaluation information was implicitly obtained through questionnaires, expert meetings, and other means.

-

(6)

The tunnel evaluation method introduced for tunnel project planners and stakeholders helps to prioritize different tunnel structural indicators that affect tunnel performance when designing the tunnels. Although this research is carried out on the scale of important transportation hubs such as highway tunnels, it may have important uses on a smaller level, such as ordinary road tunnels and mountain tunnels.

References

Angkasuwansiri T (2013) Development of wastewater pipe performance index and performance prediction model. The Faculty of the Virginia Polytechnic Institute and State University, Virginia

Arends BJ, Jonkman SN, Vrijling JK et al (2005) Evaluation of tunnel safety: towards an economic safety optimum. Reliab Eng Syst Saf 90(2–3):217–228. https://doi.org/10.1016/j.ress.2005.01.007

Bhalla S, Yang YW, Zhao J, Soh CK (2005) Structural health monitoring of underground facilities–technological issues and challenges. Tunn Undergr Space Technol 20(2005):487–500. https://doi.org/10.1016/j.tust.2005.03.003

Ebrahimiana A, Ardeshir A, Rad IZ, S.H., Ghodsypourc, (2015) Urban stormwater construction method selection using a hybrid multi-criteria approach. Autom Constr 58(2015):118–128. https://doi.org/10.1016/j.autcon.2015.07.014

Golinska P, Kosacka M, Mierzwiak R, Werner-Lewandowska K (2015) Grey decision making as a tool for the classification of the sustainability level of remanufacturing companies. J Clean Prod 105:28–40. https://doi.org/10.1016/j.jclepro.2014.11.040

Huang Z, Fu H, Zhang J et al (2019) Structural damage evaluation method for metro shield tunnel. J Perform Constr Facil. https://doi.org/10.1061/(ASCE)CF.1943-5509.0001248

JTG H12-2015 (2015) Technical specification for road tunnel maintenance, Beijing: China Communications Press (in Chinese)

Karasan A, Ilbahar E, Cebi S, Kahraman C (2018) A new risk assessment approach: safety and critical effect analysis (SCEA) and its extension with pythagorean fuzzy sets. Saf Sci 108:173–187. https://doi.org/10.1016/j.ssci.2018.04.031

Lai JX, Qiu JL, Fan HB et al (2017) Structural safety assessment of existing multi-arch tunnel: a case study. Adv Mater Sci Eng. https://doi.org/10.1155/2017/1697041

Li K, Liu L, Zhai J, Khoshgoftaar TM, Li T (2016) The improved grey model based on particle swarm optimization algorithm for time series prediction. Eng Appl Artif Intell 55(2016):285–291. https://doi.org/10.1016/j.engappai.2016.07.005

Lyu HM, Shen SL, Zhou AN, Yang J (2019) Perspectives for flood risk assessment and management for mega-city metro System. Tunn Undergr Space Technol 84(2019):33–44. https://doi.org/10.1016/j.tust.2018.10.019

Lyu HM, Zhou WH, Shen SL, Zhou AN (2020) (2020) Inundation risk assessment of metro system using AHP and TFN-AHP in Shenzhen. Sustain Cities Soc 56:102103. https://doi.org/10.1016/j.scs.2020.102103

Maleki M, Mousivand M (2014) Safety evaluation of shallow tunnel based on elastoplastic-viscoplastic analysis. Sci Iran 21(5): 1480–1491

McFeat-Smith I (2000) Risk assessment for tunneling in adverse geological conditions in Asia. In: proceedings of ICTUS

McFeat-Smith I (2005) Risk assessment and management for tunneling projects Hong Kong association of project management, Hong Kong

Menendez E, Victores JG, Montero R, Martínez S, Balaguer C (2018) Tunnel structural inspection and assessment using an autonomous robotic system. Autom Constr 87:117–126. https://doi.org/10.1016/j.autcon.2017.12.001

Minardo A, Catalano E, Coscetta A, Zeni G, Zhang L, Di Maio C, Vassallo R, Coviello R, Macchia G, Picarelli L, Zeni L (2018) Distributed fiber optic sensors for the monitoring of a tunnel crossing a landslide. Remote Sens 10(8):1291. https://doi.org/10.3390/rs10081291

Olsson L, Sturk R (1994) The Northern Link, soft tunneling through the Bellevue park risk analysis, fault tress. Vgverket rapport RAP 0037, R/YT, Stockholm: 1994.

Prakash C, Barua MK (2017) Flexible modelling approach for evaluating reverse logistics adoption barriers using fuzzy AHP and IRP framework. Int J Oper Res. https://doi.org/10.1504/IJOR.2017.086523

Rao J, Xie T, Liu Y (2016) Fuzzy evaluation model for in-service karst highway tunnel structural safety. KSCE J Civ Eng 20(4):1242–1249. https://doi.org/10.1007/s12205-015-0596-5

Vladeanu GJ, Matthews JC (2019) Consequence-of-failure model for risk-based asset management of wastewaterpPipes using AHP. J Pipeline Syst Eng Pract. https://doi.org/10.1061/(ASCE)PS.1949-1204.0000370

Wang M, Wang Y, Shen F, Jin J (2021) A novel classification approach based on integrated connection cloud model and game theory. Commun Nonlinear Sci Numer Simul https://doi.org/10.1016/j.cnsns.2020.105540

Wu X, Jiang Y, Wang J et al (2017) A new health assessment index of tunnel lining based on the digital inspection of surface cracks. Appl Sci Basel. https://doi.org/10.20944/preprints201704.0163.v1

Wu YN, Tao Y, Deng ZQ, Zhou JL, Xu CB, Zhang BY (2020) A fuzzy analysis framework for waste incineration power plant comprehensive benefit evaluation from refuse classification perspective. J Clean Prod 258(2020):120734. https://doi.org/10.1016/j.jclepro.2020.120734

Xun L (2006) Highway tunnel structure safety and health status identification system [Ph. D. Thesis], Southwest Jiaotong University (in Chinese)

Yuan Y, Bai Y, Liu J (2012) Assessment service state of tunnel structure. Tunn Undergr Space Technol 27(1):72–85. https://doi.org/10.1016/j.tust.2011.07.002

Yuan J, Li X, Xu C, Zhao C, Liu Y (2019) Investment risk assessment of coal-fired power plants in countries along the Belt and Road initiative based on ANP Entropy-TODIM method. Energy 176:623–640. https://doi.org/10.1016/j.energy.2019.04.038

Zhou B, Xie X, Li Y (2014) A structural health assessment method for shield tunnels based on torsional wave speed. Sci China Technol Sci 57(6):1109–1120. https://doi.org/10.1007/s11431-014-5554-9

Zhou L, Lü K, Yang P, Wang L, Kong B (2015) An approach for overlapping and hierarchical community detection in social networks based on coalition formation game theory. Expert Syst Appl 42(24):9634–9646. https://doi.org/10.1016/j.eswa.2015.07.023

Zhou X, Zhao X, Liu Y, Sun G (2018) A game theoretic algorithm to detect overlapping community structure in networks. Phys Lett A 382(13):872–879. https://doi.org/10.1016/j.physleta.2018.01.036

Zhou Y, Cai JM, Xu YW, Wang YH, Jiang C, Zhang QQ (2021) (2021) Operation performance evaluation of green public buildings with AHP-fuzzy synthetic assessment method based on cloud model. J Build Eng 42:102775. https://doi.org/10.1016/j.jobe.2021.102775

Acknowledgements

The work described in this paper was fully supported by grants from the Key Projects of the Ministry of Railways. Hesong Jin is responsible for thesis writing and constructing thesis writing ideas; Xueyan Jin is responsible for the revision of the thesis, summarizing the data, and giving the project financial supports.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jin, H., Jin, X. Performance Assessment Framework and Deterioration Repairs Design for Highway Tunnel Using a Combined Weight-Fuzzy Theory: A Case Study. Iran J Sci Technol Trans Civ Eng 46, 3259–3281 (2022). https://doi.org/10.1007/s40996-021-00734-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40996-021-00734-4