Abstract

Purpose

Arsenic is a toxic metalloid that is present in the environment as arsenate and arsenite anions. Exposure to arsenic anions caused skin problems, degenerative diseases, kidney, liver, and lung cancer. The synthesized iron nanoparticles (NPs) were examined as a green low-cost adsorbent for the removal of arsenite anions from aqueous solution via batch adsorption procedure.

Methods

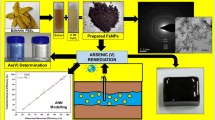

Iron NPs were prepared in a single step by the reaction of Fe+3 0.01 M solution with a fresh aqueous solution of 2% w/v pomegranate peel extract (PPE) as both reducing and capping agents. The physicochemical properties of peel were investigated by some experiments and functional groups were determined by the FT-IR spectrum. The electrochemical behavior of PPE was studied using cyclic voltammetry on a glassy carbon electrode as produced a cathodic peak at range 120–400 mV. The progress of nZVI production was monitored by a decrease of 372 nm wavelength UV-Vis spectra of PPE. The 27 adsorption experiments were carried out as a function of solution pH, initial arsenite concentration, mass adsorbent, and contact time according to DOE.

Results

The rapid rate of adsorption was observed at 20–60 min, indicating that the principal mechanism dominating the sorption process was reduction and chemical adsorption. The arsenite removal efficiency was found to be dependent on the solution pH, adsorbent dose, and initial concentration, respectively.

Conclusion

The experimental data show the ability of the synthesized iron NPs to remove arsenate from solution in both synthetic and polluted natural water. The thermodynamic study suggested the spontaneous and endothermic nature of adsorption of arsenite by green synthesized iron NPs. The iron NPs synthesized with PPE increased the removal of arsenite with an increase in the active surface, indicating some chemical interactions between the adsorbent and oxoanions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

It is known that iron compounds play a very significant role in environmental remediation and are attractive for the treatment of various water pollutants because of their individual physicochemical properties. ZVI has zero oxidation state with incompletely filled d-orbitals, which has the potential to readily lose electrons and making it very reactive [1]. Iron is cheap, easy to get, and a strong reducing agent even in the powder form. The practical applicability of these particles lies in the fact that they reduce organic as well as inorganic impurities to get oxidized into +2 and +3 oxidation states [2].

Iron nanoparticles (NPs) have been extensively used in the degradation and removal of toxic and hazardous organic pollutants and heavy metals such as arsenic anions [3]. The arsenite anions, especially, can readily accept the electrons from iron zero-valent in a common solvent and be reduced to arsenic according to reaction 1:

Various chemical methods are applied to synthesis nZVI of specific structural. Chemically, these NPs can be synthesized by reducing dissolved iron (Fe2+ or Fe3+) as chloride, nitrate, and sulfate using sodium borohydride, NaBH4, as a reducing agent [4], but the synthesized nZVI can oxide by dissolved oxygen (DO) and water as reaction 2 and 3:

In addition, the aggregation of NPs is one of the known problems in the synthesis and application of NPs. Prevention of oxidation and stability of NPs against aggregation can be treated using organic surfactants or through the use of capping agents [5]. A wide variety of plant extracts has been employed to stabilize nZVI as a capping agent. Hoag et al. were improved tea polyphenols to synthesize stable nZVI and applied them to the degradation of bromothymol blue dyes [6]. Machado et al. utilized 25 trees leaf to produce extracts that are capable of producing stable nZVI [7]. The green synthesis of gold and silver NPs have been performed using various plants extract such as tea extract, sorghum bran extract, and pomegranate extract [8,9,10]. The pomegranate peel extracts were demonstrated to be high in antioxidant activity related to a rich source of natural antioxidants [11]. This activity may be related to polyphenolic compounds present in PPE, including punicalagin isomers, ellagic acid derivatives, and anthocyanins [12]. Polyphenols are the compounds that, when added to metals ions, can complexion with ions and reduce it to metal. There are several studies performed to use extract plant polyphenols such as tea leaf [13], Sorghum brass [14] for synthesizing metal NPs Au [15], Ag [16], and Pd [17].

Among all processes designed to treat wastewater, modified adsorbents based on iron or iron oxides are extremely explored in environmental usages due to environmentally friendly, low cost, and high abundance of iron [18]. Generally, it is well known that arsenic removal depends on the affinity of the adsorbent towards as species and the oxidation state [19, 20]. Hence, chemical and physicochemical structural of the adsorbent and changing the oxidation state of as species are significant parameters which that increase the removal efficiency. Also, the simultaneous reduction and adsorption of toxic compounds by nZVI has been presented in the literature [21].

The overall objective of this work was to the synthesis of iron NPs via a green synthesis for determining the ability of the green synthesis iron could increase arsenite uptake from contaminated waters. The especial goals were: (1) to evaluate the effects of pomegranate peel extract, high level of freely extractable and soluble water polyphenolic compounds, to the synthesis of iron NPs as a powerful adsorbent for applications on arsenic uptake in arsenite from contaminated waters; (2) to investigate the effects of important parameters such as initial pH, initial concentration and adsorbent mass in the removal of arsenite from aqueous solutions based on experimental design, and (3) to identify possible adsorption mechanisms responsible for As removal in aqueous solution after reduction by the synthesis of iron NPs .

Materials and methods

Materials

Double distilled water was used in the preparation of solutions and synthesis of NPs. Iron (III) chloride hexahydrate and sodium arsenite were purchased from Fluka. Filter paper with 0.45 μ pore size was used to separate any insoluble in the suspension.

Uv-Vis spectra studies were performed in the range of 300–500 nm during the synthesis step using UV/Vis Lambda 25 spectrophotometer. An IR spectrum was done in the range 600–4000 cm−1 by FT-IR PU 9600 servies spectrophotometer. A scanning electron microscope (SEM) was achieved to obtain NPs size and morphology at a 13.07 KV voltage. For SEM sample preparation, a droplet of NP solution in acetone deposited on the aluminum foil and after evaporation of the solvent, the surface coated with Au particles.

Cyclic voltammeter experiments were performed on an atuoLab 302 M computerize instrument (Switzerland). The triple-electrode system consisted of a working glassy carbon (GC) electrode, a reference calomel electrode (0.23 V), and a platinum wire as a counter electrode. Before each experiment, the GC electrode was polished with alumina powder (0.5 lm), rinsed thoroughly with distilled water. All measurements were done in the 0.0–0.4 V potential range at Lab temperature.

Physicochemical properties measurement

For pH determination, 2 g of peel particles dissolved in 100 ml of double-distilled water and was measured with a digital pH meter. Titrable acidity was estimated by extract titration with 0.1 N NaOH to the endpoint of phenolphthalein as an indicator and expressed as ellagic acid content [22]. The moisture content of peel particles was measured by drying in the digital oven within 2 h. The residual ash was determined by heating at the 500 °C temperature in a programmable furnace for 4 h. Total extractable materials were detected by dissolved of 2 g peel particles in 100 ml, washed threefold, and determinate the loss of weight.

Pomegranate peel extract (PPE) preparation

Pomegranate peel was collected from the local market at Yazd city in the center of Iran. After washing with double distilled water, it dried in the air and in the absence of sunlight. The dried peels were milled by electric milling and sieved to 60–40 mesh. Ten grams of such granules were introduced to 500 ml of distilled water in a beaker and heated to 80°C for 15 min. After cooling to lab temperature, the extract was filtered with 0.45 μ filter paper. The light-yellow solution was freshly used to react with the Fe3+ solution.

Iron nanoparticles synthesis

PPE was used as a reducing agent for the synthesis of iron NPs. For this purpose, the 0.01 M of Fe3+ solution was added to a constant volume of PPE (20 g/l). The mixture stirred at lab temperature for 5 min without additional reducing agent or surfactant. The intense black precipitation of iron NPs was observed, after 3 days of storage. For separation of NPs, the mixture was slowly heated to evaporate to half and centrifuged at 11,000 rpm for 10 min. After decanting the supernatant, the nano-powder was washed with ethanol and dried in the vacuum.

Sample preparation for CV

Working solutions of PPE were freshly prepared for cyclic voltammetry analysis by diluting 2 ml of the PPE extracts (2% w/v) in a phosphate buffer with 65% w/v 50 mM disodium hydrogen phosphate and 35% w/v 50 mM sodium dihydrogen phosphate at pH 7.0. Using a procedure already described by Kilmartin [23], cyclic voltammograms were recorded in triplicate using a freshly polished GC electrode from 100 to 400 mV at a scan rate of 100 mV.S−1. The electrode potential was recorded against a calomel reference electrode (+0.24 V) and the current was taken against the response due to the buffer solution as a blank.

Batch adsorption experiments

The statistical method of the design of experiment (DOE) was applied to better describe the interaction effect of the effective parameters and provides a smaller number of experimental runs [24]. The 3-level 3-factor design was used to achieve the optimum conditions for maximum removal efficiency of arsenite by synthesized NPs. The three efficient independent variables: initial pH (pH), initial concentration (C0), and adsorbent mass (m) were chosen to design batch experiments, and its levels were coded as −1 (low), 0 (middle), and 1 (high) (Table 1).

To optimum contact time, some experiments were done in 20 mg/l initial concentration of arsenite with 0.2 g adsorbent at the initial pH solution. Samples were collected from the flasks at the predesigned time intervals (5, 10, 20, 30, 60, and 120 min) for determining the residual as a concentration in solution. For considering arsenite removal, the batch experiments were done using synthesized iron NPs as the adsorbent for reduction and adsorption of arsenite in solutions. The 27 experiments were carried out by 50 mL solution of the desired initial arsenite concentration (10, 20, and 30), three levels of initial pH (3, 7, and 11), and the known amount of the adsorbent (0.10, 0.25, and 0.5). Then, the suspensions were agitated on a temperature-controlled orbital shaker at 180 rpm. For this purpose, the suspensions were centrifuged at 5500 rpm for 7 min, and the concentration of the residual arsenic was measured at the maximum absorbance wavelength of 197.2 nm by furnace AAS after calibration by the standard solutions [25].

Statistical analysis

All results were reported as an average of three measurement replicates, and the main effects were determined by analysis of variance according to the general linear model procedure of the statistical analysis. Significance was at the 0.05 probability levels. The removal efficiency of arsenite was calculated by Eq. 3:

Where RE is the removal efficiency of arsenite, C0 is the initial concentration of arsenite, and Ce is the equilibrium arsenite concentration (mg/L). The amounts of adsorption capacity at equilibrium was obtained by Eq. 4:

Where qe is the adsorption capacity at equilibrium (mg/g), V and m are the solution volume (L) and the mass of adsorbent (g), respectively. The relationship between the dependent and the independent variables can be explained by the quadratic equation, as Eq. 5 [24]:

Where RE is the predicted removal efficiency of arsenite, X1 to X3 are the independent variables, α 0 is the intercept of the quadratic model, and α 1– α 9 are the estimated coefficients.

Result and discussion

Some physicochemical properties of pomegranate peel were measurement and are listed in Table 2.

Commonly, the phenolic compound includes a wide range of substances that contain one or more hydroxyl substituted on the aromatic ring. These compounds have a well-known spectrum in the infrared region that can be indicated by the FT-IR spectrum. Figure 1 represents the FT-IR spectrum of PP.

FT-IR measurements were carried out to identify the phenolic compounds in the PP responsible for reaction with Fe+3 ions and also the capping agent for stabilizing the synthetic NPs in solution. FT-IR spectrum of PP indicated that prominent absorption bands at 1710, 1610, and 3450 cm−1. The shoulder bond at 1710 cm−1 is a characteristic of C=O stretch vibrations in carboxylic acids and phenols, while the resonance at 3450 cm−1 arises due to the O–H groups present in the phenols.

Cyclic Voltammetry of PPE was carried out in an aqueous buffer solution at pH 7.0 and is given in Fig. 2. As can be seen in Fig. 2, a broad anodic peak was observed within the investigated potential range (E = 0.12–0.4 V). In the reverse scan, no peaks appear which shows that electro-oxidation of PPE was followed by an irreversible chemical oxidation reaction. Repeated cycling 16-fold led to a decrease in oxidation current (I), presumably due to the generation of electro-inactive species which adsorb on the GC electrode surface.

It was surprising; the electrochemical response was completely decreased after the first 2 h. This reduction indicates that the phenolic compounds in PPE were expected to be oxidized by dissolved oxygen, which will lead to a loss of oxidizable groups with time. On the other hand, the decreased values after the 2 h may be due to the degradation of antioxidant polyphenols formerly bound to other compounds. Kimartin et al. have found that phenolic compounds of Green tea and Oolong tea decrease after 6 h [26]. Finally, the 30-old repeat cyclic voltammetry showed clearly the composition and state of the phenolic in PPE changes rapidly with time, while the overall reducing strength of the solution changes more slowly.

When PPE was combined with 0.01 M aqueous FeCl3 solution, the color changed from light yellow to dark green due to the formation of iron NPs that is shown in Fig. 3(a). Also, this reaction was confirmed using visible spectra, so the blank solution has begun a scattering at 400 nm, and the peak centered at 372 nm was rapidly eliminated after the addition of Fe+3 ion, as shown in Fig. 3(b). The two phenomena indicate that the complex was first formed and then Fe+3 ions reduced with reduction groups of anthocyanidins.

One of the most suitable techniques for the characterization of NPs is UV–Vis spectroscopy. Spectral analyses of the reaction progress Fe3+ with PPE were studied at different Fe3+ concentrations. For this purpose the amount of PPE (2% W/V) and Fe3+ were diluted in the constant volume by double distilled water (Table 3).

This reaction was instantaneous with the color changed from shiny pink to dark black, as shown in Fig. 4a, and subsequently, the progress of the reaction was monitored by UV/Vis spectrophotometer in the range 300–500 nm.

The UV-Vis absorption spectra of iron NPs, formed using different quantities of Fe3+, are shown in Fig. 4(b). Spectra 1 to 6 corresponds to S0-S5, respectively. Spectra 1, 2, and 3 show a single absorption band centered at 372 nm. In contrast, spectra 4, 5, and 6 exhibits an insignificant intensity band at 372 nm width, which can be attributable to a sufficient amount of Fe3+ ions for reduction by reducing agents consequently, iron NPs are formed.

According to Fig. 4(b), the peak centered at 372 nm in the absorption spectrum of PPE disappeared with increasing Fe3+ amount from 0.10 to 0.50 ml, whereas the visible spectra had broad adsorption beginning at 440 nm. No sharp adsorption at 400 nm in contrast FeCl3 solution, was indicated that the Fe3+ complex was completely reduced by the addition of PPE. Also, NPs scatter visible light rather than adsorption [27]. The Fe NPs had light scattering in all ranges of the UV–Vis spectrum, and scattering increased with the decrease of wavelength. Then, the baseline of absorption increased with increasing of Fe3+ as well as the produce of iron NPs (Fig. 3b). Unfortunately, the residual molecules that act as capping and reducing agents have a strong absorption band in the region between 210 and 260 nm, cause interference with the UV band of the produced Fe NPs in suspension.

Recently, several synthetic methods have been focused on the production of controlled size NPs and enhance to produce regular shape [28]. Size and shape distribution of synthesized iron NPs investigated from the SEM micrograph that is shown in Fig. 5. It can be from SEM image that iron NPs synthesized by PPE yield relatively uniform spherical shape in diameter. This image suggests that the NPs agglomerate with polyphenols produce regular clusters. Also, they have a regular spherical shape in the average range of 40–60 nm calculated from the SEM micrograph.

As mentioned, the chemical composition of PP is considered as a source of natural polyphenol compounds such as phenolic, anthocyanidins, and flavonoids [29], higher than 37 mg/100 g of dry matter, which is mainly responsible for antioxidant activity [30]. As well, it has been demonstrated by Herrera-Becerra et al. that iron NPs can be obtained directly and simply by reduction of Fe (III) ions with Tannic and Gallic acid as a reducing agent. These types of compounds play a considerable role in complex with metal ions and reduction processes in biosynthetic methods, as previously reported by Mohanpuria P. et al. [31]. It seems that the three steps take place for the formation of iron NPs using PPE (1) complexion of Fe3+ with polyphenol biomolecules, (2) simultaneous reduction of Fe3+ in complex with oxidant groups, and (3) capping of produced nZVI with oxidized polyphenols.

Accordingly, the reduction potential of anthocyanin is in the range 0.3–0.8 V, which is enough to reduce Fe3+ that has a reduction potential of −0.44 V [29]. It seems that neighboring hydroxyl groups that confer them the ability to form complexes with Fe3+ ions and carboxyl groups present in the polyphenols of the PPE play an important role in the reduction of the Fe+3 ions and can also control the size and the stability of the synthesized nanostructures.

The consideration effect of contact time is significant to reach equilibrium for designing the batch adsorption process. Therefore, the effect of contact time on the adsorption of arsenite ions was checked out by several batch experiments. Figure 6 represents the changes in the adsorption of arsenite ions by synthesized iron NPs as a function of contact time in 20 mg/l initial arsenite concentration and the fixed values of other factors. It is seen that the adsorption of arsenite was slow with increasing in contact time up to 20 min. Further increase contact time up to 60 min had a high increase in adsorption. The rapid rate of adsorption, between 20 and 60 min, is due to reduce of arsenite anions by the synthesized iron NPs that produce the chemical-active anions and then adsorption of ions onto the outer surface. After this time, the ions enter into pores (inner surface), a relatively slow process. The faster rates of adsorption may be attributed to a large number of surface-active sites for adsorption, and the slower adsorption rates further are due to the saturation of the functional groups and achievement of equilibrium. Similar conclusions have been reported by Salmani et al. for adsorption of arsenite ions by Lemon peel [32]. The adsorption was not changed significantly after 60 min and reached equilibrium.

In this study, the removal of arsenite oxoanions by adsorption on green iron nanoparticle was found to be rapid at the initial period of contact time (until 60 min) and then to become slow and stable with the increase in contact time (Fig. 6). It was also observed that the intraparticle diffusion model had a contribution to the control of adsorption kinetics however intraparticle diffusion was not the dominating mechanism in the overall adsorption process.

The results for the analysis of variance (ANOVA) are summarized in Table 4, which can be used to investigate the significant factors.

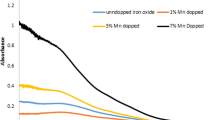

The solution pH as an important independent variable does not only affect the chemistry of solutes but also affects the surface-active sites of the adsorbents. The zero point charge (pHzpc) indicates a net surface charge equal to zero that was reported 6.5 for iron oxides [33]. The surface of nZVI is positive when the solution pH is above 6.5, whereas the surface of nZVI is negative when the solution pH is below the pH of 6.5. Arsenite has a pKa = 10.3, becomes more protonated in acidic solutions, and deprotonated in basic solutions [34]. From Fig. 7, it can be observed that an increase in pH enhances the removal efficiency of arsenite so, an increase in pH until 7.0 (level 0) is unfavorable, and pH between 7.0 and 11.0 is favorable for chemical adsorption. In the pH range of 7.0–11.0, the numbers of negatively charged sites increase, so the adsorption was favored between the adsorbent and the deprotonate arsenite anions due to a strong electrostatic attraction.

All first-order terms, initial pH (pH), initial concentration (C0), and mass adsorbent (m), reveal a high significance on the removal efficiency of arsenite based on the p-values less than 0.05. The interaction effects of initial pH and initial concentration (pH. C0), initial pH and mass adsorbent (pH.m), and initial concentration and mass adsorbent (C0.m) exhibits insignificance on the removal efficiency of arsenite at the 95% confidence level. The best prediction model with significant variables for arsenite removal by iron NPs was selected that is shown by Eq. 6:

The F-value and R2 for the model are 1909.94 and 0.938, respectively, indicated that the model was significant. According to the coefficient values of independent variables, the order for the effective parameters on the arsenite removal efficiency was initial pH > mass adsorbent > initial concentration. Remarkably, the positive values of coefficients for pH and mass adsorbent indicate the synergistic effect on the removal efficiency.

The Gibbs free energy change (ΔG0) thermodynamic parameter was calculated using the Eq. 7 [35]:

Where R is a general constant of gas, T is the absolute temperature, and KC is the distribution coefficient for adsorption, which is determined as Eq. 8:

Where Cs is the equilibrium arsenite concentration on the adsorbent, and Ce is the equilibrium arsenite concentration in solution (mg/L).

The Gibb’s free energy (ΔG0) was obtained for adsorption of arsenite anions by experimental data. The result is presented in Table 5. The values of ΔG0 were negative in 298 K that confirms the feasibility and the spontaneous nature of the adsorption process at optimum condition.

The main point in an adsorption process is to illustrate the mechanism of adsorption. However, two points are necessary to consider before understanding the mechanism of adsorption: the adsorbate structure; and the surface properties of adsorbent. It is known that the removal of organic and inorganic pollutants by nZVI involves chemical reduction [36]. In aqueous solutions, nZVI reacts with water via the following reaction (Eq. 9).

The products such as Fe (II) ions and molecular hydrogen can to reduce most of the oxidable species (OX). However, Fe (II) may participate in further oxidative reactions (Eqs. 10 and 11).

Various precipitates, such as Fe(OH)3, Fe3O4, Fe2O3, and FeOOH, may form during the progress of reactions. These precipitates know as good sorbents for adsorption of various pollutants from aqueous solutions. On the other hand, iron oxide consists of hydroxyl and oxygen functional groups on the outer surface of active sites and acts as a chemically reactive functional group for oxoanions [34].

According to the findings of the present study, and based on the structure of the adsorbate and adsorbent surface properties, the mechanism for the removal of arsenite anions by adsorption on green nano iron may be assumed to involve the following steps:

-

Reduction of arsenite anions to lower oxidation state by green synthesized nZVI

-

Migration of the oxidized arsenite anions from the solution to the surface of the green synthesized nano iron oxides

-

Diffusion of the oxidized arsenite anions to the adsorbent surface through the boundary layer

-

Chemical adsorption of the oxidized arsenite anions on the functional groups of green synthesized nano iron oxides, which may be due to the formation of surface hydrogen bonds between the hydroxyl groups on green synthesized nano iron oxides surface and the oxygen atoms of the oxidized arsenite anions or by an ion exchange process as shown in reaction 12 and 13.

Treatment of polluted consume water

Consume water from Yazd city, which had a hardness of 216 mg/l CaCO3, EC = 495 μs/cm, and pH = 6.85 was sampled at the city water distribution network and spiked with arsenite anions to obtain 20 ppm As pollutant water. Despite the presence of a competitive effect of ions, about 99% decrease in arsenite concentration (50 mg/L) was achieved at the 60 min as a result of treatment with the 0.5 g/100 ml by the synthesized iron NPs adsorbent.

Conclusion

Recently, many efforts were put into the development of new green nano metal synthesis methods. One of these is synthesis by plant extract that has a high potential for the production of nano metals with the desired size and shape. Moreover, plant extracts contain the most effective compounds for enhancing the synthesis rate. Pomegranate peel preferred to the synthesis of iron nanoparticles due to their high antioxidant, environmental friendliness, and cost-effectiveness.

The adsorption experiments show that the green synthesized iron NPs can be used as a reducing agent and adsorbent for adsorption of arsenite anions from contaminated water. The removal process of arsenite anions from solution was exhibited to be influenced by several factors. It was highly dependent on the pH, and for maximum removal was found to be at pH 7.0–11.0. Based on the values of ΔG, the adsorption of arsenite ions onto green synthesized iron NPs was simultaneous. It indicates that the synthesized iron NPs are having an energetically heterogeneous surface, and there may be some chemical interactions between the adsorbent functional groups and the adsorbed arsenite anions. According to the obtained results of the present study, it can be concluded that the synthesized iron NPs can be an alternative economic material to costlier adsorbents used for arsenic species removal in wastewater treatment processes.

References

Shimizu A, Tokumura M, Nakajima K, Kawase Y. Phenol removal using zero-valent iron powder in the presence of dissolved oxygen: roles of decomposition by the Fenton reaction and adsorption/precipitation. J Hazard Mater. 2012;201:60–7.

Poursaberi T, Hassanisadi M, Nourmohammadian F. Application of synthesized nanoscale zero-valent iron in the treatment of dye solution containing basic yellow 28. Prog Color Colorants Coat. 2012;5:35–40.

Shahwan T, Abu Sirriah S, Nairat M, Boyacı E, Eroğlu AE, Scott TB, Hallam KR. Green synthesis of iron nanoparticles and their application as a Fenton-like catalyst for the degradation of aqueous cationic and anionic dyes. Chem Eng J. 2011;172(1):258–66.

Yuvakkumar R, Elango V, Rajendran V, Kannan N. Preparation and characterization of zero valent iron nanoparticles. Dig J Nanomater Biostruct. 2011;6:1771–6.

Sun Y-P, Li X-Q, Zhang W-X, Wang HP. A method for the preparation of stable dispersion of zero-valent iron nanoparticles. Colloids Surf A Physicochem Eng Asp. 2007;308(1):60–6.

Hoag GE, Collins JB, Holcomb JL, Hoag JR, Nadagouda MN, Varma RS. Degradation of bromothymol blue by ‘greener’nano-scale zero-valent iron synthesized using tea polyphenols. J Mater Chem. 2009;19(45):8671–7.

Machado S, Pinto S, Grosso J, Nouws H, Albergaria JT, Delerue-Matos C. Green production of zero-valent iron nanoparticles using tree leaf extracts. Sci Total Environ. 2013;445:1–8.

Nadagouda MN, Castle AB, Murdock RC, Hussain SM, Varma RS. In vitro biocompatibility of nanoscale zerovalent iron particles (NZVI) synthesized using tea polyphenols. Green Chem. 2010;12(1):114–22.

Solgi M, Taghizadeh M. Silver nanoparticles ecofriendly synthesis by two medicinal plants. Int J Nanomater Biostructures. 2012;2(4):60–4.

Iravani S. Green synthesis of metal nanoparticles using plants. Green Chem. 2011;13(10):2638–50.

Saad H, Charrier-El Bouhtoury F, Pizzi A, Rode K, Charrier B, Ayed N. Characterization of pomegranate peels tannin extractives. Ind Crop Prod. 2012;40:239–46.

Madrigal-Carballo S, Rodriguez G, Krueger C, Dreher M, Reed J. Pomegranate (Punica granatum) supplements: authenticity, antioxidant and polyphenol composition. J Funct Foods. 2009;1(3):324–9.

Wang Z, Pan Z, Ma H, Atungulu GG. Extract of phenolics from pomegranate peels. Open Food Sci J Open Food Sci J. 2011;5(5):17–25.

Njagi EC, et al. Biosynthesis of iron and silver nanoparticles at room temperature using aqueous sorghum bran extracts. Langmuir. 2010;27(1):264–71.

Sharma R, Gulati S, Mehta S. Preparation of gold nanoparticles using tea: a green chemistry experiment. J Chem Educ. 2012;89(10):1316–8.

Ahmad N, Sharma S, Rai R. Rapid green synthesis of silver and gold nanoparticles using peels of Punica granatum. Adv Mater Lett. 2012;3(5):376–80.

Nadagouda MN, Varma RS. Green synthesis of silver and palladium nanoparticles at room temperature using coffee and tea extract. Green Chem. 2008;10(8):859–62.

Hao L, Liu M, Wang N, Li G. A critical review on arsenic removal from water using iron-based adsorbents. RSC Adv. 2018;8(69):39545–60.

J. Hua, Synthesis and characterization of gold nanoparticles (AuNPs) and ZnO decorated zirconia as a potential adsorbent for enhanced arsenic removal from aqueous solution. J Mol Struct. 2021;1228:129482.

Salehi H, Ebrahimi AA, Ehrampoush MH, Salmani MH, Fard RF, Jalili M, Gholizadeh A. Integration of photo-oxidation based on UV/Persulfate and adsorption processes for arsenic removal from aqueous solutions. Groundw Sustain Dev. 2020;10:100338.

Ma F, Philippe B, Zhao B, Diao J, Li J. Simultaneous adsorption and reduction of hexavalent chromium on biochar-supported nanoscale zero-valent iron (nZVI) in aqueous solution. Water Sci Technol. 2020;82(7):1339–49.

Akbarpour V, Hemmati K, Sharifani M. Physical and chemical properties of pomegranate (Punica granatum L.) fruit in maturation stage. American-Eurasian J Agric Environ Sci. 2009;6(4):411–6.

Kilmartin PA. Electrochemical detection of natural antioxidants: principles and protocols. Antioxid Redox Signal. 2001;3(6):941–55.

Rezić I, Kiš A. Design of experiment approach to optimize hydrophobic fabric treatments. Polymers. 2020;12(9):2131.

Salmani M, Malek M, Vakili M, Motavaselian M. Determining the arsenic and cadmium level in the consuming water in Yazd by optimized furnace atomic absorption spectroscopy. Toloo-e-behdasht. 2009;8(26):54–61.

Kilmartin PA, Hsu CF. Characterisation of polyphenols in green, oolong, and black teas, and in coffee, using cyclic voltammetry. Food Chem. 2003;82(4):501–12.

Allabaksh MB, Mandal BK, Kesarla MK, Kumar KS, Reddy PS. Preparation of stable zero valent iron nanoparticles using different chelating agents. J Chem Pharm Res. 2010;2(5):67–74.

Nurmi JT, Tratnyek PG, Sarathy V, Baer DR, Amonette JE, Pecher K, Wang C, Linehan JC, Matson DW, Penn RL, Driessen MD. Characterization and properties of metallic iron nanoparticles: spectroscopy, electrochemistry, and kinetics. Environ Sci Technol. 2005;39(5):1221–30.

Singh R, Chidambara Murthy K, Jayaprakasha G. Studies on the antioxidant activity of pomegranate (Punica granatum) peel and seed extracts using in vitro models. J Agric Food Chem. 2002;50(1):81–6.

Manasathien J, Indrapichate K, Intarapichet K-O. Antioxidant activity and bioefficacy of pomegranate Punica granatum Linn. peel and seed extracts. Global J Pharmacol. 2012;6(2):131–41.

Mohanpuria P, Rana NK, Yadav SK. Biosynthesis of nanoparticles: technological concepts and future applications. J Nanopart Res. 2008;10(3):507–17.

Salmani Nodoushan MHS, Parvizi Z, Nodoushan FM, Ghaneian MT. Adsorption of arsenite from aqueous solutions using granola modified lemon peel. Avicenna J Environ Health Eng. 2017;4(1):11667–11667.

FaY, M. A. Mehmedany, and Merween L. A. Surface charge properties of the dominant soil orders in northern Iraq. J University Dohuk. 2016;19(1):91–107

Yang M. In situ arsenic speciation using surface-enhanced Raman spectroscopy. 2017.

Zdziennicka A, Jańczuk B. Thermodynamic parameters of some biosurfactants and surfactants adsorption at water-air interface. J Mol Liq. 2017;243:236–44.

Wang S, Zhao M, Zhou M, Li YC, Wang J, Gao B, Sato S, Feng K, Yin W, Igalavithana AD, Oleszczuk P, Wang X, Ok YS. Biochar-supported nZVI (nZVI/BC) for contaminant removal from soil and water: a critical review. J Hazard Mater. 2019;373:820–34.

Acknowledgments

The authors are grateful to the Iranian Research Organization for Science and Technology (IROST) and the Institute of Environmental Health of the Shahid Sadoughi University of Medical Science for support of this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors contributed sufficiently to the study and read this final manuscript, and gave their approval for the manuscript to be submitted in the present form.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Salmani, M.H., Abedi, M., Mozaffari, S.A. et al. Simultaneous reduction and adsorption of arsenite anions by green synthesis of iron nanoparticles using pomegranate peel extract. J Environ Health Sci Engineer 19, 603–612 (2021). https://doi.org/10.1007/s40201-021-00631-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40201-021-00631-y