Abstract

Damage accumulation and failure in the cement polymethylmethacrylate (PMMA) is the most prominent scenario in a cemented total hip arthroplasty (THA) leading to eventual implant loosening. In this study, a three-dimensional finite element method (FEM) is used to analyse by computing the stress intensity factor (SIF) along the crack tip, the behaviour of a rectangular crack emanating from bone inclusion and an elliptical crack in the cement mantle of hip stem. To predict the location of crack initiation, stress distribution around the bone inclusion under body load is computed. From stress results, it has been found that the bone inclusion located in the proximal zone of the prosthesis is subjected to the higher stress field. Stress intensity factors for crack emanating from bone inclusion are higher than those for the elliptical crack; therefore, the risk of crack propagation by opening mode in the proximal zone is more significant than distal and medial ones.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The PMMA is commonly used for fixing prosthesis inside the bone in cemented arthroplasty [1]. Loosening of femoral prostheses is one of the most important modes of failure in cemented total hip Arthroplasty [2]. However, there was no agreement on the main causes for implant loosening [3]. Fracture of the cement mantle of a total hip replacement is often considered as a precursor for eventual clinical loosening of the implant [1]. Among the problems encountered in cemented arthroplasty is the presence of defects in the cement mantle (PMMA). These defects can create a local region of stress concentrations, leading to the fracture of cement and, consequently, the failure of the bone/implant junction. In general, there are three kinds of defects that may exist in the cement: porosities, inclusions and cracks [4]. In the cement, the crack can be initiated at the proximal, distal and medial region of the cement mantle. In addition, there are other discontinuities such as, bone inclusion, blood entrapment and interface irregularities. Any of them could act as sites of crack initiation [5]. Several authors examined the effects of the microdefects in the orthopaedic cement on mechanical behaviour of total hip Arthroplasty [6–10]. Griffith suggested that for a linear elastic material, brittle fracture is initiated through tensile stress concentrations at the tips of small, thin cracks randomly distributed within an otherwise isotropic material. Particle disease is a result of polyethylene wear; you will not always see evident findings of polyethylene wear in the acetabular cup [11]. Large focal defects may be seen while the prosthesis is still stable. Particle disease is relentlessly progressive with loosening, fracture and destruction of bone. Sometimes revision of a stable THA is needed because more bone loss would make revision surgery impossible. Due to the high rigidity of the bone compared to the cement, bone debris in the cement can, particularly if they have sharp edges, present regions of stress concentration and consequently zones of crack initiation. Crack propagation leads to sudden fracture and, subsequently, leads to the loosening of the prosthesis [12]. Numerical simulation of crack initiation and propagation has been used by a number of researchers. Ingraffea [13], Kemeny and Cook [14] and Dyskin et al. [15] used the linear elastic fracture mechanics (LEFM) to model crack stability and propagation trajectories by incorporating a stress intensity factor into the numerical formulation to dictate whether crack propagation would occur or not. The geometrical shape of the crack has a significant effect on the crack propagation rate and consequently on the lifespan of the cemented hip prosthesis [16]. In this study, the 3D finite element analysis is used for analysing the behaviour of two types of cracks: an elliptical crack and rectangular crack emanation. These shapes of the crack are important because of their sharp edges. The stress intensity factor (SIF) at the crack tip was chosen as fracture criteria. The determination of SIF at the crack tip allows the estimation of the fatigue life of cemented hip prosthesis. Indeed, this factor characterises the crack propagation rate and can give an estimation of the loosening conditions of the cement mantle in the total hip prosthesis. The mechanical loosening remains the most common indication for revision.

2 Finite element analysis

A three-dimensional finite element model was developed to determine the stress distribution and stress intensity factors of a rectangular crack emanating from bone inclusion and an elliptical crack in the cement mantle. Finite element analyses of cracked reconstruction were performed and the stress intensity factor K β was calculated for each crack:

for β = 1, the mode I stress intensity factor (opening mode), for β = 2, the mode II stress intensity factor (sliding mode), for β = 3, the mode III stress intensity factor (tearing mode).

In our study, the mode I stress intensity factor is calculated (β = 1) because the opening mode of the crack propagation is the most dangerous mode, a is the length of the crack, σ ij are the stress distribution near the crack tip and f ij is a dimensionless quantity that depends on the load and geometry [17].

The following assumptions were introduced to realise the finite element model:

-

The materials of the stem and the cement are elastic and isotropic

-

The bone material is elastic and orthotropic

-

The bone inclusion has a pyramidal shape.

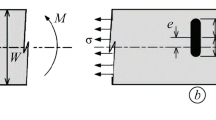

The geometry and loading model of the idealised cylindrical hip stem surrounded by cement mantle and bone, as shown in the Fig. 1, are similar to Nuño model [18]. Due to the geometric symmetry, only one-half of the model had been simulated. Finite element mesh was generated using tetrahedron elements with four nodes for the stem and for the cement, and hexahedral element with four nodes for the bone with a total number of 60,000 elements.

Assuming the entire body weight to be applied on one hip only, a 600 N of transverse load was applied to the whole model, on the stem lateral side at 4 mm to the left of the proximal end (Fig. 1). The femur is primarily loaded in bending [19].

The length and width of the rectangular crack are, respectively, 0.5 mm and 0.2 mm. The crack is emanating from a square pyramidal-shaped bone inclusion with sharp angles, which create stress concentrations in the cement around the micro-defect (Fig. 2). The bone inclusion has the following dimensions 0.2 mm × 0.2 mm × 0.2 mm. The displacement at the interface between the bone inclusion and cement is considered as continuous (fully bonded contact). One supposes the existing of these defects (the first is a crack emanating from bone inclusion and the second is an elliptical crack) in the cement mantle for different positions: proximal, medial and distal of the cemented femoral stem. The dimension of the elliptical crack (Fig. 3) is 0.5 mm × 0.2 mm. The bone inclusion and the cracks are assumed to be within the cement mantle of the cemented femoral stem.

3 Results

The crack stability is affected by the crack geometry. For example, the crack growth depends on the crack separating distance and the loading conditions [16]. The stress intensity factor of the crack emanating from the bone inclusion and elliptical crack in the cement mantle for different positions: proximal, medial and distal of the cemented femoral stem has been calculated.

To predict the location of crack initiation, it is necessary to analyse the stress distribution around the bone inclusion without a crack before calculating the stress intensity factors along the crack tip. It was considered useful to determine the distribution of Von Mises about normal and shear stresses in the cement around the bone inclusion. The stress distribution in the orthopaedic cement around the microdefects has been analysed by many researchers [6, 7]. In this study, a three-dimensional finite element method was used to analyse the fracture behaviour of the cement, by computing the stress intensity factors along the crack front. The mechanical properties of materials are reported in the Table 1.

3.1 Von Mises stresses

Von Mises stress distribution in the cement mantle and the cortical bone, around the bone inclusion, for different positions (proximal, medial and distal zones), is illustrated in Fig. 4. In all positions of the prosthesis, it can be seen that the stress distribution around the inclusion is not uniformly distributed. Furthermore, the tension stress in the cement, in the three zones of the inclusion, is not uniformly distributed; thus, the presence of bone inclusion in different regions can provoke the fracture of the cement mantle, and consequently lead to the loosening of THA. It is known, generally, that the cement does not resist well-tensile loadings (tensile strength: 25 MPa, compressive strength: 80 MPa and shearing strength: 40 MPa) [20, 21]. The maximum stress values around the bone debris at the different positions are located next to the square base of the bone debris. These high stresses can lead to the initiation of cracks in the cement and thus, to the prosthesis loosening.

Table 2 illustrates the comparison of stress distribution. The highest principal stresses in the cement mantle occurred around the bone inclusion in the proximal part; the level of stresses can reach 19.4 MPa in the cement mantle (Fig. 4a) and 45.7 MPa in the inclusion (Fig. 4a). This phenomenon can be explained by the existence of an interaction between the microdefect and the edge effect at the neck of the femoral stem. Therefore, both effects contribute to increase the stresses around the bone inclusion. For the distal part, one can see high stresses around the bone inclusion and the maximum value is about 9.2 MPa in the cement mantle (Fig. 4c) and 27.7 MPa in the bone debris (Fig. 4c). The stem tip action on the distal part of the cement increases the stresses.

Finally, the stress values around bone inclusion, in the medial part, are the lowest (Fig. 4b). Thus, the presence of the bone inclusion in this position presents the least risk case.

Normal stress in the direction X (σ xx ), in the cement mantle around the square base of the bone inclusion for the three zones (proximal, medial and distal), is shown in the Fig. 5. Stress concentration in the cement structure at the mating surface can be readily seen, especially at the tips of the square base of the bone inclusion. The high stress level due to the existence of the microdefects at this site could cause crack formation. The maximum normal stress in the cement mantle occurred around the bone debris in the proximal part and the stress level can reach 10.6 MPa; therefore, the risk of the crack initiation is significant with the presence of the bone inclusion in this region. Concerning the distal region, the cement mantle around the inclusion is subjected to compression loading in the direction X; the maximum compressive stress value is about 7 MPa. Because the cement, in general, has a good resistance to compressive loading, the risk of fracture in this region is less important. In the medial zone, the stresses around the bone inclusion are the least; the maximum stress value is about 1.5 MPa (see Table 3). We can note that, in the direction X for the medial region, the failure risk of the cement mantle is less important.

3.2 Normal stresses (σ yy )

Figure 6 presents the normal stress distribution, in the direction Y(σ yy ) and around the square base of bone inclusion, for the three positions case. One notices that normal stresses in the direction Y (σ yy ) are more important than the stresses in the direction X (σ xx ). Thus, the risk of the fracture of the cement mantle is very significant in the direction Y. High stress in the cement mantle, around the bone inclusion, is observed at proximal region of the prosthesis; the maximum value is about 12.9 MPa (see Table 3). In the distal region, the normal stresses in the direction Y are in the range −2 to 7 MPa; in the medial region stresses are in the range 1.2–4.4 MPa.

3.3 Shear stresses (τ xy )

Figure 7 shows the distribution of shear stresses (τ xy ) around the bone debris for different zones; proximal, medial and distal. High values of shear stress in the cement mantle around the bone inclusion are observed. At the proximal region of the prosthesis, the maximum stress value is about 10 MPa (see Table 3); in this case, the crack risk initiation is significant by shearing mode. Besides, the values of the shear stress lie between 3.3 and 4.2 MPa for distal region and between 0.6 and 1.2 MPa for medial region. For these regions, the risk of the crack initiation by shearing mode is less important.

3.4 The behaviour of a crack emanating from bone inclusion

Figure 8 shows Mode I stress intensity factors (K I) along the crack front emanating from bone debris for different zones; proximal, medial and distal. The K I varies by decreasing and increasing along the front crack for all cases. In proximal part, it can be noted that the opening SIF is relatively high; at this position the value of K I is the highest and hence, crack presents the most dangerous case. It is known that the crack opening stress is the most dangerous mode. The SIF values lie between 0.12 and 0.51 MPa m1/2; this causes the tendency of crack propagation to increase significantly in the acrylic cement. It can lead to the damage of cement layer and the loss of stem stability. In the distal zone, the risk of propagation by opening mode is important, due to the high values of K I, which vary from 0.01 to 0.3 MPa m1/2. In the medial zone, the mode I stress intensity factors are weak; hence, the risk of the cement failure in this zone is less important compared to the other zones of the prosthesis (see Table 4).

3.5 The behaviour of an elliptical crack

Figure 9 reveals the evolution of stress intensity factors in mode I (K I) at the elliptical crack tip, in the three zones of the hip prosthesis (proximal, medial and distal). The values of stress intensity factors for rectangular crack emanating from bone inclusion are higher than those for the elliptical crack. The greater values of opening mode (K I) are noted in the case of an elliptical crack located in the proximal zone; therefore, the risk of propagation is definitely higher. Moreover, the distal part gives high SIF values at the crack tip. The maximum K I value is about 0.28 MPa m1/2. Finally, in the medial part, the K I values are lower than those in the two other regions. Thus, the presence of the crack in this position presents the least dangerous case (see Table 4).

4 Discussion

Microcracking may lead to PMMA particle release, which can induce local inflammation and osteolysis [22, 23]. The relative position, the geometry and size of any cracks have a significant effect on the crack propagation. Similar results have been described by other authors. McCormack and Prendergast [24] found that cracks, which initiate early on in the loading history, occur at locations of high stress levels in the cement mantle. Gravius et al. [25] found that the crack length in the cement mantle, in the different types of the femoral prostheses, lies between 0.5 and 0.7 mm. Kim et al. [26] found that the SIF values decrease from 0.2 to 0.37 MPa m1/2, which suggests that the propensity of crack propagation will decrease as the crack grows in the cement mantle. Ries et al. [27] found that the critical stress intensity factor (K IC) lies between 0.96 and 1.76 MPa m1/2.

Because the values of K I in proximal part are the highest, a comparison of stress intensity factors K I of rectangular and elliptical cracks in this part will be performed and discussed. Table 4 shows the comparison between the variation of stress intensity factors K I of an elliptical crack and a rectangular crack emanating from bone inclusion. We can see that, the rectangular crack leads to the highest values of SIF, especially for the two-tip of crack line in the proximal and the distal zones; unlike the medial one, the elliptical crack values of K I present the dangerous case.

In general, cracks can inhibit or promote propagation of adjacent cracks depending on their relative position, size, shape and the degree of interaction between the induced crack tip concentrations. The results of this analysis enable us to provide solutions to stop the crack propagation in the bone cement, such as: using a grid in the cement mantle to reinforce cement in the crack path, or using nanotechnology to create area with higher mechanical properties.

5 Conclusion

The aim of this study was to analyse the behaviour of crack emanating from bone debris. The obtained results lead to the following conclusion:

-

The bone inclusion situated in the proximal part presents the highest risk of crack initiation in orthopaedic cement; the interaction between the edge effect of the femoral stem and the microdefect induces this behaviour.

-

The inclusion located in the distal part of the cement also presents a high risk of crack initiation in the cement mantle; the interaction effect of the implant tip on the cement increases the stresses.

-

The inclusion situated in the medial part is subjected to a weak stresses; therefore, the risk of the rupture is not considerable.

-

For the crack emanating from the bone debris in proximal and distal positions, the risk of propagation by opening mode increases as the values of KI increase; therefore, the crack located in the medial zone is more significant.

-

Rectangular cracks in proximal and distal zones present higher risk of damage comparing to elliptical ones; on the other hand, elliptical cracks are more dangerous in medial part.

References

Lewis G (1997) Properties of acrylic bone cement. J Biomed Mater Res 38(Fasc.2):155–182

Pèrez M, Garcia JM, Doblare M (2005) Analysis of the debonding of the stem–cement interface in intramedullary fixation using a non-linear fracture mechanics approach. Eng Fract Mech, pp 1125–1147

Jasty M, Maloney WJ, Bragdon CR, O’Connor DO, Haire T, Harris WH (1991) The initiation of failure in cemented femoral components of hip arthroplasties. J Bone Joint Surg 73-B:551–558

Bhambrik SK, Gilbertson LN (1995) Micromechanisms of fatigue crack initiation and propagation in bone cements. J Biomed Mater Res 29:233–237

Murphy BP, Prendergast PJ (2001) The relationship between stress, porosity, and nonlinear damage accumulation in acrylic bone cement. J Biomed Mater Res 59:646–654

Benbarek S, Bachir Bouiadjra B, Achour T, Belhouari M, Serier B (2007) Finite element analysis of the behaviour of crack emanating from microvoid in cement of reconstructed acetabulum. Mater Sci Eng 457:385–391

Bouziane MM, Bachir Bouiadjra B, Benbarek S, Tabeti MSH, Achour T (2009) Finite element analysis of the behaviour of microvoids in the cement mantle of cemented hip stem: static and dynamic analysis. Mater Des 31:545–550

Serier B, Bachir Bouiadjra B, Benbarek S, Achour T (2009) Analysis of the effect of the forces during gait on the fracture behaviour in cement of reconstructed acetabulum. J Comput Mater Sci 47(3):672–677

Bouziane MM, Tabeti, Bachir Bouiadjra B, Benbarek S (2010) Influence de la présence des microcavités dans le ciment de la partie fémorale sur le comportement mécanique de la prothèse totale de hanche. Journal de Sciences et Technologies pour le Handicap 4(2):189–202

Flitti A, Ouinas D, Bachir Bouiadjra B, Benderdouche N (2010) Effect of the crack position in the cement mantle on the fracture behavior of the total hip prosthesis. J Comput Mater Sci 49:598–602

Griffith AA (1920) The phenomena of rupture and flow in solids. Trans R London Ser A 221(587):163–198

Bachir Bouiadjra B, Belarbi A, Benbarek S, Achour T, Serier B (2007) FE analysis of the behaviour of microcracks in the cement mantle of reconstructed acetabulum in the total hip prosthesis. Comput Mater Sci 40(4):485–491

Ingraffea AR (1979) The strength ratio effect in the fracture of rock structure. In: Proceedings 20th U.S. symposium on rock Mechanics, University of Texas at Austin, pp 153–162

Kemeny JA, Cook NGW (1991) Micromechanics of deformation in rocks. In: Shah SP (ed) Toughening mechanics in quasi-brittle materials. Kluwer Academic, The Netherlands, pp 155–188

Dyskin AV, Germanovich LN, Lee K, Ring LM, Ingreaffea AR (1994) Modeling crack propagation in compression. In: Nelson PP, Laubach, SE (eds.) Rock Mechanics: Models and measurements. Challengers from Industry. Proc. Ist North American Rock Mechanics Symposium. Austin. Balkema. Rotterdam, pp 451–460

Eberhardt E, Stead D, Stimpson B, Lajtai EZ (1998) The effect of neighbouring cracks on elliptical crack initiation and propagation in uniaxial and triaxial stress field. J Eng Fract Mech 59:103–115

Irwing GR (1957) Analysis of stress and strain near the end of a crack traversing a plate. J Appl Mech ASME 24:361–364

Nuño N, Avanzolini G (2002) Residual stresses at the stem–cement interface of an idealized cemented hip stem. J Biomech 35:849–852

Rohlmann A, Oner UM, Bergmann GK, Olbel R (1983) Finite element analysis and experimental investigation in a femur with hip endoprosthesis. J Biomech 16:727–742

Levai JP, Boisgard S (1996) Technique pour optimiser les propriétés du ciment chirurgical. Actualités en biomatériaux. Romillat, Paris, vol 3, pp 199–209

Merckx D (1993) Les ciments orthopédiques dans la conception des prothèses articulaires. Biomécanique et biomatériaux, Cahiers d’enseignement de la SOFCOT, Expansion scientifique française, vol 44, pp 67–76

Horowitz S, Doty S, Lane J, Burstein AH (1993) Studies of the mechanism by which the mechanical failure of polymethylmethacrylate leads to bone resorption. J Bone Joint Surg, pp 803–813

Hughes KF, Ries MD, Pruitt LA (2003) Structural degradation of acrylic bone cements due to in vivo and simulated aging. J Biomed Mater Res, pp 126–135

McCormack. BAO, Prendergast PJ (1999) Microdamage accumulation in the cement layer of hip replacements under flexural loading. J Biomech, pp 467–475

Gravius S, Wirtz DC, Siebert CH, Andereya ST, Mueller-Rath R, Maus U, Mumme T (2008) In vitro interface and cement mantle analysis of different femur stem designs. J Biomech, pp 2021–2028

Kim B, Moon B, Mann KA, Kim H, Boo K-S (2007) Simulated crack propagation in cemented total hip replacements. Mater Sci Eng, pp 0921–5093

Ries MD, Young E, Al-Marashi L, Goldstein P, Hetherington A, Petrie T, Pruitt L (2006) In vivo behavior of acrylic bone cement in total hip arthroplasty. Biomaterials, pp 256–261

Acknowledgments

The Authors extend their appreciation to the Deanship of Scientific Research at King Saud University for funding the work through the research group No. RGP-VPP-035.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Marcos Pinotti.

Rights and permissions

About this article

Cite this article

Bouziane, M.M., Bachir Bouiadjra, B., Benbarek, S. et al. Analysis of the behaviour of cracks emanating from bone inclusion and ordinary cracks in the cement mantle of total hip prosthesis. J Braz. Soc. Mech. Sci. Eng. 37, 11–19 (2015). https://doi.org/10.1007/s40430-014-0143-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40430-014-0143-1