Abstract

Sustainable end-of-life vehicles (ELVs) management has become a top important issue for automotive industries in many countries to tackle environmental and economic challenges. Currently, parts of the ELVs are used in many different ways, which often increase environmental hazards and reduce economic benefits. The selection of the best compromise ELVs management alternative (e.g., reuse, remanufacturing, and recycling) can bring maximum sustainability performances for any society or organization when things are to be settled professionally. The present paper proposes a multi-criteria decision-making approach using Decision-Making Trial and Evaluation Laboratory (DEMATEL) and extent analysis method on fuzzy AHP (FEAHP) to aid the decision maker in selecting the best compromise ELV management alternative with respect to the sustainable criteria. Here, DEMATEL is used to evaluate the sustainable criteria and then FEAHP is applied to evaluate the best alternatives. A case study is presented to demonstrate the applicability of the proposed approach in real-world applications. The results show that it is a viable approach and can be used as an effective tool for criteria and alternative evaluation. Finally, the implication of this study and limitations are also discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

With growing awareness for environmental protection and for economic and social benefits, sustainable end-of-life vehicles (ELVs) management has become an important issue in many countries. Sustainability is an outcome of complex real-world phenomenon where a large number of intriguing factors act and react in varied degree of orders simultaneously. It is commonly defined as utilizing resources to meet the needs of the present without compromising rights and abilities of future generations to meet their expected and potential needs [1]. Most developed and developing countries like USA, Japan, Australia, Taiwan, Korea, and China established legislations that enforced the original equipment manufacturers (OEMs) to accept responsibility of the complete life cycle of vehicles [2] for their proper management. The European Union end-of-life (EOL) directive forced the respective countries to achieve the recycling target of 85 % and a total recovery of 95 % by 2015. By that time, only 5 % of a vehicle will be admitted into a landfill and not more than 10 % will undergo thermal recovery [3].

In recent years, Malaysian’s automotive industry has entered a rapid development period, and Malaysia has become the major market in auto production and sales within the Asian region. The total vehicle production in 2012 was 569,620 in numbers as compared to 287,634 numbers in 1999. This growth of vehicles production and motorization rate (375 vehicles per thousand people in 2011, where world average was 176) has become an important alarming concern to think about ELVs waste in Malaysia. According to a statistics, there are more than 22 million vehicles on roads in Malaysia with more than 5 million cars are aged between 10 and 15 years [4]. Many of them already entered into the retired phase. Now it is an important concern that how to deal with those retired vehicles to get economic benefit and preserve the environmental issues from its bad impact. Even though the local ELV directive or legislation has not yet established [5], but the government is trying to manage ELVs around the country by making different policies. However, it is the time to make standard policies for a proper ELVs management to sustain the environment and reduce man-made impact towards the nature. When a product reaches its EOL, there could be a number of recovery options available such as reusing the product or its components, remanufacturing, material recycling, incineration, and landfill [6]. Large environmental and economic benefits may be expected when applying an appropriate sustainable ELVs recovery strategy. The purpose of an appropriate ELVs recovery-alternative evaluation is to manage and monitor corporate economic, environmental, social, and technological activities to minimize their environmental impacts, maintaining the minimal regulatory standards for acceptable pollution levels and reducing the wasteful use of natural resources.

Suitable dimensions, criteria, and alternative selections can increase the level of sustainability during long-term strategic decision for EOL product management. In this research, a multi-criteria ELV management framework-based model is proposed for evaluating sustainable alternatives. A multi-criteria decision-making (MCDM) method in real-world systems very often deals with subjective human preferences. Because human judgments and preferences are often vague and complex [7] due to the uncertainty and imprecision of the human decision-making process [8]. The decision makers cannot estimate their preferences with an exact scale, linguistic assessments can only be given instead of exact assessments. Therefore, fuzzy set theory is introduced into the proposed MCDM framework, which is put forward to solve such uncertainty problems [9]. Decision-Making Trial and Evaluation Laboratory (DEMATEL) and extent analysis method on fuzzy AHP (FEAHP) methods have been applied in many cases for evaluation of criteria and alternatives that involve imprecise data, i.e., human preferences.

A long-term strategic decision is always influenced by multi-dimensional criteria, where some criteria are strongly important and some criteria have less importance in decision activities. If decision makers consider all criteria which have low influence then decision-making activities would be more complex, time-consuming, and inappropriate. DEMATEL method is using worldwide to avoid such kind of problems to identify the most important criteria and alternatives. In this study, DEMATEL is used to identify important criteria by avoiding low influences then FEAHP-based model has been applied to evaluate the appropriate sustainable ELV management alternative by considering those important criteria.

2 Literature Review: End-of-life Vehicle Management

End-of-life vehicles have become one of the major global concerns due to large number of vehicles demand worldwide. Those large numbers of vehicles are also increasing hug wastes at the end of their life cycle as a result of improper management of ELV. Increasing forces and competitions to improve economic and environmental performance, the OEMs require considering sustainable ELV management to reduce environmental impacts and increase economic profit. The previous studies on ELV management emphasized many areas such as ELV directive implementation, legislation, recycling, environmental impact reduction, and so on.

Sakai et al. [10] had shown an international comparative analysis of ELV recycling systems to examine the characteristics and effectiveness of legislative systems for ELV recycling in several countries and regions. Che et al. [11] had also shown a comparative analysis of ELV recycling laws, advance dismantling experiments, and scenario analysis of Japan, Korea, and China to promote international cooperation. Forslind [12] studied on implementing extended producer responsibility in Sweden. Harraz and Galal [13] showed the design of a sustainable recovery network for ELVs in Egypt. Saavedra et al. [14] had presented an investigative study on the current remanufacturing prospects and opportunities in Brazil. Chen et al. [15] had reviewed the establishment of the ELV recycling system, analyze the existing system and its performance, and provide some recommendations for future development in Taiwan. Bellmann and Khare [16] conducted a comprehensive study on economic issues in recycling ELVs. Simic and Dimitrijevic [17] proposed the strategic automotive shredder residue (ASR) recycling planning model to assist Japanese vehicle recyclers to improve their profitability and ASR recycling efficiency. Diabat et al. [18] shown an exploration of green supply chain practices and performances in an automotive industry using Fuzzy set theory and TOPSIS. Abdulrahman et al. [19] had used case studies to investigate the status of remanufacturing practices, key determinants for strategic decision-making in Chinese auto parts companies using an analytic hierarchy process (AHP). Simic [20] had developed Fuzzy risk explicit interval linear programing model for ELV recycling planning in the European Union (EU). Arsovski and Aleksić [21] had provide a short summary of different approaches of MCDM method to calculate criteria weights of management problems in ELV recycling research area. Tadić et al. [22] had used a Fuzzy AHP and TOPSIS methods to determine the sequence of dismantling of ELV which arrive to dismantling center. Keivanpour et al. [23] had presented a modeling approach based on fuzzy logic-based system to analyze the economic sustainability of ELV dismantlers under uncertainties. Ling [24] had used Fuzzy Multi-attribute decision method to evaluate ELV take-back partners.

Based on literature review, it is incidental that several researchers have attempted to solve different ELV related problems. They also used some mathematical methods for several applications to improve economic and environment performances. But the usage of integrated MCDM in the context of sustainable ELV management and best compromise alternatives selection is found to be scant. Evaluation of the best compromise sustainable alternatives involves complex decision variables. To select the right dimensions, criteria, sub-criteria, and alternatives for EOL product management decision by predicting the future conditions are one of the most critical issues which control the prestige of the company among its competitors. To avoid the effect of uncertainty in decision-making stages, the analysis methods that take the current uncertainty into account have to be used in modeling. DEMATEL and FEAHP methods have been widely used to incorporate current uncertainty into the mathematical models. Chou et al. [25] evaluated the criteria for human resource for science and technology based on an integrated Fuzzy AHP and fuzzy DEMATEL approach. Wu and Tsai [26] used DEMATEL and AHP method for evaluating the causal relations among the criteria in auto spare parts industries in Taiwan. Chang et al. [27] used Fuzzy DEMATEL method for developing supplier selection criteria. Ren et al. [28] identified the critical criteria and cause–effect analysis for enhancing the sustainability using DEMATEL method. Wang and Chan [29] used Fuzzy extent analysis and TOPSIS approach for evaluating remanufacturing alternatives of a product design. Torfi et al. [30] used Fuzzy AHP to determine the relative weights of evaluation criteria and Fuzzy TOPSIS to rank the alternatives. Shaw et al. [31] and Lee [32] applied fuzzy extent analysis for supplier selection model. Shumon et al. [33] used FEAHP to evaluate EOL electronic products collection system in a reverse supply chain. In this research, a multi-criteria framework-based approach is proposed to evaluate most influencing sustainable dimensions, criteria, and alternatives for ELV management decision-making.

3 Methodology: DEMATEL and FEAHP

3.1 Decision-Making Trial and Evaluation Laboratory (DEMATEL)

Decision-Making Trial and Evaluation Laboratory method was originally developed by the Science and Human Affairs Program of the Battelle Memorial Institute of Geneva to study and resolve the complicated and intertwined complex problems to clarify the essential issues of the defined problems [26]. DEMATEL approach can identify the interactions among alternative systems and evaluation criteria because it can calculate the impacts among the criteria consistently [34, 35]. This technique is widely used to solve various types of complex studies that can effectively understand the complex structure and provide various options of problem-solving [36].

Based on Wu and Tsai [26], the three major steps of DEMATEL are summarized as follows:

-

Step 1 Calculate the average matrix. Each respondent was asked to evaluate the direct influence between any two factors by an integer score ranging from 0 to 3, representing "no influence", "low influence", "medium influence", and "high influence", respectively. The notation of x ij indicates the degree to which the respondent believes that factor i affects factor j. For i = j, the diagonal elements are set to zero, indicating no influence.

-

For each respondent, an (n × n) non-negative matrix can be established as \(X^{k} = [x_{ij}^{k}]\) , where k is the number of respondents with 1 ≤ k ≤ H, and n is the number of factors. Thus, X 1, X 2, X 3,…, X H are the matrices from H respondents. To incorporate all opinions from H respondents, the average matrix A = [a ij ] can be constructed as follows [35, 37]:

$$a_{ij} = \frac{1}{H}\sum\limits_{k = 1}^{H} {x_{ij}^{k}}$$(1) -

Step 2 Calculate the normalized initial direct-relation matrix. Normalize initial direct-relation matrix D by D = A × S, where

$$S = \frac{1}{{\mathop {\max}\limits_{1 \le i \le n} \sum\nolimits_{j = 1}^{n} {a_{ij}}}}$$(2)Each element in matrix D falls between zero and one [37].

-

Step 3 Calculate the total relation matrix T. D m is the power of the normalized initial direct-relation matrix D which is identified as a m-indirect effect and can be used to demonstrate the effect of length m or the effect propagated after m − 1 intermediates [38]. A continuous reduction of the indirect effects of problems besides the powers of matrix D, like an engrossing Markov chain matrix, guarantees convergent solutions to the matrix inversion. The total influence or total relation can be obtained by summing up

$$\begin{aligned}&D^{2}, D^{3}, \ldots,D^{\infty}, \\ &\mathop {\lim}\nolimits_{m \to \infty} \left(D \right)^{m} = [0]_{n \times n} , \\ &[0]_{n \times n}\,{\text {is}}\, {\text{a}}\,n \times n \,{\text {null}}\, {\text {matrix}}\end{aligned}.$$(3)

The total relation matrix \(T_{n \times n}\) is achieved as follows:

The total relation matrix T is defined as T = (I − D)−1, where I is the identity matrix [35–37].

The sum of rows and sum of columns of the total relation matrix T are computed as

Define r and c be n × 1 and 1 × n vectors representing the sum of rows and sum of columns of the total relation matrix T, respectively [36]. Suppose r i be the sum of ith row in matrix T, then r i summarizes both direct and indirect effects given by factor i to the other factors. If c j denotes the sum of jth column in matrix T, then c j shows both direct and indirect effects by factor j from the other factors. When j = i, the sum (r i + c j ) shows the total effects given and received by factor i. Thus, (r i + c j ) indicates the degree of importance for factor i in the entire system. On the contrary, the difference (r i − c j ) represents the net effect that factor i contributes to the system. Specifically, if (r i − c j ) is positive, factor i is a net cause, while factor i is a net receiver or result if (r i − c j ) is negative.

3.2 Extent Analysis Method on Fuzzy AHP (FEAHP)

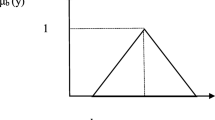

Zadeh [39] first introduced the fuzzy set theory to deal with vagueness in human judgment and imprecise data in decision-making [40, 41] through the use of linguistic terms and degrees of membership [7]. A membership function in fuzzy sets assigns to each object a grade of membership in [0, 1]. A tilde ‘‘~’’ is used above the symbol that represents a fuzzy set. A triangular fuzzy number (TFN) \(\tilde{A}\) is shown in Fig. 1. A TFN is denoted simply as (l, m, u). The parameters l, m, and u denote the smallest possible value, the most promising value, and the largest possible value that describe a fuzzy event. When l = m = u, it is a non-fuzzy number by convention. Each TFN has linear representations on its left and right side such that its membership function can be defined as [42]:

A fuzzy number can always be given by its corresponding left and right representation of each degree of membership

where l(y) and r(y) denote the left side representation and the right side representation of a fuzzy number, respectively.

The algebraic operations with two fuzzy numbers M 1 and M 2 can be expressed as below:

The linguistic variables and their corresponding triangular fuzzy numbers are shown in Table 1.

Let \(X = \{x_{1},x_{2}, \ldots , x_{n} )\) is an object set and \(G = \{g_{1}, g_{2}, \ldots , g_{m})\) be a goal set. According to the method of Chang [43] extent analysis, each object is taken, and extent analysis is done for each goal g i , respectively [7]. Therefore, m extent analysis values for each object can be obtained with the following signs:

where all the \(M_{{g_{i}}}^{j} (j = 1,2, \ldots, m)\) are TFNs.

The steps of Chang’s extent analysis can be given as in the following manner [7, 42]:

-

Step 1 The value of fuzzy synthetic extent with respect to the ith object is defined as

-

$$S_{i} = \mathop \sum \limits_{j = 1}^{m} M_{{g_{i}}}^{j} \otimes \left[{\mathop \sum \limits_{i = 1}^{n} \mathop \sum \limits_{j = 1}^{m} M_{{g_{i}}}^{j}} \right]^{- 1}$$(10)

To obtain, \(\mathop \sum \nolimits_{j = 1}^{m} M_{{g_{i}}}^{j}\) perform the fuzzy addition operation of m extent analysis values for a particular matrix such that

$$\mathop \sum \limits_{j = 1}^{m} M_{{g_{i}}}^{j} = \left({\mathop \sum \limits_{j = 1}^{m} l_{j}, \mathop \sum \limits_{j = 1}^{m} m_{j}, \mathop \sum \limits_{j = 1}^{m} u_{j}} \right)$$(11)and to obtain, \(\left[{\mathop \sum \nolimits_{i = 1}^{n} \mathop \sum \nolimits_{j = 1}^{m} M_{{g_{i}}}^{j}} \right]^{- 1}\) perform the fuzzy addition operation of \(M_{{g_{i}}}^{j} (j = 1,2,\ldots,m)\) values such that

$$\mathop \sum \limits_{i = 1}^{n} \mathop \sum \limits_{j = 1}^{m} M_{{g_{i}}}^{j} = \left({\mathop \sum \limits_{i = 1}^{n} l_{i} \mathop \sum \limits_{i = 1}^{n} m_{i} \mathop \sum \limits_{i = 1}^{n} u_{i}} \right)$$(12)and then compute the inverse of the vector in Eq. (12) such that

$$\left[{\mathop \sum \limits_{i = 1}^{n} \mathop \sum \limits_{j = 1}^{m} M_{{g_{i}}}^{i}} \right]^{- 1} = \left({\frac{1}{{\mathop \sum \nolimits_{i = 1}^{n} u_{i}}},\frac{1}{{\mathop \sum \nolimits_{i = 1}^{n} m_{i}}},\frac{1}{{\mathop \sum \nolimits_{i = 1}^{n} l_{i}}}} \right)$$(13) -

Step 2 The degree of possibility of \(M_{2} = \left({l_{2}, m_{2},u_{2}} \right) \ge M_{1} = \left({l_{1},m_{1,} u_{1}} \right)\) is defined as

$$V\left({M_{2} \ge M_{1}} \right) = \sup \left[{\mathop {\min}\limits_{y \ge x} \left({\mu_{{M_{1}}} \left(x \right),\mu_{{M_{2}}} \left(y \right)} \right)} \right]$$(14)and can be equivalently expressed as follows:

$$\begin{aligned}&V\left({M_{2} \ge M_{1}} \right) = hgt\left({M_{1} \mathop \cap \nolimits M_{2}} \right) = \mu_{{M_{2}}} \left(d \right) \\ &\left\{ {\begin{array}{ll} {1,} & {{\text{if}}\;m_{2} \ge m_{1}}, \\ {0,} & {{\text{if}}\;l_{2} \ge u_{1}}, \\ {\frac{{l_{1} - u_{2} }}{{(m_{2} - u_{2} ) - (m_{1} - l_{1} )}}} & {{\text{otherwise}}} \\ \end{array} } \right\} \end{aligned},$$(15)where d is the ordinate of the highest intersection point D between \(\mu_{{M_{1}}}\) and \(\mu_{{M_{2}}}\). In Fig. 2, the intersection between M 1 and M 2 can be seen. To compare M 1 and M 2 , require both the values of \(V\left({M_{1} \ge M_{2}} \right)\) and \(V\left({M_{2} \ge M_{1}} \right)\).

-

Step 3 The degree of possibility for a convex fuzzy number to be greater than k convex fuzzy numbers \(M_{i} \left({i = 1,2, \ldots ,k} \right)\) can be defined by

$$\begin{aligned}&V\left({M \ge M_{1},M_{2}, \ldots,M_{K}} \right) \\ &\quad = V\left[{\left({M \ge M_{1}} \right)\, {\rm {and}}\,\left({M \ge M_{2}} \right) \,{\text{and}}\, \ldots \,{\text{and}}\,\left({M \ge M_{k}} \right)} \right] \\ &\quad= \min V\left({M \ge M_{i}} \right), \quad i = 1,2, \ldots, k \end{aligned}$$(16)Assume that

$$d^{\prime}\left( {A_{i} } \right) = \min V\left( {S_{i} \ge S_{k} } \right);\quad {\text{For}}\; k = 1,2, \ldots ,n;\;k \ne i.$$(17)Then the weight vector is given by

$$W^{\prime} = \left({d^{\prime} \left({A_{1}} \right),d^{\prime} \left({A_{2}} \right), \ldots, d^{\prime} \left({A_{n}} \right)} \right)^{T}$$(18) -

Step 4 Via normalization, the normalized weight vectors are

$$W = \left({d\left({A_{1}} \right),d\left({A_{2}} \right), \ldots ,d\left({A_{n}} \right)} \right)^{T},$$(19)where W is a non-fuzzy number.

4 A Case Study on Automobile Industries in Malaysia

From an extensive literature review, four dimensions and 18 criteria (Table 2) are identified and used in this case study. Surveys were conducted in one local automobile parts manufacturing, in one local automobile remanufacturing company, and in one ELVs parts recycler. In each of them, competent persons in managerial positions were invited to answer the questionnaires. Therefore, five valid questionnaires have been received. Two learned academicians working in reputed universities in Malaysia and India were consulted to execute all procedures for evaluating the influencing sustainable ELVs management criteria and alternatives. Methodology diagraph (Fig. 3) represents the whole workflow from the dimensions, criteria, and alternatives selection to the final result.

4.1 Dimensions and Criteria Evaluation Using DEMATEL Method

The calculation using DEMATEL method is based on the opinion of five managers. The average matrix (A) of DEMATEL method established in accordance with Eq. (1). Calculation of normalized initial direct-relation matrix (D) is done in accordance with Eq. (2). And determination of the total relationship matrix (T) is established by the following formula: T = D (I − D)−1, as shown below (Tables 3, 4) .

Based on Table 5, the economic dimension (D1) is considered to be the most important one, with the highest (r + c) value of 10.8408, whereas the social dimension (D3) scores the least with 7.2114. Generally, the importance of dimensions can be ranked by the (r + c) values. In contrast to the importance of each dimension, the social dimension (D3) is the net cause towards sustainable ELV management based on (r–c) values. The economic (D1), environmental (D2), and technology (D4) dimensions are net receivers or effects.

Similar calculation of 18 criteria under individual dimension is shown in Tables 6, 7, 8, and 9.

The criterion with larger (r + c) values represents higher importance under the same dimension. In contrast to the importance, Table 6 shows that the financial benefit (C3), operational cost (C2), and resource utilization (C1) criteria are more important than the plant’s initial set-up cost (C5) and core collection cost (C4). Based on Table 7, pollution (C6) is the most important criterion with the highest (r + c) value of 24.0454, whereas environmental legislation requirements (C9) are the least important dimension, with a value of 16.9504. Table 8 shows that personnel occupational health and safety management (C10) has higher importance under the sustainable social dimension, with the largest (r + c) value of 25.2307. Then the remaining important criteria are risk assessment (C12), employment opportunities and job satisfaction (C13), employee training (C14), and brand image and customer satisfaction (C11), respectively. Green technology innovation (C16) and expert’s decisions and skill manpower (C18) are the net causes, as shown in Table 9, but technology transfer (C15) and research and development for new products (C17) are net receivers. Moreover, technology transfer (C15) might be the most critical criterion since it affects the other three criteria.

After evaluating important criteria using DEMATEL method, the selected 8 criteria (Table 10) are used to evaluate the sustainable ELVs management model. Because pairwise comparisons become a difficult and time-consuming if there are too many criteria is considerate. It may also lead to evaluators’ assessment bias. To overcome these problems, some criteria are combined in such a way that those 8 criteria will reflect reaming all criteria by the help of experts and academicians.

4.2 Sustainable ELVs Management Alternatives Evaluation Using FEAHP Method

The detail explanations of FEAHP method shown in Figs. 4 and 5 represent the model and decision environment graphically for sustainable ELVs management alternatives selection. To decide the preferences among decision variables, triangular fuzzy numbers (Table 1) are used in this research.

In this phase, hierarchical structure of the FEAHP model is formulated that included the goal, dimensions, criteria, and the pertinent alternatives. The goal is to found at the first level of the hierarchy as shown in Fig. 5. Four dimensions such as economic, environmental, social, and technology are identified to achieve this goal and placed in the second level in the decision tree. The third level consists of 8 criteria, which are evaluated by DEMATEL method (Table 10). Alternatives are placed at the lowest level of the hierarchy, namely different sustainable ELVs management systems to be evaluated in order to select the appropriate alternative(s) for a particular context (only for model assessment we used alternatives shown in Table 11). Generally, as many as possible systems can be included as the authority wishes to evaluate before selecting the suitable one.

After constructing the hierarchy, next step is to determine the priority weights of the criteria using fuzzy AHP approach. A three-member expert panel is formed to achieve comparison of the importance of the attributes with the aid of the questionnaire. The experts are the most senior persons and have more than 8 years’ experience in automobile manufacturing. The questionnaires facilitate the answering of pair-wise comparison questions. Judgments by linguistic variables are converted to triangular fuzzy numbers using membership functions as shown in Table 1. Then the judgments from the experts are combined using operational laws for two triangular fuzzy numbers as shown in Eq. (6). Due to the space constraints, we present here the pairwise comparisons of the dimensions with respect to the goal (Table 12).

Satty [48] introduced AHP methodology and provided a consistency index to measure the inconsistencies accompanied by the judgments provided by the experts. For this, first we used the defuzzification method of fuzzy triangular numbers to convert the fuzzy comparison matrices into crisp matrices by the Eq. (20).

The consistency index (CI) of each matrix is found using \({\text{CI}} = (\lambda_{\text{max}} - n)/(n - 1)\) and then consistency ratios (CR) are calculated by \({\text{CR}} = \left(\frac{\text{CI}}{\text{RI}}\right)\) in crisp-AHP once the fuzzy comparison matrices are converted to crisp matrices. Hence, n = order of matrix and RI = random index. We have found that consistency ratio (CR) of this matrix is 0.0232 (which is less than 0.10), so the matrices are acceptable for further analysis (Table 13).

After consistency test, FEAHP method is applied to obtain the normalized weight vector (W) of each dimension. Fuzzy synthetic degree value (S i ) and degree of possibility (V) of dimension are as follows (Tables 14, 15).

The normalized weight vector (W) of main dimension shown that the economic dimension (0.4449) occupies the top-most weight. Then environmental (0.3095), technology (0.1719), and social (0.0737) dimensions are ranked, respectively. The same calculations are done to achieve the global weights of each criterion which is shown in Table 16.

Based on the results from the data, the consistency of the pairwise comparisons of each expert is examined. For instance, the pairwise comparison matrix, fuzzy synthetic degree value (S i ), and degree of possibility (V) for the alternative(s) under the criteria of an expert are as follows (Tables 17, 18, 19).

A similar procedure is carried out to calculate the weight vector (W) of the remaining alternatives. The final score and results are shown in Table 20.

5 Result and Discussion

According to the data analysis based on experts’ opinions, the most important criterion is financial benefit (Cr1) (Table 16), with a priority of 0.3080. The next seven important criteria are pollution (Cr3), resource utilization (Cr2), technology transfer (Cr7), global warming (Cr4), social performance (Cr5), green technology innovation (Cr8), and occupational health & safety management (Cr6) with priorities of 0.2078, 0.1369, 0.1190, 0.1017, 0.0616, 0.0529, and 0.0121, respectively. As per the final scores (Table 20), recycling (A3) is the most preferred sustainable ELVs management alternative with a priority weight of 0.2887. The second to sixth alternatives are remanufacture finished product (0.2537), remanufacture parts (0.1644), recondition/repair (0.1196), resale/reuse (0.0921), and used vehicles export (0.0815), respectively. The weighting of the alternatives indicates their value in terms of satisfying the maximum sustainability according to their organizational structure. Expert’s decision result shown that recycling (A3) should be selected for best alternatives here. But according to the material efficiency and energy efficiency, resale/reuse is the best alternatives, then remanufacturing and recycling, respectively. This is totally dependent on organizational economic benefit. But we considered sustainable dimensions for evaluating the best alternatives by giving priority of economic, environmental, social, and technology dimensions as well as considering the current organizational objectives. After discussion with experts about the result of our model, it is clear that at the EOL cycle of a vehicle, if resale/reuse is done then it is again becoming a waste within a short period of time as well as it may bring their poor brand image. Because reuse means disassembling and reclamation of parts, components, and modules within discarded products. On the other hand, reconditioning/repair has less work content than remanufacturing but more than that of reuse. Usually, it requires the rebuilding of major components to a working condition. This is more profitable, and economically, environmentally, and socially sustainable than resale/reuse. Remanufacturing is to reprocess the used products in such a manner that the quality of the products is as good or better than new in terms of appearance, reliability, and performance [49]. According to the available statistics, comparing to the new products, the remanufacturing products can save 60 % of the energy, 70 % of the materials, and 50 % of the cost [50]. Remanufacturing plays a key role in increasing economic and environmental benefits including organizational reputation and brand image. A vehicle is a complex product consisting of a variety of materials. The estimated composition of ferrous material is the major component of a ELVs accounting for 68 % of a vehicle’s weight. Other major materials included in the vehicle are plastics, non-ferrous metals, rubber, glass, and fluids contributing to 10, 8, 2, 3, and 2 %, respectively [4]. We know that remanufacturing/reconditioning requires appropriate decision, heavy technological facilities, skill operators, and ELVs raw material’s good physical condition. Thus, according to their organizational objectives, recycling could be the best alternatives to recover the valuable materials and satisfying the environmental interest.

6 Managerial Implications

Sustainable ELV management has a great impression to reduce the environmental impact and ensure economic and social benefit. The OEMs or related organizations should to establish an appropriate ELV management policy to reduce pressure on the environment and the wastage of resources. Thus, lots of qualitative and quantitative factors and criteria are required to be considered during ELV management decision-making such as economic factors, environmental factors, legislative factors, social factors, and the technological factors. This study will help decision makers to identify important factors, criteria, sub-criteria, and appropriate alternatives, and result also suggests several managerial implications for managers. First, it will enable the OEMs and recycling organizations to understand which type of dimension and criteria is significant in achieving organizational strategic objectives and increase the sustainable performance in managing ELV. Second, the manager would be able to identify most important criteria from high and low influence criteria and cause-and-effect relationship between or among the criteria using DEMATEL method. Third, the manager would be able to develop a MCDM model to evaluate best sustainable ELV management alternative using FEAHP. Finally, this methodology will help the researchers or related members to evaluate the influencing factors, criteria, and sub-criteria to solve multi-criteria decision-making problem according to their objectives.

7 Conclusions

Determination of the best compromise sustainable option for EOL product is an important problem faced by OEMs or related EOL management organizations. Each EOL alternative has its own consequences from an economic, environmental, social, and technology point of view. This paper proposed a model to select the sustainable dimensions and criteria for evaluating best compromise ELVs management alternative. The DEMATEL method is applied first to select the most important dimensions and criteria for alternative selection model. Then FEAHP model is constructed next based on the hierarchy to evaluate best sustainable ELVs management alternative for an anonymous automobile manufacturer in Malaysia. Recycling is the best compromise sustainable alternative for this particular industry according to case study results. Nevertheless, this implies that the selection of best alternatives should not only consider those dimensions, criteria, or alternatives, but also be suitable to add different attributes as per organizational needs and available facilities. The strength of the proposed model is that the vagueness of experts’ opinions is considered in the evaluation process, and the model is almost easy to apply. This may be noted that manufacturers of the related industries can use this model, or tailor the model to meet their own needs, to evaluate their alternative or to select the best alternatives to satisfy the organizational goals and objectives. There are some limitations of this research need to be documented. Firstly, this study deals with DEMATEL and FEAHP methods only, but it would be useful to examine by different MCDM methods to compare the results. Secondly, this study took most experienced three to five managerial expert’s decision due to limited opportunities of data collection. Last but not least, future researchers should collect data from multiple sources in this area. Environmental impacts of ELV, sustainable ELV collection in reverse supply chain, and sustainable design for recovery can be the future research direction for researches.

References

Ahi, P., Searcy, C.: A comparative literature analysis of definitions for green and sustainable supply chain management. J. Clean. Prod. 52, 329–341 (2013)

Go, T., Wahab, D., Rahman, M.A., Ramli, R., Azhari, C.: Disassemblability of end-of-life vehicle: a critical review of evaluation methods. J. Clean. Prod. 19, 1536–1546 (2011)

Ruffino, B., Fiore, S., Zanetti, M.C.: Strategies for the enhancement of automobile shredder residues (ASRs) recycling: results and cost assessment. Waste Manag 34, 148–155 (2014)

Ahmed, S., Shamsuddin Ahmed, M., Shumon, R.H., Quader, M.A.: End-of-life vehicles (ELVs) management and future transformation in Malaysia. J. Appl. Sci. Agric. 9, 227–237 (2014)

Amelia, L., Wahab, D.A., Che Haron, C.H., Muhamad, N., Azhari, C.H.: Initiating automotive component reuse in Malaysia. J. Clean. Prod. 17, 1572–1579 (2009)

Mansour, S., Zarei, M.: A multi-period reverse logistics optimisation model for end-of-life vehicles recovery based on EU Directive. Int. J. Comput. Integr. Manuf. 21, 764–777 (2008)

Kahraman, C.: Fuzzy Multi-Criteria Decision Making: Theory and Applications with Recent Developments, vol. 16. Springer Science & Business Media, New York (2008)

Yeh, C.-H., Deng, H., Wibowo, S., Xu, Y.: Fuzzy multicriteria decision support for information systems project selection. Int. J. Fuzzy Syst. 12, 170–174 (2010)

Govindan, K., Khodaverdi, R., Jafarian, A.: A fuzzy multi criteria approach for measuring sustainability performance of a supplier based on triple bottom line approach. J. Clean. Prod. 47, 345–354 (2013)

Sakai, S.-I., Yoshida, H., Hiratsuka, J., Vandecasteele, C., Kohlmeyer, R., Rotter, V.S., et al.: An international comparative study of end-of-life vehicle (ELV) recycling systems. J. Mater. Cycles Waste Manag. 16, 1–20 (2014)

Che, J., Yu, J.-S., Kevin, R.S.: End-of-life vehicle recycling and international cooperation between Japan, China and Korea: present and future scenario analysis. J. Environ. Sci. 23, S162–S166 (2011)

Forslind, K.: Implementing extended producer responsibility: the case of Sweden’s car scrapping scheme. J. Clean. Prod. 13, 619–629 (2005)

Harraz, N.A., Galal, N.M.: Design of sustainable end-of-life vehicle recovery network in Egypt. Ain Shams Eng. J. 2, 211–219 (2011)

Saavedra, Y.M.B., Barquet, A.P.B., Rozenfeld, H., Forcellini, F.A., Ometto, A.R.: Remanufacturing in Brazil: case studies on the automotive sector. J. Clean. Prod. 53, 267–276 (2013)

Chen, K.-C., Huang, S.-H., Lian, I.-W.: The development and prospects of the end-of-life vehicle recycling system in Taiwan. Waste Manag. 30, 1661–1669 (2010)

Bellmann, K., Khare, A.: Economic issues in recycling end-of-life vehicles. Technovation 20, 677–690 (2000)

Simic, V., Dimitrijevic, B.: Modelling of automobile shredder residue recycling in the Japanese legislative context. Expert Syst. Appl. 40, 7159–7167 (2013)

Diabat, A., Khodaverdi, R., Olfat, L.: An exploration of green supply chain practices and performances in an automotive industry. Int. J. Adv. Manuf. Technol. 68, 949–961 (2013)

Abdulrahman, M.D.-A., Subramanian, N., Liu, C., Shu, C.: Viability of remanufacturing practice: a strategic decision making framework for Chinese auto-parts companies. J. Clean. Prod. (2014)

Simic, V.: Fuzzy risk explicit interval linear programming model for end-of-life vehicle recycling planning in the EU. Waste Manag. 35, 265–282 (2015)

Arsovski, S., Aleksić, A.: Fazzy rating of criteria weights of management problems in elv recycling research area. Cent. Q. (2011)

Tadić, D., Arsovski, S., Stefanovic, M., Aleksic, A.: A fuzzy AHP and TOPSIS for ELV dismantling selection. Int. J. Q. Res. vol. 4 (2010)

Keivanpour, S., Kadi, D.A., Mascle, C.: Economic sustainability of end-of-life vehicle recycling infrastructure under uncertainty a fuzzy logic approach. In: Proceedings of 2013 International Conference on Industrial Engineering and Systems Management (IESM), pp. 1–6 (2013)

Ling, Z.: Fuzzy multi-attribute self-adaptive evaluation of end-of-life vehicle take-back partners. J. Converg. Inf. Technol. vol. 8 (2013)

Chou, Y.-C., Sun, C.-C., Yen, H.-Y.: Evaluating the criteria for human resource for science and technology (HRST) based on an integrated fuzzy AHP and fuzzy DEMATEL approach. Appl. Soft Comput. 12, 64–71 (2012)

Wu, H.-H., Tsai, Y.-N.: A DEMATEL method to evaluate the causal relations among the criteria in auto spare parts industry. Appl. Math. Comput. 218, 2334–2342 (2011)

Chang, B., Chang, C.-W., Wu, C.-H.: Fuzzy DEMATEL method for developing supplier selection criteria. Expert Syst. Appl. 38, 1850–1858 (2011)

Ren, J., Manzardo, A., Toniolo, S., Scipioni, A.: Sustainability of hydrogen supply chain. Part I: identification of critical criteria and cause–effect analysis for enhancing the sustainability using DEMATEL. Int. J. Hydrog. Energy 38, 14159–14171 (2013)

Wang, X., Chan, H.K.: An integrated fuzzy approach for evaluating remanufacturing alternatives of a product design. J. Remanuf. 3, 1–19 (2013)

Torfi, F., Farahani, R.Z., Rezapour, S.: Fuzzy AHP to determine the relative weights of evaluation criteria and Fuzzy TOPSIS to rank the alternatives. Appl. Soft Comput. 10, 520–528 (2010)

Shaw, K., Shankar, R., Yadav, S.S., Thakur, L.S.: Supplier selection using fuzzy AHP and fuzzy multi-objective linear programming for developing low carbon supply chain. Expert Syst. Appl. 39, 8182–8192 (2012)

Lee, A.H.: A fuzzy supplier selection model with the consideration of benefits, opportunities, costs and risks. Expert Syst. Appl. 36, 2879–2893 (2009)

Shumon, M.R.H., Ahmed, S., Ahmed, S.: Fuzzy analytical hierarchy process extent analysis for selection of end of life electronic products collection system in a reverse supply chain. In: Proc. Inst. Mech. Eng., Part B, p. 0954405414553980 (2014)

Shafiee, M., Hosseinzadeh Lotfi, F., Saleh, H.: Supply chain performance evaluation with data envelopment analysis and balanced scorecard approach. Appl. Math. Model. (2014)

Shen, K.-Y., Tzeng, G.-H.: DRSA-based neuro-fuzzy inference systems for the financial performance prediction of commercial banks. Int. J. Fuzzy Syst. 16, 173–183 (2014)

Lu, M.-T., Tzeng, G.-H., Tang, L.-L.: Environmental strategic orientations for improving green innovation performance in fuzzy environment-using new fuzzy hybrid MCDM model. Int. J. Fuzzy Syst. 15, 297 (2013)

Hu, S.-K., Chuang, Y.-C., Yeh, Y.-F., Tzeng, G.-H.: Combining hybrid MADM with fuzzy integral for exploring the smart phone improvement in M-Generation. Int. J. Fuzzy Syst. 14, 204–214 (2012)

Falatoonitoosi, E., Ahmed, S., Sorooshian, S.: Expanded DEMATEL for determining cause and effect group in bidirectional relations. Sci. World J. vol. 2014 (2014)

Zadeh, L.A.: Fuzzy sets. Inf. Control 8, 338–353 (1965)

Liu, P., Chu, Y., Li, Y., Chen, Y.: Some generalized neutrosophic number Hamacher aggregation operators and their application to Group Decision Making. Int. J. Fuzzy Syst. 16, 242–255 (2014)

Meng, F., Chen, X., Zhang, Q.: Generalized hesitant fuzzy generalized Shapley-Choquet integral operators and their application in decision making. Int. J. Fuzzy Syst. 16, 400 (2014)

Veerabathiran, R., Srinath, K.: Application of the extent analysis method on fuzzy AHP. Int. J. Eng. Sci. Technol. 4, 3472–3480 (2012)

Chang, D.: Extent Analysis and Synthetic Decision, Optimization Techniques and Applications, vol. 1. World Scientific, Singapore (1992)

Vermeulen, I., Van Caneghem, J., Block, C., Baeyens, J., Vandecasteele, C.: Automotive shredder residue (ASR): reviewing its production from end-of-life vehicles (ELVs) and its recycling, energy or chemicals’ valorisation. J. Hazard. Mater. 190, 8–27 (2011)

Tseng, M.-L.: Modeling sustainable production indicators with linguistic preferences. J. Clean. Prod. 40, 46–56 (2013)

Lin, R.-J., Chen, R.-H., Nguyen, T.-H.: Green supply chain management performance in automobile manufacturing industry under uncertainty. Procedia-Soc. Behav. Sci. 25, 233–245 (2011)

Yeh, C.-H., Xu, Y.: Sustainable planning of e-waste recycling activities using fuzzy multicriteria decision making. J. Clean. Prod. (2013)

Satty, T.L.: The Analytic Hierarchy Process. McGraw-Hill New York, New York (1980)

Gerrard, J., Kandlikar, M.: Is European end-of-life vehicle legislation living up to expectations? Assessing the impact of the ELV Directive on ‘green’innovation and vehicle recovery. J. Clean. Prod. 15, 17–27 (2007)

Xiaoyan, W.: Research on design management based on green remanufacturing engineering. Syst. Eng. Procedia 4, 448–454 (2012)

Acknowledgments

The authors thankfully acknowledge the financial support from University of Malaya through HIR PROJECT UM.C/HIR/MOHE/ENG/31.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ahmed, S., Ahmed, S., Shumon, M.R.H. et al. Prioritizing Strategies for Sustainable End-of-Life Vehicle Management Using Combinatorial Multi-Criteria Decision Making Method. Int. J. Fuzzy Syst. 18, 448–462 (2016). https://doi.org/10.1007/s40815-015-0061-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40815-015-0061-0