Abstract

Bauhinia tomentosa leaves extract (BTLE) as a corrosion inhibitor in 1M HCl was investigated by using weight-loss method and electrochemical techniques. The inhibition efficiency of BTLE was found to increase with increasing concentration. The effect of temperature on the corrosion inhibition of mild steel in the temperature range of 308–333 K was studied. Polarization measurements revealed that the BTLE acted as a mixed-type inhibitor. Nyquist plots showed that on increasing the BTLE concentration, the charge-transfer resistance increased and double-layer capacitance decreased. The adsorption of BTLE on mild steel obeyed the Langmuir adsorption isotherm. The maximum inhibition efficiency was found (93.47% in HCl) at 308 K in the presence of 700 ppm of BTLE. Mechanism of corrosion inhibition of BTLE on mild steel is explored with the help of FT-IR, UV, SEM and AFM techniques.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Corrosion is the destruction of materials by chemical interaction with their environment [1]. The term corrosion is also applied to the degradation of plastics, concrete and wood. In common, most of the metals are found in a chemically combined state as oxides, carbonates, sulfates. Their combined forms are thermodynamically stable state. A large amount of energy is supplied to extract metals from ores and is a natural tendency to go back to the low-energy state that is a combined state by recombining with the elements present in the environment. Corrosion is a natural phenomenon that cannot be avoided, but it can be controlled or prevented using appropriate preventive measures. Most effective and practical methods of corrosion prevention are electrodes protection, coatings, alloying and the use of chemical and green inhibitors.

Acid solutions are widely used as agents in several industries for the removal of undesirable oxide films, and the main problems associated with these agents are scaling, corrosion, fouling and shutdown of thermal power plant, etc. [2]. A corrosion inhibitor is an additive which reduces the rate of metal wastage by adsorption of ions or molecules into metal surface. It blocks the surface from the corrosion environment or by retarding the electrochemical processes. Even though many synthetic inhibitors showed anticorrosive activity, most of them are highly toxic. Therefore, to develop most effective and environmentally friendly corrosion inhibitors, much attraction is focused on synthesis of green corrosion inhibitors. Green inhibitors can be used in the form of extracts or essential oils. Various parts of the plants are now used as corrosion inhibitor [3]. Green corrosion inhibitions do not contain heavy metals and toxic compounds. Sribharathy et al. [4] have studied Aloe Vera extract for the corrosion inhibition of carbon steel in sea water. The effect of Inula Visoa extracts on the corrosion of copper in 1M NaOH was studied by Nawaflah et al. [5]. The inhibitive action of Santorin chamaceyparissus extract as a natural inhibitor on corrosion of 304 steel in 3.5% NaCl solution was investigated [6]. The corrosion inhibitory action of Bauhinia purpurea extract on steel in acid medium has also been investigated [7].

This work prompted us to investigate the inhibitory effect of Bauhinia tomentosa leaf extract as corrosion inhibitor for steel in 1M HCl medium. Bauhinia tomentosa (BT) is a member of the family Fabaceae. The objective of the present work is to study the corrosion-inhibiting effect of BTLE in acid medium (1M HCl) by the mass loss method, electrochemical method UV, FT-IR, SEM and AFM. In addition, thermodynamic and kinetic parameters are calculated and discussed.

2 Experimental

2.1 Preparation of the Specimens

Composition of mild steel specimen (%) was C: 0.13, Si: 0.18, P: 0.39, S: 0.04, Cu: 0.025 and rest Fe. The specimens were mechanically cut into sizes with 2.5 cm × 2.5 cm × 0.4 cm dimensions and abraded by emery paper of different grades and finally polished with 4/0 grades emery paper to obtain mirror-like finish. Each specimen was then degreased by washing with acetone, dried at room temperature and preserved in moisture-free desiccators. All chemicals and reagents are AnalaR grade. The concentration of test solution (1M HCl) was prepared by using triple-distilled water and AR-grade HCl.

2.2 Extraction of BT Leaf Extract

BT leaves were collected from Alagar kovil hills, Madurai, TN, India. The leaves were dried, grained and soaked in deionized water for 6 h. After 6 h, the crude extracts were boiled, cooled and triple-filtered. The amount of plant material extracted into solution was quantified by comparing the weight of dried residue with the initial weight of the dried plant material before extraction. From the respective stock solutions, inhibitor test solution was prepared in the concentration range from 550 to 700 ppm.

2.3 Weight-Loss Method

Weight-loss experiments were done at various temperatures ranging 308–333 K for 2 h in 1M HCl. The specimens were immersed in 100 mL of the respective inhibitor and the test solution in a thermo-stated bath. The specimens were weighed before and after immersion. The difference in weight was taken as the weight loss of mild steel. From the weight loss (ΔW), corrosion rate (CR) and the percentage of inhibition efficiency (IE %) were calculated using the following equation:

K = 534 to give CR in mpy and K = 87.6 to give CR in mm/year, where W = weight loss (W b − W a), where W b and W a are the specimen weights before and after immersion in the tested solution, D is the density of the specimen (g/cm3), A is the area of the specimen in inch2 and T is the period of immersion in hours.

The k value is constant and its magnitude depends on the system of units used. The CR expressed in terms of either mils (1/1000 inch) per year (mpy) or millimeters per year (m/year). W 0 and W 1 are the weight loss of mild steel in the absence and presence of inhibitor, respectively.

2.4 Electrochemical Impedance Spectroscopy Measurements (EIS)

Tafel polarization curves and Nyquist impedance curves were recorded using CH electrochemical workstation (Model No. CHI604D, manufactured by CH instruments, Austin, USA), and a cell containing three compartments for electrode was used. The working polished mild steel electrode with exposed area of 0.5 cm2 was immersed in a test solution. A platinum electrode and saturated calomel electrode were used as the counter and the reference electrode, respectively. Before electrochemical impedance experiment, the electrode was allowed to corrode freely and its open-circuit potential was recorded. Potentiodynamic polarization curves were recorded from −300 to +300 m Vsce (verses OCP) with a scan rate of 1 mVs−1. Electrochemical impedance spectroscopy measurements were taken in the frequency range of 0.1 Hz to 100 KHz. All electrochemical measurements were studied at 308 K using 100 mL of electrolyte (1M HCl) in stationary condition. Each experiment was repeated in triplicate to check the reproducibility of the data.

2.5 Surface Analysis Studies

2.5.1 Fourier Transform Infrared Spectroscopy (FT-IR)

FT-IR spectra were recorded in SHIMADZU-FTIR-8400S spectrophotometer. The mild steel was immersed for 2 h in 100 mL 1M HCl solution containing 700 ppm of BTLE. After 2 h, the specimens were taken out and dried and then rubbed with the small amount of KBr powder and made into a disk.

2.5.2 SEM and AFM Characterizations

The mild steel specimens were immersed in acid solutions in the absence and presence of optimum concentration (700 ppm) of inhibitor for a period of 2 h. After 2 h, the specimens were taken out and dried. The nature of the surface film formed on the surface of the mild steel specimen was examined by using a JEOL (JSM 6390) scanning electron microscope (SEM) and atomic force microscope (AFM) (Akilan Technology, UK, 5500 series).

2.6 UV–visible Spectroscopic Studies

The phytochemical constituents of BTLE treated with 1M HCl and after 2 h of mild steel immersion were analyzed using JASCOW-32 spectrophotometer. The absorption spectra of these solutions were recorded with test solution as a reference.

3 Results and Discussion

3.1 Weight-Loss Measurements

Based on the weight-loss measurements, corrosion rate and inhibition efficiency (IE %) for various concentrations of BTLE, after 2 h of immersion at the temperatures 308, 313, 323, 333 K in 1M HCl, are given in Table 1. The following equation is used to determine the inhibition efficiency (IE %):

where CR0 and CRinh are the corrosion rates of steel without and with the inhibitors, respectively. Table 1 gives the inhibition efficiencies calculated from the weight-loss measurements of different concentrations of BTLE in 1M HCl. The inhibition efficiency increases with increasing concentration of the inhibitors in HCl medium. The maximum inhibition efficiency was obtained (93.47% in 1M HCl) at 308 K.

3.2 Thermodynamic Activation Parameters

The apparent activation energy E *a , the enthalpy of activation ΔH * and the entropy of activation ΔS * for the corrosion of mild steel samples in 1M HCl solution in the absence and presence of different concentrations of BTLE were calculated from Arrhenius Eqs. (4) and (5)

where CR is the corrosion rate, A is the frequency factor, h is the Planck’s constant, N is the Avogadro’s number and R is the universal gas constant. A plot of log CR/T versus 1/T gives a straight line with a slope of ΔH/2.303R and intercepts of log R/Nh + ΔS/2.303, and Fig. 1 represents the plot of log CR versus 1/T in 1M HCl at concentration ranging from 0.055 to 0.070 g/L. From the slope in Fig. 1, the values of E a were calculated, and Fig. 2 represents the plot of log CR/T versus 1/T in 1M HCl. The values of activation energy for the inhibited solution were greater than that of uninhibited solutions indicating that the corrosion of mild steel was decreased due to the formation of a barrier by the adsorption of the inhibitors on the mild steel [8]. The calculated values of the apparent activation energy (E a), activation enthalpies (ΔH *) and the entropy of activation (ΔS *) are given in Table 2. It is clear that the presence of tested compounds increases the activation energy and consequently decreases the corrosion rate of mild steel by making a barrier to mass and charge transfer and by their adsorption on the mild steel surface. The negative values of ΔH * reflect the exothermic reaction of corrosion process. This suggests a strong adsorption of BTLE on the mild steel surface. The values of ΔS * in the absence and presence of tested compounds are negative which indicates that the activated complex in the rate-determining step represents an association rather than dissociation [8, 9]. This means that the activated molecules are in a higher-order state than that at the initial state.

3.3 Adsorption Isotherm

The adsorption characteristics of the studied inhibitors were investigated by fitting data obtained for the degree of surface coverage into different adsorption isotherms including Langmuir, Temkin, Frumkin, Freundlich, Florry Huggins, Bockris-Swinkel adsorption isotherms. The tests indicate that the adsorption of the studied BTLE on a mild steel surface is best described by the Langmuir adsorption model in 1M HCl medium which can be expressed as follows:

where C is the concentration of the inhibitors in the bulk electrolyte and K is the equilibrium constant of adsorption. Figure 3 presents the Langmuir isotherms for the adsorption of the studied BTLE in 1M HCl. Values of adsorption parameters deduced from the isotherms are presented in Table 3. From the results obtained, the slopes and R 2 values for the plots are closer to unity, indicating that the adsorption of the studied BTLE is consistent with the Langmuir adsorption model [10]. The equilibrium constant of adsorption deduced from the Langmuir adsorption isotherm is related to the free energy of adsorption of the inhibitors as follows:

where K ads is the equilibrium constant of adsorption of water, ΔG 0ads is the free energy of adsorption, the value 55.5 is the concentration of water in solution in mol L−1, R is the gas constant and T is the temperature. Table 3 displays the equilibrium constants, interaction parameter and free energies for adsorption of various inhibitor concentrations. If the calculated ΔG ads are negative and less than threshold value of −20 kJ/mol, it confirms that the adsorption of inhibitors on mild steel is spontaneous and that the physical adsorption mechanism is applicable [11–13]. It is seen that all free-energy values (Table 3) are negative indicating spontaneous adsorption of the inhibitors on mild steel surface and range of free energy values around −20 kJ/mol indicating that the nature of adsorption is physical for BTLE inhibitor in acid medium [14–16].

3.4 Electrochemical Impedance Spectroscopy (EIS)

The corrosion of mild steel immersed in acid solution in the presence and absence of BTLE was investigated by EIS at 308 K after exposure period of 2 h. Figure 4 shows Nyquist plots for mild steel in 1M HCl in the presence and absence of BTLE inhibitor in various concentrations. The Nyquist plot for Randles cell shows (impedance diagram) a depressed semicircle with center under the real axis. Such behavior is characteristic for solid electrode which might be the result of surface roughness, dislocations, distribution of the active sites or adsorption of the inhibitor molecules [14]. In 1M HCl medium, the impedance spectra exhibit one single capacitive loop, which indicates that the corrosion of mild steel is mainly controlled by the charge-transfer process. Inhibition was increased with increasing the concentration of BTLE [15], indicating that the strengthening of protective layer of BTLE molecules formed on the electrode surface [16, 17]. Acid environment (1M HCl) showed maximum inhibition efficiency (94.56% in HCl at 700 ppm) at 308 K. After increasing the concentration of BTLE, no further change in charge-transfer resistance and inhibition efficiency was observed. The impedance parameters such as R s, R ct and C dl derived from Nyquist plots are given in Table 4. The inhibition efficiencies for each concentration were calculated using the formula:

where R ct and R ct(inh) are charge-transfer resistance in the absence and presence of inhibitor, respectively. From Table 4, it is clear that charge-transfer values increase and C dl values decrease after the addition of inhibitor in both solutions. The decrease in C dl values may be due to the adsorption of inhibitor on mild steel surface leading to the formation of productive film on mild steel surface [18, 19]. Thin film acts as barrier between steel surface and corrosion medium. The inhibitor shows maximum inhibition efficiency 94.56% in 1M HCl.

3.5 Polarization Curves

Figure 5 shows potentiodynamic polarization curves of mild steel in 1M HCl in the absence and presence of BTLE. Figure 5 shows that both anodic and cathodic reactions of mild steel corrosion are suppressed in the presence of BTLE in 1M HCl medium and the suppression effect increases with the increase in the concentration of BTLE. Electrochemical kinetic parameters, i.e., corrosion potential (E corr), cathodic and anodic Tafel slopes (β c and β a) and corrosion current density (I corr), obtained by extrapolation of the Tafel are presented in Table 5. The inhibition efficiencies of BTLE in 1M HCl are also given in Table 5. The inhibition efficiency is defined as:

where I corr and I corr(inh) are the corrosion current density values without and with inhibitor, respectively. Increasing inhibitor concentrations decreases the corrosion current densities. The presence of inhibitors results in a slight shift of the corrosion potential toward the active directions in comparison with the result obtained in the absence of inhibitor. The decrease in both the anodic and cathodic densities in acid solution indicates that the inhibitor suppresses both the anodic and cathodic reactions. This phenomenon may be due to the presence of BTLE on mild steel surface [20–22]. On the other hand, in the presence of inhibitors the values of β a were changed more than β c values. This suggests that the anodic reaction was controlled predominantly than cathodic reactions at all concentrations. From the overall magnitude of the difference in β a and β c values compared to the blank results, it is revealed that the inhibition effects of the BTLE are anodic dominating since the changes in β a values are more significant than the change in β c values. The overall results suggest that the investigated inhibitor acts as mixed-type inhibitor [23, 24]. It is observed that the inhibition efficiency increases with increasing concentration of the inhibitors. Highest inhibition efficiency reaches a maximum value of 93.23% in 1M HCl at 700 ppm.

These results permit to conclude that I corr decreases with increasing inhibitor concentration, and further addition of BTLE does not change the values of E corr and β c. IE increases with inhibitor concentration reaching a maximum value at 700 ppm of BTLE in 1M HCl. All the results obtained from weight loss, polarization and EIS studies are in good agreement.

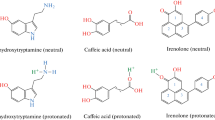

3.6 FT-IR Studies

The FT-IR spectroscopy is used to determine the type of bonding for organic inhibitors adsorbed on the metal surface. FT-IR spectra have been used to analyze the protective film formed on metal surface. FT-IR spectrum of crude BTLE is shown in Fig. 6. There were many compounds present in the BTLE which contributed in effective working of the inhibitor. It is very difficult to identify each compound separately although efforts have been made to know groups present in the BTLE. Figure 6 shows FT-IR spectrum of the BTLE. A broad peak is obtained at 3394 cm−1 an assigned to N–H/O–H stretching vibration. The frequency at 2917 cm−1 corresponds to C–H stretching frequency. Absorption of strong peak at 1610 cm−1 corresponds to C=C or C=N stretching or N–H bending vibrations. Absorption band at 1440 cm−1 can be assigned to C–H bending in –CH3 or O–H bending vibrations. Peaks obtained at 1063 and 1104 cm−1 are observed due to C–N and C–O stretching vibrations. A few weak peaks can also be observed at 1371, 779 and 663 cm−1 corresponding to C=C stretching vibrations of aromatic rings. On the basis of results, it can be said that BTLE contains nitrogen and oxygen (N–H, N=C=S, C=N, C–N, OH, C=O, C–O) in various functional groups and aromatic rings, which make this extract attractive for being used as inhibitor.

3.7 UV–visible Spectroscopy

Corrosion inhibition of mild steel in acidic solution by BT leaves extract can be explained on the basis of molecular adsorption. It contains many organic components as per information provided in the literature [25]. It is quite complex to separate every compound present in the extract. In order to confirm the possibility of the formation of BTLE-Fe complex, UV–visible absorption spectra obtained for crude plant extract is shown in Fig. 7b, and spectrum of mild steel immersed for 2 h, in solution containing 1M HCl with 700 ppm concentration of BTLE, is depicted Fig. 7a. The electronic absorption spectra of BTLE crude extract display a main visible band at 318, 284 and 210 nm. From Fig. 7a, it was noted that the absorption spectra shifted to 341 and 266 nm. Change in position of the absorption maximum and or change in the value of absorbance indicates the formation of a complex between two species in solution [26]. On the basis of this fact, it can be concluded that the phytochemical components present in the BT leaves extract were adsorbed on the mild steel surface.

3.8 Scanning Electron Microscope (SEM)

Figure 8a shows the SEM images of mild steel surface after immersion in 1M HCl for 2 h. Figure 8b shows the SEM images of mild steel surface after immersion in 1M HCl with the presence of inhibitor for 2 h. After 2 h, the specimens were taken out and dried. SEM images showed that the surface of the inhibited sample of mild steel specimens was better than the uninhibited sample. This examination indicated that the corrosion rate was reduced in the presence of inhibitors. This might be due to the adsorption of inhibitor molecules on the metal surface as a protective layer [27].

3.9 Atomic Force Microscope (AFM) Surface Examination

Atomic force microscope is a powerful tool to investigate the surface morphology studies which have been useful to study the influence of inhibitors on the metal/solution interface [28, 29]. The topography AFM images of mild steel surface in 1M HCl in the absence of BTLE are shown in Fig. 9a. AFM images of mild steel surface in 1M HCl in the presence of BTLE at 700 ppm are shown in Fig. 9b. As shown in Fig. 9a, the surface of mild steel electrode exposed to 1M HCl solution had a considerable porous structure with large and deep pores. On the other hand, in the presence of BTLE inhibitor, Fig. 9b shows that the mild steel surface appears more flat, homogeneous and uniform, which indicated that BTLE shows an appreciable resistance to corrosion. Therefore, it could be concluded that the molecules of leaf extract were adsorbed on the mild steel surface and protected the metal against corrosion.

4 Conclusions

In the present study, BTLE was studied as green inhibitors on the corrosion of mild steel in 1M HCl. The mechanistic aspects of corrosion inhibition are based on the results obtained from the weight-loss method, the polarization study, AC impedance measurements and surface examination techniques such as SEM, AFM, UV and FT-IR spectroscopy. The inhibition efficiency of the studied inhibitor (BTLE) increases with increasing inhibitor concentration. Polarization study reveals that the BTLE acts as a mixed-type inhibitor controlling predominantly anodic process in 1M HCl. Electrochemical impedance spectrum confirms the formation of protective layer on the mild steel surface. The adsorption of studied inhibitor obeys Langmuir adsorption at all temperatures (308–333 K). The ΔG ads values (−20 kJ/mol) shows that the adsorption is physisorption. SEM and AFM images indicate the possibility of formation of film on the surface of the mild steel. FT-IR spectrum reveals that the inhibitor adsorbed on the metal surface. The BTLE has good inhibition efficiency in 1M HCl. The maximum inhibition efficiency was found (93.47% in 1M HCl) at 308 K.

References

Rozenfeld IL (1981) Corrosion inhibitors. McGraw-Hilt publications, New York

Bothi Raja P, Sethuraman MG (2008) Natural products as corrosion inhibitor for metals in corrosive medi-a review. Mater Lett 62:113–116

Etre AY (2008) Iihibition of C-steel corrosion in acidic solution using the aqueous extract of Zallosh root. Mater Chem Phys 108:278–282

Sribhrathy V, Rajendran S, Rengan P, Nagalakshmi R (2013) Aloe vera extract for the corrosion inhibition of carbon steel in sea water Eur. Chem Bull 2(7):471–476

Nawafleh E, Irshed M, Batainch T, Muhaidat R, Al crudah M, Alomany A (2012) The effect of Inula Visoa extracts an the corrosion of copper in 1M NaOH Res. J Chem Sci 2(9):37–41

Shabani-Nooshabadi M, Ghandchi MS (2015) Santolina chamaecyparissus extract as a natural source inhibitor for 304 stainless steel corrosion in 3.5% NaCl. J Ind Eng Chem 31:231–237

Bauos IB, Kappel MA, Santos PM, Veiga Junior VF, Elia ED, Bastos IN (2016) The inhibitory action of Bauhinia purpurea extract on the corrosion of carbeen steel in H2SO4 medium. Mater Res 19:187–194

Karthik R, Muthukrishnan P, Elangovan A, Jeyaprabha B, Prakash P (2014) Spectroscopic analysis of crystal violet dye removal by Sida rhombifolia: kinetic, equilibrium, thermodynamic studies. Adv Civ Eng Mater 3:413–433

Muthukrishnan P, Karthik R, Jeyaprabha R, Prakash R (2014) Benevolent behavior of Kleinia grandiflora leaf extract as a green corrosion inhibitor for mild steel in sulfuric acid solution. Int J Miner Metall Metals 21:1083–1095

Behpour M, Ghoreishi SM, Khayatkashani M, Soltani N (2011) Corrosion inhibition and adsorption behaviour for mild steel by Ficus glumosa gum in H2SO4 solution. Corros Sci 53:2489–2501

Avci Gulsen (2008) Study of corrosion inhibition by electrochemical impedance spectroscopy method of 5083 aluminum alloy in 1M HCl solution containing propolis extract. Colloids Surf A 317:730–736

Gunavathy N, Murugavel SC (2012) Corrosion inhibition studies of mild steel in acid medium using Musa acuminata fruit peel extract. J Chem 9:487–495

Eduok UM, Umoren SA, Udoh AP (2012) Origanum majorana extracts as mild steel corrosion green inhibitors in aqueous chloride medium. Arab J Chem 5:325–337

Shukla SK, Quraishi MA (2009) 4-Substituted anilinomethylpropionate: new and efficient corrosion inhibitors for mild steel in hydrochloric acid solution. Corros Sci 51:1990–1994

Taleb I, Mehad H (2011) Adsorption and corrosion inhibiting behavior of Lannea coromandelica leaf extract on mild steel corrosion. Int J Electrochem Sci 6:5357–5371

Vinod kumar KP, Narayanan pillai MS, Rexin Thusnavis G (2010) Pericarp of the fruit of Garcinia mangostana as corrosion inhibitor for mild steel in hydrochloric acid medium. Electrochim Acta 28:373–383

Sobhi M, Abdallah M, Khairou KS (2012) Corrosion inhibition of stainless steel type 316L in hydrochloric acid solution using p-aminoazobenzene derivatives. Prot Metal Phys Chem Surf 143:1379

Ibrahim T, Habbab M (2011) Corrosion inhibition of mild steel in 2M HCl using aqueous extract of eggplant peel. Int J Electrochem Sci 6:5357–5371

Kamal C, Sethuraman MG (2012) Hydroclathrus clathratus marine alga as a green inhibitor of acid corrosion of mild steel. Ind Eng Chem Res 51:10399–10402

Wu TX, Li ZJ, Zhao JC (1998) Inhibition of cast iron corrosion in acid, base, and neutral media using schiff base derivatives. Chem J Chin Univ 19:1617–1621

Wang J, Cao C, Chen J, Zhang M, Ye G, Lin H (1995) Corrosion inhibition of AISI 316L and modified-AISI 630 stainless steel by the new organic inhibitor [(CH3)2N]3PSe in chloride media: electrochemical and physical study. J Chin Soc Corros Prot 15:241–246

Hosseini SMA, Azimi A (2009) The inhibition of mild steel corrosion in acidic medium by 1-methyl-3-pyridin-2-yl-thiourea. Corros Sci 51:728–732

Scendo M (2007) Theoretical and experimental studies on the corrosion inhibition potentials of some purines for aluminum in 0.1M HCl. Corros Sci 49:373–378

Behpour M, Ghoreishi SMG, Salavati-Niasari M, Ebrahimi B (2008) Evaluating two new synthesized S-N Schiff bases on the corrosion of copper in 15% hydrochloric acid. Mater Chem Phys 107:153–157

Sandhya Rani M, Rao Pippalla S, Mohan K (2009) Dodonaea viscosa Linn.-an overview. JPRHC 1:97–102

Abboud Y, Abourriche A, Saffaj T, Berrada M, Charrouf M, Bennamara A, Al Himidi N, Hannache H (2007) 2-(o-hydroxyphenyl)benzimidazole as a new corrosion inhibitor for mild steel in hydrochloric acid solution. Mater Chem Phys 105:1–8

Prabhu RA, Venkatesha TV, Shanbhag AV (2009) Carmine and fast green as corrosion inhibitors for mild steel in hydrochloric acid solution. J Iran Chem Soc 6:353–363

Solmaz R (2010) Investigation of the inhibition effect of 5-((E)-4-phenylbuta-1, 3-dienylideneamino)-1, 3, 4-thiadiazole-2-thiol Schiff base on mild steel corrosion in hydrochloric acid. Corros Sci 52:3321–3330

Wang B, Du Zhang M, Gao J (2011) Nickel-based superalloys for advanced turbine engines: chemistry, microstructure and properties. Corros Sci 53:354–361

Acknowledgements

One of the authors (S. Perumal) thanks UGC, New Delhi, for granting the Teacher Fellowship (FDP) and the Management of Saraswathi Narayanan college, Madurai, India, for encouragement to carry out this work. The authors are thankful to Head, PG and Research Department of Chemistry, Thiagarajar College, Madurai, India, for providing instrumental facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Perumal, S., Muthumanickam, S., Elangovan, A. et al. Bauhinia tomentosa Leaves Extract as Green Corrosion Inhibitor for Mild Steel in 1M HCl Medium. J Bio Tribo Corros 3, 13 (2017). https://doi.org/10.1007/s40735-017-0072-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-017-0072-5