Abstract

Earth loads acting on buried structures are known to be influenced by the characteristics of the soil, and the stiffness and geometry of the structure. To reduce earth pressure acting on buried structures, the induced trench installation technique has been recommended and applied in practice for several decades. It involves the installation of a soft zone immediately above the buried structure to mobilize shear strength in the backfill material. In this study an experimental investigation is conducted to measure the changes in contact pressure on the walls of a rigid structure buried in granular backfill with a U-shaped geofoam wrap. The results are compared with the conventional induced trench method as well as the positive projection installation with no geofoam. Contact pressures on the walls of the structure are measured using the tactile sensing technology. The experimental results are used to validate a finite element model that has been developed to analyze this soil–geosynthetic–structure interaction problem. The numerical model is then used to study the soil arching and the stresses developing in the backfill material for three different EPS densities. In addition, the role of geofoam density and the maximum fill height that can be carried safely without exceeding the design strain levels are examined. Conclusions are made regarding the effectiveness of this type of EPS inclusion on the earth pressure distribution around the buried structure.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The magnitude and distribution of earth pressures on buried structures are known to be dependent on the relative stiffness of the buried structure and the backfill material. To reduce earth loads on buried structures, the induced trench installation (ITI) method introduced by Marston [1, 2] can be used. In this method, the loads are redistributed around the buried structure by introducing a compressible material above the top of the culvert to promote positive arching. Significant modifications were made by Spangler [3, 4] to establish what is known as Marston-Spangler theory. Expanded polystyrene (EPS) has low stiffness and exhibits a desirable elastic–plastic behavior. When an embankment is constructed over a buried conduit with EPS inclusion, the EPS zone compresses more than its surrounding fill, and thus positive arching is induced above the culvert.

The ITI method of installation for rigid conduits buried under high embankments dates back to the early 1900s. Researchers studied the relevant soil–structure interaction using experimental testing and field instrumentation [e.g., 5–9] as well as numerical modelling [e.g., 10–14] to help understand the method and to address uncertainties with this design approach.

The soft zone geometry is traditionally defined by three parameters width, height, and the distance from the top of the pipe to the bottom of the soft zone. For circular pipes, Vaslestad et al. [6] studied a condition where the pipe is inserted into a zone of soft material. Yoo and Kang [15] concluded, based on a large number of parametric studies that, compared to other configurations, surrounding the pipe with a soft zone was found to be the most effective in reducing earth pressures. Limited efforts have been made to date to investigate the effect of EPS configuration on the loads transferred to the walls of a buried conduit, particularly for box sections under high embankments.

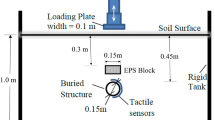

The objective of the present study is to examine the role of geofoam configuration in reducing earth pressures on a rigid box-shaped conduit. This is achieved using experimental investigation and numerical analysis. A test chamber was designed and built to allow for the earth pressure to be measured on three sides of the structure. Induced trench installation was investigated by comparing two different soft zone configurations as illustrated in Fig. 1. The second configuration involves U-shaped EPS blocks placed around the buried structure and the measured pressures are compared with those measured in the first configuration where one EPS block is placed only above the structure. A finite element model that is capable of capturing the response of EPS geofoam material is developed. The model is first validated using the experimental data and then used to investigate different EPS configurations and the acceptable embankment height under the maximum allowable strain typically used for EPS design. The finite element (FE) analyses presented throughout this study have been performed using the general finite element software ABAQUS/Standard, version 6.13 [16].

Experimental Program

The experimental setup used in this study consists of an instrumented square hollow structural section (HSS) embedded in a test chamber. The HSS is instrumented using tactile sensing pads wrapped around the middle third of the structure. The chamber dimensions (1.4 × 1.2 × 0.45 m) are selected such that they represent two-dimensional loading condition. The rigid walls are placed far enough from the instrumented HSS section to minimize boundary effects. The distance from each side of the HSS to the side wall of the chamber is 0.575 m which is more than twice the width of the buried structure. All steel wall surfaces were painted with epoxy coating and a double layer of plexiglass (2 mm thick) was placed on the back and front of the chamber. The layer in contact with the box was fixed while the layer in direct contact with the soil was free providing a smooth sliding surface hence minimizing friction effects. A partial view of the test chamber is shown in Fig. 2a. Dry sandy gravel with average unit weight of 16.28 kN/m3 is used as backfill material. Sieve analysis, conducted on selected samples, indicated a coarse-grained material with 77% gravel and 23% sand. The friction angle of the backfill soil determined using direct shear tests for the above density is found to be 47°.

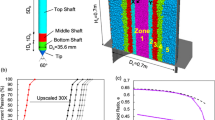

A rigid HSS section with dimensions 0.25 × 0.25 × 0.435 m and 1 cm in wall thickness is used as a buried structure throughout this study. The structure is instrumented using three custom made pressure sensing pads (TactArray sensors) placed directly on the upper, side and lower walls as shown in Fig. 2b. The measured pressure ranges from 0 to 140 kPa for the upper and side walls and from 0 to 350 kPa for the lower wall. The sensors are protected from the backfill abrasion by wrapping the whole conduit with a thin layer of PVC (see Fig. 2b).

In addition to the calibration performed by the manufacturer, the accuracy of the sensing pads was checked by applying known pressure and recording the sensor readings using the data acquisition system. Further calibration details are provided elsewhere [17, 23].

A total of nine experiments were conducted including three benchmark tests with only the instrumented HSS box inside the backfill and then two sets of tests are performed for different geofoam configurations. For all tests, a well tamped bedding zone of 25 cm in height is created to ensure consistent initial conditions. The HSS box is placed over the bedding layer and leveled to minimize concentration of stresses under the box. Soil placement continued in layers over the HSS up to the desired height resulting in a backfill thickness of 0.5 m. Air bag is used to apply uniform surface pressure of up to 140 kPa over the prepared sand. The thickness of the EPS block (5 cm) has been chosen such that it represents about 25% of the height of the box.

A typical pressure distribution as recorded by the sensing pads located on the upper wall of the buried box is shown in Fig. 3. These readings are averaged and the results are used to compare contact pressures in the different investigated cases. The earth pressure on the buried structure generally increased with the increase in surface pressure. At an applied pressure of about 140 kPa, the average readings of the benchmark case (with no EPS installed) at the upper, lower and side walls are 155, 169 and 68 kPa, respectively. A summary of the measured and calculated results for the two different soft zone configurations is provided in the next section.

Numerical Analysis

A series of 2D finite element analyses is performed using ABAQUS software to investigate the role of geofoam configuration on the earth pressure transferred to the walls of the buried structure. The backfill soil is modeled using elasto-plastic Mohr–Coulomb failure criteria with non-associated flow rule. The HSS is treated as linear elastic material with density of 7850 kg/m3. The Poisson’s ratio and Young’s modulus of the HSS are 0.3 and 200 GPa, respectively. The properties of the different materials used in the analysis are summarized in Table 1.

The EPS geofoam inclusion generally behaves as nonlinear elasto-plastic strain hardening material. A constitutive model that is capable of describing the details of geofoam behavior, including the nonlinearity, elasticity, isotropic hardening and plasticity, is needed. These components have been combined using the commercial finite element software ABAQUS and used to represent the EPS geofoam material throughout this study. The approach used to combine these model features is based on the conversion of the measured strains and stresses into the appropriate input parameters in ABAQUS [18, 19]. This is achieved by decomposing the total strain values into elastic and plastic strains to cover the entire range of the EPS response. The finite element (FE) mesh that represents the geometry of the experiment, the boundary conditions, and the different soil zones around the HSS section is shown in Fig. 4. The mesh size was adjusted around the structure to provide sufficient details within the studied area. The complete mesh comprises a total of 1962 plane strain elements (CPE8) and about 6500 nodes for the two examined configurations. Boundary conditions were defined such that nodes along the vertical boundaries may translate freely in the vertical direction but are fixed against displacements normal to the boundaries (smooth rigid). The nodes at the base are fixed against displacements in both directions (rough rigid).

Three different contact conditions are considered in this study; namely, (i) soil–EPS interaction, (ii) soil–structure interaction and (iii) EPS–structure interaction. These interactions are simulated using the surface-to-surface, master/slave contact technique available in ABAQUS. Contact formulation in 2D space covers both tangential and normal directions. In the tangential direction, Coulomb friction model is used to describe the shear interaction between the geofoam, the structure, and the surrounding soil. This model involves two material parameters- a friction coefficient (µ), and a tolerance parameter (E slip ). The shearing resistance (τ) is considered as a function of the shear displacement that represents the relative movement between the two contacting parties. On the other hand, a ‘hard’ contact model is used to simulate the contact pressure in the normal direction.

The soil-EPS interface friction angle has been reported by several researchers [e.g. 20, 21] and was found to range from 27° to 33° for different backfill materials. This range corresponds to a friction coefficient of 0.5 to 0.65. Given the internal friction angle for the backfill material used in this study (ϕ = 47°), a soil-EPS interface friction coefficient of 0.6 is used in the analysis. The friction coefficient between the soil and the PVC sheet covering the buried structure is taken as 0.45 based on the values reported by Vaid and Rinne [22]. The parameters used to describe these interface conditions are given in Table 1.

Model Validation

The numerical model is first validated by comparing the calculated pressures with the measured values for the three investigated cases (a) the benchmark test with no geofoam, (b) using EPS15, and (c) using EPS22. As shown in Fig. 5, the measured contact pressures on the upper wall of the structure increased almost linearly with the increase in the applied surface pressure. This is particularly true for the cases where EPS blocks were installed (Fig. 5b, c). For the benchmark case (Fig. 5a), however, the pressure on the upper wall was found to fluctuate around the linear pattern which may be attributed to the particulate nature of the sand that is in direct contact with the sensors. In general, the introduction of U-shaped EPS geofoam resulted in a significant decrease in earth pressure. For example, at applied surface pressure of 140 kPa, the earth pressure on the upper wall decreased by 60% (from 149 kPa for the benchmark case to 60 kPa) for the induced trench installation using EPS22 and the reduction in pressure reached about 70% (43 kPa) when EPS15 was introduced. It was also found that the numerical model is able to capture the pressure changes with a reasonable accuracy for the induced trench cases using two different EPS materials.

Stress Distribution Around the Buried Structure

Figure 6 shows the distribution of stresses around the buried structure when U-shaped EPS15 blocks are used under a surface pressure of 140 kPa. The vertical and lateral stress components are presented separately in Fig. 6a. Vertical pressure decreased within the soil column located immediately above the structure from 140 kPa at the loaded surface to 54 kPa near the upper wall. The soil column adjacent to the structure experienced an increase in vertical pressure to values that are more than 200 kPa. This is attributed to the soil arching that resulted in a redistribution of vertical stresses away from the soil column containing the soft zone to the adjacent soil columns located on both sides of the structure. Similarly, the presence of EPS geofoam on the side walls resulted in a significant reduction in lateral pressure from about 70 to 15 kPa.

Another way of presenting the soil arching results is by plotting the contours of in-plane principal stresses around the structure as shown in Fig. 6b. The pressure redistribution is evident in this figure particularly in the close vicinity of the structure. The distribution was found to be symmetric with stresses gradually decreasing in the backfill material as the EPS blocks are approached. The slight difference in contact pressure between the upper (54 kPa) and lower (56 kPa) walls is attributed mainly to the self-weight of the box. The maximum pressure (267 kPa) was found to develop within the right and left soil columns at a point located approximately 0.5B (B = the width of the box) away from the side walls of the buried structure.

Effect of EPS Density on Contact Pressure

Contact pressures acting on the upper, lower and side walls of the structure are presented in Fig. 7 for different surface pressures. The calculated pressure is normalized with respect to that of the embankment construction with no EPS geofoam. The maximum contact pressure that corresponds to 1% EPS strain is used as a reference value for the comparison between the various investigated cases. For the upper wall (Fig. 7a), the lowest contact pressure is calculated for the case of EPS15 with pressure reduction of about 64% compared to the benchmark at an applied pressure of 87 kPa. The pressure reduction ratios for EPS22 and EPS39 were found to be 53 and 27% at applied surface pressures of 97 and 124 kPa, respectively. The pressure reduction ratios for the lower wall (Fig. 7b), at 1% strain, were found to be 63, 54 and 23% for EPS15, EPS22 and EPS39, respectively. At the side walls (Fig. 7c), the geofoam blocks installed against the side walls resulted in significant pressure reduction ratios of 81, 75 and 60% for EPS15, EPS22 and EPS39, respectively.

Comparison of Two Different EPS Configurations

To illustrate the merits of using U-shaped geofoam blocks around buried structures, the absolute pressure reduction is first calculated and compared with the conventional ITI installation using one EPS block above the structure. The comparison is further expanded to include the allowable strain criterion typically used in design.

Vertical and Lateral Pressures on the Structure

A comparison between the two EPS configurations utilizing EPS15 as a soft material to promote positive arching is shown in Fig. 8. It can be seen that, for the investigated range of surface pressures, the U-shaped EPS material was found to have superior effects on the earth pressure as compared to the conventional ITI installation with one EPS block above the structure. The largest effect was found at the side walls where pressures dropped from 60 to 17 kPa which corresponds to about 70% pressure reduction as shown in Fig. 8c. Despite the presence of the EPS15 block above the upper wall, the soil arching mechanism in this case resulted in a slight increase in pressure at the upper wall as shown in Fig. 8a. This behavior seems to be dependent on the geofoam density as the pressure was found to decrease on the upper wall when EPS22 and EPS39 are used under high surface pressure. Further comparison is provided in “Performance of EPS at small strain” section.

Contact Pressure Distribution

The contact pressure distributions on the walls of the buried structure for the three different installation methods are illustrated in Fig. 9 for EPS15 geofoam. For the embankment installation with no EPS, the distribution was generally characterized by stress concentration at the corners which was more pronounced at the upper and lower walls. Adding a geofoam block immediately above the upper wall resulted in a more uniform pressure distribution at that location with a significant drop in pressure from an average value of 149 to 43 kPa. It is noted that the average pressure on the upper wall represents 100% of the overburden pressure for the positive projecting analysis (no EPS) and about 28% of that value for the induced trench method. Similarly, the average pressure on the lower wall decreased from 153 kPa for positive projecting to 81 kPa for the conventional ITI method. For the side walls, the average pressure decreased from 80 to 59 kPa representing a reduction of about 26%.

Installing the U-shaped EPS blocks around the structure resulted in average pressures of 54, 56 and 15 kPa at the upper, lower, and side walls, respectively. Compared with the conventional ITI method, the U-shaped configuration resulted in significant pressure reduction at the side and lower walls with a small change at the upper wall compared to the first configuration.

Performance of EPS at Small Strain

Based on the previous results, the reduction in pressure on the sidewalls of the structure is associated with more stresses developing in the EPS geofoam blocks resisting these pressures. For EPS15, although more compression can result in a significant load reduction on the structure, EPS is usually designed for a maximum strain level that would minimize excessive compression and long-term creep. A balance between the load reduction and EPS strain for a given fill height is, therefore, needed. As an example, Fig. 10 shows a performance comparison of three EPS materials, namely, EPS15, EPS22, and EPS39, for a maximum allowable strain of 1%. The vertical axes represent the contact pressure reduction ratio for different EPS densities as compared to the benchmark case with no geofoam. The figure illustrates that, at a given location (e.g. the upper wall), there is a relationship between the EPS density and the maximum fill height that can be sustained without exceeding the 1% EPS strain. For the first configuration (Fig. 10a), using EPS15 results in about 72% reduction in pressure at the upper wall allowing a maximum fill height of about 7 m to be achieved. For the same configuration, EPS39 allows for a fill height of up to 8.9 m with a smaller load reduction ratio of about 35%. Using the second configuration (Fig. 10b), EPS39 resulted in a pressure reduction of about 27% at the upper wall with a maximum fill height of 8.1 m. It can be seen from Fig. 9b that the slight increase in pressure on the upper wall for EPS15 changed as the EPS density increased with a maximum pressure reduction of 28% at the upper wall when EPS39 is used.

Similar approach can be used to study the performance of EPS blocks at different strain levels (e.g. 2 or 3%) where the maximum applied pressure or backfill height that corresponds to a given strain level can be determined.

Calculated Earth Pressures Versus Positive Projecting Method

In this section, the earth pressures calculated using the numerical model is compared with the theoretical overburden pressures. Figure 11 shows the results for the upper, lower and side walls using three different types of EPS geofoam materials and a fill height that corresponds to 1% EPS strain. The horizontal axis represents the fill height above the box which includes the effect of both the backfill material and the applied surface pressure. At the upper wall (Fig. 11a), the positive projecting case (no EPS) showed no difference from the theoretical overburden pressure γH (where H is the height of the backfill above the upper wall and γ is the unit weight of the backfill). For the induced trench condition the calculated earth pressure values on the upper wall were found to be 0.73γH, 0.48γH and 0.36γH for EPS39, EPS22 and EPS15, respectively. These values correspond to pressure reductions of 27, 52 and 64% respectively.

A comparison between the contact pressure at the lower wall and the theoretical overburden pressure (γH) plus the self-weight of the box (w) is presented in Fig. 11b. For the positive projecting case (no EPS), the contact pressure at the lower wall was found to be 1.02 (γH + w). Using EPS blocks, the calculated pressures were found to be 0.66 (γH + w), 0.48 (γH + w) and 0.39 (γH + w) for EPS39, EPS22 and EPS15, respectively.

Similarly, the lateral pressure on the sidewalls is compared with the theoretical overburden pressure at the mid-height of the box, γH m (where H m = H + L/2 and L is the vertical height of the box) as shown in Fig. 11c. For the positive projecting case, the calculated lateral pressure was found to be 0.53γH m , while for the induced trench conditions the lateral pressure decreased to 0.22γH m , 0.14γH m , and 0.1γH m for EPS39, EPS22 and EPS15, respectively. These results suggest that careful selection of a suitable EPS geofoam density is important to ensure that earth pressure induced by a proposed embankment height can be carried safely without exceeding the allowable strain limit of the EPS material.

Based on the previous results, normalized charts are proposed for the examined cases to guide in selecting a proper EPS material that satisfies a given embankment height. Figure 12 shows three separate charts developed for the investigated EPS densities at 1% maximum allowable strain. The vertical axes represent the pressure reduction ratio which is related to the EPS type through the expected fill height. For example, if the expected fill height is 6 m, EPS22 is considered a reasonable choice as it will allow for up to 6.4 m of fill height with 52% pressure reduction at the upper wall. It should be noted that these results are based on a soil unit weight of 16.28 kN/m3 used for the backfill material.

Summary and Conclusions

In this study, the earth pressure distribution on a rigid HSS box buried in granular material and wrapped with U-shaped EPS geofoam was investigated using laboratory experiments and numerical analysis. The earth pressures acting on the upper, side, and lower walls are measured using tactile sensing pads and compared with those of the positive projecting technique. Three benchmark tests without EPS geofoam and two sets of tests for each EPS configuration were performed in the study. The height of the embankment was simulated by applying a uniform pressure on the surface of the soil using airbag restrained by a strong reaction frame in both the vertical and lateral directions. The experimental results showed that for applied surface pressure of 140 kPa, the contact pressure acting on the upper wall of the buried box decreased by up to 64% when a U-shaped EPS15 was used.

A numerical procedure for modeling this class of soil–EPS–structure interaction is developed using ABAQUS software. A series of 2D finite element analyses is conducted to study the role of EPS in reducing the earth loads acting on the walls of the structure. Two different EPS configurations were simulated in this study: (1) conventional ITI with one EPS block placed directly above the structure; and (2) three geofoam blocks placed on the upper wall and next to the sidewalls of the structure. The calculated pressures are first compared with experimental data and then used to study the role of EPS density and configuration on the earth pressure distribution on the structure. Charts were proposed to allow for the proper choice of EPS material that satisfies the design criterion for a specific embankment height.

This study suggests the following:

-

Using U-shaped EPS material can have significant effects on the earth pressure transferred to the walls of a buried structure.

-

The largest effect was found at the sidewalls where contact pressures was found to drop by up to 70%.

-

Given the added cost, using U-shaped EPS wrap can be justified if reducing in lateral earth pressure on the sidewalls is a design requirement (e.g. culverts built near creeping slopes).

It should be noted that the results presented in this study are based on a laboratory experimental program and a large-scale investigation or field tests are needed to confirm these results.

References

Marston A (1922) Second progress report to the Joint Concrete Culvert Pipe Committee. Iowa Engineering Experimental Station, Ames, IA, USA

Marston A (1930) The theory of external loads on closed conduits in the light of the latest experiments. In: The 9th annual meeting of the highway research board. Highway Research Board, Washington, D.C., USA, pp 138–170

Spangler MG (1950) Field measurements of the settlement ratios of various highway culverts, Bulletin No. 170. Iowa Engineering Experiment Station, Ames, Iowa, USA, p 99

Spangler MG (1951) A theory on loads on negative projecting conduits. In: The 13th annual meeting of the highway research board. Washington, D.C., USA, pp 153–161

Sladen JA, Oswell JM (1988) The induced trench method—a critical review and case history. Can Geotech J 25(3):541–549

Vaslestad J, Johansen TH,Holm W (1993) Load reduction on rigid culverts beneath high fills: long-term behavior. Transp Res Record 1415:58–68

Liedberg NSD (1997) Load reduction on a rigid pipe: pilot study of a soft cushion installation. Transp Res Record 1594:217–223

Sun L, Hopkins T, Beckham T (2011) Long-term monitoring of culvert load reduction using an imperfect ditch backfilled with geofoam. Transp Res Record 2212:56–64

Oshati OS, Valsangkar AJ, Schriver AB (2012) Earth pressures exerted on an induced trench cast-in-place double-cell rectangular box culvert. Can Geotech J 49(11):1267–1284

Kim K, Yoo CH (2002) Design loading for deeply buried box culverts. Highway Research Center, Report No. IR-02-03. Auburn University, Alabama, p 215

Kang J, Parker F, Kang YJ, Yoo CH (2008) Effects of frictional forces acting on sidewalls of buried box culverts. Int J Numer Anal Methods Geomech 32(3):289–306

Sun C, TC H, Benkham TL (2009) Reduction of stresses on buried rigid highway structures using the imperfect ditch method and expanded polysterene (geofoam). Kentucky Transportaion Center, Report No. KTC-07-14-SPR-228-01-1F. University of Kentucky, Kentucky, USA, p 49

McGuigan BL, Valsangkar AJ (2010) Centrifuge testing and numerical analysis of box culverts installed in induced trenches. Can Geotech J 47(2):147–163

McGuigan BL, Valsangkar AJ (2011) Earth Pressures on twin positive projecting and induced trench box culverts under high embankments. Can Geotech J 48(2):173–185

Yoo CH, Kang J (2007) Soil-structure interaction for deeply buried corrugated pvc and steel pipes. Highway Research Center, Auburn University

ABAQUS (2013) ABAQUS user’s manuals, version 6.13. Dassault Systems Simulia Corp., Providence

Ahmed MR, Tran VDH, Meguid MA (2015) On the role of geogrid reinforcement in reducing earth pressure on buried pipes: experimental and numerical investigations. Soils Found 55(3):588–599

Meguid MA, Hussein MG (2017) A numerical procedure for the assessment of contact pressures on buried structures overlain by EPS geofoam inclusion. Int J of Geosynth Ground Eng. doi:10.1007/s40891-016-0078-y

Hussein MG, Meguid MA, Whalen J (2015) On the numerical modeling of buried structures with compressible inclusion. In: GeoQuebec 2015, the 68th Canadian Geotechnical Conference. Canadian Geotechnical Society, Quebec City, Canada, Paper No. 577, p 8

Bartlett S, Negussey D, Kimble M, Sheeley M (2000) Use of geofoam as super-lightweight fill for I-15 reconstruction. In: The 79th annual meeting for the transportation research board. Transportation Research Board, Washington, DC, p 21

Stark TD, Arellano D, Horvath JS, Leshchinsky D (2004) Guideline and recommended standard for geofoam applications in highway embankments. National Cooperative Highway Research Program (NCHRP), Report No. 529. Transportation Research Board, Washington, D.C., USA, p 71

Vaid YP, Rinne N (1995) Geomembrane coefficients of interface friction. Geosynth Int 2(1):309–325

Meguid MA, Hussein MG, Ahmed MR, Omeman Z, Whalen J (2017) Investigation of soil-geosynthetic-structure interaction associated with induced trench installation. Geotext and Geomembr. doi:10.1016/j.geotexmem.2017.04.004

Acknowledgements

This research is supported by the Natural Sciences and Engineering Research Council of Canada (NSERC) CRD Project No. 452760-13. The generous support of Plasti-Fab Ltd. throughout this study is appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meguid, M.A., Ahmed, M.R., Hussein, M.G. et al. Earth Pressure Distribution on a Rigid Box Covered with U-Shaped Geofoam Wrap. Int. J. of Geosynth. and Ground Eng. 3, 11 (2017). https://doi.org/10.1007/s40891-017-0088-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40891-017-0088-4