Abstract

This study investigated the electrochemical behavior of the Ti6Al4V alloy under the influence of dynamic action of mouthwashes. Ti6Al4V alloy disks (n = 5) were dynamically exposed to mouthwashes (0.12% chlorhexidine digluconate [CHX], cetylpyridinium chloride [CC], and hydrogen peroxide [HP]) by immersion 3 times a day for 1 min. Artificial saliva [AS] is a control solution. The electrochemical behavior of the Ti6Al4V (n = 5) was tested at the baseline, and after 7 and 14 days of mouthwashes dynamic action. Surfaces characteristics were investigated using scanning electron microscopy (SEM), energy-dispersive spectroscopy, surface roughness, and Vickers microhardness. CC had the highest values of polarization resistance (Rp), and CHX reduced the capacitance values (Q) compared to the other groups (p < 0.05). HP generated the lowest Rp values in all periods, and the highest Q values after 14 days immersion (p < 0.05). CC and CHX did not alter the alloy potentiodynamic curves when compared to AS. HP increased the corrosion and passivation current densities, and the corrosion rate in relation to the other groups (p < 0.05). SEM micrographs showed minors surface changes with the presence of pitting corrosion for HP. No differences were found for roughness and microhardness after all immersion periods (p > 0.05). Dynamic mouthwash simulation with HP impairs the corrosion stability of Ti6Al4V alloy, and CC presents the greatest electrochemical stability over time. Our data shed light on how the dynamic action of mouthwashes affects the Ti electrochemical behavior aiming at ensuring a safer indication for patients receiving dental implant.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Titanium (Ti) material has favorable features as biocompatibility, corrosion resistance, and low elastic modulus that ensure the success of implantable devices for rehabilitative treatments [1,2,3,4]. One of the main characteristics of Ti is the spontaneous formation of a passive layer on its surface when in contact with water, air, or biofluids. Ti ions upon contact with oxygen form a thin oxide layer (named as titanium dioxide—TiO2), which protects the release of ions to adjacent tissues [5, 6]. However, in vitro studies [7,8,9,10] have shown that solid, liquid, and/or gaseous external factors can deteriorate this oxide layer and impair Ti properties. For example, this passive film can be degraded by exposure to salivary fluids, temperature variations, pH changes, and contact with other substances in the oral cavity that may be aggressive to implants surfaces and harm the metal repassivation, initiating the process of localized corrosion or pitting corrosion [7,8,9,10].

Among these substances, mouthwashes have been used to control the biofilm formation and prevent mucositis and peri-implantitis in postoperative dental implant cases with immediate prosthetic installation [11,12,13]. Chlorhexidine digluconate (C22H30Cl2N10) is a routinely used mouthwash due to its high antimicrobial potential [1, 8]. However, in longer periods of use, it is suggested that chlorhexidine may promote changes in tooth coloration [13] and may lead to symptoms of hypogeusia [14]. In this sense, cetylpyridinium chloride (C21H38ClN) [15,16,17] and hydrogen peroxide (H2O2) [12, 18] are other types of mouthwashes that have been indicated to control oral biofilm.

Previous in vitro studies [19,20,21,22] investigated the electrochemical behavior of titanium when exposed to commercially available mouthwashes. Even that titanium presents adequate corrosion resistance, it was reported a reduction in the protective characteristics of the spontaneously formed oxide film in the presence of the combination of sodium fluoride (NaF) and triclosan (C12H7Cl3O2) [23, 24]. In addition, it was possible to observe the release of Ti ions in the oral environment in the presence of fluorine [24, 24]. Our previous study [21] evaluated the long-term corrosion kinetics and structural properties of Ti-6Al-4 V disks immersed for up to 14 days in 3 mouthwash solutions (0.12% chlorhexidine digluconate, 3% hydrogen peroxide, and 0.053% chloride cetylpyridinium). Our data pointed out that the use of hydrogen peroxide should be avoid in the postoperative installation of metal-based dental implants due to its harmful effects on the titanium electrochemical stability, while chlorhexidine digluconate and cetylpyridinium chloride did not change the corrosive behavior of titanium.

A limitation observed in these studies was the static immersion of Ti in mouthwashes, which may not translate the clinical dynamics setting where different thermal and mechanical oscillations are presented. Additionally, only continuously immersions for a certain period of time were tested (up to 14 days), which are not close to the hygiene protocol commonly indicated in post-surgical conditions: rinse for 1 min at least 3 times a day for a period of 7 to 14 days. Besides, there are no studies in the literature that simulate the clinical use of mouthwashes regarding time, frequency, and dynamic immersion. In this context, this study evaluated the electrochemical behavior, topographic, and structural changes (roughness and microhardness) of Ti6Al4V alloy at different periods (7 and 14 days) after daily agitation (3 times per day) with commonly prescribed mouthwashes (0.12% chlorhexidine digluconate, cetylpyridinium chloride, and hydrogen peroxide) for the postoperative phase of implant installation. The results found in this study will guide a better understanding on how the dynamic action of mouthwashes affects the Ti electrochemical behavior and will ensure a safer indication for patients receiving dental implant treatment.

2 Materials and Methods

2.1 Samples Preparation

Ti-6Al-4 V alloy disks (15 mm in diameter and 2 mm thickness) were processed and supplied by DSP Biomedical® (Campo Largo, Paraná, Brazil). The chemical composition (in percentage by weight%) of the Ti6Al4V alloy was Ti (89.62), Al (6.1), V (4.0). A total of 20 disks were initially polished with sequential #320, #400, #600, and #800 grit sandpaper (Carbimet 2, Buehler, Lake Bluff, IL, USA). Then, TextMet Polishing Cloth (Buehler) with diamond paste (MetaDi 9-micron, Buehler) and lubricant (MetaDi Fluid, Buehler) were used. To obtain a mirror finishing, disks were polished with a cloth (Chemomet I, Buheler) and colloidal silica (MasterMed, Buehler). Finally, disks were ultrasonic cleaned with deionized water and 70% propanol and dried with hot air [25]. The specimens were randomly divided into 4 groups considering the immersion solution: AS (control): artificial saliva (pH = 6.5); CHX: 0.12% chlorhexidine digluconate; CC: 0.053% cetylpyridinium chloride; and HP: 3% hydrogen peroxide. The composition (g/L) of the artificial saliva was KCl (0.4), NaCl (0.4), CaCl2·2H2O (0.906), NaH2PO4·2H2O (0.690), Na2S·9H2O (0.005), and urea (1) (Sigma-Aldrich, MO, USA).

2.2 Dynamic Mouthwash Simulation

To simulate the daily mouthwash dynamics with CHX, CC, HP, and AS, disks were placed in a plastic container with 10 mL of immersion solution and subjected to agitation for 1 min at a constant speed (100 rpm / min) on a mechanical orbital shaker (Kline CT-150 Shaker Table, Cientec Laboratory Equipment Ind. Bras., Belo Horizonte, Minas Gerais, Brazil). This process was repeated 3 times per day with 4 h of interval for up to 14 days. Then, the specimens were washed with distilled water, and in the remaining time, they were stored in artificial saliva in an incubator at 37 °C, simulating the environment of the oral cavity.

2.3 Electrochemical Study

Electrochemical tests were carried out independently in 3 periods: baseline (before starting the immersion in mouthwash solutions), and after 7 and 14 days of incubation and agitation with CHX, CC, HP, and AS. Different disks (n = 5) were used according to the period of analysis. The electrochemical assessment followed our previous protocol [7, 21, 25,26,27]. Briefly, tests were performed on an electrochemical cell made of polysulfone. A standardized method of three-electrode cells as required by the American Society for Testing of Materials (ASTM; G61 and G31-72) was applied in association with a potentiostat (Interface 1000, Gamry Instruments,Warminster, PA, USA). A total of 10 mL of each mouthwash (CHX, CC or HP) was used for each corrosion experiment, which was maintained at 37 ± 1 °C [21]. Artificial saliva (pH 6.5) was also used as a control electrolyte [21]. Initially, Ti disks were subjected to a cathodic potential (− 0.9 V vs SCE) to standardize the oxide layer on the sample surface. Open circuit potential (OCP) was monitored for a period of 3600 s to assess the potential of the material in each solution. Electrochemical impedance spectroscopy (EIS) was performed at a frequency of 100 kHz to 5 mHz with an AC amplitude curve of 10 mV applied with OCP as initial potential [25]. Finally, the specimens were anodically polarized from − 0.8 V to 1.8 V at a scan rate of 2 mV/s. Data were analyzed by Gamry Echem Analyst software (Gamry Instruments). Experiments were repeated at least 5 times to ensure reproducibility.

2.4 Surface Characterization

2.4.1 Scanning Electron Microscopy (SEM)

Independent disks were analyzed using a scanning electron microscope (Jeol, model JSM-5600LV, Oregon, USA) at baseline and after 7 and 14 days of immersion to characterize the possible alterations in the surface morphology (n = 5).

2.4.2 Energy Dispersive Spectroscopy (EDS)

Elemental chemical composition of the samples after immersion in the different monthwashes was performed in small volumes, in the order of 1 μm3, using EDS technique (VANTAGE Digital Microanalysis System, Noran Instruments Inc., Middleton, USA) (n = 5).

2.4.3 Surface Roughness

In order to understand the changes in the surface of the specimens caused by the immersion and corrosion process, the surface roughness (Ra—average roughness) was investigated in the baseline period and after the electrochemical tests at 7 and 14 days by means of a profilometer (Surftest SJ-400, Mitutoyo, Tokyo, Japan). Each sample was measured three times in different areas using 0.25 mm cut-off at 0.05 mm/s speed (n = 5). Independent disks were analyzed at baseline and after 7 and 14 days of immersion.

2.4.4 Microhardness Analysis

The Vickers microhardness was also evaluated in the established time points by means of an indenter (Shimadzu HMV-2000 Micro Hardness Tester; Shimadzu Corporation, Kyoto, Japan). Four measurements in different areas/regions were performed on each specimen by applying a 0.5-Kgf load for 15 s (n = 5). Microhardness was expressed in Vicker hardness unit (VHN) [28]). Independent disks were analyzed at baseline and after 7 and 14 days of immersion.

2.5 Statistical Analysis

Statistical analysis was performed with a statistical software (SPSS v. 20.0, SPSS Inc.). Data were subjected to the Shapiro–Wilk homogeneity test. Two-way ANOVA for repeated measures (between-subject factor: solution/mouthwash and within-subject factor: immersion time) and Bonferroni test as post hoc technique were used for multiple comparisons at a significance level of 5%.

3 Results

3.1 Electrochemical Behavior

3.1.1 Open Circuit Potential

The evolution of OCP as a function of time is shown in Fig. 1. It is observed that for all solutions, Ti showed a surface passivation characteristic by spontaneous formation of an oxide layer and consequent stability of OCP over time. For all periods, the HP presented the most electropositive values, but it shows a tendency to decrease after reaching its maximum value, unlike the other groups that the material potential initially increases and stabilizes over time. HP and CHX did not show OCP stabilization after 1 h for the results of 7 days. However, it is clear that these groups showed a significant improvement in their values (more positive values) at 14 days when compared to the baseline. In general, CC was the most stable solution in all time points.

When evaluating the material potential after 1 h of immersion with each electrolyte (Table 1), HP and CHX revealed a nobler characteristic compared to AS, demonstrating that these mouthwashes may decrease the corrosion tendency of Ti. HP significantly increased OCP values when compared to AS even after 14 days of immersion (p < 0.01). In general, after 14 days of immersion, all solutions showed statistically more electropositive values than baseline (p < 0.01), which may be due to the thickening of the oxide layer over time.

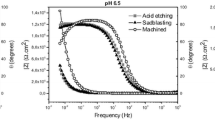

3.1.2 Electrochemical Impedance Spectroscopy

EIS assessment in the presence of different electrolytes are represented by the Bode and Nyquist diagrams (Fig. 2). In general, the CC and CHX groups presented the highest impedance values and the highest phase angle values, indicating that a more stable oxide layer was formed when in contact with these mouthwashes. The HP presented the worst behavior in the three evaluated periods, with impedance values significantly lower than the one noted in the other groups. Moreover, when evaluating the phase angle, HP presented low values at both high and low frequencies, and a maximum phase angle at baseline (approximately 70°) but still considerably lower than the other groups. This behavior may indicate the formation of a porous oxide layer. In fact, when Nyquist plot was evaluated, the HP presented a closed semicircle in a magnitude much smaller than the other groups. Congruent with the impedance values, CC and CHX presented the largest semicircular capacitance looping, especially at baseline and 14 days.

The AS and CC electrolytes presented a single time constant at phase angle, suggesting the formation of a single compact film on the surface. On the other hand, HP and CHX electrolytes presented more than one time constant, which demonstrate the presence of a double oxide layer formed on the metal surface in the presence of these electrolytes. Figure 3 shows the circuits used to adjust the EIS data. The corrosion parameters for AS and CC were obtained using a simple electrical circuit composed of Rsol (electrolyte resistance), Rp (polarization resistance), and Q (constant phase element, CPE). To represent the presence of another electrochemical interface observed for HP and CHX groups, a second circuit was used by adding a new set of pairs: Rpout/Qout and Rpin/Qin, namely polarization resistance and CPE of the outer and inner interfaces, respectively. To model 7- and 14-day data, the Warburg element was inserted in series with the outer layer for the CHX group, which may indicate the phenomenon of substrate diffusion to the electrolyte. The good quality of fit was confirmed by the chi-square (χ2) evaluation, which presented values in the order of 10−3 (Table 2).

Equivalent circuits used to fit EIS data of a AS, CC, b HP, CHX (only at baseline), and c CHX after 7 and 14 days of immersion. Rsol represents the solution resistance; Q represents the constant phase element of a single compact oxide layer; Qout and Qin represent the constant phase element of the outer and inner oxide layers, respectively; Rpout and Rpin represent the polarization resistance of the outer and inner oxide layers, respectively; and Wdiff represent the Warburg diffusion element

Based on the electrical parameters (Table 2), TiAlV alloy exhibited greater polarization resistance (Rptot) in all time periods in the presence of CC electrolyte with significant higher values than the other groups at 7 and 14 days (p < 0.05), indicating that a more resistant and protective oxide film was formed on the metal surface. CHX showed decreased capacitance values (Q) over time compared to the other groups (p < 0.05). In the presence of HP, the TiAlV surface exhibited the lowest Rptot value in all periods and increased capacitance value over time, indicating the formation of a less protective oxide layer or a deterioration of the oxide layer compared to the other groups (p < 0.05).

3.1.3 Potentiodynamic Polarization Curve

For the potentiodynamic polarization curves, all groups presented active–passive transition regions regardless of the time period (Fig. 4). At baseline, 7 and 14 days, the AS, CC, and CHX groups presented the same passivation constant, being faster than the HP group. After 7 days, TiAlV passivated in lower current densities and potentials for AS, CC, and CHX, but it can be observed the occurrence of depassivation in high potentials. The potentiodynamic polarization results are in agreement with the EIS measurements, since the CC and CHX electrolytes present a better electrochemical stability, with their curves shifting to lower current density values.

Based on the evaluation of the electrical parameters by the Tafel extrapolation method (Table 3), CC and CHX electrolytes improved significantly the corrosion potential (Ecorr) of TiAlV alloy when compared to AS (p < 0.05). Although HP had the highest values of Ecorr, it showed the worst electrochemical stability, showing the highest values for corrosion current density (icorr), corrosion rate, and passivation current density (ipass) in almost all periods. Only HP showed a significant improvement of its results at 14 days of immersion regarding icorr and corrosion rate compared to the baseline. Immersion time positively affected ipass values for CC, CHX, and AS (p < 0.01).

3.2 Surface Characterization

3.2.1 SEM and EDS

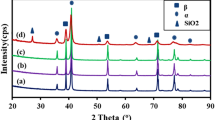

Figure 5 shows the micrographs obtained by SEM. In general, no major differences in topographies among the groups were noted, except for HP group where some pitting corrosion areas are noted with the presence of small holes (see arrows). Lighter grains in the image are suggestive of chemical deposits (see asterisks), while darker regions were already seen for the polished sample. The elemental chemical composition of the Ti6Al4V alloy by EDS (Fig. 6) showed no significant changes in Ti and V elements composition for all groups and periods evaluated, but there is a higher percentage of aluminum (Al) in the alloy composition at baseline (8.59 ± 0,08) when compared to the other periods (2.81 ± 0,12 to 4.68 ± 0,05). In addition, silicon was observed within 7 and 14 days for all groups.

Scanning electron microscopy micrographs (magnification of 1000 × and 5000x) of Ti6Al4V alloy before (as-received) and after final immersion period (14 days) in artificial saliva, chlorhexidine, cetylpyridinium chloride, and hydrogen peroxide. Asterisks indicate chemical deposits and arrows indicate pitting corrosion areas

3.2.2 Roughness and Microhardness

The surface roughness and Vickers microhardness did not differ across the groups nor among evaluation periods (p > 0.05) (Fig. 6). However, it is possible to observe a slightly increase of Ra values for CHX and HP after 7 days of immersion when compared to baseline (Fig. 7).

4 Discussion

The use of mouthwashes for postoperative care of implants to prevent the proliferation of microorganisms may present relevant impacts on titanium surfaces, damaging its surface, biocompatibility, and osseointegration process. In this way, it is essential to investigate the effects of mouthwashes on the corrosion resistance of implantable materials. According to authors’ best knowledge, this is the first study to investigate the corrosion kinetics of Ti6Al4V alloy in the presence of mouthwashes on a dynamic situation. Most of studies evaluated the effect of mouthwashes in a static condition [20,21,22], while the present study showed a new approach to simulate a more realistic clinical use of these solutions.

In general, the more positive the OCP values, the nobler the material [21, 25]. CC and CHX showed nobler OCP values than AS at baseline and after 7 days of immersion. Surprisingly, HP showed the most electropositive OCP values across all evaluated periods, and this may be a result of the strong oxidizing nature with a great reduction potential of H2O2 [29, 30] that forms a thin layer of hydroxy-titanium- and titanium-peroxy-rich layer on alloy surface [31]. This thin layer reduces the diffusion of the electrolyte into the TiO2 layer, generating the nobler potentials. However, the HP OCP value decreased over time, probably due to its dissolution and instability. Such instability can be clearly noted in the EIS and potentiodynamic curves data, which is discussed afterwards.

Regarding EIS assessment, greater amplitude of semi-arches at Nyquist diagrams followed by higher impedance and phase angles on Bode plot characterize greater resistance to charge transfer and reduced ion exchange with the external environment and, consequently, less corrosion [20, 21, 31]. Besides that, Rp parameter evaluates the material resistance to ions transfer, and its value is inversely proportional to Q, which represents the capacity of the passive layer to perform ions exchange [20, 25, 26]. Based on these principles, in the presence of the CC mouthwash, Ti6Al4V alloy showed greater amplitude in the capacitance curve in the baseline period and after 14 days of immersion, which emphasizes the stability of the passive film when in contact with this solution. In previous studies [20, 21], CC presented similar results as herein. In general, Ti6Al4V alloy was positively influenced when exposed to CC and CHX, displaying greater and more stable electrochemical parameters over time compared to control. The corrosion inhibition observed by these two mouthwashes is not totally understood yet it is possible that the corrosion is inhibited by blocking reactive sites of the metal surface by a simple adsorption process of molecules from the solutions that forms a protective layer for both anodic and cathodic processes [32,33,34].

On the other hand, in the presence of HP, the material presented a flatter capacitance curve in all periods, which may mean the occurrence of higher ion exchange and lower corrosion resistance. When analyzing the Bode diagram, HP group generated noticeably lower impedance values at low frequencies for all time points, as well as lower phase angles, which indicates aggressiveness of this solution to the alloy surface, reducing the passivation capacity of the oxide layer [19, 20]. This deleterious effect of HP, but in higher concentrations (35%), was also reported in our previous study [21] that observed changes in the electrochemical and structural behavior of Ti after static immersion in HP by the possible dissociation of peroxide in a unidirectional reaction when exposed to light and high temperatures, making it more active against Ti alloy surface. Also, HP can promote corrosion of TiAlV alloy by increasing both anodic and cathodic reactions [30].

Concerning the potentiodynamic curves, the most evident difference was observed in the passivation region. AS, CHX, and CC presented a similar behavior with small differences that may be explained by changes in film porosity and thickness [22]. Conversely, HP showed the worst electrochemical stability with unclear passive regions that might be explained by the prolonged contact of the solution with the material that impaired the growth of the oxide layer or caused the partial dissolution of this protective film. Although HP presented the highest values of Ecorr among the groups that can be justified by its strong oxidative behavior, the oxide layer formed is porous and therefore incapable of providing passivity [31]. In fact, HP generated the highest values of icorr and corrosion rate among groups, which imply the higher dissolution of the passive film [30].

After 7 and 14 days of immersion and agitation, there was a trend of Ra increasing across the tested solutions. This information also corroborates with previous studies [6, 33] that observed a corrosive process when in prolonged presence of mouthwashes containing fluoride or chloride. Especially for HP group, it occurred due to the dissolution of the oxide layer and high affinity of hydrogen for Ti, which may potentiate oxidative and corrosive reactions and provoke pitting corrosion. However, its more active corrosive behavior may have promoted the degradation of the surface material as a whole after 14 days of agitation, explaining the reduced roughness at this time point. Although there was evidence of surface degradation, it was not deleterious to alloy microhardness, which is in accordance to previous study that evaluated the effect of CHX in different metals [34,35,36].

Regarding to EDS analysis, it was noted a reduction on Al concentration after immersion periods. It is possible that this element was released to the solution during the immersion and agitation, as well as during the electrochemical assessment due to corrosive processes [33,34,35]. Previous studies [12, 13, 18] have shown the dissolution of elements from TiAlV stainless steel after immersion in chlorhexidine or H2O2, demonstrating that the release of ions to the body may occur due to corrosion processes initiated by mouthwashes. The differences between immersion times can be explained by the depletion and enrichment of elements from the outermost surface [35].

Although the results of the present study corroborate with some points of previous reports that used long-term and static immersion periods [20,21,22], herein, only small structural and topographic changes on alloy surface were found. Many factors influence the corrosion of metals in contact to electrolytes, including pH, oxygen content, temperature, and duration of immersion [37]. That because the contact with the surface changes and the movement of the solution against the surface can produce a different behavior in function of the physical aggression on the surface caused by movement, it is proved by tribocorrosion studies that mechanical action against Ti surfaces, arising from the mechanical removal of the passive film [38, 39]. It is important to emphasize that in this study, the exposure time to the solutions was shorter (3 times per day, for 1 min) and it was carried out by a dynamic protocol that used agitation to simulate the mouthwash action. Also, samples were kept in artificial saliva when not in contact to the mouthwashes. Besides that, a similar concentration with the products commercially available was chosen for the solutions, which could have diminished the expected effects. Despite that, the results found by the present investigation may provide more reliable information about the influence of these mouthwashes on Ti6Al4V alloy degradation and electrochemical behavior, since it was used a protocol recommended in clinical situations that require the use of mouthwashes in the postoperative period of dental implants installation [21, 22].

Regardless of the mouthwash, it is essential to analyze its indication not only according to their antimicrobial capacity but also considering their adverse effects, such as degradation and corrosion of the metal-implant material. Thus, it is important that dentists are aware of such information to properly indicate the ideal mouthwash, concentration, and protocol of use for each type of dental implant material. In this sense, CC appears as an alternative solution for chlorhexidine in view of its better influence on the Ti6Al4V electrochemical behavior.

5 Conclusion

It was concluded that the dynamic mouthwash simulation following the clinical protocol of use (3 times per day for 1 min up to 14 days) with hydrogen peroxide impaired the corrosion resistance of the TiAlV alloy, while the cetylpyridinium chloride showed the best electrochemical stability overtime.

References

Oliveira NT, Guastaldi PSF, Perrotti V et al (2013) Biomedical Ti-mo alloys with surface machined and modified by laser beam: biomechanical, histological, and histometric analysis in rabbits. Clin Implant Dent Relat Res 15(3):427–437. https://doi.org/10.1111/j.1708-8208.2011.00354.x

Oliveira NT, Guastaldi AC (2009) Electrochemical stability and corrosion resistance of Ti-Mo alloys for biomedical applications. Acta Biomater. England 5:399–405. https://doi.org/10.1016/j.actbio.2008.07.010

Branemark PI, Hansson BO, Adell R et al (1977) Osseointegrated implants in the treatment of the edentulous jaw. Experience from a 10-year period. Scand J Plast Reconstr Surg Suppl 16:1–132

Ekelund JA, Lindquist LW, Carlsson GE et al (2003) Implant treatment in the edentulous mandible: a prospective study on Branemark system implants over more than 20 years. Int J Prosthodont 16(6):602–608

Queiroz TP, Souza FA, Guastaldi AC et al (2013) Commercially pure titanium implants with surfaces modified by laser beam with and without chemical deposition of apatite. Biomechanical and topographical analysis in rabbits. Clin Oral Implants Res 24(8):896–903. https://doi.org/10.1111/j.1600-0501.2012.02471.x

Pi Y, Faure J, Agoda-Tandjawa G et al (2013) Microstructural characterization of Ti-6Al-4V alloy subjected to the duplex SMAT/plasma nitriding. Microsc Res Tech 76(9):897–903. https://doi.org/10.1002/jemt.22245

Faverani LP, Barão VAR, Ramalho-Ferreira G et al (2014) Effect of bleaching agents and soft drink on titanium surface topography. J Biomed Mater Res B Appl Biomater 102(1):22–30. https://doi.org/10.1002/jbm.b.32949

Barao VA, Mathew MT, Assunção WG et al (2012) Stability of cp-Ti and Ti-6Al-4V alloy for dental implants as a function of saliva pH - an electrochemical study. Clin Oral Implants Res 23(9):1055–1062. https://doi.org/10.1111/j.1600-0501.2011.02265.x

Ho WF, Ju CP, Lin JH (1999) Structure and properties of cast binary Ti-Mo alloys. Biomaterials Netherlands 20:115–122. https://doi.org/10.1016/s0142-9612(99)00114-3

Gosau M, Hahnel S, Schwarz F et al (2010) Effect of six different peri-implantitis disinfection methods on in vivo human oral biofilm. Clin Oral Implants Res Denmark 2:866–872. https://doi.org/10.1111/j.1600-0501.2009.01908.x

Pizzo G, Guiglia R, Imburgia M et al (2006) The effects of antimicrobial sprays and mouthrinses on supragingival plaque regrowth: a comparative study. J Periodontol 77(2):248–256. https://doi.org/10.1902/jop.2006.050116

Hoenderdos NL, Rosema NAM, Slot DE et al (2009) The influence of a hydrogen peroxide and glycerol containing mouthrinse on plaque accumulation: a 3-day non-brushing model. Int J Dent Hyg. England 7:294–298. https://doi.org/10.1111/j.1601-5037.2009.00367.x

Marinone MG, Savoldi E (2000) Chlorhexidine and taste Influence of mouthwashes concentration and of rinsing time. Minerva Stomatol 49(5):221–226

Wicht MJ, Haak R, Lummert D et al (2003) Treatment of root caries lesions with chlorhexidine-containing varnishes and dentin sealants. Am J Dent, 25A-30A.

Sreenivasan PK, Haraszthy VI, Zambon JJ (2013) Antimicrobial efficacy of 0.05% cetylpyridinium chloride mouthrinses. Lett Appl Microbiol 56(1):14–20. https://doi.org/10.1111/lam.12008

Rosema NA, Timmerman MF, Versteeg PA et al (2008) Comparison of the use of different modes of mechanical oral hygiene in prevention of plaque and gingivitis. J Periodontol 79(8):1386–1394. https://doi.org/10.1902/jop.2008.070654

De Waal YC et al (2013) Implant decontamination during surgical peri-implantitis treatment: a randomized, double-blind, placebo-controlled trial. J Clin Periodontol 40(2):186–195. https://doi.org/10.1111/jcpe.12034

Hossainian N, Raghoebar GM, Slater JJRH et al (2011) The effects of hydrogen peroxide mouthwashes on the prevention of plaque and gingival inflammation: a systematic review. Int J Dent Hyg 9(3):171–181. https://doi.org/10.1111/jcpe.12034

Milosev I, Kapun B, Selih VS (2013) The effect of fluoride ions on the corrosion behaviour of Ti metal, and Ti6-Al-7Nb and Ti-6Al-4V alloys in artificial saliva. Acta Chim Slov Slovenia 60:543–555

Quaranta A, Ronconi LF, Di Carlo F et al (2010) Electrochemical behaviour of titanium in ammine and stannous fluoride and chlorhexidine 0.2 percent mouthwashes. Int J Immunopathol Pharmacol 23:335–343. https://doi.org/10.1177/039463201002300132

Faverani LP, Barao VAR, Pires MFA et al (2014) Corrosion kinetics and topography analysis of Ti-6Al-4V alloy subjected to different mouthwash solutions. Mater Sci Eng C Mater Biol Appl 43:1–10. https://doi.org/10.1016/j.msec.2014.06.033

Alves-Rezende MC, Alves APR, Codaro EN et al (2007) Effect of commercial mouthwashes on the corrosion resistance of Ti-10Mo experimental alloy. J Mater Sci Mater Med 18(1):149–154. https://doi.org/10.1007/s10856-006-0674-9

Muguruma T, Iijima M, Brantley WA et al (2011) Effects of sodium fluoride mouth rinses on the torsional properties of miniscrew implants. Am J Orthod Dentofacial Orthop 139:588–593. https://doi.org/10.1016/j.ajodo.2009.05.042

Schiff N, Grosgogeat B, Lissac M et al (2002) Influence of fluoride content and pH on the corrosion resistance of titanium and its alloys. Biomaterials 23(9):1995–2002. https://doi.org/10.1016/s0142-9612(01)00328-3

Barão VA, Mathew MT, Assunção WG et al (2011) The role of lipopolysaccharide on the electrochemical behavior of titanium. J Dent Res 90(5):613–618. https://doi.org/10.1177/0022034510396880

Faverani LP, Assunção WG, de Carvalho PS et al (2014) Effects of dextrose and lipopolysaccharide on the corrosion behavior of a Ti-6Al-4V alloy with a smooth surface or treated with double-acid-etching. PLoS ONE 9(3):e93377. https://doi.org/10.1371/journal.pone.0093377

Landolt D, Stemp MS (2011) Electrochemical methods in tribocorrosion: a critical appraisal. Electrochim Acta 46(24–25):3913–3929. https://doi.org/10.1016/S0013-4686(01)00679-X

Assuncao WG, Jorge JRP, Dos Santos PH et al (2011) The effect of mechanical cycling and different misfit levels on Vicker’s microhardness of retention screws for single implant-supported prostheses. J Prosthodont 20(7):523–527. https://doi.org/10.1111/j.1532-849X.2011.00753.x

Yu F, Addison O, Davenport AJ (2015) A synergistic effect of albumin and H2O2 accelerates corrosion of Ti6Al4V. Acta Biomater 26:355–365. https://doi.org/10.1016/j.actbio.2015.07.046

Gopal V, Manivasagam G (2020) Wear – Corrosion synergistic effect on Ti–6Al–4V alloy in H2O2 and albumin environment. J Alloys Compd 830:154539. https://doi.org/10.1016/j.jallcom.2020.154539

Bearinger JP, Orme CA, Gilbert JL (2003) Effect of hydrogen peroxide on titanium surfaces: In situ imaging and step-polarization impedance spectroscopy of commercially pure titanium and titanium, 6-aluminum, 4-vanadium. J Biomed Mater Res - Part A 67:702–712. https://doi.org/10.1002/jbm.a.10116

Khamis A, Saleh MM, Awad MI (2013) Synergistic inhibitor effect of cetylpyridinium chloride and other halides on the corrosion of mild steel in 0.5M H2SO4. Corros Sci 66:343–349. https://doi.org/10.1016/j.corsci.2012.09.040

ArockiaSelvi J, Kamaraj P, Arthanareeswari M et al (2019) Effect of Cetylpyridinium chloride on corrosion inhibition of mild steel in chloride environment. Mater Today Proc. https://doi.org/10.1016/j.matpr.2019.04.146

Deyab MA, Keera ST, El Sabagh SM (2011) Chlorhexidine digluconate as corrosion inhibitor for carbon steel dissolution in emulsified diesel fuel. Corros Sci 53:2592–2597. https://doi.org/10.1016/j.corsci.2011.04.018

Pavlic A, Perissinotto F, Turco G et al (2019) Do Chlorhexidine and probiotics solutions provoke corrosion of orthodontic mini-implants? An in vitro study. Int J Oral Maxillofac Implants 34:1379–1388. https://doi.org/10.11607/jomi.7392

Danaei SM, Safavi A, Roeinpeikar SMM et al (2011) Ion release from orthodontic brackets in 3 mouthwashes: An in-vitro study. Am J Orthod Dentofac Orthop 139:730–734. https://doi.org/10.1016/j.ajodo.2011.03.004

Peñarrieta-Juanito G, Sordi MB, Henriques B et al (2019) Surface damage of dental implant systems and ions release after exposure to fluoride and hydrogen peroxide. J Periodontal Res 54:46–52. https://doi.org/10.1111/jre.12603

Licausi MP, Igual Muñoz A, Amigó Borrás V (2013) Influence of the fabrication process and fluoride content on the tribocorrosion behaviour of Ti6Al4V biomedical alloy in artificial saliva. J Mech Behav Biomed Mater 20:137–148. https://doi.org/10.1016/j.jmbbm.2013.01.019

Olvano I, Garcia I, Conde A, Tato W, Aginagalde A (2015) Influence of fluoride content and pH on corrosion and tribocorrosion behaviour of Ti13Nb13Zr alloy in oral environment. J Mech Behav Biomed Mater 49:186–196. https://doi.org/10.1016/j.jmbbm.2015.05.008

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sousa, C.A., Cordeiro, J.M., Silva, A.O. et al. Dynamic Action of Mouthwashes Affects the Electrochemical Behavior of Ti6Al4V Alloy. J Bio Tribo Corros 7, 158 (2021). https://doi.org/10.1007/s40735-021-00591-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-021-00591-8