Abstract

Incorporation of three-dimensional geocell is a soil reinforcement technique which is extensively used today and has proved to be reliable due to its confining capability which increases the load-carrying capacity of the soil. The concern over the deterioration of soil and the escalating costs of the presently used synthetic geocells has steered the need for a natural replacement. This research provides a précis of the sand bed being reinforced with jute geocell, developed with jute geotextile and its effectiveness evaluated through model plate load tests in the laboratory using a square footing. The parameters administering the performance, such as the depth of sand cushion above geocell (u), width of geocell (b), and height of geocell (h) with respect to the width of the footing (B) are varied to realize the optimum of the ratios. The results obtained from the test conducted to optimize the ratios are scrutinized to study the improvement in bearing capacity of soil. The bearing pressure of the jute geocell-reinforced soil at 10% settlement is 3.5 times higher than that of the unreinforced soil. The inherent properties of natural fibres like jute can meet the requirement of synthetic geocells and their eco-compatibility make them to rule over existing geocells. According to the procured results and discussion through the study, it is proven that jute geocells could very well be an alternative for reinforcing the soil.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the historical timeline of geotechnical engineering, there has always been a continuous development in techniques for improving the strength of soil while trying to minimize the failure to an extent. The conventional techniques such as the replacement of in situ soil with another material, improvement by addition of admixture like cement, lime, fly ash, etc., although proved to be effective, seem to be time-consuming and uneconomical. Moreover, the major problem is that the chemical properties of the soil are altered drastically. To counter this effect various methods have been researched upon. One such technique which proved to improve the soil properties is inclusion of discrete fibres which has increased the ductility of the soil as presented by Yetimoglu et al. [1]. A composite of cement and synthetic discrete fibres also improved the soil strength considerably when used as a reinforcement material which is substantiated by the work done by Tang et al. [2] and Hamadi et al. [3]. Akbulut et al. [4] shed light on the fact that even the scrap fibre material such as rubber tyre could function as a reinforcement material. Many researchers have experimented using natural fibres as a mode of soil reinforcement to increase the bearing capacity and decrease the settlement and shear failure. Many researchers have studied on a variety of natural fibres as reinforcement like the palmyra fibres [5], sisal fibres [6], the wasted corn silk fibres [7], and a combination of Pinus Roxburghii and Grewia Optivia [8]. When these are found to be easily deteriorate when included in soil due to their biodegradable nature, they are treated chemically which have worked successfully as observed by Dutta et al. [9] when he used coir, treated with sodium hydroxide and carbon tetra chloride as soil reinforcement. Similarly, works of Herrera-Franco et al. [10] and Ghavamai et al. [11] have shown that the treatment of natural fibres has improved their durability.

Many studies have reported the effect of inclusion of reinforcement material in soil in its discrete fibre form. The application of discrete fibres in field is difficult as the mixing of fibres in soil is a tedious task. This problem is taken care, when geosynthetics are used as reinforcements in soil for strength betterment which could be easily incorporated into soil. Geosynthetics could be of various forms like planar (Geogrid, Geotextile, Geomembrane, Geonet, etc.), three-dimensional configuration (Geocell). Natural fibre planar reinforcement is a common method of reinforcement which is used for a long time, along with the effect of vegetation which protected the soil from erosion. Varying the different parameters like the depth of placement, breadth of geosynthetics, and number of layers of reinforcement affects the performance of geosynthetics as inferred from Haeri et al. [12], Omar et al. [13], Lal et al. [14], Latha et al. [15, 16], and Makkar et al. [17]. Das et al. [18] investigated the variation of bearing capacity of sand when reinforced with biaxial geogrid. Effects of multi-layered geocells are also developing simultaneously, and that has produced some additional increase in the improvement of strength of soil as deliberated by Patra et al. [19]. The increase in stiffness of geosynthetics has found to have reduced the settlement especially when used in soft subgrade soil as presented by Kazimierowicz-Frankowska [20] and Wang et al. [21]. Ouria et al. [22] highlight the amount of increase in the bearing capacity of soil when reinforced with geotextile treated with cement compared to that of soil reinforced solely with the planar geosynthetics. Geotextile composites have a greater effect on the increase of soil strength. The demand for the planar reinforcements manufactured from the natural fibres is huge considering their performance and environmental efficiency [23]. Many such novel methods that incorporated natural materials include the use of jute geotextiles in pond ash [24], braided coir rope in loose sand [25], and jute geotextile with flyash [26]. The treatment of the planar reinforcements enhances the durability of natural geosynthetics when used as reinforcement. The treatment just need not be always chemical; Saha et al. [27] presented a technique for treating jute geotextile using plant-based ingredients and by increasing its longevity by 50%. Sumi et al. [28] also used solution with natural agents to treat coir geotextiles and reported that the degradable geotextile is able to retain more than 70% of its initial tensile strength.

Three-dimensional confining structure with a honey-comb like structure which has gained huge popularity and is extensively used for protection of the banks of the canals and slopes, increases the load-carrying capacity of soil, helps in the prevention of soil erosion, etc. It provides the cellular confinement to the soil, such that it gets greater density and acquires a larger load-carrying capacity [23, 29]. There are innumerable studies about the soil reinforced with geocells. This is one of the successful techniques at present, and has been researched upon various studies with different materials like high-density polyethylene (HDPE) geocells [30, 31] and other composite polymers [32]. Also, the geocells could be synthesised in various textures, materials, and sizes according to the requirement of the site and nature of the soil. Han et al. [33] in their study used perforated geocells to reinforce poorly graded soil. Factors like dimensions of geocell [34], the material from which it is fabricated [15] affect the performance of geocell-soil system. The performance of geocell in soil is also affected by the geocell infill material. The substitution of appropriate quantity seashell for sand in geocell infill significantly improved the bearing capacity of soil [35]. Cement is the most commonly used admixture for the improvement of the strength of soil, and when it is used along with cellular confinement, the increase is huge and highly effective [36]. Several studies have been carried out to compare the performance of different forms of reinforcement and have reported that when compared to discrete fibres and planar form, geocell works efficiently and performs better [14,15,16, 37,38,39,40]. Performance of geocells while changing the parameters like width, placement depth, height of geocell [41], and geocell pattern [42] is studied to obtain the optimal parameters. Coir, one of the strongest natural fibres, has shown to greatly improve the bearing capacity of soil when included in the form of geocell [41] and also has the capacity to perform better than HDPE geocells [35]. Bamboo is a natural grass which can be used as geocell possesses higher tensile strength than the HDPE geocell Neoloy [43]. However, jute is also another potential alternative that could serve well when used for the fabricated as geocell, as it has shown to increase the soil strength used as a planar reinforcement [26]. India being the highest producer of jute, it could be availed easily in a much cheaper rate. This technical note presents a study on varying the dimensional parametric ratios of the jute geocell and optimizing the same to yield an improved bearing capacity with reduced settlement of soil.

Materials

Sand

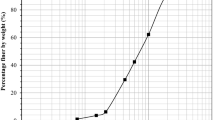

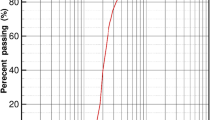

River sand passing through 4.75 mm sieve was used for the study. The sand was classified as poorly graded sand (SP) according to Unified Soil Classification System (USCS) and the grain size distribution in shown in Fig. 1. Table 1 presents the properties of soil used for the preparation of sand bed. The soil properties were found as per IS2720—Part-3, 4, 13, and 14.

Jute Geocell

Woven jute geotextile is used to develop jute geocell for the present study. Photograph of jute geotextile used for the study is shown in Fig. 2.

The properties of jute geotextile are presented in Table 2. When any reinforcement material is incorporated in soil an important parameter to be defined is its tensile strength. The tensile property of jute geotextile was determined as per DIN EN ISO 29073-1992-08. The thickness of geotextile was measured as per DIN EN ISO 9073-2-1995 (Method A). The mass per unit area of the jute geotextile was found in accordance with ASTM D3776 M-Option 3:2017.

In earlier studies, geocells are made by cutting geogrids and geonets into strips of required dimensions (length and height) from full rolls and connected with bodkin joints at necessary places after placing them in transverse and diagonal directions [15, 42, 44]. Tafreshi et al. [38] in their study fabricated geocells by thermo-welding nonwoven planar geotextile.

In the present study, jute geocells are developed by stitching the jute geotextile strips of requisite dimensions using yarn, similar to that of coir geocells fabricated by Lal et al. [41]. The geocell pocket size was kept constant (100 mm × 100 mm). The photograph of jute geocell is shown in Fig. 3. The height and width of geocell were varied for different trials.

Laboratory Tests

Reinforcement Arrangement

The arrangement of geocell reinforcement in the tank is shown in Fig. 4.

The parameters varied in the tests are thickness of sand layer between geocell and footing (u), width of geocell (b), and height of geocell (h). The parameters u, b, and h are expressed in terms of the footing width (B) as u/B, b/B, and h/B.

Preparation of Sand Bed

A steel tank of dimensions 500 mm × 500 mm × 500 mm was fabricated to conduct the model plate load tests. The sand was filled in the tank setup by sand raining technique also known as sand pluviation technique. The height of fall required for achieving a relative density of 50% was found by pouring sand from varying heights. To hold uniformity in the series of tests performed, it was ensured that throughout the filling process, this height was constantly maintained. All the test series were maintained the same range of relative density to attain medium dense state of sand. After filling until the level of placement of geocell, the geocell was positioned in the tank and sand raining was to be continued up to level of model footing. The different levels indicating the level of placement of geocell which varies between different trials were marked on all four sides of the tank before filling the tank with sand. The schematic view of the model tank setup is shown in Fig. 5.

Testing Procedure and Experimental Program

Laboratory model plate load tests were performed to study the effect of inclusion of jute geocell. A 100 mm × 100 mm square plate of thickness 10 mm made of steel was used as model footing. To make the base of model footing plate rough, a thin film of sand was glued to the bottom face of the footing with the help of epoxy glue. The footing was placed centrally on the prepared sand bed. The load was applied to the footing through a loading frame fitted with hydraulic jack and a manually operated pump. The tank was positioned with care under the hydraulic jack to avoid eccentric loading. A load cell was placed between the footing and the hydraulic jack to measure the load applied. The settlement was measured with the help of two dial gauges of least count 0.01 mm. The two dial gauges were supported on the sides of the tank using magnetic stand and were placed with their tips touching the top of the model footing plate on its two opposite corners, as shown in Fig. 5. The load was applied in small increments of 0.1 kN and the corresponding settlement readings in the dial gauges were noted down. The load application was continued until a footing settlement (s/B) of 25%. The average settlement was calculated by averaging the two dial gauge readings. A dimensionless quantity called improvement factor (I) is calculated to evaluate the performance of the jute geocell-reinforced soil with respect to the unreinforced soil [46]:

where qr is the bearing pressure of geocell-reinforced sand bed and qu is the bearing pressure of unreinforced sand bed, both measured at same level of settlement. The settlement ‘s’ is also denoted in terms of the footing width as s/B (%). The improvement factor is calculated at different settlement levels (s/B) 10%, 15%, and 20% to evaluate extent of improvement due to the inclusion of geocell and also to serve as an index to find the optimum ratio of the parameters.

Results and Discussion

The incorporation of jute geocell in soil has shown an improvement between the applied pressure and settlement behaviour of soil. The results of the series of tests are discussed below.

Thickness of Sand Layer Above Geocell (u)

Initially, model plate load test was done on unreinforced soil to provide a comparative study (Series I). Tests of Series II involved the variation of thickness of sand layer above geocell (depth of geocell layer from footing).

Figure 6 shows applied pressure-settlement behaviour of reinforced soil system with jute geocell positioned at varying depths. The depth of geocell was varied as mentioned in Table 3. It can be seen that irrespective of the position of jute geocell, all reinforced cases have shown an improved applied pressure-settlement behaviour. This can be attributed to the confinement effect produced by the interconnected cellular network of geocell and the friction developed between the geocell wall and sand. It can be seen that at lower settlements below 5% of the footing width, the improvement does not vary significantly with varying depth of geocell. Figure 7 shows a graph plotted between improvement factor and thickness of sand layer above geocell at different levels of settlements 5%, 10%, 15%, and 20% of the footing width, respectively. The improvement in the performance of reinforced sand increased when the depth of geocell layer was increased from 0 to 0.1 times the footing width; afterwards, as the thickness of sand layer between geocell and footing was increased, the improvement factor has reduced significantly. This clearly indicates that placement of geocell at depth u = 0.1B from footing level is the optimum placement depth that gives maximum improvement in performance when compared to the unreinforced sand bed. This finding is in agreement with the observations of Dash et al. [42] and Lal et al. [41]. A small sand cushion layer is required between the bottom of footing and geocell layer for the development of effective interface friction between the geocell and sand. The sand cushion also prevents the direct contact of footing with the geocell, thereby eliminating buckling of geocell in the initial stages. At a settlement of about 20% of the footing width, the improvement factor increased from 2.4 when geocell was placed at level of footing to 3.2 when the depth of geocell layer was 0.1B. Later, the improvement factor followed a decreasing trend when the depth to layer of geocell was increased to 0.2B, 0.3B, and 0.4B, respectively.

Width of Geocell (b)

In the third series of tests, the optimum thickness of sand layer above geocell (u) obtained was incorporated. The width of jute geocell was varied in relation with the footing width as mentioned in Table 3. Figure 8 shows the applied pressure-settlement behaviour of sand bed when the width of jute geocell was varied.

Figure 9 shows the graph between improvement factor and width of geocell at different settlement levels. It can be observed that at all the settlement levels depicted in the graph, the improvement factor has shown an increasing trend with increase in the width of jute geocell from b = 1B to b = 4B and a very small improvement in performance when b/B varied from 4 to 5. When we consider the improvement factor versus width of geocell plot at 10% (s/B) settlement level, the improvement factor has increased by about 29% when width of geocell was increased from b = 1B to b = 2B and by 10% and 12% when width of geocell was increased from 2B to 3B and then from 3B to 4B. Later, when the width was increased from 4B to 5B, the improvement was small, only about 2%. Since there was no significant improvement when width of jute geocell was varied from 4B to 5B, the optimum width was taken as 4B. The soil-geocell system performs effectively only up to a certain width beyond which there is negligible improvement in its performance. Only up to a certain width of reinforcement below the footing, the development of frictional resistance is efficacious. Dash et al. [42] also found a very minimal improvement in the performance of geocell-reinforced sand beyond a width of 4B. Lal et al. [41] observed no remarkable improvement beyond a value of b/B = 3 in their study with coir geocell. The variations in optimum width of geocell obtained in different studies can be attributed to various factors such as properties of soil and properties of the reinforcement used.

Height of Geocell (h)

The optimum depth of placement of geocell and width of geocell obtained in the previous series of tests (Series II and III) was used, and the height of geocell was varied in relation with the footing width as mentioned in Table 3. The applied pressure-settlement behaviour of sand bed reinforced with varying height of jute geocell (Series IV) is shown in Fig. 10. The graph plotted between improvement factor and height of geocell for different settlement levels is shown in Fig. 11.

It can be clearly seen that the improvement factor (I) increased significantly with increase in the height of geocell from h = 0.2B to h = 0.6B, but only a marginal improvement when height of geocell is increased from 0.6B to 0.8B. When the performance at 15% settlement (s/B) was observed, there was a 31% increase in the improvement factor when geocell height was increased from 0.2B to 0.4B, and 30% increase when height was increased from 0.4B to 0.6B, whereas only an increase of about 1.9% was observed when the geocell height was increased from 0.6B to 0.8B. Beyond a certain height of geocell, the improvement in the pressure-settlement behaviour was insignificant due to the buckling of walls of geocell under load application. Lal et al. [41] and Sitharam et al. [45] have also reported the insignificance of increase in geocell height (h) beyond a certain value on the performance of reinforced sand bed. Since there is no remarkable increase in the improvement factor beyond h/B ratio of 0.6, h = 0.6B is taken to be the optimum height of geocell.

Table 4 shows the summarized values of the improvement factor (I) at 10% settlement reported by the various researchers for different conditions.

Conclusions

A series of laboratory model plate load tests were performed to assess the performance of jute geocell-reinforced shallow foundation. The parameters such as thickness of sand layer above geocell, width of geocell, and height of geocell have a significant impact on the behaviour of geocell-reinforced sand beds.

The following conclusions are drawn from the study:

-

1.

The inclusion of jute geocell improves the performance of the shallow footing due to internal confinement and increased stiffness of the soil.

-

2.

The optimum placement depth of the top of geocell from the footing is required for a productive development of frictional resistance between geocell and soil. There is a noteworthy improvement in the performance of jute geocell-reinforced foundation system when the geocell is placed at a depth u = 0.1B.

-

3.

A maximum improvement in performance of jute geocell is observed when the width of geocell is four times the width of the footing, beyond which only a marginal improvement is observed.

-

4.

The enhancement in performance of geocell-reinforced sand bed is significant only up to a geocell height of 0.6B beyond which only a marginal improvement is seen.

-

5.

At 20% settlement level (s/B), the provision of geocell at optimum depth, width, and height has shown to improve the bearing capacity by a factor of 3.5 This result shows the potential of jute geocell reinforcement in various geotechnical applications.

References

Yetimoglu T, Salbas O (2003) A study on shear strength of sands reinforced with randomly distributed discrete fibers. Geotext Geomembr 21(2):103–110

Tang C, Shi B, Gao W, Chen F, Cai Y (2007) Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext Geomembr 25(3):194–202

Hamidi A, Hooresfand M (2013) Effect of fiber reinforcement on triaxial shear behavior of cement treated sand. Geotext Geomembr 36:1–9

Akbulut S, Arasan S, Kalkan E (2007) Modification of clayey soils using scrap tire rubber and synthetic fibers. Appl Clay Sci 38(1–2):23–32

Attom MF, Al-Akhras NM, Malkawi AI (2009) Effect of fibres on the mechanical properties of clayey soil. Proc Inst Civ Eng-Geotech Eng 162(5):277–282

Prabakar J, Sridhar RS (2002) Effect of random inclusion of sisal fibre on strength behaviour of soil. Constr Build Mater 16(2):123–131

Tran KQ, Satomi T, Takahashi H (2018) Effect of iste cornsilk fiber reinforcement on mechanical properties of soft soils. Transp Geotech 16:76–84

Sharma V, Vinayak H, Marwaha B (2015) Enhancing compressive strength of soil using natural fibers. Constr Build Mater 93:943–949

Dutta RK, Gayathri V (2012) Effect of addition of treated coir fibres on the compression behaviour of clay. Jordan J Civ Eng 6(4):476–488

Herrera-Franco PJ, Valadez-Gonzalez A (2004) Mechanical properties of continuous natural fibre-reinforced polymer composites. Compos Part A Appl Sci Manuf 35(3):339–345

Ghavami K, Toledo Filho RD, Barbosa NP (1999) Behaviour of composite soil reinforced with natural fibres. Cem Concr Compos 21(1):39–48

Haeri SM, Noorzad R, Oskoorouchi AM (2000) Effect of geotextile reinforcement on the mechanical behavior of sand. Geotext Geomembr 18(6):385–402

Omar MT, Das BM, Yen SC, Puri VK, Cook EE (1993) Ultimate bearing capacity of rectangular foundations on geogrid-reinforced sand. Geotech Test J 16(2):246–252

Lal D, Sankar N, Chandrakaran S (2017) Effect of reinforcement form on the behaviour of coir geotextile reinforced sand beds. Soils Found 57(2):227–236

Latha GM, Somwanshi A (2009) Effect of reinforcement form on the bearing capacity of square footings on sand. Geotext Geomembr 27(6):409–422

Latha GM, Murthy VS (2007) Effects of reinforcement form on the behaviour of geosynthetic reinforced sand. Geotext Geomembr 25(1):3–32

Makkar FM, Chandrakaran S, Sankar N (2019) Performance of 3-D geogrid-reinforced sand under direct shear mode. Int J Geotech Eng 13:227–235. https://doi.org/10.1080/19386362.2017.1336297

Das BM, Omar MT (1994) The effects of foundation width on model tests for the bearing capacity of sand with geogrid reinforcement. Geotech Geol Eng 12(2):133–141

Patra CR, Das BM, Atalar C (2005) Bearing capacity of embedded strip foundation on geogrid-reinforced sand. Geotext Geomembr 23(5):454–462

Kazimierowicz-Frankowska K (2007) Influence of geosynthetic reinforcement on the load-settlement characteristics of two-layer subgrade. Geotext Geomembr 25(6):366–376

Wang JQ, Zhang LL, Xue JF, Tang Y (2018) Load-settlement response of shallow square footings on geogrid-reinforced sand under cyclic loading. Geotext Geomembr 46(5):586–596

Ouria A, Mahmoudi A (2018) Laboratory and numerical modeling of strip footing on geotextile-reinforced sand with cement-treated interface. Geotext Geomembr 46(1):29–39

Shukla SK (2017) Fundamentals of fibre-reinforced soil engineering. Springer, Berlin

Ghosh A, Ghosh A, Bera AK (2005) Bearing capacity of square footing on pond ash reinforced with jute-geotextile. Geotext Geomembr 23(2):144–173

Vinod P, Bhaskar AB, Sreehari S (2009) Behaviour of a square model footing on loose sand reinforced with braided coir rope. Geotext Geomembr 27(6):464–474

Bera AK, Chandra SN, Ghosh A, Ghosh A (2009) Geotextiles and Geomembranes Unconfined compressive strength of fly ash reinforced with jute geotextiles. Geotext Geomembr 27(5):391–398

Saha P, Roy D, Manna S, Adhikari B, Sen R, Roy S (2012) Durability of transesterified jute geotextiles. Geotext Geomembr 35:69–75

Sumi S, Unnikrishnan N, Mathew L (2018) Durability studies of surface-modified coir geotextiles. Geotext Geomembr 46(6):699–706

Demir A, Laman M, Yildiz A, Ornek M (2013) Large scale field tests on geogrid-reinforced granular fill underlain by clay soil. Geotext Geomembr 38:1–15

Pincus H, Bathurst R, Karpurapu R (1993) Large-scale triaxial compression testing of geocell-reinforced granular soils. Geotech Test J 16(3):296

Mehrjardi GT, Motarjemi F (2018) Interfacial properties of geocell-reinforced granular soils. Geotext Geomembr 46(4):384–395

Pokharel SK, Han J, Leshchinsky D, Parsons RL, Halahmi I (2010) Investigation of factors influencing behaviour of single geocell-reinforced bases under static loading. Geotext Geomembr 28(6):570–578

Han J, Yang X, Leshchinsky D, Parsons R (2007) Behavior of geocell-reinforced sand under a vertical load. Transp Res Rec J Transp Res Board 2045(1):95–101

Shin EC, Kang HH, Kang JK, Shin HS (2010) Effect of geocell shape and filling material characteristics on bearing capacity geocell reinforced soils. Jpn Geotech Soc Spec Publ 2(66):2244–2247

Kolathayar S, Suja P, Nair V, Krishna S, Tamilarasi G (2019) Performance evaluation of seashell and sand as infill materials in HDPE and coir geocells. Innov Infrastruct Solut 4(1):17

Wang YM, Chen YK, Liu W (2008) Large-scale direct shear testing of geocell reinforced soil. J Cent South Univ Technol 15(6):895

Zhou H, Wen X (2008) Model studies on geogrid- or geocell-reinforced sand cushion on soft soil. Geotext Geomembr 26(3):231–238

Tafreshi SM, Dawson AR (2010) Comparison of bearing capacity of a strip footing on sand with geocell and with planar forms of geotextile reinforcement. Geotext Geomembr 28(1):72–84

Lal D, Sankar N, Chandrakaran S (2019) Triaxial test on saturated sands reinforced with coir products. Int J Geotech Eng 13(3):270–276

Hegde A, Sitharam TG (2014) Use of bamboo in soft-ground engineering and its performance comparison with geosynthetics: experimental studies. J Mater Civ Eng 27(9):04014256

Lal D, Sankar N, Chandrakaran S (2017) Behaviour of square footing on sand reinforced with coir geocell. Arabian J Geosci 10(15):345

Dash SK, Krishnaswamy NR, Rajagopal K (2001) Bearing capacity of strip footings supported on geocell-reinforced sand. Geotext Geomembr 19(4):235–256

Hegde A, Sitharam TG (2015) Experimental and analytical studies on soft clay beds reinforced with bamboo cells and geocells. Int J Geosynth Gr Eng. https://doi.org/10.1007/s40891-015-0015-5

Krishnaswamy NR, Rajagopal K, Latha GM (2000) Model studies on geocell supported embankments constructed over a soft clay foundation. Geotech Test J 23(1):45–54

Sitharam T, Sireesh S (2005) Behavior of embedded footings supported on geogrid cell reinforced foundation beds. Geotech Test J 28(5):12751

Hegde AM, Sitharam TG (2015) Effect of infill materials on the performance of geocell reinforced soft clay beds. Geomech Geoengin 10:163–173. https://doi.org/10.1080/17486025.2014.921334

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Muthukumar, S., Sakthivelu, A., Shanmugasundaram, K. et al. Performance Assessment of Square Footing on Jute Geocell-Reinforced Sand. Int. J. of Geosynth. and Ground Eng. 5, 25 (2019). https://doi.org/10.1007/s40891-019-0176-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40891-019-0176-8