Abstract

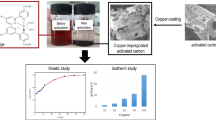

Release of cadmium, a non-essential and highly toxic heavy metal, into aquatic ecosystem through discharge of effluents from various industries such as electroplating, photographic, steel/iron production and tanneries, is of considerable environmental conern at global level. Hence, it is essential to develop economic methods to remove cadmium from industrial effluents before their discharge into water bodies. The aim of present study was to explore the efficiency of Nitrilotriacetic acid (NTA) for the surface modification of Dendrocalamus strictus charcoal powder (DCP) and application of both unmodified DCP and NTA modified DCP (NTA-MDCP) as adsorbents to remove cadmium (II) ions from aqueous solution. Isotherms, thermodynamic and kinetic studies were carried out to describe the adsorption behavior of both adsorbents for the removal of Cd(II) ions. Maximum adsorption capacity calculated from Langmuir isotherm was found to be higher for NTA-MDCP (166.66 mg/g) as compared to DCP (142.85 mg/g) which may be attributed to the complex formation (1:1 & 2:1) between NTA on the surface of adsorbent and Cd(II) ions in the solution at optimum conditions: pH = 6, temperature = 25 °C, adsorbent dose = 2 g/l and contact time = 2 h. Thermodynamic studies confirmed endothermic as well as spontaneous nature of adsorption process and kinetic investigation revealed that the adsorption process followed pseudo second-order for both DCP and NTA-MDCP. Physical characterization of both adsorbents before and after adsorption was studied using Scanning Electron Microscope, Brunauer-Emmett-Teller surface analyzer, Energy Dispersion X-ray Spectrometer, CHNS analyzer and X-Ray diffractometer which confirmed the adsorption of cadmium(II) ions. Further, the desorption studies for regeneration of adsorbents were successfully carried out using two eluents viz., 1 M sulfuric acid and 0.5% calcium chloride. The present study revealed that NTA-MDCP could be used as an effective adsorbent for the removal of cadmium(II) ions from aqueous solution.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Water pollution has become a serious problem throughout the world for past few decades. Different heavy metals including lead, cadmium, mercury, copper, chromium and zinc have been released into aquatic ecosystem through mining activities and discharge of effluents without treatment from various industries such as electroplating, photographic, steel/iron production and tanneries [1]. Toxic heavy metals do not only contaminate surface water bodies such as lake, sea and ponds but also contaminate ground water and ultimately posing threat to all forms of life surviving on the mother earth. These non-biodegrable contaminants have a potential to accumulate in different soft tissues of human body often entering through drinking water, food chain or dermal contact. Among different heavy metals, cadmium is highly toxic in nature and exposure to it can lead to “itai-Itai” disease, insomnia, hypertension, prostate cancer and testicular disfunction etc. [2,3,4,5,6]. Cadmium also causes detrimental effects in the plants such as chlorosis, necrosis, leaf roll, reduction of biomass and growth [7].

Due to its highly toxic nature, it is essential to remove cadmium from industrial effluents before discharging them into water bodies. In recent past, many technologies have been developed to remove various pollutants/heavy metals from wastewater. Various technologies such as membrane filtration, precipitation, coagulation, solvent extraction, ion-exchange, neutralization, electro-dialysis, ultra filtration and reverse osmosis have been used for the removal of heavy metals from aqueous solutions [8]. Although these technologies are efficient but also suffer from certain limitations such as high operation cost, heavy instrumentation and can operate well only for small scale water treatments. Among various clean up technologies, adsorption method has come up as an effective technique for the removal of heavy metals from industrial effluents as well as aquatic systems throughout the world. Major reasons to adopt adsorption as water treatment technique are: it is economic, simple to operate and do not require bulky instrumentation. Attention has been focused on application of various low-cost materials as adsorbents which include chitosan, zeolites, clay, peat moss, fly ash, coal, industrial waste and activated carbon [9]. For adsorption studies, some researchers have emphasized on the use of non-conventional adsorbents such as saw dust, bamboo plant material, coconut material as well as their charcoal for removal of heavy metals [10, 11]. The adsorption capacity of an adsorbent depends upon its pore size and chemical structure of active sites available on the surface of adsorbent [12].

Bamboo, a member of ‘Poaceae’ family is considered as the cheapest material and a renewable bioresource for adsorption studies due to its short growth period. Bamboo in the form of raw powder as well as charcoal powder has been used as an adsorbent because of its porous nature and large surface area [13,14,15]. Bamboo charcoal, although exhibits good adsorptive properties but researchers attempted to explore different methods to increase its adsorptive properties. In order to enhance the adsorption capacity of an adsorbent, chemical surface modification processes have been documented and applied as an effective method for generation of efficient adsorbent to remove different pollutants [16, 17]. For instance, different chelating agents have been widely used for surface modification of adsorbents and applied in cleaning formulation, especially, to remove toxic metals from contaminated aquatic systems due to their sequestering effects. Different chelating agents present on the surface of chemically modified adsorbents have capacity to form complexes with different metal ions due to the presence of various functional groups viz., amino acid, ligno-sulfonates, humic or fulvic acids, organic acids and proteins [18]. However, affinity of chelating agents towards adsorbate metal ions is reported to be dependent upon its physico-chemical characteristics viz., ionic radius, ionic charge and its bonding with functional groups of ligands on the surface of adsorbent [19]. Following this direction, the present work was planned to investigate the adsorptive behavior of DCP as such and to enhance the adsorption capacity of adsorbent, nitrilotriacetic acid (NTA), a chelating agent was used for its surface modification (NTA-MDCP). Equilibrium data so obtained were further analyzed using isotherm, kinetic and thermodynamic models. Scanning Electron Microscope (SEM), Scanning Electron Microscope-Energy dispersive X-ray spectroscope (SEM-EDX), CHNS analyzer, BET surface and porosity analyzer and X-ray diffractometer (XRD) were used to study the physical and chemical characteristics of sorbents before and after adsorption.

Materials and methods

Chemicals used

All chemicals used were of analytical reagnt (AR) grade. AR grade chemicals such as nitrilotriacetic acid (Laboratory Rasayan, India), sulfuric acid (Sigma Aldrich), calcium chloride (Spectrochem, India) were used as received. Double distilled water was used for the preparation of all solutions.

Preparation of solutions

Stock solution of 1000 ppm Cd(II):

2.744 g of cadmium nitrate (Cd(NO3)2.4H2O) was dissolved in 1000 ml of double distilled water to prepare the stock solution of 1000 mg/l of cadmium (II).

NTA solution:

1 g of nitrilotriacetic acid (C6H9NO6) was dissolved in 100 ml of double distilled water to prepare 1% NTA solution.

Adsorbent preparation

Culms of Dendrocalamus strictus (Bamboo) were collected from Botanical Garden of Guru Nanak Dev University, Amritsar, Punjab (India) to prepare its charcoal powder. Pre-weighed Dendrocalamus strictus culms were cut into small pieces, washed thoroughly with tap water to remove dust, rinsed with distilled water and dried at 60 °C in oven for preparation of charcoal powder. For preparation of charcoal of Dendrocalamus strictus, washed and dried culms were carbonized in Muffle furnace at 450 °C for 2 h and then allowed to cool to room temperature. Charcoal was crushed to fine powder using grinder and was then passed through sieve with mesh size of 150 μm. One part of bamboo charcoal powder was stored at room temperature for further adsorption experiments and was considered as unmodified charcoal powder (DCP) while second part was treated with 1% NTA and considered as NTA-modified Dendrocalamus strictus charcoal powder (NTA-MDCP). The schematic presentation of preparation of adsorbents is shown in Fig. 1.

Surface modification of adsorbent

For surface modification, 10 g of DCP was added to 500 ml of 1% NTA solution and shaken at 25 ± 2 °C, 120 rpm for 24 h. The contents were then filtered through Whatman filter paper No. 1. The residue was rinsed 3–4 times with double distilled water and oven dried at 60 ± 2 °C for 24 h. NTA treated residue so obtained was considered as NTA-modified Dendrocalamus strictus charcoal powder (NTA-MDCP) and was used for adsorption studies (Fig. 1).

Batch experiment

Batch adsorption experiments were systematically performed using various conditions such as pH (1, 2, 3, 4, 5, 6, 7), adsorbent dose (1, 2, 3, 4 g/l) and contact time (0.5, 1, 2, 4 h) at temperatures (15, 25, 35, 45 °C) and different initial metal ions concentrations (1, 10, 25, 50, 100, 200, 300, 400, 500 mg/l), at 120 rpm using shaker in 250 ml flasks. The contents were then filtered through Whatman filter paper No. 1 and filtrates were analyzed for remaining cadmium content using atomic absorption spectrophotometer at wave length of 326.1 nm (Model: AA240 FS, Make: Agilent). All the experiments were conducted in triplicates.

Calculation of percentage removal and adsorption capacity

Percentage removal of cadmium was calculated as follows:

Adsorption capacity (qe, mg/g) of adsorbents at equilibrium was calculated as:

- Ci (mg/l):

-

initial concentration of cadmium (II) ions

- Cf (mg/l):

-

final concentration of cadmium (II) ions

- V (l):

-

volume of the solution

- W (g):

-

mass of adsorbent

Adsorbent characterization

Surface morphology and elemental composition of DCP and NTA-MDCP, before and after sorption, was investigated using Scanning Electron Microscope-Energy dispersion X-ray spectroscopy (SEM-EDX). CHNS analyzer was used to determine the carbon, hydrogen, nitrogen and sulfur contents in both adsorbents before and after the adsorption process. XRD spectra of both sorbents were recorded with Cu Kα (1.540) radiation, 40 kV and 30 mA, over a wide range from 10° to 80° at room temperature using X-ray diffraction (XRD). Surface parameters of adsorbents were examined using BET surface area and porosity analyzer before and after adsorption process.

Desorption process

Desorption process allow the recovery of adsorbent for its reapplication. Desorption experiments were carried out to regenerate both DCP and NTA-MDCP using two eluents viz., 1 M sulfuric acid and 0.5% calcium chloride solution. 0.1 g of metal loaded DCP (or NTA-MDCP) was added to 250 ml flask containing 50 ml of eluent and contents were shaked for different contact times viz., 2, 4 and 6 h at 120 rpm and 25 °C. After that, the contents were filtered through Whatman filter paper No. 1 and residues were further analyzed for cadmium (II) ions content using digestion method. For that, 0.1 g of residues was weighed and digested with 2 ml of aqua regia (3:1::HCl:HNO3). After digestion, digested residue was mixed with 2 ml of double distilled water, cooled; filtered and final volume was made up to 20 ml. Further, the samples were analyzed for cadmium concentration using atomic absorption spectrophotometer. Both regenerated adsorbents were reused and investigated for the adsorption behavior for 2 or 3 cycles of applications.

Results and discussions

Adsorbent characterization

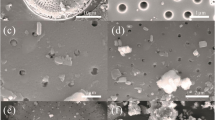

Morphological and elemental analysis

Surface morphology of adsorbents was studied using Scanning Electron Microscopy. SEM micrographs of both adsorbents (DCP and NTA-MDCP) before and after adsorption of Cd(II) ions are shown in Fig. 2. SEM imaging confirmed the porous and heterogeneous surface of both unmodified (DCP) and NTA modified adsorbents (NTA-MDCP) before the adsorption process. After adsorption, surface of both adsorbents was found to be less porous as most of pores were fully loaded with Cd(II) ions.

From SEM-EDX studies, it was observed that the percentage weight of cadmium in DCP and NTA-MDCP were observed to be 2.18% and 24.84%, respectively after adsorption process which confirmed significantly better adsorption of Cd(II) ions using NTA-MDCP. This may be attributed the presence of NTA molecules on the surface of adsorbent which is responsible for enhanced adsorption capacity of NTA-MDCP towards Cd(II) ions.

CHNS analysis

Contents of nitrogen, carbon and hydrogen in DCP were found to be 11.20%, 52.10% and 8.04%, respectively before adsorption process which was reduced to 7.89%, 34.79% and 5.34%, respectively after cadmium adsorption. Similarly, in case of NTA-MDCP, the contents of nitrogen, carbon and hydrogen were found to be 16.02%, 72.11% and 8.66%, respectively before adsorption while the contents of nitrogen and carbon were found to be 11.27% and 54.15%, respectively after cadmium adsorption (Fig. 3). The hydrogen content was observed to be negligible in NTA-MDCP after adsorption of Cd(II) ions. The contents of nitrogen, carbon and hydrogen were observed to be decreased after adsorption process due to adsorption of Cd(II) ions on the surface of DCP and NTA-MDCP.

BET surface analysis

Surface area parameters such as single point surface area, BET surface area, Langmuir surface area, t-plot micropore area and t-plot external surface area of DCP were found to be 27.81 m2/g, 27.15 m2/g, 46.65 m2/g, 29.14 m2/g and 4.53 m2/g, respectively before surface modification which were observed to be increased as 153.09 m2/g, 156.52 m2/g, 212.90 m2/g, 102.81 m2/g and 53.71 m2/g, respectively after surface modification with NTA (Table 1). The isotherm plots of DCP and NTA-MDCP found to be Type I isotherm according to IUPAC classification that represent behavior of microporous solids and uptake of adsorbate being managed by the accessible micropore volume of adsorbent [20, 21]. Similar results were observed for bamboo charcoal and cobalt coated bamboo charcoal by Wang et al. [22]. BET surface area of bamboo charcoal and cobalt coated bamboo were found to be increased from 15 to 265 m3/g and total pore volume from 0.14 to 0.27 cm3/g due to activation of the bamboo charcoal with Co(NO3)2 and HNO3 during the pyrolysis process.

Surface parameters such as single point surface area, BET surface area, Langmuir surface area, t-plot micropore area and t-plot external surface area of cadmium loaded DCP were found to be decreased as 25.93 m2/g, 24.54 m2/g, 45.70 m2/g, 25.07 m2/g and 1.99 m2/g, respectively. Similarly, single point surface area, BET surface area, Langmuir surface area, t-plot micropore area and t-plot external surface area of cadmium loaded NTA-MDCP were observed to be decreased as 66.77 m2/g, 68.39 m2/g, 92.26 m2/g, 42.88 m2/g, and 25.51 m2/g, respectively (Table 1). This decrease in surface parameters confirmed the adsorption of Cd(II) ions. Similarly, pore volume of both DCP and NTA-MDCP were found to be decreased after the adsorption of Cd(II) ions. Nitrogen adsorption isotherm plots of Cd (II) loaded MDCP and NTA-MDCP obtained after adsorption process were found to be Type IV which may be attributed to monolayer-multilayer adsorption.

On the other hand, particle size of cadmium loaded NTA-MDCP was observed to be increased due to accumulation of Cd(II) ions onto the surface. The significant changes on the surface parameter, pore volume and particle size confirmed the adsorption of Cd(II) ions on the surface of both adsorbent. Further, it is also clearly visible that the changes are more significant for NTA-MDCP in comparison to DCP.

XRD analysis

Crystalline structure of different sorbents was characterized by X-ray diffraction. XRD patterns of DCP and NTA-MDCP, before and after adsorption of Cd(II) ions are shown in Fig. 4. Diffraction peaks on XRD spectrum of DCP were identified as: (a) 4-Nitro-4′-amino-chaltone (PDF: 492482; 2θ: 12.842, 21.817, 26.018, 33.918, 36.455, 43.657, 53.361); (b) 3-keto-5-methyl-2-(4’methylphenyl hydrazine) pent4-enolactone (PDF: 451562; 2θ: 31.700, 39.020, 61.160, 62.880); (c) D-Serine (PDF; 2θ: 58.330). After surface modification with NTA, XRD spectrum of NTA-MDCP revealed the presence of: (a) 4-Nitro-4′-amino-chaltone (PDF: 492482; 2θ: 20.035, 24.597, 28.710, 29.740, 33.918, 36.455, 44.348); (b) Thymine (PDF: 391850; 2θ: 37.683, 45.128); (c) 3-keto-5-methyl-2-(4’methylphenyl hydrazine) pent4-enolactone (PDF: 451562; 2θ: 53.00, 62.283) and (d) potassium carbonate (PDF: 700292; 2θ: 64.249, 77.685).

Diffractions peaks of cadmium loaded DCP exhibited typical crystalline peaks corresponding to: (a) cadmium acetate acetamide (PDF: 331610; 2θ: 12.431, 26.289); (b) (Hydrazinecarboxylato-N′,O) cadmium (PDF: 721758; 2θ: 13.731, 19.459, 61.759, 63.608); (c) cadmium L-glutamate dihydrate (PDF: 492016; 2θ: 17.285); (d) cadmium hydrate hydrazine carbonate (PDF: 771418; 2θ: 24.026, 30.354, 33.417, 38.359, 64.445, 77.516). Cadmium loaded NTA-MDCP have shown crystalline peaks which corresponding to: (a) cadmium acetate acetamide (PDF: 331610; 2θ: 12.431); (b) (Hydrazinecarboxylato-N′,O) cadmium (PDF: 721758; 2θ: 13.731, 42.018); (c) cadmium L-glutamate dihydrate (PDF: 492016; 2θ: 17.285, 37.799, 43.290); (d) cadmium diethylenetriamine nitrate (PDF: 461869; 2θ: 19.817) and (e) cadmium hydrate hydrazine carbonate (PDF: 771418; 2θ: 24.026, 28.871, 29.564, 30.354, 33.417, 38.359, 45.035, 45.851, 50.082). It can be concluded that the crystalline nature of DCP was retained after surface modification with NTA as well as after adsorption of Cd(II) ions with introduction of new chemical species on the surface.

pH

pH is one of the most key factors for removal of Cd(II) ions from aqueous solution using DCP and NTA-MDCP. Effects of pH on the adsorption of Cd(II) ions using DCP and NTA-MDCP are presented in Fig. 5a. Percentage removal of Cd(II) ions was observed to be increased from 32.43 to 85.59% with increase in pH from 1 to 6 and then slightly deceased up to 84.60% at pH (7) using DCP as an adsorbent. While the percentage removal of Cd(II) ions was found to be increased from 58.17 to 91.47% with increase in pH from 1 to 6 using NTA-MDCP. No further noteworthy improvement was observed at pH 7. Decrease in percentage removal at pH <6 could be probably due to the competition between protons and Cd(II) ions present in solution for vacant active sites on the surface of adsorbent. At pH >7, precipitation occurred in the cadmium solution. Hence, no experiments were carried out beyond pH 7. Similar observations were made by many authors [23,24,25]. For example, Meena et al. [26] reported that the maximum percentage removal of mercury, copper, lead and chromium (VI) was found at pH (6) using NaOH and H2SO4 treated sawdust of Acacia arabica. In another report by Jiang et al. [24], the maximum percentage removal of copper was observed at pH 6 using amidoximated bagasse. From the results so obtained, it was concluded that maximum removal of Cd(II) was observed at pH 6 for both adsorbents, DCP and NTA-MDCP and Ph 6 was selected as an optimum pH for further adsorption studies.

Contact time

Contact time of adsorbent is also one of the important parameters for successful adsorption process. In the present study, percentage removal of cadmium was observed to be increased from 44.44 to 54.10% for DCP and 73.43% to 90.37% for NTA-MDCP with increase in contact time from 0.5 to 2 h initially and then remained constant with increase in contact time up to 4 h (Fig. 5b). The apparent reason could be the availability of large number of active sites for adsorption at initial stages of adsorption course, after 2 h the maximum number of adsorption sites get occupied Cd(II) ions which leads to creation of a repulsive force between the adsorbate, Cd(II) ions adsorbed on the adsorbent surface and in bulk phase [27,28,29,30,31,32]. Sometimes, even the vacant active site do not get occupied by metal ions during adsorption process which results in delayed contact time due to decreased concentration gradient between adsorbent and adsorbate. Meena et al. [26] reported an optimum contact time of 48 h for the removal of mercury, chromium (VI), lead and 72 h for copper using NaOH and H2SO4 modified sawdust (Acacia arabica). In the present work, the maximum percentage of cadmium removal i.e. 54.10% and 90.37% for DCP and NTA-MDCP, respectively was found at contact time of 2 h. Therefore, contact time of 2 h was considered as optimum contact time for the adsorption of Cd(II) ions using DCP and NTA-MDCP.

Dose

Another factor affecting the percentage removal of cadmium is the adsorbent dose. In order to optimize the dose of adsorbent, different doses viz., 1, 2, 3 and 4 g/l of DCP and NTA-MDCP were used for adsorption of cadmium from aqueous solutions (Fig. 5c). It was observed that percentage removal of cadmium increased rapidly from 1 to 2 g/l of dose followed by very negligible increase up to 4 g/l dose of both adsorbents. At higher dose, Cd(II) ions interacted with more number of active sites available on the surface of adsorbent resulting in the maximum percentage removal of Cd(II) ions from aqueous solutions. Koduru et al. [33] reported the maximum percentage removal of cobalt using 2 g/l dose of Morus alba fruit peel treated with iron. Jiang et al. [24] observed the optimum dose of 2.5 g/l of amidoximated bagasse for removal of copper ions from aqueous solution. Therefore, 2 g/l dose of DCP and NTA-MDCP was chosen as optimum dose for adsorbent.

Initial concentration

The effect of initial Cd(II) ion concentration was investigated by taking various concentrations of Cd(II) solution ranging from 1 to 500 mg/L at pH 6, optimum dose of 2 g/L and contact time of 2 h. Effects of initial concentration of Cd(II) ions on the adsorption phenomenon is shown in Fig. 5d. Percentage removals were observed to be 98.33, 95.33, 88.47, 81.17, 68.17, 55.92, 55.28, 50.21 and 48.67% using DCP and 99.33, 98.83, 92.53, 89.06, 88.37, 77.30, 66.85, 62.42 and 58.69% using NTA-MDCP at 1, 10, 25, 50, 100, 200, 300, 400 and 500 mg/l initial concentrations of Cd(II) ions, respectively. Maximum percentage removals of Cd(II) were found to be 98.33% and 99.33% using DCP and NTA-MDCP, respectively at the lowest initial Cd(II) concentration of 1 mg/l. Decrease in percentage removal of Cd(II) at higher initial concentrations was due to greater driving force gradient between Cd(II) concentration in solution and Cd(II) concentration on surface of the adsorbent. Similar observations were made in different studies for removal of different heavy metals such as cobalt using iron oxide impregnated Morus alba fruits [33]; mercury, chromium, lead using NaOH and H2SO4 modified sawdust of Acacia arabica [26] and copper using amidoximated bagasse [24].

Adsorption studies

Isotherm models

Different isotherm models viz., Langmuir, Freundlich and Temkin were used to analyze the adsorption equilibrium behavior of DCP and NTA-MDCP for the removal of cadmium (II) ions. The study depicted direct relationship between adsorbed cadmium (II) ions and their concentration in solution at equilibrium.

Langmuir isotherm

Langmuir isotherm indicates the adsorption process to be a monolayer type over a homogenous surface of any adsorbent [3, 34,35,36,37]. The linear form of the Langmuir isotherm is expressed as:

- Ce (mg/l):

-

equilibrium concentration of Cd(II)l ions

- qe (mg/g):

-

amount of Cd(II) ions adsorbed per gram of adsorbent (DCP or NTA-MDCP)

- qo (mg/g):

-

maximum adsorption capacity of adsorbent

- b (l/mg):

-

Langmuir constant related with rate of adsorption

Langmuir [37] stated dimensionless constant separation factor or equilibrium parameter (RL) as an important parameter of Langmuir isotherm which is expressed as:

- b:

-

Langmuir constant related with rate of adsorption

- Ci (mg/l):

-

initial concentrations of Cd(II) ions

The values (RL > 1) indicates unfavorable adsorption process, (RL < 1) indicates favorable adsorption process and RL = 1 indicates a linear adsorption. The values (RL = 0) confirms the irreversible adsorption process [38,39,40].

During the present study, adsorption of cadmium was observed to be of monolayer type on the surface of DCP and NTA-MDCP. RL values for Cd(II) adsorption were found to be in the range of 0.309–0.659 and 0.444–0.616 for DCP and NTA-MDCP, respectively. RL values were less than 1and indicated favorable adsorption process (Table 2). Adsorption capacity of NTA-MDCP (166 mg/g) was found to be higher for removal of Cd(II) ions than DCP (142 mg/g) at 45 °C which can be attributed to presence of NTA on the surface of NTA-MDCP. NTA being a chelating agent, has greater capacity to bind with heavy metal ions by forming either 1:1 or 2:1 complex [41, 42]. In 1:1 complex, NTA forms a four-coordinate complex with metal ion while in 2:1 complex, two molecules of NTA on the surface of NTA-MDCP form a hexa-coordinate complex with metal ion (Fig. 6). Adsorption capacity of adsorbent was documented to be enhanced after chemical modifications [33]. Ho et al. [43] reported that adsorption of metal ions was dependent on the functional groups present on the surface of adsorbent, nature and size of metal ions. Some of the authors reported the introduction of new adsorption effective functional groups on the surface of adsorbent after the modification of adsorbent with different chemical agents [44]. In the present work, it was observed that adsorption capacity of NTA-MDCP was higher than DCP due to presence of carboxylate functional groups of NTA on the surface of surface modified adsorbent, NTA-MDCP.

Freundlich isotherm

Freundlich isotherm model indicates two types of adsorption processes viz., monolayer and multilayer types onto the heterogeneous surface of adsorbent [34,35,36]. The linear form of the Freundlich isotherm model is described as:

- Ce (mg/l):

-

equilibrium concentration of Cd(II) ions

- qe (mg/g):

-

amount of Cd(II) ions adsorbed per unit mass of adsorbent (DCP or NTA-MDCP)

- KF (mg/g):

-

Freundlich isotherm constant related to adsorption capacity

- 1/n:

-

Freundlich isotherm constant related to adsorption intensity

The value of 1/n less than 1 indicates a normal adsorption and more than 1 represents the cooperative adsorption [3, 34, 36]. Smaller the value of 1/n, greater is the probability of heterogeneity on the surface of adsorbent. All values of adsorption intensity obtained from Cd(II) adsorption using DCP and NTA-MDCP were found to be <1 which indicated that the adsorption processes were normal and of monolayer type on heterogeneous surfaces of both adsorbents, DCP and NTA-MDCP.

Temkin isotherm

Temkin isotherm assumes that heat of adsorption of all the molecules in a layer would decrease linearly during chemisorptions or physiosorption of an adsorbate on the surface of adsorbent [39]. The linear isotherm equation is expressed as:

- Ce (mg/l):

-

equilibrium concentration of Cd(II) ions

- qe (mg/g):

-

adsorption capacity of adsorbent (DCP or NTA-MDCP)

- B and b (J/mol):

-

Temkin constants related with heat of adsorption

- R (J/mol/K):

-

universal gas constant

- T (Kelvin):

-

absolute temperature

- KT (l/mg):

-

equilibrium binding constant corresponding to the maximum binding energy

The heat of adsorption (B) less than 40 kJ/mol indicates a physical adsorption and its value more than 40 kJ/mol represents the chemical adsorption. In present work, the values of heat of adsorption of Cd(II) ions using both adsorbents (DCP and NTA-MDCP) were found to be less than 40 kJ/mol indicating physical adsorption.

Moreover, correlation-coefficient (r) for all Isotherms were found to be highly correlated suggesting best fit of regression line to data obtained for the adsorption of Cd(II) ions using DCP and NTA-MDCP. These results confirmed that the adsorption of cadmium was well described by Langmuir followed by Freundlich and Temkin isotherms. The isotherm studies indicated the monolayer and physical adsorption of Cd(II) ions on the heterogeneous surface of both DCP and NTA-MDCP.

Kinetic studies

Adsorption kinetics is of paramount importance as it provides valuable insights into reaction pathway and mechanism of adsorption processes [32, 33, 35]. Adsorption behavior of DCP and NTA-MDCP towards Cd(II) ions was analyzed using pseudo-first order and pseudo-second order kinetics. Pseudo-first order confirms that the rate of occupation of adsorption sites is directly proportional to the number of unoccupied sites. The linear form of pseudo-first order model is expressed as:

- qe (mg/g):

-

adsorption capacity at equilibrium

- qt (mg/g):

-

adsorption capacity at time (t)

- k1 (min−1):

-

rate constant of first order adsorption

- t (h):

-

time

Pseudo-second order represents chemisorption which takes into account the chemical interaction between functional groups present on the adsorbent sites and metal ions in aqueous solution and linearly expressed as:

- qe (mg/g):

-

adsorption capacity at equilibrium

- qt (mg/g):

-

adsorption capacity at time (t)

- k2 (g/mg/min):

-

rate constant of second order adsorption

- t (h):

-

time

The parameters associated with pseudo-first order and second order for adsorption of Cd(II) ions so obtained are summarized in Table 3. Adsorption kinetics described the relationship between adsorbent and adsorbate as well as rate of adsorption with respect to time. On the basis of significant agreement between experimental adsorption capacity and calculated adsorption capacity, it can be concluded that the adsorption of Cd(II) ions using DCP and NTA-MDCP followed pseudo-second order kinetic model at all temperature (15, 25, 35 and 45 °C). Moreover, correlation-coefficients (r) for second order kinetic orders were found to be highly correlated than pseudo-first order kinetic model for adsorption of Cd(II) ions using DCP and NTA-MDCP .

Thermodynamic studies

Thermodynamic model for adsorption of metal ions is another important parameter to study the effect of temperature on adsorbent-adsorbate interactions and energy changes during adsorption process [39]. Thermodynamic parameters such as change in free energy (ΔG, kJ/mol), enthalpy (ΔH, kJ/mol) and entropy (ΔS, kJ/mol.K) associated with adsorption process were obtained from slope and intercept of linear plots of lnqe/ce versus 1/T.

- Ce (mg/l):

-

equilibrium concentration of Cd(II) ions

- R (J/mol/K):

-

universal gas constant

- qe (mg/g):

-

adsorption capacities at equilibrium

- ΔG (kJ/mol):

-

change in free energy associated with adsorption process

- ΔH (kJ/mol):

-

change in enthalpy associated with adsorption process

- ΔS (kJ/mol.K):

-

change in entropy associated with adsorption process

Negative values of ΔG indicate spontaneous nature whereas positive values confirm non-spontaneous nature of adsorption. The positive values of ΔH indicate that adsorption process is endothermic while negative values indicate exothermic nature. The positive values of ΔS indicate an increase in randomness during adsorbent and adsorbate interactions while negative values indicate less disorder and randomness between adsorbent and adsorbate during adsorption [33, 39]. In the present study, negative value of ΔG confirmed feasible and spontaneous nature of adsorption process using DCP and NTA-MDCP (Table 4). Positive value of ΔH for cadmium adsorption indicated endothermic nature of adsorption where as positive value of ΔS reflected the increased randomness during adsorption of Cd(II) with both adsorbents (DCP and NTA-MDCP). Similar observation were reported for the adsorption of mercury using anionic surfactant SDS and non-ionic surfactant Triton X-10 modified bamboo leaf powder and iron oxide impregnated Morus alba fruit peel in various studies [33].

Regeneration of adsorbents using desorption studies

Regeneration of adsorbent after one time application is one of the main requirements to establish good adsorbent in order to achieve economical and eco-friendly adsorbent with high recovery. Desorption process enable one to recover the adsorbent for reapplication. For recovery of DCP and NTA-MDCP form cadmium loaded DCP and NTA-MDCP, 1 M sulfuric acid and the 0.5% calcium chloride solution, respectively were applied as eluents. Percentage removals of cadmium loaded DCP and NTA-MDCP were found to be 99.84% and 99.99% respectively, after 6 h (Table 5).

Similarly, Lalhruaitluanga et al. [45] observed desorption of 77% and 63% of lead from lead loaded M. baccifera activated charcoal (MBAC) and M. baccifera raw charcoal (MBRA), respectively after 6 h using 0.1 M HCl. In the present study, it was observed that H2SO4 and CaCl2 could serve as effective eluents for desorption of cadmium ions from cadmium loaded DCP and NTA-MDCP, respectively and allow regeneration of adsorbent for further reuse.

Regenerated adsorbents were further applied for 2 cycles of adsorption studies with at pH 6, contact time of 2 h, adsorbent dose of 2 g/l and 50 mg/l concentration of Cd(II) ions. Percentage removals of Cd(II) were observed to be 75% and 65.40% in cycle 1 and cycle 2 respectively, using regenerated DCP. Similarly, percentage removals Cd(II) were observed to be 89% and 82.20% in cycle 1 and cycle 2 respectively, using regenerated NTA-MDCP. Although the efficiency of regenerated adsorbents was found to be less effective in comparison to their first application, yet the reutilization of adsorbent not only reduces the burden on resource exploitation but also reduce environmental pollution.

Comparative studies

A comparison of adsorption capacities of present adsorbent (NTA-MDCP) and other adsorbents already reported in literature for the removal of Cd(II) ions is summarized in Table 6. It can be concluded that the maximum adsorption capacity of NTA-MDCP for cadmium was superior than most of other chemically modified adsorbent materials investigated in earlier studies [46,47,48,49,50].

Conclusion

NTA was applied successfully as a surface modifying agent and found to enhance the adsorptive properties of DCP towards Cd(II) ions. SEM-EDX, XRD, CHNS and BET analysis confirmed the adsorption of Cd(II) on both adsorbents, DCP and NTA-MDCP. Maximum adsorption capacity calculated from Langmuir isotherm was found to be higher for NTA-MDCP (166.66 mg/g) as compared to DCP (142.85 mg/g) which may be attributed to the complex formation (1:1 & 2:1) between NTA on the surface of adsorbent and Cd(II) ions in the solution at pH 6, temperature 25 °C, adsorbent dose of 2 g/l and contact time of 2 h. Equilibrium data were best fitted in Langmuir isotherm followed by Freundlich and Temkin isotherm. The pseudo second-order kinetic model accurately described the adsorption kinetics. Thermodynamic analysis confirmed the endothermic and spontaneous nature of adsorption processes. For desorbing Cd(II) ions from used adsorbents to regenerate adsorbent, both H2SO4 and CaCl2 were found to be equally effective. It can be concluded that NTA-MDCP could be used as a promising adsorbent for the removal of Cd(II) ions from aqueous solution in comparison to DCP and could be further applied for removal of other heavy metals from wastewater.

References

Asberry HB, Kuo C, Gung C, Conte ED, Suen S. Characterization of water bamboo husk biosorbents and their application in heavy metals ion trapping. Microchem J. 2014;113:59–63.

El-Sayed MT. The use of Saccharomyces cerevisiae for removing cadmium (II) from aqueous waste solutions. Afr J Microbiol Res. 2012;6:6900–10.

Saini S, Kaur I, Katnoria JK. Potential of Saccharomyces cerevisiae flocculent strain to biosorb copper and cadmium ions from aqueous solution. Desalin Water Treat. 2017;83:111–22.

Maleki A, Mahvi AH, Zazouli MA, Izanloo H, Barati AH. Aqueous cadmium removal by adsorption on barley hull and barley hull ash. Asian J Chem. 2011;23(3):1373–6.

Baraket MA. New trends in removing heavy metals from industrial wastewater. Arab J Chem. 2011;4:361–77.

Sirilamduan C, Umpuch C, Kaewsarn P. Removal of copper from aqueous solutions by adsorption using modify Zalacca edulis peel modify. Songklanakarin J Sci Technol. 2011;33:725–32.

Qian H, Li J, Sun L, Chen W, Sheng GD, Liu W, et al. Combined effect of copper and cadmium on Chorella vulgaris growth and photosynthesis-related gene transcription. Aquat Toxicol. 2009;94:56–61.

Bazrafshan E, Mohammadi L, Moghaddam AA, Mahvi AH. Heavy metals removal from aqueous environments by electrocoagulation process–a systematic review. J Environ Health Sci Eng. 2015;13(74):1–16.

Babel S, Kurniawan TA. Low-cost adsorbents for heavy metals uptake from contaminated water: a review. J Hazard Mater B. 2003;97:219–43.

Igwe JC, Abia AA. Equilibrium sorption isotherm studies of cd (II), Pb (II) and Zn (II) ions detoxification from waste water using unmodified and EDTA modified maize husk. Electron J Biotechnol. 2007a;10:536–48.

Igwe JC, Abia AA. Adsorption kinetics and intraparticulate diffusivities for bioremediation of co (II), Fe (II) and cu (II) ions from wastewater using modified and unmodified maize cob. Int J Phys Sci. 2007b;2:119–27.

Onundi YB, Mamum AA, Al-Khatib MF, Ahmed YM. Adsorption of copper, nickel and lead ions from synthetic semiconductor industrial wastewater by palm shell activated carbon. Int J Environ Sci Technol. 2010;7:751–8.

Mizuta K, Matsumoto T, Hatate Y, Nishihara K, Nakanishi T. Removal of nitrate - nitrogen from drinking water using bamboo powder charcoal. Bioresour Technol. 2004;95:255–7.

Wang SY, Tsai MH, Lo SF, Tsai MJ. Effects of manufacturing conditions on the adsorption capacity of heavy metals ions by Makino bamboo charcoal. Bioresour Technol. 2008;99:7027–33.

Ademiluyi FT, Ujile AA. Kinetics of batch adsorption of iron (II) from aqueous solution using activated carbon from Nigerian bamboo. Int J Eng Technol. 2013;3:623–31.

Monser L, Adhoum N. Modified activated carbon for the removal of copper, zinc, chromium and cyanide from waste water. Sep Purif Technol. 2002;26:137–46.

Nadeem M, Mahmood A, Shahid SA, Shah SS, Khalid AM, Mckay G. Sorption of lead from aqueous solution by chemically modified carbon adsorbents. J Hazard Mater B. 2006;138:604–13.

Gupta VK, Jain CK, Ali I, Sharma M, Saini VK. Removal of cadmium and nickel from wastewater using bagasse fly ash - a sugar industry waste. Water Res. 2003;37:4038–44.

Szlag DC, Wolf NJ. Recent advances in ion exchange materials and processes for pollution prevention. Clean Prod Process. 1999;1:117–31.

Sing KSW, Everett DH, Haul RAW, Moscou L, Pierotti RA, Rouquerol J, et al. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. Pure Appl Chem. 1985;57:603–9.

Saini S, Arora S, Kirandeep, Singh BP, Katnoria JK, Kaur I. Nitrilotriacetic acid modified bamboo charcoal (NTA-MBC): an effective adsorbent for the removal of Cr (III) and Cr (VI) from aqueous solution. J Environ Chem Eng. 2018;6:2965–74.

Wang Y, Wang XJ, Liu M, Wang X, Wu Z, Yang LZ, et al. Cr (VI) removal from water using cobalt - coated bamboo charcoal prepared microwave heating. Ind Crop Prod. 2012;39:81–8.

Sekar M, Sakthi V, Rengaraj S. Kinetics and equilibrium adsorption study of lead (II) onto activated carbon prepared from coconut shell. J Colloid Interface Sci. 2004;279:307–13.

Jiang Y, Pang H, Liao B. Removal of copper (II) ions from aqueous solution by modified bagasse. J Hazard Mater. 2009;164:1–9.

Tangjuank S, Insuk N, Udeye V, Tontrakoon J. Chromium (III) sorption from aqueous solutions using activated carbon prepared from cashew nut shells. Int J Phys Sci. 2009;4:412–7.

Meena AK, Kadiruvelu K, Mishra GK, Rajagopal C, Nagar PN. Adsorptive removal of heavy metals from aqueous solution by treated sawdust (Acacia arabica). J Hazard Mater. 2008;150:604–11.

Cheng MH, Yang L. Heavy metal uptake by activated sludge. J Water Pollut Control Fed. 1975;47:362–8.

Huang CP, Wu MH. Removal of chromium (VI) from diluted aqueous solution by activated carbon. J Water Pollut Control Fed. 1975;47:389–93.

Namsivayam C, Ranganathan K. Removal of cadmium (II) from wastewater by adsorption on “waste” Fe (III)/Cr (III) hydroxide. Water Res. 1995;29:1737–44.

Suraj G, Lyer CSP, Lalithambika M. Adsorption of cadmium and copper by modified kaolonites. Appl Clay Sci. 1998;13:293–306.

Shibi IG, Anirudhan TS. Synthesis, characterization and application as mercury (II) sorbent of banana stalk (Musa paradisiacal) - polyacrylamide grafted copolymer bearing carboxyl groups. Ind Eng Chem Res. 2012;41:5341–52.

Montanher SF, Oliveira EA, Rollemberg MC. Removal of metal ions from aqueous solutions by sorption onto rice bran. J Hazard Mater B. 2005;117:207–11.

Koduru JR, Chang Y, Yang J, Kim I. Iron oxide impregnated Morus alba L. fruit peel for biosorption of co (II): biosorption properties and mechanism. Sci World J. 2013;2013:1–14.

Fard RF, Sar MEK, Fahiminia M, Mirzaei N, Yousefi N, Mansoorian HJ, et al. Efficiency of multi walled carbon nanotubes for removing direct blue 71 from aqueous solutions. Eurasian J Anal Chem. 2018;13(3):1–10.

Kamranifar M, Khodadadi M, Samiei V, Dehdashti B, Sepehr MN, Rafati L, et al. Comparison the removal of reactive red 195 dye using powder and ash of barberry stem as a low cost adsorbent from aqueous solutions: isotherm and kinetic study. J Mol Liq. 2018;255:572–7.

Rafati L, Mahvi AH, Asgari AR, Hosseini SS. Removal of chromium (VI) from aqueous solutions using Lewatit FO36 nano ion exchange resin. Int J Environ Sci Technol. 2009;7(1):147–56.

Langmuir I. The adsorption gasses on plane surface of glass, mica and platinum. J Am Chem Soc. 1918;40:1361–403.

Rafatullah M, Sulaiman O, Hashim R, Ahmad A. Adsorption of copper (II), chromium (III), nickel (II) and lead (II) ions from aqueous solutions by meranti sawdust. J Hazard Mater. 2009;170:969–77.

Khan MA, Alemayehu A, Duraisamy R, Berekete AK. Removal of lead ions from aqueous solution by bamboo activated carbon. Int J Water Res. 2015;5:33–46.

Ebrahimi R, Maleki A, Shahmoradi B, Daraei H, Mahvi AH, Barati AH, et al. Elimination of arsenic contamination from water using chemically modified wheat straw. Desalin Water Treat. 2009;51:2306–16.

Hull JA, Davies RH, Staveley LAK. Thermodynamics of the formation of complexes of nitrilotriacetic acid and bivalent cations. J Chem Soc. 1964;1033:5422–5.

Souaya ER, Hanna WG, Ismail EH, Milad NE. Studies on some acid divalent-metal nitrilotriacetate complexes. Molecules. 2000;5:1121–9.

Ho YS, Wase DAJ, Forster CF. Batch nickel removal from aqueous solution by Sphagnum moss peat. Water Res. 1995;29:1327–32.

Chen JP, Yang L. Chemical modification of Sargassum sp. for prevention of organic leaching and enhancement of uptake during metal biosorption. Ind Eng Chem Res. 2005;44:9931–42.

Lalhruaitluanga H, Jayaram K, Prasad MNV, Kumar KK. Lead (II) adsoption from aqueous solutions by raw and activated charcoals of Melocanna baccifera Roxburgh (bamboo)-a comparative study. J Hazard Mater. 2010;175:311–8.

Zheng L, Dang Z, Yi X, Zhang H. Equilibrium and kinetic studies of adsorption of cd (II) from aqueous solution using modified corn stalk. J Hazard Mater. 2010;176:650–6.

El-Sherif I, Fathy NA. Modification of adsorptive properties of bagasse Fly ash for Uptaking cadmium from aqueous solution. Environ Res Eng Manag. 2013;(2):19–28.

Pandey R, Prasad RL, Ansari NG, Murthy RC. Utilization of NaOH modified Desmostachya bipinnata (Kush grass) leaves and Bambusa arundinacea (bamboo) leaves for cd (II) removal from aqueous solution. J Environ Chem Eng. 2015;3:593–602.

Alamin AH, Kaewsichan L. Adsorption of Zn (II) and cd (II) ions from aqueous solutions by bamboo biochar co-operation with hydroxyapatite and calcium sulphate. Int J Chem Tech Res. 2015;7:2159–70.

Harja M, Buema G, Bulgariu L, Bulgariu D, Sutiman DM, Ciobanu G. Removal of cadmium(II) from aqueous solution by adsorption onto modified algae and ash. Korean J Chem Eng. 2015;32:1804–11.

Acknowledgements

The authors gratefully acknowledge the University Grants Commission for providing the financial support and University with Potential for Excellence (UPE) program. The first author is recipient of UGC-BSR fellowship under RFSMS scheme. We are also thankful to Central Department of Emerging Life Sciences, Guru Nanak Dev University, Amritsar for providing the necessary research facilities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Saini, S., Katnoria, J.K. & Kaur, I. A comparative study for removal of cadmium(II) ions using unmodified and NTA-modified Dendrocalamus strictus charcoal powder. J Environ Health Sci Engineer 17, 259–272 (2019). https://doi.org/10.1007/s40201-019-00345-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40201-019-00345-2